transaxle SUZUKI SX4 2006 1.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 421 of 1556

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-7

1) Set parking brake and place automatic transaxle in

PARK (NEUTRAL on manual transaxle). Turn off

ignition, turn off lights and all other electrical loads.

2) Check electrolyte level. If it is below low level line,

add distilled water.

3) Attach end of one jumper cable to positive terminal

of booster battery and the other end of the same

cable to positive terminal of discharged battery. (Use

12-volt battery only to jump start engine).

4) Attach one end of the remaining negative cable to

negative terminal of booster battery, and the other

end to a solid engine ground (such as exhaust

manifold) at least 45 cm (18 in.) away from battery of

vehicle being started.

5) Start engine of vehicle with booster battery and turn

off electrical accessories. Then start engine of the

vehicle with discharged battery.

6) Disconnect jumper cables in the exact reverse order.

With Charging Equipment

CAUTION!

When jump starting engine with charging

equipment, be sure equipment used is 12-

volt and negative ground. Do not use 24-volt

charging equipment. Using such equipment

can cause serious damage to electrical

system or electronic parts.

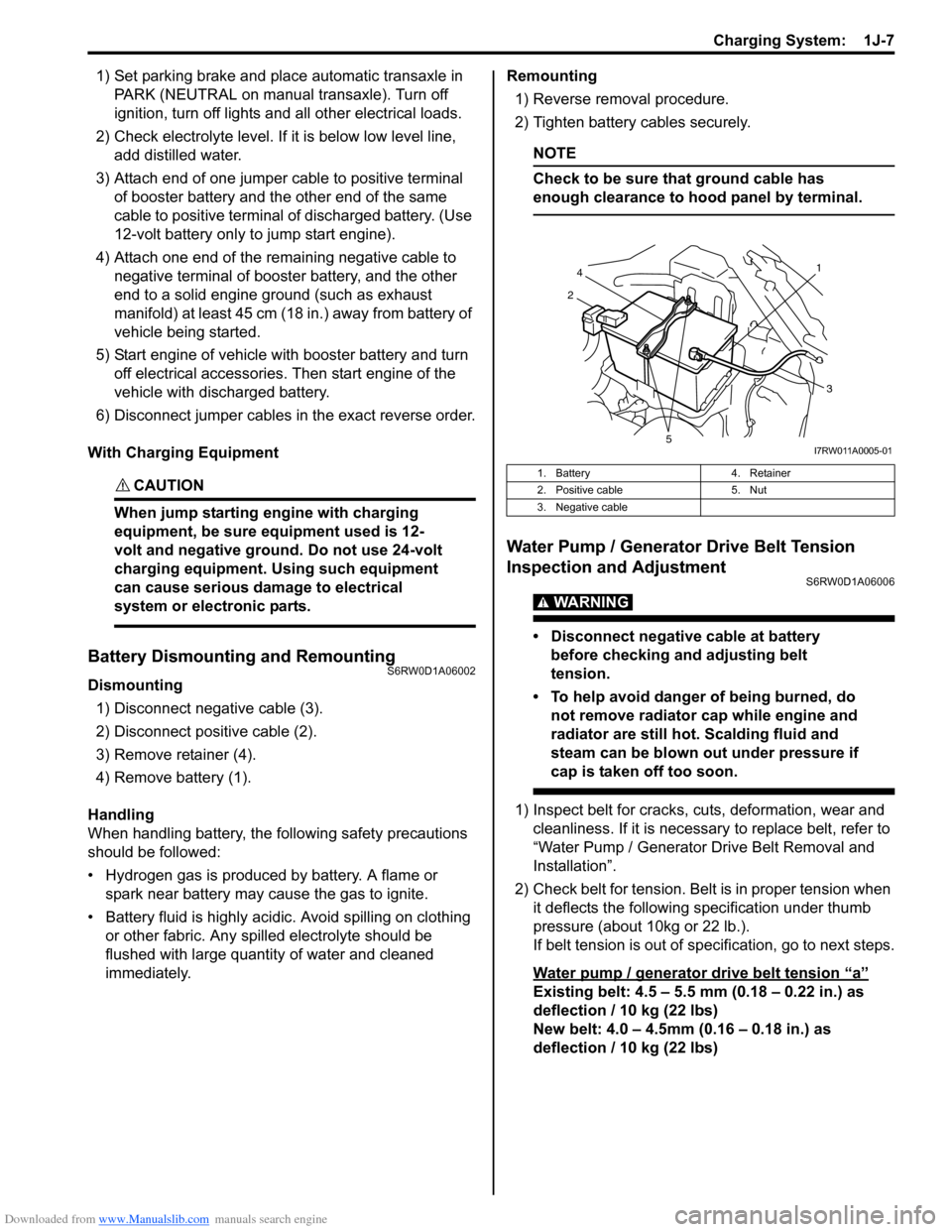

Battery Dismounting and RemountingS6RW0D1A06002

Dismounting

1) Disconnect negative cable (3).

2) Disconnect positive cable (2).

3) Remove retainer (4).

4) Remove battery (1).

Handling

When handling battery, the following safety precautions

should be followed:

• Hydrogen gas is produced by battery. A flame or

spark near battery may cause the gas to ignite.

• Battery fluid is highly acidic. Avoid spilling on clothing

or other fabric. Any spilled electrolyte should be

flushed with large quantity of water and cleaned

immediately.Remounting

1) Reverse removal procedure.

2) Tighten battery cables securely.

NOTE

Check to be sure that ground cable has

enough clearance to hood panel by terminal.

Water Pump / Generator Drive Belt Tension

Inspection and Adjustment

S6RW0D1A06006

WARNING!

• Disconnect negative cable at battery

before checking and adjusting belt

tension.

• To help avoid danger of being burned, do

not remove radiator cap while engine and

radiator are still hot. Scalding fluid and

steam can be blown out under pressure if

cap is taken off too soon.

1) Inspect belt for cracks, cuts, deformation, wear and

cleanliness. If it is necessary to replace belt, refer to

“Water Pump / Generator Drive Belt Removal and

Installation”.

2) Check belt for tension. Belt is in proper tension when

it deflects the following specification under thumb

pressure (about 10kg or 22 lb.).

If belt tension is out of specification, go to next steps.

