Tires SUZUKI SX4 2006 1.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 917 of 1556

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-37

3) Inspect for proper toe referring to “Front Wheel

Alignment Inspection and Adjustment in Section 2B”.

4) After confirming proper toe, tighten tie-rod end lock

nut to specified torque.

Tightening torque

Tie-rod end lock nut (a): 45 N·m (4.5 kgf-m, 32.5

lb-ft)

5) Tighten wheel bolts to specified torque and lower

hoist.

Tightening torque

Wheel bolt: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

Tie-Rod End InspectionS6RW0D6306004

• Inspect for play in ball joint.

• Inspect for play in rack end ball joint.

In either case, if found defective, replace.

Steering Shaft Joint On-Vehicle InspectionS6RW0D6306005

Check shaft joint for wear, breakage and any other

damage and replace if any defect exists.

Steering Gear Case Assembly Removal and

Installation

S6RW0D6306006

Removal

CAUTION!

Be sure to set front wheels (tires) in straight

direction and remove ignition key from key

cylinder before performing the following

steps, otherwise, contact coil of air bag

system may get damaged.

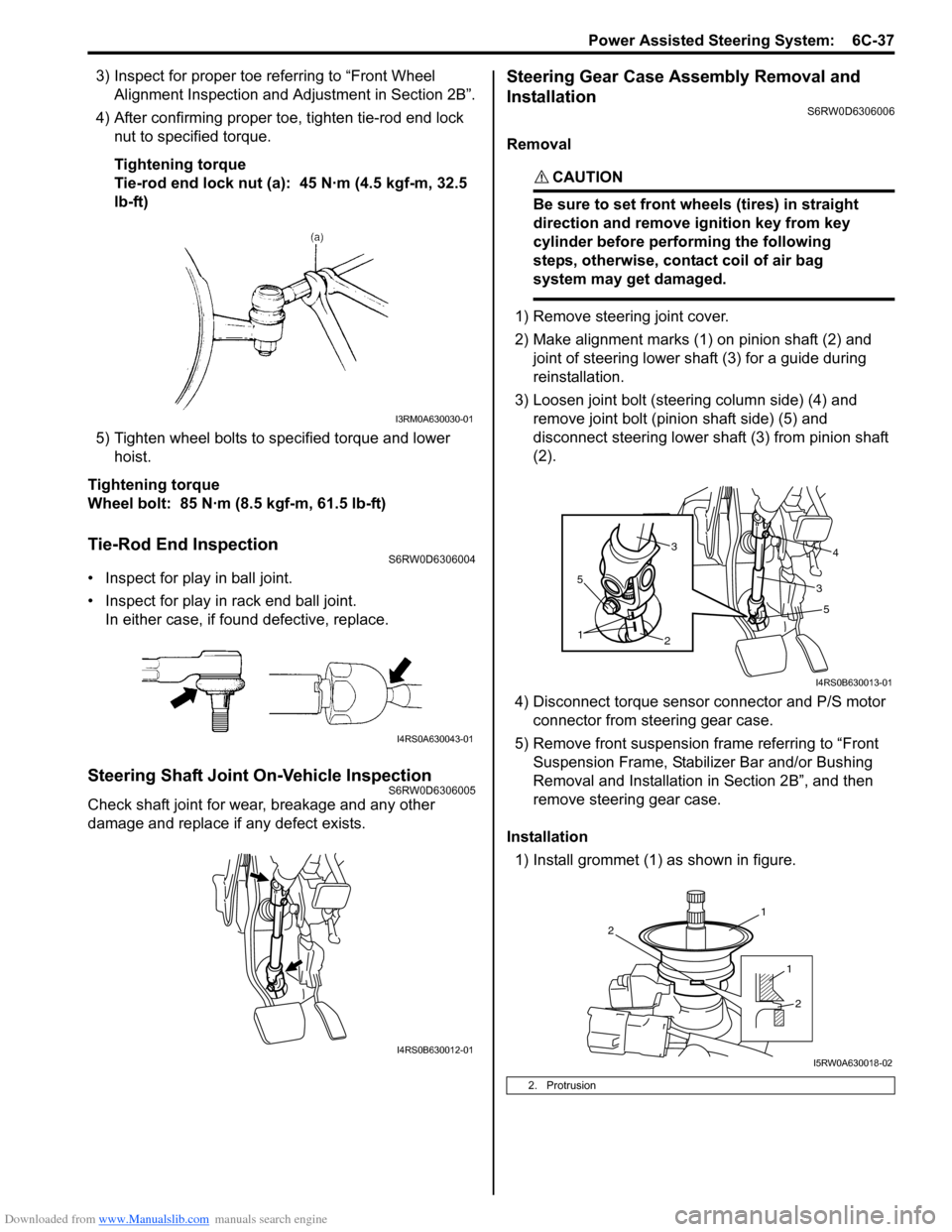

1) Remove steering joint cover.

