clutch SUZUKI SX4 2006 1.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 365 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Lubrication System: 1E-9

Specifications

Tightening Torque SpecificationsS6RW0D1507001

NOTE

The specified tightening torque is also described in the following.

“Oil Pan and Oil Pump Strainer Components”

“Oil Pump Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Service MaterialS6RW0D1508001

NOTE

Required service material is also described in the following.

“Oil Pan and Oil Pump Strainer Components”

“Oil Pump Components”

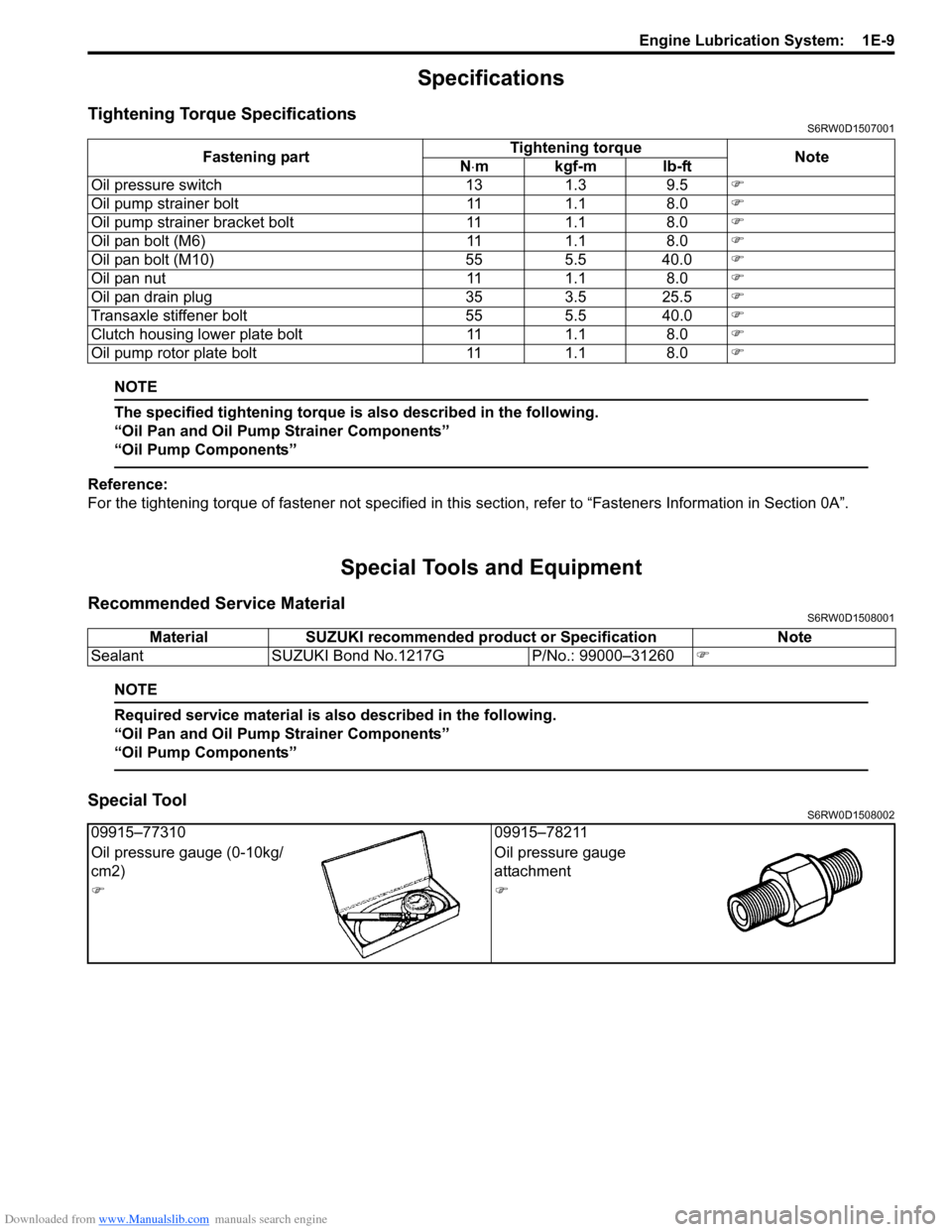

Special ToolS6RW0D1508002

Fastening partTightening torque

Note

N⋅mkgf-mlb-ft

Oil pressure switch 13 1.3 9.5�)

Oil pump strainer bolt 11 1.1 8.0�)

Oil pump strainer bracket bolt 11 1.1 8.0�)

Oil pan bolt (M6) 11 1.1 8.0�)

Oil pan bolt (M10) 55 5.5 40.0�)

Oil pan nut 11 1.1 8.0�)

Oil pan drain plug 35 3.5 25.5�)

Transaxle stiffener bolt 55 5.5 40.0�)

Clutch housing lower plate bolt 11 1.1 8.0�)

Oil pump rotor plate bolt 11 1.1 8.0�)

Material SUZUKI recommended product or Specification Note

Sealant SUZUKI Bond No.1217G P/No.: 99000–31260�)

09915–77310 09915–78211

Oil pressure gauge (0-10kg/

cm2)Oil pressure gauge

attachment

�)�)

Page 368 of 1556

Downloaded from www.Manualslib.com manuals search engine 1F-3 Engine Cooling System:

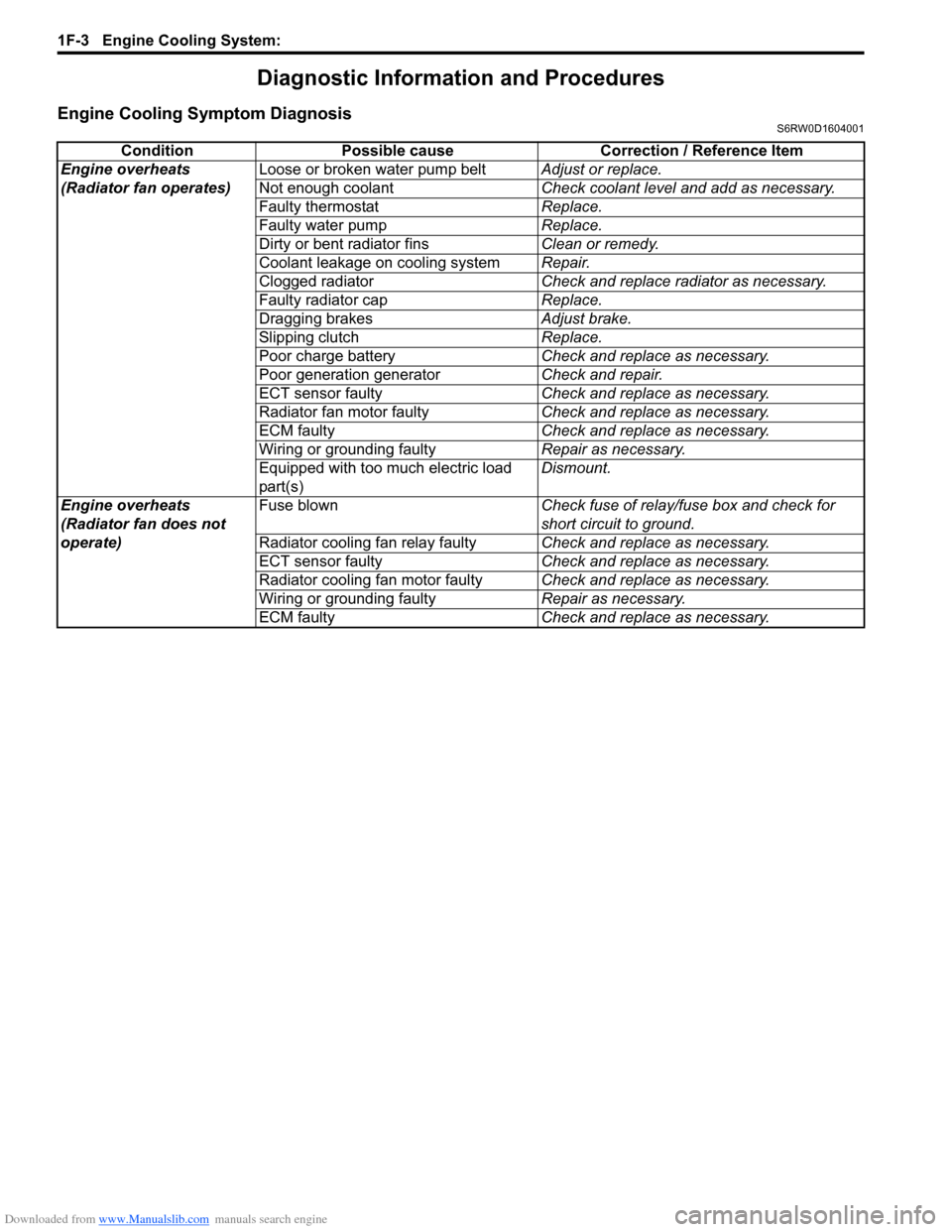

Diagnostic Information and Procedures

Engine Cooling Symptom DiagnosisS6RW0D1604001

Condition Possible cause Correction / Reference Item

Engine overheats

(Radiator fan operates)Loose or broken water pump beltAdjust or replace.

Not enough coolantCheck coolant level and add as necessary.

Faulty thermostatReplace.

Faulty water pumpReplace.

Dirty or bent radiator finsClean or remedy.

Coolant leakage on cooling systemRepair.

Clogged radiatorCheck and replace radiator as necessary.

Faulty radiator capReplace.

Dragging brakesAdjust brake.

Slipping clutchReplace.

Poor charge batteryCheck and replace as necessary.

Poor generation generatorCheck and repair.

ECT sensor faultyCheck and replace as necessary.

Radiator fan motor faultyCheck and replace as necessary.

ECM faultyCheck and replace as necessary.

Wiring or grounding faultyRepair as necessary.

Equipped with too much electric load

part(s)Dismount.

Engine overheats

(Radiator fan does not

operate)Fuse blownCheck fuse of relay/fuse box and check for

short circuit to ground.

Radiator cooling fan relay faultyCheck and replace as necessary.

ECT sensor faultyCheck and replace as necessary.

Radiator cooling fan motor faultyCheck and replace as necessary.

Wiring or grounding faultyRepair as necessary.

ECM faultyCheck and replace as necessary.

Page 406 of 1556

Downloaded from www.Manualslib.com manuals search engine 1I-1 Starting System:

Engine

Starting System

Schematic and Routing Diagram

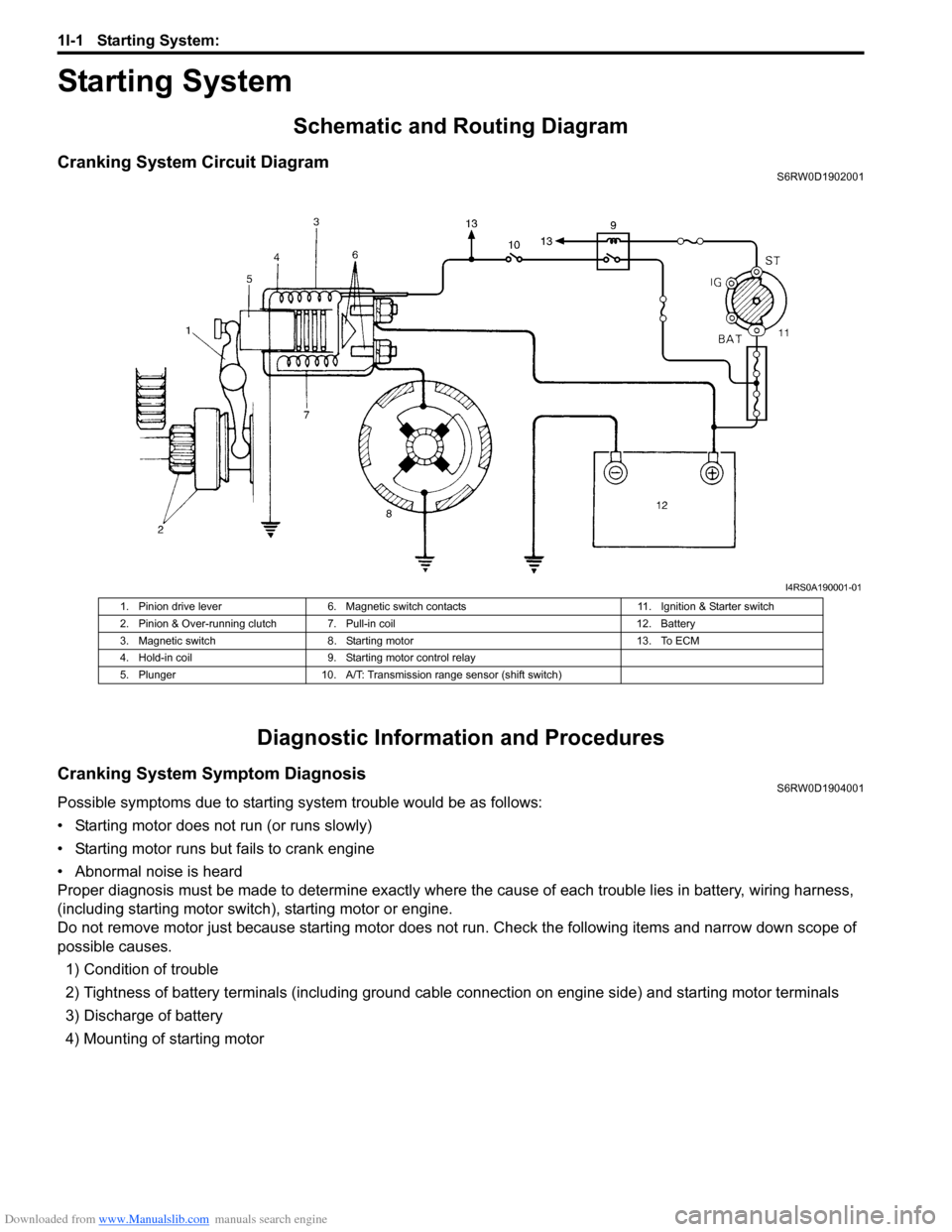

Cranking System Circuit DiagramS6RW0D1902001

Diagnostic Information and Procedures

Cranking System Symptom DiagnosisS6RW0D1904001

Possible symptoms due to starting system trouble would be as follows:

• Starting motor does not run (or runs slowly)

• Starting motor runs but fails to crank engine

• Abnormal noise is heard

Proper diagnosis must be made to determine exactly where the cause of each trouble lies in battery, wiring harness,

(including starting motor switch), starting motor or engine.

Do not remove motor just because starting motor does not run. Check the following items and narrow down scope of

possible causes.

1) Condition of trouble

2) Tightness of battery terminals (including ground cable connection on engine side) and starting motor terminals

3) Discharge of battery

4) Mounting of starting motor

I4RS0A190001-01

1. Pinion drive lever 6. Magnetic switch contacts 11. Ignition & Starter switch

2. Pinion & Over-running clutch 7. Pull-in coil 12. Battery

3. Magnetic switch 8. Starting motor 13. To ECM

4. Hold-in coil 9. Starting motor control relay

5. Plunger 10. A/T: Transmission range sensor (shift switch)

Page 407 of 1556

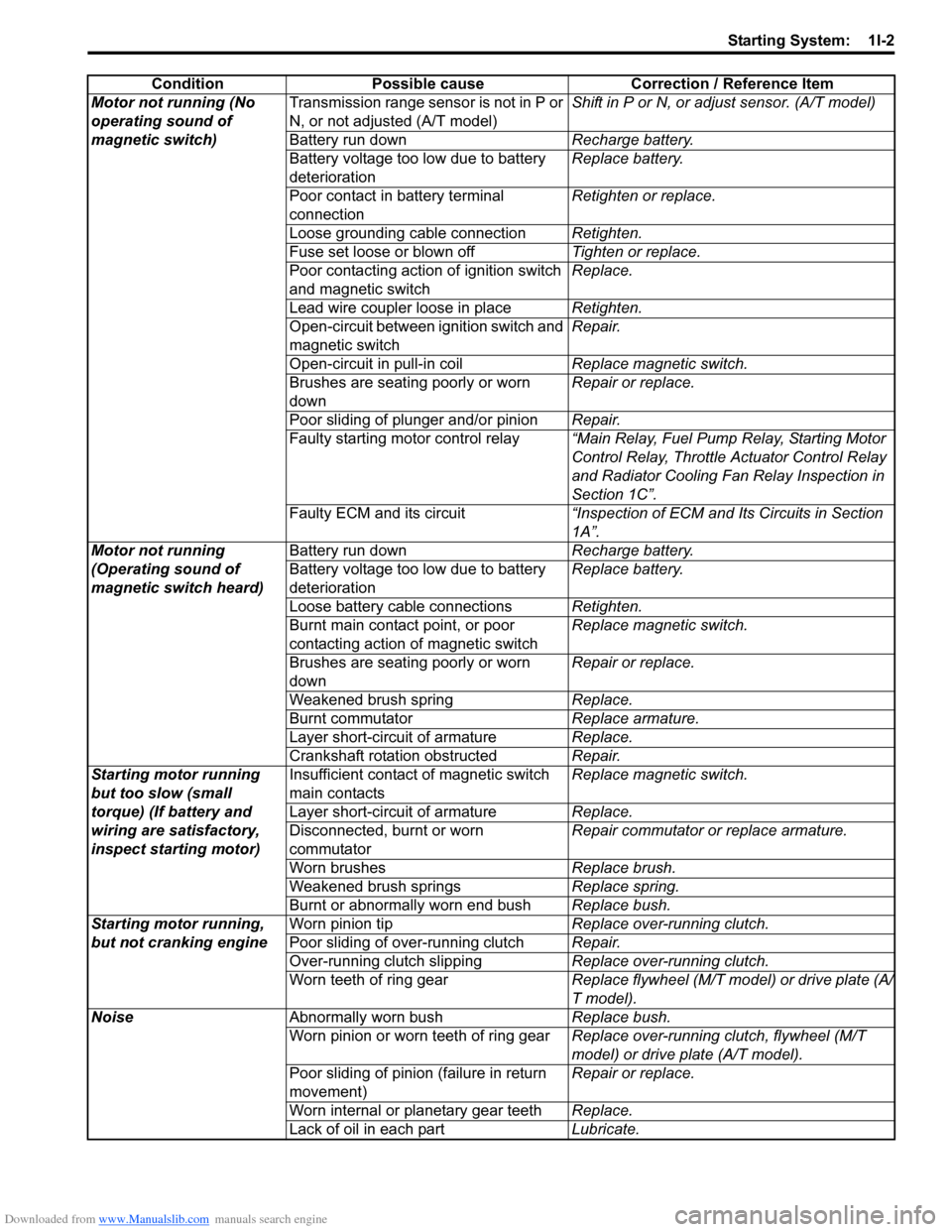

Downloaded from www.Manualslib.com manuals search engine Starting System: 1I-2

Condition Possible cause Correction / Reference Item

Motor not running (No

operating sound of

magnetic switch)Transmission range sensor is not in P or

N, or not adjusted (A/T model)Shift in P or N, or adjust sensor. (A/T model)

Battery run downRecharge battery.

Battery voltage too low due to battery

deteriorationReplace battery.

Poor contact in battery terminal

connectionRetighten or replace.

Loose grounding cable connectionRetighten.

Fuse set loose or blown offTighten or replace.

Poor contacting action of ignition switch

and magnetic switchReplace.

Lead wire coupler loose in placeRetighten.

Open-circuit between ignition switch and

magnetic switchRepair.

Open-circuit in pull-in coilReplace magnetic switch.

Brushes are seating poorly or worn

downRepair or replace.

Poor sliding of plunger and/or pinionRepair.

Faulty starting motor control relay“Main Relay, Fuel Pump Relay, Starting Motor

Control Relay, Throttle Actuator Control Relay

and Radiator Cooling Fan Relay Inspection in

Section 1C”.

