Ignition system SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1498 of 1556

Downloaded from www.Manualslib.com manuals search engine 10B-25 Body Electrical Control System:

Junction block connector “L314”

Junction block connector “L315”Terminal Circuit Normal voltage Condition

L314-4 Ground for BCM 0 V Ignition switch is at all positions

L314-6Right side door mirror heater

(if equipped)10 – 14 VEngine is running and rear end door window

defogger is in operation

0 VEngine is running and rear end door window

defogger is not in operation

L314-7Left side door mirror heater (if

equipped)10 – 14 VEngine is running and rear end door window

defogger is in operation

0 VEngine is running and rear end door window

defogger is not in operation

L314-8Rear end door window

defogger wire10 – 14 VEngine is running and rear end door window

defogger is in operation

0 VEngine is running and rear end door window

defogger is not in operation

L314-9 Rear wiper control10 – 14 VIgnition switch is at ON position and rear

wiper is not in operation

0 VIgnition switch is at ON position and rear

wiper is in operation

Terminal Circuit Normal voltage Condition

L315-1Door lock actuator control

(Dead lock) (if equipped)10 – 14 VDriver side key cylinder is turned to lock twice

with in 3 seconds

0 VManual door lock switch is at any position

other than LOCK position and driver side door

key cylinder switch is at any position other

than LOCK position

L315-9Door lock actuator control

(Unlock) (if equipped)10 – 14 VUnlock signal is output for rear door lock

actuator

0 VUnlock signal is not output for rear door lock

actuator

L315-10Door lock actuator control

(Lock) (if equipped)10 – 14 V Lock signal is output for all door lock actuators

0 VLock signal is not output for all door lock

actuators

Page 1499 of 1556

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-26

Reference waveform No. 1

Parking brake or brake fluid level switch signal (1)

Reference waveform No. 2

Driver seat belt switch signal (1)Reference waveform No. 3

CAN communication signal

Reference waveform No. 4

Oil pressure switch signal (1) Measurement terminal Parking brake switch

CH2: “L01-6” to “G271-3”

Brake fluid level switch

CH2: “E04-5” to “G271-3”

Oscilloscope setting CH1: 5 V / DIV

TIME: 10 ms / DIV

Measurement

conditionParking brake switch:

• Ignition switch is at ON

position, parking brake lever

is released

Brake fluid level switch

• Ignition switch is at ON

position, brake fluid level is in

normal

Measurement terminal CH2: “L01-14” to “G271-3”

Oscilloscope setting CH2: 5 V/DIV

TIME: 4 ms/DIV

Measurement

conditionIgnition switch is at ON position

and driver side seat belt is

fastened

I4RS0AA20018-02

I4RS0AA20016-02

Measurement terminal CAN communication signal for

ABS control module

CH2: “E04-1” to “G271-3”

CH3: “E04-2” to “G271-3”

CAN communication signal for

DLC

CH2: “G04-3” to “G271-3”

CH3: “G04-1” to “G271-3”

CAN communication signal for

each control module

CH2: “G04-4” to “G271-3”

CH3: “G04-2” to “G271-3”

Oscilloscope setting CH2: 1 V/DIV

CH3: 1 V/DIV

TIME: 40 µs/ DIV

Measurement

conditionIgnition switch is at ON position

1. CAN communication line signal (High)

2. CAN communication line signal (Low)

Measurement terminal CH2: “E04-11” to “G271-3”

Oscilloscope setting CH2: 5 V / DIV

TIME: 10 ms / DIV

Measurement

conditionEngine is running and oil

pressure is in normal condition

I4RS0AA20017-02

I4RS0AA20018-02

Page 1500 of 1556

Downloaded from www.Manualslib.com manuals search engine 10B-27 Body Electrical Control System:

Reference waveform No. 5

Information display and HVAC control module serial

communication signal (1)

Reference waveform No. 6

Keyless entry receiver signal (1)Reference waveform No. 7

Vehicle speed pulse output signal (1)

Reference waveform No. 8

A/C or rear end door window defogger switch signal (1) Measurement terminal CH2: “G04-11” to “G271-3”

Oscilloscope setting CH2: 5 V / DIV

TIME: 2 ms / DIV

Measurement

conditionIgnition switch is at ON position

Measurement terminal CH2: “G04-14” to “G271-3”

Oscilloscope setting CH2: 2 V / DIV

TIME: 200 ms / DIV

Measurement

conditionLock or unlock button of

keyless entry transmitter is

pushed

I4RS0AA20021-02

I4RS0AA20022-02

Measurement terminal CH1: “G04-15” to “G271-3”

Oscilloscope setting CH1: 2 V / DIV

TIME: 100 ms / DIV

Measurement

conditionVehicle speed at 10 km/h (6

mph)

Measurement terminal Rear end door window

defogger switch

CH2: “G04-17” to “G271-3”

A/C switch

CH2: “G04-18” to “G271-3”

Oscilloscope setting CH2: 5 V/DIV

TIME: 10 ms/DIV

Measurement

conditionRear end door window

defogger switch:

• Ignition switch is at ON

position and rear end door

window defogger switch is

not pushed

A/C switch:

• Ignition switch is at ON

position, A/C switch or

blower speed selector is at

OFF position

I5RW0AA20014-01

I4RS0AA20023-02

Page 1501 of 1556

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-28

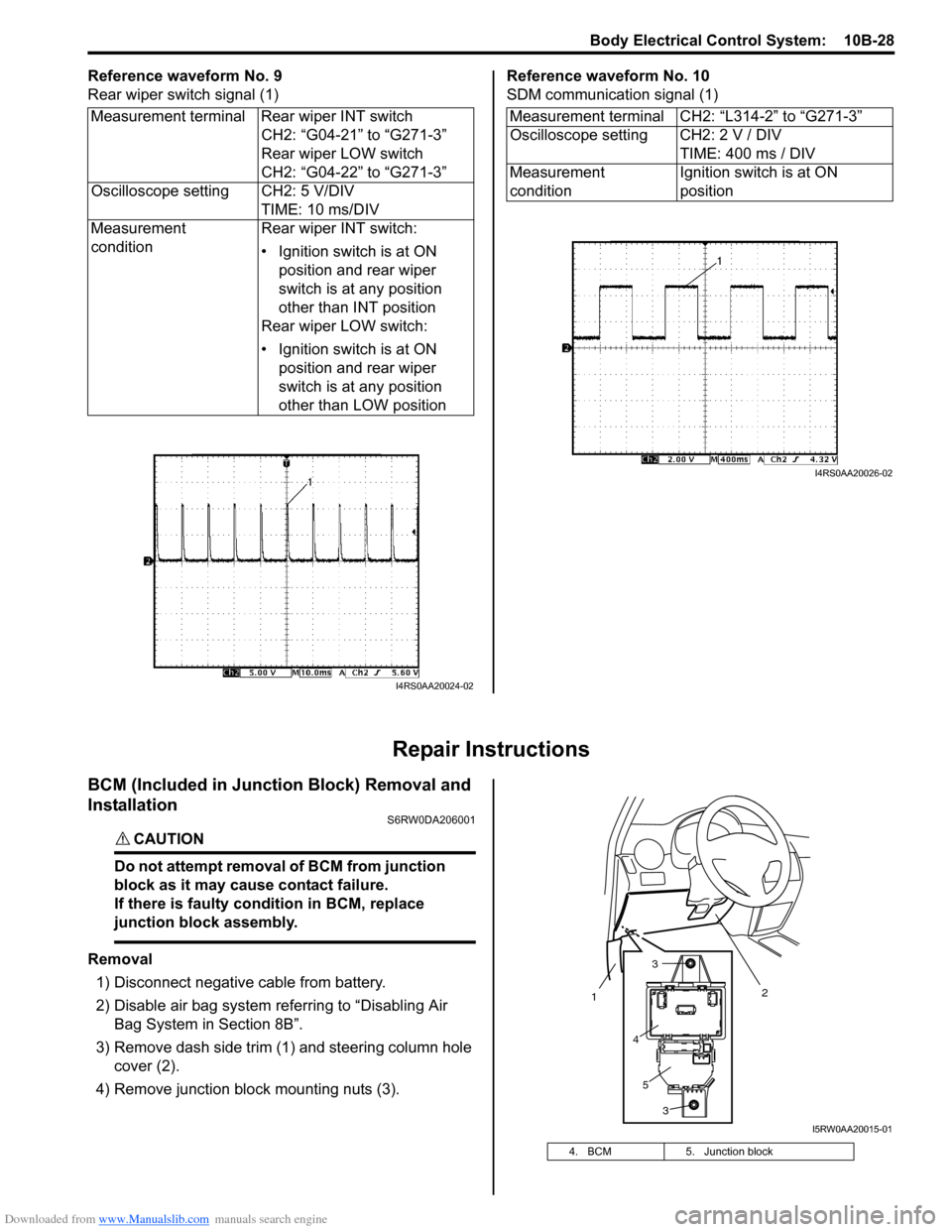

Reference waveform No. 9

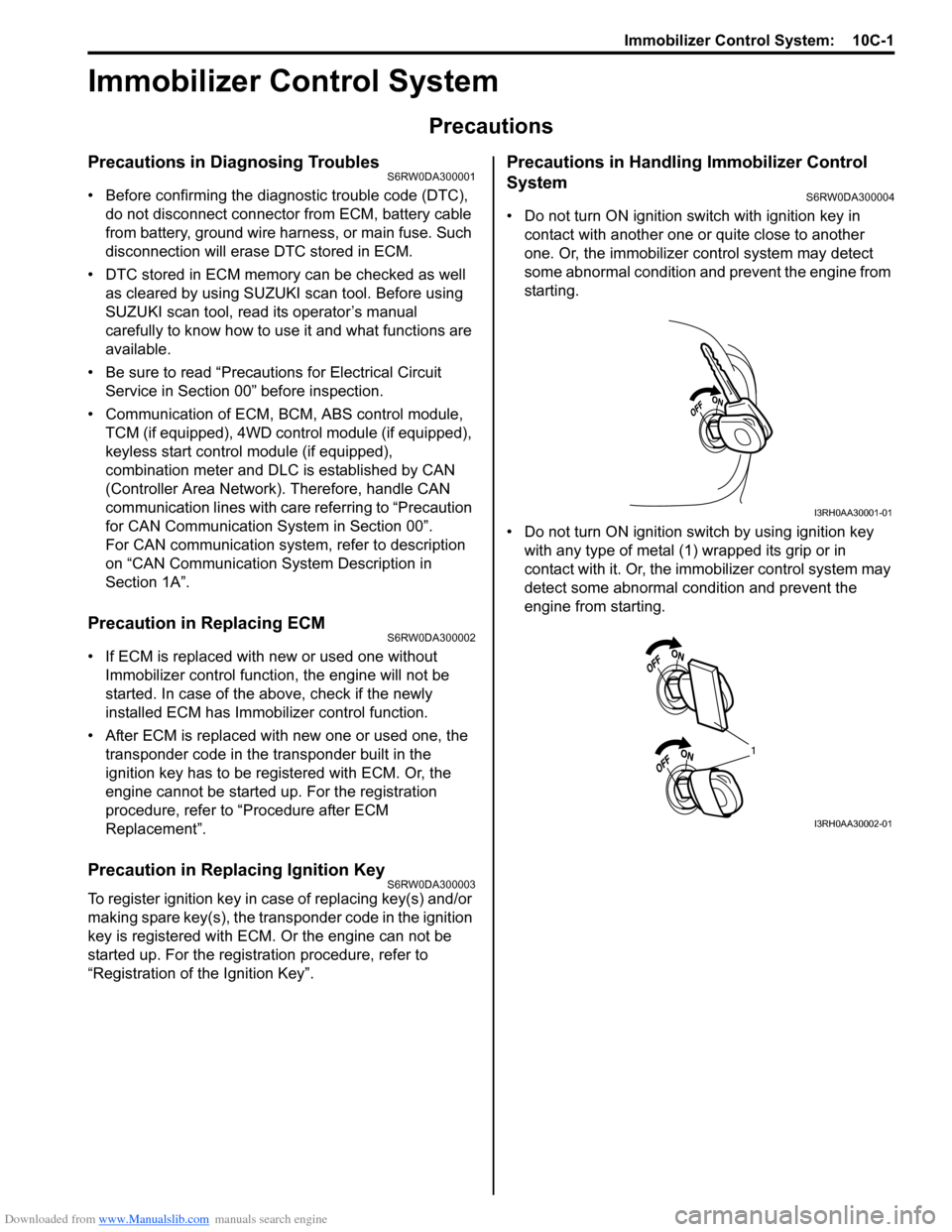

Rear wiper switch signal (1)Reference waveform No. 10

SDM communication signal (1)