2) Make alignment marks (1) on pinion shaft (2) and

joint of steering lower shaft (3) for a guide during

reinstallation.

3) Loosen joint bolt (steering column side) (4) and

remove joint bolt (pinion shaft side) (5) and

disconnect steering lower shaft (3) from pinion shaft

(2).

4) Disconnect torque sensor connector and P/S motor

connector from steering gear case.

5) Remove front suspension frame referring to “Front

Suspension Frame, Stabilizer Bar and/or Bushing

Removal and Installation in Section 2B”, and then

remove steering gear case.

Installation

1) Install grommet (1) as shown in figure.

I3RM0A630030-01

I4RS0A630043-01

I4RS0B630012-01

2. Protrusion

5

2

1

5

34

3

I4RS0B630013-01

1

2

1

2

I5RW0A630018-02

Page 1132 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-93 Air Bag System:

Repair Instructions

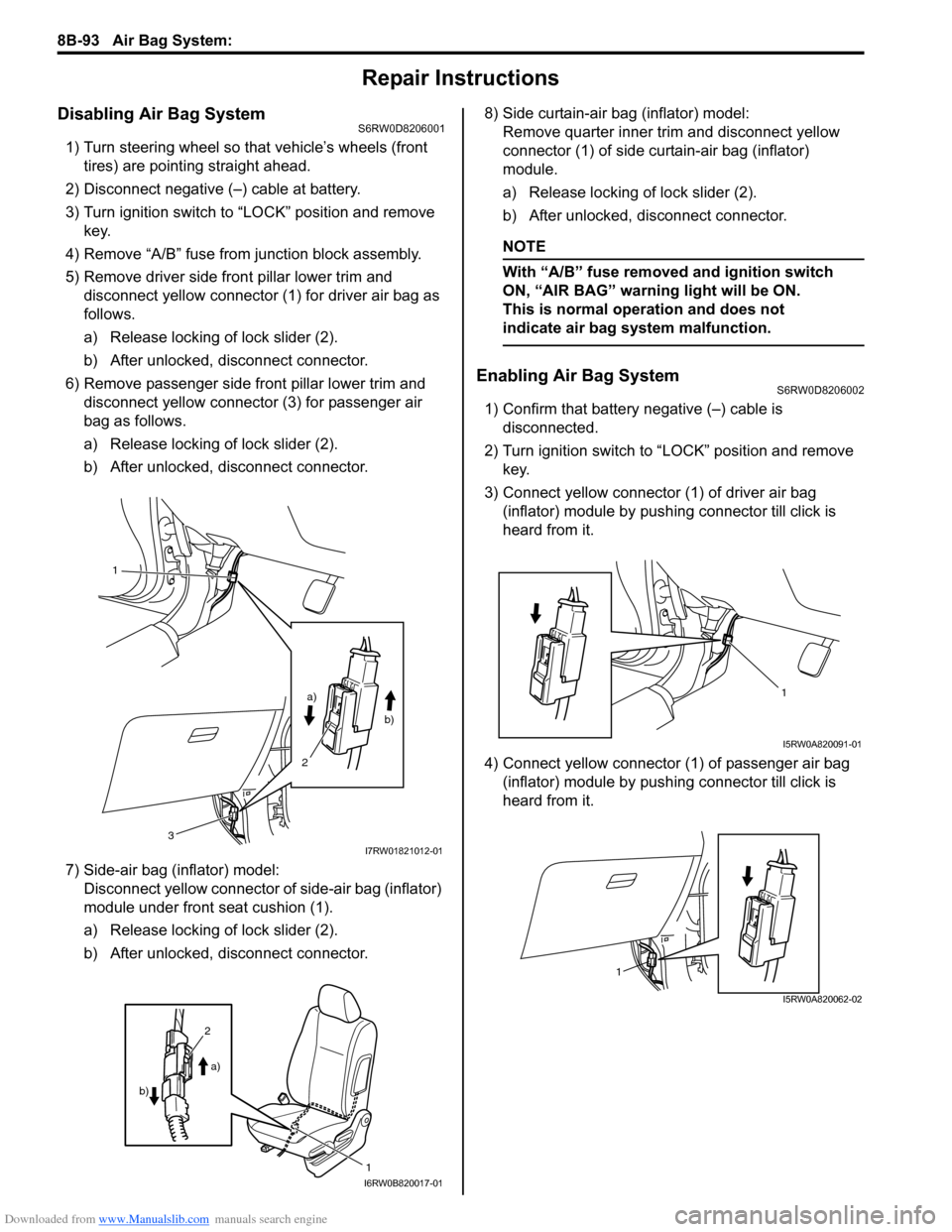

Disabling Air Bag SystemS6RW0D8206001

1) Turn steering wheel so that vehicle’s wheels (front

tires) are pointing straight ahead.

2) Disconnect negative (–) cable at battery.

3) Turn ignition switch to “LOCK” position and remove

key.

4) Remove “A/B” fuse from junction block assembly.

5) Remove driver side front pillar lower trim and

disconnect yellow connector (1) for driver air bag as

follows.

a) Release locking of lock slider (2).

b) After unlocked, disconnect connector.

6) Remove passenger side front pillar lower trim and

disconnect yellow connector (3) for passenger air

bag as follows.

a) Release locking of lock slider (2).

b) After unlocked, disconnect connector.

7) Side-air bag (inflator) model:

Disconnect yellow connector of side-air bag (inflator)

module under front seat cushion (1).

a) Release locking of lock slider (2).

b) After unlocked, disconnect connector.8) Side curtain-air bag (inflator) model:

Remove quarter inner trim and disconnect yellow

connector (1) of side curtain-air bag (inflator)

module.

a) Release locking of lock slider (2).

b) After unlocked, disconnect connector.

NOTE

With “A/B” fuse removed and ignition switch

ON, “AIR BAG” warning light will be ON.

This is normal operation and does not

