AIR SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1018 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-78 Air Conditioning System: Automatic Type

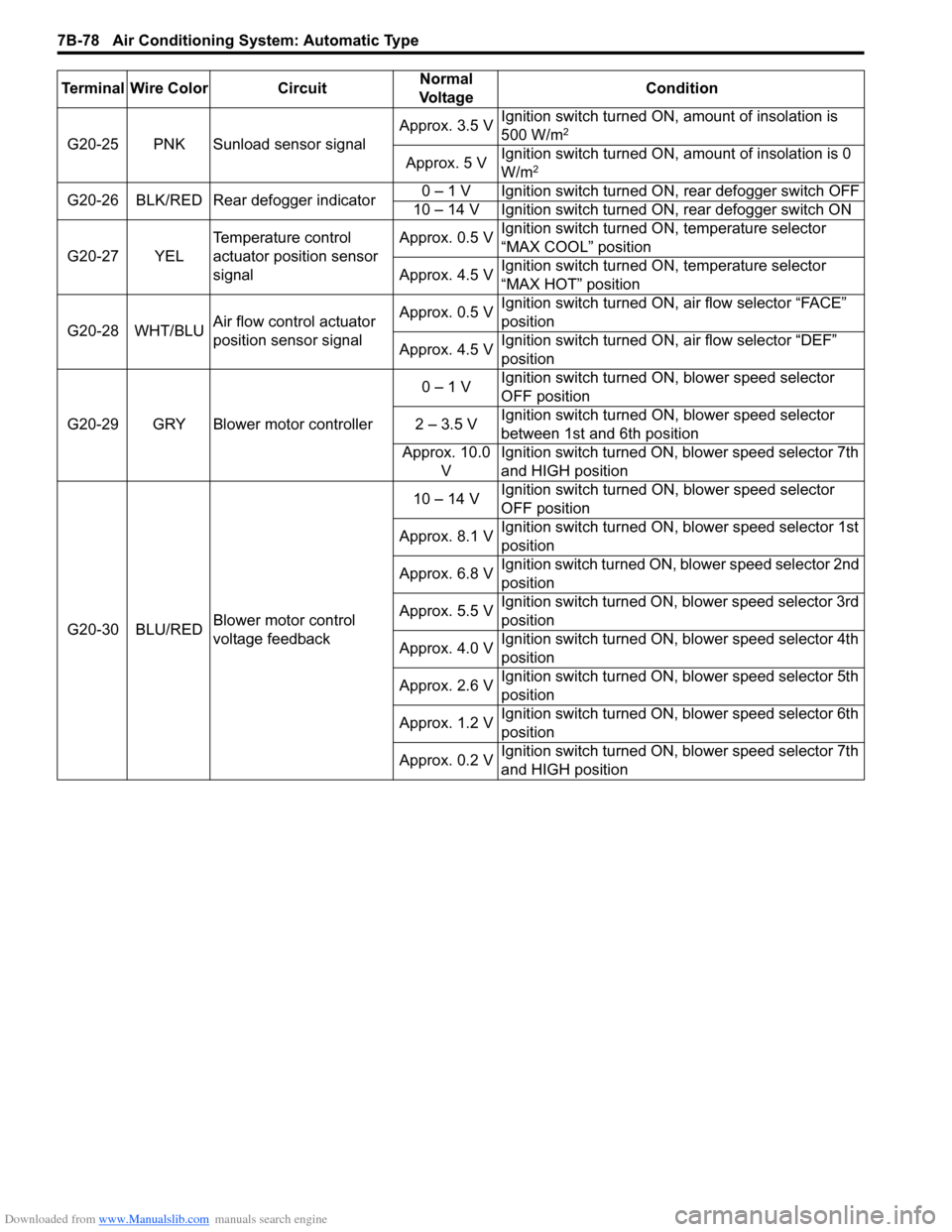

G20-25 PNK Sunload sensor signalApprox. 3.5 VIgnition switch turned ON, amount of insolation is

500 W/m2

Approx. 5 VIgnition switch turned ON, amount of insolation is 0

W/m2

G20-26 BLK/RED Rear defogger indicator0 – 1 V Ignition switch turned ON, rear defogger switch OFF

10 – 14 V Ignition switch turned ON, rear defogger switch ON

G20-27 YELTemperature control

actuator position sensor

signalApprox. 0.5 VIgnition switch turned ON, temperature selector

“MAX COOL” position

Approx. 4.5 VIgnition switch turned ON, temperature selector

“MAX HOT” position

G20-28 WHT/BLUAir flow control actuator

position sensor signalApprox. 0.5 VIgnition switch turned ON, air flow selector “FACE”

position

Approx. 4.5 VIgnition switch turned ON, air flow selector “DEF”

position

G20-29 GRY Blower motor controller0 – 1 VIgnition switch turned ON, blower speed selector

