horn SUZUKI SX4 2006 1.G Service Service Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1366 of 1556

Downloaded from www.Manualslib.com manuals search engine 9C-14 Instrumentation / Driver Info. / Horn:

Repair Instructions

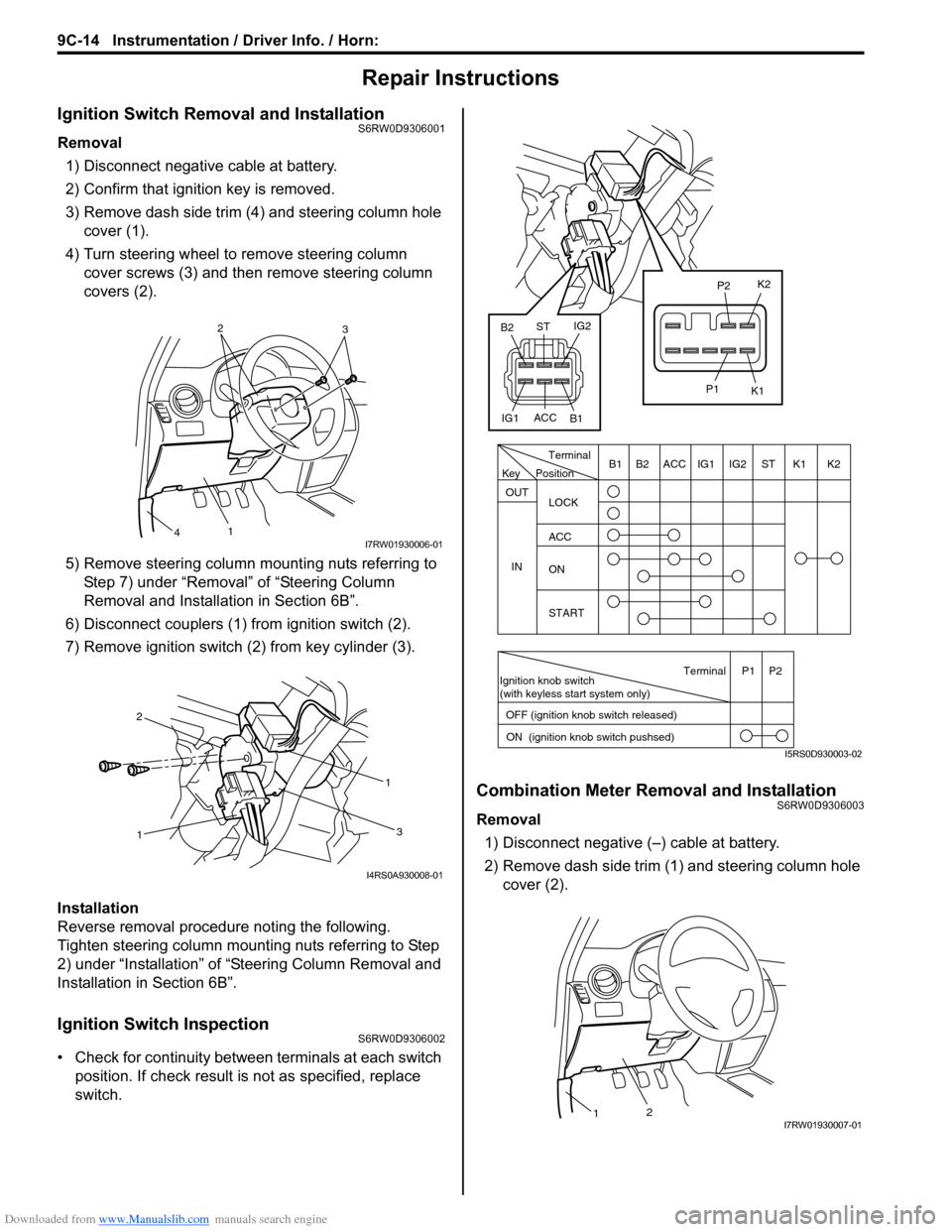

Ignition Switch Removal and InstallationS6RW0D9306001

Removal

1) Disconnect negative cable at battery.

2) Confirm that ignition key is removed.

3) Remove dash side trim (4) and steering column hole

cover (1).

4) Turn steering wheel to remove steering column

cover screws (3) and then remove steering column

covers (2).

5) Remove steering column mounting nuts referring to

Step 7) under “Removal” of “Steering Column

Removal and Installation in Section 6B”.

6) Disconnect couplers (1) from ignition switch (2).

7) Remove ignition switch (2) from key cylinder (3).

Installation

Reverse removal procedure noting the following.

Tighten steering column mounting nuts referring to Step

2) under “Installation” of “Steering Column Removal and

Installation in Section 6B”.

Ignition Switch InspectionS6RW0D9306002

• Check for continuity between terminals at each switch

position. If check result is not as specified, replace

switch.

Combination Meter Removal and InstallationS6RW0D9306003

Removal

1) Disconnect negative (–) cable at battery.

2) Remove dash side trim (1) and steering column hole

cover (2).

2

3

1

4I7RW01930006-01

11

2

3

I4RS0A930008-01

PositionTerminal

LOCK

ACC

ON

START OUT

INK2 K1 ST IG2 IG1 ACC B1 B2

Ignition knob switch

(with keyless start system only)

ACC

IG1IG2

ST

B2

B1K2

K1

P2

P1

Terminal

OFF (ignition knob switch released)

