air filter SUZUKI SX4 2006 1.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 299 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-17

Engine Assembly Removal and InstallationS6RW0D1406013

Removal

1) Relieve fuel pressure according to “Fuel Pressure

Relief Procedure in Section 1G”.

2) Disconnect negative and positive cable at battery.

3) Disconnect ECM connectors.

4) Remove battery and battery tray with ECM.

5) Remove right and left side engine under covers.

6) Remove A/C compressor belt by referring to

“Compressor Drive Belt Removal and Installation in

Section 7B” or “Compressor Drive Belt Removal and

Installation in Section 7B”.

7) Drain engine oil referring to “Engine Oil and Filter

Change in Section 0B”.

8) Drain transaxle oil referring to “Manual Transaxle Oil

Change in Section 5B” or “A/T Fluid Change in

Section 5A”.

9) Drain transfer oil referring to “Transfer Oil Change in

Section 3C”.

10) Drain coolant referring to “Cooling System Draining

in Section 1F”

11) Remove air cleaner assembly referring to “Air

Cleaner Assembly Removal and Installation”.

12) With hose connected, detach A/C compressor from

its bracket referring to “Compressor Assembly

Removal and Installation in Section 7B” or

“Compressor Assembly Removal and Installation in

Section 7B”.

CAUTION!

Suspend removed A/C compressor at a place

where no damage will be caused during

removal and installation of engine assembly.

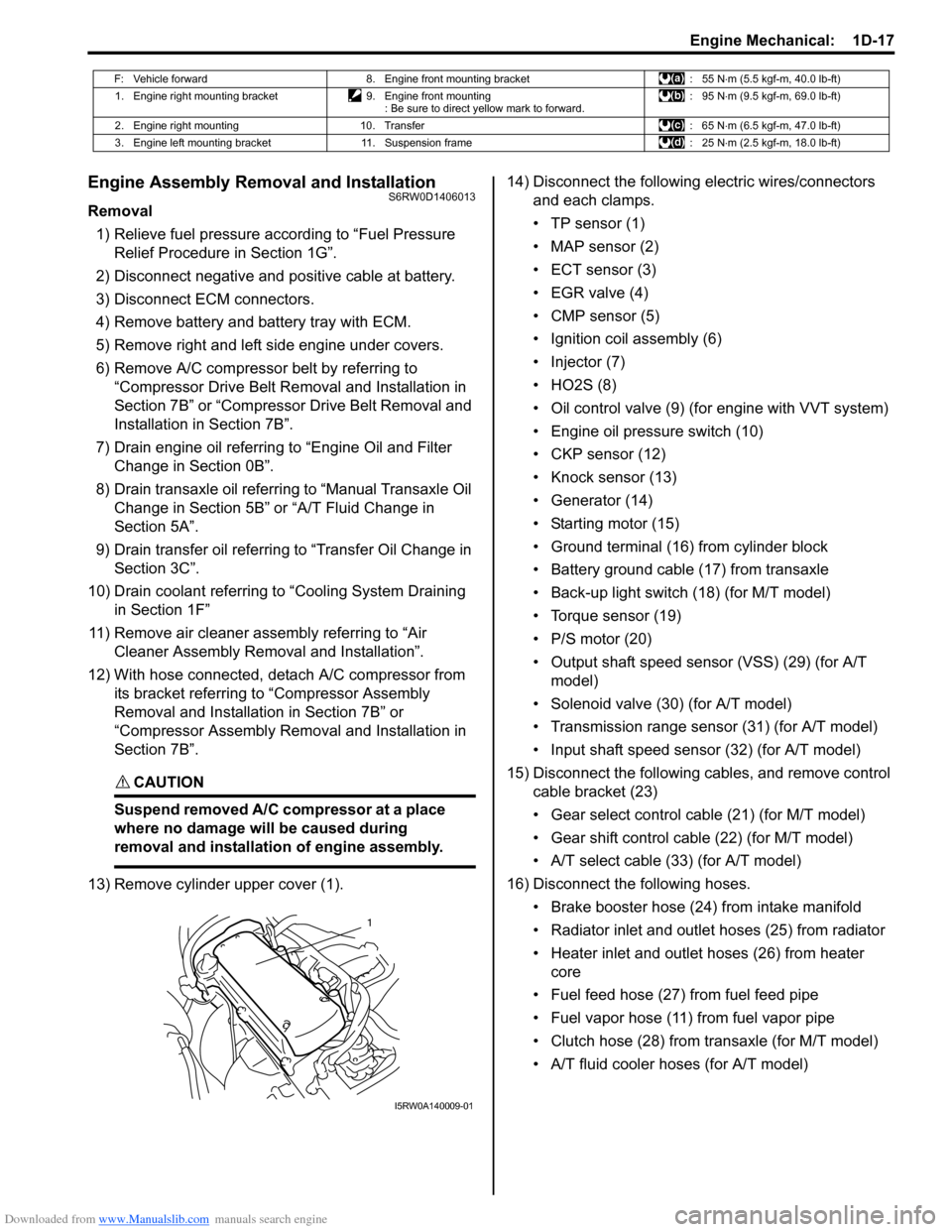

13) Remove cylinder upper cover (1).14) Disconnect the following electric wires/connectors

and each clamps.

• TP sensor (1)

• MAP sensor (2)

• ECT sensor (3)

•EGR valve (4)

• CMP sensor (5)

• Ignition coil assembly (6)

• Injector (7)

•HO2S (8)

• Oil control valve (9) (for engine with VVT system)

• Engine oil pressure switch (10)

• CKP sensor (12)

• Knock sensor (13)

• Generator (14)

• Starting motor (15)

• Ground terminal (16) from cylinder block

• Battery ground cable (17) from transaxle

• Back-up light switch (18) (for M/T model)

• Torque sensor (19)

• P/S motor (20)

• Output shaft speed sensor (VSS) (29) (for A/T

model)

• Solenoid valve (30) (for A/T model)

• Transmission range sensor (31) (for A/T model)

• Input shaft speed sensor (32) (for A/T model)

15) Disconnect the following cables, and remove control

cable bracket (23)

• Gear select control cable (21) (for M/T model)

• Gear shift control cable (22) (for M/T model)

• A/T select cable (33) (for A/T model)

16) Disconnect the following hoses.

