lighting SUZUKI SX4 2006 1.G Service Owner's Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1336 of 1556

Downloaded from www.Manualslib.com manuals search engine 9B-17 Lighting Systems:

Terminal Circuit Specification Condition

1 Power source 10 – 14 VIgnition switch is at ON

position.

2———

3 Lighting switchLess than 1.5 VLighting switch is at “HEAD”

position.

10 – 14 VLighting switch is at OFF

position.

4———

5 Diagnosis switch terminal About 5 VIgnition switch is at ON

position.

6Headlight auto leveling

indicatorLess than 1.5 VFor about 3 seconds after

ignition switch is turned on (i.e.,

headlight auto leveling

indicator is lit up).

10 – 14 VMore than about 3 seconds

after ignition switch is turned

on (i.e., headlight auto leveling

indicator is not lit up).

7———

8———

9Ground for headlight auto

leveling control unit0 VIgnition switch is at ON

position.

10Power supply for right

headlight leveling actuator10 – 14 VIgnition switch is at ON

position.

11Power supply for left headlight

leveling actuator10 – 14 VIgnition switch is at ON

position.

12Power supply for rear height

sensorAbout 5 VIgnition switch is at ON

position.

13Power supply for front height

sensorAbout 5 VIgnition switch is at ON

position.

14———

15———

16 Vehicle speed signal Refer to “Reference waveform No.1: ”.

17Signal for right headlight

leveling actuatorLess than 1 VLighting switch is at OFF

position.

1.0 – 12.6 VFor 17 seconds after turning

lighting switch to ON position.

18Signal for left headlight leveling

actuatorLess than 1 VLighting switch is at OFF

position.

1.0 – 12.6 VFor 17 seconds after turning

lighting switch to ON position.

19Input signal for rear height

sensorAbout 2.5 VIgnition switch is at ON

position.

20Input signal for front height

sensorAbout 2.5 VIgnition switch is at ON

position.

21 Ground for rear height sensor 0 VIgnition switch is at ON

position.

22 Ground for front height sensor 0 VIgnition switch is at ON

position.

23Ground for right headlight

leveling actuator0 VIgnition switch is at ON

position.

24

Ground for left headlight

leveling actuator0 VIgnition switch is at ON

position.

