section 1l SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1388 of 1556

Downloaded from www.Manualslib.com manuals search engine 9E-3 Glass / Windows / Mirrors:

Diagnostic Information and Procedures

Rear End door Window Defogger Symptom DiagnosisS6RW0D9504001

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, refer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Power Window Control System Symptom DiagnosisS6RW0D9504002

Condition Possible cause Correction / Reference Item

Rear end door window

defogger does not

operateCircuit fuse blownReplace fuse and check for short circuit.

Rear end door window defogger switch

faultyCheck rear end door window defogger switch

referring to “Rear End Door Window Defogger

Switch Inspection”.

Rear end door window defogger relay

faultyCheck rear end door window defogger relay

referring to “Rear End Door Window Defogger

Relay Inspection”.

Defogger wire faultyCheck defogger wire referring to “Rear End

Door Window Defogger Wire Inspection”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Condition Possible cause Correction / Reference Item

All power windows do not

operateCircuit fuse blownReplace fuse and check for short circuit.

Power window main switch faultyCheck power window main switch referring to

“Power Window Main Switch Inspection”.

Ignition switch faultyCheck ignition switch referring to “Ignition

Switch Inspection in Section 9C”.

Wiring or grounding faultyRepair circuit.

Only one power window

does not operatePower window main switch faultyCheck power window main switch referring to

“Power Window Main Switch Inspection”.

Power window sub switch faultyCheck power window sub switch referring to

“Power Window Sub Switch Inspection”.

Wiring and/or coupler faultyCheck wiring and/or coupler.

Power window regulator faultyCheck window regulator.

Power window motor faultyCheck power window motor.

Wiring or grounding faultyRepair circuit.

Driver side door glass

fails to perform auto-up /

auto-down function

(Pinching Prevention

Function Model)Power window main switch faultyCheck power window main switch referring to

“Power Window Main Switch Inspection”.

Power window motor faultyCheck power window motor referring to “Pulse

Sensor and Its Circuit Inspection (Pinching

Prevention Function Model)”.

Wiring or grounding faultyRepair circuit.

Driver side door glass

fails to lower back even

when a foreign matter is

pinched (Pinching

Prevention Function

Model)Power window main switch has not been

initializedExecute the initial setting of power window

main switch referring to “Power Window Main

Switch Initialization (Pinching Prevention

Function Model)”.

Power window main switch faultyCheck power window main switch referring to

“Power Window Main Switch Inspection”.

Power window motor faultyCheck power window motor referring to “Pulse

Sensor and Its Circuit Inspection (Pinching

Prevention Function Model)”.

Page 1390 of 1556

Downloaded from www.Manualslib.com manuals search engine 9E-5 Glass / Windows / Mirrors:

Door Mirror Heater Symptom Diagnosis (If Equipped)S6RW0D9504004

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, refer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Repair Instructions

Windshield ComponentsS6RW0D9506001

Condition Possible cause Correction / Reference Item

All door mirror heaters

does not operateCircuit fuse blownReplace fuse and check for short circuit.

Rear end door window defogger switch

faultyCheck rear end door window defogger switch

referring to “Rear End Door Window Defogger

Switch Inspection”.

Rear end door window defogger relay

faultyCheck rear end door window defogger relay

referring to “Rear End Door Window Defogger

Relay Inspection”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Only one door mirror

heater does not operateDoor mirror heater faultyCheck door mirror heater refiring to “Door

Mirror Heater Inspection (If Equipped)”.

Wiring or grounding faultyRepair circuit.