• Brake booster hose (24) from intake manifold

• Radiator inlet and outlet hoses (25) from radiator

• Heater inlet and outlet hoses (26) from heater

core

• Fuel feed hose (27) from fuel feed pipe

• Fuel vapor hose (11) from fuel vapor pipe

• Clutch hose (28) from transaxle (for M/T model)

• A/T fluid cooler hoses (for A/T model)

F: Vehicle forward 8. Engine front mounting bracket : 55 N⋅m (5.5 kgf-m, 40.0 lb-ft)

1. Engine right mounting bracket 9. Engine front mounting

: Be sure to direct yellow mark to forward.: 95 N⋅m (9.5 kgf-m, 69.0 lb-ft)

2. Engine right mounting 10. Transfer : 65 N⋅m (6.5 kgf-m, 47.0 lb-ft)

3. Engine left mounting bracket 11. Suspension frame : 25 N⋅m (2.5 kgf-m, 18.0 lb-ft)

1

I5RW0A140009-01

Page 303 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-21

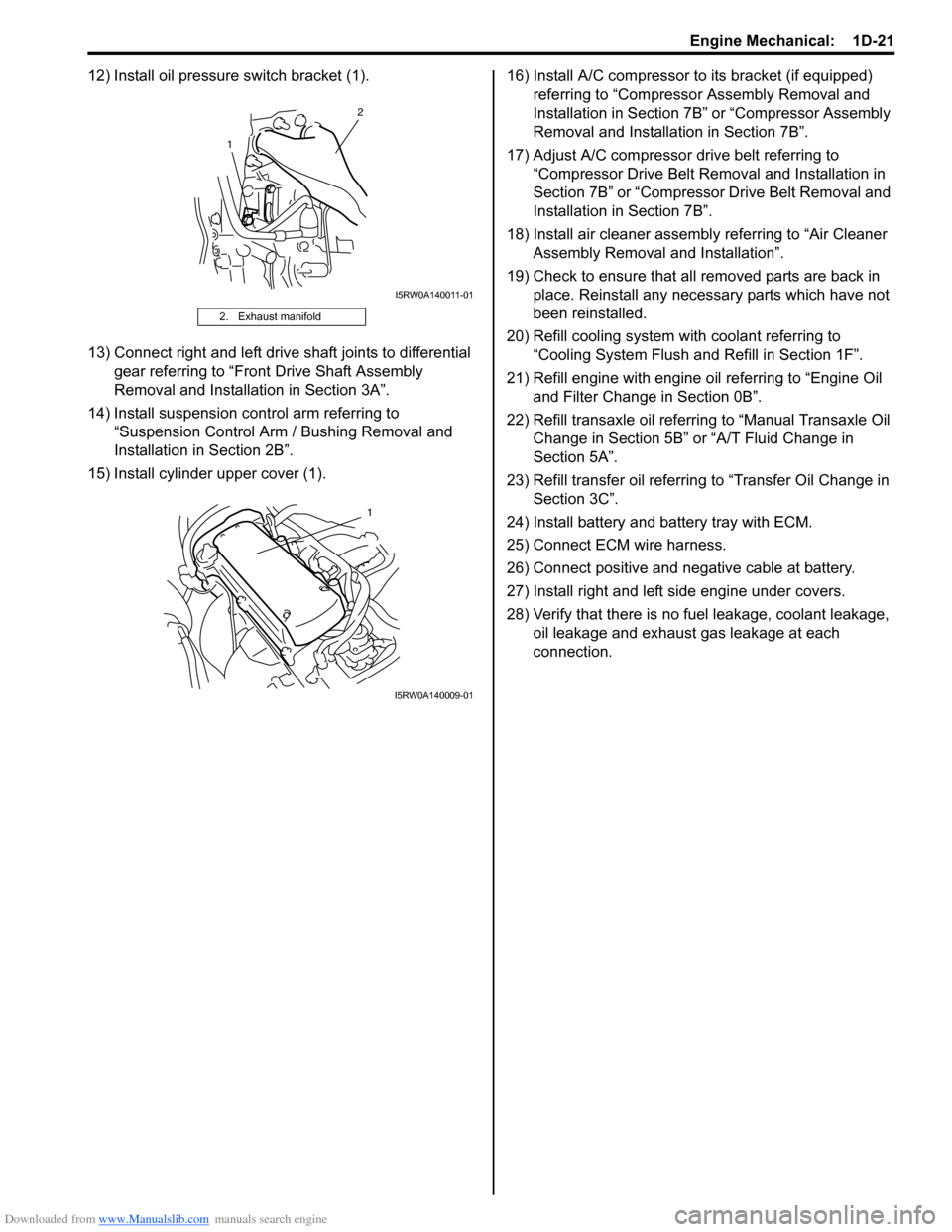

12) Install oil pressure switch bracket (1).

13) Connect right and left drive shaft joints to differential

gear referring to “Front Drive Shaft Assembly

Removal and Installation in Section 3A”.

14) Install suspension control arm referring to

“Suspension Control Arm / Bushing Removal and

Installation in Section 2B”.

15) Install cylinder upper cover (1).16) Install A/C compressor to its bracket (if equipped)

referring to “Compressor Assembly Removal and

Installation in Section 7B” or “Compressor Assembly

Removal and Installation in Section 7B”.

17) Adjust A/C compressor drive belt referring to

“Compressor Drive Belt Removal and Installation in

Section 7B” or “Compressor Drive Belt Removal and

Installation in Section 7B”.

18) Install air cleaner assembly referring to “Air Cleaner

Assembly Removal and Installation”.

19) Check to ensure that all removed parts are back in

place. Reinstall any necessary parts which have not

been reinstalled.

20) Refill cooling system with coolant referring to

“Cooling System Flush and Refill in Section 1F”.

21) Refill engine with engine oil referring to “Engine Oil

and Filter Change in Section 0B”.

22) Refill transaxle oil referring to “Manual Transaxle Oil

Change in Section 5B” or “A/T Fluid Change in

Section 5A”.

23) Refill transfer oil referring to “Transfer Oil Change in

Section 3C”.

24) Install battery and battery tray with ECM.

25) Connect ECM wire harness.

26) Connect positive and negative cable at battery.

27) Install right and left side engine under covers.

28) Verify that there is no fuel leakage, coolant leakage,

oil leakage and exhaust gas leakage at each

connection.

2. Exhaust manifold

1

2

I5RW0A140011-01

1

I5RW0A140009-01

Page 358 of 1556

Downloaded from www.Manualslib.com manuals search engine 1E-2 Engine Lubrication System:

Diagnostic Information and Procedures

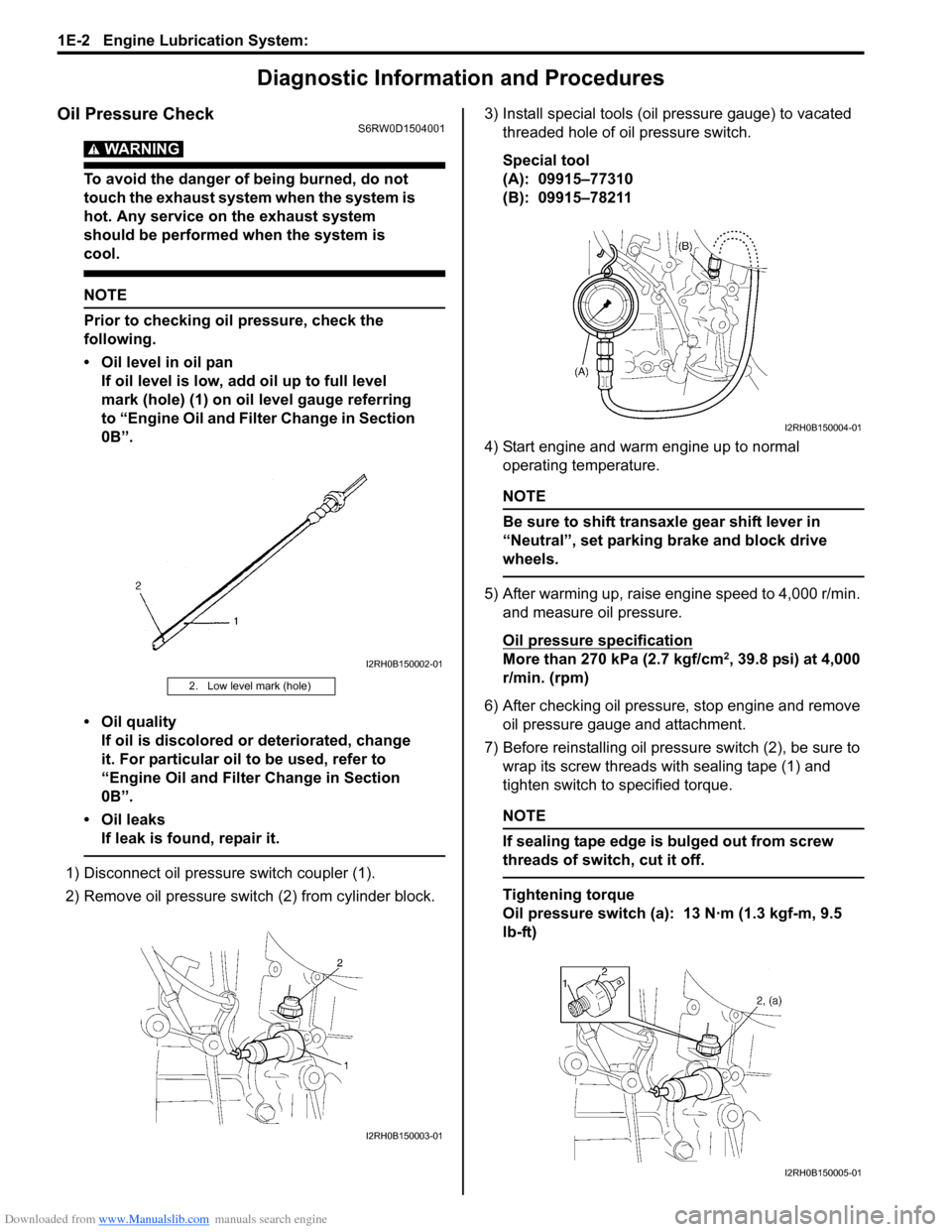

Oil Pressure CheckS6RW0D1504001

WARNING!

To avoid the danger of being burned, do not

touch the exhaust system when the system is

hot. Any service on the exhaust system

should be performed when the system is

cool.

NOTE

Prior to checking oil pressure, check the

following.

• Oil level in oil pan

If oil level is low, add oil up to full level

mark (hole) (1) on oil level gauge referring

to “Engine Oil and Filter Change in Section

0B”.

• Oil quality

If oil is discolored or deteriorated, change

it. For particular oil to be used, refer to

“Engine Oil and Filter Change in Section

0B”.

• Oil leaks

If leak is found, repair it.

1) Disconnect oil pressure switch coupler (1).

2) Remove oil pressure switch (2) from cylinder block.3) Install special tools (oil pressure gauge) to vacated

threaded hole of oil pressure switch.

Special tool

(A): 09915–77310

(B): 09915–78211

4) Start engine and warm engine up to normal

operating temperature.

NOTE

Be sure to shift transaxle gear shift lever in

“Neutral”, set parking brake and block drive

wheels.

5) After warming up, raise engine speed to 4,000 r/min.

and measure oil pressure.

Oil pressure specification

More than 270 kPa (2.7 kgf/cm2, 39.8 psi) at 4,000

r/min. (rpm)

6) After checking oil pressure, stop engine and remove

oil pressure gauge and attachment.

7) Before reinstalling oil pressure switch (2), be sure to

wrap its screw threads with sealing tape (1) and

tighten switch to specified torque.

NOTE

If sealing tape edge is bulged out from screw

threads of switch, cut it off.

Tightening torque

Oil pressure switch (a): 13 N·m (1.3 kgf-m, 9.5

lb-ft)

2. Low level mark (hole)

I2RH0B150002-01

I2RH0B150003-01

I2RH0B150004-01

I2RH0B150005-01

Page 666 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-18 Automatic Transmission/Transaxle:

Step 2. DTC / Freeze Frame Data Check, Record and

Clearance

First, referring to “DTC Check”, check DTC and pending

DTC. If DTC exists, print or write down DTC and freeze

frame data and then clear malfunction DTC(s) by

referring to “DTC Clearance”. Malfunction DTC indicates

malfunction in the system but it is not possible to know

from it whether the malfunction is occurring now or it

occurred in the past and normal condition has been

restored. In order to know that, check symptom in

question according to Step 5 and then recheck DTC

according to Step 6.

Diagnosing a trouble based on the DTC in this step only

or failure to clear the DTC in this step may result in an

faulty diagnosis, trouble diagnosis of a normal circuit or

difficulty in troubleshooting which is otherwise

unnecessary.

Step 3 and 4. Visual Inspection

As a preliminary step, be sure to perform visual check of

the items that support proper function of the engine and

automatic transaxle referring to “Visual Inspection”.

Step 5. Trouble Symptom Confirmation

Check trouble symptoms based on information obtained

in “Step 1. Customer Complaint Analysis: ” and “Step 2.

DTC / Freeze Frame Data Check, Record and

Clearance: ”.

Also, reconfirm DTC according to “DTC Confirmation

Procedure” described in each DTC flow.

Step 6 and 7. Rechecking and Record of DTC and

Freeze Frame Data

Refer to “DTC Check” for checking procedure.Step 8. A/T Basic Check and A/T Symptom

Diagnosis

Perform basic check of A/T according to “A/T Basic

Check” first. When the end of the flow has been reached,

check the parts of the system suspected as a possible

cause referring to “A/T Symptom Diagnosis” and based

on symptoms appearing on the vehicle (symptoms

obtained through steps of customer complaint analysis,

trouble symptom confirmation and/or A/T basic check)

and repair or replace faulty parts, if any.

Step 9. Troubleshooting for DTC

Based on the DTC indicated in Step 6 / 7 and referring to

“applicable DTC flow”, locate the cause of the trouble,

namely in a sensor, switch, wire harness, connector,

actuator, TCM or other part and repair or replace faulty

parts.

Step 10. Check for Intermittent Problem

Check parts where an intermittent trouble is easy to

occur (e.g. wire harness, connector, etc.), referring to

“Intermittent and Poor Connection Inspection in Section

00” and related circuit of DTC recorded in Step 2.