Page 1337 of 1556

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-18

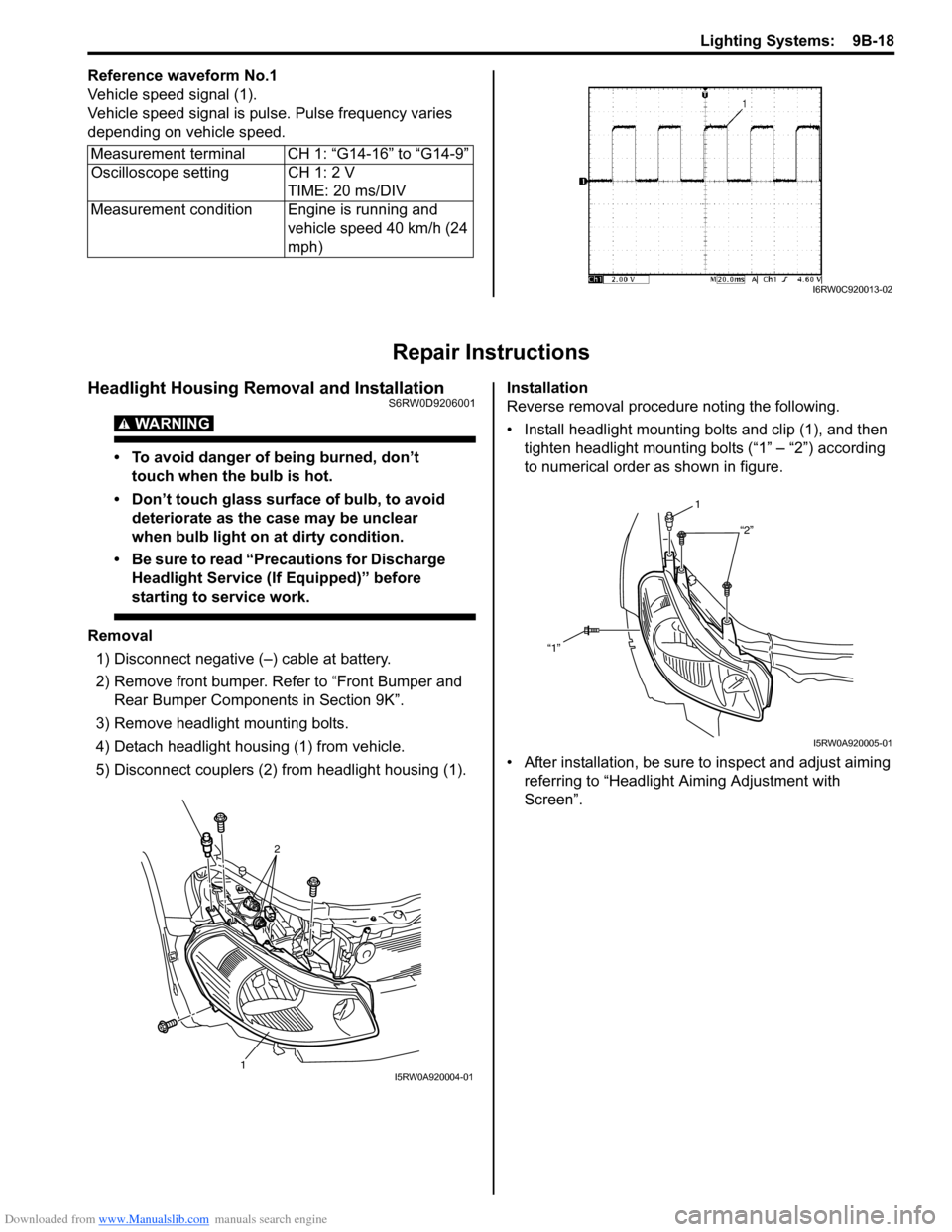

Reference waveform No.1

Vehicle speed signal (1).

Vehicle speed signal is pulse. Pulse frequency varies

depending on vehicle speed.

Repair Instructions

Headlight Housing Removal and InstallationS6RW0D9206001

WARNING!

• To avoid danger of being burned, don’t

touch when the bulb is hot.

• Don’t touch glass surface of bulb, to avoid

deteriorate as the case may be unclear

when bulb light on at dirty condition.

• Be sure to read “Precautions for Discharge

Headlight Service (If Equipped)” before

starting to service work.

