PPL SUZUKI SX4 2006 1.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 221 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-171

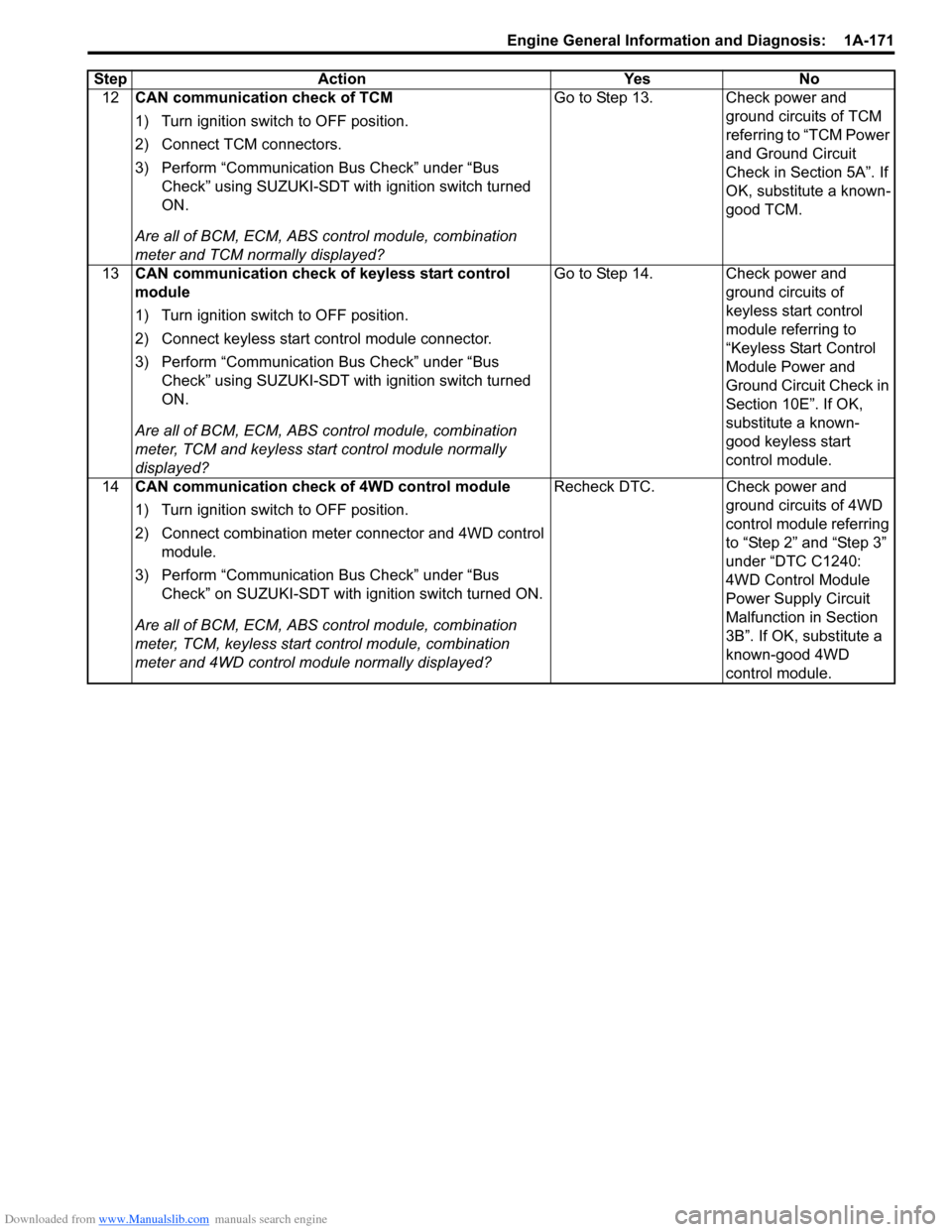

12CAN communication check of TCM

1) Turn ignition switch to OFF position.

2) Connect TCM connectors.

3) Perform “Communication Bus Check” under “Bus

Check” using SUZUKI-SDT with ignition switch turned

ON.

Are all of BCM, ECM, ABS control module, combination

meter and TCM normally displayed?Go to Step 13. Check power and

ground circuits of TCM

referring to “TCM Power

and Ground Circuit

Check in Section 5A”. If

OK, substitute a known-

good TCM.

13CAN communication check of keyless start control

module

1) Turn ignition switch to OFF position.

2) Connect keyless start control module connector.

3) Perform “Communication Bus Check” under “Bus

Check” using SUZUKI-SDT with ignition switch turned

ON.