3 31

2

44

4

I5RW0A950001-02

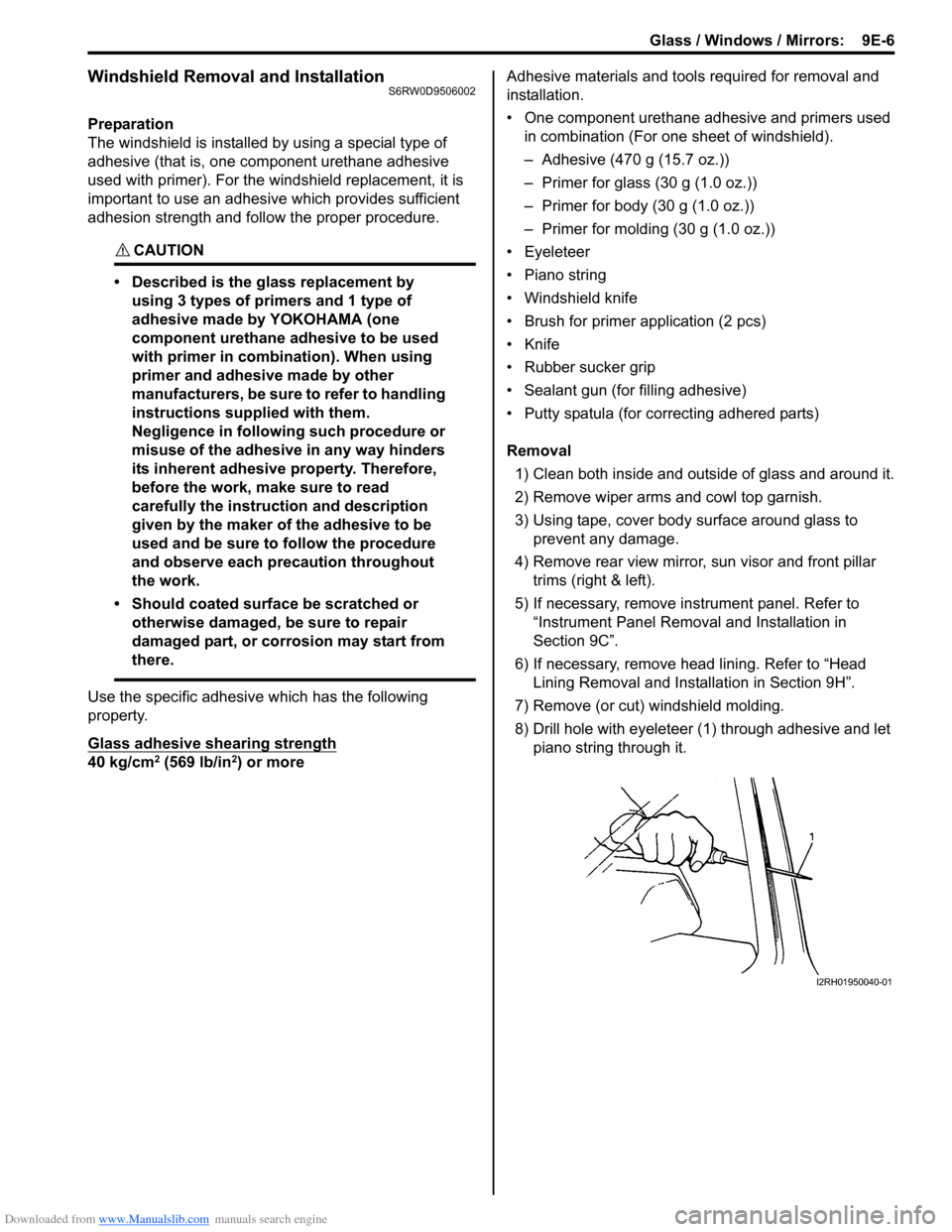

1. Windshield glass 3. Windshield glass stopper : Do not reuse.

2. Windshield molding 4. Spacer

Page 1391 of 1556

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-6

Windshield Removal and InstallationS6RW0D9506002

Preparation

The windshield is installed by using a special type of

adhesive (that is, one component urethane adhesive

used with primer). For the windshield replacement, it is

important to use an adhesive which provides sufficient

adhesion strength and follow the proper procedure.

CAUTION!

• Described is the glass replacement by

using 3 types of primers and 1 type of

adhesive made by YOKOHAMA (one

component urethane adhesive to be used

with primer in combination). When using

primer and adhesive made by other

manufacturers, be sure to refer to handling

instructions supplied with them.

Negligence in following such procedure or

misuse of the adhesive in any way hinders

its inherent adhesive property. Therefore,

before the work, make sure to read

carefully the instruction and description

given by the maker of the adhesive to be

used and be sure to follow the procedure

and observe each precaution throughout

the work.

• Should coated surface be scratched or

otherwise damaged, be sure to repair

damaged part, or corrosion may start from

there.

Use the specific adhesive which has the following

property.

Glass adhesive shearing strength

40 kg/cm2 (569 lb/in2) or moreAdhesive materials and tools required for removal and

installation.

• One component urethane adhesive and primers used

in combination (For one sheet of windshield).

– Adhesive (470 g (15.7 oz.))

– Primer for glass (30 g (1.0 oz.))

– Primer for body (30 g (1.0 oz.))

– Primer for molding (30 g (1.0 oz.))

• Eyeleteer

•Piano string

• Windshield knife

• Brush for primer application (2 pcs)

•Knife

• Rubber sucker grip

• Sealant gun (for filling adhesive)

• Putty spatula (for correcting adhered parts)

Removal

1) Clean both inside and outside of glass and around it.

2) Remove wiper arms and cowl top garnish.

3) Using tape, cover body surface around glass to

prevent any damage.

4) Remove rear view mirror, sun visor and front pillar

trims (right & left).

5) If necessary, remove instrument panel. Refer to

“Instrument Panel Removal and Installation in

Section 9C”.

6) If necessary, remove head lining. Refer to “Head

Lining Removal and Installation in Section 9H”.