indicate air bag system malfunction.

Enabling Air Bag SystemS6RW0D8206002

1) Confirm that battery negative (–) cable is

disconnected.

2) Turn ignition switch to “LOCK” position and remove

key.

3) Connect yellow connector (1) of driver air bag

(inflator) module by pushing connector till click is

heard from it.

4) Connect yellow connector (1) of passenger air bag

(inflator) module by pushing connector till click is

heard from it.

1

a)

b)

2

3

I7RW01821012-01

1

2

a)

b)

I6RW0B820017-01

1

I5RW0A820091-01

1

I5RW0A820062-02

Page 1151 of 1556

![SUZUKI SX4 2006 1.G Service Owners Guide Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-112

10) Connect adapter cable (B) as follows.

Special tool

(B): 09932–76510

• For driver air bag (inflator) module [A] SUZUKI SX4 2006 1.G Service Owners Guide Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-112

10) Connect adapter cable (B) as follows.

Special tool

(B): 09932–76510

• For driver air bag (inflator) module [A]](/img/20/7612/w960_7612-1150.png)

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-112

10) Connect adapter cable (B) as follows.

Special tool

(B): 09932–76510

• For driver air bag (inflator) module [A]:

Check that driver air bag (inflator) module is

placed with its vinyl trim cover facing up, and

connect adapter cable (B) to driver air bag

(inflator) module.

• For passenger air bag (inflator) module [B]:

Check that passenger air bag (inflator) module is

firmly and properly secured on deployment fixture

(special tool), and connect adapter cable (B) to

passenger air bag (inflator) module.

NOTE

Wind wire harness (5) around at least 2 times.

• For side-air bag (inflator) module [C]:

Verify that side-air bag (inflator) module is firmly

and properly on deployment fixture (special tool),

and connect adapter cable (B) to side-air bag

(inflator) module.

• For side curtain-air bag (inflator) module [D]:

a. Connect adapter cable (B) to side curtain-air

bag (inflator) module.

b. Pile 2 tires (2) and wheel-installed tire (3) on

top of tire with side curtain-air bag (inflator)

(4), and tie them with wire harness (5) as

shown.