Are all of BCM, ECM, ABS control module, combination

meter, TCM and keyless start control module normally

displayed?Go to Step 14. Check power and

ground circuits of

keyless start control

module referring to

“Keyless Start Control

Module Power and

Ground Circuit Check in

Section 10E”. If OK,

substitute a known-

good keyless start

control module.

14CAN communication check of 4WD control module

1) Turn ignition switch to OFF position.

2) Connect combination meter connector and 4WD control

module.

3) Perform “Communication Bus Check” under “Bus

Check” on SUZUKI-SDT with ignition switch turned ON.

Are all of BCM, ECM, ABS control module, combination

meter, TCM, keyless start control module, combination

meter and 4WD control module normally displayed?Recheck DTC. Check power and

ground circuits of 4WD

control module referring

to “Step 2” and “Step 3”

under “DTC C1240:

4WD Control Module

Power Supply Circuit

Malfunction in Section

3B”. If OK, substitute a

known-good 4WD

control module. Step Action Yes No

Page 227 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-177

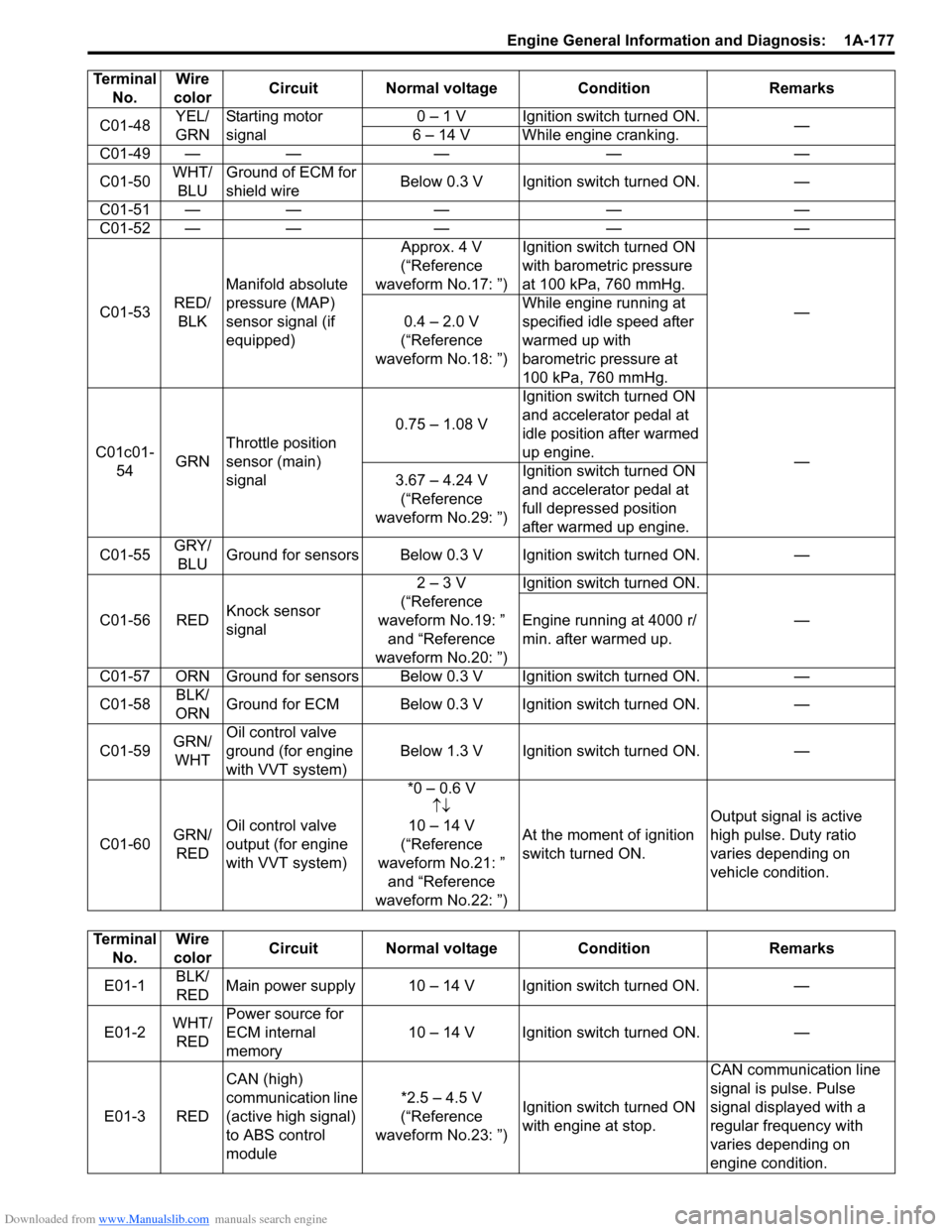

C01-48YEL/

GRNStarting motor

signal0 – 1 V Ignition switch turned ON.