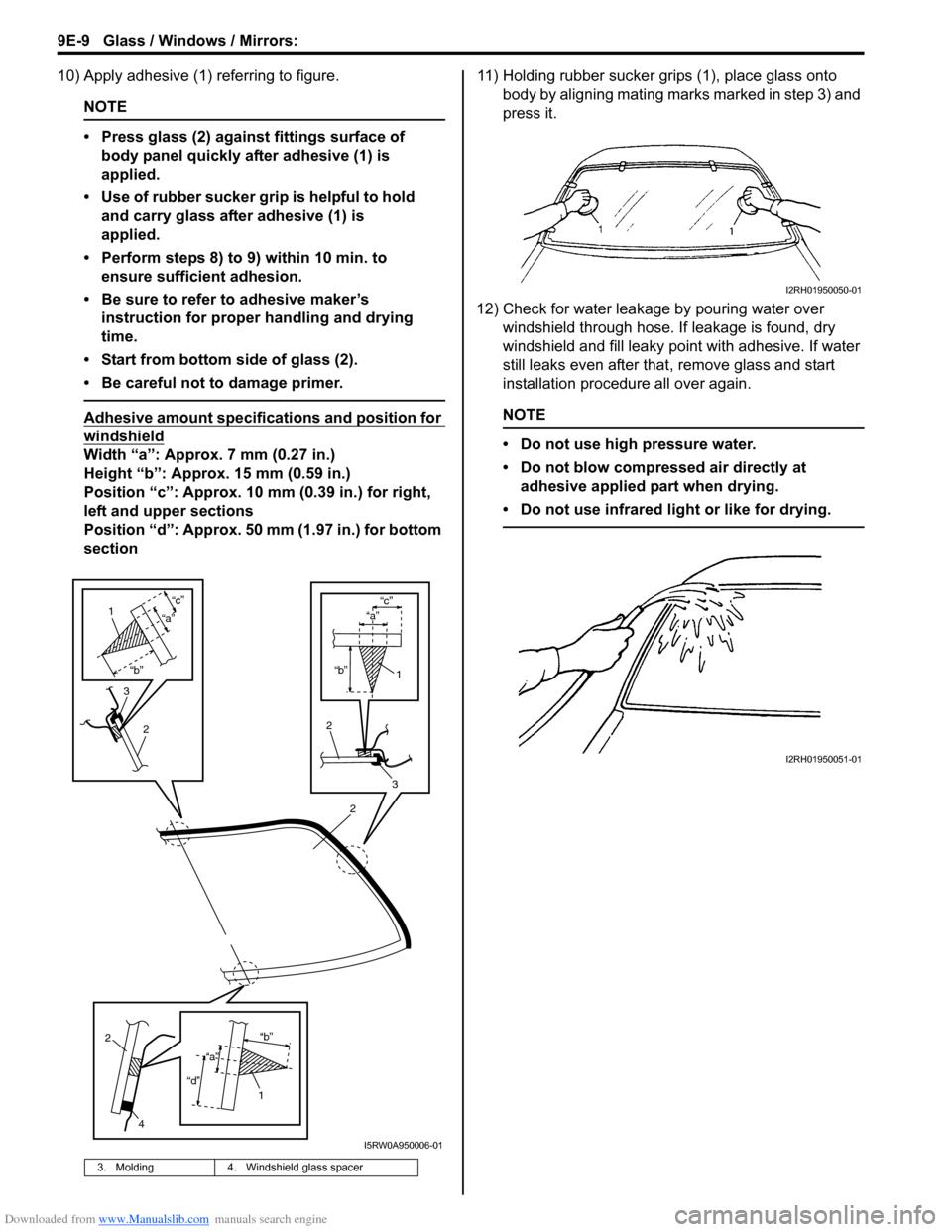

7) Remove (or cut) windshield molding.

8) Drill hole with eyeleteer (1) through adhesive and let

piano string through it.

I2RH01950040-01

Page 1394 of 1556

Downloaded from www.Manualslib.com manuals search engine 9E-9 Glass / Windows / Mirrors:

10) Apply adhesive (1) referring to figure.

NOTE

• Press glass (2) against fittings surface of

body panel quickly after adhesive (1) is

applied.

• Use of rubber sucker grip is helpful to hold

and carry glass after adhesive (1) is

applied.

• Perform steps 8) to 9) within 10 min. to

ensure sufficient adhesion.

• Be sure to refer to adhesive maker’s

instruction for proper handling and drying

time.

• Start from bottom side of glass (2).

• Be careful not to damage primer.

Adhesive amount specifications and position for

windshield

Width “a”: Approx. 7 mm (0.27 in.)

Height “b”: Approx. 15 mm (0.59 in.)

Position “c”: Approx. 10 mm (0.39 in.) for right,

left and upper sections

Position “d”: Approx. 50 mm (1.97 in.) for bottom

section11) Holding rubber sucker grips (1), place glass onto

body by aligning mating marks marked in step 3) and

press it.

12) Check for water leakage by pouring water over

windshield through hose. If leakage is found, dry

windshield and fill leaky point with adhesive. If water

still leaks even after that, remove glass and start

installation procedure all over again.

NOTE

• Do not use high pressure water.

• Do not blow compressed air directly at

adhesive applied part when drying.

• Do not use infrared light or like for drying.

3. Molding 4. Windshield glass spacer

2

“b”

“c”

2

3

1

“a”

3

2

1

“b”

“c”

“a”

2

4

1“b”

“d”

“a”

