length SUZUKI SX4 2006 1.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 919 of 1556

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-39

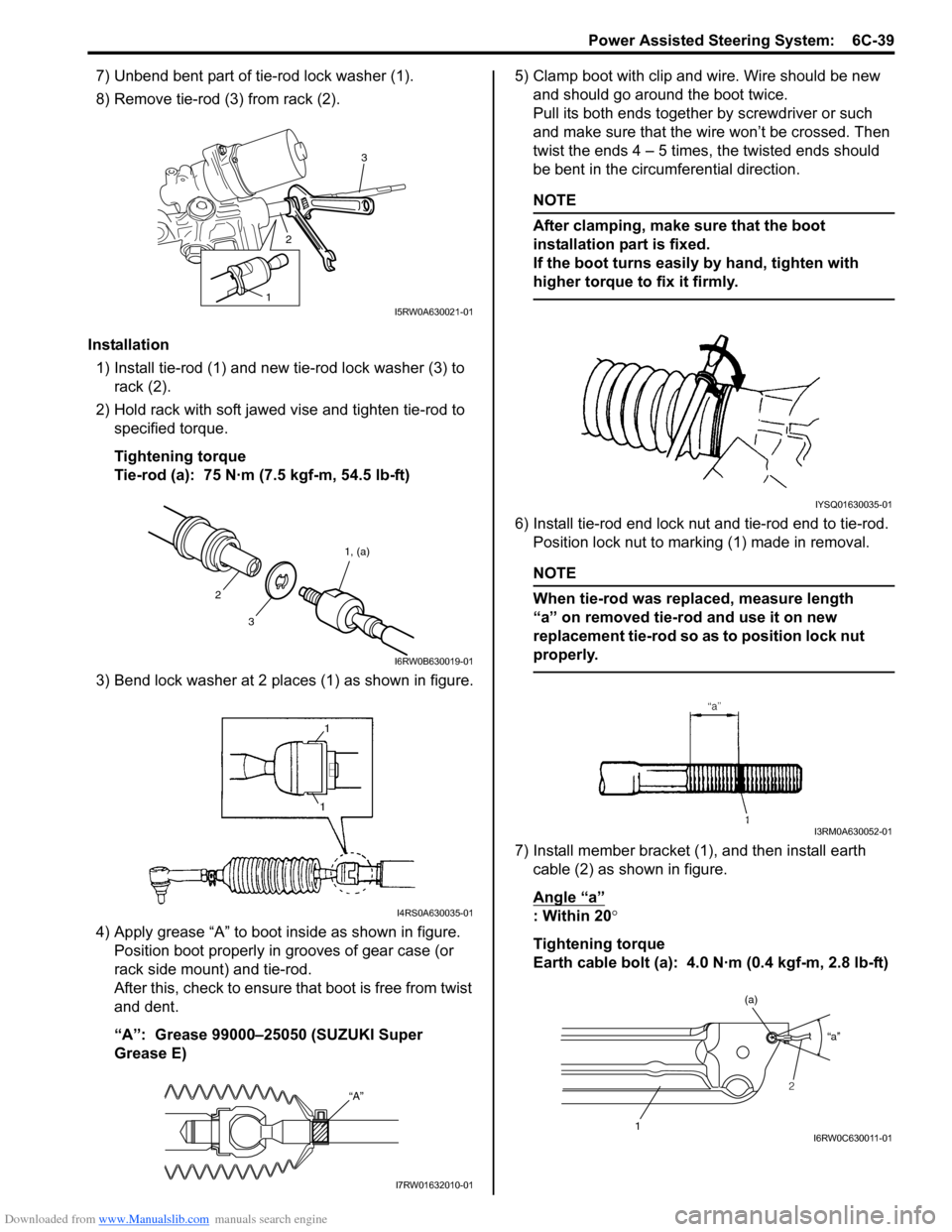

7) Unbend bent part of tie-rod lock washer (1).

8) Remove tie-rod (3) from rack (2).

Installation

1) Install tie-rod (1) and new tie-rod lock washer (3) to

rack (2).

2) Hold rack with soft jawed vise and tighten tie-rod to

specified torque.

Tightening torque

Tie-rod (a): 75 N·m (7.5 kgf-m, 54.5 lb-ft)

3) Bend lock washer at 2 places (1) as shown in figure.

4) Apply grease “A” to boot inside as shown in figure.