Water pump / generator drive belt tension

“a”

Existing belt: 4.5 – 5.5 mm (0.18 – 0.22 in.) as

deflection / 10 kg (22 lbs)

New belt: 4.0 – 4.5mm (0.16 – 0.18 in.) as

deflection / 10 kg (22 lbs)

1. Battery 4. Retainer

2. Positive cable 5. Nut

3. Negative cable

21

4

3

5I7RW011A0005-01

Page 480 of 1556

Downloaded from www.Manualslib.com manuals search engine 3A-1 Drive Shaft / Axle: Front

Driveline / Axle

Drive Shaft / Axle

Front

General Description

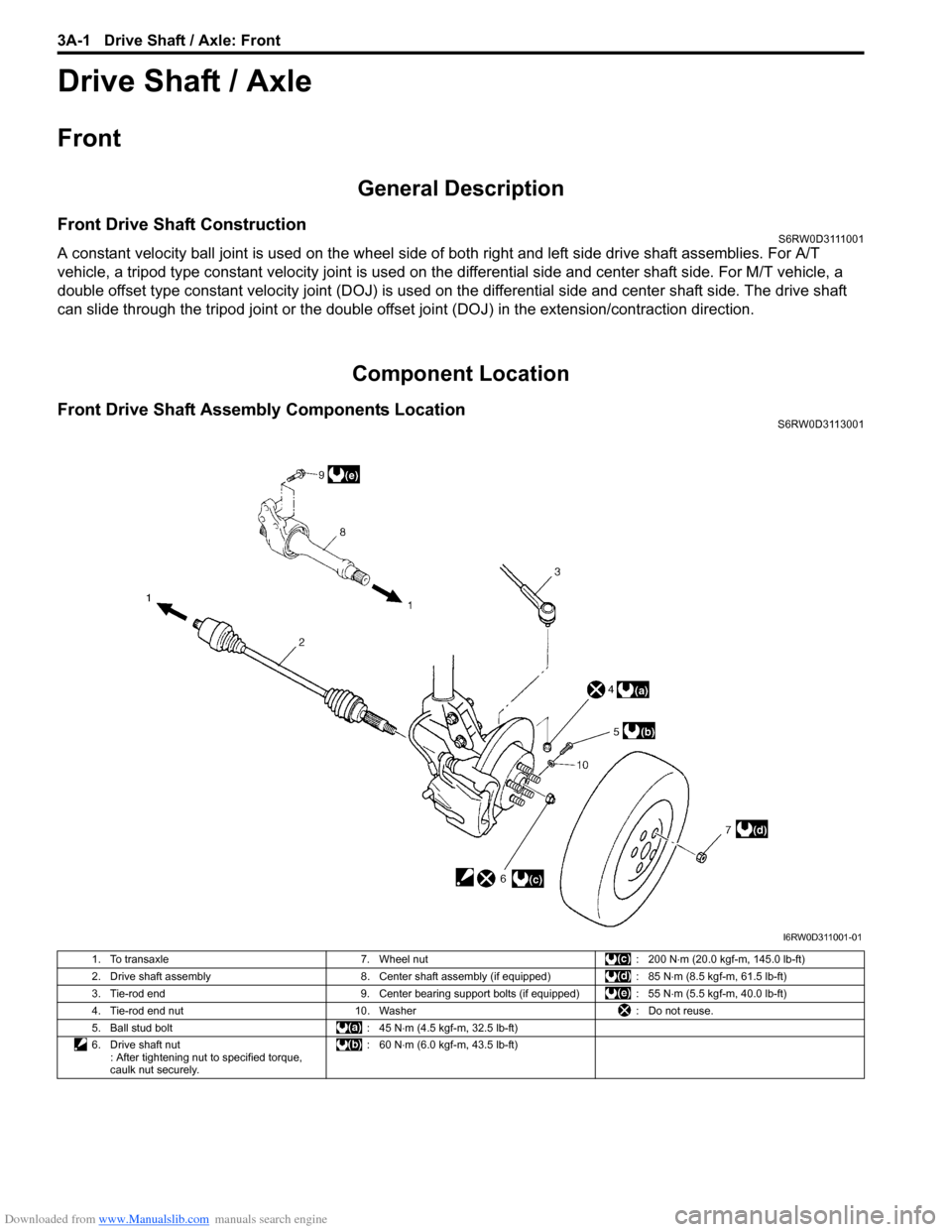

Front Drive Shaft ConstructionS6RW0D3111001

A constant velocity ball joint is used on the wheel side of both right and left side drive shaft assemblies. For A/T

vehicle, a tripod type constant velocity joint is used on the differential side and center shaft side. For M/T vehicle, a

double offset type constant velocity joint (DOJ) is used on the differential side and center shaft side. The drive shaft

can slide through the tripod joint or the double offset joint (DOJ) in the extension/contraction direction.

Component Location

Front Drive Shaft Assembly Components LocationS6RW0D3113001

I6RW0D311001-01

1. To transaxle 7. Wheel nut : 200 N⋅m (20.0 kgf-m, 145.0 lb-ft)

2. Drive shaft assembly 8. Center shaft assembly (if equipped) : 85 N⋅m (8.5 kgf-m, 61.5 lb-ft)

3. Tie-rod end 9. Center bearing support bolts (if equipped) : 55 N⋅m (5.5 kgf-m, 40.0 lb-ft)

4. Tie-rod end nut 10. Washer : Do not reuse.

5. Ball stud bolt : 45 N⋅m (4.5 kgf-m, 32.5 lb-ft)

6. Drive shaft nut

: After tightening nut to specified torque,

caulk nut securely.:60 N⋅m (6.0 kgf-m, 43.5 lb-ft)

Page 482 of 1556

Downloaded from www.Manualslib.com manuals search engine 3A-3 Drive Shaft / Axle: Front

Front Drive Shaft Assembly On-Vehicle

Inspection

S6RW0D3116002

• Check boots for breakage or deterioration.

• Check wheel side joint for rattle or smooth rotation.

• Check differential side (or center shaft side) joint for

smooth rotation.

If any abnormality is found, replace.

