shaft SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 880 of 1556

Downloaded from www.Manualslib.com manuals search engine 6B-11 Steering Wheel and Column:

Specifications

Tightening Torque SpecificationsS6RW0D6207001

NOTE

The specified tightening torque is also described in the following.

“Steering Wheel and Column Construction”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Special ToolS6RW0D6208001

Fastening partTightening torque

Note

N⋅mkgf-mlb-ft

Steering shaft nut 33 3.3 24.0�)

Steering column mounting nut No.1 14 1.4 10.5�)

Steering column mounting nut No.2 14 1.4 10.5�)

Steering lower shaft assembly upper joint bolt 25 2.5 18.5�) / �)

Steering lower shaft assembly lower joint bolt 25 2.5 18.5�)

09944–36011

Steering wheel remover

�)

Page 884 of 1556

![SUZUKI SX4 2006 1.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 6C-4 Power Assisted Steering System:

Schematic and Routing Diagram

EPS System Wiring Circuit DiagramS6RW0D6302001

[A]

123

45

3 21

4

567

8

9 11 SUZUKI SX4 2006 1.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 6C-4 Power Assisted Steering System:

Schematic and Routing Diagram

EPS System Wiring Circuit DiagramS6RW0D6302001

[A]

123

45

3 21

4

567

8

9 11](/img/20/7612/w960_7612-883.png)

Downloaded from www.Manualslib.com manuals search engine 6C-4 Power Assisted Steering System:

Schematic and Routing Diagram

EPS System Wiring Circuit DiagramS6RW0D6302001

[A]

123

45

3 21

4

567

8

9 11

10 12 13

141516

17 18 19201

2

[B]

1

2

[C] [D]

10 9 8 7654 3 21

16 15 14 13 12 11

26 25 24 2322 21 20 19 18 17

32 31 30 29 28 27

[F][E]

12

BRN RED/

BLU GRY LT GRN/

BLK

BLK

RED

WHT GRN

BLK

E11-1

E11-5

E11-14

E11-12

[J]:E01-44E01-4

[J]:E01-27E01-26

E12-1

E12-2

E11-10E11-8

E11-9

E11-19

E13-1 GRN

GRY

GRN

WHT

G241-25G241-31

RED/BLK

11

12

1314 3 18

20

21

7 19

4 12

22

12V

E13-2BLK

9V

REDE11-20

12V

12V

E61-2

E61-1

610

55

5V

8

E11-115V

PPL

E11-4

9

23

+BB

BLU/

WHTE04-9

1524YELE11-18E31-5

E31-2

E31-39V

3V

E31-4

E31-1IG11617

C07-25

[H]

[G]

G04-15

[I]:G04-22

25L313-3

[I]

I6RW0D630001-01

[A]: P/S control module connector No.1 “E11” (viewed from harness side) 3. Junction block assembly 15. BCM

[B]: P/S control module connector No.2 “E13” (viewed from harness side) 4. Main fuse 16. Output shaft speed sensor

[C]: P/S control module connector No.3 “E12” (viewed from harness side) 5. Front (left/right) wheel speed sensor 17. TCM

[D]: Combination meter connector “G241” (viewed from harness side) 6. ABS control module 18. Individual circuit fuse box No.1

[E]: Torque sensor connector “E31” (viewed from harness side) 7. Combination meter 19. “IGN” fuse

[F]: Motor connector “E61” (viewed from harness side) 8. “EPS” warning light 20. “P/S” fuse

[G]: M/T model 9. Data link connector (DLC) 21. “IG1 SIG” fuse

[H]: A/T model 10. ECM 22. “MTR” fuse

[I]: Junction block without BCM model (Taiwan model) 11. P/S control module 23. To ABS control module

[J]: M15A engine with 4A/T equipped with slip control model (Hong Kong

model)12. P/S motor 24. To HVAC control module

1. Main fuse box 13. Shield 25. To SDM

2. Ignition switch 14. Torque sensor (built into steering gear case)

Page 902 of 1556

Downloaded from www.Manualslib.com manuals search engine 6C-22 Power Assisted Steering System:

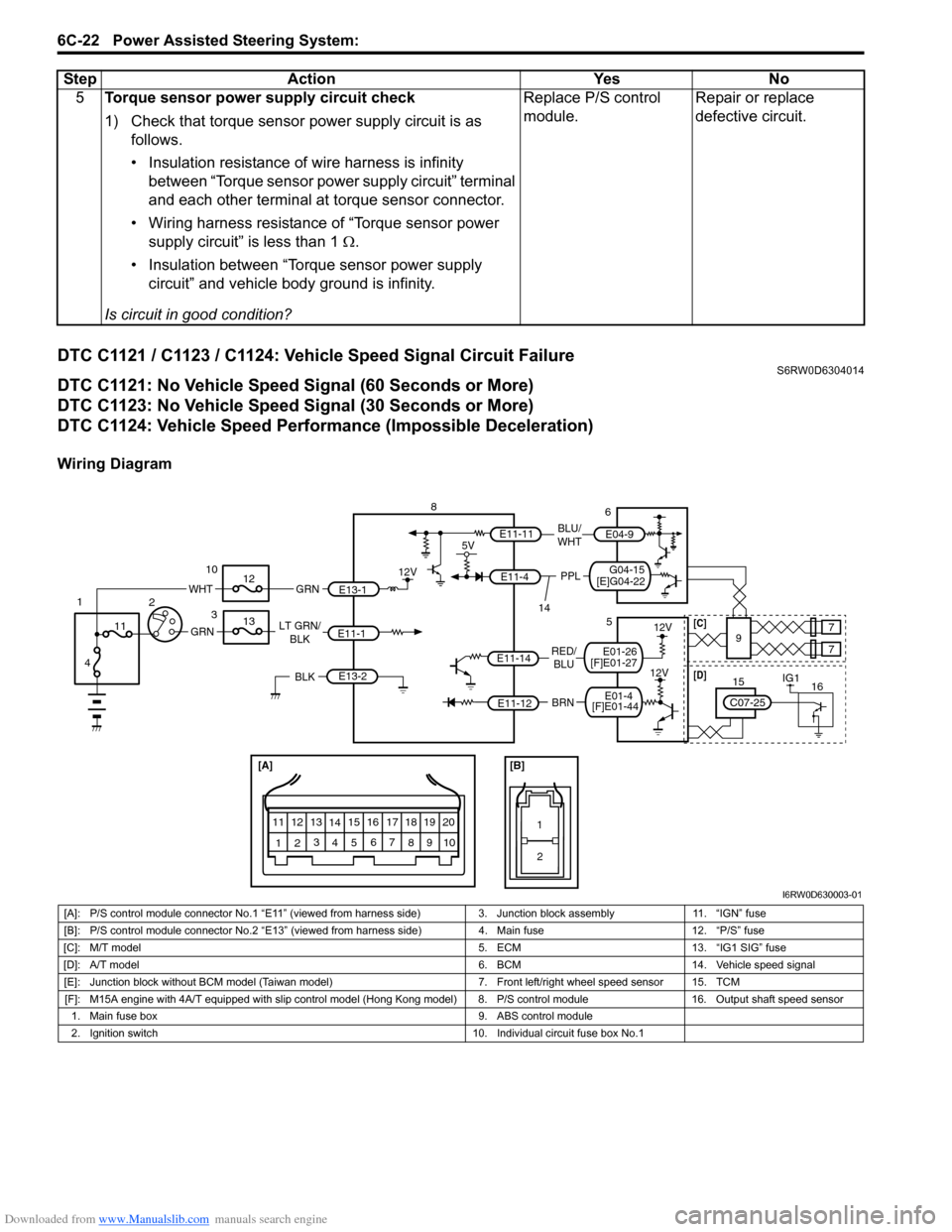

DTC C1121 / C1123 / C1124: Vehicle Speed Signal Circuit FailureS6RW0D6304014

DTC C1121: No Vehicle Speed Signal (60 Seconds or More)

DTC C1123: No Vehicle Speed Signal (30 Seconds or More)

DTC C1124: Vehicle Speed Performance (Impossible Deceleration)

Wiring Diagram5Torque sensor power supply circuit check

1) Check that torque sensor power supply circuit is as

follows.

• Insulation resistance of wire harness is infinity

between “Torque sensor power supply circuit” terminal

and each other terminal at torque sensor connector.

• Wiring harness resistance of “Torque sensor power

supply circuit” is less than 1 Ω.

• Insulation between “Torque sensor power supply

circuit” and vehicle body ground is infinity.

Is circuit in good condition?Replace P/S control

module.Repair or replace

defective circuit. Step Action Yes No

[A]

123

4567

8

9 11

10 12 13

141516

17 18 1920

1

2

[B]

BRN RED/

BLU LT GRN/

BLK

E11-1

E11-14

E11-12

E13-1 GRN

GRN

WHT

8

3 10

12

13

11

4 1

2

12V

E13-2BLK

12V

12V

9 5

77

E11-11

G04-15

[E]G04-22

5V

PPL

E11-4

BLU/

WHTE04-9

6

14

IG11615

C07-25

[D][C]

[F]E01-44E01-4

[F]E01-27E01-26

I6RW0D630003-01

[A]: P/S control module connector No.1 “E11” (viewed from harness side) 3. Junction block assembly 11. “IGN” fuse

[B]: P/S control module connector No.2 “E13” (viewed from harness side) 4. Main fuse 12. “P/S” fuse

[C]: M/T model 5. ECM 13. “IG1 SIG” fuse

[D]: A/T model 6. BCM 14. Vehicle speed signal

[E]: Junction block without BCM model (Taiwan model) 7. Front left/right wheel speed sensor 15. TCM