Step 11. Final Confirmation Test

Confirm that the problem symptom has gone and the

vehicle is free from any abnormal conditions. If what has

been repaired is related to the malfunction DTC, clear

the DTC once and check to ensure that no malfunction

DTC is indicated.

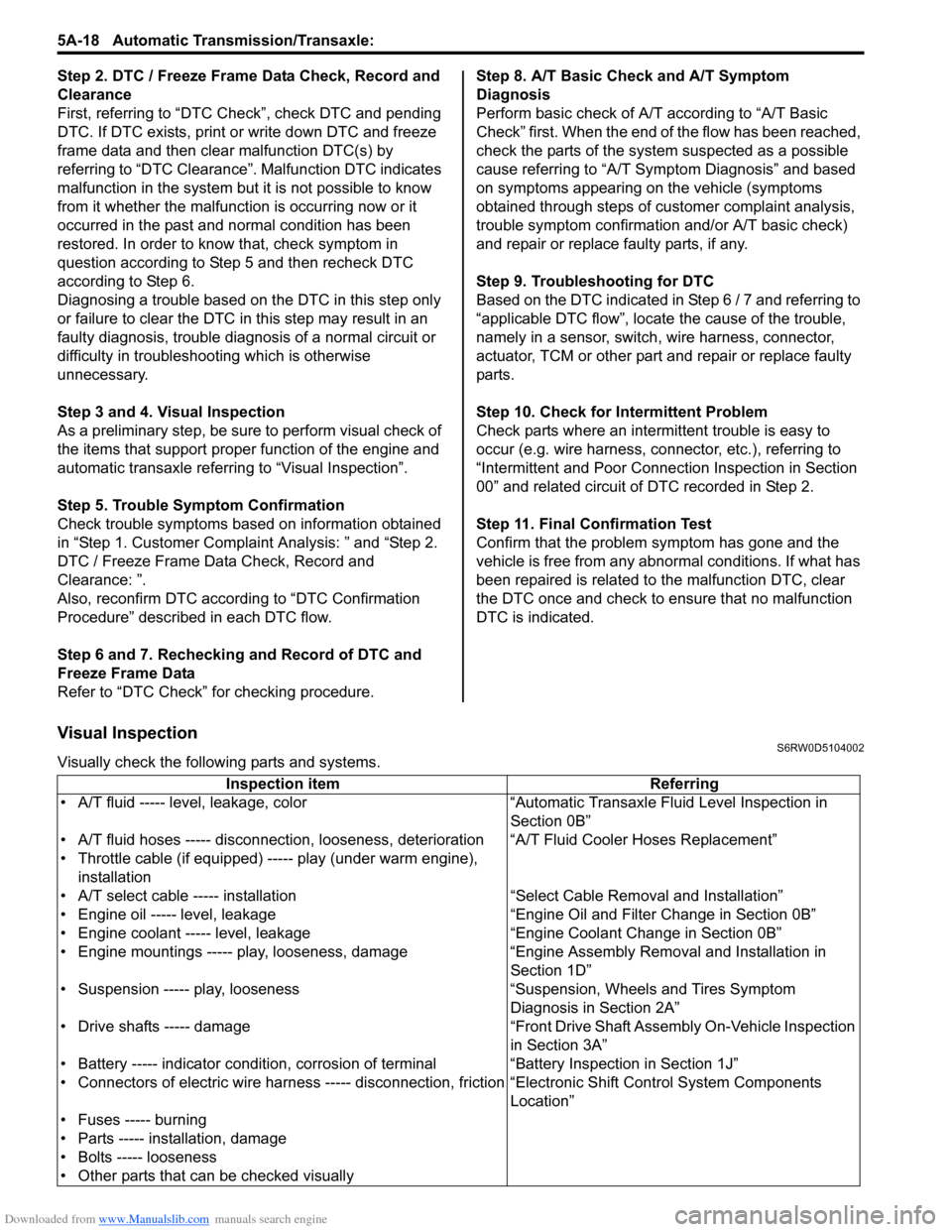

Visual InspectionS6RW0D5104002

Visually check the following parts and systems.

Inspection item Referring

• A/T fluid ----- level, leakage, color “Automatic Transaxle Fluid Level Inspection in

Section 0B”

• A/T fluid hoses ----- disconnection, looseness, deterioration “A/T Fluid Cooler Hoses Replacement”

• Throttle cable (if equipped) ----- play (under warm engine),

installation

• A/T select cable ----- installation “Select Cable Removal and Installation”

• Engine oil ----- level, leakage “Engine Oil and Filter Change in Section 0B”

• Engine coolant ----- level, leakage “Engine Coolant Change in Section 0B”

• Engine mountings ----- play, looseness, damage “Engine Assembly Removal and Installation in

Section 1D”

• Suspension ----- play, looseness “Suspension, Wheels and Tires Symptom

Diagnosis in Section 2A”

• Drive shafts ----- damage “Front Drive Shaft Assembly On-Vehicle Inspection

in Section 3A”

• Battery ----- indicator condition, corrosion of terminal “Battery Inspection in Section 1J”

• Connectors of electric wire harness ----- disconnection, friction “Electronic Shift Control System Components

Location”

• Fuses ----- burning

• Parts ----- installation, damage

• Bolts ----- looseness

• Other parts that can be checked visually

Page 925 of 1556

Downloaded from www.Manualslib.com manuals search engine Table of Contents 7- i

7

Section 7

CONTENTS

HVAC

Precautions ................................................. 7-1

Precautions............................................................. 7-1

Precautions on HVAC ........................................... 7-1

Heater and Ventilation............................. 7A-1

General Description ............................................. 7A-1

Heater and Ventilation Construction ................... 7A-1

Schematic and Routing Diagram ........................ 7A-2

Heater and Ventilation Wiring Circuit Diagram .... 7A-2

Component Location ........................................... 7A-2

Electronic Control System Components

Location ............................................................ 7A-2

Diagnostic Information and Procedures ............ 7A-3

Heater and Ventilation Symptom Diagnosis........ 7A-3

Repair Instructions .............................................. 7A-4

HVAC Unit Components ..................................... 7A-4

HVAC Unit Removal and Installation (Non-A/

C) ...................................................................... 7A-4

Blower Motor Removal and Installation............... 7A-4

Blower Motor Inspection ..................................... 7A-4

Blower Motor Resistor Removal and

Installation ......................................................... 7A-5

Blower Motor Resistor Inspection ....................... 7A-5

Blower Motor Relay Inspection ........................... 7A-6

HVAC Control Unit Components ......................... 7A-6

HVAC Control Unit Removal and Installation ...... 7A-7

Blower Speed Selector Inspection ...................... 7A-9

Air Intake Selector Inspection ............................. 7A-9

Air Intake Control Actuator Removal and

Installation ......................................................... 7A-9

Air Intake Control Actuator Inspection .............. 7A-10

Center Ventilation Louver Removal and

Installation ....................................................... 7A-11

Side Ventilation Louver Removal and

Installation ....................................................... 7A-11

Rear Duct Removal and Installation (If

Equipped)........................................................ 7A-12

HVAC Air Filter Removal and Installation (If

Equipped)........................................................ 7A-12

HVAC Air Filter Inspection (If Equipped) ........... 7A-12

Air Conditioning System......................... 7B-1

Manual Type ............................................................ 7B-1

Precautions........................................................... 7B-1A/C System Caution ............................................ 7B-1