OFF position

2 – 3.5 VIgnition switch turned ON, blower speed selector

between 1st and 6th position

Approx. 10.0

VIgnition switch turned ON, blower speed selector 7th

and HIGH position

G20-30 BLU/REDBlower motor control

voltage feedback10 – 14 VIgnition switch turned ON, blower speed selector

OFF position

Approx. 8.1 VIgnition switch turned ON, blower speed selector 1st

position

Approx. 6.8 VIgnition switch turned ON, blower speed selector 2nd

position

Approx. 5.5 VIgnition switch turned ON, blower speed selector 3rd

position

Approx. 4.0 VIgnition switch turned ON, blower speed selector 4th

position

Approx. 2.6 VIgnition switch turned ON, blower speed selector 5th

position

Approx. 1.2 VIgnition switch turned ON, blower speed selector 6th

position

Approx. 0.2 VIgnition switch turned ON, blower speed selector 7th

and HIGH position Terminal Wire Color CircuitNormal

Vo l ta g eCondition

Page 1019 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-79

Reference waveform No. 1

Rear defogger switch or A/C switch signal (1)Reference waveform No. 2

Serial communication line of BCM (1)

A/C System Inspection at ECMS6RW0D7224030

When checking voltage at ECM terminals related to A/C system, refer to “Inspection of ECM and Its Circuits in Section

1A”.

Repair Instructions

Operation Procedure for Refrigerant ChargeS6RW0D7226001

Refer to “Operation Procedure for Refrigerant Charge”.Measurement terminal Rear defogger switch

CH1: “G20-4” to “G20-23” A/

C switch

CH1: “G20-21” to “G20-23”

Oscilloscope setting CH1: 5 V / DIV

TIME: 10 ms / DIV

Measurement condition Rear defogger switch:

• Ignition switch is at ON

position and rear defogger

switch is not pushed

A/C switch:

• Ignition switch is at ON

position and A/C switch is

not pushed

I7RW01722014-02

Measurement terminal CH1: “G20-13” to “G20-23”

Oscilloscope setting CH1: 5 V / DIV

TIME: 20 ms / DIV

Measurement condition Ignition switch is at ON

position

I7RW01722015-02

Page 1020 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-80 Air Conditioning System: Automatic Type