Faulty ECM and its circuit“Inspection of ECM and Its Circuits in Section

1A”.

Motor not running

(Operating sound of

magnetic switch heard)Battery run downRecharge battery.

Battery voltage too low due to battery

deteriorationReplace battery.

Loose battery cable connectionsRetighten.

Burnt main contact point, or poor

contacting action of magnetic switchReplace magnetic switch.

Brushes are seating poorly or worn

downRepair or replace.

Weakened brush springReplace.

Burnt commutatorReplace armature.

Layer short-circuit of armatureReplace.

Crankshaft rotation obstructedRepair.

Starting motor running

but too slow (small

torque) (If battery and

wiring are satisfactory,

inspect starting motor)Insufficient contact of magnetic switch

main contactsReplace magnetic switch.

Layer short-circuit of armatureReplace.

Disconnected, burnt or worn

commutatorRepair commutator or replace armature.

Worn brushesReplace brush.

Weakened brush springsReplace spring.

Burnt or abnormally worn end bushReplace bush.

Starting motor running,

but not cranking engineWorn pinion tipReplace over-running clutch.

Poor sliding of over-running clutchRepair.

Over-running clutch slippingReplace over-running clutch.

Worn teeth of ring gearReplace flywheel (M/T model) or drive plate (A/

T model).

NoiseAbnormally worn bushReplace bush.

Worn pinion or worn teeth of ring gearReplace over-running clutch, flywheel (M/T

model) or drive plate (A/T model).

Poor sliding of pinion (failure in return

movement)Repair or replace.

Worn internal or planetary gear teethReplace.

Lack of oil in each partLubricate.

Page 410 of 1556

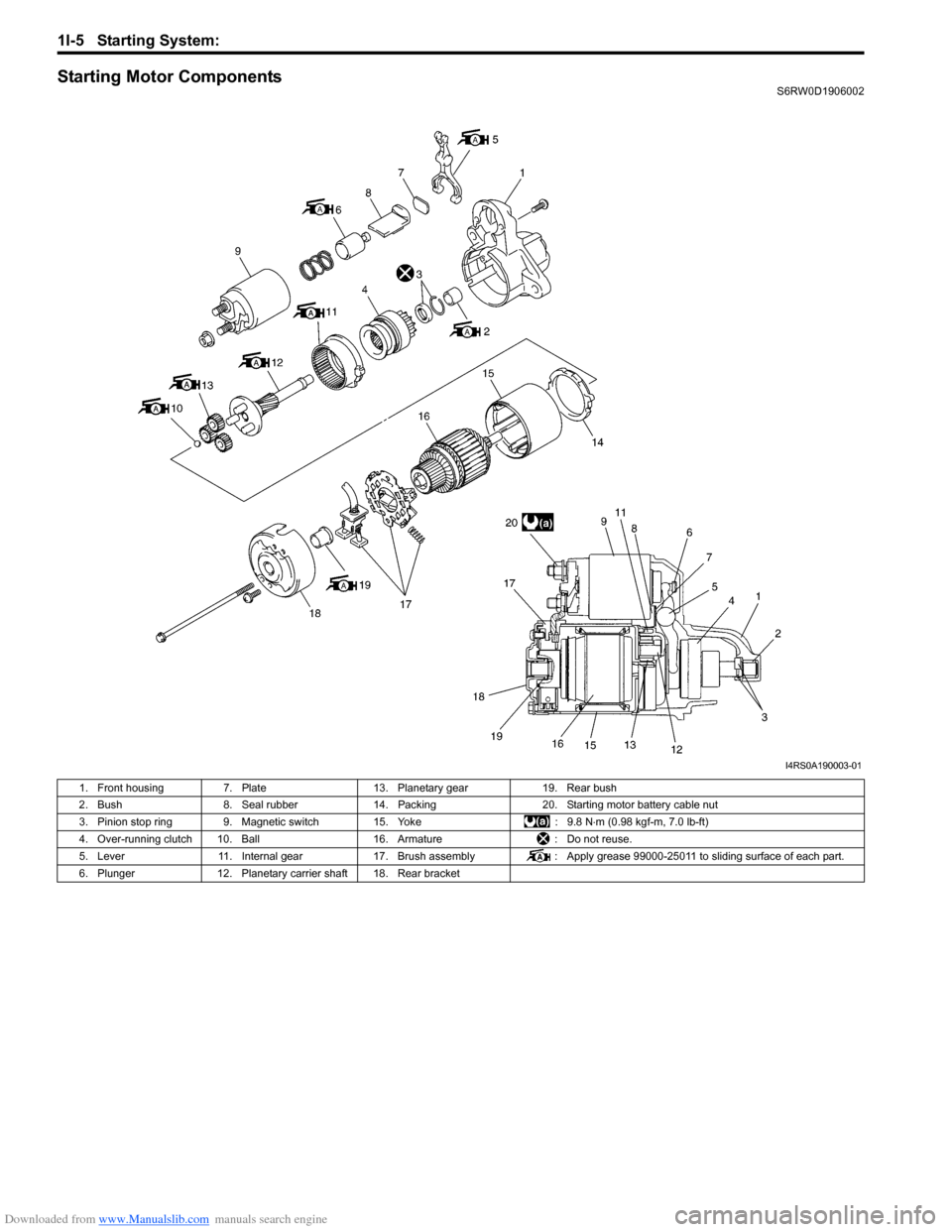

Downloaded from www.Manualslib.com manuals search engine 1I-5 Starting System:

Starting Motor ComponentsS6RW0D1906002

I4RS0A190003-01

1. Front housing 7. Plate 13. Planetary gear 19. Rear bush

2. Bush 8. Seal rubber 14. Packing 20. Starting motor battery cable nut

3. Pinion stop ring 9. Magnetic switch 15. Yoke : 9.8 N⋅m (0.98 kgf-m, 7.0 lb-ft)

4. Over-running clutch 10. Ball 16. Armature : Do not reuse.

5. Lever 11. Internal gear 17. Brush assembly : Apply grease 99000-25011 to sliding surface of each part.

6. Plunger 12. Planetary carrier shaft 18. Rear bracket

Page 413 of 1556

Downloaded from www.Manualslib.com manuals search engine Starting System: 1I-8

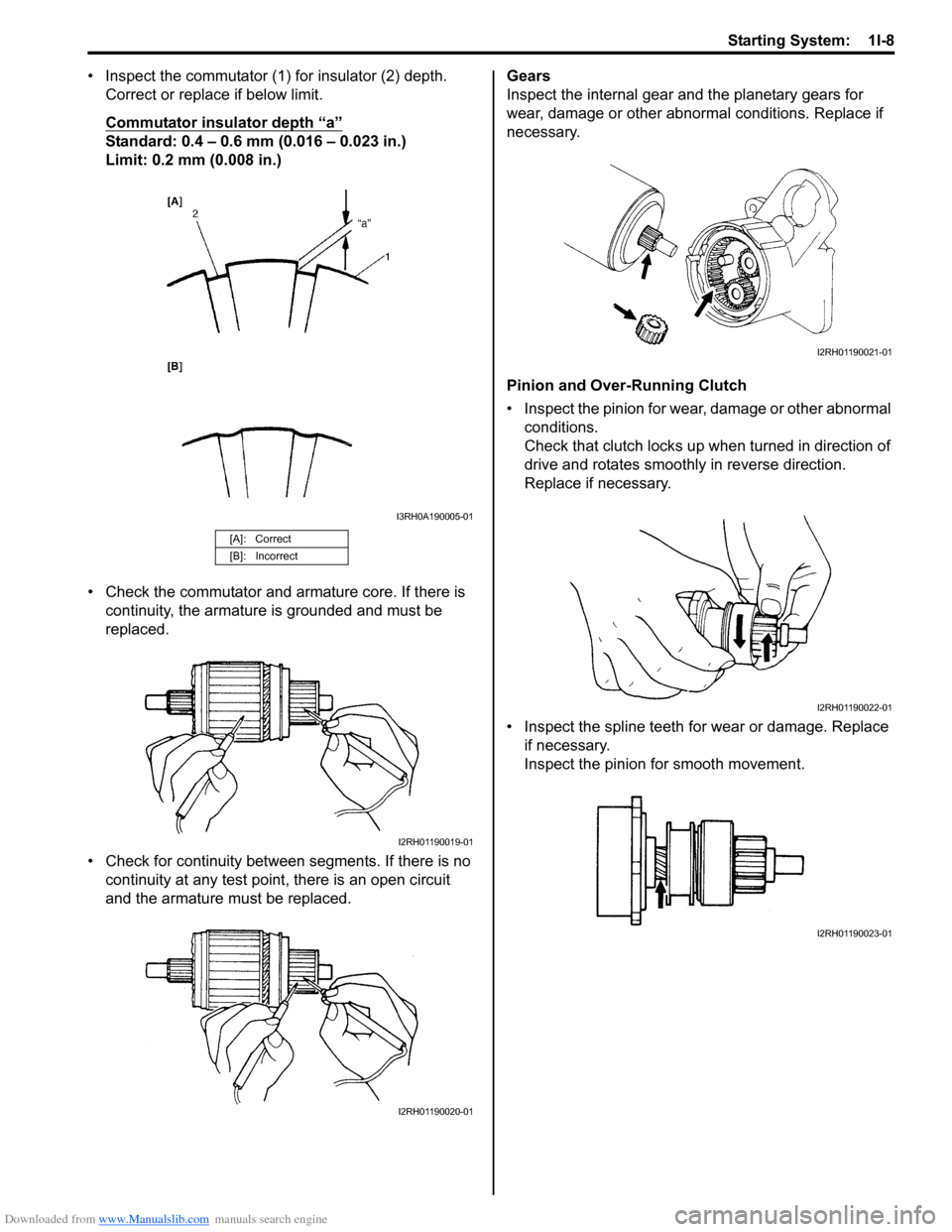

• Inspect the commutator (1) for insulator (2) depth.

Correct or replace if below limit.

Commutator insulator depth “a”

Standard: 0.4 – 0.6 mm (0.016 – 0.023 in.)

Limit: 0.2 mm (0.008 in.)

• Check the commutator and armature core. If there is

continuity, the armature is grounded and must be

replaced.

• Check for continuity between segments. If there is no

continuity at any test point, there is an open circuit

and the armature must be replaced.Gears

Inspect the internal gear and the planetary gears for

wear, damage or other abnormal conditions. Replace if

necessary.

Pinion and Over-Running Clutch

• Inspect the pinion for wear, damage or other abnormal

conditions.

Check that clutch locks up when turned in direction of

drive and rotates smoothly in reverse direction.

Replace if necessary.

• Inspect the spline teeth for wear or damage. Replace

if necessary.

Inspect the pinion for smooth movement.

[A]: Correct

[B]: Incorrect

I3RH0A190005-01

I2RH01190019-01

I2RH01190020-01

I2RH01190021-01

I2RH01190022-01

I2RH01190023-01

Page 504 of 1556

Downloaded from www.Manualslib.com manuals search engine 3B-7 Differential:

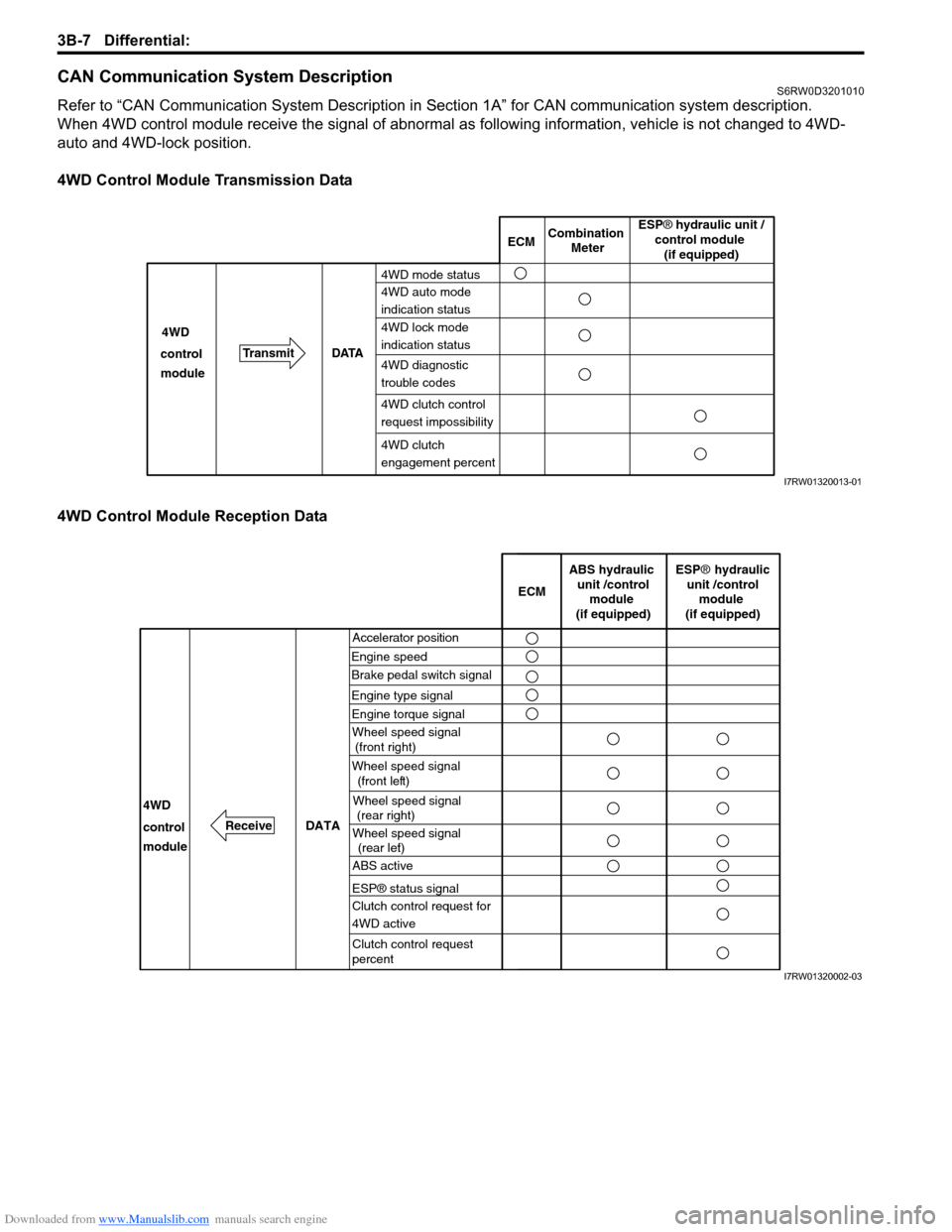

CAN Communication System DescriptionS6RW0D3201010

Refer to “CAN Communication System Description in Section 1A” for CAN communication system description.

When 4WD control module receive the signal of abnormal as following information, vehicle is not changed to 4WD-

auto and 4WD-lock position.

4WD Control Module Transmission Data

4WD Control Module Reception Data

ECMCombination

Meter

TransmitDATA 4WD

4WD mode status

4WD auto mode

indication status

4WD lock mode

indication status

4WD diagnostic

trouble codes control

module

4WD clutch

engagement percent

ESP® hydraulic unit /

control module

(if equipped)

4WD clutch control

request impossibility

I7RW01320013-01

Accelerator position

Engine speedECM

DATA

Brake pedal switch signal

4WD

control

moduleWheel speed signal

(front right)

Wheel speed signal

(front left)

Wheel speed signal

(rear right)

Wheel speed signal

(rear left)

ABS hydraulic

unit /control

module

(if equipped)

ESP® hydraulic

unit /control

module

(if equipped)

ABS active

ESP® status signal

Clutch control request for

4WD active

Clutch control request

percent

Engine type signal

Engine torque signal

Receive

I7RW01320002-03

Page 583 of 1556

Downloaded from www.Manualslib.com manuals search engine Brake Control System and Diagnosis: 4A-12

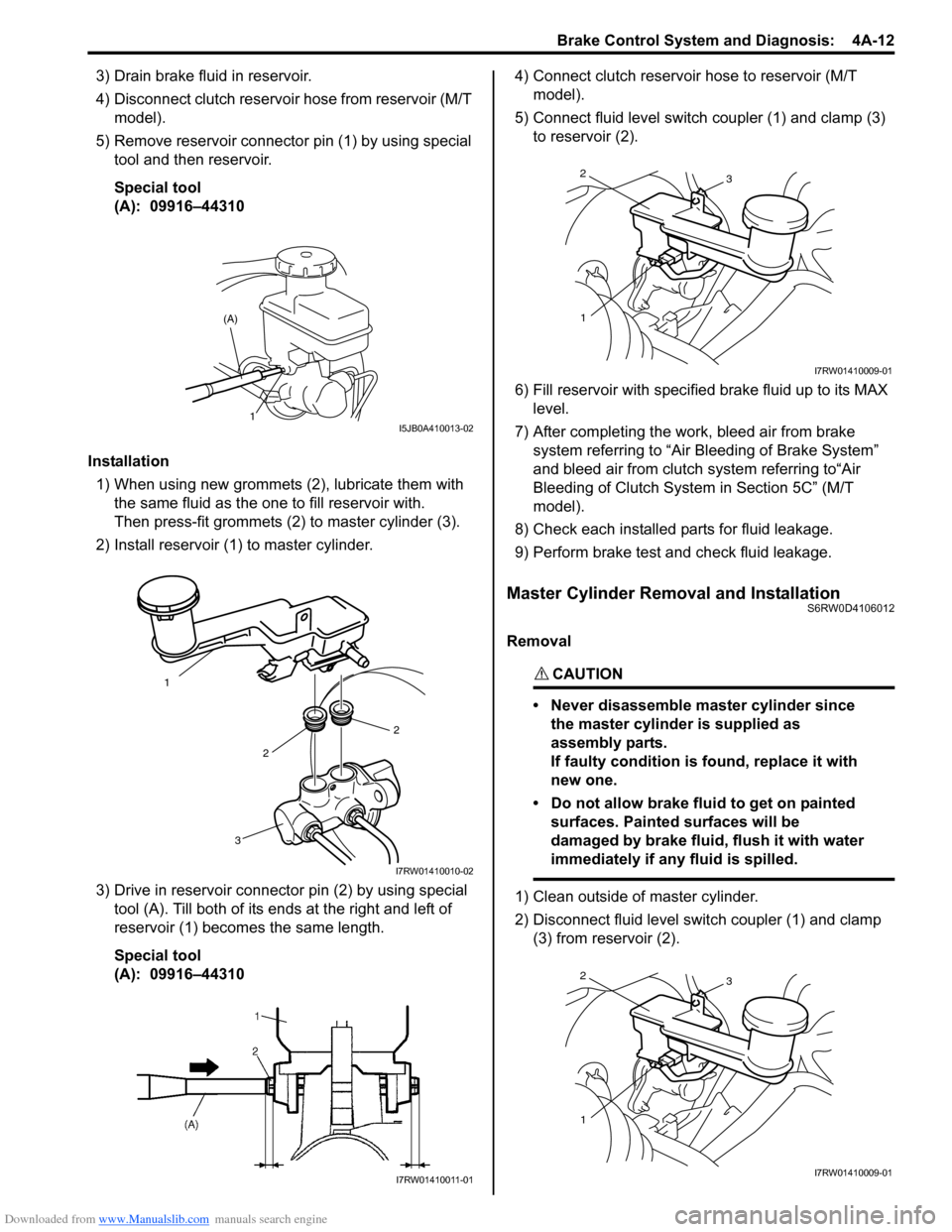

3) Drain brake fluid in reservoir.

4) Disconnect clutch reservoir hose from reservoir (M/T

model).

5) Remove reservoir connector pin (1) by using special

tool and then reservoir.

