charging system SUZUKI SX4 2006 1.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 959 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-19

Evacuation

CAUTION!

Do not evacuate before recovering

refrigerant in A/C system.

NOTE

Once air conditioning system circuit is

opened (exposed) to atmospheric air, system

must be evacuated by using a vacuum pump.

The A/C system should be attached with a

manifold gauge set, and should be evacuated

for approximately 15 minutes.

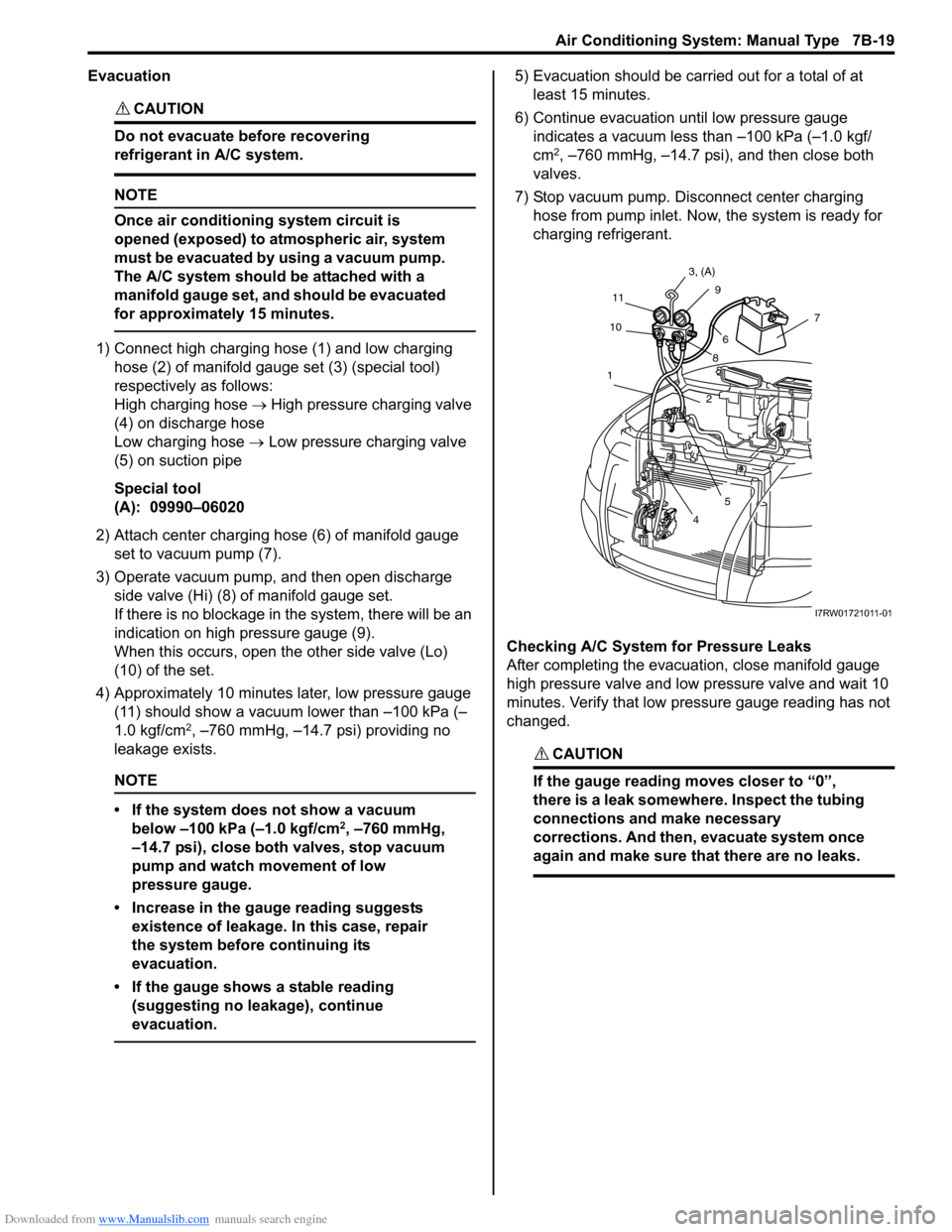

1) Connect high charging hose (1) and low charging

hose (2) of manifold gauge set (3) (special tool)

respectively as follows:

High charging hose → High pressure charging valve

(4) on discharge hose

Low charging hose → Low pressure charging valve

(5) on suction pipe

Special tool

(A): 09990–06020

2) Attach center charging hose (6) of manifold gauge

set to vacuum pump (7).

3) Operate vacuum pump, and then open discharge

side valve (Hi) (8) of manifold gauge set.

If there is no blockage in the system, there will be an

indication on high pressure gauge (9).

When this occurs, open the other side valve (Lo)

(10) of the set.

4) Approximately 10 minutes later, low pressure gauge

(11) should show a vacuum lower than –100 kPa (–

1.0 kgf/cm

2, –760 mmHg, –14.7 psi) providing no

leakage exists.

NOTE

• If the system does not show a vacuum

below –100 kPa (–1.0 kgf/cm

2, –760 mmHg,

–14.7 psi), close both valves, stop vacuum

pump and watch movement of low

pressure gauge.

• Increase in the gauge reading suggests

existence of leakage. In this case, repair

the system before continuing its

evacuation.

• If the gauge shows a stable reading

(suggesting no leakage), continue

evacuation.

5) Evacuation should be carried out for a total of at

least 15 minutes.

6) Continue evacuation until low pressure gauge

indicates a vacuum less than –100 kPa (–1.0 kgf/

cm

2, –760 mmHg, –14.7 psi), and then close both

valves.

7) Stop vacuum pump. Disconnect center charging

hose from pump inlet. Now, the system is ready for

charging refrigerant.

Checking A/C System for Pressure Leaks

After completing the evacuation, close manifold gauge

high pressure valve and low pressure valve and wait 10

minutes. Verify that low pressure gauge reading has not

changed.

CAUTION!

If the gauge reading moves closer to “0”,

there is a leak somewhere. Inspect the tubing

connections and make necessary

corrections. And then, evacuate system once

again and make sure that there are no leaks.