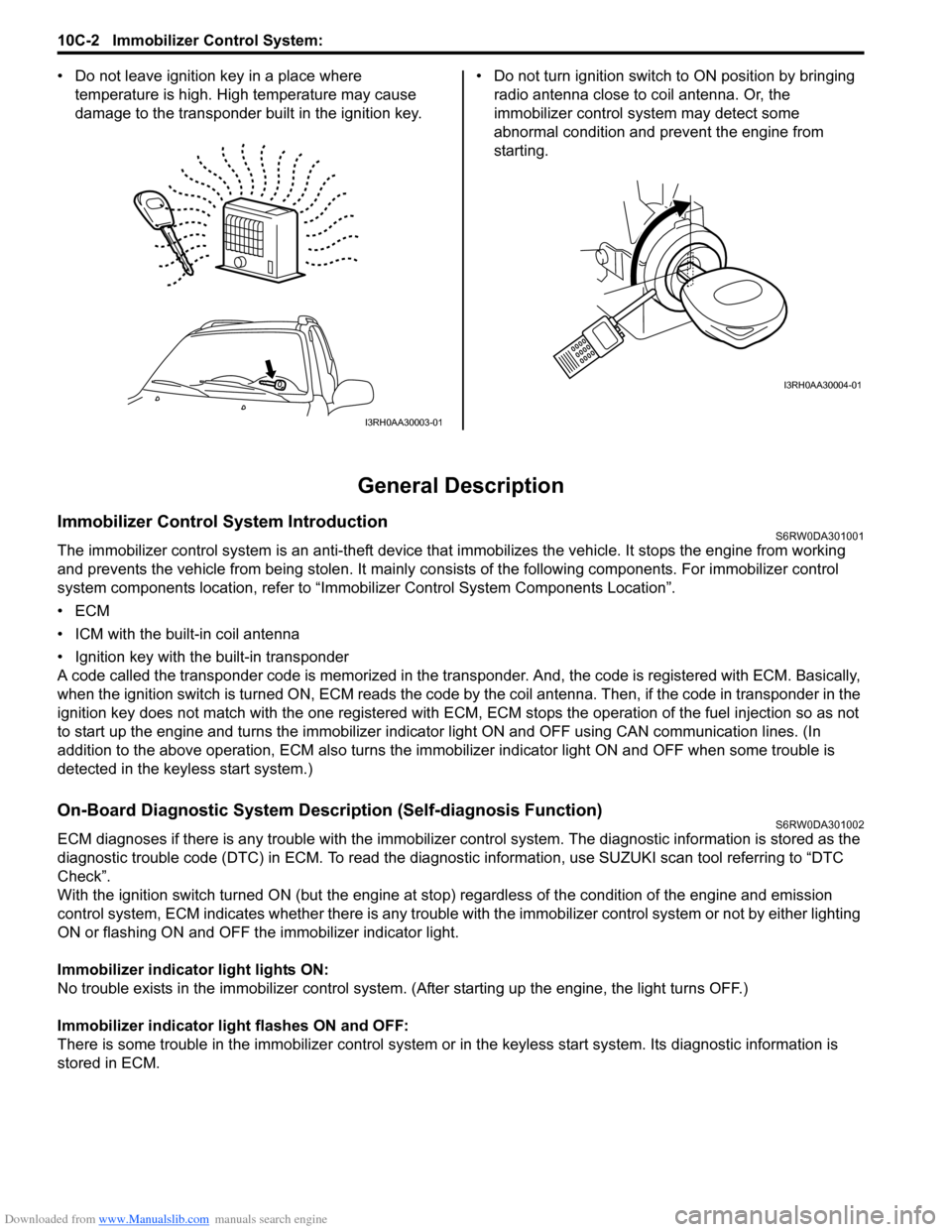

Repair Instructions

BCM (Included in Junction Block) Removal and

Installation

S6RW0DA206001

CAUTION!

Do not attempt removal of BCM from junction

block as it may cause contact failure.

If there is faulty condition in BCM, replace

junction block assembly.

Removal

1) Disconnect negative cable from battery.

2) Disable air bag system referring to “Disabling Air

Bag System in Section 8B”.

3) Remove dash side trim (1) and steering column hole

cover (2).

4) Remove junction block mounting nuts (3). Measurement terminal Rear wiper INT switch

CH2: “G04-21” to “G271-3”

Rear wiper LOW switch

CH2: “G04-22” to “G271-3”

Oscilloscope setting CH2: 5 V/DIV

TIME: 10 ms/DIV

Measurement

conditionRear wiper INT switch:

• Ignition switch is at ON

position and rear wiper

switch is at any position

other than INT position

Rear wiper LOW switch:

• Ignition switch is at ON

position and rear wiper

switch is at any position

other than LOW position

I4RS0AA20024-02

Measurement terminal CH2: “L314-2” to “G271-3”

Oscilloscope setting CH2: 2 V / DIV

TIME: 400 ms / DIV

Measurement

conditionIgnition switch is at ON

position

I4RS0AA20026-02

4. BCM 5. Junction block

2

1

3

3

4

5

I5RW0AA20015-01

Page 1502 of 1556

Downloaded from www.Manualslib.com manuals search engine 10B-29 Body Electrical Control System:

5) Disconnect connectors from BCM and junction

block.

6) Detach wiring harness clamp from junction block.

Installation

Reverse removal procedure for installation, noting

following points.

• Connect connectors securely.

• Enable air bag system referring to “Enabling Air Bag

System in Section 8B”.

• With keyless entry system (other than keyless start

model), if BCM is replaced, register transmitter code

into BCM, referring to “Programming Transmitter

Code for Keyless Entry System (Other than Keyless

Start Model) in Section 9F”.

Security Alarm Mode Selection Procedure (If

Equipped)

S6RW0DA206005

Security alarm mode can be selected by performing the

following procedure.

1) Confirm that all doors are closed, all doors are

unlocked and ignition key is inserted in ignition key

cylinder.

2) Remove ignition key from ignition key cylinder.

3) Perform Step a) through e) described below within

15 seconds.

a) Insert ignition key (1) in ignition key cylinder (2).

b) Remove ignition key from ignition key cylinder.

c) Repeat Step a) and b) twice.

d) Insert ignition key in ignition key cylinder.

e) Push lock side (3) of driver side manual lock

switch (4) 3 times.4) When Step 3) is completed, the mode changes to

the next one automatically. The warning buzzer

(located in BCM) sounds by the number of specified

for each mode as follows.

• Changed from A mode to B mode: Buzzer sounds

4 times

• Changed from B mode to A mode: Buzzer sounds

once

Outside Air Temperature Sensor Removal and

Installation

S6RW0DA206002

For removal and installation, refer to “Outside Air

Temperature Sensor Removal and Installation (If

Equipped) in Section 9C”.

Outside Air Temperature Sensor InspectionS6RW0DA206003

For inspection, refer to “Outside Air Temperature Sensor

Inspection (If Equipped) in Section 9C”.

Special Tools and Equipment

Special ToolS6RW0DA208001

1 2

4

3

I7JB01A20007-01

SUZUKI scan tool

—

This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12. �)

Page 1503 of 1556

Downloaded from www.Manualslib.com manuals search engine Immobilizer Control System: 10C-1

Control Systems

Immobilizer Control System

Precautions

Precautions in Diagnosing TroublesS6RW0DA300001

• Before confirming the diagnostic trouble code (DTC),

do not disconnect connector from ECM, battery cable

from battery, ground wire harness, or main fuse. Such

disconnection will erase DTC stored in ECM.