Special tool

(A): 09916–44310

Installation

1) When using new grommets (2), lubricate them with

the same fluid as the one to fill reservoir with.

Then press-fit grommets (2) to master cylinder (3).

2) Install reservoir (1) to master cylinder.

3) Drive in reservoir connector pin (2) by using special

tool (A). Till both of its ends at the right and left of

reservoir (1) becomes the same length.

Special tool

(A): 09916–44310 4) Connect clutch reservoir hose to reservoir (M/T

model).

5) Connect fluid level switch coupler (1) and clamp (3)

to reservoir (2).

6) Fill reservoir with specified brake fluid up to its MAX

level.

7) After completing the work, bleed air from brake

system referring to “Air Bleeding of Brake System”

and bleed air from clutch system referring to“Air

Bleeding of Clutch System in Section 5C” (M/T

model).

8) Check each installed parts for fluid leakage.

9) Perform brake test and check fluid leakage.

Master Cylinder Removal and InstallationS6RW0D4106012

Removal

CAUTION!

• Never disassemble master cylinder since

the master cylinder is supplied as

assembly parts.

If faulty condition is found, replace it with

new one.

• Do not allow brake fluid to get on painted

surfaces. Painted surfaces will be

damaged by brake fluid, flush it with water

immediately if any fluid is spilled.

1) Clean outside of master cylinder.

2) Disconnect fluid level switch coupler (1) and clamp

(3) from reservoir (2).

1 (A)I5JB0A410013-02

1

2

2

3

I7RW01410010-02

I7RW01410011-01

2

13

I7RW01410009-01

2

13

I7RW01410009-01

Page 584 of 1556

Downloaded from www.Manualslib.com manuals search engine 4A-13 Brake Control System and Diagnosis:

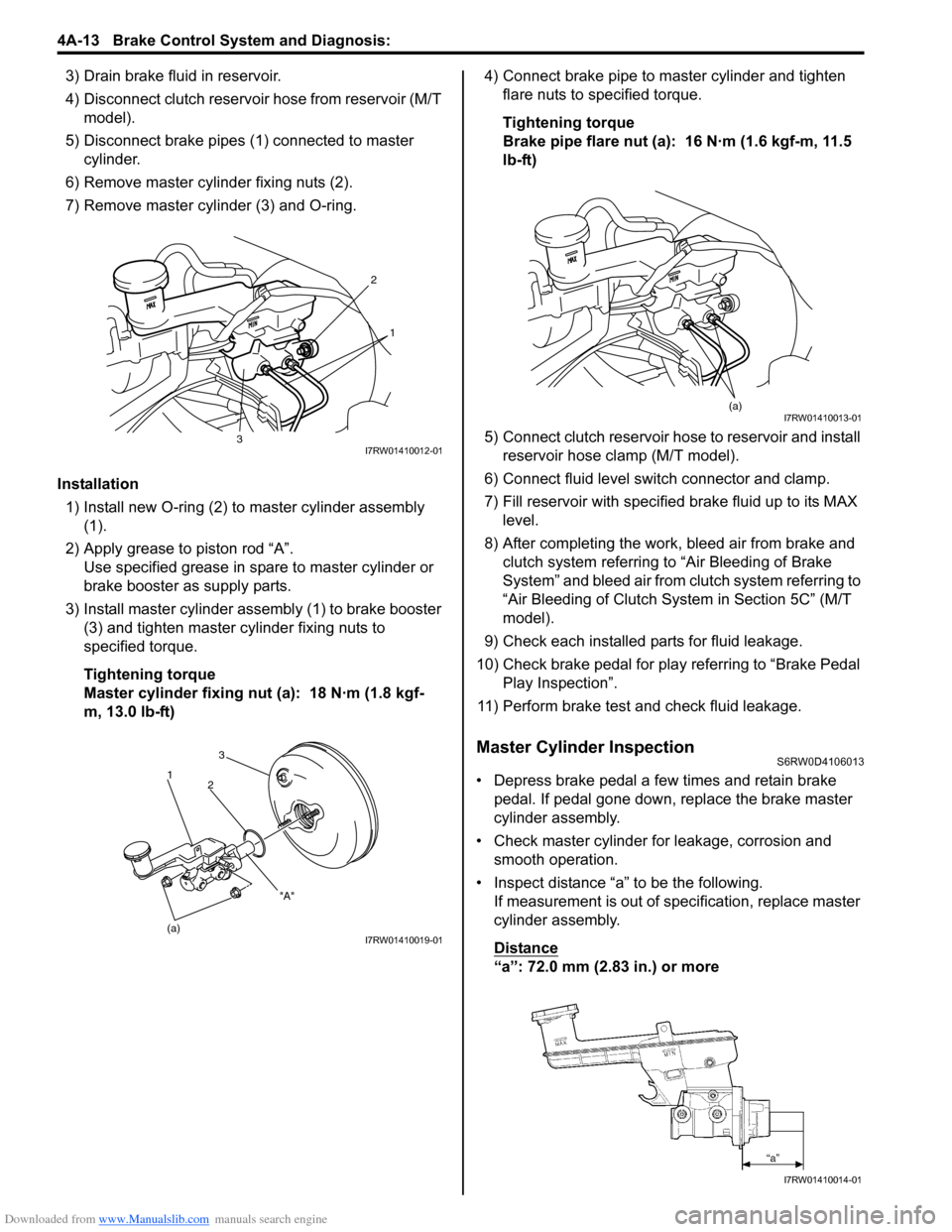

3) Drain brake fluid in reservoir.

4) Disconnect clutch reservoir hose from reservoir (M/T

model).

5) Disconnect brake pipes (1) connected to master

cylinder.

6) Remove master cylinder fixing nuts (2).

7) Remove master cylinder (3) and O-ring.

Installation

1) Install new O-ring (2) to master cylinder assembly

(1).

2) Apply grease to piston rod “A”.

Use specified grease in spare to master cylinder or

brake booster as supply parts.

3) Install master cylinder assembly (1) to brake booster

(3) and tighten master cylinder fixing nuts to

specified torque.

Tightening torque

Master cylinder fixing nut (a): 18 N·m (1.8 kgf-

m, 13.0 lb-ft)4) Connect brake pipe to master cylinder and tighten

flare nuts to specified torque.

Tightening torque

Brake pipe flare nut (a): 16 N·m (1.6 kgf-m, 11.5

lb-ft)

5) Connect clutch reservoir hose to reservoir and install

reservoir hose clamp (M/T model).

6) Connect fluid level switch connector and clamp.

7) Fill reservoir with specified brake fluid up to its MAX

level.

8) After completing the work, bleed air from brake and

clutch system referring to “Air Bleeding of Brake

System” and bleed air from clutch system referring to

“Air Bleeding of Clutch System in Section 5C” (M/T

model).