7

89 3, (A)

11

10

1

2

5

4

6

I7RW01721011-01

Page 960 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-20 Air Conditioning System: Manual Type

Charge

CAUTION!

• Because the sight glass is not used for this

A/C system, do not perform an additional

charge to the A/C system. To charge the

proper amount of refrigerant, recover and

evacuate the A/C system first. And then,

charge the proper amount of refrigerant

into the A/C system.

• Always charge refrigerant through low

pressure side of A/C system after the initial

charge is performed from the high

pressure side with the engine stopped.

• Never charge refrigerant through high

pressure side of A/C system with engine

running.

• Do not charge refrigerant while

compressor is hot.

• When installing tap valve to refrigerant

container to make a hole there through,

carefully follow directions given by

manufacturer.

• A pressure gauge should always be used

before and during refrigerant charge.

• The refrigerant container should be

emptied of refrigerant when discarding it.

• The refrigerant container should not be

heated up to 40 °C (104 °F) or over.

• Refrigerant container should not be

reversed in direction during refrigerant

charge. Reversing in direction causes

liquid refrigerant to enter compressor,

causing troubles, such as compression of

liquid refrigerant and the like.

NOTE

The air conditioning system contains HFC-

134a (R-134a).

Described here is a method to charge the air

conditioning system with refrigerant from the

refrigerant service container.

When charging refrigerant recovered by

using the refrigerant and recycling

equipment (when recycling refrigerant),

follow the procedure described in the

equipment manufacturer’s instruction

manual.

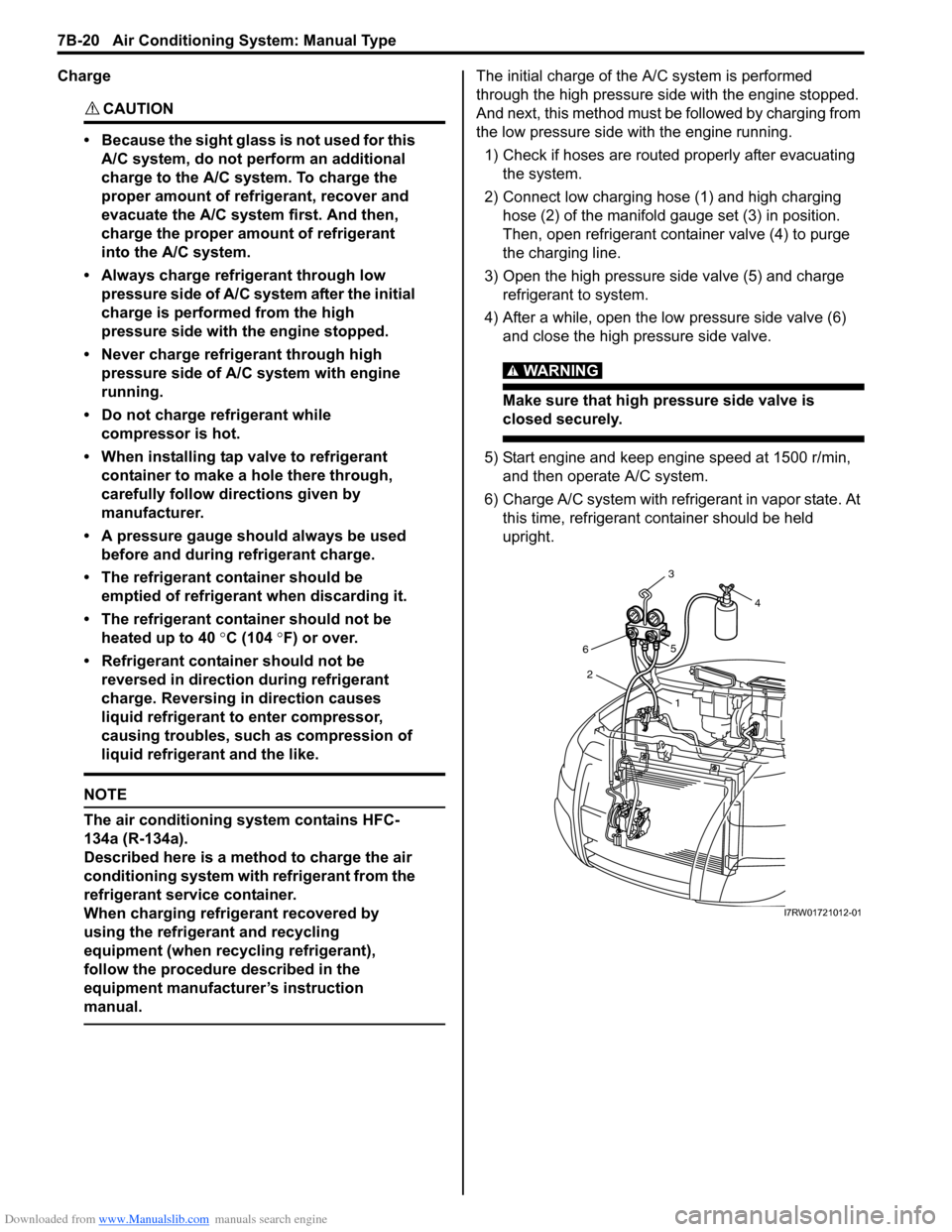

The initial charge of the A/C system is performed

through the high pressure side with the engine stopped.

And next, this method must be followed by charging from

the low pressure side with the engine running.

1) Check if hoses are routed properly after evacuating

the system.

2) Connect low charging hose (1) and high charging

hose (2) of the manifold gauge set (3) in position.

Then, open refrigerant container valve (4) to purge

the charging line.

3) Open the high pressure side valve (5) and charge

refrigerant to system.

4) After a while, open the low pressure side valve (6)

and close the high pressure side valve.

WARNING!

Make sure that high pressure side valve is

closed securely.

5) Start engine and keep engine speed at 1500 r/min,

and then operate A/C system.

6) Charge A/C system with refrigerant in vapor state. At

this time, refrigerant container should be held

upright.