Position boot properly in grooves of gear case (or

rack side mount) and tie-rod.

After this, check to ensure that boot is free from twist

and dent.

“A”: Grease 99000–25050 (SUZUKI Super

Grease E) 5) Clamp boot with clip and wire. Wire should be new

and should go around the boot twice.

Pull its both ends together by screwdriver or such

and make sure that the wire won’t be crossed. Then

twist the ends 4 – 5 times, the twisted ends should

be bent in the circumferential direction.

NOTE

After clamping, make sure that the boot

installation part is fixed.

If the boot turns easily by hand, tighten with

higher torque to fix it firmly.

6) Install tie-rod end lock nut and tie-rod end to tie-rod.

Position lock nut to marking (1) made in removal.

NOTE

When tie-rod was replaced, measure length

“a” on removed tie-rod and use it on new

replacement tie-rod so as to position lock nut

properly.

7) Install member bracket (1), and then install earth

cable (2) as shown in figure.

Angle “a”

: Within 20°

Tightening torque

Earth cable bolt (a): 4.0 N·m (0.4 kgf-m, 2.8 lb-ft)

3

2

1I5RW0A630021-01

31, (a)

2

I6RW0B630019-01

I4RS0A630035-01

“A”

I7RW01632010-01

IYSQ01630035-01

I3RM0A630052-01

“a”

1

(a)

2

I6RW0C630011-01

Page 956 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-16 Air Conditioning System: Manual Type

Abnormal Noise from Tubing

Abnormal Noise from Condenser Assembly

Abnormal Noise from Crankshaft Pulley

Abnormal Noise from Tension Pulley

Abnormal Noise from A/C Evaporator

Abnormal Noise from Blower MotorCondition Possible cause Correction / Reference Item

A droning noise is heard

from inside of the vehicle,

but not particularly

noticeable in engine

compartmentFaulty tubing clampsReposition clamps or increase the number of

clamps.

Resonance caused by pulsation from

variations in refrigerant pressureAttach a silencer to tubing, or modify its

position and length.

Condition Possible cause Correction / Reference Item

Considerable vibration in

condenser assemblyResonance from condenser assembly

bracket and bodyFirmly insert a silencer between condenser

assembly bracket and body.

Condition Possible cause Correction / Reference Item

A large rattling noise is

heard at idle or sudden

accelerationLoosen crankshaft pulley boltRetighten bolt.

Condition Possible cause Correction / Reference Item

Clattering noise is heard

from pulleyWorn or damaged bearingReplace tension pulley.

Pulley cranks upon

contactCracked or loose bracketReplace or retighten bracket.

Condition Possible cause Correction / Reference Item

Whistling sound is heard

from A/C evaporatorDepending on the combination of the

interior / exterior temperatures, engine

rpm and refrigerant pressure, the

refrigerant flowing out of the expansion

valve may, under certain conditions,

make a whistling soundAt times, slightly decreasing refrigerant volume

may stop this noise.

Inspect expansion valve and replace if faulty.

Condition Possible cause Correction / Reference Item

Blower motor emits a

chirping sound in

proportion to its speed of

rotationWorn or damaged motor brushes or

commutatorReplace blower motor.

Fluttering noise or large

droning noise is heard

from blower motorLeaves or other debris introduced from

fresh air inlet to blower motorRemove debris and make sure that the screen

at fresh air inlet is intact.

Page 1130 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-91 Air Bag System:

CAUTION!

After detecting one time of such collision as

to meet deployment conditions, the SDM

must not be used.

Refer to “Air Bag Diagnostic System Check”

when checking the SDM.

Accident with Deployment / Activation – Component

Replacement

When driver and passenger air bags are deployed, the

following components must be replaced.

• Driver and passenger air bag (inflator) modules

• Driver and passenger seat belt pretensioners

• SDM after detecting such collision as to meet

deployment conditions

• Forward impact-sensor

• Instrument panel

When side-air bag and side curtain-air bag are deployed,

the following components must be replaced.

• Deployed side-air bag (inflator) module

• Deployed side curtain-air bag (inflator) module

• Side impact-sensor

•SDM

Accident with or without Deployment / Activation –

Component Inspections

Certain air bag and restraint system components must

be inspected after any crash, whether the air bag system

activated or not. If any faulty condition is found in the

following checks, replace faulty part.