Precautions on Servicing A/C System ................ 7B-1

General Description .............................................7B-2

Sub-Cool A/C System Description ...................... 7B-2

Manual A/C Electronic Input Output Table .......... 7B-3

A/C Operation Description at ECM ..................... 7B-3

Schematic and Routing Diagram ........................7B-4

A/C System Air Flow Diagram............................. 7B-4

A/C System Wiring Diagram ............................... 7B-5

Component Location ...........................................7B-6

A/C System Major Components Location ........... 7B-6

Electronic Control System Components

Location............................................................. 7B-7

Diagnostic Information and Procedures ............7B-8

A/C System Performance Inspection .................. 7B-8

Trouble Diagnosis for Abnormal Pressure ........ 7B-11

A/C System Inspection at ECM ......................... 7B-12

A/C System Symptom Diagnosis ...................... 7B-13

Abnormal Noise Symptom Diagnosis of A/C

System ............................................................ 7B-15

Repair Instructions ............................................7B-17

Operation Procedure for Refrigerant Charge .... 7B-17

Condenser Cooling Fan Removal and

Installation ....................................................... 7B-22

Condenser Cooling Fan Inspection ................... 7B-23

Condenser Assembly On-Vehicle Inspection .... 7B-23

Condenser Assembly Removal and

Installation ....................................................... 7B-23

Desiccant Removal and Installation .................. 7B-24

HVAC Unit Components ................................... 7B-25

HVAC Unit Removal and Installation ................ 7B-26

Evaporator Inspection ....................................... 7B-27

Evaporator Temperature Sensor Removal

and Installation ................................................ 7B-27

Evaporator Temperature Sensor Inspection ..... 7B-28

Expansion Valve Removal and Installation ....... 7B-28

Expansion Valve Inspection .............................. 7B-28

A/C Refrigerant Pressure Sensor and Its

Circuit Inspection............................................. 7B-29

A/C Refrigerant Pressure Sensor Removal

and Installation ................................................ 7B-29

A/C Switch Inspection ....................................... 7B-29

A/C System Relay Inspection............................ 7B-30

Compressor Drive Belt Inspection and

Adjustment ...................................................... 7B-30

Page 940 of 1556

Downloaded from www.Manualslib.com manuals search engine 7A-12 Heater and Ventilation:

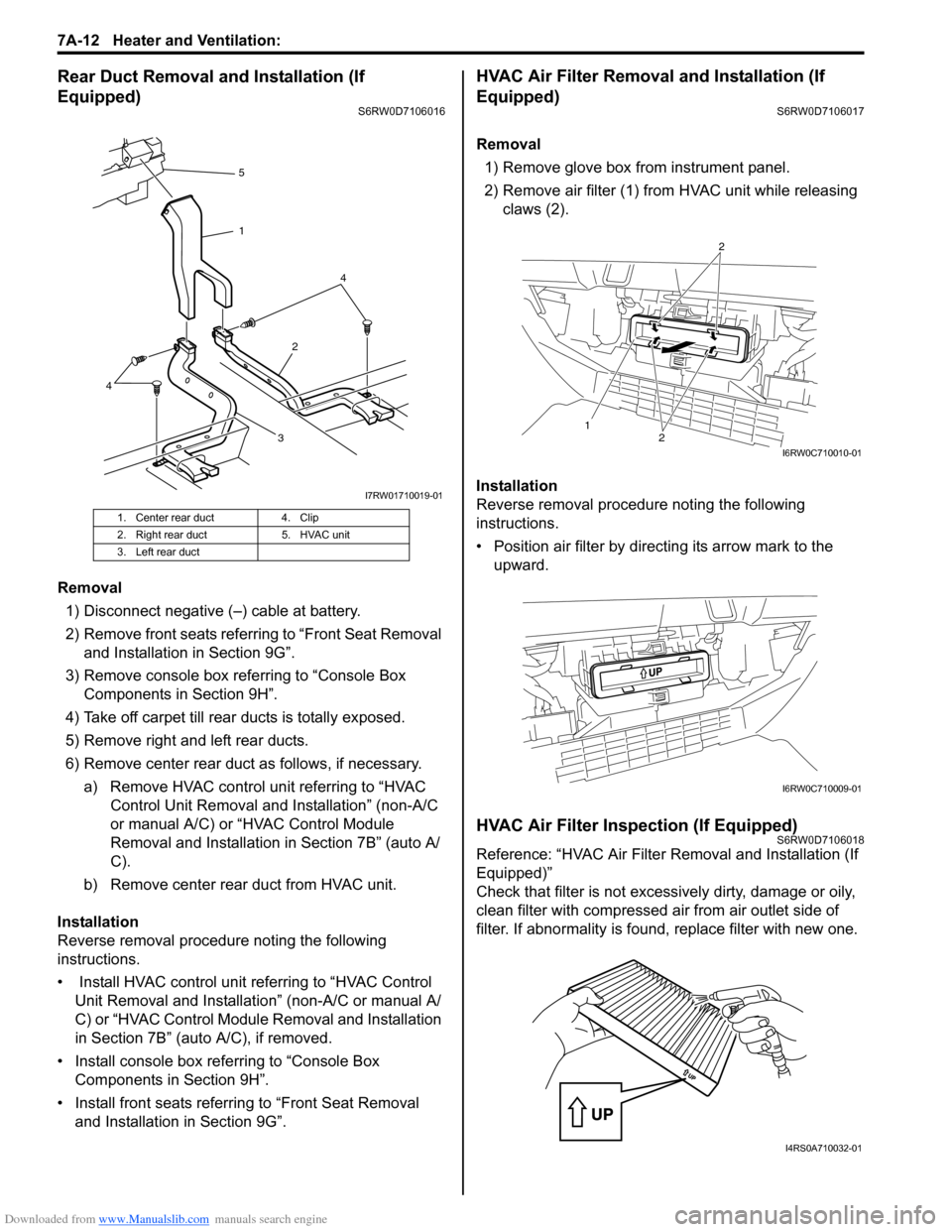

Rear Duct Removal and Installation (If

Equipped)

S6RW0D7106016

Removal

1) Disconnect negative (–) cable at battery.

2) Remove front seats referring to “Front Seat Removal

and Installation in Section 9G”.

3) Remove console box referring to “Console Box

Components in Section 9H”.

4) Take off carpet till rear ducts is totally exposed.

5) Remove right and left rear ducts.

