terminal SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1423 of 1556

Downloaded from www.Manualslib.com manuals search engine Security and Locks: 9F-12

Rear End Door Lock Assembly Removal and

Installation

S6RW0D9606011

Removal

1) Remove door trim (1) from rear end door panel (2).

2) Disconnect door lock motor lead wire (if equipped).

3) Loosen door latch bolts (1) and remove door latch

assembly (2).

Installation

Reverse removal procedure to install rear end door lock

assembly noting the following instruction.

• Tighten rear end door latch bolt to specified torque.

Tightening torque

Rear end door latch bolt (a): 10 N·m (1.0 kgf-m,

7.5 lb-ft)• Adjust door latch striker so that its center aligns with

the center of groove in door latch base.

Tightening torque

Rear end door striker screw (a): 23 N·m (2.3 kgf-

m, 17.0 lb-ft)

Rear End Door Lock Assembly InspectionS6RW0D9606012

• Check that door opens and closes smoothly and

properly.

• Check that door stops in the secondary latched

position properly (preventing door from opening

freely) and that door closes completely in the fully

latched position.

• Adjust door latch striker position referring to “Front

Door Lock Assembly Removal and Installation”, if

necessary.

Rear End Door Opener Switch Inspection (If

Equipped)

S6RW0D9606013

1) Remove rear end door trim.

2) Disconnect rear end door switch coupler.

3) Check that there is continuity between terminals “a”

and “b” when rear end door opener switch (1) is

pushed.

4) Check that there is no continuity between terminals

when rear end door opener switch (1) is not pushed.

2

1

I5RW0A960008-02

1

2

I4RS0A960017-01

(a)

I4RS0A960018-01

(a)

I4RS0A960019-01

Page 1424 of 1556

Downloaded from www.Manualslib.com manuals search engine 9F-13 Security and Locks:

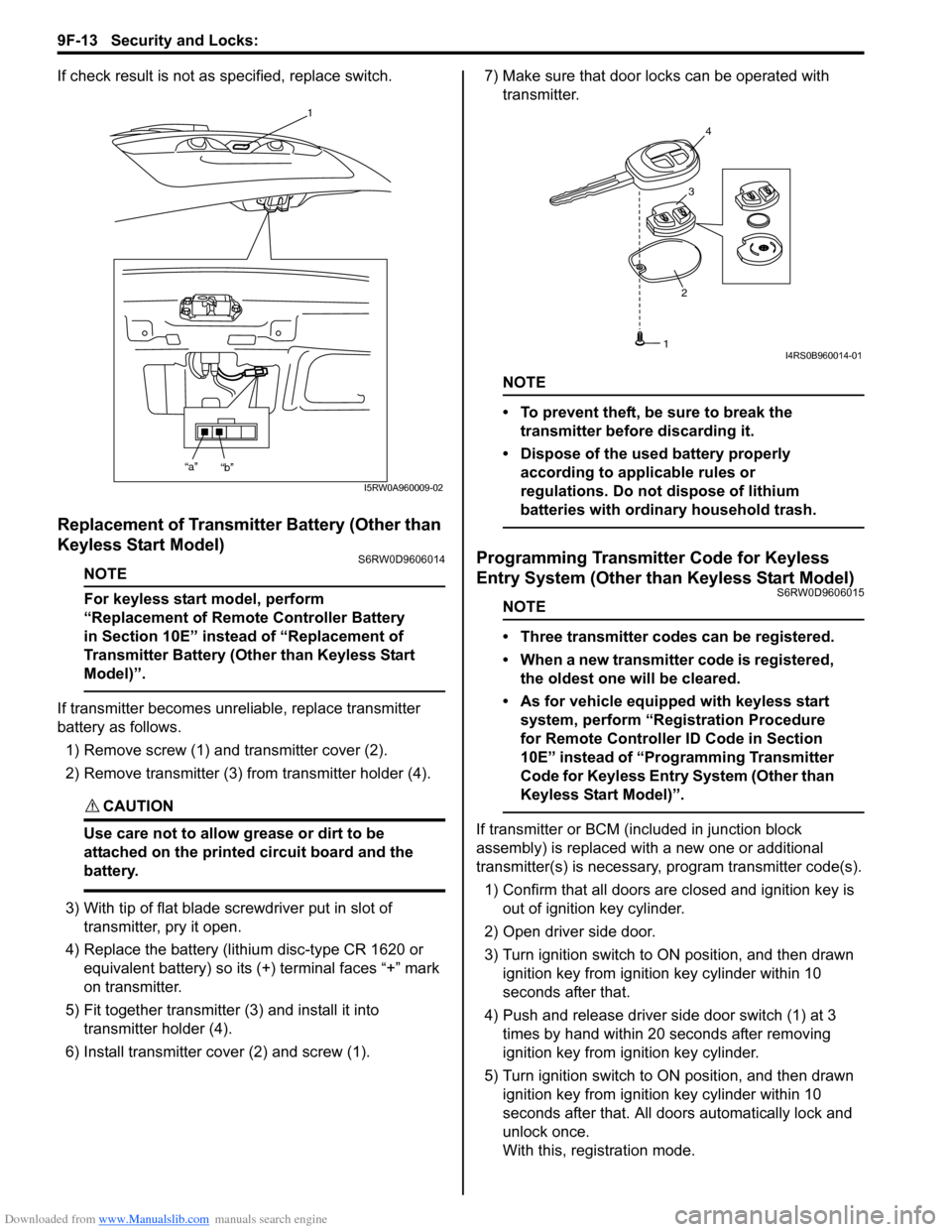

If check result is not as specified, replace switch.

Replacement of Transmitter Battery (Other than

Keyless Start Model)

S6RW0D9606014

NOTE

For keyless start model, perform

“Replacement of Remote Controller Battery

in Section 10E” instead of “Replacement of

Transmitter Battery (Other than Keyless Start

Model)”.

If transmitter becomes unreliable, replace transmitter

battery as follows.

1) Remove screw (1) and transmitter cover (2).

2) Remove transmitter (3) from transmitter holder (4).

CAUTION!

Use care not to allow grease or dirt to be

attached on the printed circuit board and the

battery.

3) With tip of flat blade screwdriver put in slot of

transmitter, pry it open.

4) Replace the battery (lithium disc-type CR 1620 or

equivalent battery) so its (+) terminal faces “+” mark

on transmitter.

5) Fit together transmitter (3) and install it into

transmitter holder (4).

6) Install transmitter cover (2) and screw (1).7) Make sure that door locks can be operated with

transmitter.

NOTE

• To prevent theft, be sure to break the

transmitter before discarding it.

• Dispose of the used battery properly

according to applicable rules or

regulations. Do not dispose of lithium

batteries with ordinary household trash.

Programming Transmitter Code for Keyless

Entry System (Other than Keyless Start Model)

S6RW0D9606015

NOTE

• Three transmitter codes can be registered.

• When a new transmitter code is registered,

the oldest one will be cleared.

• As for vehicle equipped with keyless start

system, perform “Registration Procedure

for Remote Controller ID Code in Section

10E” instead of “Programming Transmitter

Code for Keyless Entry System (Other than

Keyless Start Model)”.

If transmitter or BCM (included in junction block

assembly) is replaced with a new one or additional

transmitter(s) is necessary, program transmitter code(s).

1) Confirm that all doors are closed and ignition key is

out of ignition key cylinder.

2) Open driver side door.

3) Turn ignition switch to ON position, and then drawn

ignition key from ignition key cylinder within 10

seconds after that.

4) Push and release driver side door switch (1) at 3

times by hand within 20 seconds after removing

ignition key from ignition key cylinder.

5) Turn ignition switch to ON position, and then drawn

ignition key from ignition key cylinder within 10

seconds after that. All doors automatically lock and

unlock once.

With this, registration mode.

1

“a”

“b”

I5RW0A960009-02

234

1I4RS0B960014-01

Page 1426 of 1556

Downloaded from www.Manualslib.com manuals search engine 9F-15 Security and Locks:

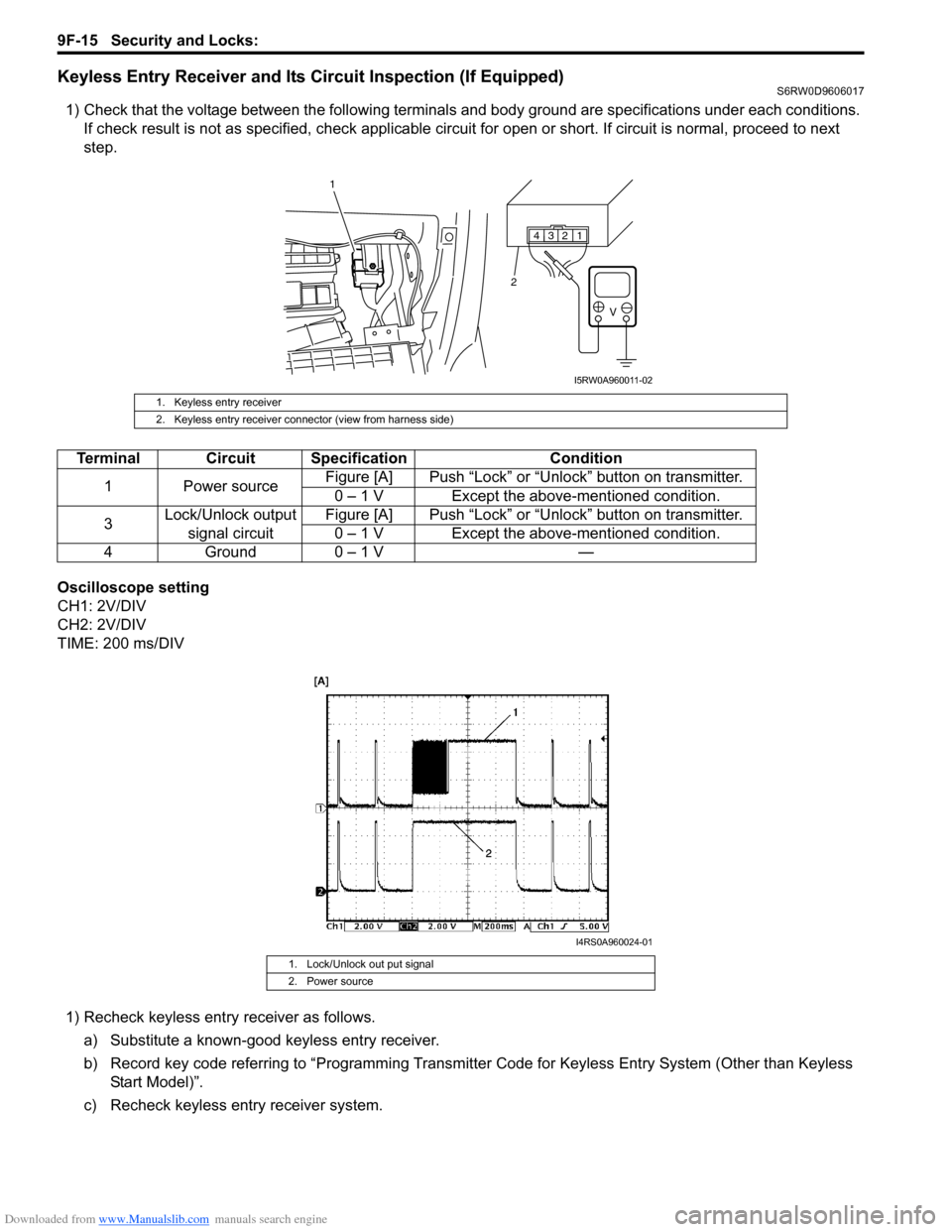

Keyless Entry Receiver and Its Circuit Inspection (If Equipped)S6RW0D9606017

1) Check that the voltage between the following terminals and body ground are specifications under each conditions.

If check result is not as specified, check applicable circuit for open or short. If circuit is normal, proceed to next

step.

Oscilloscope setting

CH1: 2V/DIV

CH2: 2V/DIV

TIME: 200 ms/DIV

1) Recheck keyless entry receiver as follows.

a) Substitute a known-good keyless entry receiver.

b) Record key code referring to “Programming Transmitter Code for Keyless Entry System (Other than Keyless

Start Model)”.

c) Recheck keyless entry receiver system.

1. Keyless entry receiver

2. Keyless entry receiver connector (view from harness side)

Terminal Circuit Specification Condition

1 Power sourceFigure [A] Push “Lock” or “Unlock” button on transmitter.

0 – 1 V Except the above-mentioned condition.

3Lock/Unlock output

signal circuitFigure [A] Push “Lock” or “Unlock” button on transmitter.