—

6 – 14 V While engine cranking.

C01-49 — — — — —

C01-50WHT/

BLUGround of ECM for

shield wireBelow 0.3 V Ignition switch turned ON. —

C01-51 — — — — —

C01-52 — — — — —

C01-53RED/

BLKManifold absolute

pressure (MAP)

sensor signal (if

equipped)Approx. 4 V

(“Reference

waveform No.17: ”)Ignition switch turned ON

with barometric pressure

at 100 kPa, 760 mmHg.

—

0.4 – 2.0 V

(“Reference

waveform No.18: ”)While engine running at

specified idle speed after

warmed up with

barometric pressure at

100 kPa, 760 mmHg.

C01c01-

54GRNThrottle position

sensor (main)

signal0.75 – 1.08 VIgnition switch turned ON

and accelerator pedal at

idle position after warmed

up engine.

—

3.67 – 4.24 V

(“Reference

waveform No.29: ”)Ignition switch turned ON

and accelerator pedal at

full depressed position

after warmed up engine.

C01-55GRY/

BLUGround for sensors Below 0.3 V Ignition switch turned ON. —

C01-56 REDKnock sensor

signal2 – 3 V

(“Reference

waveform No.19: ”

and “Reference

waveform No.20: ”)Ignition switch turned ON.

— Engine running at 4000 r/

min. after warmed up.

C01-57 ORN Ground for sensors Below 0.3 V Ignition switch turned ON. —

C01-58BLK/

ORNGround for ECM Below 0.3 V Ignition switch turned ON. —

C01-59GRN/

WHTOil control valve

ground (for engine

with VVT system)Below 1.3 V Ignition switch turned ON. —

C01-60GRN/

REDOil control valve

output (for engine

with VVT system)*0 – 0.6 V

↑↓

10 – 14 V

(“Reference

waveform No.21: ”

and “Reference

waveform No.22: ”)At the moment of ignition

switch turned ON.Output signal is active

high pulse. Duty ratio

varies depending on

vehicle condition. Terminal

No.Wire

colorCircuit Normal voltage Condition Remarks

Terminal

No.Wire

colorCircuit Normal voltage Condition Remarks

E01-1BLK/

REDMain power supply 10 – 14 V Ignition switch turned ON. —

E01-2WHT/

REDPower source for

ECM internal

memory10 – 14 V Ignition switch turned ON. —

E01-3 REDCAN (high)

communication line

(active high signal)

to ABS control

module*2.5 – 4.5 V

(“Reference

waveform No.23: ”)Ignition switch turned ON

with engine at stop.CAN communication line

signal is pulse. Pulse

signal displayed with a

regular frequency with

varies depending on

engine condition.

Page 228 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-178 Engine General Information and Diagnosis:

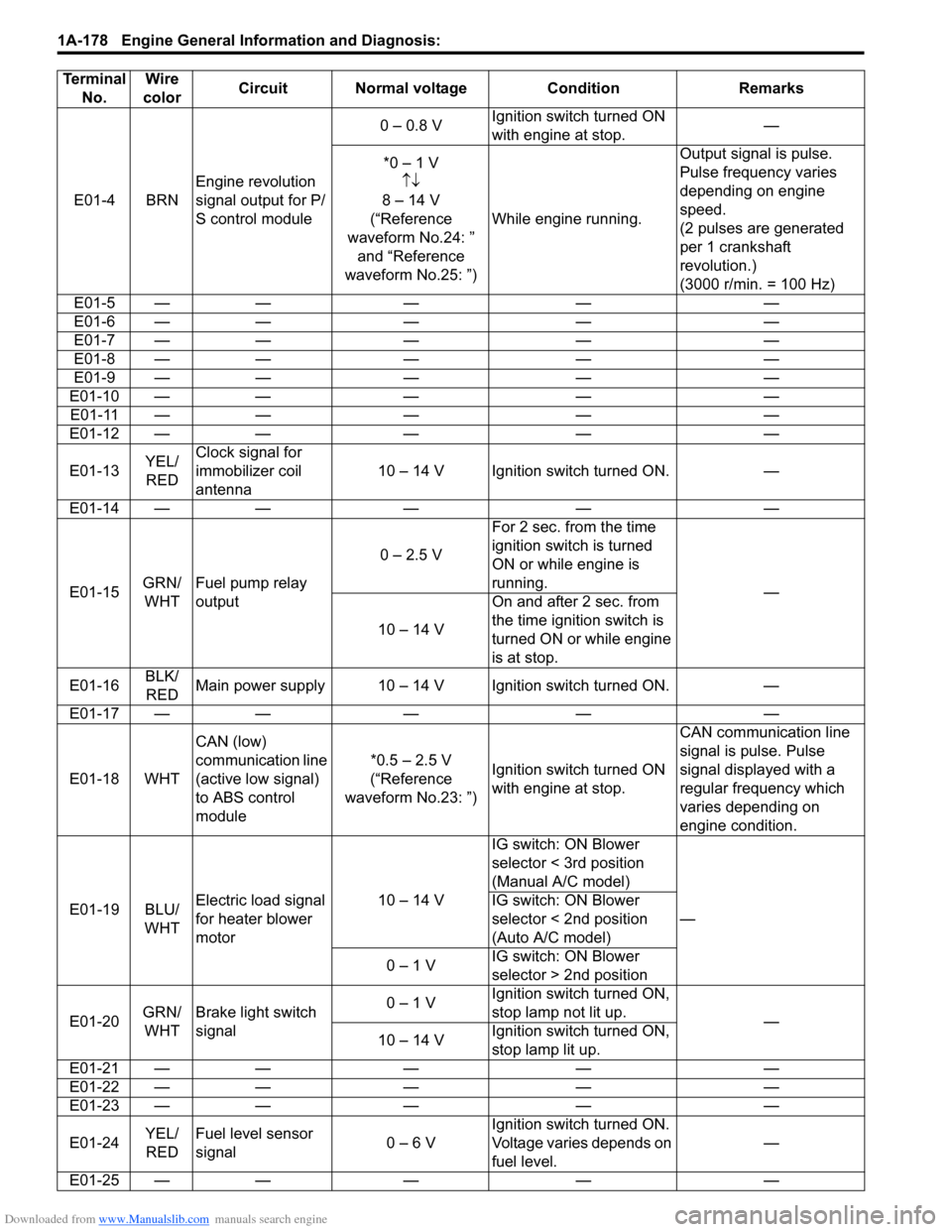

E01-4 BRNEngine revolution

signal output for P/

S control module0 – 0.8 VIgnition switch turned ON

with engine at stop.—

*0 – 1 V

↑↓

8 – 14 V

(“Reference

waveform No.24: ”

and “Reference

waveform No.25: ”)While engine running.Output signal is pulse.

Pulse frequency varies

depending on engine

speed.

(2 pulses are generated

per 1 crankshaft

revolution.)

(3000 r/min. = 100 Hz)

E01-5 — — — — —

E01-6 — — — — —

E01-7 — — — — —

E01-8 — — — — —

E01-9 — — — — —

E01-10 — — — — —

E01-11 — — — — —

E01-12 — — — — —

E01-13YEL/

REDClock signal for

immobilizer coil

antenna10 – 14 V Ignition switch turned ON. —

E01-14 — — — — —

E01-15GRN/

WHTFuel pump relay

output0 – 2.5 VFor 2 sec. from the time

ignition switch is turned

ON or while engine is

running.

—

10 – 14 VOn and after 2 sec. from

the time ignition switch is

turned ON or while engine

is at stop.

E01-16BLK/

REDMain power supply 10 – 14 V Ignition switch turned ON. —

E01-17 — — — — —

E01-18 WHTCAN (low)

communication line

(active low signal)

to ABS control

module*0.5 – 2.5 V

(“Reference

waveform No.23: ”)Ignition switch turned ON

with engine at stop.CAN communication line

signal is pulse. Pulse

signal displayed with a

regular frequency which

varies depending on

engine condition.

E01-19 BLU/

WHTElectric load signal

for heater blower

motor10 – 14 VIG switch: ON Blower

selector < 3rd position

(Manual A/C model)

— IG switch: ON Blower

selector < 2nd position

(Auto A/C model)

0 – 1 VIG switch: ON Blower

selector > 2nd position

E01-20GRN/

WHTBrake light switch

signal0 – 1 VIgnition switch turned ON,

stop lamp not lit up.

—

10 – 14 VIgnition switch turned ON,

stop lamp lit up.

E01-21 — — — — —

E01-22 — — — — —

E01-23 — — — — —

E01-24YEL/

REDFuel level sensor

signal0 – 6 VIgnition switch turned ON.