Wire harness specifications

Stripped wire harness section 1.25 mm2

(0.0019 in.2) or more (Stripped wire harness

diameter 1.25 mm (0.05 in.) or more)

NOTE

Wind wire harness (5) around at least 2 times.

• For seat belt pretensioner [E]:

a. Connect adapter cable (B) to seat belt

pretensioner.

b. Pile 2 wheel-installed tires (3) on top of tire

with seat belt pretensioner (6), and tie them

with wire harness (5) as shown.

Wire harness specifications

Stripped wire harness section 1.25 mm2

(0.0019 in.2) or more (Stripped wire harness

diameter 1.25 mm (0.05 in.) or more)

NOTE

Wind wire harness (5) around at least 2 times.

c. Drape blanket (7) over those tires.

11) Connect adapter cable (B) to deployment harness

(A) connector and lock connectors with lock lever.

[A]

10 m (33 ft)

(A)

(B)

1

10 m (33 ft)

(A)

(B)1

5

3

2

4

(A)

[B]

[C]

[D]

[E]

7

3

6

5 (A)(B)

1

10 m (33 ft)

10 m (33 ft) (A)

(B)

1

1

10 m (33 ft)

I5JB0A820102-01

Page 1339 of 1556

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-20

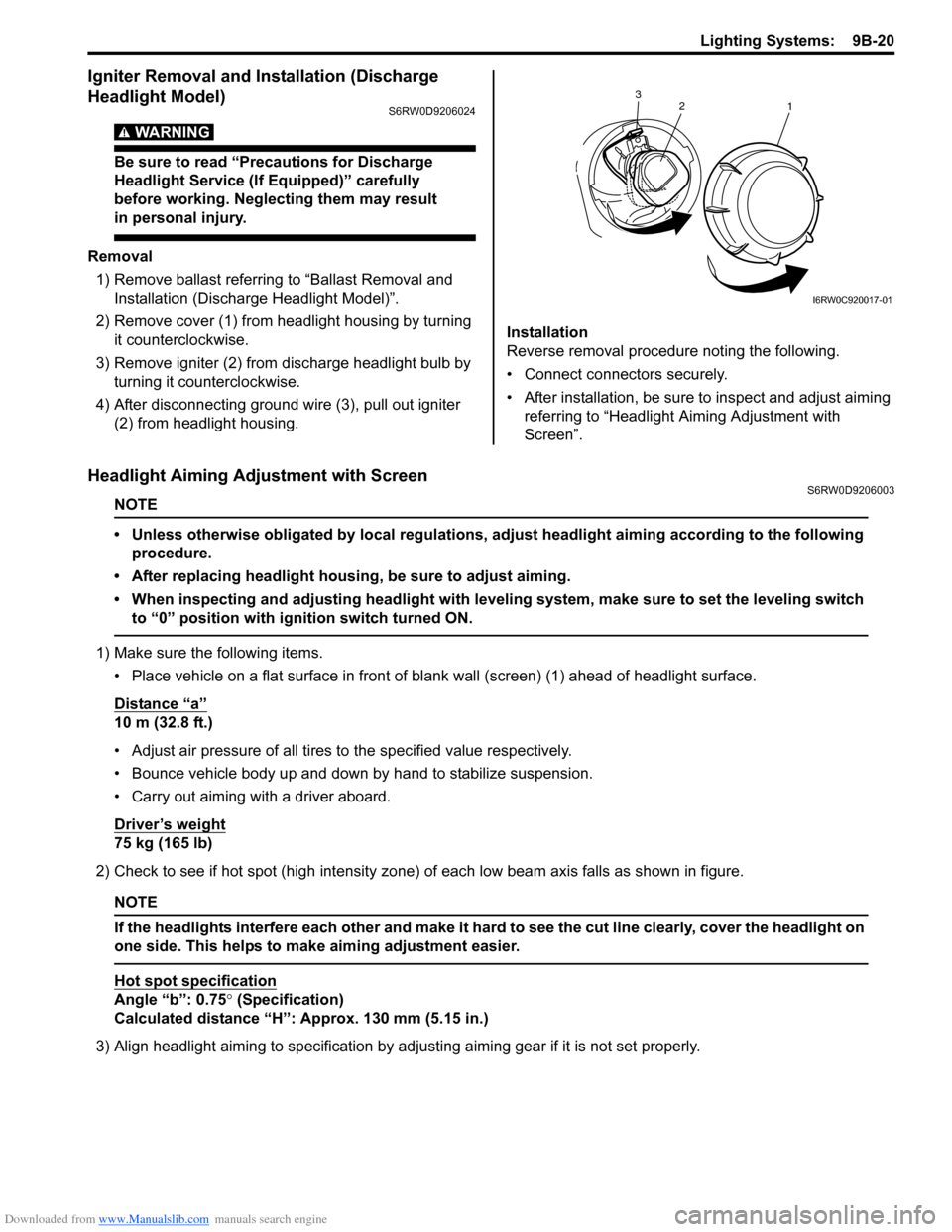

Igniter Removal and Installation (Discharge

Headlight Model)

S6RW0D9206024

WARNING!

Be sure to read “Precautions for Discharge

Headlight Service (If Equipped)” carefully

before working. Neglecting them may result

in personal injury.

Removal

1) Remove ballast referring to “Ballast Removal and

Installation (Discharge Headlight Model)”.

2) Remove cover (1) from headlight housing by turning

it counterclockwise.

3) Remove igniter (2) from discharge headlight bulb by

turning it counterclockwise.

4) After disconnecting ground wire (3), pull out igniter