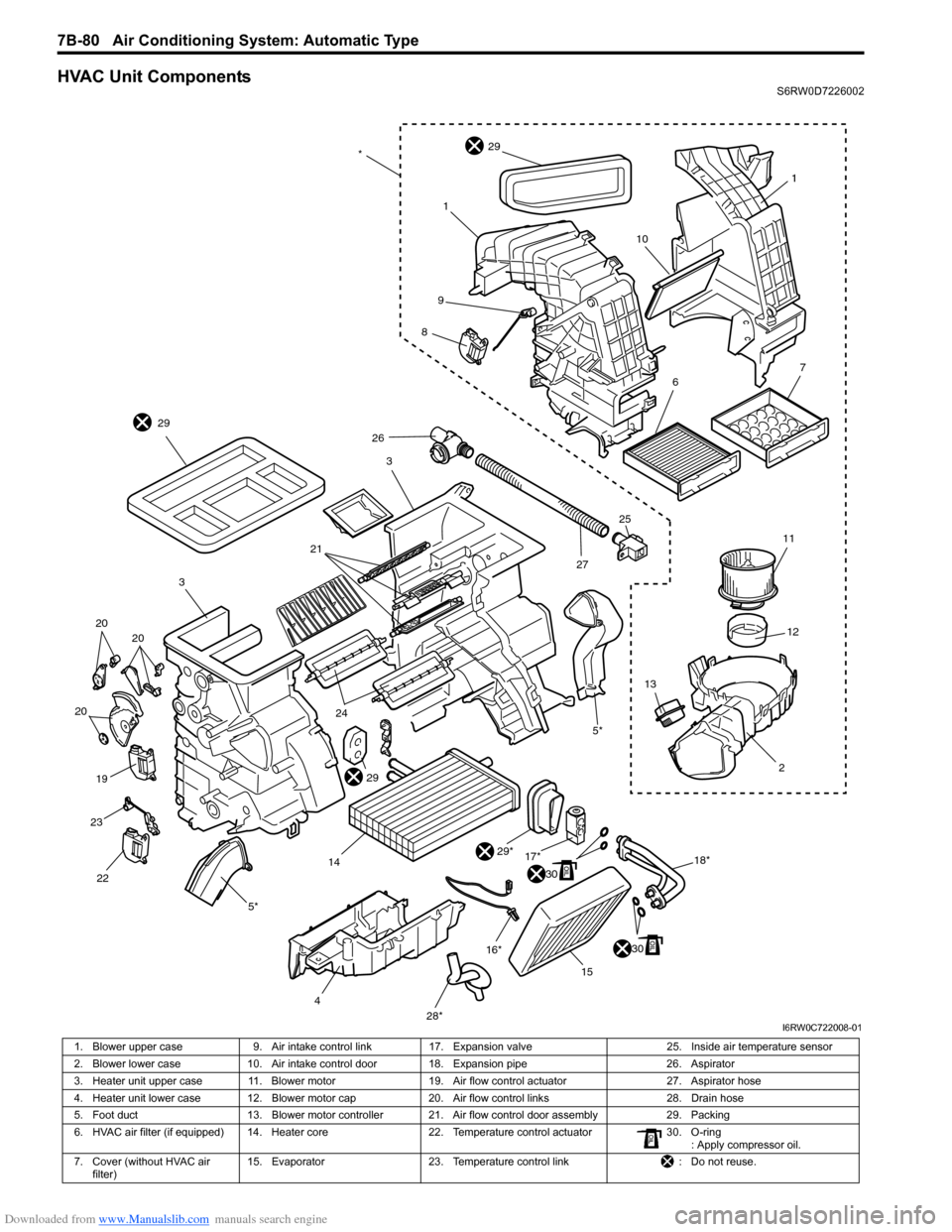

HVAC Unit ComponentsS6RW0D7226002

1

10

1

29

9

8

3

29

21

3

20 20

20

19

23

22

5*

4

28*15 16*

30

29*

30

17*

18*2 1312 11

5*

26

2725

1424

29

67

*

I6RW0C722008-01

1. Blower upper case 9. Air intake control link 17. Expansion valve 25. Inside air temperature sensor

2. Blower lower case 10. Air intake control door 18. Expansion pipe 26. Aspirator

3. Heater unit upper case 11. Blower motor 19.Air flow control actuator 27. Aspirator hose

4. Heater unit lower case 12. Blower motor cap 20. Air flow control links 28. Drain hose

5. Foot duct 13. Blower motor controller 21. Air flow control door assembly 29. Packing

6. HVAC air filter (if equipped) 14. Heater core 22. Temperature control actuator 30. O-ring

: Apply compressor oil.

7. Cover (without HVAC air

filter)15. Evaporator 23. Temperature control link : Do not reuse.

Page 1021 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-81

HVAC Unit Removal and InstallationS6RW0D7226003

Refer to “HVAC Unit Removal and Installation”.

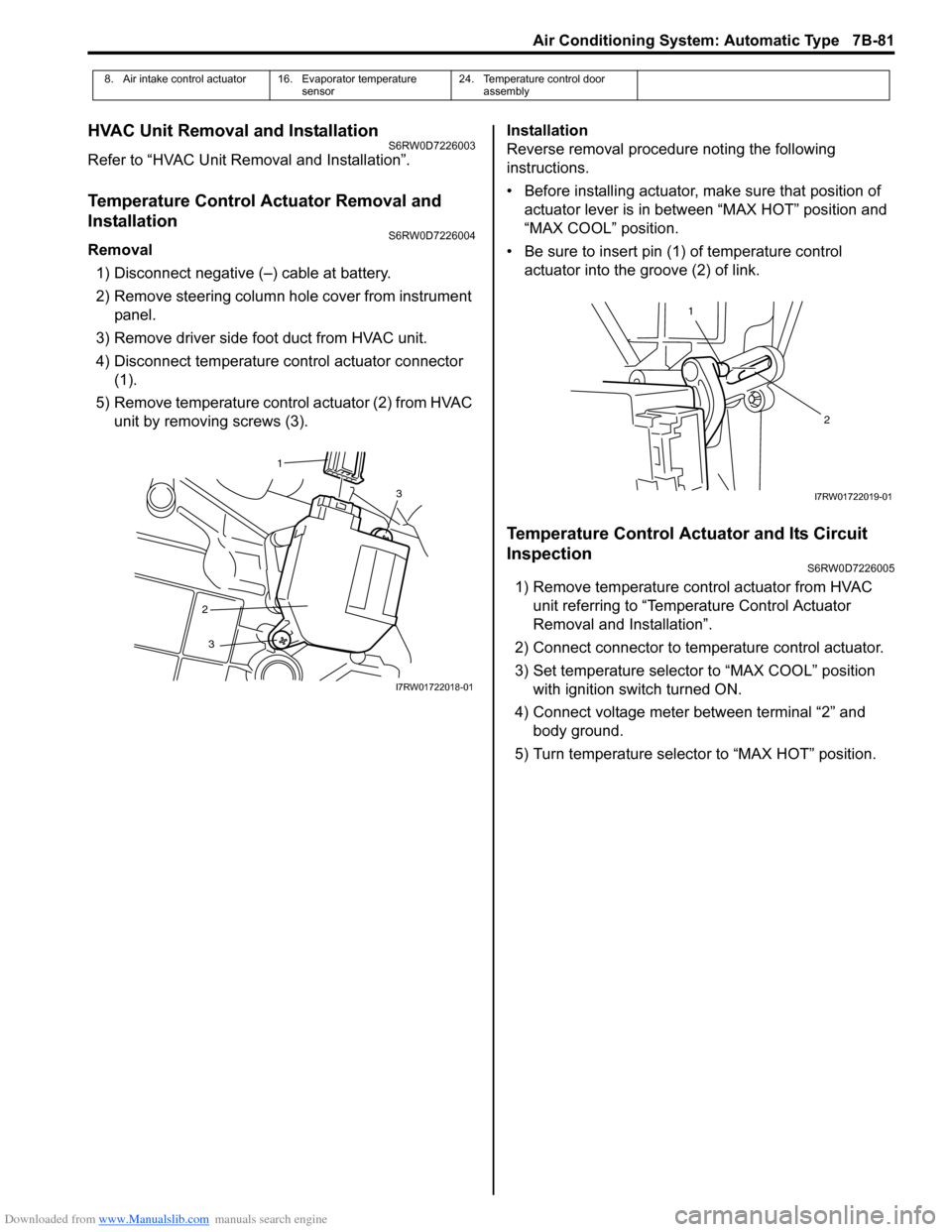

Temperature Control Actuator Removal and

Installation

S6RW0D7226004

Removal

1) Disconnect negative (–) cable at battery.