6) Remove center rear duct as follows, if necessary.

a) Remove HVAC control unit referring to “HVAC

Control Unit Removal and Installation” (non-A/C

or manual A/C) or “HVAC Control Module

Removal and Installation in Section 7B” (auto A/

C).

b) Remove center rear duct from HVAC unit.

Installation

Reverse removal procedure noting the following

instructions.

• Install HVAC control unit referring to “HVAC Control

Unit Removal and Installation” (non-A/C or manual A/

C) or “HVAC Control Module Removal and Installation

in Section 7B” (auto A/C), if removed.

• Install console box referring to “Console Box

Components in Section 9H”.

• Install front seats referring to “Front Seat Removal

and Installation in Section 9G”.

HVAC Air Filter Removal and Installation (If

Equipped)

S6RW0D7106017

Removal

1) Remove glove box from instrument panel.

2) Remove air filter (1) from HVAC unit while releasing

claws (2).

Installation

Reverse removal procedure noting the following

instructions.

• Position air filter by directing its arrow mark to the

upward.

HVAC Air Filter Inspection (If Equipped)S6RW0D7106018

Reference: “HVAC Air Filter Removal and Installation (If

Equipped)”

Check that filter is not excessively dirty, damage or oily,

clean filter with compressed air from air outlet side of

filter. If abnormality is found, replace filter with new one.

1. Center rear duct 4. Clip

2. Right rear duct 5. HVAC unit

3. Left rear duct

324 5

1

4

I7RW01710019-01

12

2

I6RW0C710010-01

I6RW0C710009-01

I4RS0A710032-01

Page 942 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-2 Air Conditioning System: Manual Type

Refrigerant Recovery

When discharging refrigerant out of A/C system, always recover it by using refrigerant recovery and recycling

equipment because discharging refrigerant HFC-134a (R-134a) into atmosphere would cause adverse effect to

environments referring to “Recovery” in “Operation Procedure for Refrigerant Charge”.

Refrigerant Charge

After performing compressor oil replenishment and evacuation, charge a proper amount of refrigerant to A/C system

referring to “Charge” in “Operation Procedure for Refrigerant Charge”.

General Description

Sub-Cool A/C System DescriptionS6RW0D7211001

In the sub-cool A/C system (condenser integrated with receiver / dryer), the inside of the condenser is divided into the

condensation part and the sub-cooler part, and the receiver / dryer is located between those. In the receiver / dryer,

the refrigerant is separated into the vapor refrigerant and the liquid refrigerant. Only the liquid refrigerant is delivered to

the sub-cooler part of the condenser. The refrigerant is supercooled by the sub-cooler part of the condenser.

I5RW0A721003-02

[A]: Liquid 2. Magnet clutch 6. Expansion valve 10. Desiccant

[B]: Vapor 3. Condenser 7. A/C evaporator 11. Filter

[C]: Superheated vapor 4. Receiver/dryer 8. Condensation part 12. Vapor refrigerant

1. Compressor 5. Refrigerant pressure sensor 9. Sub-cooler part 13. Liquid refrigerant

Page 948 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-8 Air Conditioning System: Manual Type

Diagnostic Information and Procedures

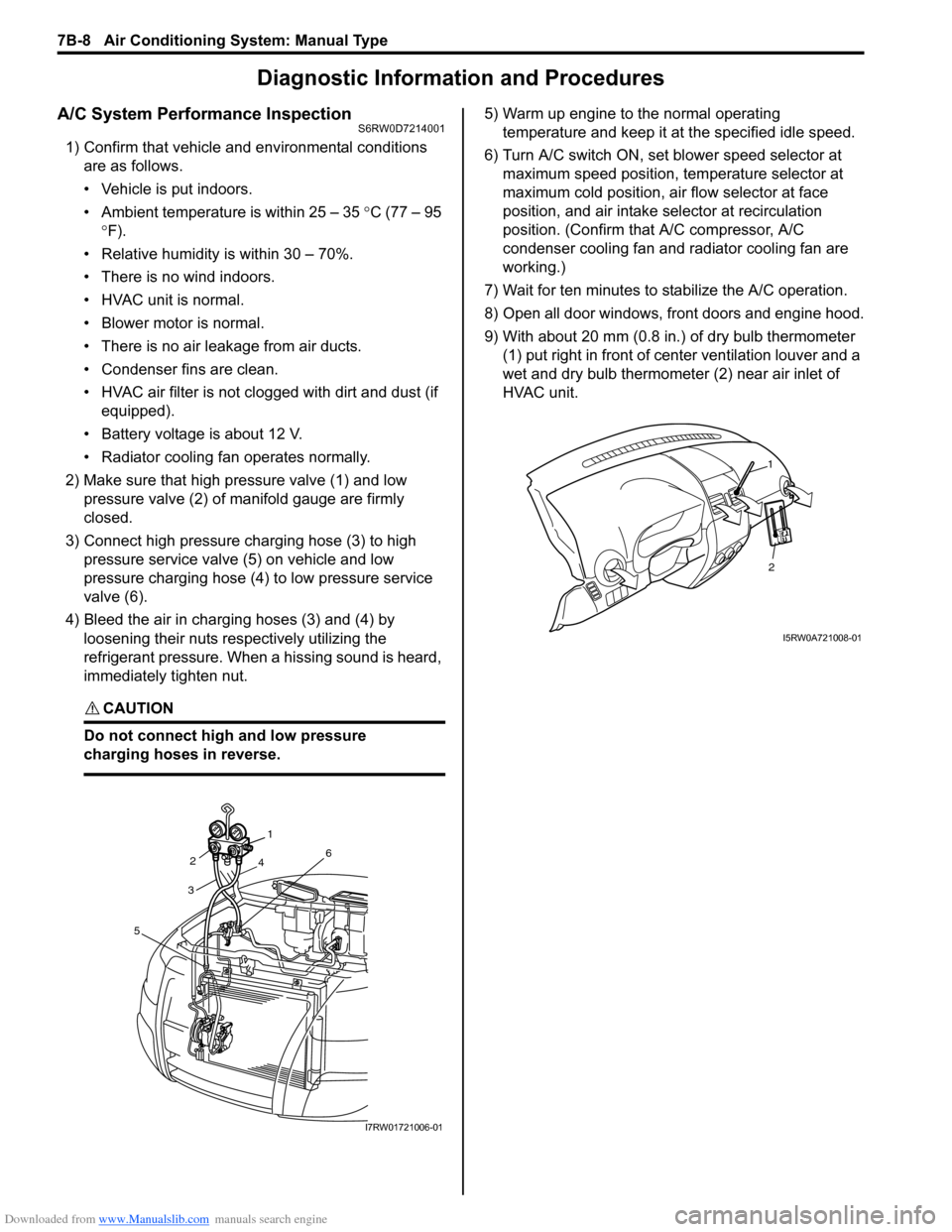

A/C System Performance InspectionS6RW0D7214001

1) Confirm that vehicle and environmental conditions

are as follows.

• Vehicle is put indoors.

• Ambient temperature is within 25 – 35 °C (77 – 95

°F).