ON (ignition knob switch pushsed)P1 P2

Key

I5RS0D930003-02

21I7RW01930007-01

Page 1367 of 1556

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-15

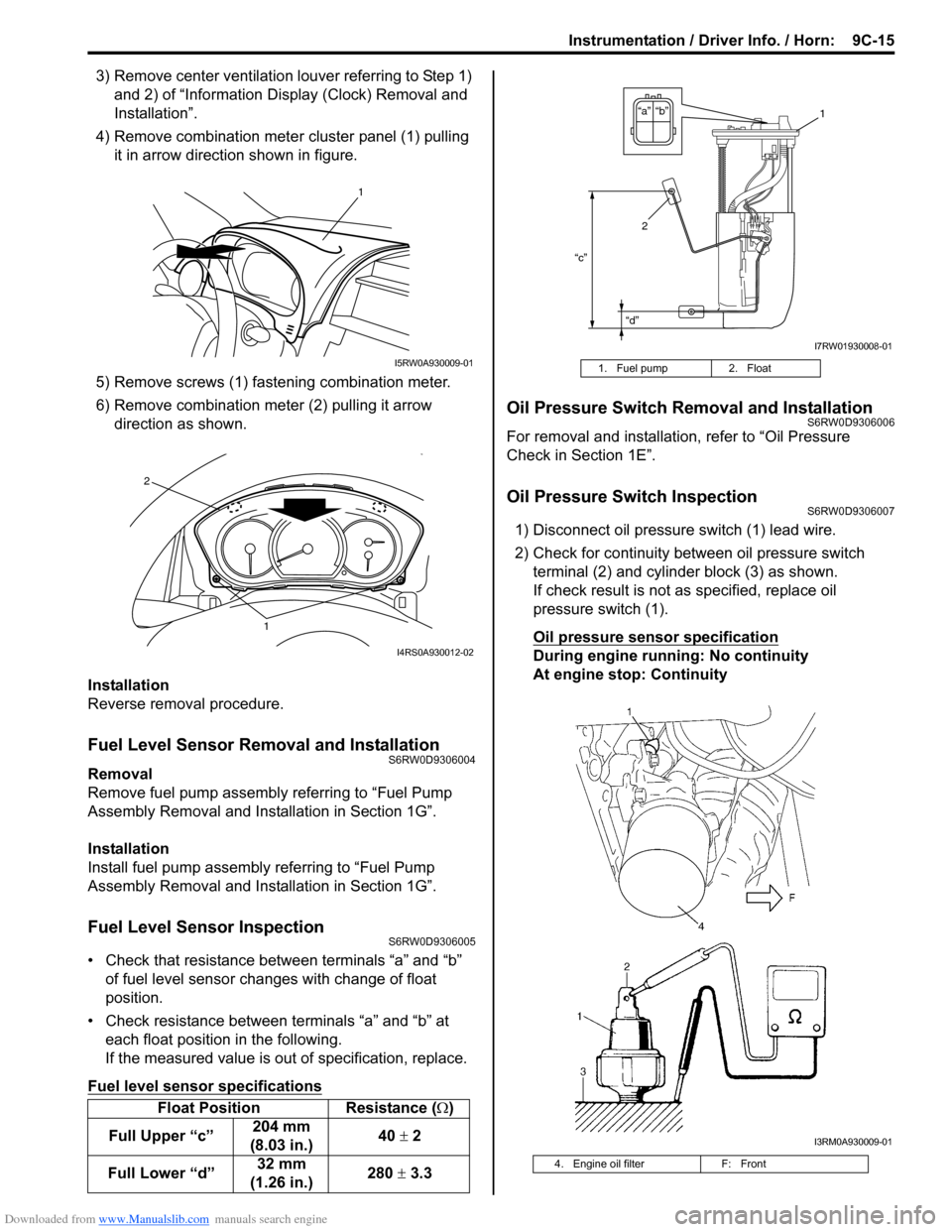

3) Remove center ventilation louver referring to Step 1)

and 2) of “Information Display (Clock) Removal and

Installation”.

4) Remove combination meter cluster panel (1) pulling

it in arrow direction shown in figure.

5) Remove screws (1) fastening combination meter.

6) Remove combination meter (2) pulling it arrow

direction as shown.

Installation

Reverse removal procedure.

Fuel Level Sensor Removal and InstallationS6RW0D9306004

Removal

Remove fuel pump assembly referring to “Fuel Pump

Assembly Removal and Installation in Section 1G”.

Installation

Install fuel pump assembly referring to “Fuel Pump

Assembly Removal and Installation in Section 1G”.

Fuel Level Sensor InspectionS6RW0D9306005

• Check that resistance between terminals “a” and “b”

of fuel level sensor changes with change of float

position.

• Check resistance between terminals “a” and “b” at

each float position in the following.

If the measured value is out of specification, replace.

Fuel level sensor specifications

Oil Pressure Switch Removal and InstallationS6RW0D9306006

For removal and installation, refer to “Oil Pressure

Check in Section 1E”.

Oil Pressure Switch InspectionS6RW0D9306007

1) Disconnect oil pressure switch (1) lead wire.

2) Check for continuity between oil pressure switch

terminal (2) and cylinder block (3) as shown.

If check result is not as specified, replace oil

pressure switch (1).

Oil pressure sensor specification

During engine running: No continuity

At engine stop: Continuity

Float Position Resistance (Ω)

Full Upper “c”204 mm

(8.03 in.)40 ± 2

Full Lower “d”32 mm

(1.26 in.)280 ± 3.3

1

I5RW0A930009-01

1

2

I4RS0A930012-02

1. Fuel pump 2. Float

4. Engine oil filter F: Front

“c”

“d”

“b” “a”1

2

I7RW01930008-01

I3RM0A930009-01

Page 1368 of 1556

Downloaded from www.Manualslib.com manuals search engine 9C-16 Instrumentation / Driver Info. / Horn:

Engine Coolant Temperature (ECT) Sensor

Inspection

S6RW0D9306008

Check engine coolant temperature sensor for resistance,

refer to “Engine Coolant Temperature (ECT) Sensor

Inspection in Section 1C”.

Brake Fluid Level Switch InspectionS6RW0D9306009

Check for continuity between terminals of brake fluid

level switch coupler (1). If found defective, replace

switch.

Brake fluid level switch specification

OFF position (float up): No continuity

ON position (float down): Continuity

Parking Brake Switch InspectionS6RW0D9306010

Check for continuity between parking brake switch

terminal and body ground as shown in figure. If found

defective, replace switch.

Parking brake switch specification

OFF position (parking brake released): No continuity

ON position (parking brake lever pulled up):

Continuity

Door Switch (Front / Rear Door) InspectionS6RW0D9306011

Remove door switch from body and check switch for

continuity. If found defective, replace switch.

Door switch (front / rear door) specification

OFF position (Door closed): No continuity

ON position (Door open): Continuity

Rear End Door Switch InspectionS6RW0D9306012

Check for continuity between terminal “a” and “b” shown

in the following.

If check result is not as specified, replace switch.