Front Drive Shaft Assembly Removal and

Installation

S6RW0D3116003

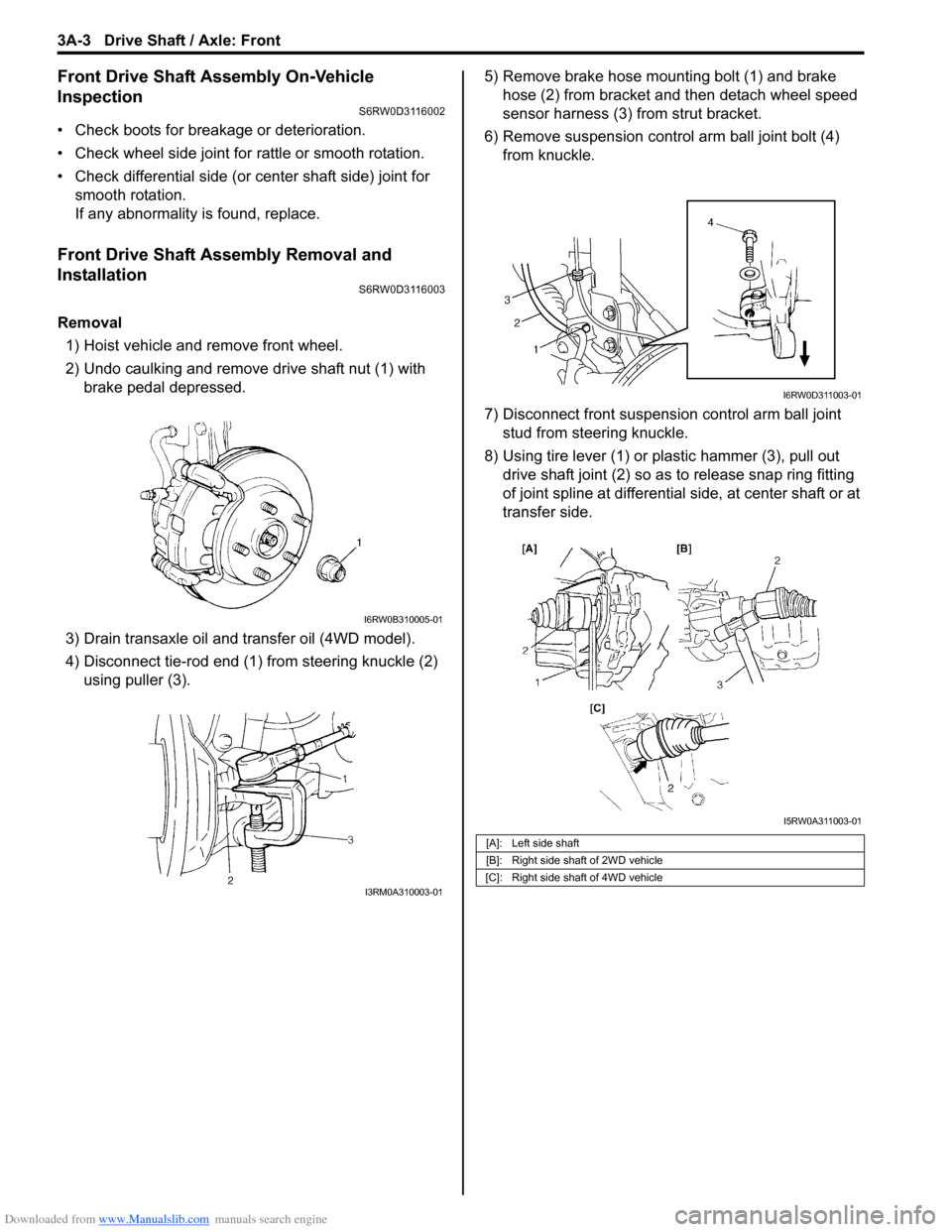

Removal

1) Hoist vehicle and remove front wheel.

2) Undo caulking and remove drive shaft nut (1) with

brake pedal depressed.

3) Drain transaxle oil and transfer oil (4WD model).

4) Disconnect tie-rod end (1) from steering knuckle (2)

using puller (3).5) Remove brake hose mounting bolt (1) and brake

hose (2) from bracket and then detach wheel speed

sensor harness (3) from strut bracket.

6) Remove suspension control arm ball joint bolt (4)

from knuckle.

7) Disconnect front suspension control arm ball joint

stud from steering knuckle.

8) Using tire lever (1) or plastic hammer (3), pull out

drive shaft joint (2) so as to release snap ring fitting

of joint spline at differential side, at center shaft or at

transfer side.

I6RW0B310005-01

I3RM0A310003-01

[A]: Left side shaft

[B]: Right side shaft of 2WD vehicle

[C]: Right side shaft of 4WD vehicle

I6RW0D311003-01

I5RW0A311003-01

Page 483 of 1556

Downloaded from www.Manualslib.com manuals search engine Drive Shaft / Axle: Front 3A-4

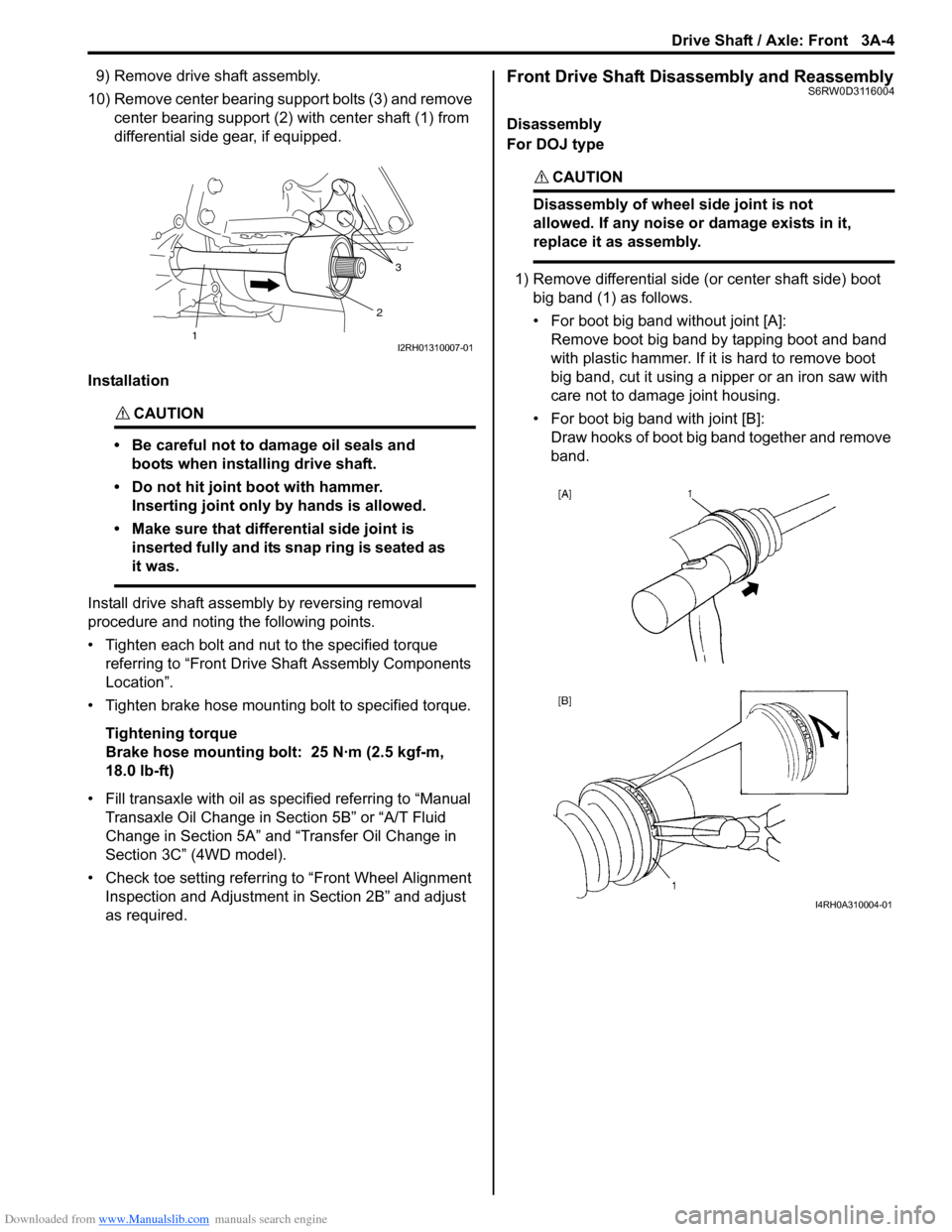

9) Remove drive shaft assembly.