[F]: M15A engine with 4A/T equipped with slip control model (Hong Kong model) 8. P/S control module 16. Output shaft speed sensor

1. Main fuse box 9. ABS control module

2. Ignition switch 10. Individual circuit fuse box No.1

Page 914 of 1556

Downloaded from www.Manualslib.com manuals search engine 6C-34 Power Assisted Steering System:

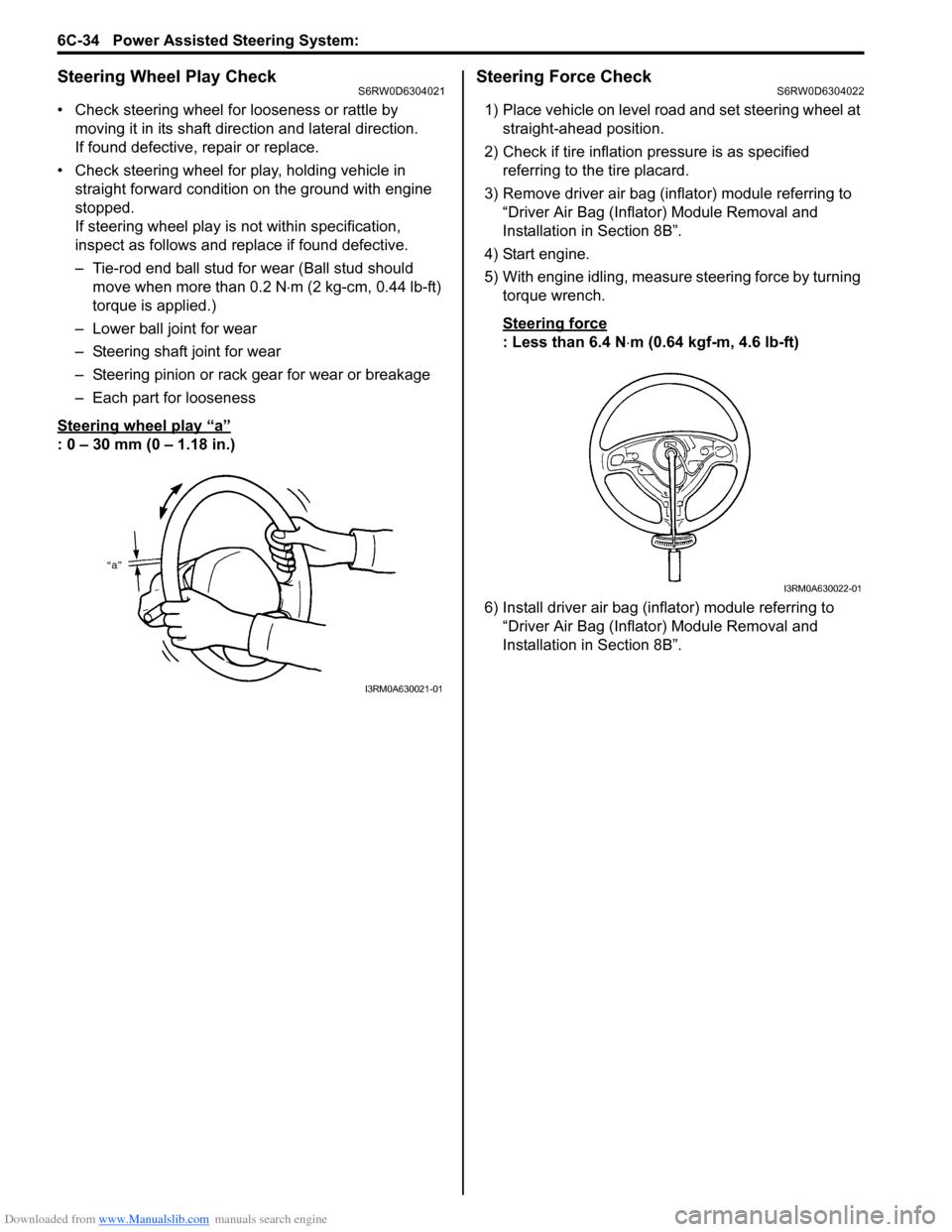

Steering Wheel Play CheckS6RW0D6304021

• Check steering wheel for looseness or rattle by

moving it in its shaft direction and lateral direction.

If found defective, repair or replace.

• Check steering wheel for play, holding vehicle in

straight forward condition on the ground with engine

stopped.

If steering wheel play is not within specification,

inspect as follows and replace if found defective.

– Tie-rod end ball stud for wear (Ball stud should

move when more than 0.2 N⋅m (2 kg-cm, 0.44 lb-ft)

torque is applied.)

– Lower ball joint for wear

– Steering shaft joint for wear

– Steering pinion or rack gear for wear or breakage

– Each part for looseness

Steering wheel play

“a”

: 0 – 30 mm (0 – 1.18 in.)