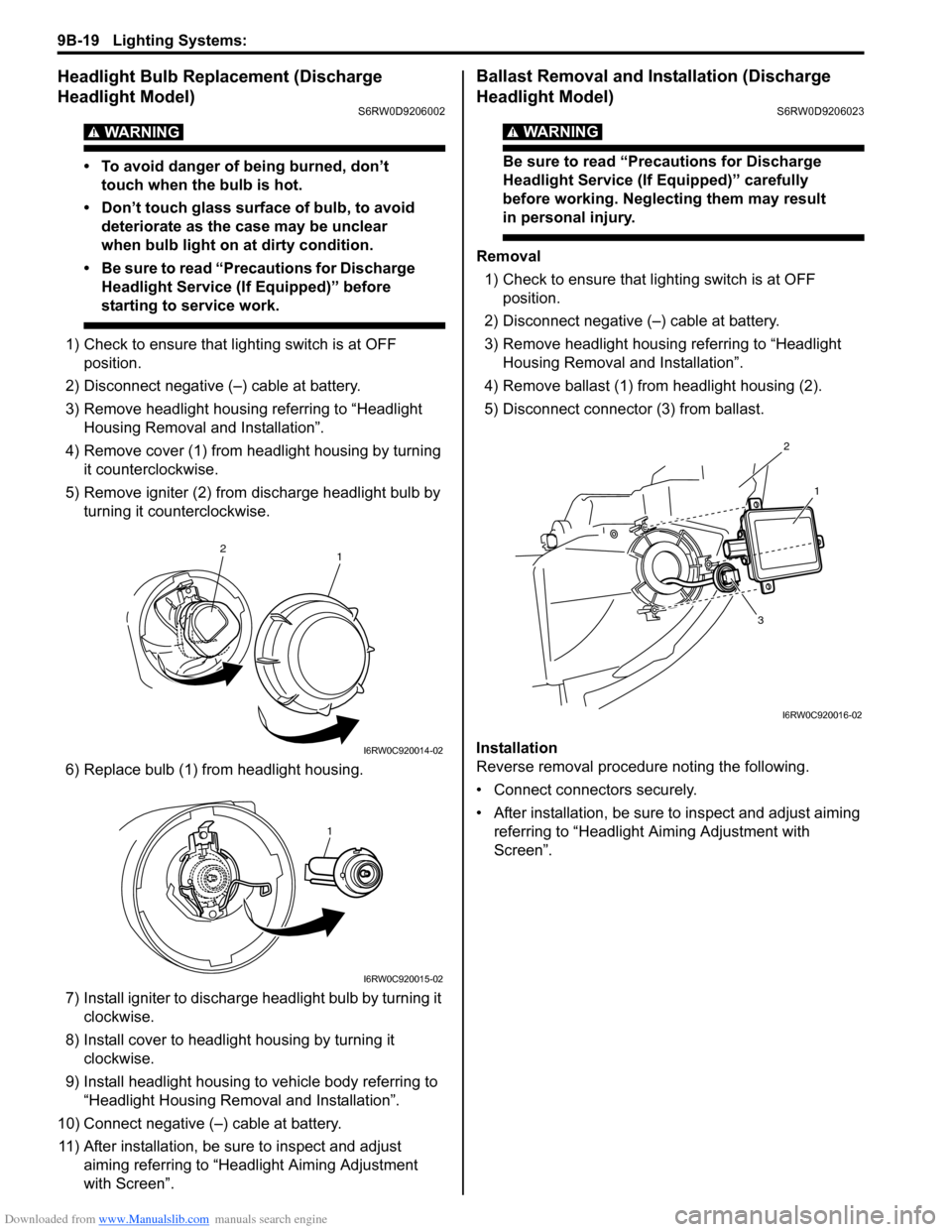

Removal

1) Disconnect negative (–) cable at battery.

2) Remove front bumper. Refer to “Front Bumper and

Rear Bumper Components in Section 9K”.

3) Remove headlight mounting bolts.

4) Detach headlight housing (1) from vehicle.

5) Disconnect couplers (2) from headlight housing (1).Installation

Reverse removal procedure noting the following.

• Install headlight mounting bolts and clip (1), and then

tighten headlight mounting bolts (“1” – “2”) according

to numerical order as shown in figure.

• After installation, be sure to inspect and adjust aiming

referring to “Headlight Aiming Adjustment with

Screen”. Measurement terminal CH 1: “G14-16” to “G14-9”

Oscilloscope setting CH 1: 2 V

TIME: 20 ms/DIV

Measurement condition Engine is running and

vehicle speed 40 km/h (24

mph)

I6RW0C920013-02

2

1I5RW0A920004-01

1

“2”

“1”

I5RW0A920005-01

Page 1338 of 1556

Downloaded from www.Manualslib.com manuals search engine 9B-19 Lighting Systems:

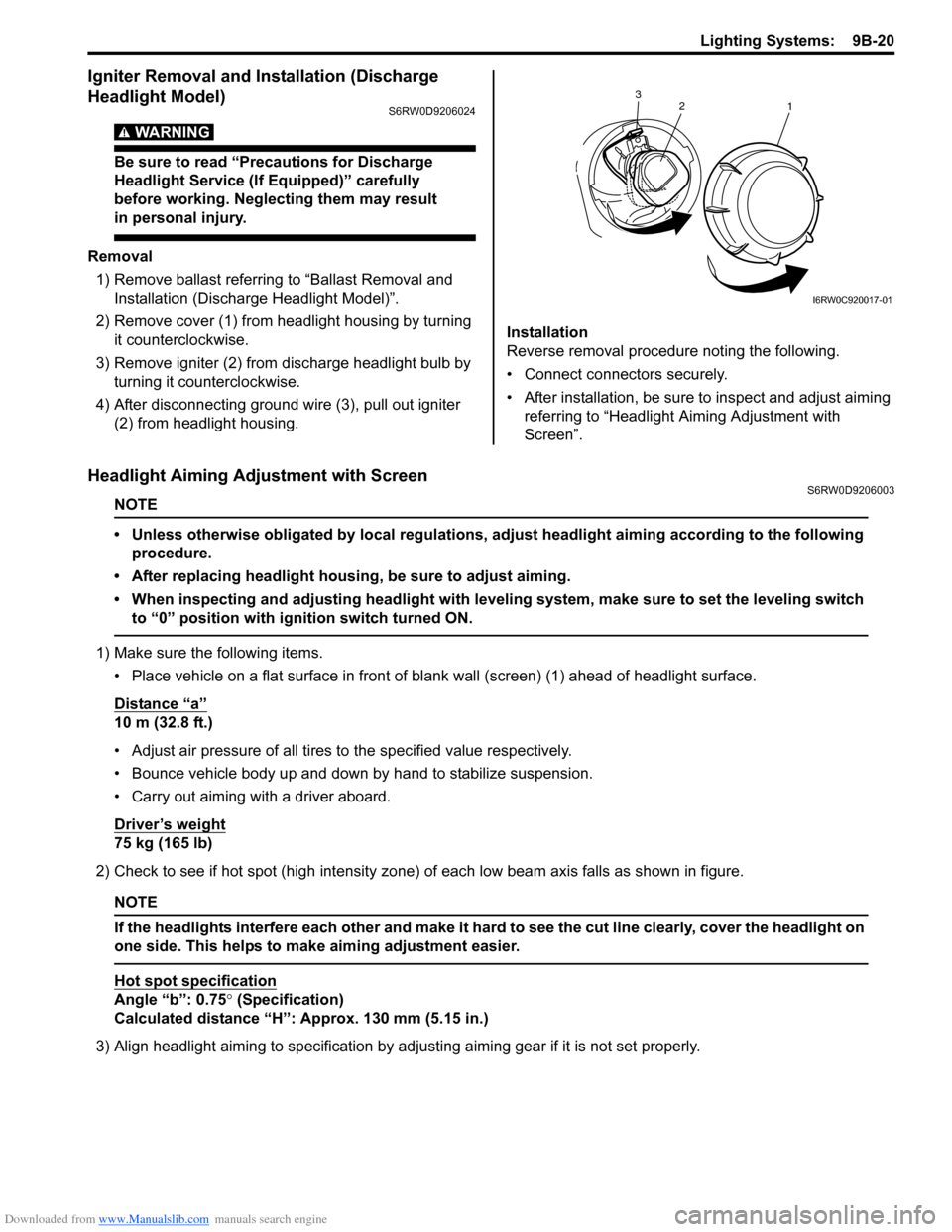

Headlight Bulb Replacement (Discharge

Headlight Model)

S6RW0D9206002

WARNING!

• To avoid danger of being burned, don’t

touch when the bulb is hot.

• Don’t touch glass surface of bulb, to avoid

deteriorate as the case may be unclear

when bulb light on at dirty condition.

• Be sure to read “Precautions for Discharge

Headlight Service (If Equipped)” before

starting to service work.

1) Check to ensure that lighting switch is at OFF

position.

2) Disconnect negative (–) cable at battery.

3) Remove headlight housing referring to “Headlight

Housing Removal and Installation”.

4) Remove cover (1) from headlight housing by turning

it counterclockwise.

5) Remove igniter (2) from discharge headlight bulb by

turning it counterclockwise.

6) Replace bulb (1) from headlight housing.

7) Install igniter to discharge headlight bulb by turning it

clockwise.

8) Install cover to headlight housing by turning it

clockwise.

9) Install headlight housing to vehicle body referring to

“Headlight Housing Removal and Installation”.

10) Connect negative (–) cable at battery.

11) After installation, be sure to inspect and adjust

aiming referring to “Headlight Aiming Adjustment

with Screen”.

Ballast Removal and Installation (Discharge

Headlight Model)

S6RW0D9206023

WARNING!

Be sure to read “Precautions for Discharge

Headlight Service (If Equipped)” carefully

before working. Neglecting them may result

in personal injury.

Removal

1) Check to ensure that lighting switch is at OFF

position.

2) Disconnect negative (–) cable at battery.

3) Remove headlight housing referring to “Headlight

Housing Removal and Installation”.

4) Remove ballast (1) from headlight housing (2).

5) Disconnect connector (3) from ballast.

Installation

Reverse removal procedure noting the following.

• Connect connectors securely.

• After installation, be sure to inspect and adjust aiming

referring to “Headlight Aiming Adjustment with

Screen”.

1 2

I6RW0C920014-02

1

I6RW0C920015-02

2

1

3

I6RW0C920016-02

Page 1339 of 1556

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-20

Igniter Removal and Installation (Discharge

Headlight Model)

S6RW0D9206024

WARNING!

Be sure to read “Precautions for Discharge

Headlight Service (If Equipped)” carefully

before working. Neglecting them may result

in personal injury.

Removal

1) Remove ballast referring to “Ballast Removal and

Installation (Discharge Headlight Model)”.

2) Remove cover (1) from headlight housing by turning

it counterclockwise.

3) Remove igniter (2) from discharge headlight bulb by

turning it counterclockwise.

4) After disconnecting ground wire (3), pull out igniter

(2) from headlight housing.Installation

Reverse removal procedure noting the following.

• Connect connectors securely.

• After installation, be sure to inspect and adjust aiming

referring to “Headlight Aiming Adjustment with

Screen”.

Headlight Aiming Adjustment with ScreenS6RW0D9206003

NOTE

• Unless otherwise obligated by local regulations, adjust headlight aiming according to the following

procedure.

• After replacing headlight housing, be sure to adjust aiming.

• When inspecting and adjusting headlight with leveling system, make sure to set the leveling switch

to “0” position with ignition switch turned ON.

1) Make sure the following items.