Voltage varies depends on

fuel level.—

E01-25 — — — — — Terminal

No.Wire

colorCircuit Normal voltage Condition Remarks

Page 229 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-179

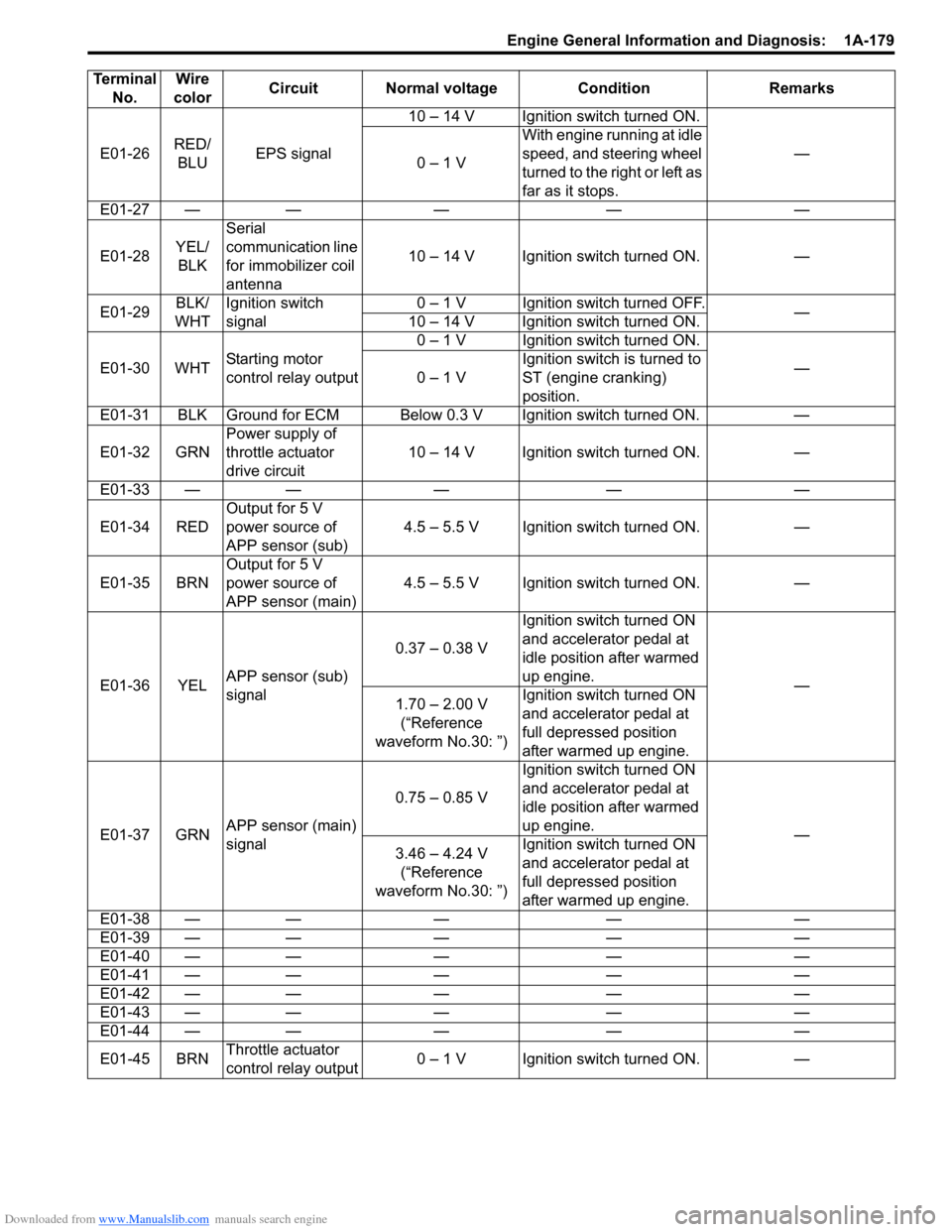

E01-26RED/

BLUEPS signal10 – 14 V Ignition switch turned ON.

—

0 – 1 VWith engine running at idle

speed, and steering wheel

turned to the right or left as

far as it stops.

E01-27 — — — — —

E01-28YEL/

BLKSerial

communication line

for immobilizer coil

antenna10 – 14 V Ignition switch turned ON. —

E01-29BLK/

WHTIgnition switch

signal0 – 1 V Ignition switch turned OFF.

—

10 – 14 V Ignition switch turned ON.

E01-30 WHTStarting motor

control relay output0 – 1 V Ignition switch turned ON.

—

0 – 1 VIgnition switch is turned to

ST (engine cranking)

position.