Rear end door switch specification

Rear end door closed: No continuity

Rear end door opened: Continuity

1. Parking brake switch 2. Parking brake lever

1

I5RW0A930011-01

12

I4RS0A930014-01

I3RH0A930004-01

a

b

I4RS0A930015-01

Page 1369 of 1556

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-17

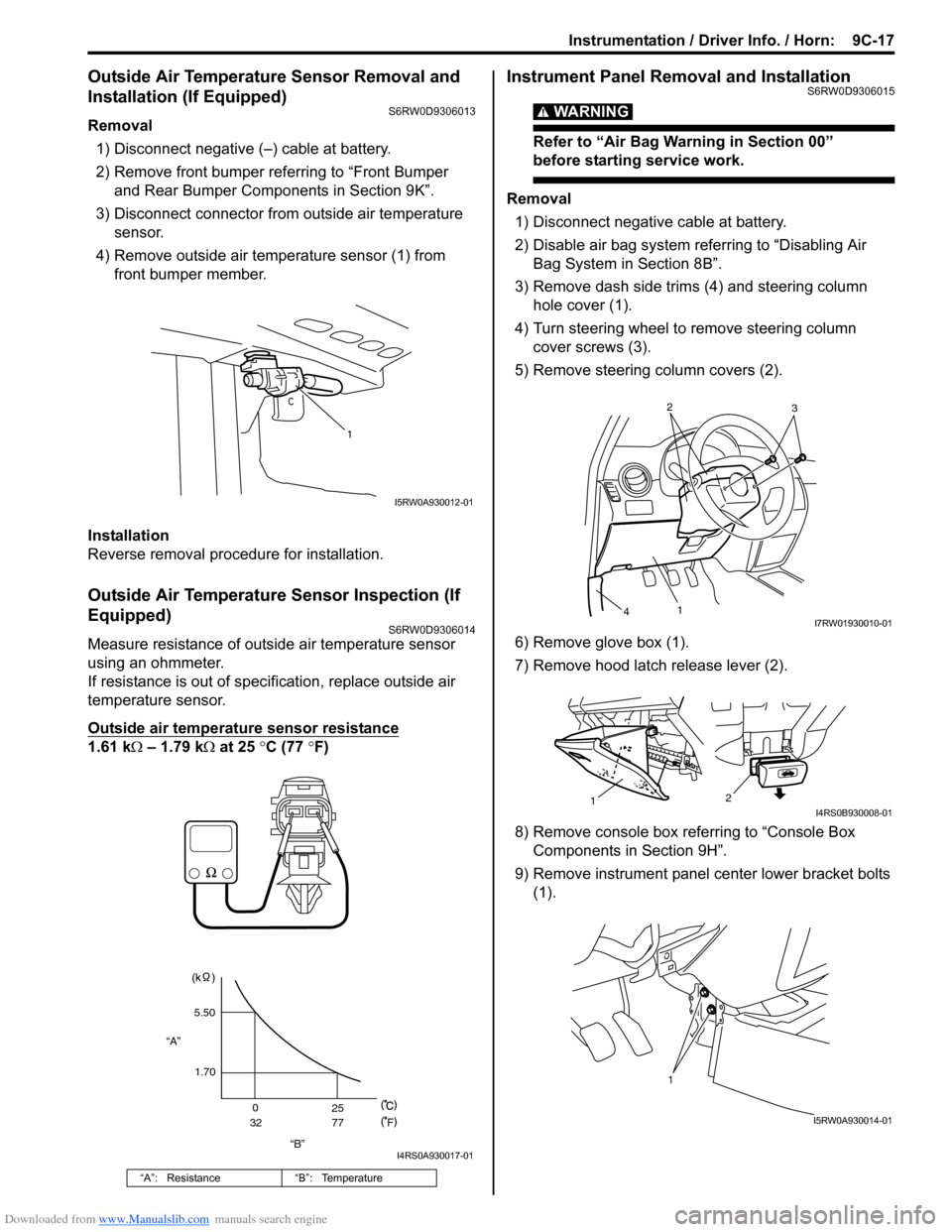

Outside Air Temperature Sensor Removal and

Installation (If Equipped)

S6RW0D9306013

Removal

1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper

and Rear Bumper Components in Section 9K”.

3) Disconnect connector from outside air temperature

sensor.

4) Remove outside air temperature sensor (1) from

front bumper member.

Installation

Reverse removal procedure for installation.

Outside Air Temperature Sensor Inspection (If

Equipped)

S6RW0D9306014

Measure resistance of outside air temperature sensor

using an ohmmeter.

If resistance is out of specification, replace outside air

temperature sensor.

Outside air temperature sensor resistance

1.61 kΩ – 1.79 kΩ at 25 °C (77 °F)

Instrument Panel Removal and InstallationS6RW0D9306015

WARNING!

Refer to “Air Bag Warning in Section 00”

before starting service work.

Removal

1) Disconnect negative cable at battery.

2) Disable air bag system referring to “Disabling Air

Bag System in Section 8B”.

3) Remove dash side trims (4) and steering column

hole cover (1).

4) Turn steering wheel to remove steering column

cover screws (3).

5) Remove steering column covers (2).

6) Remove glove box (1).

7) Remove hood latch release lever (2).

8) Remove console box referring to “Console Box

Components in Section 9H”.

9) Remove instrument panel center lower bracket bolts

(1).

“A”: Resistance “B”: Temperature

1

I5RW0A930012-01

“B” “A”5.50

1.70

0

3225

77

F

I4RS0A930017-01

2

3

1

4I7RW01930010-01

2

1I4RS0B930008-01

1

I5RW0A930014-01

Page 1370 of 1556

Downloaded from www.Manualslib.com manuals search engine 9C-18 Instrumentation / Driver Info. / Horn:

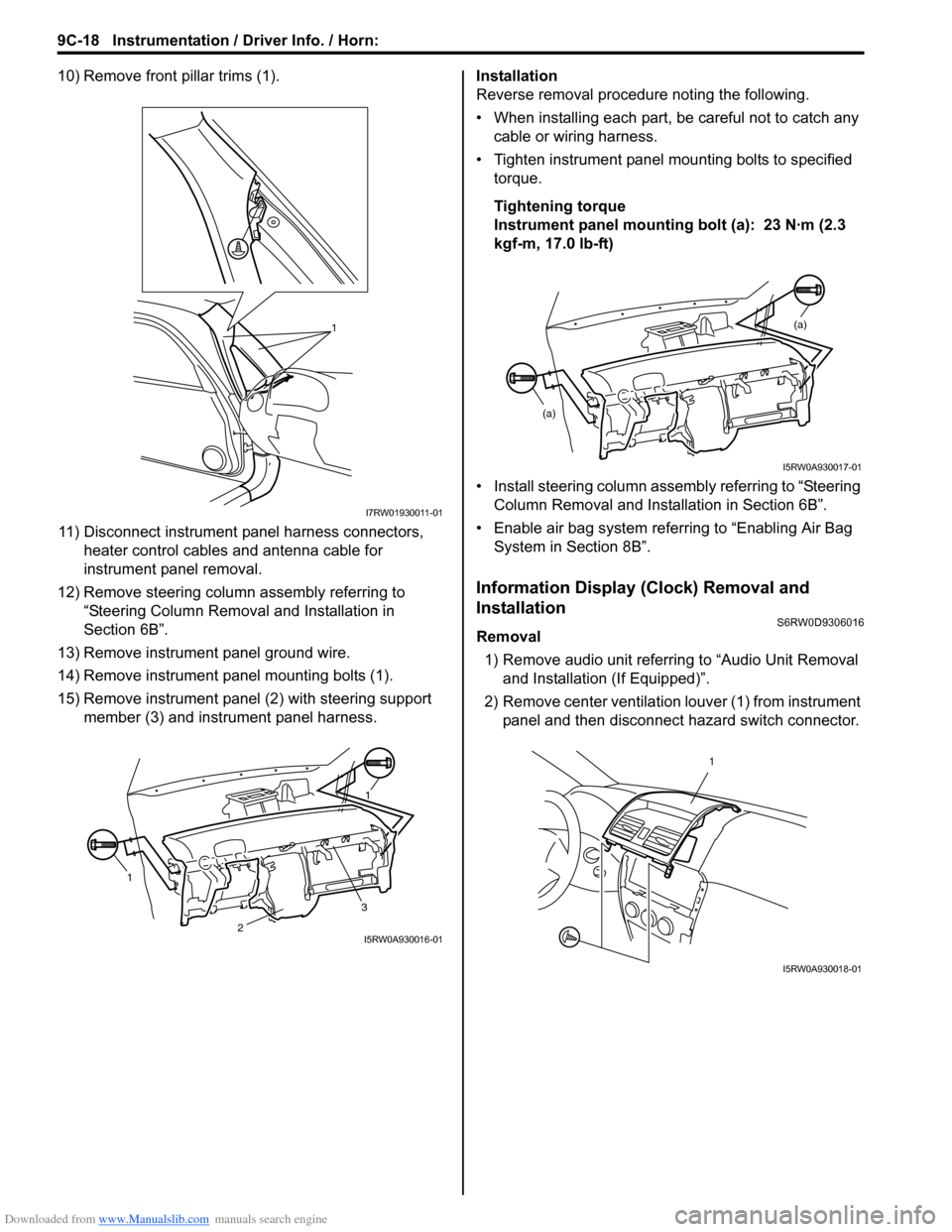

10) Remove front pillar trims (1).

11) Disconnect instrument panel harness connectors,

heater control cables and antenna cable for

instrument panel removal.

12) Remove steering column assembly referring to

“Steering Column Removal and Installation in

Section 6B”.

13) Remove instrument panel ground wire.

14) Remove instrument panel mounting bolts (1).

15) Remove instrument panel (2) with steering support

member (3) and instrument panel harness.Installation

Reverse removal procedure noting the following.

• When installing each part, be careful not to catch any

cable or wiring harness.

• Tighten instrument panel mounting bolts to specified

torque.

Tightening torque

Instrument panel mounting bolt (a): 23 N·m (2.3

kgf-m, 17.0 lb-ft)

• Install steering column assembly referring to “Steering

Column Removal and Installation in Section 6B”.

• Enable air bag system referring to “Enabling Air Bag

System in Section 8B”.

Information Display (Clock) Removal and

Installation

S6RW0D9306016

Removal

1) Remove audio unit referring to “Audio Unit Removal

and Installation (If Equipped)”.

2) Remove center ventilation louver (1) from instrument

panel and then disconnect hazard switch connector.

1

I7RW01930011-01

11

3

2I5RW0A930016-01

(a)

(a)