10) Remove center bearing support bolts (3) and remove

center bearing support (2) with center shaft (1) from

differential side gear, if equipped.

Installation

CAUTION!

• Be careful not to damage oil seals and

boots when installing drive shaft.

• Do not hit joint boot with hammer.

Inserting joint only by hands is allowed.

• Make sure that differential side joint is

inserted fully and its snap ring is seated as

it was.

Install drive shaft assembly by reversing removal

procedure and noting the following points.

• Tighten each bolt and nut to the specified torque

referring to “Front Drive Shaft Assembly Components

Location”.

• Tighten brake hose mounting bolt to specified torque.

Tightening torque

Brake hose mounting bolt: 25 N·m (2.5 kgf-m,

18.0 lb-ft)

• Fill transaxle with oil as specified referring to “Manual

Transaxle Oil Change in Section 5B” or “A/T Fluid

Change in Section 5A” and “Transfer Oil Change in

Section 3C” (4WD model).

• Check toe setting referring to “Front Wheel Alignment

Inspection and Adjustment in Section 2B” and adjust

as required.

Front Drive Shaft Disassembly and ReassemblyS6RW0D3116004

Disassembly

For DOJ type

CAUTION!

Disassembly of wheel side joint is not

allowed. If any noise or damage exists in it,

replace it as assembly.

1) Remove differential side (or center shaft side) boot

big band (1) as follows.

• For boot big band without joint [A]:

Remove boot big band by tapping boot and band

with plastic hammer. If it is hard to remove boot

big band, cut it using a nipper or an iron saw with

care not to damage joint housing.

• For boot big band with joint [B]:

Draw hooks of boot big band together and remove

band.3

2

1I2RH01310007-01

I4RH0A310004-01

Page 508 of 1556

Downloaded from www.Manualslib.com manuals search engine 3B-11 Differential:

Visual InspectionS6RW0D3204004

Check the following parts and systems visually.

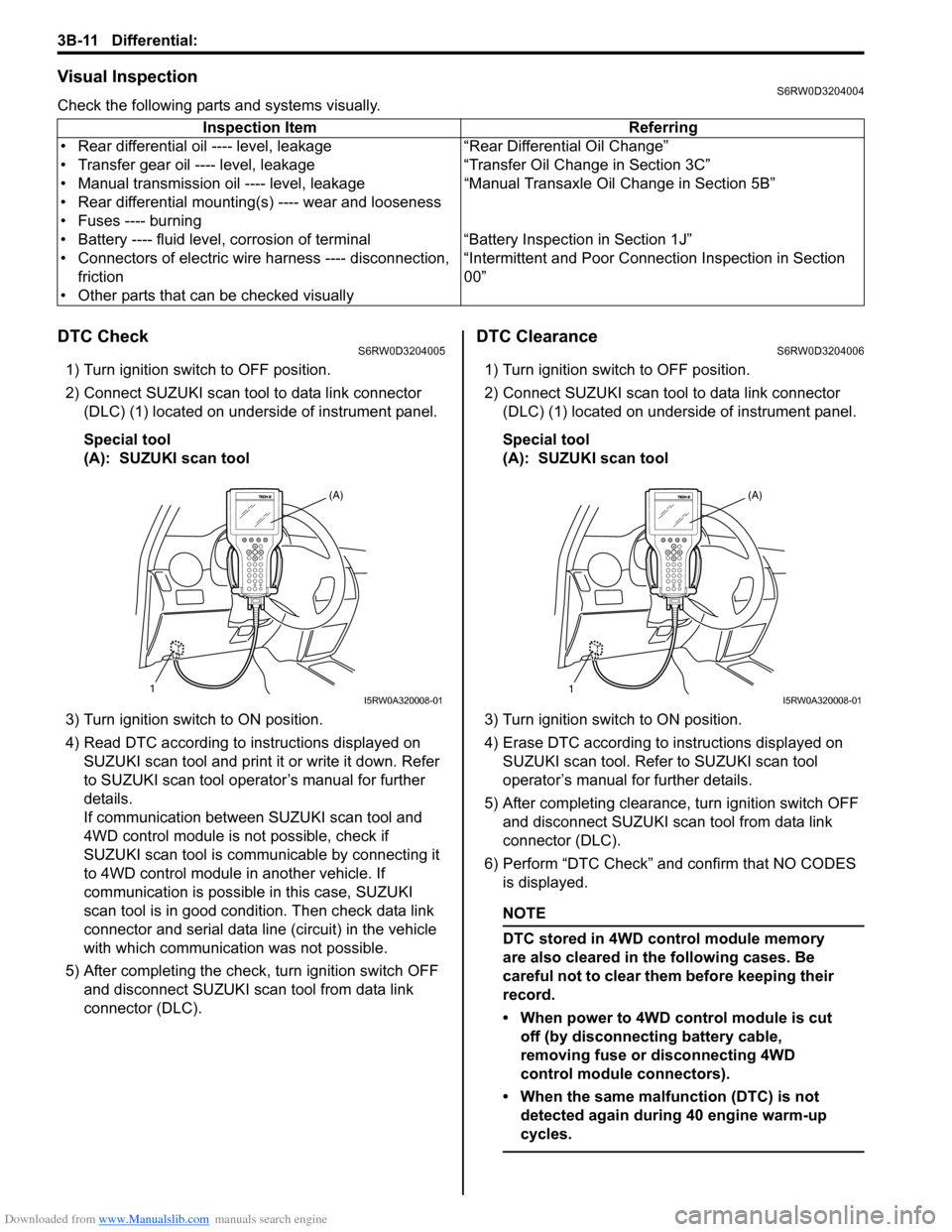

DTC CheckS6RW0D3204005

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector

(DLC) (1) located on underside of instrument panel.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch to ON position.

4) Read DTC according to instructions displayed on

SUZUKI scan tool and print it or write it down. Refer

to SUZUKI scan tool operator’s manual for further

details.

If communication between SUZUKI scan tool and

4WD control module is not possible, check if

SUZUKI scan tool is communicable by connecting it

to 4WD control module in another vehicle. If

communication is possible in this case, SUZUKI

scan tool is in good condition. Then check data link

connector and serial data line (circuit) in the vehicle

with which communication was not possible.

5) After completing the check, turn ignition switch OFF

and disconnect SUZUKI scan tool from data link

connector (DLC).

DTC ClearanceS6RW0D3204006

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector

(DLC) (1) located on underside of instrument panel.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch to ON position.