E01-31 BLK Ground for ECM Below 0.3 V Ignition switch turned ON. —

E01-32 GRNPower supply of

throttle actuator

drive circuit10 – 14 V Ignition switch turned ON. —

E01-33 — — — — —

E01-34 REDOutput for 5 V

power source of

APP sensor (sub)4.5 – 5.5 V Ignition switch turned ON. —

E01-35 BRNOutput for 5 V

power source of

APP sensor (main)4.5 – 5.5 V Ignition switch turned ON. —

E01-36 YELAPP sensor (sub)

signal0.37 – 0.38 VIgnition switch turned ON

and accelerator pedal at

idle position after warmed

up engine.

—

1.70 – 2.00 V

(“Reference

waveform No.30: ”)Ignition switch turned ON

and accelerator pedal at

full depressed position

after warmed up engine.

E01-37 GRNAPP sensor (main)

signal0.75 – 0.85 VIgnition switch turned ON

and accelerator pedal at

idle position after warmed

up engine.

—

3.46 – 4.24 V

(“Reference

waveform No.30: ”)Ignition switch turned ON

and accelerator pedal at

full depressed position

after warmed up engine.

E01-38 — — — — —

E01-39 — — — — —

E01-40 — — — — —

E01-41 — — — — —

E01-42 — — — — —

E01-43 — — — — —

E01-44 — — — — —

E01-45 BRNThrottle actuator

control relay output0 – 1 V Ignition switch turned ON. — Terminal

No.Wire

colorCircuit Normal voltage Condition Remarks

Page 231 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-181

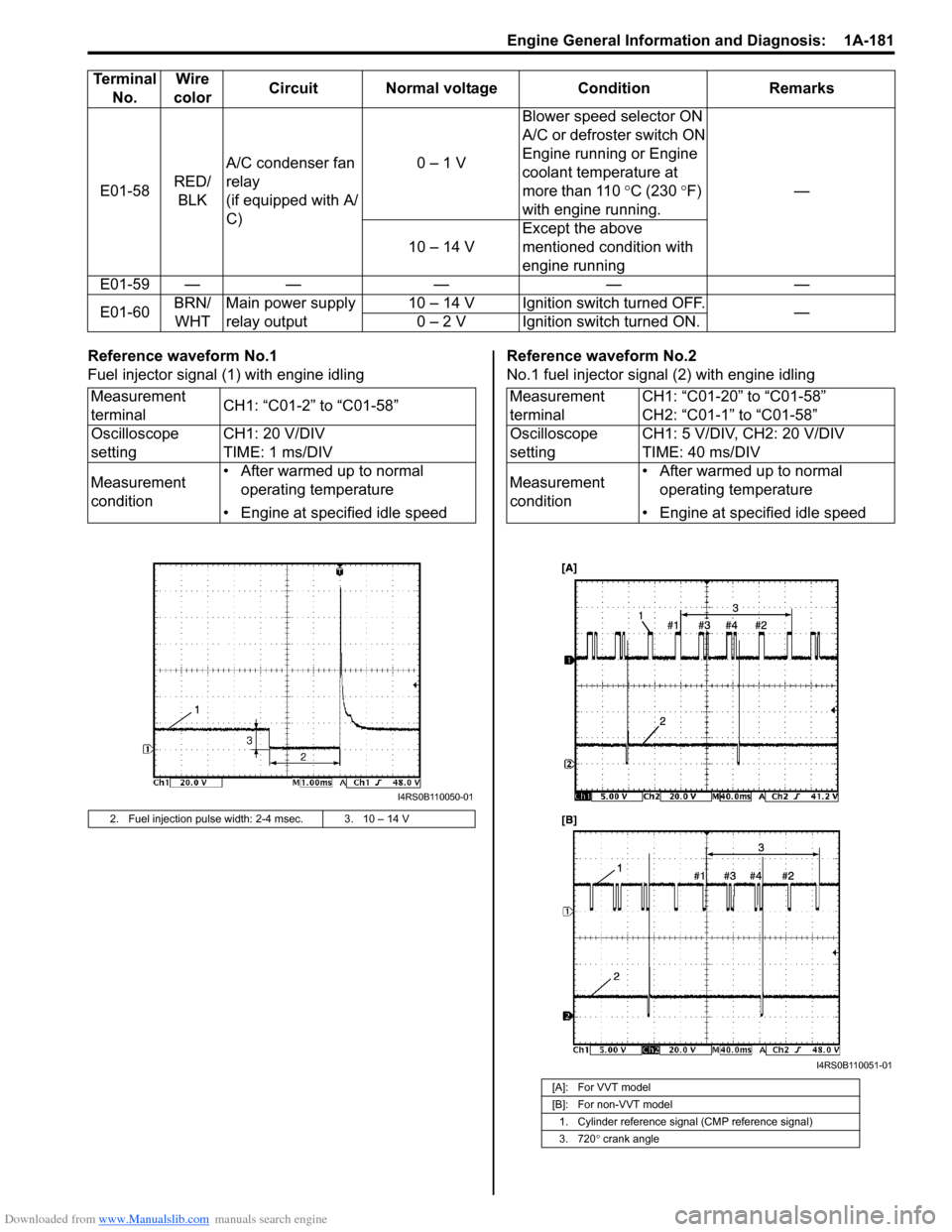

Reference waveform No.1

Fuel injector signal (1) with engine idlingReference waveform No.2

No.1 fuel injector signal (2) with engine idling E01-58RED/

BLKA/C condenser fan

relay

(if equipped with A/

C)0 – 1 VBlower speed selector ON

A/C or defroster switch ON

Engine running or Engine

coolant temperature at

more than 110 °C (230 °F)

with engine running.—

10 – 14 VExcept the above

mentioned condition with

engine running

E01-59 — — — — —

E01-60BRN/

WHTMain power supply

relay output10 – 14 V Ignition switch turned OFF.

—

0 – 2 V Ignition switch turned ON. Terminal

No.Wire

colorCircuit Normal voltage Condition Remarks

Measurement

terminalCH1: “C01-2” to “C01-58”

Oscilloscope

settingCH1: 20 V/DIV

TIME: 1 ms/DIV

Measurement

condition• After warmed up to normal

operating temperature

• Engine at specified idle speed

2. Fuel injection pulse width: 2-4 msec. 3. 10 – 14 V

I4RS0B110050-01

Measurement

terminalCH1: “C01-20” to “C01-58”

CH2: “C01-1” to “C01-58”