I5RW0A930017-01

1

I5RW0A930018-01

Page 1371 of 1556

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-19

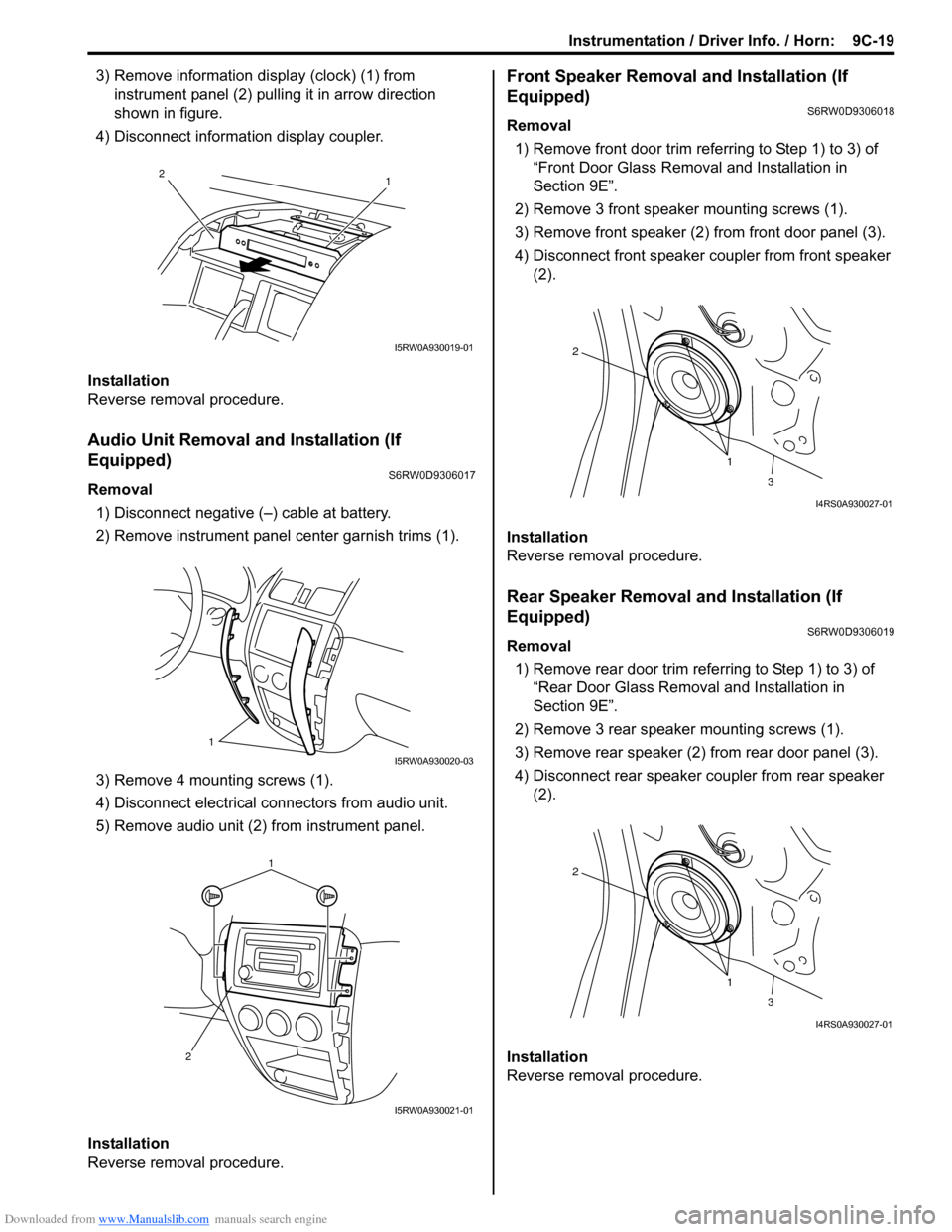

3) Remove information display (clock) (1) from

instrument panel (2) pulling it in arrow direction

shown in figure.

4) Disconnect information display coupler.

Installation

Reverse removal procedure.

Audio Unit Removal and Installation (If

Equipped)

S6RW0D9306017

Removal

1) Disconnect negative (–) cable at battery.

2) Remove instrument panel center garnish trims (1).

3) Remove 4 mounting screws (1).

4) Disconnect electrical connectors from audio unit.

5) Remove audio unit (2) from instrument panel.

Installation

Reverse removal procedure.

Front Speaker Removal and Installation (If

Equipped)

S6RW0D9306018

Removal

1) Remove front door trim referring to Step 1) to 3) of

“Front Door Glass Removal and Installation in

Section 9E”.

2) Remove 3 front speaker mounting screws (1).

3) Remove front speaker (2) from front door panel (3).

4) Disconnect front speaker coupler from front speaker

(2).

Installation

Reverse removal procedure.

Rear Speaker Removal and Installation (If

Equipped)

S6RW0D9306019

Removal

1) Remove rear door trim referring to Step 1) to 3) of

“Rear Door Glass Removal and Installation in

Section 9E”.

2) Remove 3 rear speaker mounting screws (1).

3) Remove rear speaker (2) from rear door panel (3).

4) Disconnect rear speaker coupler from rear speaker

(2).

Installation

Reverse removal procedure.

1 2

I5RW0A930019-01

1

I5RW0A930020-03

1

2

I5RW0A930021-01

1 2

3

I4RS0A930027-01

1 2

3

I4RS0A930027-01

Page 1372 of 1556

Downloaded from www.Manualslib.com manuals search engine 9C-20 Instrumentation / Driver Info. / Horn:

GPS Antenna Removal and Installation (If

Equipped)

S6RW0D9306027

Removal

1) Remove combination meter cluster panel referring to

step 1) to 4) of “Combination Meter Removal and

Installation”.

2) Disconnect GPS antenna connector from navigation

unit referring to “Audio Unit Removal and Installation

(If Equipped)”.

3) Remove GPS antenna (1).

Installation

Reverse removal procedure.