0 – 1 V Except the above-mentioned condition.

4 Ground 0 – 1 V —

1. Lock/Unlock out put signal

2. Power source

1 2 3 4

V

2

1

I5RW0A960011-02

I4RS0A960024-01

Page 1430 of 1556

Downloaded from www.Manualslib.com manuals search engine 9G-3 Seats:

Front Seat Removal and InstallationS6RW0D9706002

Removal

1) Disable air bag system referring to “Disabling Air

Bag System in Section 8B”.

2) Disconnect seat harness coupler and side air bag

coupler, if equipped.

3) Remove 4 mounting bolts to remove seat assembly.

4) Disassemble and repair seat as necessary.

Installation

Reverse removal procedure to install front seat.

• Torque to specifications as shown in “Front Seat

Components”.

• Enable air bag system referring to “Enabling Air Bag

System in Section 8B”.

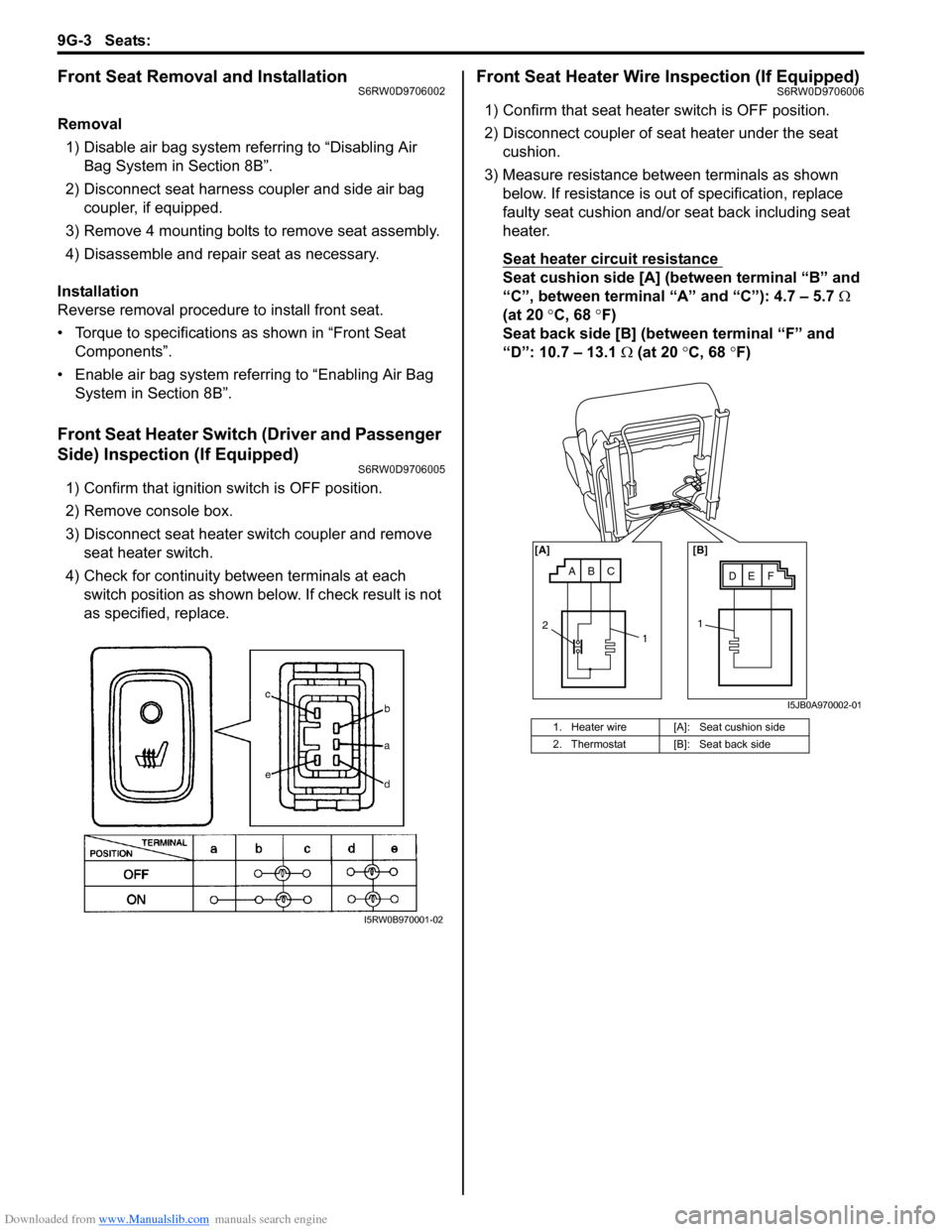

Front Seat Heater Switch (Driver and Passenger

Side) Inspection (If Equipped)

S6RW0D9706005

1) Confirm that ignition switch is OFF position.