Oscilloscope

settingCH1: 5 V/DIV, CH2: 20 V/DIV

TIME: 40 ms/DIV

Measurement

condition• After warmed up to normal

operating temperature

• Engine at specified idle speed

[A]: For VVT model

[B]: For non-VVT model

1. Cylinder reference signal (CMP reference signal)

3. 720° crank angle

I4RS0B110051-01

Page 243 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-193

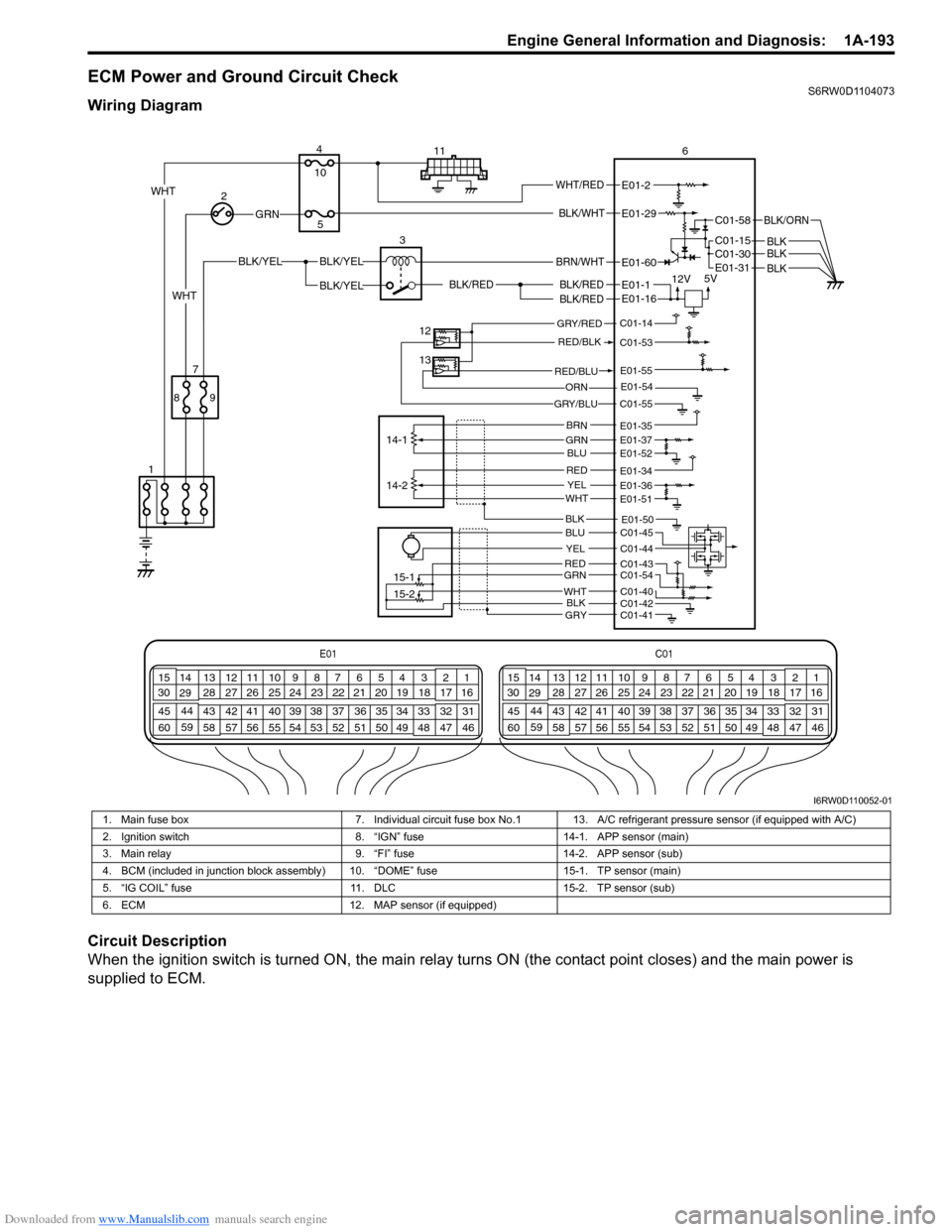

ECM Power and Ground Circuit CheckS6RW0D1104073

Wiring Diagram

Circuit Description

When the ignition switch is turned ON, the main relay turns ON (the contact point closes) and the main power is

supplied to ECM.

E01C01

3 4

18 19 5 6 7 10 11

17 20

47 46 49 50 51 21 22

5216 259

24 14

29

55 57 54 53 59

60 582

26 27 28 15

30

56 4832 31 34 35 36 37 40 42 39 38 44

45 43 41 331 12 13

238 3 4

18 19 5 6 7 10 11

17 20

47 46 49 50 51 21 22

5216 259

24 14

29

55 57 54 53 59

60 582

26 27 28 15

30

56 4832 31 34 35 36 37 40 42 39 38 44

45 43 41 331 12 13

238

BLK/WHT

BLK/RED

BLK/RED

BLK/RED

BLK/YELBLK/YEL

BLK/YEL

GRN

BRN/WHT

12V5V

2

13

12

13

14-1

15-1

15-2 14-2 4

56

E01-29

E01-1

E01-60

E01-16

9 87

1011

WHTWHT/REDE01-2

C01-58

C01-15 C01-30

BLK/ORN

BLKBLKBLK

WHT

GRY/RED

RED/BLK

GRY/BLU

C01-14

C01-53

C01-55

E01-54ORN

RED/BLUE01-55

BRNGRNBLU

REDYELWHT

E01-35E01-37E01-52

E01-51

E01-34E01-36

E01-50

REDGRN

WHTBLK

BLU

YEL

C01-43C01-54

C01-40C01-42

C01-45

C01-44

C01-41

E01-31

GRY

BLK

I6RW0D110052-01