Steering Force CheckS6RW0D6304022

1) Place vehicle on level road and set steering wheel at

straight-ahead position.

2) Check if tire inflation pressure is as specified

referring to the tire placard.

3) Remove driver air bag (inflator) module referring to

“Driver Air Bag (Inflator) Module Removal and

Installation in Section 8B”.

4) Start engine.

5) With engine idling, measure steering force by turning

torque wrench.

Steering force

: Less than 6.4 N⋅m (0.64 kgf-m, 4.6 lb-ft)

6) Install driver air bag (inflator) module referring to

“Driver Air Bag (Inflator) Module Removal and

Installation in Section 8B”.

I3RM0A630021-01

I3RM0A630022-01

Page 917 of 1556

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-37

3) Inspect for proper toe referring to “Front Wheel

Alignment Inspection and Adjustment in Section 2B”.

4) After confirming proper toe, tighten tie-rod end lock

nut to specified torque.

Tightening torque

Tie-rod end lock nut (a): 45 N·m (4.5 kgf-m, 32.5

lb-ft)

5) Tighten wheel bolts to specified torque and lower

hoist.

Tightening torque

Wheel bolt: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

Tie-Rod End InspectionS6RW0D6306004

• Inspect for play in ball joint.

• Inspect for play in rack end ball joint.

In either case, if found defective, replace.

Steering Shaft Joint On-Vehicle InspectionS6RW0D6306005

Check shaft joint for wear, breakage and any other

damage and replace if any defect exists.

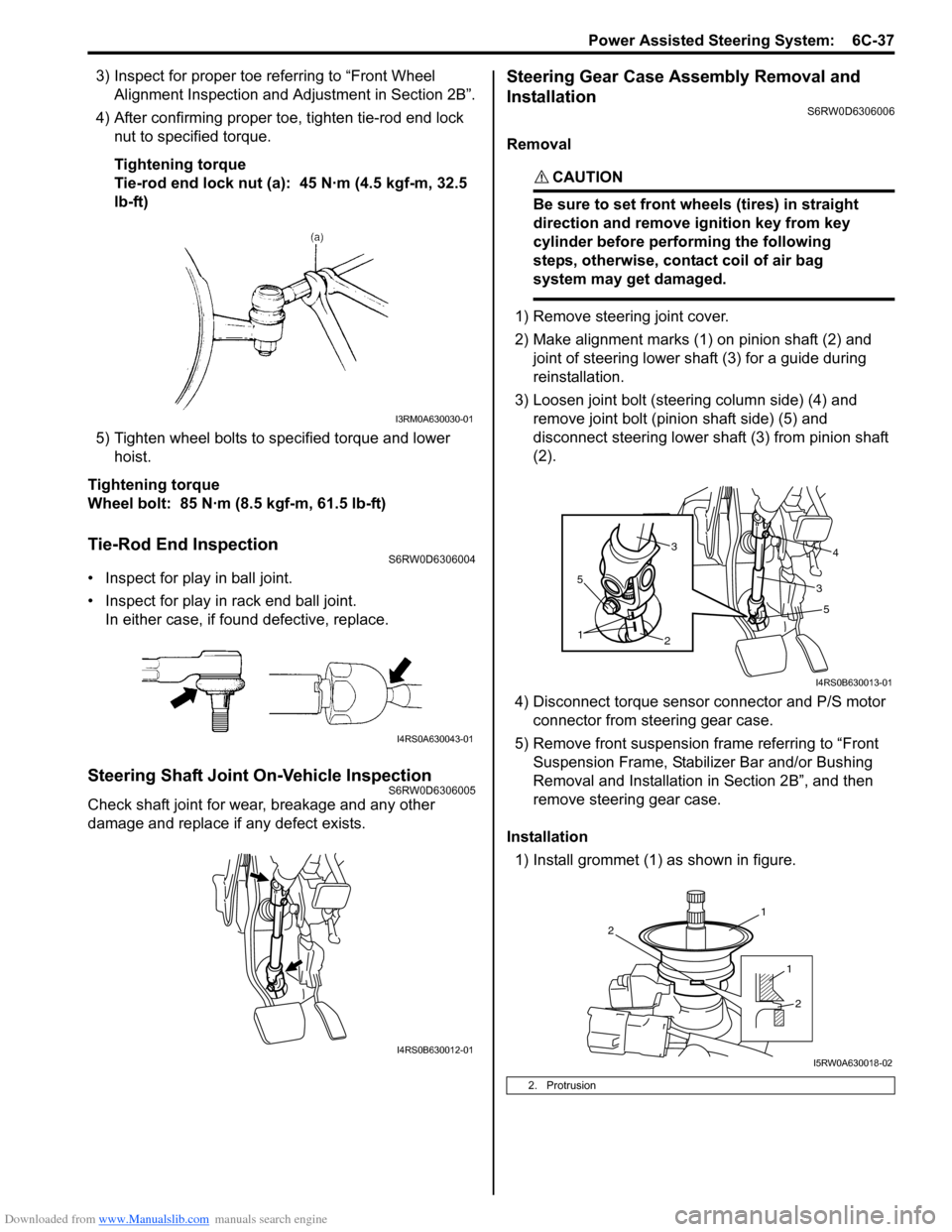

Steering Gear Case Assembly Removal and

Installation

S6RW0D6306006

Removal

CAUTION!