2) Remove steering column hole cover from instrument

panel.

3) Remove driver side foot duct from HVAC unit.

4) Disconnect temperature control actuator connector

(1).

5) Remove temperature control actuator (2) from HVAC

unit by removing screws (3).Installation

Reverse removal procedure noting the following

instructions.

• Before installing actuator, make sure that position of

actuator lever is in between “MAX HOT” position and

“MAX COOL” position.

• Be sure to insert pin (1) of temperature control

actuator into the groove (2) of link.

Temperature Control Actuator and Its Circuit

Inspection

S6RW0D7226005

1) Remove temperature control actuator from HVAC

unit referring to “Temperature Control Actuator

Removal and Installation”.

2) Connect connector to temperature control actuator.

3) Set temperature selector to “MAX COOL” position

with ignition switch turned ON.

4) Connect voltage meter between terminal “2” and

body ground.

5) Turn temperature selector to “MAX HOT” position.

8. Air intake control actuator 16. Evaporator temperature

sensor24. Temperature control door

assembly

3

2

3

1

I7RW01722018-01

1

2

I7RW01722019-01

Page 1022 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-82 Air Conditioning System: Automatic Type

6) Measure output voltage variation while temperature

control actuator is operated from “MAX COOL”

position (B) to “MAX HOT” position (A) as following

specification.

If measure voltage is out of specification or does not

vary linearly as the shown in graph, check related

wire circuit and HVAC control module. If wire circuits

and HVAC control module are OK, go to next step.

Temperature control actuator output voltage

0.48 – 4.53V (linear variation as following graph)

7) Set temperature selector of HVAC control module to

“MAX HOT” position with ignition switch turned ON,

and make sure if the position of actuator lever is

“MAX HOT” position (A).

8) Turn ignition switch to OFF position, and then

disconnect connector from temperature control

actuator.9) Measure resistance between terminal “1” and “2”.

Temperature control actuator resistance between

terminal “1” and “2” (MAX HOT position)

(Reference value)

Approx. 0.45 kΩ at 25 °C (77 °F)

10) Connect connector to temperature control actuator.

11) Set temperature selector of HVAC control module to

“MAX COOL” position with ignition switch turned ON,

and make sure if the position of actuator lever is

“MAX COOL” position (B).

12) Turn ignition switch to OFF position, and then

disconnect connector from temperature control

actuator.

13) Measure resistance between terminal “1” and “2”.

Temperature control actuator resistance between

terminal “1” and “2” (MAX COOL position)

(Reference value)

Approx. 4.3 kΩ at 25 °C (77 °F)

If measure resistance is out of specification, replace the

actuator with new one.[A]: MAX HOT

[B]: MAX COOL

[C]: Actuator lever position

123456

6

M5

3

2

1

AB

4.53

0.48 5.00(V)

[C]

[A] [B]

I7RW01722017-03

123456

6

M5

3

2

1

A

I7RW01722020-02

123456

6

M5

3

2

1

B

I7RW01722021-02

Page 1023 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-83

Air Flow Control Actuator Removal and

Installation

S6RW0D7226006

Removal

1) Disconnect negative cable at battery.

2) Remove steering column hole cover from instrument

panel.

3) Remove driver side foot duct from HVAC unit.

4) Disconnect air flow control actuator connector (2).

5) Remove air flow control actuator (1) from HVAC unit

by removing screws (3).

Installation

Reverse removal procedure noting the following

instructions.

• Before installing actuator, make sure that position of

actuator lever is in between “BENT” position and

“DEF” position.

• Be sure to insert pin (1) of air flow control actuator into

the groove (2) of link.

Air Flow Control Actuator and Its Circuit

Inspection

S6RW0D7226007

1) Remove air flow control actuator from HVAC unit

referring to “Air Flow Control Actuator Removal and

Installation”.

2) Connect connector to air flow control actuator.

3) Set air flow selector to “BENT” position with ignition

switch turned ON.

4) Connect voltage meter between terminal “2” and

body ground.

5) Turn air flow selector to “DEF” position.

6) Measure output voltage variation while air flow

control actuator is operated from “BENT” position (A)

to “DEF” position (B) as following specification.

If measure voltage is out of specification or does not

vary linearly as the shown in graph, check related

wire circuit and HVAC control module. If wire circuits

and HVAC control module are OK, go to next step.