• Place vehicle on a flat surface in front of blank wall (screen) (1) ahead of headlight surface.

Distance “a”

10 m (32.8 ft.)

• Adjust air pressure of all tires to the specified value respectively.

• Bounce vehicle body up and down by hand to stabilize suspension.

• Carry out aiming with a driver aboard.

Driver’s weight

75 kg (165 lb)

2) Check to see if hot spot (high intensity zone) of each low beam axis falls as shown in figure.

NOTE

If the headlights interfere each other and make it hard to see the cut line clearly, cover the headlight on

one side. This helps to make aiming adjustment easier.

Hot spot specification

Angle “b”: 0.75° (Specification)

Calculated distance “H”: Approx. 130 mm (5.15 in.)

3) Align headlight aiming to specification by adjusting aiming gear if it is not set properly.

2

1 3

I6RW0C920017-01

Page 1340 of 1556

![SUZUKI SX4 2006 1.G Service Owners Guide Downloaded from www.Manualslib.com manuals search engine 9B-21 Lighting Systems:

1

“H”“b”

“a”

2

10

[G] [F] [E]

7

8

9

6

7

5

10

11 8 9

7

6

5

A

A4

3

B B

A

A4

B B

“H”

“H” “H”

“H SUZUKI SX4 2006 1.G Service Owners Guide Downloaded from www.Manualslib.com manuals search engine 9B-21 Lighting Systems:

1

“H”“b”

“a”

2

10

[G] [F] [E]

7

8

9

6

7

5

10

11 8 9

7

6

5

A

A4

3

B B

A

A4

B B

“H”

“H” “H”

“H](/img/20/7612/w960_7612-1339.png)

Downloaded from www.Manualslib.com manuals search engine 9B-21 Lighting Systems:

1

“H”“b”

“a”

2

10

[G] [F] [E]

7

8

9

6

7

5

10

11 8 9

7

6

5

A

A4

3

B B

A

A4

B B

“H”

“H” “H”

“H” [C]

[D]

A

A4

B B

[A][B]

“H”“H”

XX XX XX

A

A4

B B

[A][B]

“H” “H” [I] [H]

[I] [H]

3

33

3

333

XX

[A][B]

[A][B]

6

5

8

9

I6RW0C920018-02

2. Headlight bulb 10. Headlight housing [D]: LH steering vehicle shown

3. Cut line (bounding line) 11. Headlight leveling actuator [E]: Without headlight leveling actuator

4. Hot spot X-X: Horizontal center line of headlight bulbs [F]: Headlight manual leveling model

5. Turning (for up adjustment) A-A: Vertical center line of left headlight bulb [G]: Headlight auto leveling model

6. Turning (for down adjustment) B-B: Vertical center line of right headlight bulb [H]: Other than discharge headlight model

7. Aiming gear (for right / left adjustment) [A]: Left headlight [I]: Discharge headlight model

8. Turning (for right adjustment) [B]: Right headlight

9. Turning (for left adjustment) [C]: RH steering vehicle shown

Page 1341 of 1556

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-22

Headlight Switch (in Lighting Switch) Removal

and Installation

S6RW0D9206004

Removal

1) Disconnect negative (–) cable at battery.

2) Remove steering column hole cover (3).

3) Remove steering column covers (1).

Turn steering wheel to access steering column cover

screws (2).

4) Remove lighting switch (1) from combination switch

assembly (2) and disconnect its coupler (3).

Installation

Reverse removal procedure for installation.

Headlight Switch (in Lighting Switch)

Inspection

S6RW0D9206025

Check for continuity between terminals at each switch

position. If check result is not as specified, replace

switch.Without rear fog light switch and auto-on headlight

switch

With rear fog light switch

1

2

3

I5RW0A920007-02

2

1

3

I5RW0A920008-01

[A]: LHD [D]: Shaft condition

[B]: RHD *: If equipped

[C]: Terminal

[A]: Terminal

[B]: Shaft condition

[C]

[D]3 5

LOW

PASS

HI

LOW

PASS

HI LOW

PASS

HI

[A] [B]

1

6*2 3 4 5123 4 5

1246*

I6JB0B920003-02

[A]

[B]14 356

LOW

PASS

HI

LOW

PASS

HI LOW

PASS

HI

2

5 4 3 2 16

I5JB0D920011-04

Page 1342 of 1556

Downloaded from www.Manualslib.com manuals search engine 9B-23 Lighting Systems:

With auto-on headlight switch

Hazard Warning Switch Removal and

Installation

S6RW0D9206006

Removal

1) Disconnect negative (–) cable at battery.