4

3

6

2

1 5

I7RW01721012-01

Page 961 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-21

7) When refrigerant container (1) is emptied, use the

following procedure to replace it with a new

refrigerant container.

a) Close low pressure valve.

b) Replace empty container with a refrigerant

container which has been charged with

refrigerant. When using refrigerant container tap

valve (2), use the following procedure for

replacement.

i) Retract needle (3) and remove refrigerant

container tap valve by loosening its plate nut

(4).

ii) Install the refrigerant container tap valve to a

new refrigerant container.

c) Purge any air existing in center charging hose.

When using refrigerant container tap valve, use

the following procedure to purge air.

i) Once fully tighten refrigerant container tap

valve (1), and then loosen (open) plate nut

(2) slightly.

ii) Open low pressure side valve (3) of manifold

gauge set (4) a little.

iii) As soon as refrigerant comes out with a

“hiss” through a clearance between

refrigerant container and tap valve, tighten

plate nut as well as low pressure side valve.

iv) Turn handle of tap valve clockwise so that its

needle is screwed into the new container to

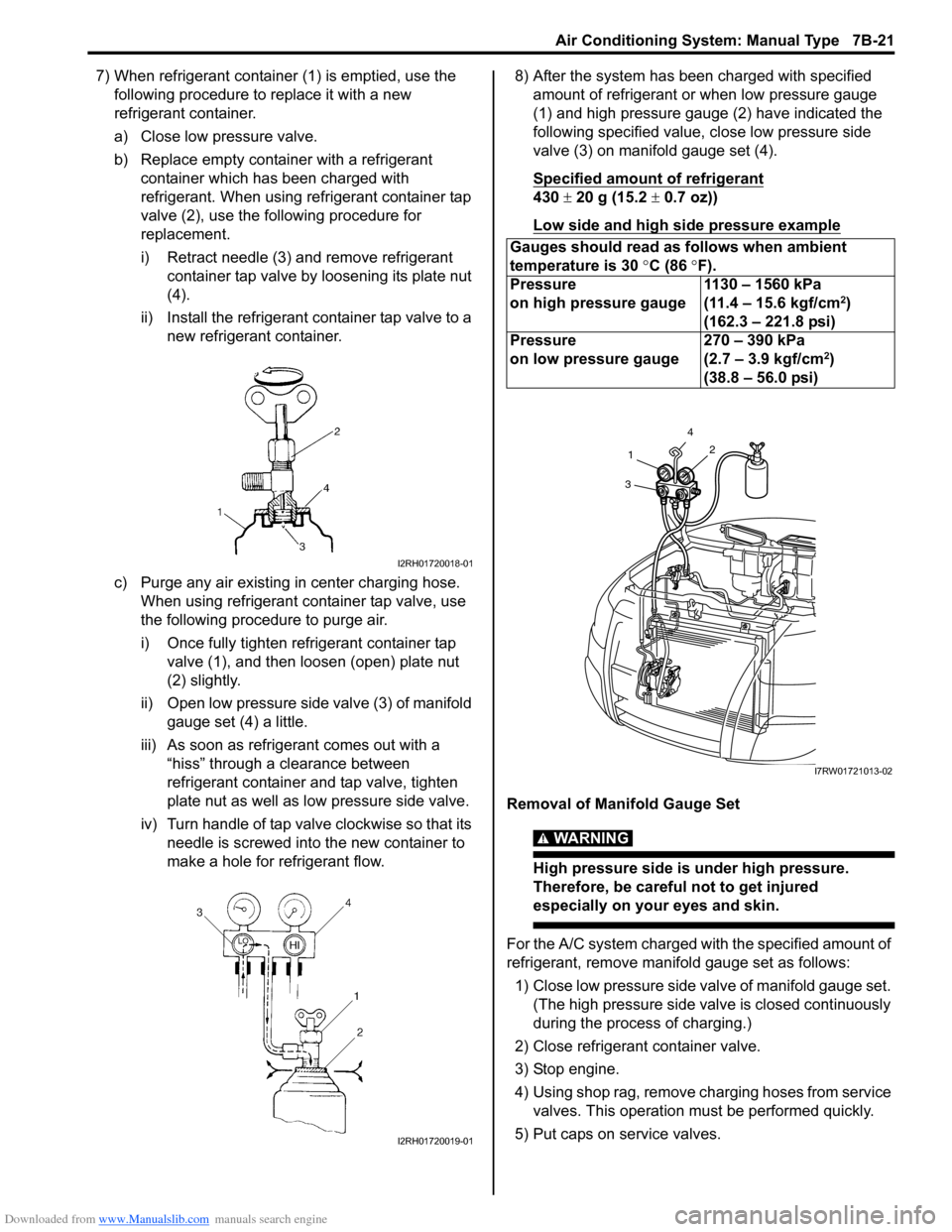

make a hole for refrigerant flow.8) After the system has been charged with specified

amount of refrigerant or when low pressure gauge

(1) and high pressure gauge (2) have indicated the

following specified value, close low pressure side

valve (3) on manifold gauge set (4).

Specified amount of refrigerant

430 ± 20 g (15.2 ± 0.7 oz))

Low side and high side pressure example

Removal of Manifold Gauge Set

WARNING!

High pressure side is under high pressure.

Therefore, be careful not to get injured

especially on your eyes and skin.

For the A/C system charged with the specified amount of

refrigerant, remove manifold gauge set as follows:

1) Close low pressure side valve of manifold gauge set.

(The high pressure side valve is closed continuously

during the process of charging.)

2) Close refrigerant container valve.

3) Stop engine.

4) Using shop rag, remove charging hoses from service

valves. This operation must be performed quickly.

5) Put caps on service valves.

I2RH01720018-01

I2RH01720019-01

Gauges should read as follows when ambient

temperature is 30 °C (86 °F).

Pressure

on high pressure gauge1130 – 1560 kPa

(11.4 – 15.6 kgf/cm

2)

(162.3 – 221.8 psi)

Pressure

on low pressure gauge270 – 390 kPa

(2.7 – 3.9 kgf/cm

2)

(38.8 – 56.0 psi)

4

2

1

3

I7RW01721013-02

Page 969 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-29

A/C Refrigerant Pressure Sensor and Its Circuit

Inspection

S6RW0D7216014

1) Disconnect A/C refrigerant pressure sensor

connector.