Air flow control actuator output voltage

0.48 – 4.53 V (linear variation as following graph)

13

2

I7RW01722022-01

1

2

I7RW01722023-02

[A]: BENT [D]: FOOT

[B]: DEF [E]: DEF / FOOT

[C]: BI-LEVEL [F]: Actuator lever position

123456

6

M5

3

2

1 A

B

(V)

4.53

3.35

2.60

1.78

0.48

[A][B]

[C] [D] [E][F]5.00

I7RW01722024-02

Page 1024 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-84 Air Conditioning System: Automatic Type

7) Set air flow selector of HVAC control module to

“DEF” position with ignition switch turned ON, and

make sure if the position of actuator lever is “DEF”

position (A).

8) Turn ignition switch to OFF position, and then

disconnect connector from air flow control actuator.

9) Measure resistance between terminal “1” and “2”.

Air flow control actuator resistance between

terminal “1” and “2” (DEF position) (Reference

value)

Approx. 0.45 kΩ at 25 °C (77 °F)

10) Connect connector to air flow control actuator.

11) Set air flow selector of HVAC control module to

“VENT” position with ignition switch turned ON, and

make sure if the position of actuator lever is “VENT”

position (B).

12) Turn ignition switch to OFF position, and then

disconnect connector from air flow control actuator.13) Measure resistance between terminal “1” and “2”.

Air flow control actuator resistance between

terminal “1” and “2” (VENT position) (Reference

value)

Approx. 4.3 kΩ at 25 °C (77 °F)

If measure resistance is out of specification, replace the

actuator with new one.

Air Intake Actuator Removal and InstallationS6RW0D7226008

Remove and install air intake actuator referring to “Air

Intake Control Actuator Removal and Installation in

Section 7A”.

Air Intake Actuator InspectionS6RW0D7226009

For inspection, refer to “Air Intake Control Actuator

Inspection in Section 7A”.

Actuator Linkage InspectionS6RW0D7226010

• Check if each actuator linkage operates smoothly.

• Check actuator rod for bend.

• Check each actuator linkage for breakage.

• Make sure if there is not any obstruction in operating

range of actuator linkage.

If any malfunction is found, repair or replace faulty

part(s).

Blower Motor Controller Removal and

Installation

S6RW0D7226011

Refer to “Blower Motor Resistor Removal and

Installation in Section 7A”.