I5RW0A950006-01

I2RH01950050-01

I2RH01950051-01

Page 1403 of 1556

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-18

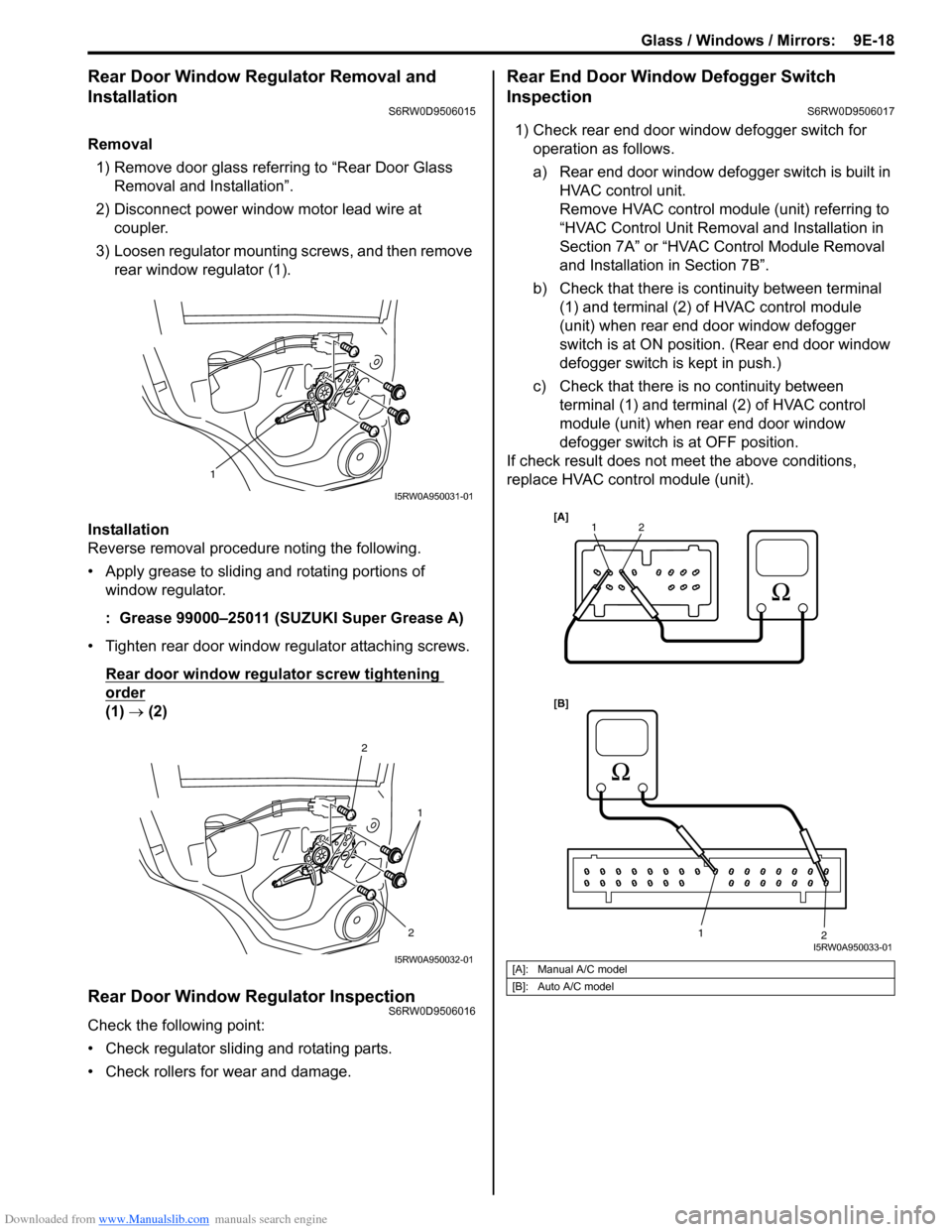

Rear Door Window Regulator Removal and

Installation

S6RW0D9506015

Removal

1) Remove door glass referring to “Rear Door Glass

Removal and Installation”.

2) Disconnect power window motor lead wire at

coupler.

3) Loosen regulator mounting screws, and then remove

rear window regulator (1).

Installation

Reverse removal procedure noting the following.

• Apply grease to sliding and rotating portions of

window regulator.

: Grease 99000–25011 (SUZUKI Super Grease A)

• Tighten rear door window regulator attaching screws.

Rear door window regulator screw tightening

order

(1) → (2)

Rear Door Window Regulator InspectionS6RW0D9506016

Check the following point:

• Check regulator sliding and rotating parts.

• Check rollers for wear and damage.

Rear End Door Window Defogger Switch

Inspection

S6RW0D9506017

1) Check rear end door window defogger switch for

operation as follows.

a) Rear end door window defogger switch is built in

HVAC control unit.

Remove HVAC control module (unit) referring to

“HVAC Control Unit Removal and Installation in

Section 7A” or “HVAC Control Module Removal

and Installation in Section 7B”.

b) Check that there is continuity between terminal

(1) and terminal (2) of HVAC control module

(unit) when rear end door window defogger

switch is at ON position. (Rear end door window

defogger switch is kept in push.)

c) Check that there is no continuity between

terminal (1) and terminal (2) of HVAC control

module (unit) when rear end door window

defogger switch is at OFF position.

If check result does not meet the above conditions,

replace HVAC control module (unit).

1

I5RW0A950031-01

2

2

1

I5RW0A950032-01[A]: Manual A/C model

[B]: Auto A/C model

1

1 2

2[A]

[B]

I5RW0A950033-01

Page 1414 of 1556

Downloaded from www.Manualslib.com manuals search engine 9F-3 Security and Locks:

Diagnostic Information and Procedures

Power Door Lock System Symptom Diagnosis (If Equipped)S6RW0D9604001

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, refer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Power Door Lock System Operation Inspection (If Equipped)S6RW0D9604002

1) Check the following operation:

a) Turn the driver side key cylinder is turned LOCK once, check all doors lock.

b) Turn the driver side door key cylinder is turned UNLOCK position with door key twice, check all doors unlock.

c) With all doors unlocked, insert key in key cylinder of driver side door and turn it to lock side, turn it again to lock

side within 3 seconds and check that no door can be opened even when door lock knob is moved to unlock

side (dead lock function, if equipped).

If malfunction is found, go to “Power Door Lock System Symptom Diagnosis (If Equipped)”. Condition Possible cause Correction / Reference Item

All door can not be locked

/ unlocked by all of

switchesCircuit fuse blownReplace fuse and check for short circuit.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

All door can not be locked

/ unlocked by only power

door lock switchCircuit fuse blownReplace fuse and check for short circuit.

Power door lock switch faultyCheck power door lock switch referring to

“Power Door Lock Switch Inspection (If

Equipped)”.

Wiring harness connected to power door

lock switch faultyRepair.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

All door can not be locked

/ unlocked by only key

cylinder switchCircuit fuse blownReplace fuse and check for short circuit.

Key cylinder switch faultyCheck key cylinder switch referring to “Door

Key Cylinder Switch Inspection (If Equipped)”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Only one door can not be

locked / unlockedPower door lock actuator faultyCheck actuator referring to “Power Door Lock

Actuator Inspection (If Equipped)”.