• DTC stored in ECM memory can be checked as well

as cleared by using SUZUKI scan tool. Before using

SUZUKI scan tool, read its operator’s manual

carefully to know how to use it and what functions are

available.

• Be sure to read “Precautions for Electrical Circuit

Service in Section 00” before inspection.

• Communication of ECM, BCM, ABS control module,

TCM (if equipped), 4WD control module (if equipped),

keyless start control module (if equipped),

combination meter and DLC is established by CAN

(Controller Area Network). Therefore, handle CAN

communication lines with care referring to “Precaution

for CAN Communication System in Section 00”.

For CAN communication system, refer to description

on “CAN Communication System Description in

Section 1A”.

Precaution in Replacing ECMS6RW0DA300002

• If ECM is replaced with new or used one without

Immobilizer control function, the engine will not be

started. In case of the above, check if the newly

installed ECM has Immobilizer control function.

• After ECM is replaced with new one or used one, the

transponder code in the transponder built in the

ignition key has to be registered with ECM. Or, the

engine cannot be started up. For the registration

procedure, refer to “Procedure after ECM

Replacement”.

Precaution in Replacing Ignition KeyS6RW0DA300003

To register ignition key in case of replacing key(s) and/or

making spare key(s), the transponder code in the ignition

key is registered with ECM. Or the engine can not be

started up. For the registration procedure, refer to

“Registration of the Ignition Key”.

Precautions in Handling Immobilizer Control

System

S6RW0DA300004

• Do not turn ON ignition switch with ignition key in

contact with another one or quite close to another

one. Or, the immobilizer control system may detect

some abnormal condition and prevent the engine from

starting.

• Do not turn ON ignition switch by using ignition key

with any type of metal (1) wrapped its grip or in

contact with it. Or, the immobilizer control system may

detect some abnormal condition and prevent the

engine from starting.

I3RH0AA30001-01

1

I3RH0AA30002-01

Page 1504 of 1556

Downloaded from www.Manualslib.com manuals search engine 10C-2 Immobilizer Control System:

• Do not leave ignition key in a place where

temperature is high. High temperature may cause

damage to the transponder built in the ignition key.• Do not turn ignition switch to ON position by bringing

radio antenna close to coil antenna. Or, the

immobilizer control system may detect some

abnormal condition and prevent the engine from

starting.