(2) from headlight housing.Installation

Reverse removal procedure noting the following.

• Connect connectors securely.

• After installation, be sure to inspect and adjust aiming

referring to “Headlight Aiming Adjustment with

Screen”.

Headlight Aiming Adjustment with ScreenS6RW0D9206003

NOTE

• Unless otherwise obligated by local regulations, adjust headlight aiming according to the following

procedure.

• After replacing headlight housing, be sure to adjust aiming.

• When inspecting and adjusting headlight with leveling system, make sure to set the leveling switch

to “0” position with ignition switch turned ON.

1) Make sure the following items.

• Place vehicle on a flat surface in front of blank wall (screen) (1) ahead of headlight surface.

Distance “a”

10 m (32.8 ft.)

• Adjust air pressure of all tires to the specified value respectively.

• Bounce vehicle body up and down by hand to stabilize suspension.

• Carry out aiming with a driver aboard.

Driver’s weight

75 kg (165 lb)

2) Check to see if hot spot (high intensity zone) of each low beam axis falls as shown in figure.

NOTE

If the headlights interfere each other and make it hard to see the cut line clearly, cover the headlight on

one side. This helps to make aiming adjustment easier.

Hot spot specification

Angle “b”: 0.75° (Specification)

Calculated distance “H”: Approx. 130 mm (5.15 in.)

3) Align headlight aiming to specification by adjusting aiming gear if it is not set properly.

2

1 3

I6RW0C920017-01

Page 1350 of 1556

Downloaded from www.Manualslib.com manuals search engine 9B-31 Lighting Systems:

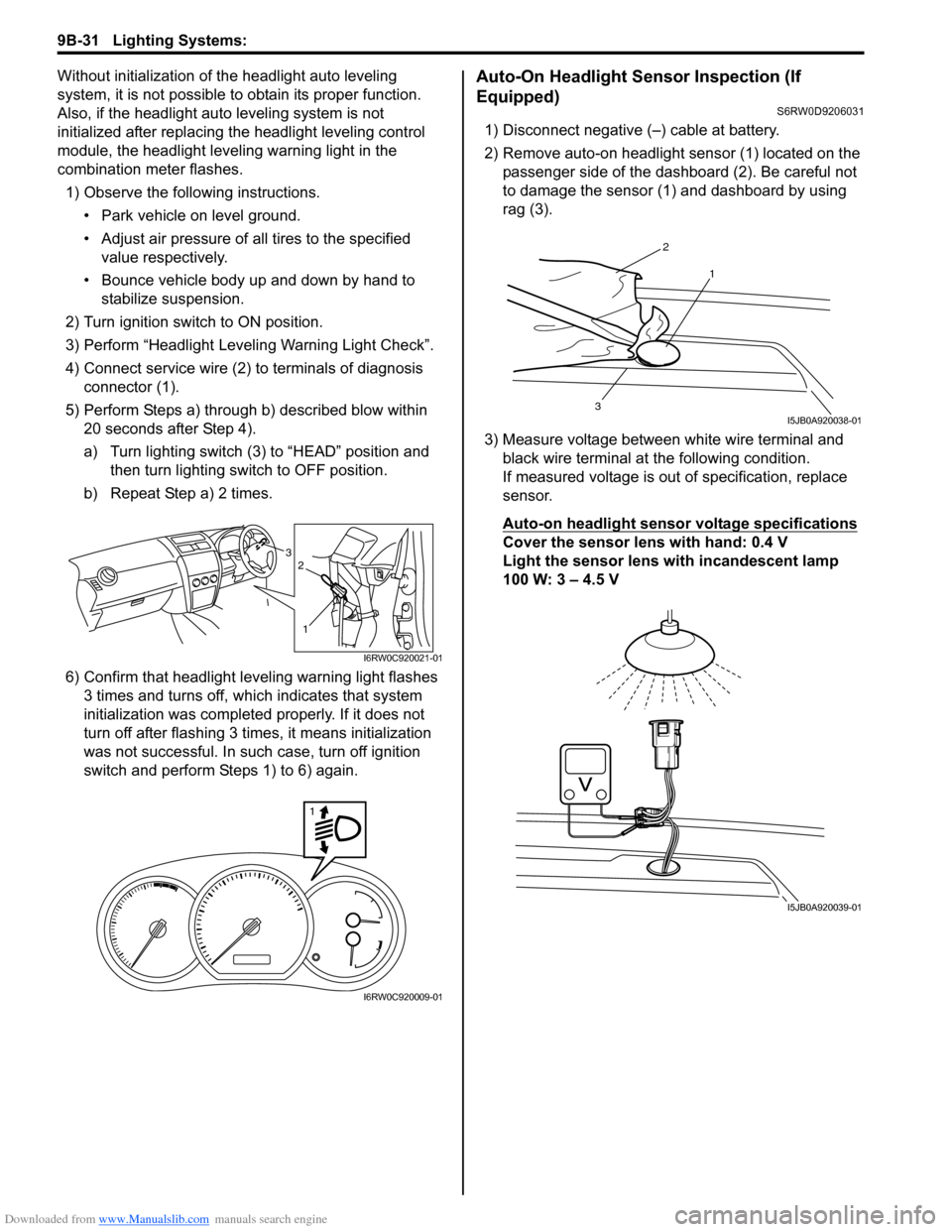

Without initialization of the headlight auto leveling

system, it is not possible to obtain its proper function.

Also, if the headlight auto leveling system is not

initialized after replacing the headlight leveling control

module, the headlight leveling warning light in the

combination meter flashes.

1) Observe the following instructions.

• Park vehicle on level ground.

• Adjust air pressure of all tires to the specified

value respectively.

• Bounce vehicle body up and down by hand to

stabilize suspension.

2) Turn ignition switch to ON position.

3) Perform “Headlight Leveling Warning Light Check”.

4) Connect service wire (2) to terminals of diagnosis

connector (1).

5) Perform Steps a) through b) described blow within

20 seconds after Step 4).

a) Turn lighting switch (3) to “HEAD” position and

then turn lighting switch to OFF position.

b) Repeat Step a) 2 times.

6) Confirm that headlight leveling warning light flashes

3 times and turns off, which indicates that system

initialization was completed properly. If it does not

turn off after flashing 3 times, it means initialization

was not successful. In such case, turn off ignition

switch and perform Steps 1) to 6) again.Auto-On Headlight Sensor Inspection (If

Equipped)

S6RW0D9206031

1) Disconnect negative (–) cable at battery.

2) Remove auto-on headlight sensor (1) located on the

passenger side of the dashboard (2). Be careful not

to damage the sensor (1) and dashboard by using

rag (3).

3) Measure voltage between white wire terminal and

black wire terminal at the following condition.

If measured voltage is out of specification, replace

sensor.

Auto-on headlight sensor voltage specifications

Cover the sensor lens with hand: 0.4 V

Light the sensor lens with incandescent lamp

100 W: 3 – 4.5 V3

1

2

I6RW0C920021-01

1

I6RW0C920009-01

2

1

3I5JB0A920038-01

I5JB0A920039-01