123456

6

M5

3

2

1 A

I7RW01722025-01

123456

6

M5

3

2

1 B

I7RW01722026-01

Page 1025 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-85

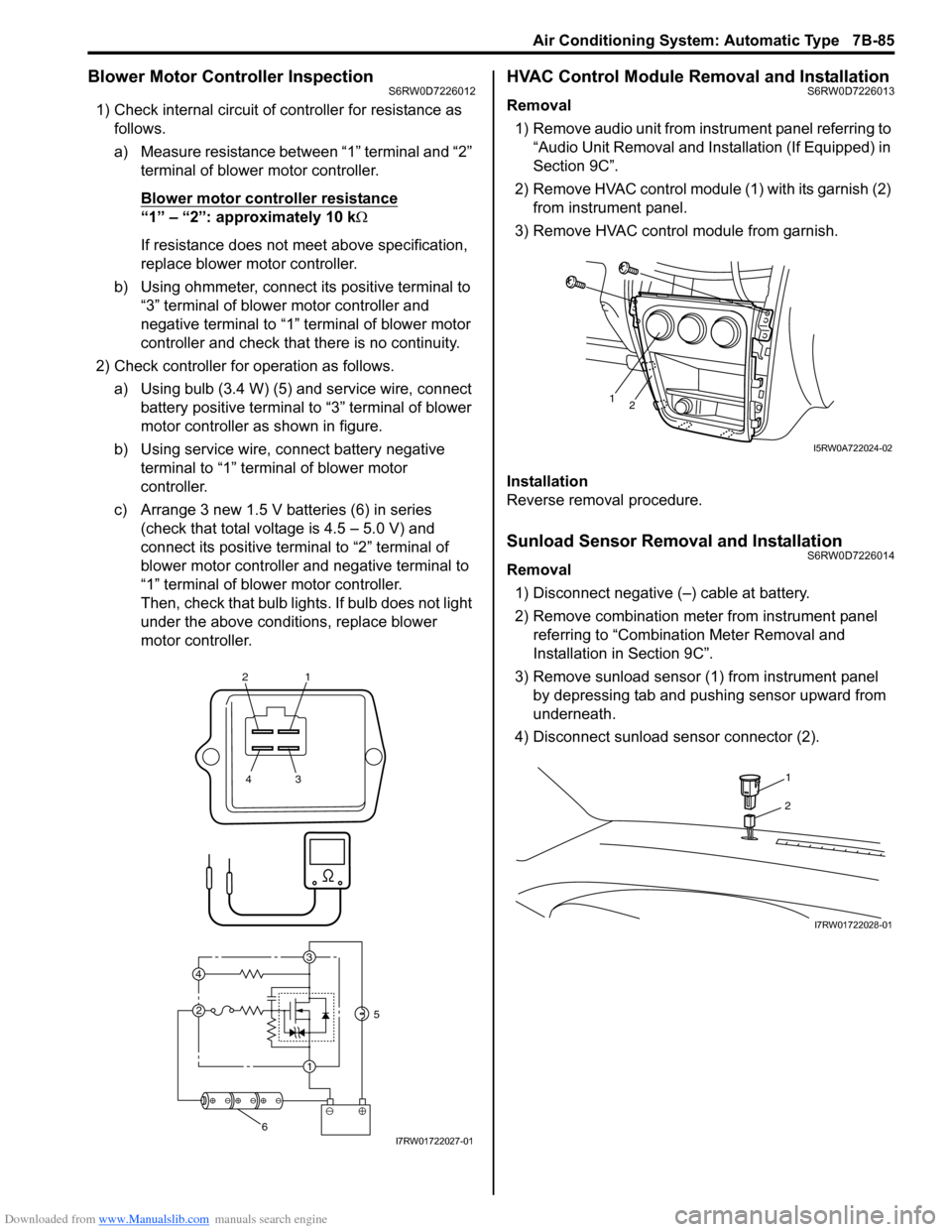

Blower Motor Controller InspectionS6RW0D7226012

1) Check internal circuit of controller for resistance as

follows.

a) Measure resistance between “1” terminal and “2”

terminal of blower motor controller.

Blower motor controller resistance

“1” – “2”: approximately 10 kΩ

If resistance does not meet above specification,

replace blower motor controller.

b) Using ohmmeter, connect its positive terminal to

“3” terminal of blower motor controller and

negative terminal to “1” terminal of blower motor

controller and check that there is no continuity.

2) Check controller for operation as follows.

a) Using bulb (3.4 W) (5) and service wire, connect

battery positive terminal to “3” terminal of blower

motor controller as shown in figure.

b) Using service wire, connect battery negative

terminal to “1” terminal of blower motor

controller.

c) Arrange 3 new 1.5 V batteries (6) in series

(check that total voltage is 4.5 – 5.0 V) and

connect its positive terminal to “2” terminal of

blower motor controller and negative terminal to

“1” terminal of blower motor controller.

Then, check that bulb lights. If bulb does not light

under the above conditions, replace blower

motor controller.

HVAC Control Module Removal and InstallationS6RW0D7226013

Removal

1) Remove audio unit from instrument panel referring to

“Audio Unit Removal and Installation (If Equipped) in

Section 9C”.

2) Remove HVAC control module (1) with its garnish (2)

from instrument panel.

3) Remove HVAC control module from garnish.

Installation

Reverse removal procedure.

Sunload Sensor Removal and InstallationS6RW0D7226014

Removal

1) Disconnect negative (–) cable at battery.

2) Remove combination meter from instrument panel

referring to “Combination Meter Removal and

Installation in Section 9C”.

3) Remove sunload sensor (1) from instrument panel

by depressing tab and pushing sensor upward from

underneath.

4) Disconnect sunload sensor connector (2).

21

43

3

1 2 4

5

6I7RW01722027-01

12

I5RW0A722024-02

1

2

I7RW01722028-01

Page 1026 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-86 Air Conditioning System: Automatic Type