• Relative humidity is within 30 – 70%.

• There is no wind indoors.

• HVAC unit is normal.

• Blower motor is normal.

• There is no air leakage from air ducts.

• Condenser fins are clean.

• HVAC air filter is not clogged with dirt and dust (if

equipped).

• Battery voltage is about 12 V.

• Radiator cooling fan operates normally.

2) Make sure that high pressure valve (1) and low

pressure valve (2) of manifold gauge are firmly

closed.

3) Connect high pressure charging hose (3) to high

pressure service valve (5) on vehicle and low

pressure charging hose (4) to low pressure service

valve (6).

4) Bleed the air in charging hoses (3) and (4) by

loosening their nuts respectively utilizing the

refrigerant pressure. When a hissing sound is heard,

immediately tighten nut.

CAUTION!

Do not connect high and low pressure

charging hoses in reverse.

5) Warm up engine to the normal operating

temperature and keep it at the specified idle speed.

6) Turn A/C switch ON, set blower speed selector at

maximum speed position, temperature selector at

maximum cold position, air flow selector at face

position, and air intake selector at recirculation

position. (Confirm that A/C compressor, A/C

condenser cooling fan and radiator cooling fan are

working.)

7) Wait for ten minutes to stabilize the A/C operation.

8) Open all door windows, front doors and engine hood.

9) With about 20 mm (0.8 in.) of dry bulb thermometer

(1) put right in front of center ventilation louver and a

wet and dry bulb thermometer (2) near air inlet of

HVAC unit.

321

4

6

5

I7RW01721006-01

2

1

I5RW0A721008-01

Page 951 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-11

Thermometer at center ventilation louver

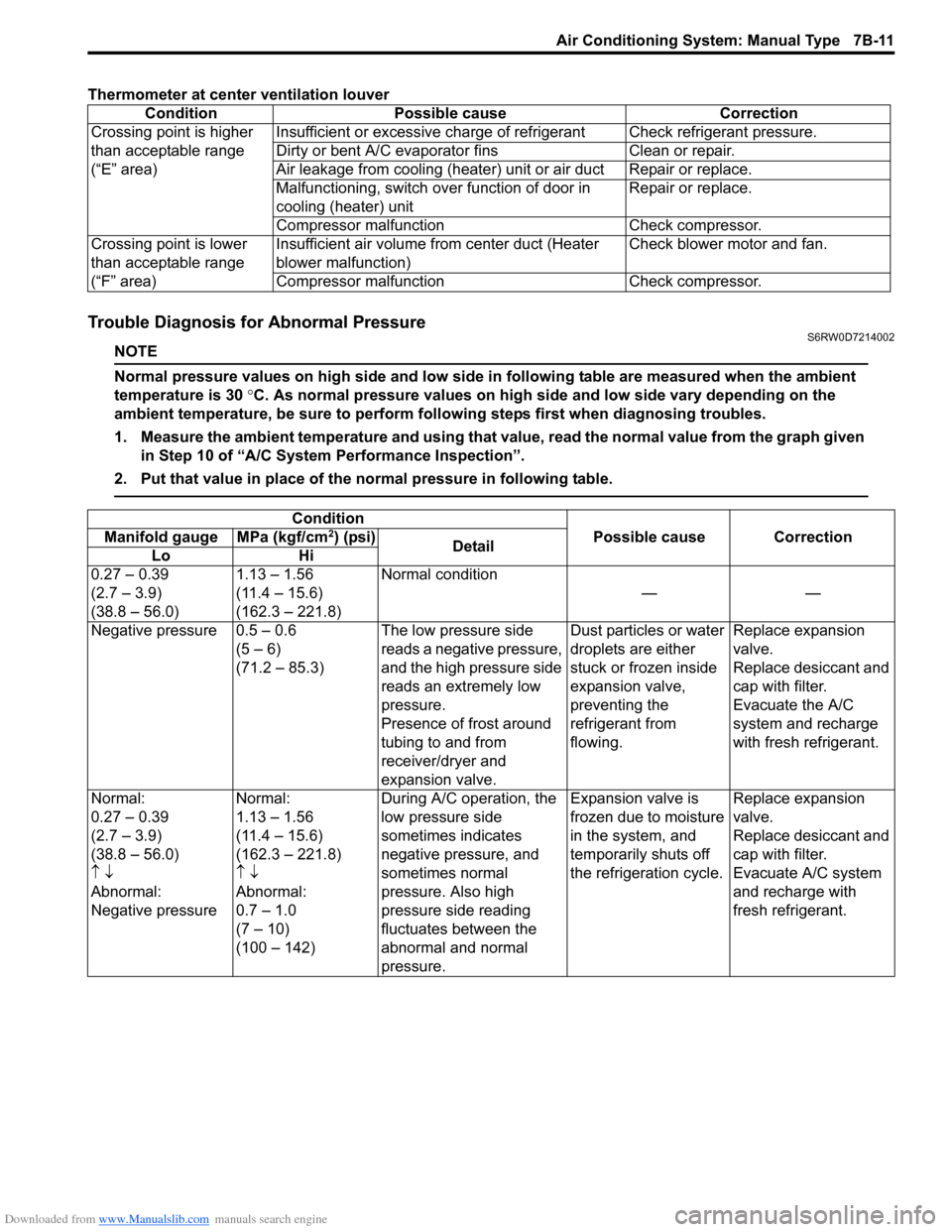

Trouble Diagnosis for Abnormal PressureS6RW0D7214002

NOTE

Normal pressure values on high side and low side in following table are measured when the ambient

temperature is 30 °C. As normal pressure values on high side and low side vary depending on the

ambient temperature, be sure to perform following steps first when diagnosing troubles.

1. Measure the ambient temperature and using that value, read the normal value from the graph given

in Step 10 of “A/C System Performance Inspection”.

2. Put that value in place of the normal pressure in following table.

Condition Possible cause Correction

Crossing point is higher

than acceptable range

(“E” area)Insufficient or excessive charge of refrigerant Check refrigerant pressure.

Dirty or bent A/C evaporator fins Clean or repair.

Air leakage from cooling (heater) unit or air duct Repair or replace.

Malfunctioning, switch over function of door in

cooling (heater) unitRepair or replace.

Compressor malfunction Check compressor.

Crossing point is lower

than acceptable range

(“F” area)Insufficient air volume from center duct (Heater

blower malfunction)Check blower motor and fan.

Compressor malfunction Check compressor.

Condition

Possible cause Correction Manifold gauge MPa (kgf/cm2) (psi)

Detail

Lo Hi

0.27 – 0.39

(2.7 – 3.9)

(38.8 – 56.0)1.13 – 1.56

(11.4 – 15.6)

(162.3 – 221.8)Normal condition

——

Negative pressure 0.5 – 0.6

(5 – 6)

(71.2 – 85.3)The low pressure side

reads a negative pressure,

and the high pressure side

reads an extremely low

pressure.