4) Erase DTC according to instructions displayed on

SUZUKI scan tool. Refer to SUZUKI scan tool

operator’s manual for further details.

5) After completing clearance, turn ignition switch OFF

and disconnect SUZUKI scan tool from data link

connector (DLC).

6) Perform “DTC Check” and confirm that NO CODES

is displayed.

NOTE

DTC stored in 4WD control module memory

are also cleared in the following cases. Be

careful not to clear them before keeping their

record.

• When power to 4WD control module is cut

off (by disconnecting battery cable,

removing fuse or disconnecting 4WD

control module connectors).

• When the same malfunction (DTC) is not

detected again during 40 engine warm-up

cycles.

Inspection Item Referring

• Rear differential oil ---- level, leakage “Rear Differential Oil Change”

• Transfer gear oil ---- level, leakage “Transfer Oil Change in Section 3C”

• Manual transmission oil ---- level, leakage “Manual Transaxle Oil Change in Section 5B”

• Rear differential mounting(s) ---- wear and looseness

• Fuses ---- burning

• Battery ---- fluid level, corrosion of terminal “Battery Inspection in Section 1J”

• Connectors of electric wire harness ---- disconnection,

friction“Intermittent and Poor Connection Inspection in Section

00”

• Other parts that can be checked visually

1(A)I5RW0A320008-011(A)I5RW0A320008-01

Page 548 of 1556

Downloaded from www.Manualslib.com manuals search engine 3C-1 Transfer:

Driveline / Axle

Transfer

General Description

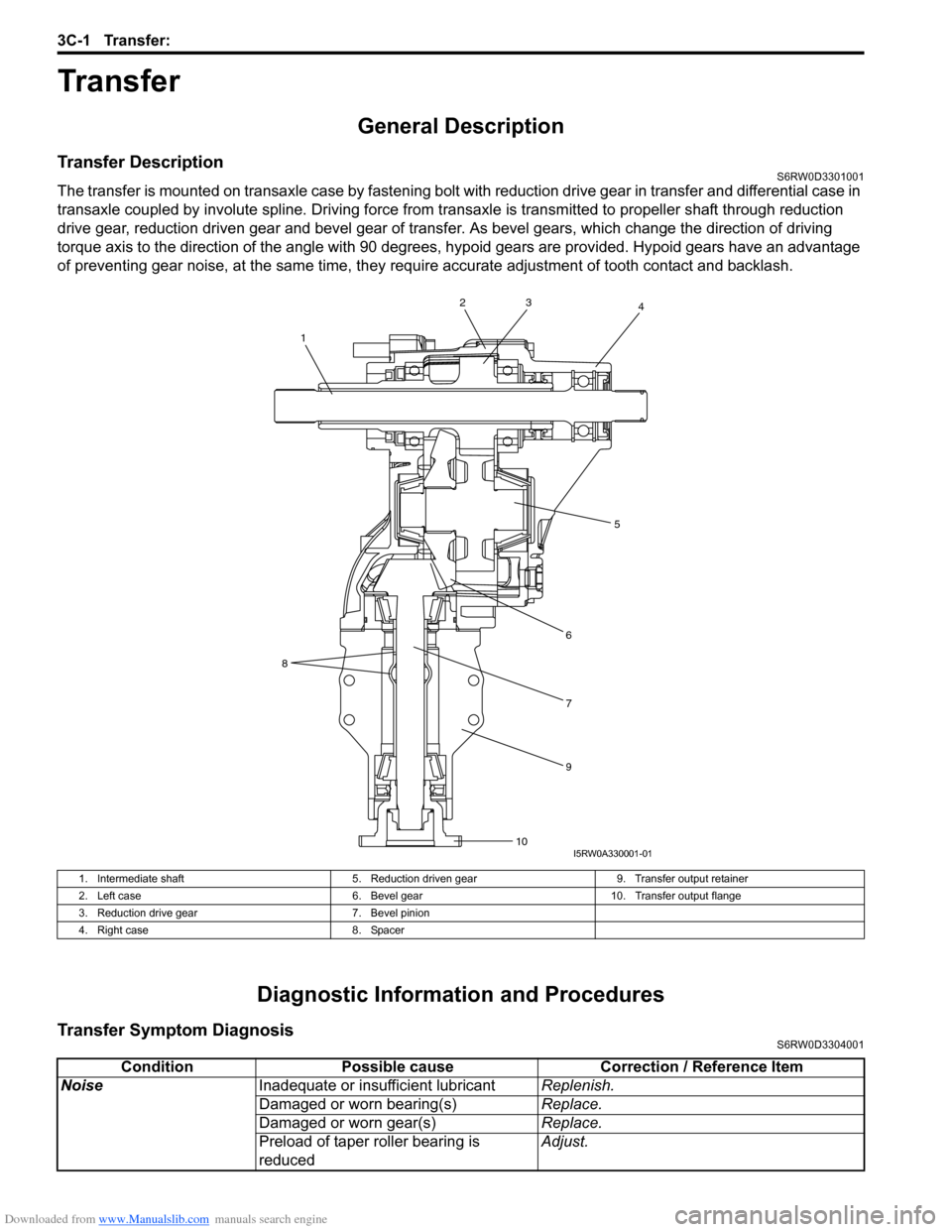

Transfer DescriptionS6RW0D3301001

The transfer is mounted on transaxle case by fastening bolt with reduction drive gear in transfer and differential case in

transaxle coupled by involute spline. Driving force from transaxle is transmitted to propeller shaft through reduction

drive gear, reduction driven gear and bevel gear of transfer. As bevel gears, which change the direction of driving

torque axis to the direction of the angle with 90 degrees, hypoid gears are provided. Hypoid gears have an advantage

of preventing gear noise, at the same time, they require accurate adjustment of tooth contact and backlash.

Diagnostic Information and Procedures

Transfer Symptom DiagnosisS6RW0D3304001

2

1

8

34

5

6

7

9

10I5RW0A330001-01

1. Intermediate shaft 5. Reduction driven gear 9. Transfer output retainer

2. Left case 6. Bevel gear 10. Transfer output flange

3. Reduction drive gear 7. Bevel pinion

4. Right case 8. Spacer

Condition Possible cause Correction / Reference Item

NoiseInadequate or insufficient lubricantReplenish.

Damaged or worn bearing(s)Replace.

Damaged or worn gear(s)Replace.

Preload of taper roller bearing is

reducedAdjust.