2) Turn ignition switch to ON position.

3) Check if voltage between “RED” wire terminal and

“ORN” wire terminal of A/C refrigerant pressure

sensor connector is 4.75 V to 5.25 V.

If not, check A/C refrigerant pressure sensor circuit.

4) Connect A/C refrigerant pressure sensor connector

with ignition switch turned OFF.

5) Connect manifold gauge set to the charging valves.

6) Check A/C refrigerant pressure sensor voltage of

ECM connector referring to “A/C System Inspection

at ECM”.

If voltage is not as specified below, replace A/C

refrigerant pressure sensor.

A/C refrigerant pressure sensor voltage

specifications (A/C refrigerant pressure measured

by manifold gauge)

0.8 MPa (8.0 kgf/cm2, 116 psi): 1.40 – 1.78 V

1.4 MPa (14 kgf/cm2, 203 psi): 2.18 – 2.64 V

1.6 MPa (16 kgf/cm2, 232 psi): 2.44 – 2.92 V

1.8 MPa (18 kgf/cm2, 261 psi): 2.70 – 3.21 V

A/C Refrigerant Pressure Sensor Removal and

Installation

S6RW0D7216015

Removal

1) Recover refrigerant from the A/C system with the

recovery and recycling equipment referring to

“Recovery” in “Operation Procedure for Refrigerant

Charge”.

2) Disconnect negative (–) cable from battery.

3) Disconnect A/C refrigerant pressure sensor

connector.

4) Remove A/C refrigerant pressure sensor (1) from

liquid pipe (2).Installation

Reverse removal procedure noting the following

instructions.

• Apply compressor oil to O-ring of A/C refrigerant

pressure sensor.

• Tighten A/C refrigerant pressure sensor to specified

torque.

Tightening torque

A/C refrigerant pressure sensor (a): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

• Evacuate and charge the A/C system referring to

“Evacuation” and “Charge” in “Operation Procedure

for Refrigerant Charge”.

A/C Switch InspectionS6RW0D7216016

• Check that there is continuity between terminal (1)

and terminal (2) when A/C switch is at ON position.

• Check that there is no continuity between terminal (1)

and terminal (2) when A/C switch is at OFF position.

If check result does not meet the above conditions,

replace HVAC control unit.

2

1

I5RW0A721029-01

(a)

I5RW0A721030-01

1

2

I5RW0A721031-01

Page 977 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-37

Specifications

Tightening Torque SpecificationsS6RW0D7217001

NOTE

The specified tightening torque is also described in the following.

“A/C System Major Components Location”

“Compressor Assembly Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Service MaterialS6RW0D7218001

NOTE

Required service material is also described in the following.

“HVAC Unit Components”

“Compressor Assembly Components”

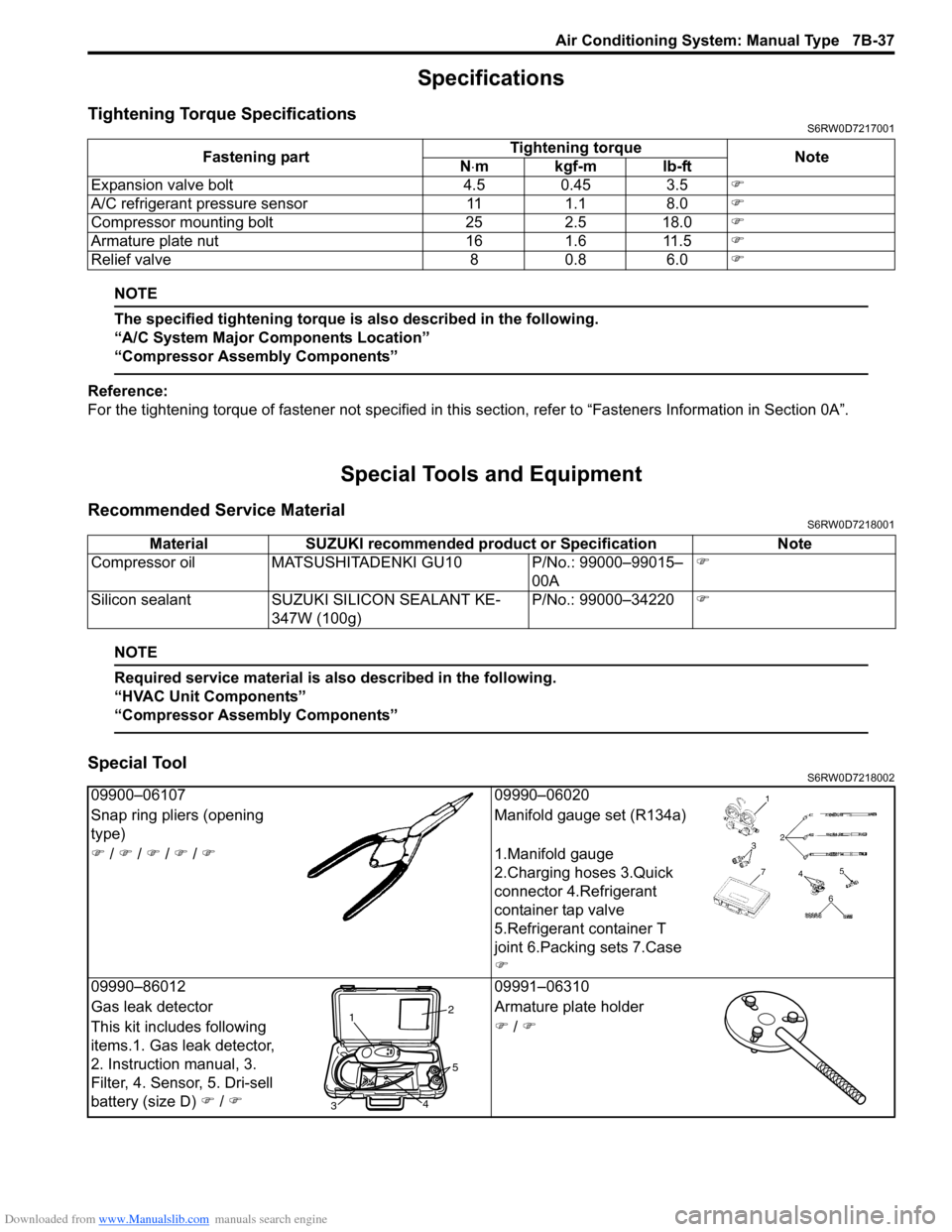

Special ToolS6RW0D7218002

Fastening partTightening torque

Note

N⋅mkgf-mlb-ft

Expansion valve bolt 4.5 0.45 3.5�)