General Description

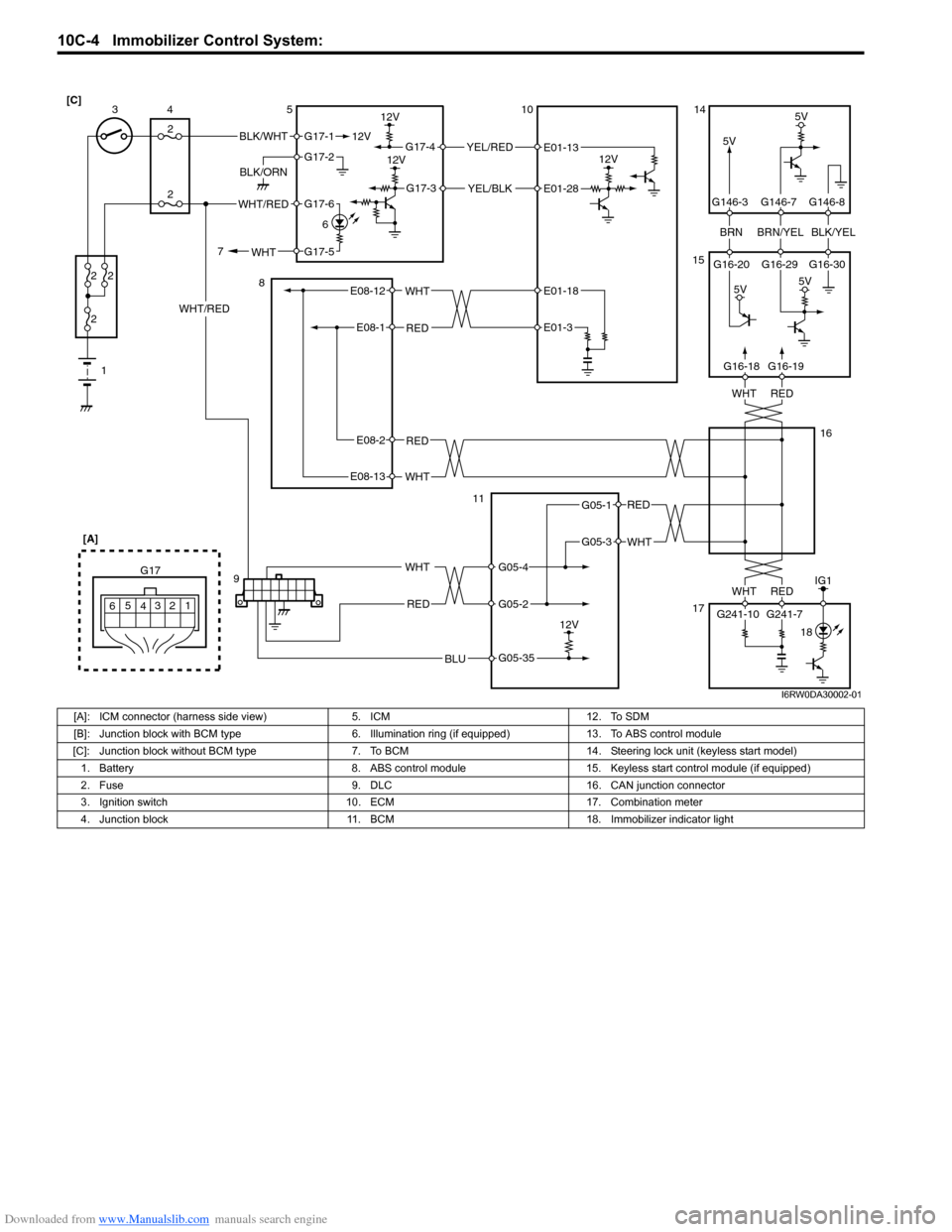

Immobilizer Control System IntroductionS6RW0DA301001

The immobilizer control system is an anti-theft device that immobilizes the vehicle. It stops the engine from working

and prevents the vehicle from being stolen. It mainly consists of the following components. For immobilizer control

system components location, refer to “Immobilizer Control System Components Location”.

•ECM

• ICM with the built-in coil antenna

• Ignition key with the built-in transponder

A code called the transponder code is memorized in the transponder. And, the code is registered with ECM. Basically,

when the ignition switch is turned ON, ECM reads the code by the coil antenna. Then, if the code in transponder in the

ignition key does not match with the one registered with ECM, ECM stops the operation of the fuel injection so as not

to start up the engine and turns the immobilizer indicator light ON and OFF using CAN communication lines. (In

addition to the above operation, ECM also turns the immobilizer indicator light ON and OFF when some trouble is

detected in the keyless start system.)

On-Board Diagnostic System Description (Self-diagnosis Function)S6RW0DA301002

ECM diagnoses if there is any trouble with the immobilizer control system. The diagnostic information is stored as the

diagnostic trouble code (DTC) in ECM. To read the diagnostic information, use SUZUKI scan tool referring to “DTC

Check”.

With the ignition switch turned ON (but the engine at stop) regardless of the condition of the engine and emission

control system, ECM indicates whether there is any trouble with the immobilizer control system or not by either lighting

ON or flashing ON and OFF the immobilizer indicator light.

Immobilizer indicator light lights ON:

No trouble exists in the immobilizer control system. (After starting up the engine, the light turns OFF.)

Immobilizer indicator light flashes ON and OFF:

There is some trouble in the immobilizer control system or in the keyless start system. Its diagnostic information is

stored in ECM.

I3RH0AA30003-01

I3RH0AA30004-01

Page 1506 of 1556

Downloaded from www.Manualslib.com manuals search engine 10C-4 Immobilizer Control System:

BLK/WHT

BLK/ORN12V

G17-1

G17-2

12V

5V

12V

12VYEL/RED

YEL/BLK

G17-4

G17-3

5V

BRNBRN/YELBLK/YEL

1 2

22

2 34

251014

15

1 2 3

4 G17

[A]

5

6

G16-20 G16-29 G16-30 G146-3 G146-7 G146-8

WHT/RED

5V

5V

9

G16-18G16-19 E01-13

E01-28

BLU

RED

WHTE08-12

E08-1E01-18

E01-3

RED

WHTE08-13

E08-2

WHT

RED

G05-4

G05-2

12V

G05-35 8

11

G17-5WHT 76

G17-6WHT/RED

17

REDWHT

REDWHT

G241-10 G241-7

IG1

18

WHT

REDG05-1

G05-3

16 [C]

I6RW0DA30002-01

[A]: ICM connector (harness side view) 5. ICM 12. To SDM

[B]: Junction block with BCM type 6. Illumination ring (if equipped) 13. To ABS control module

[C]: Junction block without BCM type 7. To BCM 14. Steering lock unit (keyless start model)

1. Battery 8. ABS control module 15. Keyless start control module (if equipped)

2. Fuse 9. DLC 16. CAN junction connector

3. Ignition switch 10. ECM 17. Combination meter

4. Junction block 11. BCM 18. Immobilizer indicator light

Page 1507 of 1556

Downloaded from www.Manualslib.com manuals search engine Immobilizer Control System: 10C-5