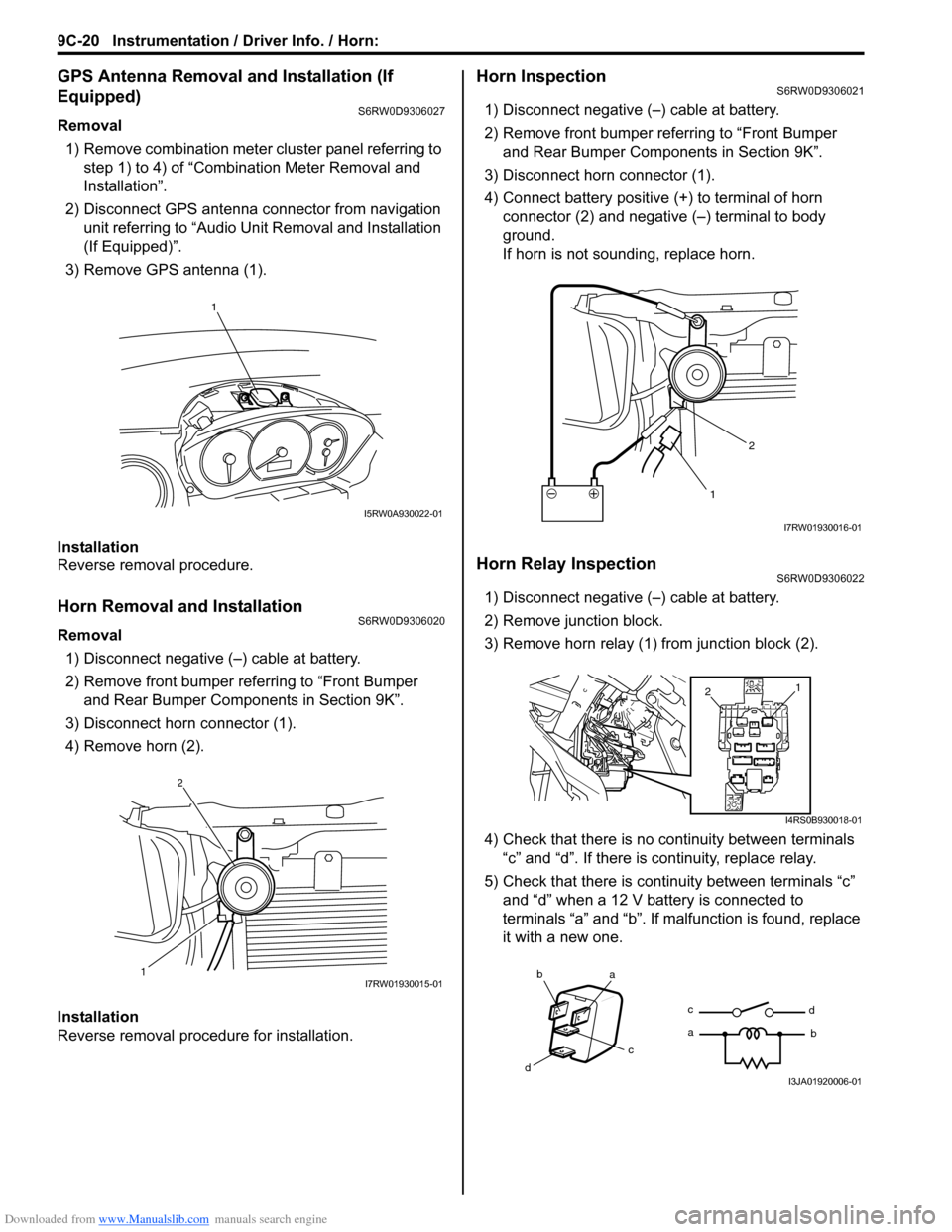

Horn Removal and InstallationS6RW0D9306020

Removal

1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper

and Rear Bumper Components in Section 9K”.

3) Disconnect horn connector (1).

4) Remove horn (2).

Installation

Reverse removal procedure for installation.

Horn InspectionS6RW0D9306021

1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper

and Rear Bumper Components in Section 9K”.

3) Disconnect horn connector (1).

4) Connect battery positive (+) to terminal of horn

connector (2) and negative (–) terminal to body

ground.

If horn is not sounding, replace horn.

Horn Relay InspectionS6RW0D9306022

1) Disconnect negative (–) cable at battery.

2) Remove junction block.

3) Remove horn relay (1) from junction block (2).

4) Check that there is no continuity between terminals

“c” and “d”. If there is continuity, replace relay.

5) Check that there is continuity between terminals “c”

and “d” when a 12 V battery is connected to

terminals “a” and “b”. If malfunction is found, replace

it with a new one.

1

I5RW0A930022-01

12I7RW01930015-01

12

I7RW01930016-01

1

2

I4RS0B930018-01

ba

c

dc

ad

bI3JA01920006-01

Page 1373 of 1556

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-21

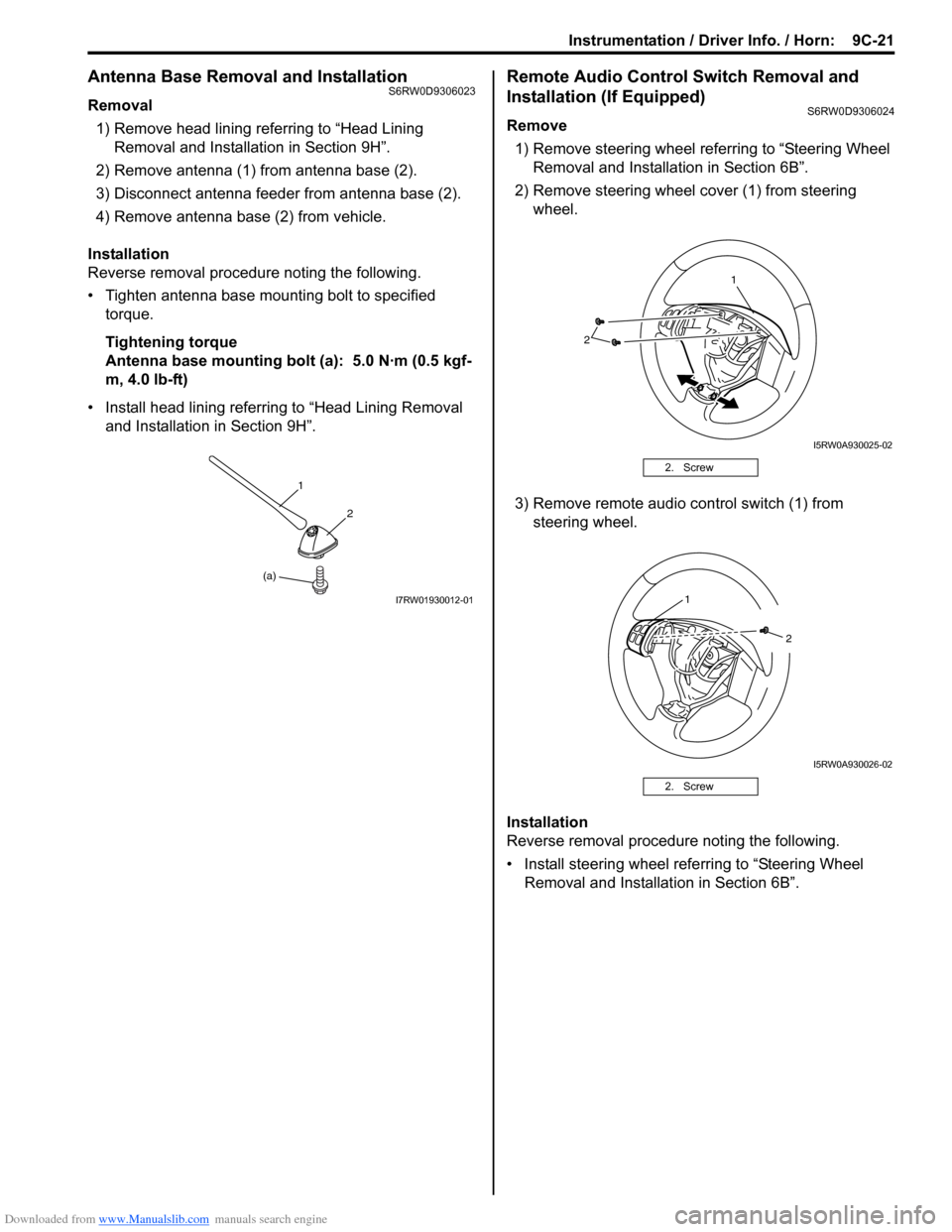

Antenna Base Removal and InstallationS6RW0D9306023

Removal

1) Remove head lining referring to “Head Lining

Removal and Installation in Section 9H”.