Be sure to set front wheels (tires) in straight

direction and remove ignition key from key

cylinder before performing the following

steps, otherwise, contact coil of air bag

system may get damaged.

1) Remove steering joint cover.

2) Make alignment marks (1) on pinion shaft (2) and

joint of steering lower shaft (3) for a guide during

reinstallation.

3) Loosen joint bolt (steering column side) (4) and

remove joint bolt (pinion shaft side) (5) and

disconnect steering lower shaft (3) from pinion shaft

(2).

4) Disconnect torque sensor connector and P/S motor

connector from steering gear case.

5) Remove front suspension frame referring to “Front

Suspension Frame, Stabilizer Bar and/or Bushing

Removal and Installation in Section 2B”, and then

remove steering gear case.

Installation

1) Install grommet (1) as shown in figure.

I3RM0A630030-01

I4RS0A630043-01

I4RS0B630012-01

2. Protrusion

5

2

1

5

34

3

I4RS0B630013-01

1

2

1

2

I5RW0A630018-02

Page 918 of 1556

Downloaded from www.Manualslib.com manuals search engine 6C-38 Power Assisted Steering System:

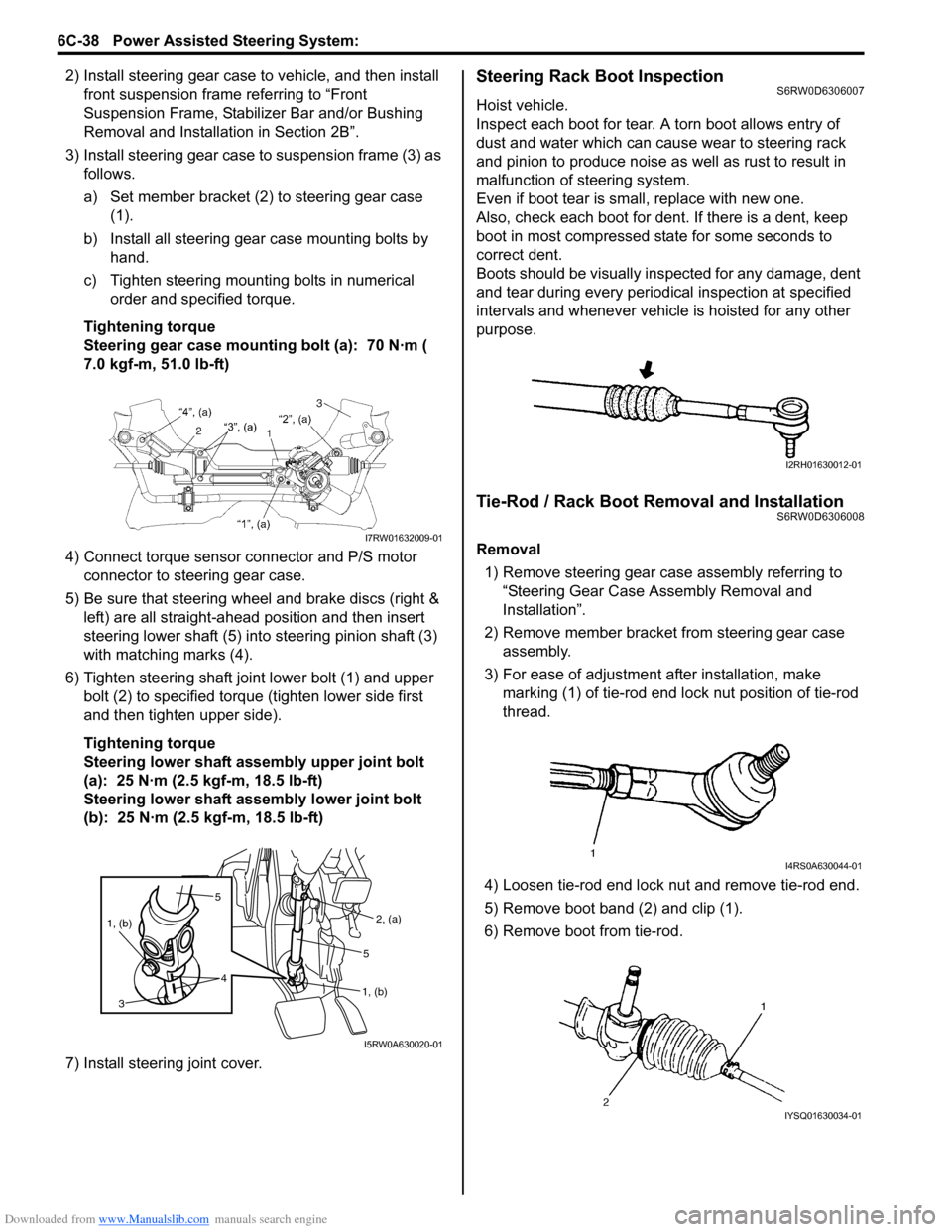

2) Install steering gear case to vehicle, and then install

front suspension frame referring to “Front

Suspension Frame, Stabilizer Bar and/or Bushing

Removal and Installation in Section 2B”.

3) Install steering gear case to suspension frame (3) as

follows.

a) Set member bracket (2) to steering gear case

(1).

b) Install all steering gear case mounting bolts by

hand.

c) Tighten steering mounting bolts in numerical

order and specified torque.

Tightening torque

Steering gear case mounting bolt (a): 70 N·m (

7.0 kgf-m, 51.0 lb-ft)

4) Connect torque sensor connector and P/S motor

connector to steering gear case.

5) Be sure that steering wheel and brake discs (right &

left) are all straight-ahead position and then insert

steering lower shaft (5) into steering pinion shaft (3)

with matching marks (4).

6) Tighten steering shaft joint lower bolt (1) and upper

bolt (2) to specified torque (tighten lower side first

and then tighten upper side).

Tightening torque

Steering lower shaft assembly upper joint bolt

(a): 25 N·m (2.5 kgf-m, 18.5 lb-ft)

Steering lower shaft assembly lower joint bolt

(b): 25 N·m (2.5 kgf-m, 18.5 lb-ft)

7) Install steering joint cover.Steering Rack Boot InspectionS6RW0D6306007

Hoist vehicle.

Inspect each boot for tear. A torn boot allows entry of

dust and water which can cause wear to steering rack

and pinion to produce noise as well as rust to result in

malfunction of steering system.

Even if boot tear is small, replace with new one.

Also, check each boot for dent. If there is a dent, keep

boot in most compressed state for some seconds to

correct dent.

Boots should be visually inspected for any damage, dent

and tear during every periodical inspection at specified

intervals and whenever vehicle is hoisted for any other

purpose.