2) Remove console box.

3) Disconnect seat heater switch coupler and remove

seat heater switch.

4) Check for continuity between terminals at each

switch position as shown below. If check result is not

as specified, replace.

Front Seat Heater Wire Inspection (If Equipped)S6RW0D9706006

1) Confirm that seat heater switch is OFF position.

2) Disconnect coupler of seat heater under the seat

cushion.

3) Measure resistance between terminals as shown

below. If resistance is out of specification, replace

faulty seat cushion and/or seat back including seat

heater.

Seat heater circuit resistance

Seat cushion side [A] (between terminal “B” and

“C”, between terminal “A” and “C”): 4.7 – 5.7 Ω

(at 20 °C, 68 °F)

Seat back side [B] (between terminal “F” and

“D”: 10.7 – 13.1 Ω (at 20 °C, 68 °F)

I5RW0B970001-02

1. Heater wire [A]: Seat cushion side

2. Thermostat [B]: Seat back side

ABCDE F [A] [B]

11

2

I5JB0A970002-01

Page 1489 of 1556

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-16

BCM Power Circuit and Ground Circuit CheckS6RW0DA204007

Wiring Diagram

Troubleshooting

+B

IG1

+BB

GRNG273-2BLKBLK/ORNG272-9

G271-3

BLK/ORNL314-4

BLU G273-5

WHTE324-22

3

1

E324 L314

1 2 4 53 6 7 8 9

10

11 12 13 14 15 16 17 181 21 2 4 53 61

2 4 53 6 7 8 9 10

7 8 9 10 11 12

11 12 13 14 15 16 17 18 19 20

G272 G271

1 2

4

65

G273[A] [A] [A]

3

[A]

I6RW0CA20006-02

[A]: Junction block connector viewed from harness side 2. Ignition switch

1. Junction block 3. Battery

Step Action Yes No

1Fuse check

1) Turn ignition switch to OFF position.

2) Check circuit fuses for condition.

Are circuit fuses in good condition?Go to Step 2. Replace fuse and check

for short circuit to

ground.

2Power supply circuit check

1) Disconnect connectors from junction block.

2) Check for proper connection to junction block connector

at terminal “E324-2”.

3) If OK, then measure voltage between “E324-2” terminal

of junction block connector and vehicle body ground.

Is voltage 10 – 14 V?Go to Step 3. Repair power supply

circuit.

3Power supply circuit check

1) Check for proper connection to junction block connector

at terminals “G273-2” and “G273-5”.

2) If OK, turn ignition switch to ON position.

3) Measure voltage between following terminals.

• Between “G273-2” terminal of junction block

connector and vehicle body ground

• Between “G273-5” terminal of junction block

connector and vehicle body ground

Is each voltage 10 – 14 V?Go to Step 4. Repair power supply

circuit.

Page 1490 of 1556

Downloaded from www.Manualslib.com manuals search engine 10B-17 Body Electrical Control System:

DTC B1133 (DTC No. 1133): Battery Voltage Too HighS6RW0DA204008

Wiring Diagram

Refer to “BCM Power Circuit and Ground Circuit Check”.

DTC Detecting Condition and Possible Cause

Flow Test Description

Step 1: Check charging system

DTC Troubleshooting4Ground circuit check

1) Turn ignition switch to OFF position.

2) Check for proper connection to junction block connector

at terminals “G271-3”, “G272-9” and “L314-4”.

3) If OK, then measure resistance between following

terminals.

• Between “G271-3” terminal of junction block

connector and vehicle body ground

• Between “G272-9” terminal of junction block

connector and vehicle body ground

• Between “L314-4” terminal of junction block connector

and vehicle body ground

Is each resistance 2

Ω or less?BCM power supply

circuit and ground circuit

are in good condition.Repair ground circuit. Step Action Yes No

DTC detecting condition Possible cause

Power voltage supplied from battery to BCM is

higher than 16V.• Charging system malfunction

• BCM malfunction

Step Action Yes No

1Charging system operation check

1) Check generator for operation referring to “Generator

Test (Overcharged Battery Check) in Section 1J”.