Wiring harness connected to applicable

door lock actuator faultyRepair.

BCM faultyReplace after making sure that none of above

parts is faulty.

Page 1415 of 1556

Downloaded from www.Manualslib.com manuals search engine Security and Locks: 9F-4

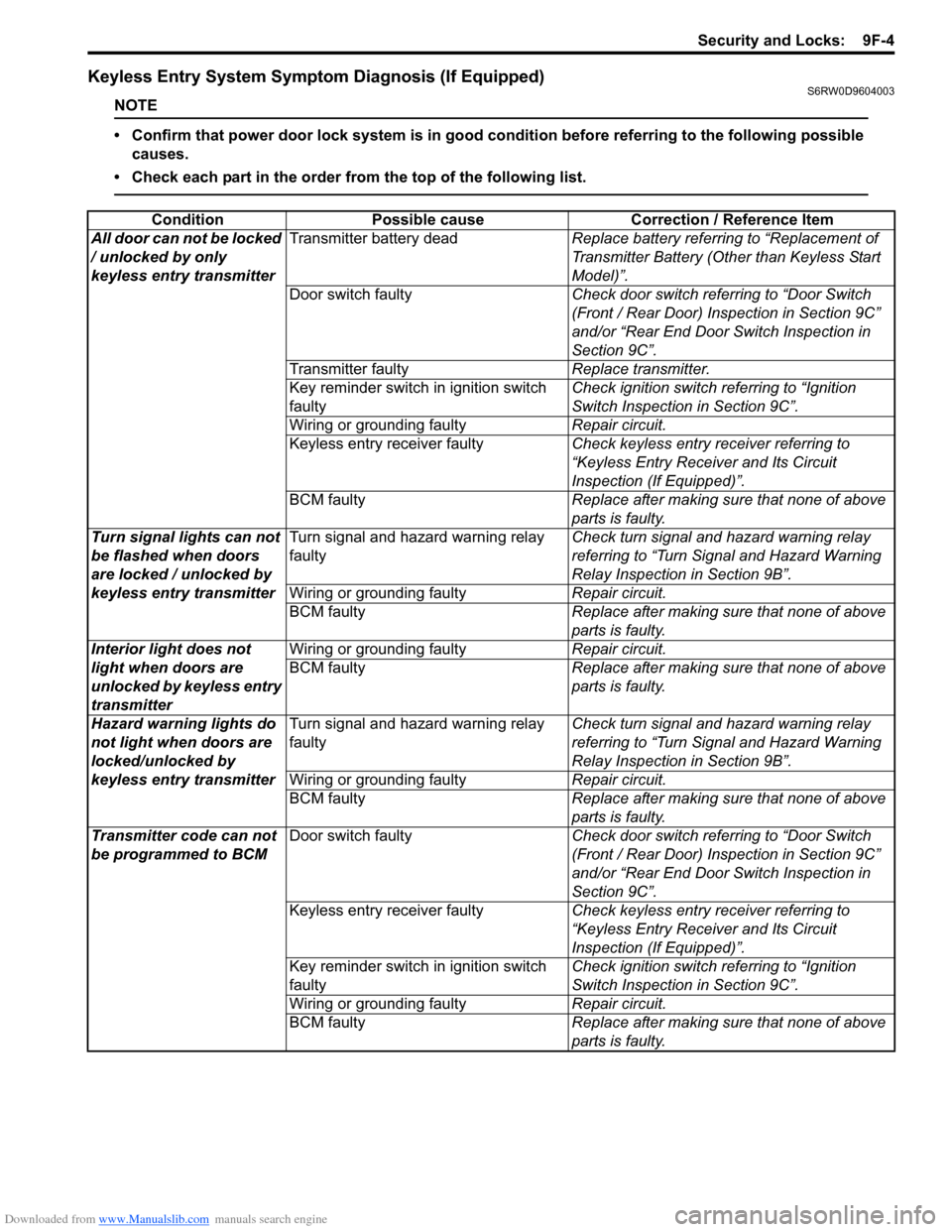

Keyless Entry System Symptom Diagnosis (If Equipped)S6RW0D9604003

NOTE

• Confirm that power door lock system is in good condition before referring to the following possible

causes.

• Check each part in the order from the top of the following list.

Condition Possible cause Correction / Reference Item

All door can not be locked

/ unlocked by only

keyless entry transmitterTransmitter battery deadReplace battery referring to “Replacement of

Transmitter Battery (Other than Keyless Start

Model)”.

Door switch faultyCheck door switch referring to “Door Switch

(Front / Rear Door) Inspection in Section 9C”

and/or “Rear End Door Switch Inspection in

Section 9C”.

Transmitter faultyReplace transmitter.

Key reminder switch in ignition switch

faultyCheck ignition switch referring to “Ignition

Switch Inspection in Section 9C”.

Wiring or grounding faultyRepair circuit.

Keyless entry receiver faultyCheck keyless entry receiver referring to

“Keyless Entry Receiver and Its Circuit

Inspection (If Equipped)”.

BCM faultyReplace after making sure that none of above

parts is faulty.

Turn signal lights can not

be flashed when doors

are locked / unlocked by

keyless entry transmitterTurn signal and hazard warning relay

faultyCheck turn signal and hazard warning relay

referring to “Turn Signal and Hazard Warning

Relay Inspection in Section 9B”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Interior light does not

light when doors are

unlocked by keyless entry

transmitterWiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Hazard warning lights do

not light when doors are

locked/unlocked by

keyless entry transmitterTurn signal and hazard warning relay

faultyCheck turn signal and hazard warning relay

referring to “Turn Signal and Hazard Warning

Relay Inspection in Section 9B”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Transmitter code can not

be programmed to BCMDoor switch faultyCheck door switch referring to “Door Switch

(Front / Rear Door) Inspection in Section 9C”

and/or “Rear End Door Switch Inspection in

Section 9C”.