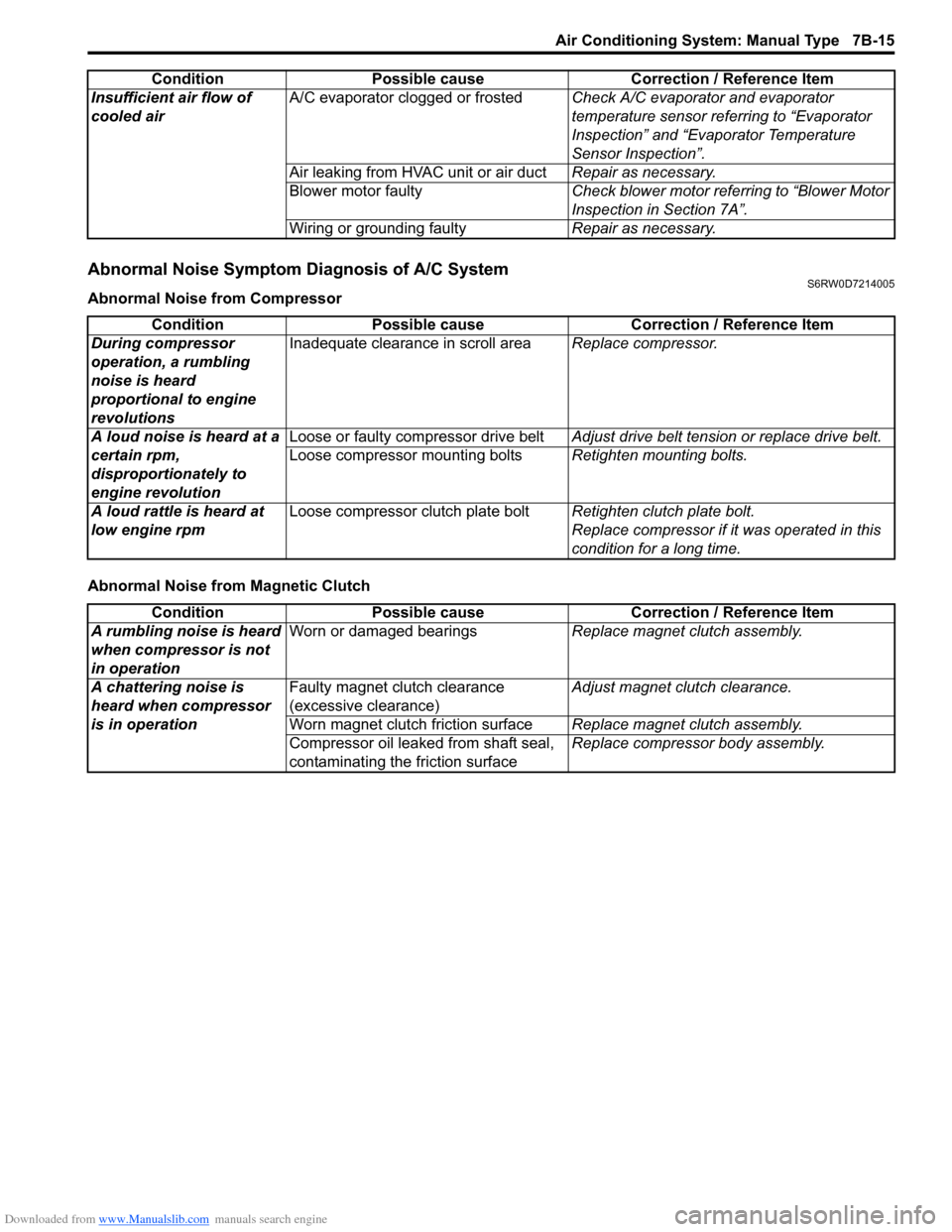

Tie-Rod / Rack Boot Removal and InstallationS6RW0D6306008

Removal

1) Remove steering gear case assembly referring to

“Steering Gear Case Assembly Removal and

Installation”.

2) Remove member bracket from steering gear case

assembly.

3) For ease of adjustment after installation, make

marking (1) of tie-rod end lock nut position of tie-rod

thread.

4) Loosen tie-rod end lock nut and remove tie-rod end.

5) Remove boot band (2) and clip (1).

6) Remove boot from tie-rod.I7RW01632009-01

5

4 1, (b)

3

2, (a)

1, (b)5

I5RW0A630020-01

I2RH01630012-01

I4RS0A630044-01

IYSQ01630034-01

Page 923 of 1556

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-43

8) Using ammeter (2), check that P/S motor current (1)

is as following table with idling engine. If check result

is not satisfactory, check P/S control module for

torque sensor signal and P/S motor output referring

to “Inspection of P/S Control Module and Its

Circuits”. If they are OK, replace steering gear case

assembly.

NOTE

When P/S motor is cold condition (that is,

armature coil of P/S motor is not heated),

motor current in the following table can be

measured

Motor current at hoisted vehicle (reference

value)

Specifications

Tightening Torque SpecificationsS6RW0D6307001

NOTE

The specified tightening torque is also described in the following.

“Steering Gear Case Assembly Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”. ConditionWhen

steering

wheel is left

at straight

position: [A]When steering

wheel is turned

left or right by

turning speed

with 90° /sec:

[B]When

steering

wheel is

kept fully

turned left

or right