A/C refrigerant pressure sensor 11 1.1 8.0�)

Compressor mounting bolt 25 2.5 18.0�)

Armature plate nut 16 1.6 11.5�)

Relief valve 8 0.8 6.0�)

Material SUZUKI recommended product or Specification Note

Compressor oil MATSUSHITADENKI GU10 P/No.: 99000–99015–

00A�)

Silicon sealant SUZUKI SILICON SEALANT KE-

347W (100g)P/No.: 99000–34220�)

09900–06107 09990–06020

Snap ring pliers (opening

type)Manifold gauge set (R134a)

�) / �) / �) / �) / �)1.Manifold gauge

2.Charging hoses 3.Quick

connector 4.Refrigerant

container tap valve

5.Refrigerant container T

joint 6.Packing sets 7.Case

�)

09990–86012 09991–06310

Gas leak detector Armature plate holder

This kit includes following

items.1. Gas leak detector,

2. Instruction manual, 3.

Filter, 4. Sensor, 5. Dri-sell

battery (size D) �) / �)�) / �)

12

34

5

Page 1053 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-14

DTC TableS6RW0D8204003

NOTE

The DTCs (B1022 and B1023) shown with asterisk (*) below have been established only for the M15A

engine model with 4A/T equipped with slip-control (i.e., Hong Kong model). These codes are meant to

be recorded when External Scrapping Deployment Controller is operated by a Japanese authorized

special scrapping trader. Therefore, normally these codes will not appear outside Japan. However,

should these codes be detected, SDM must be replaced because the cause is due to SDM detection

failure.

SDM DTC

DTC No. Detecting itemDetecting condition

(DTC will set when detecting)Trouble area

—Normal — —

�) B1013 SDM internal failureMalfunctioned SDM internal

circuit, G sensor, memory or

CPU.•SDM

�) B1014 “AIR BAG” warning light circuit“AIR BAG” warning light circuit

has been shorted to ground,

shorted to power or opened for

more than 4 sec.• “AIR BAG” warning light circuit

• Combination meter

•SDM

�) B1016 Power supply voltage too highPower supply voltage is more

than 21.4 V for, more than 16

sec.• Charging system

•SDM

�) B1017 Power supply voltage too lowPower supply voltage is less

than 7.2 V for more than 16 sec.• Charging system

•SDM

�) B1021Front air bag deployment

recordDeployment of front air bag has

been recorded in SDM.If this DTC has been recorded

even though air bag has not

been deployed

•SDM

• Driver and/or Passenger air

bag module

• Those initiator circuit.