Keyless entry receiver faultyCheck keyless entry receiver referring to

“Keyless Entry Receiver and Its Circuit

Inspection (If Equipped)”.

Key reminder switch in ignition switch

faultyCheck ignition switch referring to “Ignition

Switch Inspection in Section 9C”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Page 1416 of 1556

Downloaded from www.Manualslib.com manuals search engine 9F-5 Security and Locks:

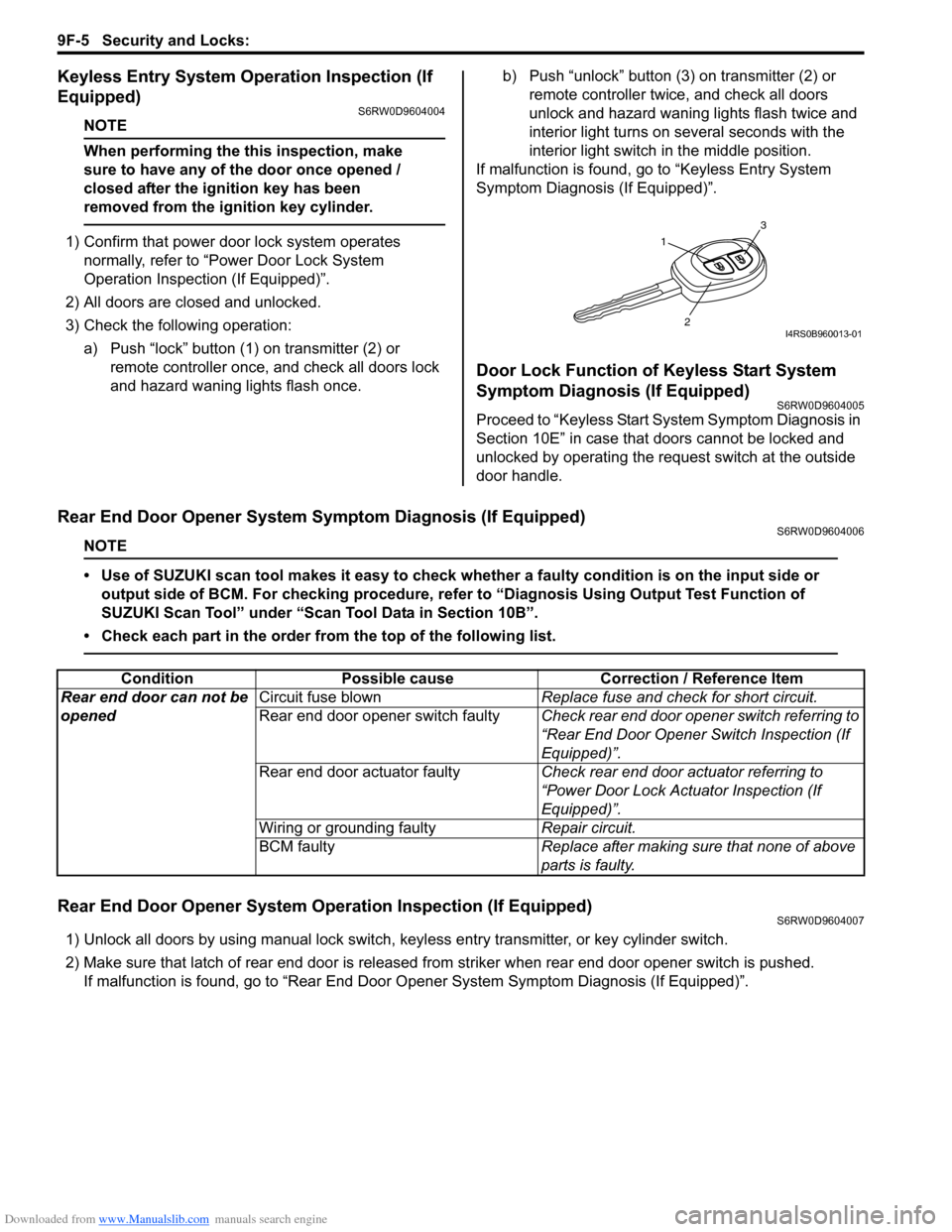

Keyless Entry System Operation Inspection (If

Equipped)

S6RW0D9604004

NOTE

When performing the this inspection, make

sure to have any of the door once opened /

closed after the ignition key has been

removed from the ignition key cylinder.

1) Confirm that power door lock system operates

normally, refer to “Power Door Lock System

Operation Inspection (If Equipped)”.

2) All doors are closed and unlocked.

3) Check the following operation:

a) Push “lock” button (1) on transmitter (2) or

remote controller once, and check all doors lock

and hazard waning lights flash once.b) Push “unlock” button (3) on transmitter (2) or

remote controller twice, and check all doors

unlock and hazard waning lights flash twice and

interior light turns on several seconds with the

interior light switch in the middle position.

If malfunction is found, go to “Keyless Entry System

Symptom Diagnosis (If Equipped)”.

Door Lock Function of Keyless Start System

Symptom Diagnosis (If Equipped)

S6RW0D9604005

Proceed to “Keyless Start System Symptom Diagnosis in

Section 10E” in case that doors cannot be locked and

unlocked by operating the request switch at the outside

door handle.