until it

stops.: [C]

Motor

currentApprox. 0 A Approx. 0 – 5 AApprox.

45 – 60 A

3. P/S control module

1

32

E12-1

E12-2

[C][A]

[B] [B]

I7RW01632012-01

Fastening partTightening torque

Note

N⋅mkgf-mlb-ft

Tie-rod end nut 45 4.5 32.5�)

Tie-rod end lock nut 45 4.5 32.5�)

Wheel bolt 85 8.5 61.5�)

Steering gear case mounting bolt 70 7.0 51.0�)

Steering lower shaft assembly upper joint bolt 25 2.5 18.5�)

Steering lower shaft assembly lower joint bolt 25 2.5 18.5�)

Tie-rod 75 7.5 54.5�)

Earth cable bolt 4.0 0.4 2.8�)

Rack damper screw Tighten 25 N⋅m (2.5 kgf-m, 18.0 lb-ft) and

loosen 180° and then tighten 3.9 N⋅m (0.39

kgf-m, 3.0 lb-ft) and turn it back by 10° or

less by the specified procedure.�)

Rotation torque of pinion 2.2 0.22 1.5�)

Steering rack damper lock nut 60 6.0 43.5�)

Page 955 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-15

Abnormal Noise Symptom Diagnosis of A/C SystemS6RW0D7214005

Abnormal Noise from Compressor

Abnormal Noise from Magnetic ClutchInsufficient air flow of

cooled airA/C evaporator clogged or frostedCheck A/C evaporator and evaporator

temperature sensor referring to “Evaporator

Inspection” and “Evaporator Temperature

Sensor Inspection”.

Air leaking from HVAC unit or air ductRepair as necessary.

Blower motor faultyCheck blower motor referring to “Blower Motor

Inspection in Section 7A”.

Wiring or grounding faultyRepair as necessary. Condition Possible cause Correction / Reference Item

Condition Possible cause Correction / Reference Item

During compressor

operation, a rumbling

noise is heard

proportional to engine

revolutionsInadequate clearance in scroll areaReplace compressor.