Is it in good condition?Substitute a known

good BCM (included in

junction block) and

recheck.Repair charging system.

Page 1491 of 1556

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-18

DTC B1141 / DTC B1142 (No. 1141 / No. 1142) Outside Air Temperature (Ambient Temp.) Sensor

Circuit Malfunction

S6RW0DA204009

Wiring Diagram

DTC Detecting Condition and Possible Cause

Flow Test Description

Step 1: Check whether malfunction is in outside air temperature sensor.

Step 2: Check outside air temperature sensor circuit.

DTC Troubleshooting

YEL/RED

YEL/BLK

5V

E04-10

E04-8

12E04

1 2 4 53 6 7

8 9 10 11 12 13 14

[A]

I6RW0CA20007-01

[A]: BCM connector viewed from harness side 2. BCM

1. Outside air temperature sensor

DTC detecting condition Possible cause

DTC B1141 (DTC No. 1141):

Input signal from outside air temperature sensor is higher

than 4.88 V.• Open in outside air temperature sensor circuit

• Outside air temperature sensor malfunction

• BCM malfunction

DTC B1142 (DTC No. 1142):

Input signal from outside air temperature sensor is lower

than 0.1 V.• Short in outside air temperature sensor circuit

• Outside air temperature sensor malfunction

• BCM malfunction

Step Action Yes No

1 Outside air temperature sensor check

1) Turn ignition switch to OFF position.

2) Disconnect connector from outside air temperature

sensor.

3) Check outside air temperature sensor for resistance

referring to “Outside Air Temperature Sensor Inspection

(If Equipped) in Section 9C”.

Is it in good condition?Go to Step 2. Replace outside air

temperature sensor.

2Outside air temperature sensor circuit check

1) Disconnect connector from BCM and check for proper

terminal connection to BCM connector.

2) If connections are OK, check outside air temperature

sensor circuit for open, short and high resistance.

Is each circuit in good condition?Substitute a known-

good BCM (included in

junction block) and

recheck.Repair circuit.

Page 1492 of 1556

Downloaded from www.Manualslib.com manuals search engine 10B-19 Body Electrical Control System:

DTC B1150 (No. 1150): Air Bag Communication Circuit MalfunctionS6RW0DA204010

Wiring Diagram

DTC Detecting Condition and Possible Cause

Flow Test Description

Step 1: Check air bag communication circuit.

Step 2: Check air bag communication circuit.

DTC Troubleshooting

YEL

5V

L313-2L04-37

2

1

L313

1 2 43

[A]

I6RW0CA20008-01

[A]: Junction block connector viewed from harness side 2. BCM

1. SDM

DTC detecting condition Possible cause

After ignition switch is turned ON, abnormal signal is fed

from SDM to BCM.• Air bag communication circuit open or short

• SDM malfunction

• BCM malfunction

Step Action Yes No

1Air bag communication circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors from junction block and SDM.

3) Check for proper terminal connection to BCM and SDM

connectors.

4) If connections are OK, check air bag communication

circuit for open, short and high resistance.

Is circuit in good condition?Go to Step 2. Repair circuit.

2Air bag communication circuit check

1) Turn ignition switch to OFF position.

2) Connect connectors to junction block.

3) Turn ignition switch to ON position.

4) Measure voltage between “L313-2” terminal of junction

block connector and vehicle body ground.

Is voltage 4 – 6 V?Substitute a known-

good SDM and recheck.Substitute a known-

good BCM (included in

junction block) and

recheck.

Page 1494 of 1556

Downloaded from www.Manualslib.com manuals search engine 10B-21 Body Electrical Control System:

Inspection of BCM and Its CircuitsS6RW0DA204017

BCM and its circuits can be checked at BCM wiring couplers by measuring voltage and resistance.

CAUTION!

BCM cannot be checked by itself. It is strictly prohibited to connect voltmeter or ohmmeter to BCM

with couplers disconnected from it.

Voltage Check

1) Disconnect negative cable (–) at battery.

2) Remove BCM (included in junction block) referring to “BCM (Included in Junction Block) Removal and Installation”.