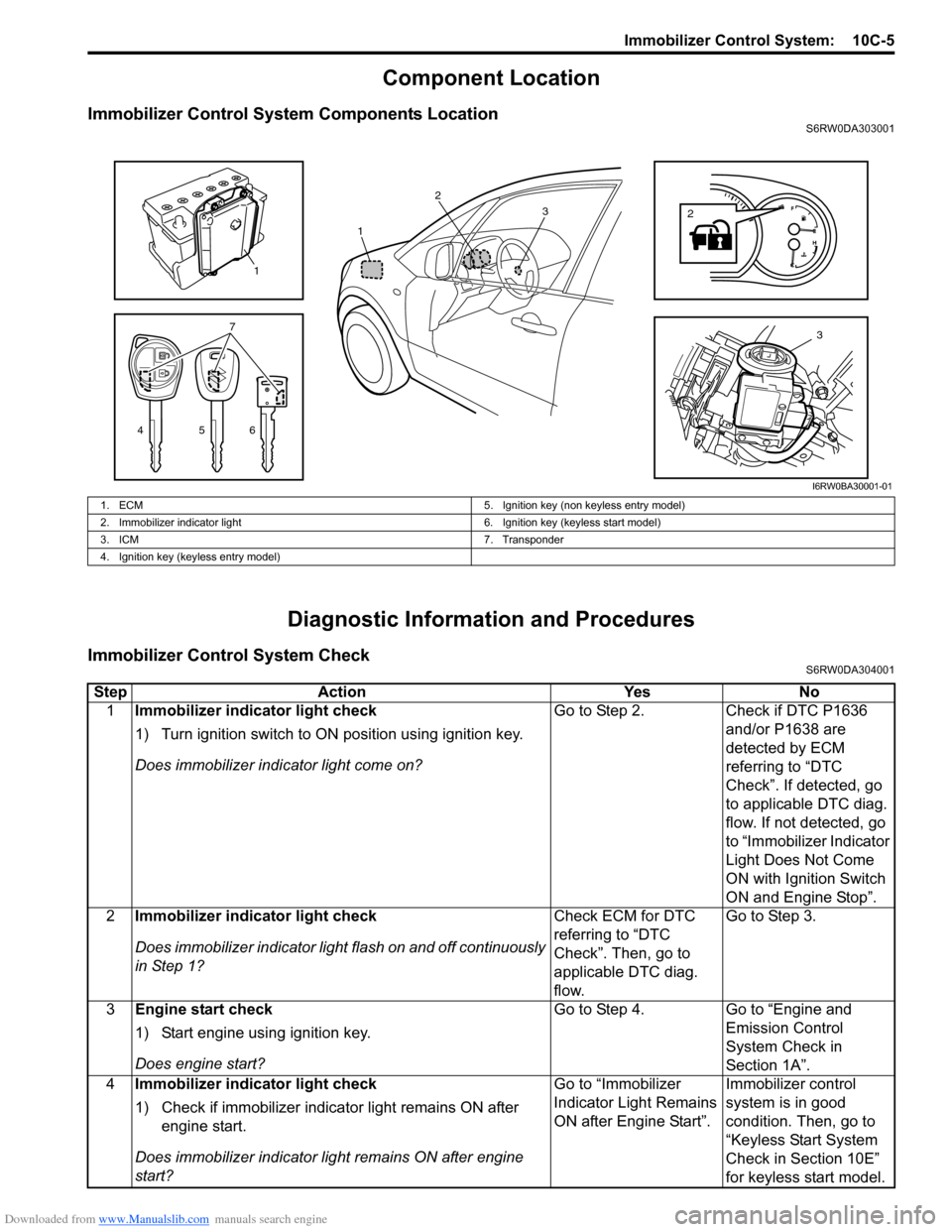

Component Location

Immobilizer Control System Components LocationS6RW0DA303001

Diagnostic Information and Procedures

Immobilizer Control System CheckS6RW0DA304001

3

4567

1

2

2

13

I6RW0BA30001-01

1. ECM 5. Ignition key (non keyless entry model)

2. Immobilizer indicator light 6. Ignition key (keyless start model)

3. ICM 7. Transponder

4. Ignition key (keyless entry model)

Step Action Yes No

1Immobilizer indicator light check

1) Turn ignition switch to ON position using ignition key.

Does immobilizer indicator light come on?Go to Step 2. Check if DTC P1636

and/or P1638 are

detected by ECM

referring to “DTC

Check”. If detected, go

to applicable DTC diag.

flow. If not detected, go

to “Immobilizer Indicator

Light Does Not Come

ON with Ignition Switch

ON and Engine Stop”.

2Immobilizer indicator light check

Does immobilizer indicator light flash on and off continuously

in Step 1?Check ECM for DTC

referring to “DTC

Check”. Then, go to

applicable DTC diag.

flow.Go to Step 3.

3Engine start check

1) Start engine using ignition key.

Does engine start?Go to Step 4. Go to “Engine and

Emission Control

System Check in

Section 1A”.

4Immobilizer indicator light check

1) Check if immobilizer indicator light remains ON after

engine start.

Does immobilizer indicator light remains ON after engine

start?Go to “Immobilizer

Indicator Light Remains

ON after Engine Start”.Immobilizer control

system is in good

condition. Then, go to

“Keyless Start System

Check in Section 10E”

for keyless start model.