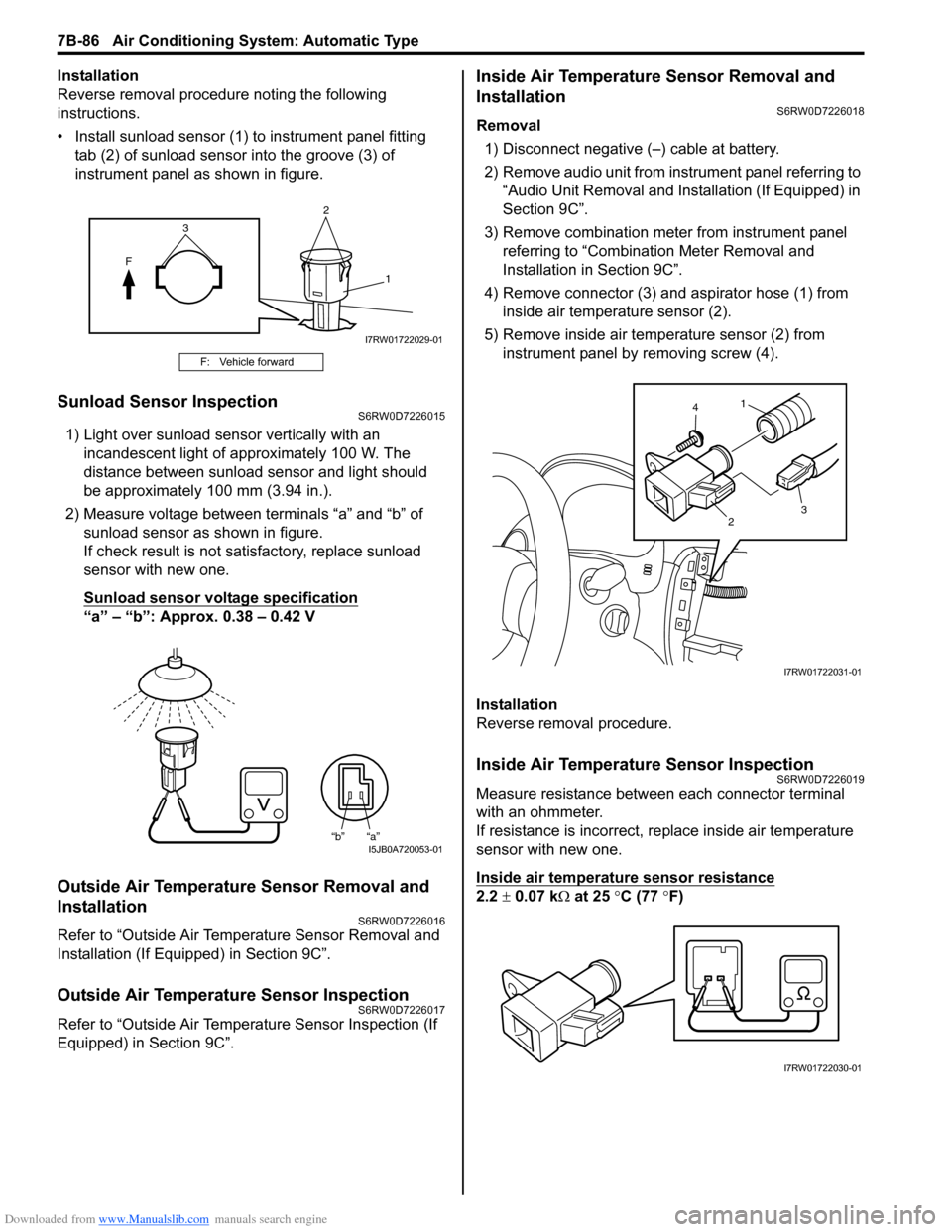

Installation

Reverse removal procedure noting the following

instructions.

• Install sunload sensor (1) to instrument panel fitting

tab (2) of sunload sensor into the groove (3) of

instrument panel as shown in figure.

Sunload Sensor InspectionS6RW0D7226015

1) Light over sunload sensor vertically with an

incandescent light of approximately 100 W. The

distance between sunload sensor and light should

be approximately 100 mm (3.94 in.).

2) Measure voltage between terminals “a” and “b” of

sunload sensor as shown in figure.

If check result is not satisfactory, replace sunload

sensor with new one.

Sunload sensor voltage specification

“a” – “b”: Approx. 0.38 – 0.42 V

Outside Air Temperature Sensor Removal and

Installation

S6RW0D7226016

Refer to “Outside Air Temperature Sensor Removal and

Installation (If Equipped) in Section 9C”.

Outside Air Temperature Sensor InspectionS6RW0D7226017

Refer to “Outside Air Temperature Sensor Inspection (If

Equipped) in Section 9C”.