*B1022Scrapping deployment

controller activatedScrapping deployment command

has been input to SDM from

external scrapping deployment

controller•SDM

*B1023 Scraping deployment recordScrapping deployment execution

has been recorded in SDM•SDM

�) B1024Driver side-air bag deployment

recordDeployment of driver side-air

bag has been recorded in SDM.If this DTC has been recorded

even though side-air bag has not

been deployed

•SDM

• Driver side-air bag module

• Its initiator circuit

�) B1025Passenger side-air bag

deployment recordDeployment of passenger side-

air bag has been recorded in

SDM.If this DTC has been recorded

even though side-air bag has not

been deployed

•SDM

• Passenger side-air bag

module

• Its initiator circuit

Page 1065 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-26

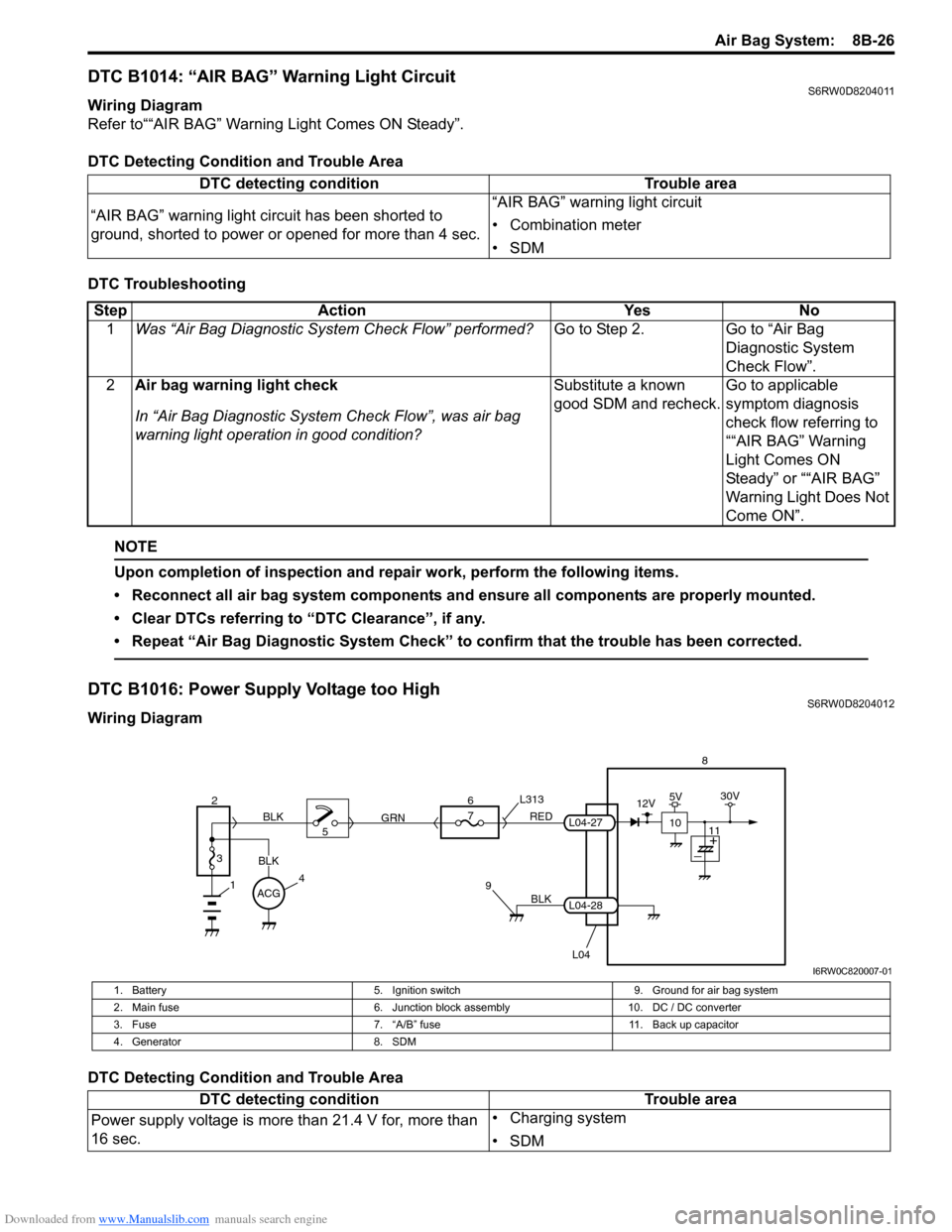

DTC B1014: “AIR BAG” Warning Light CircuitS6RW0D8204011

Wiring Diagram

Refer to““AIR BAG” Warning Light Comes ON Steady”.

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Clear DTCs referring to “DTC Clearance”, if any.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

DTC B1016: Power Supply Voltage too HighS6RW0D8204012

Wiring Diagram

DTC Detecting Condition and Trouble AreaDTC detecting condition Trouble area

“AIR BAG” warning light circuit has been shorted to

ground, shorted to power or opened for more than 4 sec.“AIR BAG” warning light circuit

• Combination meter

•SDM

Step Action Yes No

1Was “Air Bag Diagnostic System Check Flow” performed?Go to Step 2. Go to “Air Bag

Diagnostic System

Check Flow”.

2Air bag warning light check

In “Air Bag Diagnostic System Check Flow”, was air bag

warning light operation in good condition?Substitute a known

good SDM and recheck.Go to applicable

symptom diagnosis

check flow referring to

““AIR BAG” Warning

Light Comes ON

Steady” or ““AIR BAG”

Warning Light Does Not

Come ON”.

BLK

L04

7

RED

GRN L313

98

L04-28

L04-27

1

2

3

BLK

45 BLK6

ACG

10

12V5V30V

11

I6RW0C820007-01

1. Battery 5. Ignition switch 9. Ground for air bag system

2. Main fuse 6. Junction block assembly 10. DC / DC converter

3. Fuse 7. “A/B” fuse 11. Back up capacitor

4. Generator 8. SDM

DTC detecting condition Trouble area

Power supply voltage is more than 21.4 V for, more than

16 sec.• Charging system

•SDM

Page 1066 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-27 Air Bag System:

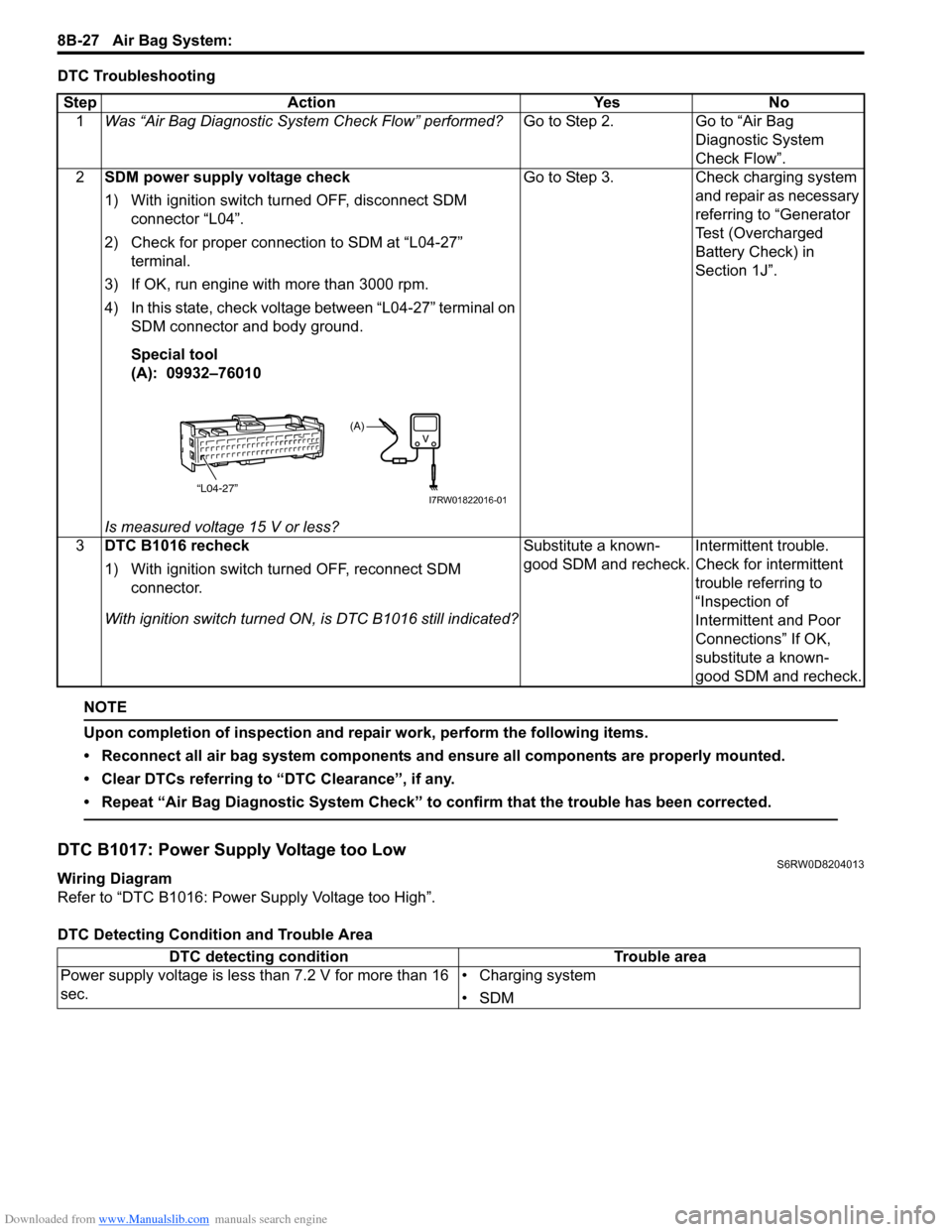

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Clear DTCs referring to “DTC Clearance”, if any.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

DTC B1017: Power Supply Voltage too LowS6RW0D8204013

Wiring Diagram

Refer to “DTC B1016: Power Supply Voltage too High”.