A loud noise is heard at a

certain rpm,

disproportionately to

engine revolutionLoose or faulty compressor drive beltAdjust drive belt tension or replace drive belt.

Loose compressor mounting boltsRetighten mounting bolts.

A loud rattle is heard at

low engine rpmLoose compressor clutch plate boltRetighten clutch plate bolt.

Replace compressor if it was operated in this

condition for a long time.

Condition Possible cause Correction / Reference Item

A rumbling noise is heard

when compressor is not

in operationWorn or damaged bearingsReplace magnet clutch assembly.

A chattering noise is

heard when compressor

is in operationFaulty magnet clutch clearance

(excessive clearance)Adjust magnet clutch clearance.

Worn magnet clutch friction surfaceReplace magnet clutch assembly.

Compressor oil leaked from shaft seal,

contaminating the friction surfaceReplace compressor body assembly.

Page 956 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-16 Air Conditioning System: Manual Type

Abnormal Noise from Tubing

Abnormal Noise from Condenser Assembly

Abnormal Noise from Crankshaft Pulley

Abnormal Noise from Tension Pulley

Abnormal Noise from A/C Evaporator

Abnormal Noise from Blower MotorCondition Possible cause Correction / Reference Item

A droning noise is heard

from inside of the vehicle,

but not particularly

noticeable in engine

compartmentFaulty tubing clampsReposition clamps or increase the number of

clamps.

Resonance caused by pulsation from

variations in refrigerant pressureAttach a silencer to tubing, or modify its

position and length.

Condition Possible cause Correction / Reference Item

Considerable vibration in

condenser assemblyResonance from condenser assembly

bracket and bodyFirmly insert a silencer between condenser

assembly bracket and body.

Condition Possible cause Correction / Reference Item

A large rattling noise is

heard at idle or sudden

accelerationLoosen crankshaft pulley boltRetighten bolt.

Condition Possible cause Correction / Reference Item

Clattering noise is heard

from pulleyWorn or damaged bearingReplace tension pulley.

Pulley cranks upon

contactCracked or loose bracketReplace or retighten bracket.

Condition Possible cause Correction / Reference Item

Whistling sound is heard

from A/C evaporatorDepending on the combination of the

interior / exterior temperatures, engine

rpm and refrigerant pressure, the

refrigerant flowing out of the expansion

valve may, under certain conditions,

make a whistling soundAt times, slightly decreasing refrigerant volume

may stop this noise.

Inspect expansion valve and replace if faulty.

Condition Possible cause Correction / Reference Item

Blower motor emits a

chirping sound in

proportion to its speed of

rotationWorn or damaged motor brushes or

commutatorReplace blower motor.

Fluttering noise or large

droning noise is heard

from blower motorLeaves or other debris introduced from

fresh air inlet to blower motorRemove debris and make sure that the screen

at fresh air inlet is intact.

Page 970 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-30 Air Conditioning System: Manual Type

A/C System Relay InspectionS6RW0D7216017

NOTE

Do not use blue relay for the substitute of

white relay because internal durability of a

blue relay is different from the durability of a

white relay.

1) Disconnect negative (–) cable from battery.

2) Remove compressor relay (1) or condenser cooling

fan relay (2) from main fuse box (3).

3) Check that there is no continuity between terminal

“c” and “d”. If there is continuity, replace relay.

4) Connect battery positive (+) terminal to terminal “b”

of relay and battery negative (–) terminal to terminal

“a” of relay, and then check continuity between

terminal “c” and “d”. If there is no continuity, replace

relay.

Compressor Drive Belt Inspection and

Adjustment

S6RW0D7216018

Inspection

• Check compressor drive belt (1) for wear, crack,

deformation and cleanliness. If any defect is found,

replace the belt with new one referring to

“Compressor Drive Belt Removal and Installation”.

• Check compressor drive belt tension by measuring

how much it deflects when pushed intermediate point

between magnet clutch pulley (6) and crankshaft

pulley (3) with about 100 N (10 kg) force after rotating

crankshaft pulley 360°. If belt tension is out of

specification, adjust belt tension referring to

“Adjustment”.

Compressor drive belt tension

“a”

: 7 – 8 mm (0.28 – 0.31 in.)

NOTE

When replacing drive belt, adjust drive belt

tension to the following specifications.

New compressor drive belt tension “a”

: 6 – 7 mm (0.24 – 0.28 in.)

Adjustment

1) Loosen tension pulley nut (4).

2) Adjust belt tension by tighten or loosen tension

pulley adjusting bolt (5).

3) Tighten tension pulley nut.

4) Rotate the crankshaft pulley 360°, and then recheck

belt tension.

3

1

2

“a”

“b”“c”

“d”

I5RW0B721023-01

2. Tension pulley

I5RW0A721033-01