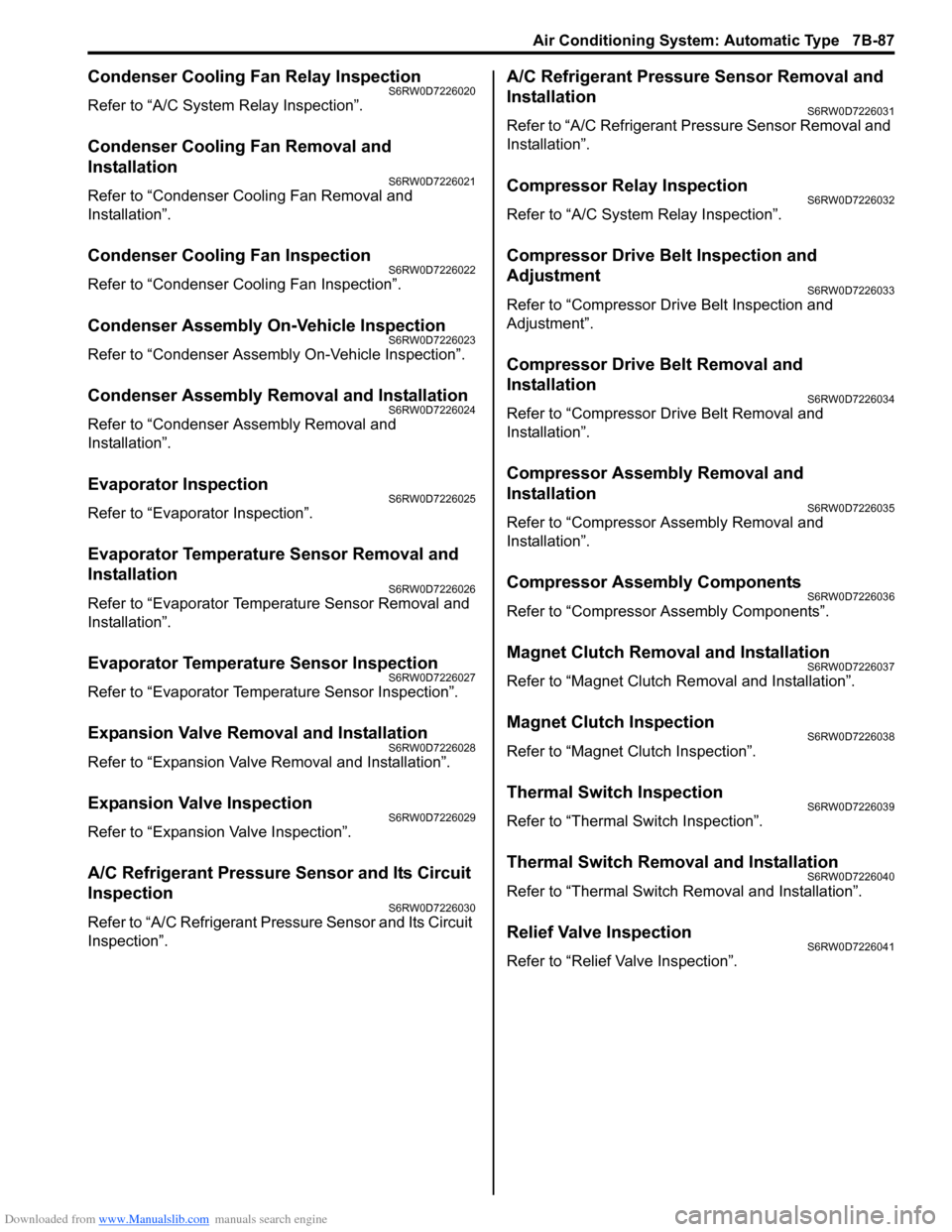

Inside Air Temperature Sensor Removal and

Installation

S6RW0D7226018

Removal

1) Disconnect negative (–) cable at battery.

2) Remove audio unit from instrument panel referring to

“Audio Unit Removal and Installation (If Equipped) in

Section 9C”.

3) Remove combination meter from instrument panel

referring to “Combination Meter Removal and

Installation in Section 9C”.

4) Remove connector (3) and aspirator hose (1) from

inside air temperature sensor (2).

5) Remove inside air temperature sensor (2) from

instrument panel by removing screw (4).

Installation

Reverse removal procedure.

Inside Air Temperature Sensor InspectionS6RW0D7226019

Measure resistance between each connector terminal

with an ohmmeter.

If resistance is incorrect, replace inside air temperature

sensor with new one.

Inside air temperature sensor resistance

2.2 ± 0.07 kΩ at 25 °C (77 °F)

F: Vehicle forward

2

F

1

3

I7RW01722029-01

“b” “a”I5JB0A720053-01

1

23 4

I7RW01722031-01

I7RW01722030-01

Page 1027 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-87

Condenser Cooling Fan Relay InspectionS6RW0D7226020

Refer to “A/C System Relay Inspection”.

Condenser Cooling Fan Removal and

Installation

S6RW0D7226021

Refer to “Condenser Cooling Fan Removal and

Installation”.

Condenser Cooling Fan InspectionS6RW0D7226022

Refer to “Condenser Cooling Fan Inspection”.

Condenser Assembly On-Vehicle InspectionS6RW0D7226023

Refer to “Condenser Assembly On-Vehicle Inspection”.

Condenser Assembly Removal and InstallationS6RW0D7226024

Refer to “Condenser Assembly Removal and

Installation”.

Evaporator InspectionS6RW0D7226025

Refer to “Evaporator Inspection”.

Evaporator Temperature Sensor Removal and

Installation

S6RW0D7226026

Refer to “Evaporator Temperature Sensor Removal and

Installation”.

Evaporator Temperature Sensor InspectionS6RW0D7226027

Refer to “Evaporator Temperature Sensor Inspection”.

Expansion Valve Removal and InstallationS6RW0D7226028

Refer to “Expansion Valve Removal and Installation”.

Expansion Valve InspectionS6RW0D7226029

Refer to “Expansion Valve Inspection”.

A/C Refrigerant Pressure Sensor and Its Circuit

Inspection

S6RW0D7226030

Refer to “A/C Refrigerant Pressure Sensor and Its Circuit

Inspection”.

A/C Refrigerant Pressure Sensor Removal and

Installation

S6RW0D7226031

Refer to “A/C Refrigerant Pressure Sensor Removal and

Installation”.

Compressor Relay InspectionS6RW0D7226032

Refer to “A/C System Relay Inspection”.

Compressor Drive Belt Inspection and

Adjustment

S6RW0D7226033

Refer to “Compressor Drive Belt Inspection and

Adjustment”.

Compressor Drive Belt Removal and

Installation

S6RW0D7226034

Refer to “Compressor Drive Belt Removal and

Installation”.

Compressor Assembly Removal and

Installation

S6RW0D7226035

Refer to “Compressor Assembly Removal and

Installation”.

Compressor Assembly ComponentsS6RW0D7226036

Refer to “Compressor Assembly Components”.

Magnet Clutch Removal and InstallationS6RW0D7226037

Refer to “Magnet Clutch Removal and Installation”.

Magnet Clutch InspectionS6RW0D7226038

Refer to “Magnet Clutch Inspection”.

Thermal Switch InspectionS6RW0D7226039

Refer to “Thermal Switch Inspection”.

Thermal Switch Removal and InstallationS6RW0D7226040

Refer to “Thermal Switch Removal and Installation”.

Relief Valve InspectionS6RW0D7226041

Refer to “Relief Valve Inspection”.