DTC Detecting Condition and Trouble AreaStep Action Yes No

1Was “Air Bag Diagnostic System Check Flow” performed?Go to Step 2. Go to “Air Bag

Diagnostic System

Check Flow”.

2SDM power supply voltage check

1) With ignition switch turned OFF, disconnect SDM

connector “L04”.

2) Check for proper connection to SDM at “L04-27”

terminal.

3) If OK, run engine with more than 3000 rpm.

4) In this state, check voltage between “L04-27” terminal on

SDM connector and body ground.

Special tool

(A): 09932–76010

Is measured voltage 15 V or less?Go to Step 3. Check charging system

and repair as necessary

referring to “Generator

Test (Overcharged

Battery Check) in

Section 1J”.

3DTC B1016 recheck

1) With ignition switch turned OFF, reconnect SDM

connector.

With ignition switch turned ON, is DTC B1016 still indicated?Substitute a known-

good SDM and recheck.Intermittent trouble.

Check for intermittent

trouble referring to

“Inspection of

Intermittent and Poor

Connections” If OK,

substitute a known-

good SDM and recheck.

“L04-27”

(A)

I7RW01822016-01

DTC detecting condition Trouble area

Power supply voltage is less than 7.2 V for more than 16

sec.• Charging system

•SDM

Page 1124 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-85 Air Bag System:

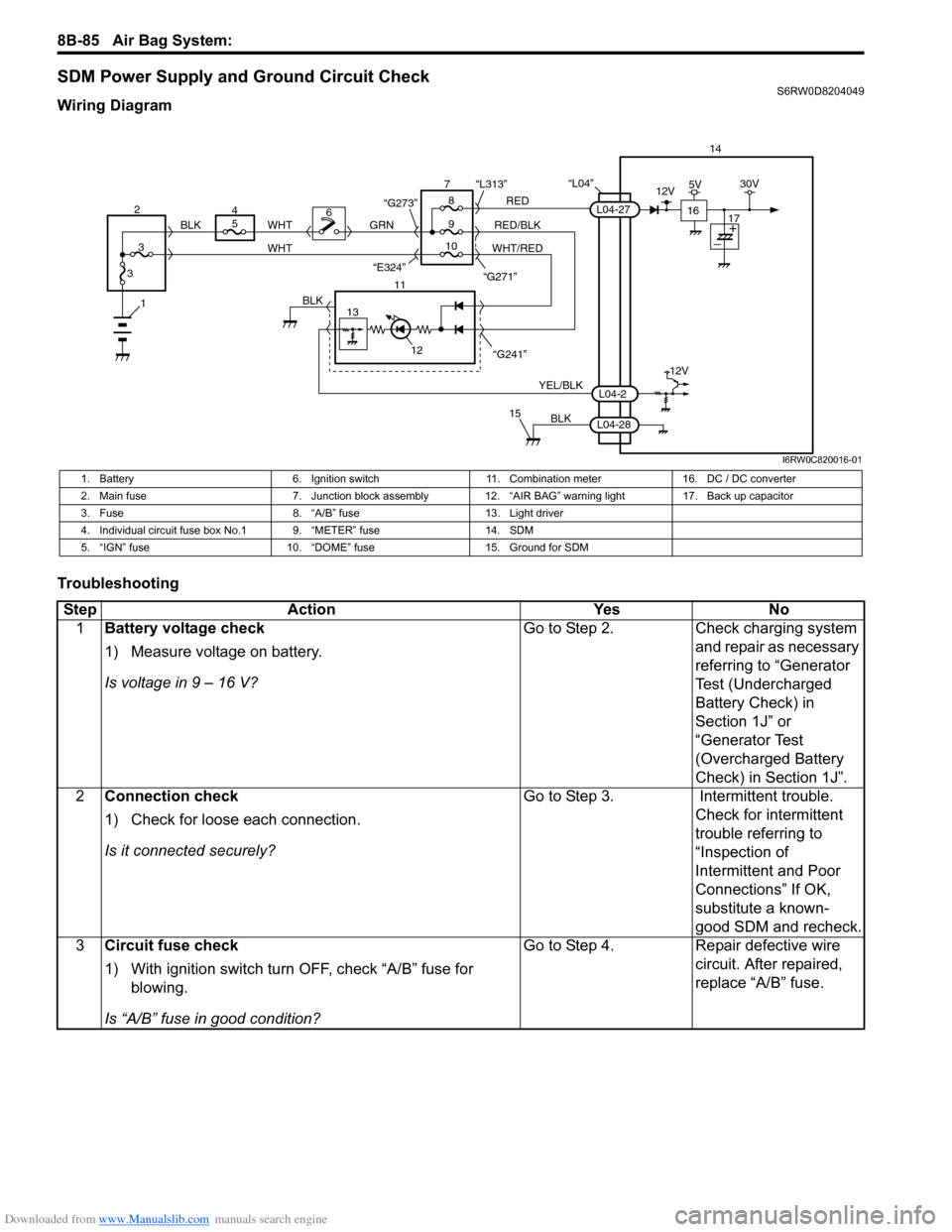

SDM Power Supply and Ground Circuit CheckS6RW0D8204049

Wiring Diagram

Troubleshooting

“L04”14

5

9RED

RED/BLK GRN

YEL/BLK

BLK

8 7

11

12

15

L04-2

L04-28

L04-27

“G241” “G271” “L313”

13

12V

6

1BLK

WHT WHT

WHT/RED 2

34

310 BLK

“G273”

“E324”16

12V5V30V

17

I6RW0C820016-01

1. Battery 6. Ignition switch 11. Combination meter 16. DC / DC converter

2. Main fuse 7. Junction block assembly 12. “AIR BAG” warning light 17. Back up capacitor

3. Fuse 8. “A/B” fuse 13. Light driver

4. Individual circuit fuse box No.1 9. “METER” fuse 14. SDM

5. “IGN” fuse 10. “DOME” fuse 15. Ground for SDM

Step Action Yes No

1Battery voltage check

1) Measure voltage on battery.