Page 550 of 1556

Downloaded from www.Manualslib.com manuals search engine 3C-3 Transfer:

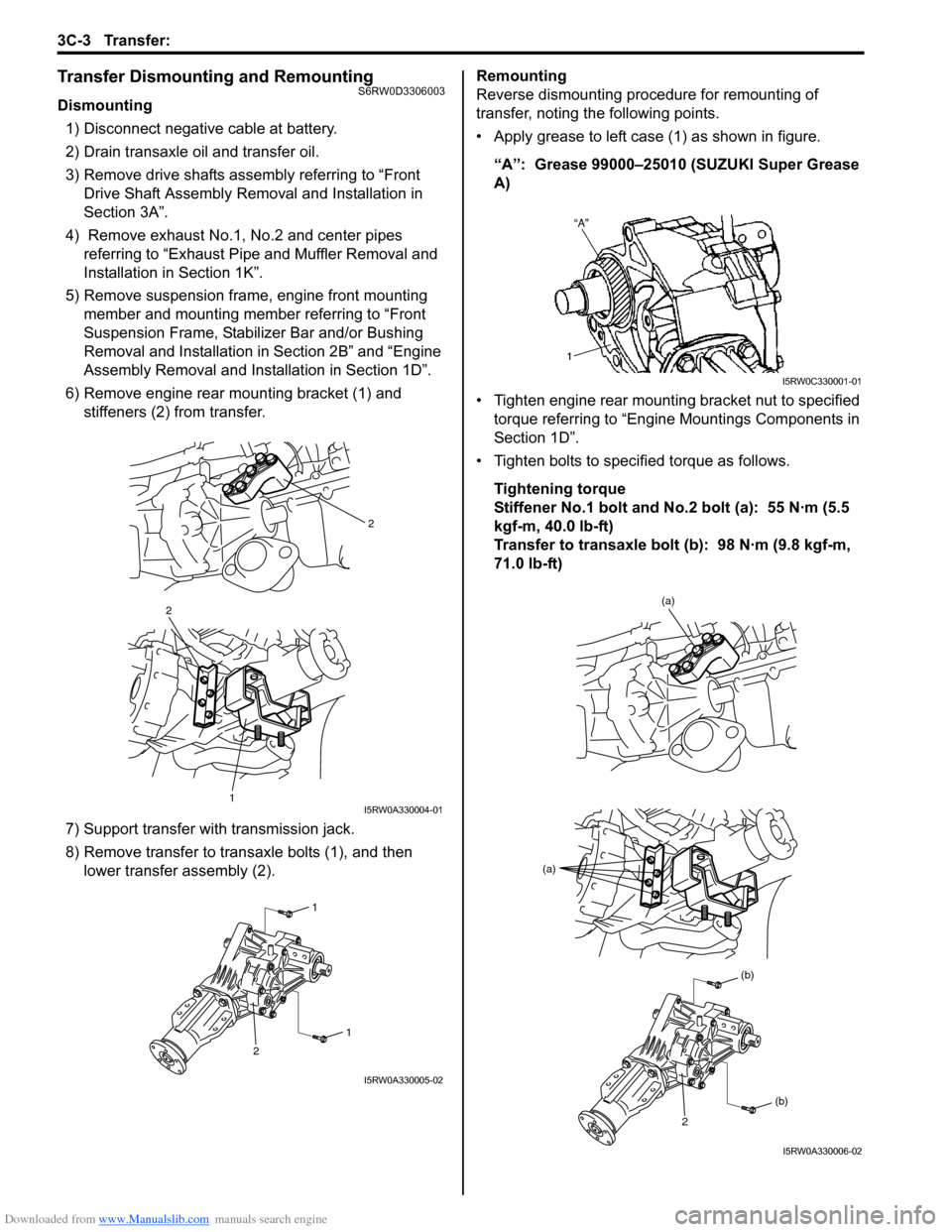

Transfer Dismounting and RemountingS6RW0D3306003

Dismounting

1) Disconnect negative cable at battery.

2) Drain transaxle oil and transfer oil.

3) Remove drive shafts assembly referring to “Front

Drive Shaft Assembly Removal and Installation in

Section 3A”.

4) Remove exhaust No.1, No.2 and center pipes

referring to “Exhaust Pipe and Muffler Removal and

Installation in Section 1K”.

5) Remove suspension frame, engine front mounting

member and mounting member referring to “Front

Suspension Frame, Stabilizer Bar and/or Bushing

Removal and Installation in Section 2B” and “Engine

Assembly Removal and Installation in Section 1D”.

6) Remove engine rear mounting bracket (1) and

stiffeners (2) from transfer.

7) Support transfer with transmission jack.

8) Remove transfer to transaxle bolts (1), and then

lower transfer assembly (2).Remounting

Reverse dismounting procedure for remounting of

transfer, noting the following points.

• Apply grease to left case (1) as shown in figure.

“A”: Grease 99000–25010 (SUZUKI Super Grease

A)

• Tighten engine rear mounting bracket nut to specified

torque referring to “Engine Mountings Components in

Section 1D”.

• Tighten bolts to specified torque as follows.

Tightening torque

Stiffener No.1 bolt and No.2 bolt (a): 55 N·m (5.5

kgf-m, 40.0 lb-ft)

Transfer to transaxle bolt (b): 98 N·m (9.8 kgf-m,

71.0 lb-ft)

2

2

1I5RW0A330004-01

1

1

2

I5RW0A330005-02

I5RW0C330001-01

(a)

(a)

(b)

(b)

2

I5RW0A330006-02

Page 551 of 1556

Downloaded from www.Manualslib.com manuals search engine Transfer: 3C-4

• Pour transaxle oil and transfer oil referring to “Manual

Transaxle Oil Change in Section 5B” and “Transfer Oil

Change”.