Those components are:

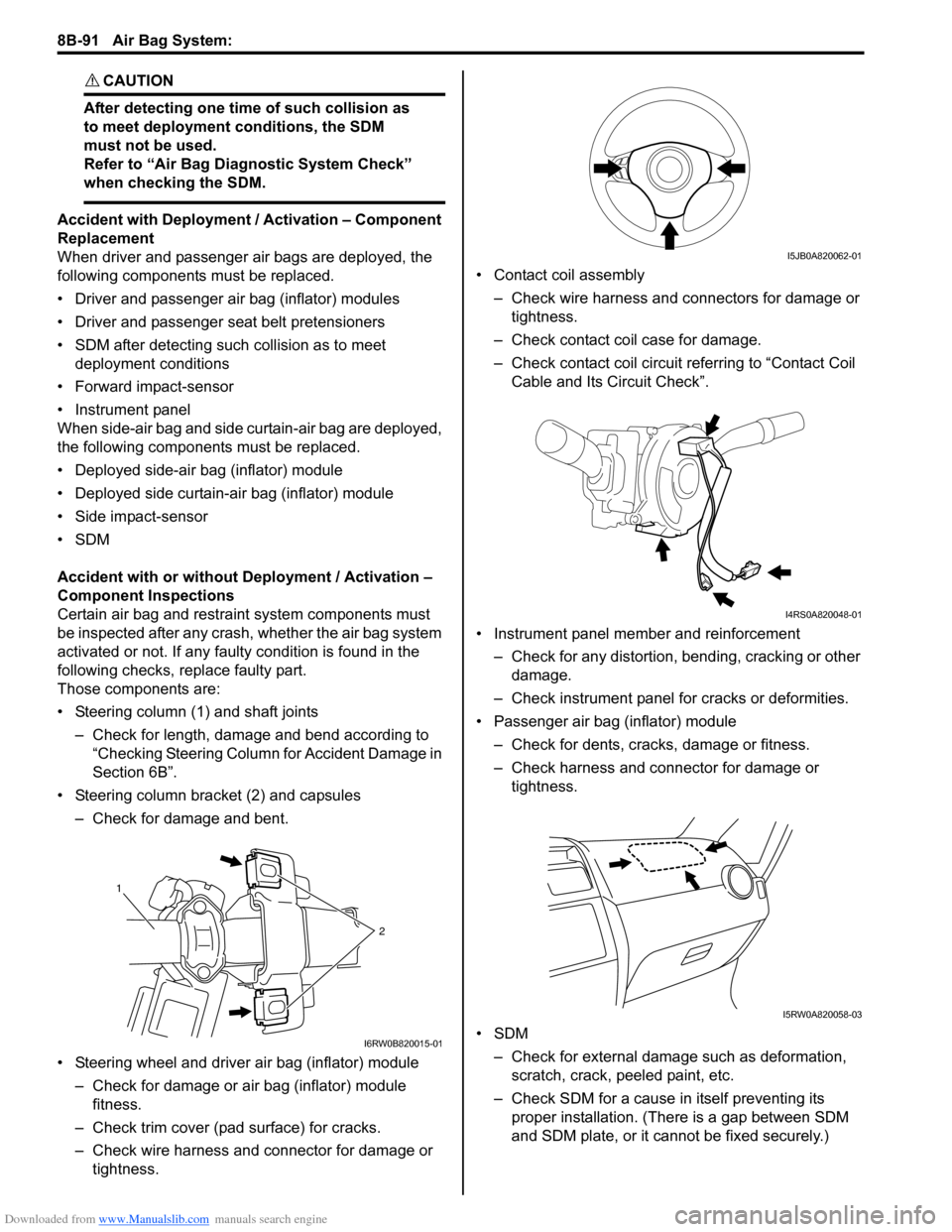

• Steering column (1) and shaft joints

– Check for length, damage and bend according to

“Checking Steering Column for Accident Damage in

Section 6B”.

• Steering column bracket (2) and capsules

– Check for damage and bent.

• Steering wheel and driver air bag (inflator) module

– Check for damage or air bag (inflator) module

fitness.

– Check trim cover (pad surface) for cracks.

– Check wire harness and connector for damage or

tightness.• Contact coil assembly

– Check wire harness and connectors for damage or

tightness.

– Check contact coil case for damage.

– Check contact coil circuit referring to “Contact Coil

Cable and Its Circuit Check”.

• Instrument panel member and reinforcement

– Check for any distortion, bending, cracking or other

damage.