Presence of frost around

tubing to and from

receiver/dryer and

expansion valve.Dust particles or water

droplets are either

stuck or frozen inside

expansion valve,

preventing the

refrigerant from

flowing.Replace expansion

valve.

Replace desiccant and

cap with filter.

Evacuate the A/C

system and recharge

with fresh refrigerant.

Normal:

0.27 – 0.39

(2.7 – 3.9)

(38.8 – 56.0)

↑ ↓

Abnormal:

Negative pressureNormal:

1.13 – 1.56

(11.4 – 15.6)

(162.3 – 221.8)

↑ ↓

Abnormal:

0.7 – 1.0

(7 – 10)

(100 – 142)During A/C operation, the

low pressure side

sometimes indicates

negative pressure, and

sometimes normal

pressure. Also high

pressure side reading

fluctuates between the

abnormal and normal

pressure.Expansion valve is

frozen due to moisture

in the system, and

temporarily shuts off

the refrigeration cycle.Replace expansion

valve.

Replace desiccant and

cap with filter.

Evacuate A/C system

and recharge with

fresh refrigerant.

Page 952 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-12 Air Conditioning System: Manual Type

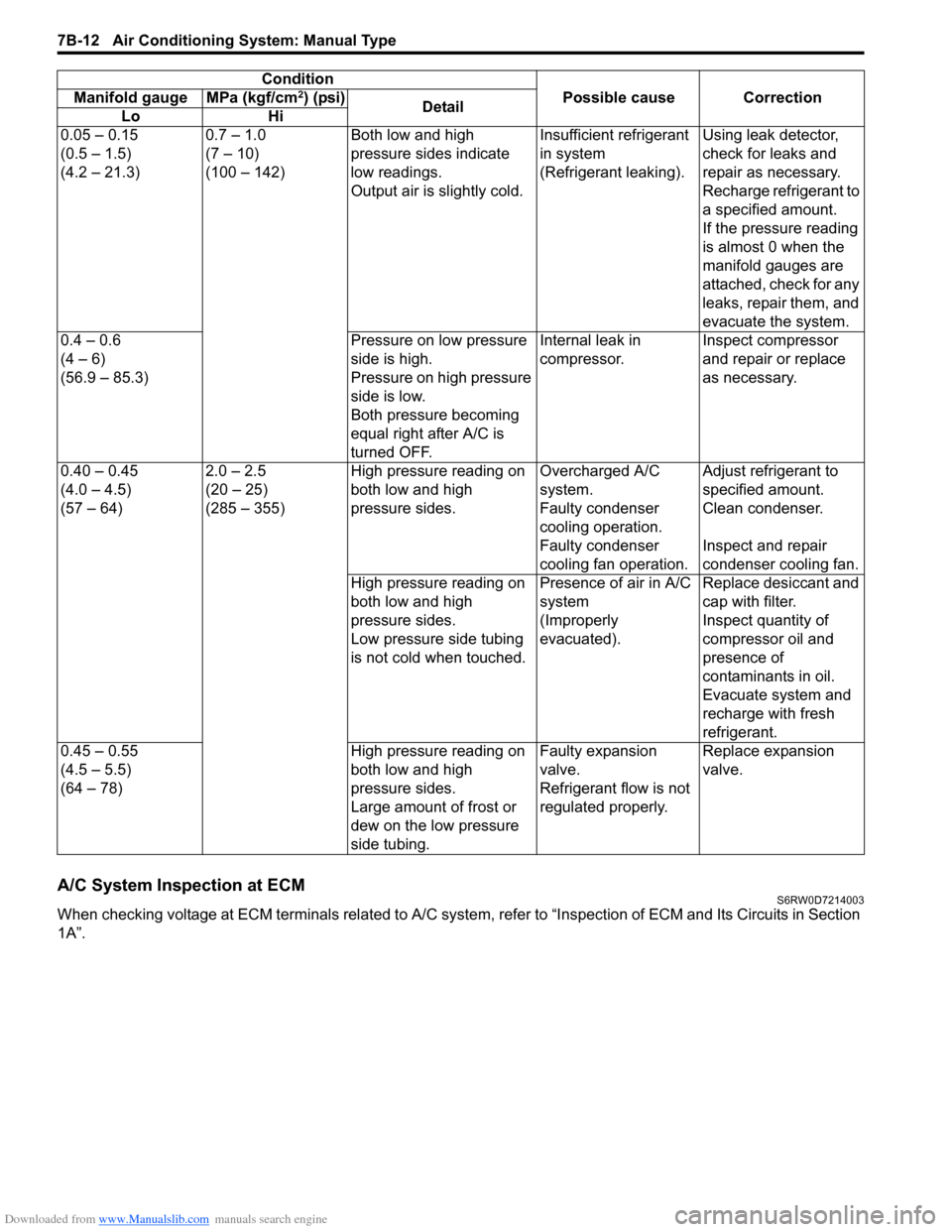

A/C System Inspection at ECMS6RW0D7214003

When checking voltage at ECM terminals related to A/C system, refer to “Inspection of ECM and Its Circuits in Section

1A”.0.05 – 0.15

(0.5 – 1.5)

(4.2 – 21.3)0.7 – 1.0

(7 – 10)

(100 – 142)Both low and high

pressure sides indicate

low readings.

Output air is slightly cold.Insufficient refrigerant

in system

(Refrigerant leaking).Using leak detector,

check for leaks and

repair as necessary.

Recharge refrigerant to

a specified amount.

If the pressure reading

is almost 0 when the

manifold gauges are

attached, check for any

leaks, repair them, and

evacuate the system.

0.4 – 0.6

(4 – 6)

(56.9 – 85.3)Pressure on low pressure

side is high.

Pressure on high pressure

side is low.

Both pressure becoming

equal right after A/C is

turned OFF.Internal leak in

compressor.Inspect compressor

and repair or replace

as necessary.

0.40 – 0.45

(4.0 – 4.5)

(57 – 64)2.0 – 2.5

(20 – 25)

(285 – 355)High pressure reading on

both low and high

pressure sides.Overcharged A/C

system.Adjust refrigerant to

specified amount.

Faulty condenser

cooling operation.Clean condenser.

Faulty condenser

cooling fan operation.Inspect and repair

condenser cooling fan.

High pressure reading on

both low and high

pressure sides.

Low pressure side tubing

is not cold when touched.Presence of air in A/C

system

(Improperly

evacuated).Replace desiccant and

cap with filter.

Inspect quantity of

compressor oil and

presence of

contaminants in oil.

Evacuate system and

recharge with fresh

refrigerant.

0.45 – 0.55

(4.5 – 5.5)

(64 – 78)High pressure reading on

both low and high

pressure sides.

Large amount of frost or

dew on the low pressure

side tubing.Faulty expansion

valve.

Refrigerant flow is not

regulated properly.Replace expansion

valve. Condition

Possible cause Correction Manifold gauge MPa (kgf/cm

2) (psi)

Detail

Lo Hi