9) Check each installed parts for fluid leakage.

10) Check brake pedal for play referring to “Brake Pedal

Play Inspection”.

11) Perform brake test and check fluid leakage.

Master Cylinder InspectionS6RW0D4106013

• Depress brake pedal a few times and retain brake

pedal. If pedal gone down, replace the brake master

cylinder assembly.

• Check master cylinder for leakage, corrosion and

smooth operation.

• Inspect distance “a” to be the following.

If measurement is out of specification, replace master

cylinder assembly.

Distance

“a”: 72.0 mm (2.83 in.) or more

2

1

3I7RW01410012-01

(a)3

2

1

"A"

I7RW01410019-01

(a)I7RW01410013-01

I7RW01410014-01

Page 586 of 1556

Downloaded from www.Manualslib.com manuals search engine 4A-15 Brake Control System and Diagnosis:

2) Hold brake pedal depressed for 30 seconds. If pedal

height does not change, condition is good. But it isn’t

if pedal rises.

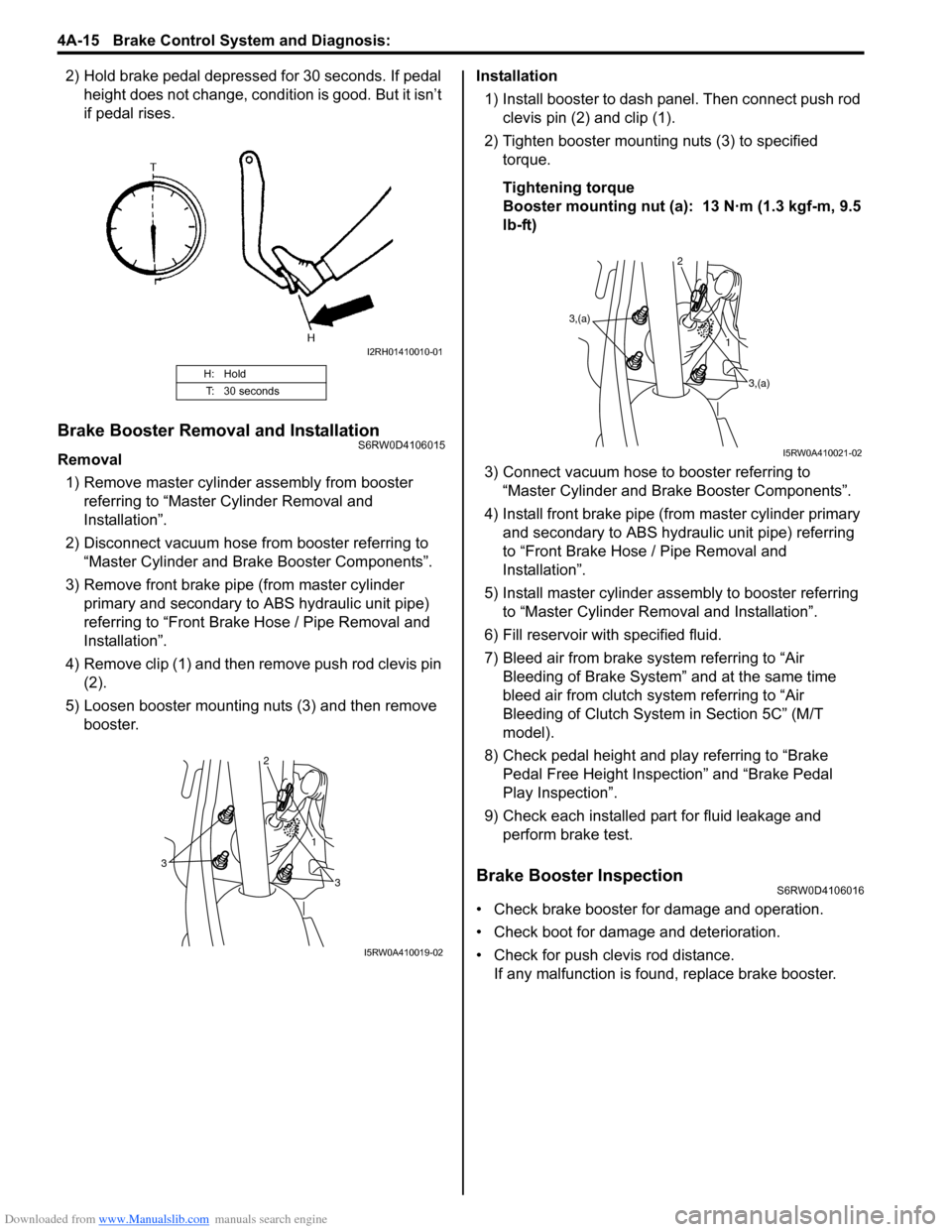

Brake Booster Removal and InstallationS6RW0D4106015

Removal

1) Remove master cylinder assembly from booster

referring to “Master Cylinder Removal and

Installation”.

2) Disconnect vacuum hose from booster referring to

“Master Cylinder and Brake Booster Components”.

3) Remove front brake pipe (from master cylinder

primary and secondary to ABS hydraulic unit pipe)

referring to “Front Brake Hose / Pipe Removal and

Installation”.

4) Remove clip (1) and then remove push rod clevis pin

(2).

5) Loosen booster mounting nuts (3) and then remove

booster.Installation

1) Install booster to dash panel. Then connect push rod

clevis pin (2) and clip (1).

2) Tighten booster mounting nuts (3) to specified

torque.

Tightening torque

Booster mounting nut (a): 13 N·m (1.3 kgf-m, 9.5

lb-ft)

3) Connect vacuum hose to booster referring to

“Master Cylinder and Brake Booster Components”.

4) Install front brake pipe (from master cylinder primary

and secondary to ABS hydraulic unit pipe) referring

to “Front Brake Hose / Pipe Removal and

Installation”.

5) Install master cylinder assembly to booster referring

to “Master Cylinder Removal and Installation”.

6) Fill reservoir with specified fluid.

7) Bleed air from brake system referring to “Air

Bleeding of Brake System” and at the same time

bleed air from clutch system referring to “Air

Bleeding of Clutch System in Section 5C” (M/T

model).

8) Check pedal height and play referring to “Brake

Pedal Free Height Inspection” and “Brake Pedal

Play Inspection”.

9) Check each installed part for fluid leakage and

perform brake test.

Brake Booster InspectionS6RW0D4106016

• Check brake booster for damage and operation.

• Check boot for damage and deterioration.

• Check for push clevis rod distance.

If any malfunction is found, replace brake booster.

H: Hold

T: 30 seconds

I2RH01410010-01

3

3 1 2

I5RW0A410019-02

3,(a)

3,(a) 1 2

I5RW0A410021-02