– Check instrument panel for cracks or deformities.

• Passenger air bag (inflator) module

– Check for dents, cracks, damage or fitness.

– Check harness and connector for damage or

tightness.

•SDM

– Check for external damage such as deformation,

scratch, crack, peeled paint, etc.

– Check SDM for a cause in itself preventing its

proper installation. (There is a gap between SDM

and SDM plate, or it cannot be fixed securely.)

1

2

I6RW0B820015-01

I5JB0A820062-01

I4RS0A820048-01

I5RW0A820058-03

Page 1150 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-111 Air Bag System:

• For seat belt pretensioner

a. Cut webbing (1) at tongue plate stopper (3) of

seat belt pretensioner (2) side as shown.

NOTE

Hold seat belt pretensioner (2) vertically in

the same condition as it is installed.

Otherwise, webbing can’t be pulled out.

b. Remove tongue plate (4) and shoulder anchor

(5) from webbing.

c. Tie webbing (1) tightly at 10 cm (3.9 in.) from

cutting edge as shown.

d. Tie seat belt pretensioner (2) with wire

harness (3) to wheel-installed tire (4) as

shown.

Wire harness specifications

Stripped wire harness section 1.25 mm2

(0.0019 in.2) or more (Stripped wire harness

diameter 1.25 mm (0.05 in.) or more)

NOTE

Wind wire harness (3) around at least 3 times.

e. Clear space (5) on ground about 185 cm (6 ft)

in diameter where seat belt pretensioner (2) is

to be activated. Paved, outdoor location where

there is no activity is preferred. If outdoor

location is not available, use space on shop

floor where there is no activity and sufficient

ventilation is provided. Ensure no loose or

flammable object exists within activation area.

f. Place wheel-installed tire (4) with seat belt

pretensioner (2) on ground in Step e.

7) Stretch deployment harness (A) from air bag

(inflator) module or seat belt pretensioner to its full

length 10 m (33 ft).

Special tool

(A): 09932-75031

8) Place 12 volts vehicle battery (1) near the shorted

end of deployment harness (A).

9) Check that area around air bag (inflator) module or

seat belt pretensioner is clear of all people and loose

or flammable objects.

31452I3JA01820037-01

10 cm (3.9 in.)