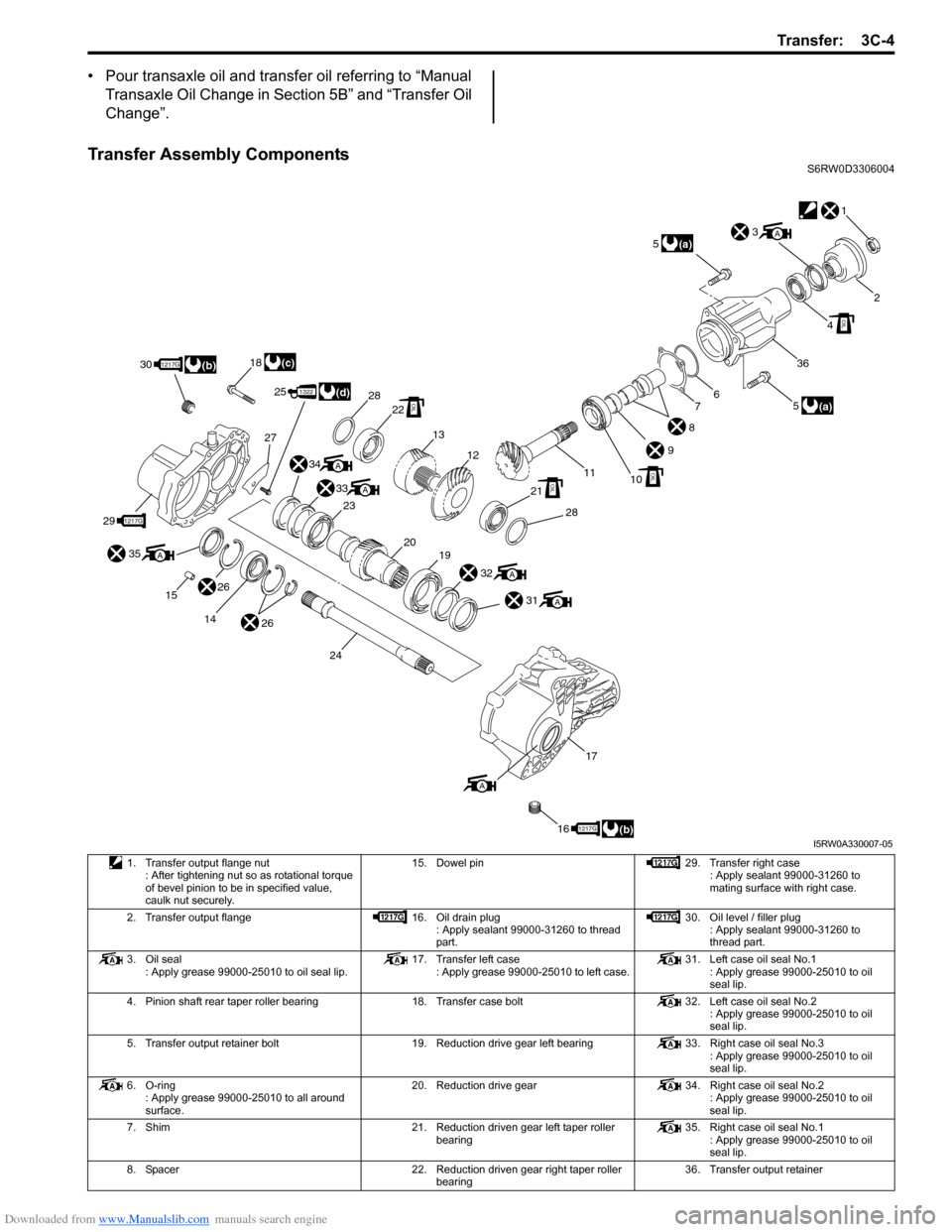

Transfer Assembly ComponentsS6RW0D3306004

1

2

6

9

1110

8

7

3A

4

5

36

OIL

(a) 5

(a)

OIL

28

18

30

27

25

21

28

13

12

22OIL

OIL

32A

31A

1322(d)

34A

33

23A

2019

(c)1217G

291217G

(b)

35

15A

26

26 14

24

17

161217G(b)

A

I5RW0A330007-05

1. Transfer output flange nut

: After tightening nut so as rotational torque

of bevel pinion to be in specified value,

caulk nut securely.15. Dowel pin 29. Transfer right case

: Apply sealant 99000-31260 to

mating surface with right case.

2. Transfer output flange 16. Oil drain plug

: Apply sealant 99000-31260 to thread

part.30. Oil level / filler plug

: Apply sealant 99000-31260 to

thread part.

3. Oil seal

: Apply grease 99000-25010 to oil seal lip.17. Transfer left case

: Apply grease 99000-25010 to left case.31. Left case oil seal No.1

: Apply grease 99000-25010 to oil

seal lip.

4. Pinion shaft rear taper roller bearing 18. Transfer case bolt 32. Left case oil seal No.2

: Apply grease 99000-25010 to oil

seal lip.

5. Transfer output retainer bolt 19. Reduction drive gear left bearing 33. Right case oil seal No.3

: Apply grease 99000-25010 to oil

seal lip.

6. O-ring

: Apply grease 99000-25010 to all around

surface.20. Reduction drive gear 34. Right case oil seal No.2

: Apply grease 99000-25010 to oil

seal lip.

7. Shim 21. Reduction driven gear left taper roller

bearing35. Right case oil seal No.1

: Apply grease 99000-25010 to oil

seal lip.

8. Spacer 22. Reduction driven gear right taper roller

bearing36. Transfer output retainer

Page 563 of 1556

Downloaded from www.Manualslib.com manuals search engine Transfer: 3C-16

Specifications

Tightening Torque SpecificationsS6RW0D3307001

NOTE

The specified tightening torque is also described in the following.

“Transfer Assembly Components”

Reference:

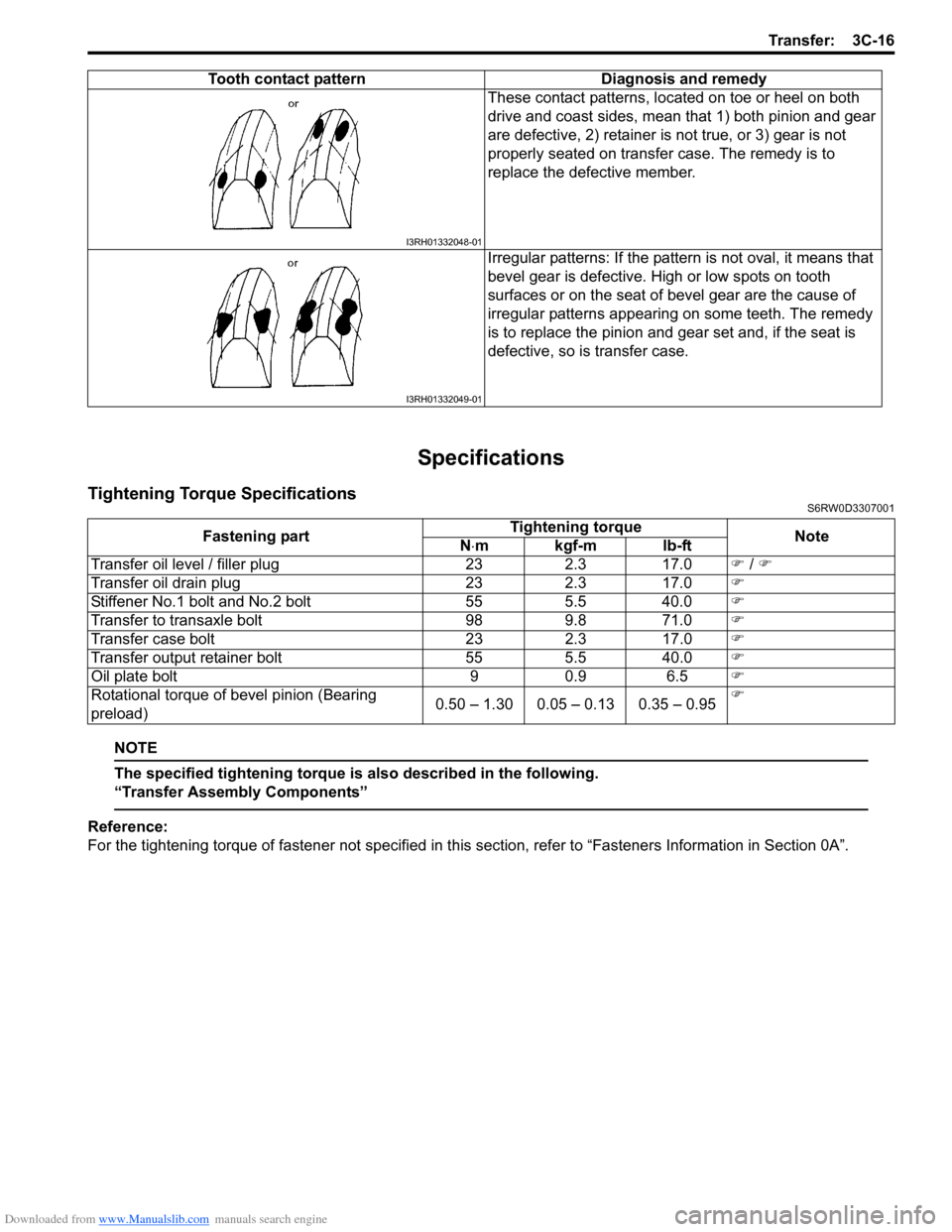

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”. These contact patterns, located on toe or heel on both

drive and coast sides, mean that 1) both pinion and gear

are defective, 2) retainer is not true, or 3) gear is not

properly seated on transfer case. The remedy is to

replace the defective member.

Irregular patterns: If the pattern is not oval, it means that

bevel gear is defective. High or low spots on tooth

surfaces or on the seat of bevel gear are the cause of

irregular patterns appearing on some teeth. The remedy

is to replace the pinion and gear set and, if the seat is

defective, so is transfer case. Tooth contact pattern Diagnosis and remedy

I3RH01332048-01

I3RH01332049-01

Fastening partTightening torque

Note

N⋅mkgf-mlb-ft

Transfer oil level / filler plug 23 2.3 17.0�) / �)

Transfer oil drain plug 23 2.3 17.0�)

Stiffener No.1 bolt and No.2 bolt 55 5.5 40.0�)

Transfer to transaxle bolt 98 9.8 71.0�)

Transfer case bolt 23 2.3 17.0�)

Transfer output retainer bolt 55 5.5 40.0�)

Oil plate bolt 9 0.9 6.5�)

Rotational torque of bevel pinion (Bearing

preload)0.50 – 1.30 0.05 – 0.13 0.35 – 0.95�)

Page 645 of 1556

Downloaded from www.Manualslib.com manuals search engine Table of Contents 5- i

5

Section 5

CONTENTS

Transmission / Transaxle

Precautions ................................................. 5-1

Precautions............................................................. 5-1

Precautions on Transmission / Transaxle ............. 5-1

Automatic Transmission/Transaxle ....... 5A-1

Precautions........................................................... 5A-1

Precautions in Diagnosing Trouble ..................... 5A-1

Precautions for Disassembly and

Reassembly ...................................................... 5A-1

General Description ............................................. 5A-3

A/T Description ................................................... 5A-3

Clutch / Brake / Planetary Gear Function of

Automatic Transaxle ......................................... 5A-6

Table of Component Operation ........................... 5A-7

A/T Diagnosis General Description ..................... 5A-7

On-Board Diagnostic System Description ........... 5A-8

CAN Communication System Description........... 5A-9

Schematic and Routing Diagram ...................... 5A-10

Transmission Control Module (TCM) Wiring

Diagram .......................................................... 5A-10

Automatic Gear Shift Table ............................... 5A-12

Component Location ......................................... 5A-14

Electronic Shift Control System Components

Location .......................................................... 5A-14

Diagnostic Information and Procedures .......... 5A-16

A/T System Check ............................................ 5A-16

Visual Inspection ............................................... 5A-18

Malfunction Indicator Lamp (MIL) Check .......... 5A-19

Transmission Warning Light Check (Non-

Euro-OBD model) ........................................... 5A-19

DTC Table ......................................................... 5A-19

DTC Check ....................................................... 5A-21

DTC Clearance ................................................. 5A-22

Fail-Safe Table .................................................. 5A-22

Scan Tool Data ................................................. 5A-24

A/T Basic Check ............................................... 5A-27

Road Test ......................................................... 5A-27

Manual Road Test ............................................. 5A-30

Engine Brake Test ............................................ 5A-30

Stall Test ........................................................... 5A-31

Time Lag Test ................................................... 5A-32

Line Pressure Test ............................................ 5A-32

“P” Range Test.................................................. 5A-33

A/T Symptom Diagnosis ................................... 5A-34Transmission Warning Light Circuit Check –

Light Remains “ON” at Ignition Switch ON

(Non-Euro-OBD Model)................................... 5A-41

Transmission Warning Light Circuit Check –

Light Does Not Come “ON” at Ignition Switch

ON (Non-Euro-OBD Model)............................ 5A-41

DTC P0602: Control Module Programming

Error ................................................................ 5A-42

DTC P0705: Transmission Range Sensor

Circuit Malfunction (PRNDL Input) .................. 5A-42

DTC P0707: Transmission Range Sensor

Circuit Low ...................................................... 5A-44

DTC P0711: Transmission Fluid Temperature

Sensor “A” Control Range / Performance ....... 5A-46

DTC P0712: Transmission Fluid Temperature

Sensor Circuit Low .......................................... 5A-47

DTC P0713: Transmission Fluid Temperature

Sensor Circuit High ......................................... 5A-48

DTC P0717: Input / Turbine Speed Sensor

Circuit Malfunction........................................... 5A-50

DTC P0722: Output Speed Sensor (VSS)

Circuit No Signal ............................................. 5A-51

DTC P0741 / P0742: TCC Circuit

Performance or Stuck OFF / TCC Circuit

Stuck ON ......................................................... 5A-53

DTC P0751 / P0752 / P0756 / P0757: Shift

Solenoid Malfunction ....................................... 5A-54

DTC P0787: Shift / Timing Solenoid Control

Circuit Low ...................................................... 5A-55

DTC P0788: Shift / Timing Solenoid Control

Circuit High...................................................... 5A-57

DTC P0961: Pressure Control Solenoid “A”

Control Circuit Range / Performance .............. 5A-58

DTC P0962: Pressure Control Solenoid

Control Circuit Low .......................................... 5A-60

DTC P0963: Pressure Control Solenoid

Control Circuit High ......................................... 5A-62

DTC P0973 / P0976: Shift Solenoid-A (No.1)

Control Circuit Low / Shift Solenoid-B (No.2)

Control Circuit Low .......................................... 5A-64

DTC P0974 / P0977: Shift Solenoid-A (No.1)

/ Shift Solenoid-B (No.2) Control Circuit High .. 5A-66

DTC P1702: Internal Control Module Memory

Check Sum Error............................................. 5A-68