2) Remove antenna (1) from antenna base (2).

3) Disconnect antenna feeder from antenna base (2).

4) Remove antenna base (2) from vehicle.

Installation

Reverse removal procedure noting the following.

• Tighten antenna base mounting bolt to specified

torque.

Tightening torque

Antenna base mounting bolt (a): 5.0 N·m (0.5 kgf-

m, 4.0 lb-ft)

• Install head lining referring to “Head Lining Removal

and Installation in Section 9H”.

Remote Audio Control Switch Removal and

Installation (If Equipped)

S6RW0D9306024

Remove

1) Remove steering wheel referring to “Steering Wheel

Removal and Installation in Section 6B”.

2) Remove steering wheel cover (1) from steering

wheel.

3) Remove remote audio control switch (1) from

steering wheel.

Installation

Reverse removal procedure noting the following.

• Install steering wheel referring to “Steering Wheel

Removal and Installation in Section 6B”.

(a)1

2

I7RW01930012-01

2. Screw

2. Screw

2

1

I5RW0A930025-02

1

2

I5RW0A930026-02

Page 1374 of 1556

Downloaded from www.Manualslib.com manuals search engine 9C-22 Instrumentation / Driver Info. / Horn:

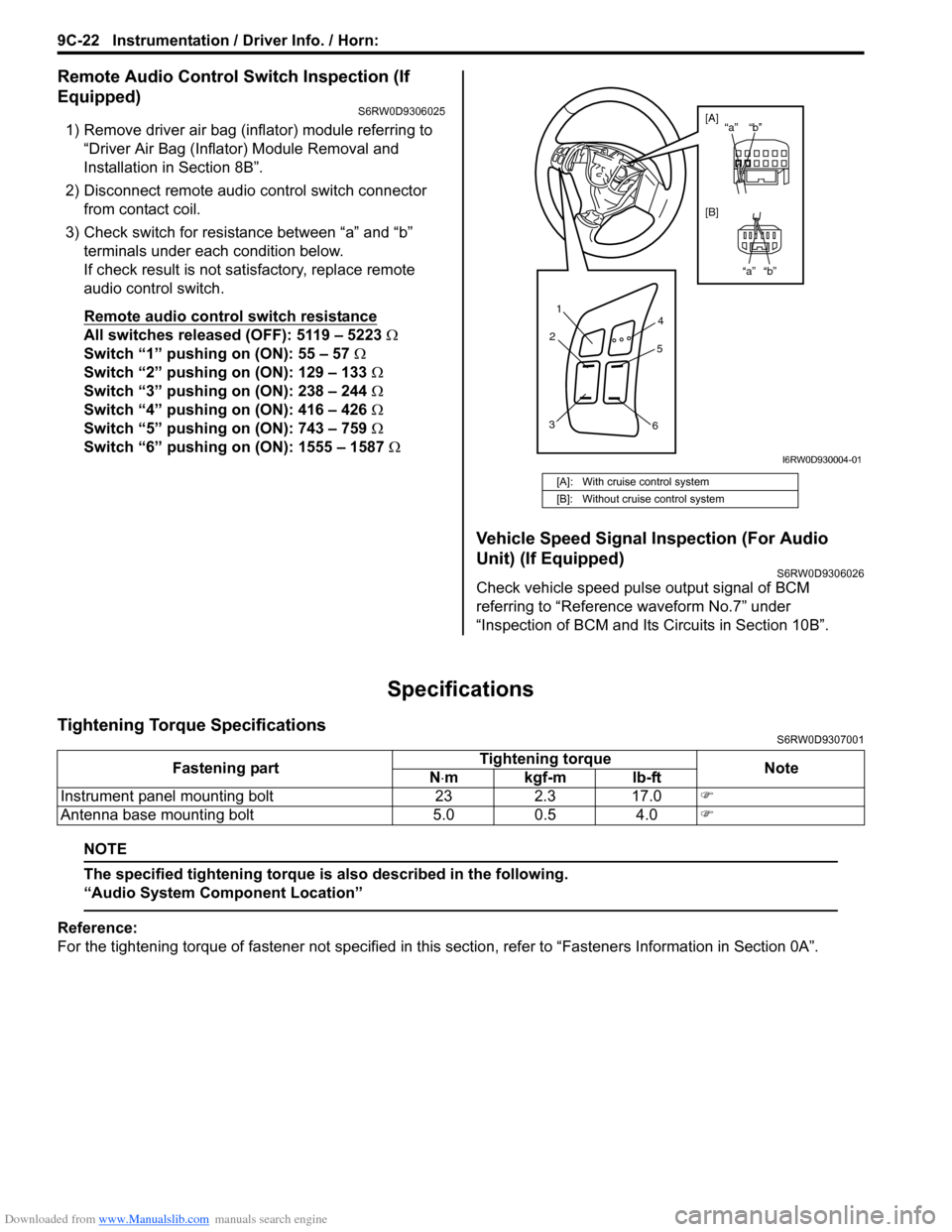

Remote Audio Control Switch Inspection (If

Equipped)

S6RW0D9306025

1) Remove driver air bag (inflator) module referring to

“Driver Air Bag (Inflator) Module Removal and

Installation in Section 8B”.

2) Disconnect remote audio control switch connector

from contact coil.

3) Check switch for resistance between “a” and “b”

terminals under each condition below.

If check result is not satisfactory, replace remote

audio control switch.

Remote audio control switch resistance

All switches released (OFF): 5119 – 5223 Ω

Switch “1” pushing on (ON): 55 – 57 Ω

Switch “2” pushing on (ON): 129 – 133 Ω

Switch “3” pushing on (ON): 238 – 244 Ω

Switch “4” pushing on (ON): 416 – 426 Ω

Switch “5” pushing on (ON): 743 – 759 Ω

Switch “6” pushing on (ON): 1555 – 1587 Ω

Vehicle Speed Signal Inspection (For Audio

Unit) (If Equipped)

S6RW0D9306026

Check vehicle speed pulse output signal of BCM

referring to “Reference waveform No.7” under

“Inspection of BCM and Its Circuits in Section 10B”.