Rear End Door Opener System Symptom Diagnosis (If Equipped)S6RW0D9604006

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, refer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Rear End Door Opener System Operation Inspection (If Equipped)S6RW0D9604007

1) Unlock all doors by using manual lock switch, keyless entry transmitter, or key cylinder switch.

2) Make sure that latch of rear end door is released from striker when rear end door opener switch is pushed.

If malfunction is found, go to “Rear End Door Opener System Symptom Diagnosis (If Equipped)”.

1

3

2I4RS0B960013-01

Condition Possible cause Correction / Reference Item

Rear end door can not be

openedCircuit fuse blownReplace fuse and check for short circuit.

Rear end door opener switch faultyCheck rear end door opener switch referring to

“Rear End Door Opener Switch Inspection (If

Equipped)”.

Rear end door actuator faultyCheck rear end door actuator referring to

“Power Door Lock Actuator Inspection (If

Equipped)”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Page 1417 of 1556

Downloaded from www.Manualslib.com manuals search engine Security and Locks: 9F-6

Repair Instructions

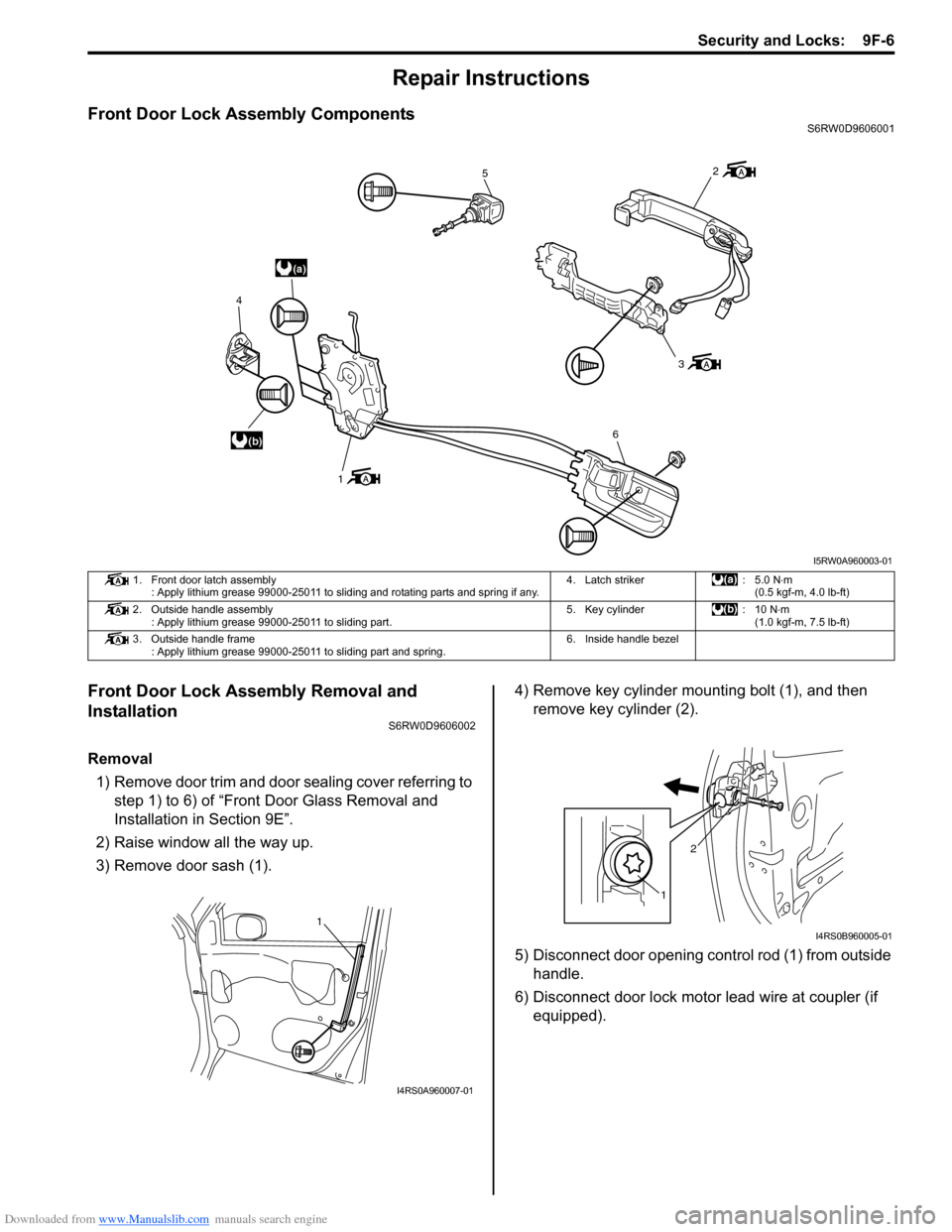

Front Door Lock Assembly ComponentsS6RW0D9606001

Front Door Lock Assembly Removal and

Installation

S6RW0D9606002

Removal

1) Remove door trim and door sealing cover referring to

step 1) to 6) of “Front Door Glass Removal and

Installation in Section 9E”.

2) Raise window all the way up.

3) Remove door sash (1).4) Remove key cylinder mounting bolt (1), and then

remove key cylinder (2).

5) Disconnect door opening control rod (1) from outside

handle.

6) Disconnect door lock motor lead wire at coupler (if

equipped).