2) Remove center ventilation louver (1) referring to

“Center Ventilation Louver Removal and Installation

in Section 7A”.

3) Disconnect coupler, and then remove hazard

warning switch (2) from center ventilation louver (1)

while releasing the locks (3).Installation

Reverse removal procedure for installation.

Hazard Warning Switch InspectionS6RW0D9206007

Check for continuity between terminals at each switch

position. If check result is not as specified, replace

switch.

Brake Light Switch InspectionS6RW0D9206008

Check brake light switch for continuity between terminals

at each switch position.

If check result is not as specified, replace switch.

[A]: Terminal

[B]: Shaft condition

5432 167

14 356

LOW

PASS

HI

LOW

PASS

HI

LOW

PASS

HI LOW

PASS

HI

27[A]

[B]

I6RW0C920019-01

1

3

2I5RW0A920009-01

Terminal

Switch

OFF

ON12 3 4

1

2

3

4

I5RW0C920004-01

Terminal

Shaft condition

FREE

PUSH12 3 4

4

23

1

I5RW0A920010-01

Page 1343 of 1556

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-24

Turn Signal Light Switch (in Lighting Switch)

Removal and Installation

S6RW0D9206009

For removal and Installation, refer to “Headlight Switch

(in Lighting Switch) Removal and Installation”.

Turn Signal Light Switch (in Lighting Switch)

Inspection

S6RW0D9206010

Check for continuity between terminals at each switch

position. If check result is not as specified, replace

switch.

Turn Signal and Hazard Warning Relay Removal

and Installation

S6RW0D9206011

Removal

1) Disconnect negative (–) cable at battery.

2) Remove junction block assembly (1) referring to

“BCM (Included in Junction Block) Removal and

Installation in Section 10B”.

3) Remove turn signal and hazard warning relay (2).

Installation

Reverse removal procedure for installation.

[A]: Other than RHD without rear for light

[B]: RHD without rear fog light

[C]: Terminal

[D]: Switch position

3 12

3 2 13 2 1

[C]

[D]

[A] [B]

N

N

I5JB0D920018-01

2

1

I7RW01920008-01

Page 1344 of 1556

Downloaded from www.Manualslib.com manuals search engine 9B-25 Lighting Systems:

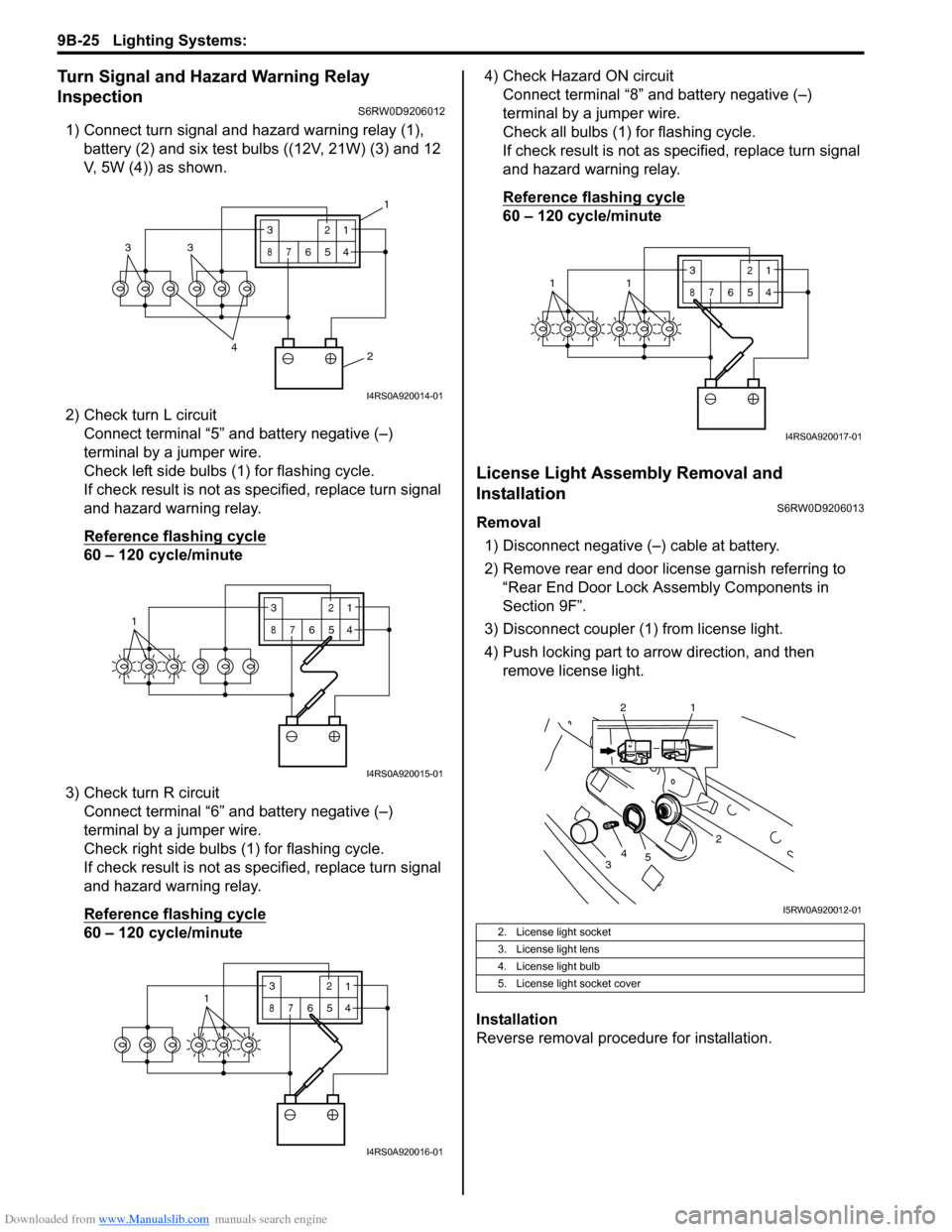

Turn Signal and Hazard Warning Relay

Inspection

S6RW0D9206012

1) Connect turn signal and hazard warning relay (1),

battery (2) and six test bulbs ((12V, 21W) (3) and 12

V, 5W (4)) as shown.

2) Check turn L circuit

Connect terminal “5” and battery negative (–)

terminal by a jumper wire.

Check left side bulbs (1) for flashing cycle.

If check result is not as specified, replace turn signal

and hazard warning relay.

Reference flashing cycle

60 – 120 cycle/minute

3) Check turn R circuit

Connect terminal “6” and battery negative (–)

terminal by a jumper wire.

Check right side bulbs (1) for flashing cycle.

If check result is not as specified, replace turn signal

and hazard warning relay.

Reference flashing cycle

60 – 120 cycle/minute4) Check Hazard ON circuit

Connect terminal “8” and battery negative (–)

terminal by a jumper wire.

Check all bulbs (1) for flashing cycle.

If check result is not as specified, replace turn signal

and hazard warning relay.

Reference flashing cycle

60 – 120 cycle/minute

License Light Assembly Removal and

Installation

S6RW0D9206013

Removal

1) Disconnect negative (–) cable at battery.

2) Remove rear end door license garnish referring to

“Rear End Door Lock Assembly Components in

Section 9F”.

3) Disconnect coupler (1) from license light.

4) Push locking part to arrow direction, and then

remove license light.

Installation

Reverse removal procedure for installation.

2 4

33

3

87

12

654

1

I4RS0A920014-01

13

87

12

654

I4RS0A920015-01

3

87

12

6541

I4RS0A920016-01

2. License light socket

3. License light lens

4. License light bulb

5. License light socket cover

3

87

12

6

5411

I4RS0A920017-01

2

34

5

2 1

I5RW0A920012-01

Page 1345 of 1556

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-26

Front Fog Light Assembly Removal and

Installation (If Equipped)

S6RW0D9206014

WARNING!

• To avoid danger of being burned, don’t

touch when the bulb is hot.

• Don’t touch glass surface of bulb to avoid

deteriorate as the case may be unclear

when bulb light on at dirty condition.

Removal

1) Disconnect negative (–) cable at battery.

2) Remove front bumper. Refer to “Front Bumper and

Rear Bumper Components in Section 9K”.

3) Disconnect coupler from fog light (1).

4) Detach fog light pushing clips to arrow direction.

Installation

Reverse removal procedure for installation nothing the

following:

• After installing, adjust aiming referring to “Front Fog

Light Aiming Adjustment with Screen (If Equipped)”.