Specifications

Tightening Torque SpecificationsS6RW0D9307001

NOTE

The specified tightening torque is also described in the following.

“Audio System Component Location”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

[A]: With cruise control system

[B]: Without cruise control system

1

2

34

5

6

“b” “a”

“b” “a” [A]

[B]

I6RW0D930004-01

Fastening partTightening torque

Note

N⋅mkgf-mlb-ft

Instrument panel mounting bolt 23 2.3 17.0�)

Antenna base mounting bolt 5.0 0.5 4.0�)

Page 1475 of 1556

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-2

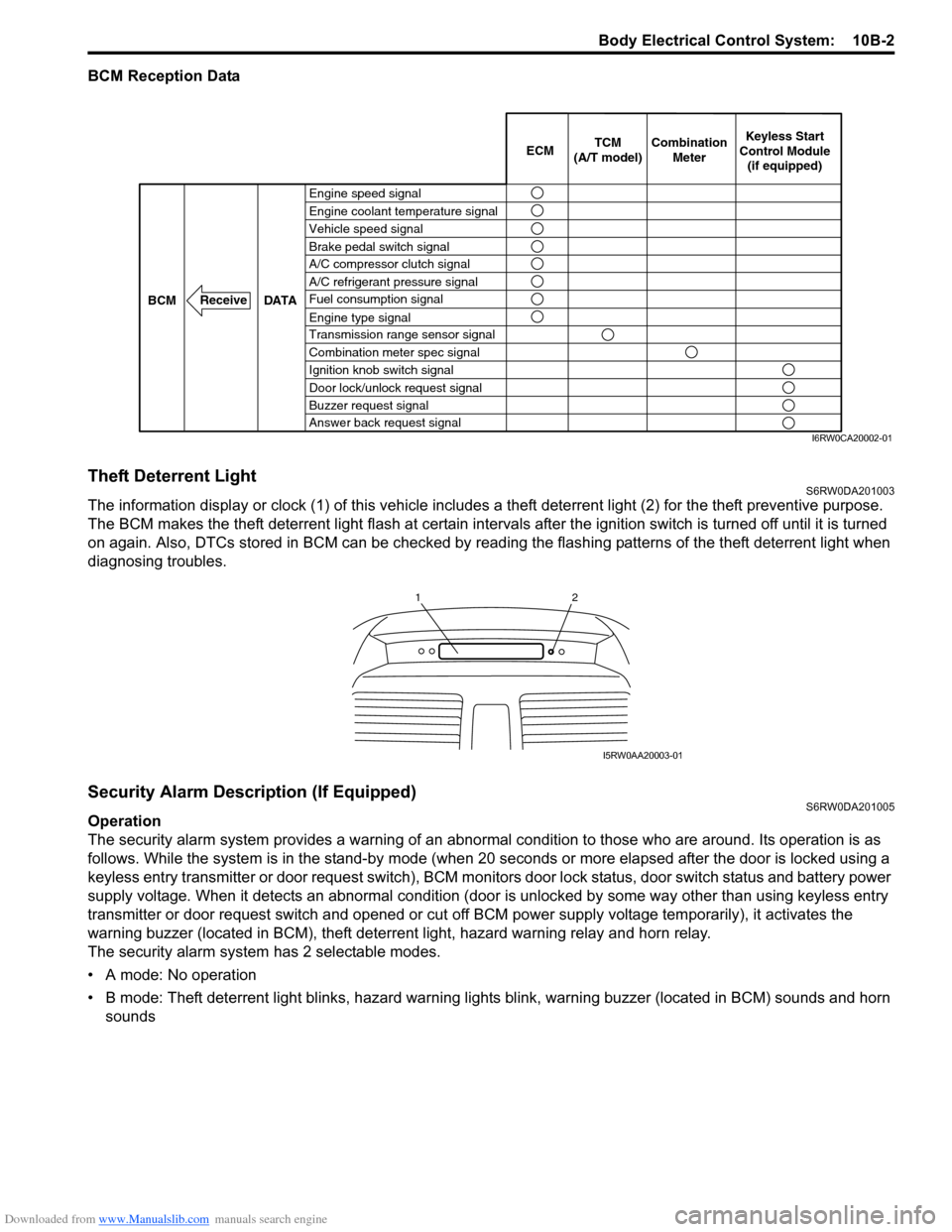

BCM Reception Data

Theft Deterrent LightS6RW0DA201003

The information display or clock (1) of this vehicle includes a theft deterrent light (2) for the theft preventive purpose.

The BCM makes the theft deterrent light flash at certain intervals after the ignition switch is turned off until it is turned

on again. Also, DTCs stored in BCM can be checked by reading the flashing patterns of the theft deterrent light when

diagnosing troubles.

Security Alarm Description (If Equipped)S6RW0DA201005

Operation

The security alarm system provides a warning of an abnormal condition to those who are around. Its operation is as

follows. While the system is in the stand-by mode (when 20 seconds or more elapsed after the door is locked using a

keyless entry transmitter or door request switch), BCM monitors door lock status, door switch status and battery power

supply voltage. When it detects an abnormal condition (door is unlocked by some way other than using keyless entry

transmitter or door request switch and opened or cut off BCM power supply voltage temporarily), it activates the

warning buzzer (located in BCM), theft deterrent light, hazard warning relay and horn relay.

The security alarm system has 2 selectable modes.

• A mode: No operation

• B mode: Theft deterrent light blinks, hazard warning lights blink, warning buzzer (located in BCM) sounds and horn

sounds

Engine speed signal

Vehicle speed signal Engine coolant temperature signal

Brake pedal switch signal

A/C refrigerant pressure signal

Fuel consumption signal A/C compressor clutch signal

Engine type signal

Transmission range sensor signal

Combination meter spec signal

Ignition knob switch signal

Door lock/unlock request signal

Buzzer request signal

Answer back request signal DATA BCM

Receive

Combination

Meter TCM

(A/T model)Keyless Start

Control Module

(if equipped) ECM

I6RW0CA20002-01

12

I5RW0AA20003-01