3) Connect connectors to BCM (1) and junction block (2).

4) Check voltage at each terminal number of couplers connected.

For connector and terminal number, refer to “Connector Layout Diagram of BCM and Junction Block”.

NOTE

• As each terminal voltage is affected by the battery voltage, confirm that it is 11 V or more when

ignition switch is ON.

• Voltage with asterisk (*) can not be measured by voltmeter because it is pulse signal.

Check it with oscilloscope if necessary.

BCM connector “L01”

1

2

1

2

I4RS0AA20030-01

Terminal Circuit Normal voltage Condition

L01-1Passenger side door lock

actuator control (Unlock) (if

equipped)10 – 14 VUnlock signal is output for passenger side

door lock actuator

0 VUnlock signal is not output for passenger side

door lock actuator

L01-2 — — —

L01-3 Rear end door switch10 – 14 V Rear end door is closed

0 V Rear end door is opened

L01-4Rear end door opener switch

(if equipped)10 – 14 V Rear end door opener switch is not pushed

0 V Rear end door opener switch is pushed

L01-5Manual door lock switch

(Unlock) (if equipped)10 – 14 VManual door lock switch is at any position

other than unlock position

0 V Manual door lock switch is at unlock position

L01-6 Parking brake switch*0 – 3 V

↑↓

10 – 14 VRefer to “Reference waveform No. 1: ”

0 VIgnition switch is at ON position and parking

brake lever is pulled up

L01-7 Driver side door switch10 – 14 V Driver side door is closed

0 V Driver side door is opened

L01-8 — — —

L01-9 — — —

Page 1495 of 1556

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-22

BCM connector “E04”L01-10Driver side door lock

actuator control (Unlock) (if

equipped)10 – 14 VUnlock signal is output for driver side door

lock actuator

0 VUnlock signal is not output for driver side

door lock actuator

L01-11Rear end door opener

actuator control (if equipped)0 VRear end door actuator motor is not in

operation

10 – 14 V Rear end door actuator motor is in operation

L01-12Manual door lock switch

(Lock) (if equipped)10 – 14 VManual door lock switch is at any position

other than lock position

0 V Manual door lock switch is at lock position

L01-13 — — —

L01-14 Driver side seat belt switch*0 – 3 V

↑↓

10 – 14 VRefer to “Reference waveform No. 2: ”

0 VIgnition switch is at ON position and driver

side seat belt is unfastened

L01-15Door switch (other than

driver side door and rear end

door)10 – 14 VRear right and left side door and passenger

side door are closed

0 VAny one of the door is opened (except driver

side door and rear end door)

L01-16Driver side door key cylinder

switch (Lock) (if equipped)10 – 14 VDriver side door key cylinder switch is at any

position other than lock position

0 VDriver side door key cylinder switch is at lock

position

L01-17Driver side door key cylinder

switch (Unlock) (if equipped)10 – 14 VDriver side door key cylinder switch is at any

position other than unlock position

0 VDriver side door key cylinder switch is at

unlock position

L01-18 — — —

Terminal Circuit Normal voltage Condition

E04-1CAN communication line (high)

for ABS control module*2.5 – 3.6 V

Refer to “Reference waveform No. 3: ”

E04-2CAN communication line (low)

for ABS control module*1.6 – 2.5 V

E04-3 — — —

E04-4 Generator “L” terminal10 – 14 V Engine is running

0 V Ignition switch is at ON position

E04-5 Brake fluid level switch*0 – 3 V

↑↓

10 – 14 VRefer to “Reference waveform No. 1: ”

0 VIgnition switch is at ON position, parking brake

lever is released and brake fluid level is lower

than MIN level

E04-6 — — —

E04-7 — — —

E04-8Sensor ground for outside air

temperature sensor (if

equipped)0 V —

E04-9Serial communication line of

data link connector for ABS

control module7 – 12 V Ignition switch is at ON position

E04-10Outside air temperature sensor

(if equipped)About 1.5 VIgnition switch is at ON position and outside

air temperature approx. 20 °C (68

°F)

E04-11 Oil pressure switch*3 – 14 V Refer to “Reference waveform No. 4: ”

0 VIgnition switch is at ON position and engine is

at stop

E04-12 — — — Terminal Circuit Normal voltage Condition