Is voltage in 9 – 16 V?Go to Step 2. Check charging system

and repair as necessary

referring to “Generator

Test (Undercharged

Battery Check) in

Section 1J” or

“Generator Test

(Overcharged Battery

Check) in Section 1J”.

2Connection check

1) Check for loose each connection.

Is it connected securely?Go to Step 3. Intermittent trouble.

Check for intermittent

trouble referring to

“Inspection of

Intermittent and Poor

Connections” If OK,

substitute a known-

good SDM and recheck.

3Circuit fuse check

1) With ignition switch turn OFF, check “A/B” fuse for

blowing.

Is “A/B” fuse in good condition?Go to Step 4. Repair defective wire

circuit. After repaired,

replace “A/B” fuse.

Page 1161 of 1556

Downloaded from www.Manualslib.com manuals search engine Table of Contents 9- i

9

Section 9

CONTENTS

Body, Cab and Accessories

Precautions ................................................. 9-1

Precautions............................................................. 9-1

Precautions on Body, Cab and Accessories ......... 9-1

Precautions for Body Service ................................ 9-1

Fastener Caution for Body Service ....................... 9-1

Wiring Systems........................................ 9A-1

Precautions........................................................... 9A-1

Cautions in Body Electrical System Servicing..... 9A-1

General Description ............................................. 9A-1

Abbreviations ...................................................... 9A-1

Wire / Connector Color Symbols ......................... 9A-1

Symbols and Marks ............................................ 9A-2

How to Read Connector Layout Diagram ........... 9A-4

How to Read Connector Codes and Terminal

Nos.................................................................... 9A-5

How to Read Ground Point ................................. 9A-8

How to Read Power Supply Diagram.................. 9A-9

How to Read System Circuit Diagram................. 9A-9

Connector Layout Diagram ............................... 9A-11

Connector Layout Diagram ............................... 9A-11

Engine Compartment ........................................ 9A-11

Instrument Panel ............................................... 9A-19

Door, Roof......................................................... 9A-25

Floor .................................................................. 9A-28

Rear .................................................................. 9A-32

Ground Point ...................................................... 9A-33

Ground (earth) Point ......................................... 9A-33

Power Supply Diagram ...................................... 9A-34

Power Supply Diagram ..................................... 9A-34

Fuses and the Protected Parts ......................... 9A-36

Fuses in Main Fuse Box ................................... 9A-36

Individual Circuit Fuse Box No. 1 ...................... 9A-37

Individual Circuit Fuse Box No. 2 (In J/B

(Except Taiwan)) ............................................. 9A-38

Individual Circuit Fuse Box No. 2 (In J/B

(Taiwan)) ......................................................... 9A-40

Junction Block (J/B) Connector / Fuse Layout .. 9A-42

Junction Block Inner Circuit (Overview

(Except Taiwan)) ............................................. 9A-43

Junction Block Inner Circuit (Detail (Except

Taiwan)) .......................................................... 9A-45

Junction Block Inner Circuit (Overview

(Taiwan)) ......................................................... 9A-50Junction Block Inner Circuit (Detail (Taiwan)) ... 9A-52

System Circuit Diagram.....................................9A-57

System Circuit Diagram .................................... 9A-57

A-1 Cranking System Circuit Diagram .............. 9A-58

A-2 Charging System Circuit Diagram .............. 9A-59

A-3 Ignition System Circuit Diagram (M15A

engine, M16A engine) ..................................... 9A-60

A-3 Ignition System Circuit Diagram (J20A

engine) ............................................................ 9A-61

A-4 Cooling System Circuit Diagram (M15A

engine, M16A engine) ..................................... 9A-62

A-4 Cooling System Circuit Diagram (J20A

engine) ............................................................ 9A-63

A-5 Engine and A/C Control System Circuit

Diagram (M15A engine) .................................. 9A-64

A-5 Engine and A/C Control System Circuit

Diagram (M16A engine) .................................. 9A-68

A-5 Engine and A/C Control System Circuit

Diagram (J20A engine) ................................... 9A-72

A-6 A/T Control System Circuit Diagram........... 9A-76

A-7 Immobilizer System Circuit Diagram .......... 9A-78

A-8 Body Control System Circuit Diagram

(Except Taiwan) .............................................. 9A-79

A-8 Body Control System Circuit Diagram

(Taiwan) .......................................................... 9A-83

A-10 4WD Control System (Except Taiwan) ..... 9A-87

B-1 Windshield Wiper and Washer Circuit

Diagram........................................................... 9A-88

B-2 Rear Wiper and Washer Circuit Diagram

(Except Taiwan) .............................................. 9A-89

B-2 Rear Wiper and Washer Circuit Diagram

(Taiwan) .......................................................... 9A-90

B-3 Rear Defogger Circuit Diagram (Except

Taiwan) ........................................................... 9A-91

B-3 Rear Defogger Circuit Diagram (Taiwan) ... 9A-92

B-4 Power Window Circuit Diagram .................. 9A-93

B-5 Power Door Lock Circuit Diagram (Except

Taiwan) ........................................................... 9A-95

B-5 Power Door Lock Circuit Diagram

(Taiwan) .......................................................... 9A-97

B-6 Power Mirror Circuit Diagram (Except

Taiwan) ........................................................... 9A-99

B-6 Power Mirror Circuit Diagram (Taiwan) .... 9A-100

B-7 Horn Circuit Diagram ................................ 9A-101

B-8 Seat Heater Circuit Diagram..................... 9A-102