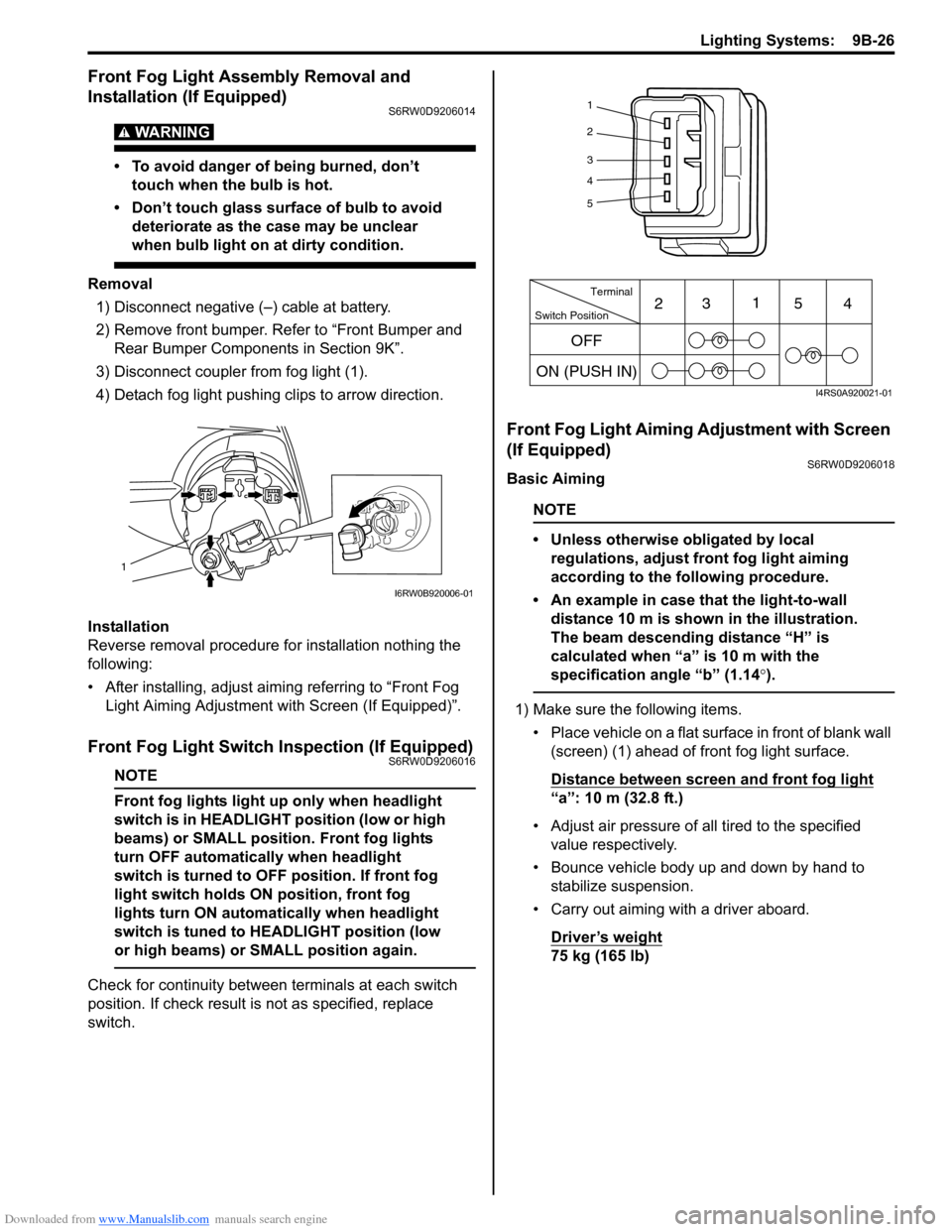

Front Fog Light Switch Inspection (If Equipped)S6RW0D9206016

NOTE

Front fog lights light up only when headlight

switch is in HEADLIGHT position (low or high

beams) or SMALL position. Front fog lights

turn OFF automatically when headlight

switch is turned to OFF position. If front fog

light switch holds ON position, front fog

lights turn ON automatically when headlight

switch is tuned to HEADLIGHT position (low

or high beams) or SMALL position again.

Check for continuity between terminals at each switch

position. If check result is not as specified, replace

switch.

Front Fog Light Aiming Adjustment with Screen

(If Equipped)

S6RW0D9206018

Basic Aiming

NOTE

• Unless otherwise obligated by local

regulations, adjust front fog light aiming

according to the following procedure.

• An example in case that the light-to-wall

distance 10 m is shown in the illustration.

The beam descending distance “H” is

calculated when “a” is 10 m with the

specification angle “b” (1.14°).

1) Make sure the following items.

• Place vehicle on a flat surface in front of blank wall

(screen) (1) ahead of front fog light surface.

Distance between screen and front fog light

“a”: 10 m (32.8 ft.)

• Adjust air pressure of all tired to the specified

value respectively.

• Bounce vehicle body up and down by hand to

stabilize suspension.

• Carry out aiming with a driver aboard.

Driver’s weight

75 kg (165 lb)

1

I6RW0B920006-01

1

2

3

4

5

Switch PositionTerminal

ON (PUSH IN)231

54

OFF

I4RS0A920021-01