(a)

(b)

5

3

6

1 4

2

I5RW0A960003-01

1. Front door latch assembly

: Apply lithium grease 99000-25011 to sliding and rotating parts and spring if any.4. Latch striker : 5.0 N⋅m

(0.5 kgf-m, 4.0 lb-ft)

2. Outside handle assembly

: Apply lithium grease 99000-25011 to sliding part.5. Key cylinder : 10 N⋅m

(1.0 kgf-m, 7.5 lb-ft)

3. Outside handle frame

: Apply lithium grease 99000-25011 to sliding part and spring.6. Inside handle bezel

1

I4RS0A960007-01

12

I4RS0B960005-01

Page 1418 of 1556

Downloaded from www.Manualslib.com manuals search engine 9F-7 Security and Locks:

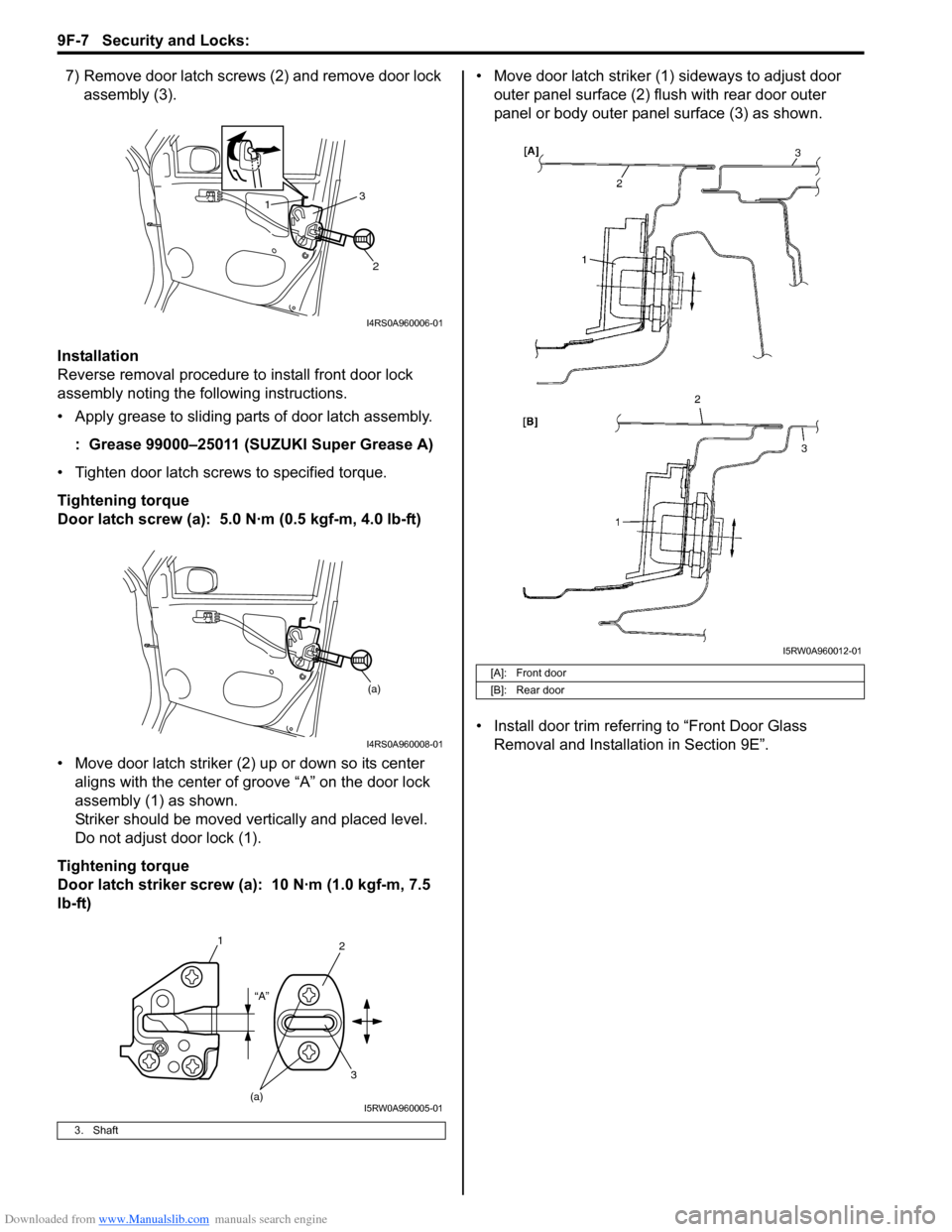

7) Remove door latch screws (2) and remove door lock

assembly (3).

Installation

Reverse removal procedure to install front door lock

assembly noting the following instructions.

• Apply grease to sliding parts of door latch assembly.

: Grease 99000–25011 (SUZUKI Super Grease A)

• Tighten door latch screws to specified torque.

Tightening torque

Door latch screw (a): 5.0 N·m (0.5 kgf-m, 4.0 lb-ft)

• Move door latch striker (2) up or down so its center

aligns with the center of groove “A” on the door lock

assembly (1) as shown.

Striker should be moved vertically and placed level.

Do not adjust door lock (1).

Tightening torque

Door latch striker screw (a): 10 N·m (1.0 kgf-m, 7.5

lb-ft)• Move door latch striker (1) sideways to adjust door

outer panel surface (2) flush with rear door outer

panel or body outer panel surface (3) as shown.

• Install door trim referring to “Front Door Glass

Removal and Installation in Section 9E”.

3. Shaft

1

2 3

I4RS0A960006-01

(a)

I4RS0A960008-01

1

2

3

(a)“A”

I5RW0A960005-01

[A]: Front door

[B]: Rear door

I5RW0A960012-01