Page 1508 of 1556

Downloaded from www.Manualslib.com manuals search engine 10C-6 Immobilizer Control System:

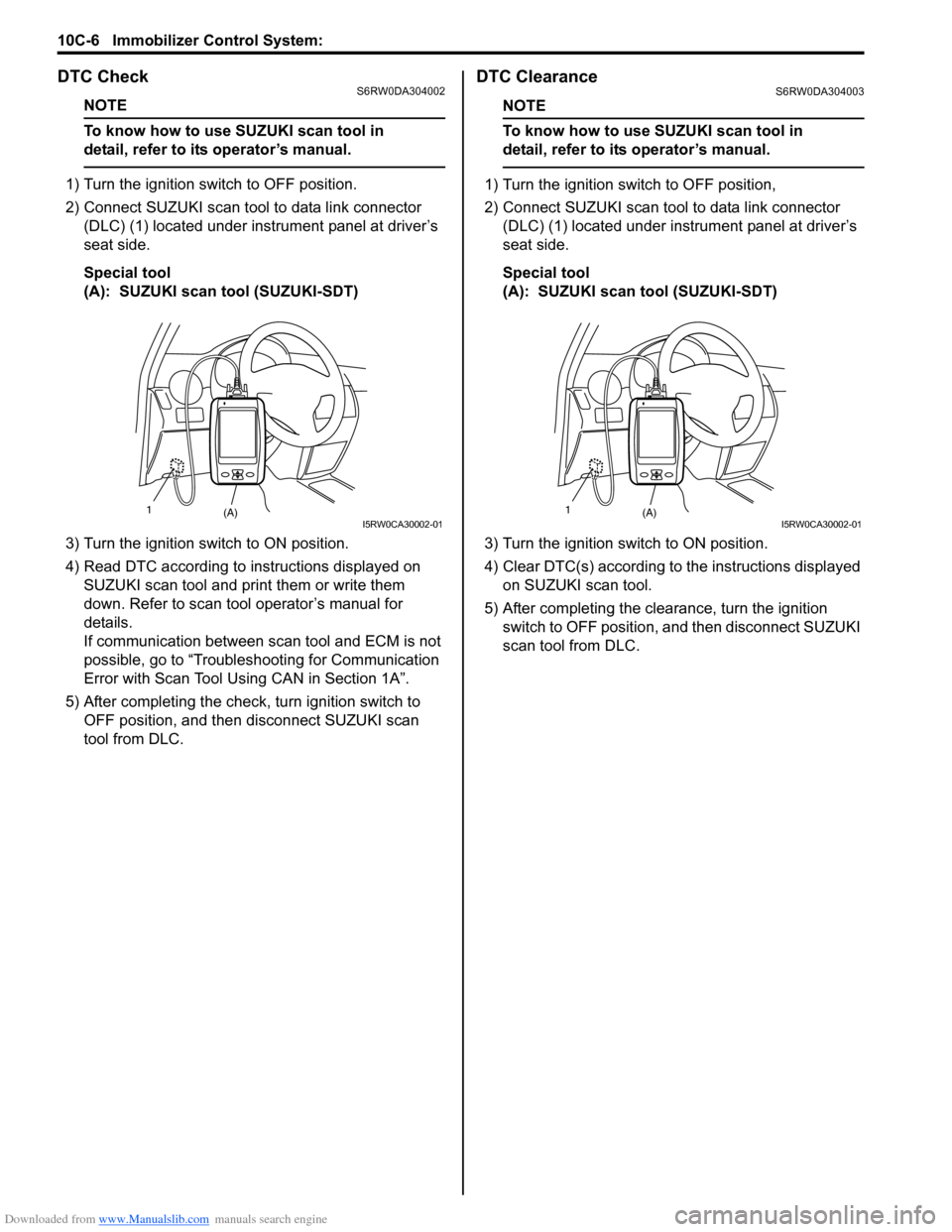

DTC CheckS6RW0DA304002

NOTE

To know how to use SUZUKI scan tool in

detail, refer to its operator’s manual.

1) Turn the ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector

(DLC) (1) located under instrument panel at driver’s

seat side.

Special tool

(A): SUZUKI scan tool (SUZUKI-SDT)

3) Turn the ignition switch to ON position.

4) Read DTC according to instructions displayed on

SUZUKI scan tool and print them or write them

down. Refer to scan tool operator’s manual for

details.

If communication between scan tool and ECM is not

possible, go to “Troubleshooting for Communication

Error with Scan Tool Using CAN in Section 1A”.

5) After completing the check, turn ignition switch to

OFF position, and then disconnect SUZUKI scan

tool from DLC.

DTC ClearanceS6RW0DA304003

NOTE

To know how to use SUZUKI scan tool in

detail, refer to its operator’s manual.

1) Turn the ignition switch to OFF position,

2) Connect SUZUKI scan tool to data link connector

(DLC) (1) located under instrument panel at driver’s

seat side.

Special tool

(A): SUZUKI scan tool (SUZUKI-SDT)

3) Turn the ignition switch to ON position.

4) Clear DTC(s) according to the instructions displayed

on SUZUKI scan tool.

5) After completing the clearance, turn the ignition

switch to OFF position, and then disconnect SUZUKI

scan tool from DLC.

(A) 1I5RW0CA30002-01(A) 1I5RW0CA30002-01