1

I4RS0A820104-01

1. Webbing

4 3

3

25

I4RS0A820105-01

Page 1155 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-116

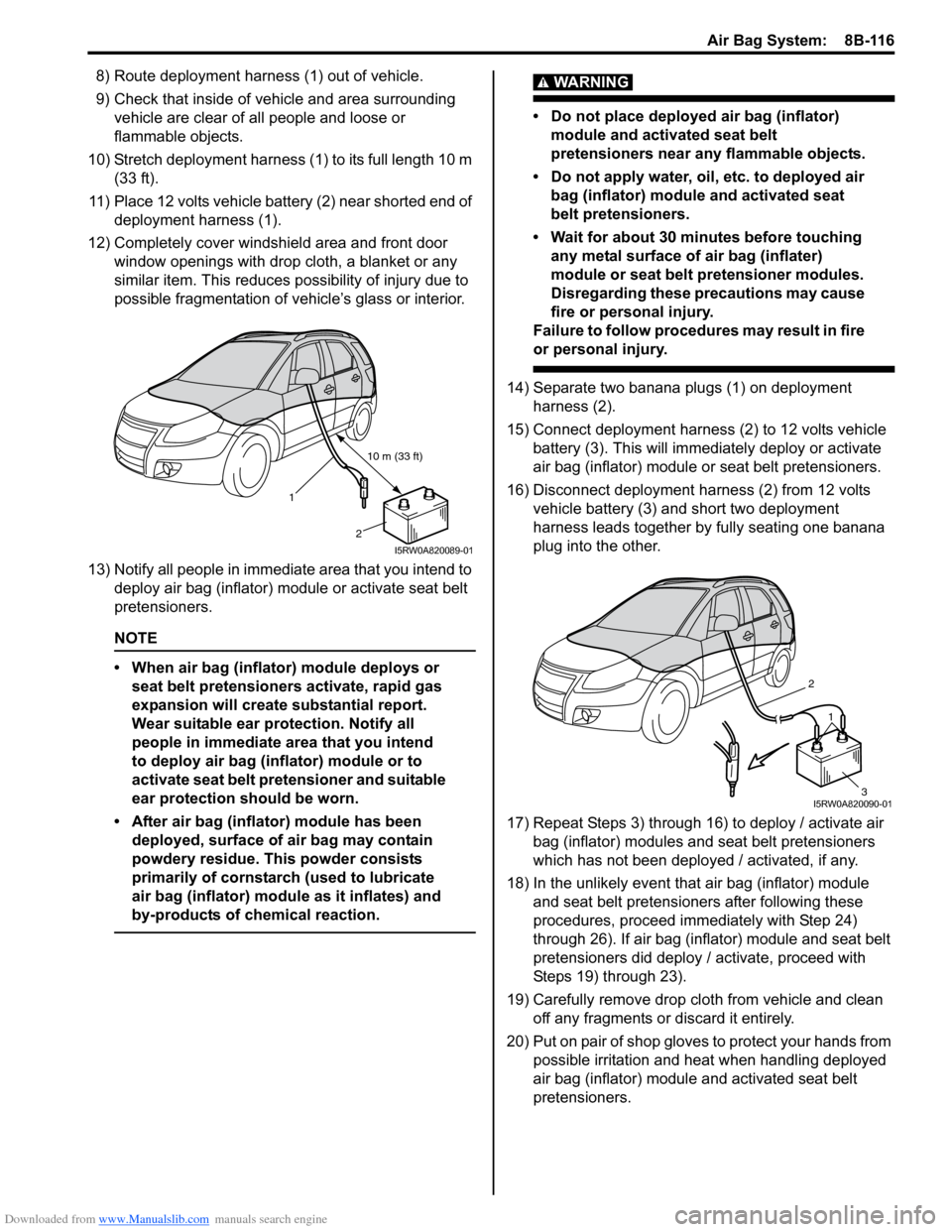

8) Route deployment harness (1) out of vehicle.

9) Check that inside of vehicle and area surrounding

vehicle are clear of all people and loose or

flammable objects.

10) Stretch deployment harness (1) to its full length 10 m

(33 ft).

11) Place 12 volts vehicle battery (2) near shorted end of

deployment harness (1).

12) Completely cover windshield area and front door

window openings with drop cloth, a blanket or any

similar item. This reduces possibility of injury due to

possible fragmentation of vehicle’s glass or interior.

13) Notify all people in immediate area that you intend to

deploy air bag (inflator) module or activate seat belt

pretensioners.

NOTE

• When air bag (inflator) module deploys or

seat belt pretensioners activate, rapid gas

expansion will create substantial report.

Wear suitable ear protection. Notify all

people in immediate area that you intend

to deploy air bag (inflator) module or to

activate seat belt pretensioner and suitable

ear protection should be worn.

• After air bag (inflator) module has been

deployed, surface of air bag may contain

powdery residue. This powder consists

primarily of cornstarch (used to lubricate

air bag (inflator) module as it inflates) and

by-products of chemical reaction.

WARNING!

• Do not place deployed air bag (inflator)

module and activated seat belt

pretensioners near any flammable objects.

• Do not apply water, oil, etc. to deployed air

bag (inflator) module and activated seat

belt pretensioners.

• Wait for about 30 minutes before touching

any metal surface of air bag (inflater)

module or seat belt pretensioner modules.

Disregarding these precautions may cause

fire or personal injury.

Failure to follow procedures may result in fire

or personal injury.

14) Separate two banana plugs (1) on deployment

harness (2).

15) Connect deployment harness (2) to 12 volts vehicle

battery (3). This will immediately deploy or activate

air bag (inflator) module or seat belt pretensioners.

16) Disconnect deployment harness (2) from 12 volts

vehicle battery (3) and short two deployment

harness leads together by fully seating one banana

plug into the other.

17) Repeat Steps 3) through 16) to deploy / activate air

bag (inflator) modules and seat belt pretensioners

which has not been deployed / activated, if any.

18) In the unlikely event that air bag (inflator) module

and seat belt pretensioners after following these

procedures, proceed immediately with Step 24)

through 26). If air bag (inflator) module and seat belt

pretensioners did deploy / activate, proceed with

Steps 19) through 23).

19) Carefully remove drop cloth from vehicle and clean

off any fragments or discard it entirely.

20) Put on pair of shop gloves to protect your hands from

possible irritation and heat when handling deployed

air bag (inflator) module and activated seat belt

pretensioners.

10 m (33 ft)

1

2

I5RW0A820089-01

1

3 2

I5RW0A820090-01