1. Main fuse box 7. Individual circuit fuse box No.1 13. A/C refrigerant pressure sensor (if equipped with A/C)

2. Ignition switch 8. “IGN” fuse 14-1. APP sensor (main)

3. Main relay 9. “FI” fuse 14-2. APP sensor (sub)

4. BCM (included in junction block assembly) 10. “DOME” fuse 15-1. TP sensor (main)

5. “IG COIL” fuse 11. DLC 15-2. TP sensor (sub)

6. ECM 12. MAP sensor (if equipped)

Page 244 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-194 Engine General Information and Diagnosis:

Troubleshooting

NOTE

• Before performed trouble shooting, be sure to read the “Precautions of ECM Circuit Inspection”.

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors referring to “Inspection of ECM and Its Circuits”.

Step Action Yes No

1Circuit fuse check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection to ECM connector at “E01-

2”, “E01-29”, “E01-60”, “E01-1”, “E01-16”, “E01-31”,

“C01-58”, “C01-15” and “C01-30” terminals.

3) If OK, check “DOME” fuse and “IG COIL” fuse for

blowing.

Are “DOME” fuse and “IG COIL” fuse in good condition?Go to Step 2. Replace fuse (s) and

check for short in

circuits connected to

fuse(s).

2Power supply circuit check

1) Measure voltage between “E01-2” terminal of ECM

connector and body ground.

Is voltage 10 – 14 V?Go to Step 3. “WHT/RED” or “WHT”

wire is open circuit.

3Ignition signal check

1) Turn ignition switch to ON position.

2) Measure voltage between “E01-29” terminal of ECM

connector and body ground.

Is voltage 10 – 14 V?Go to Step 4. “BLK/WHT” or “GRN”

wire is open circuit.

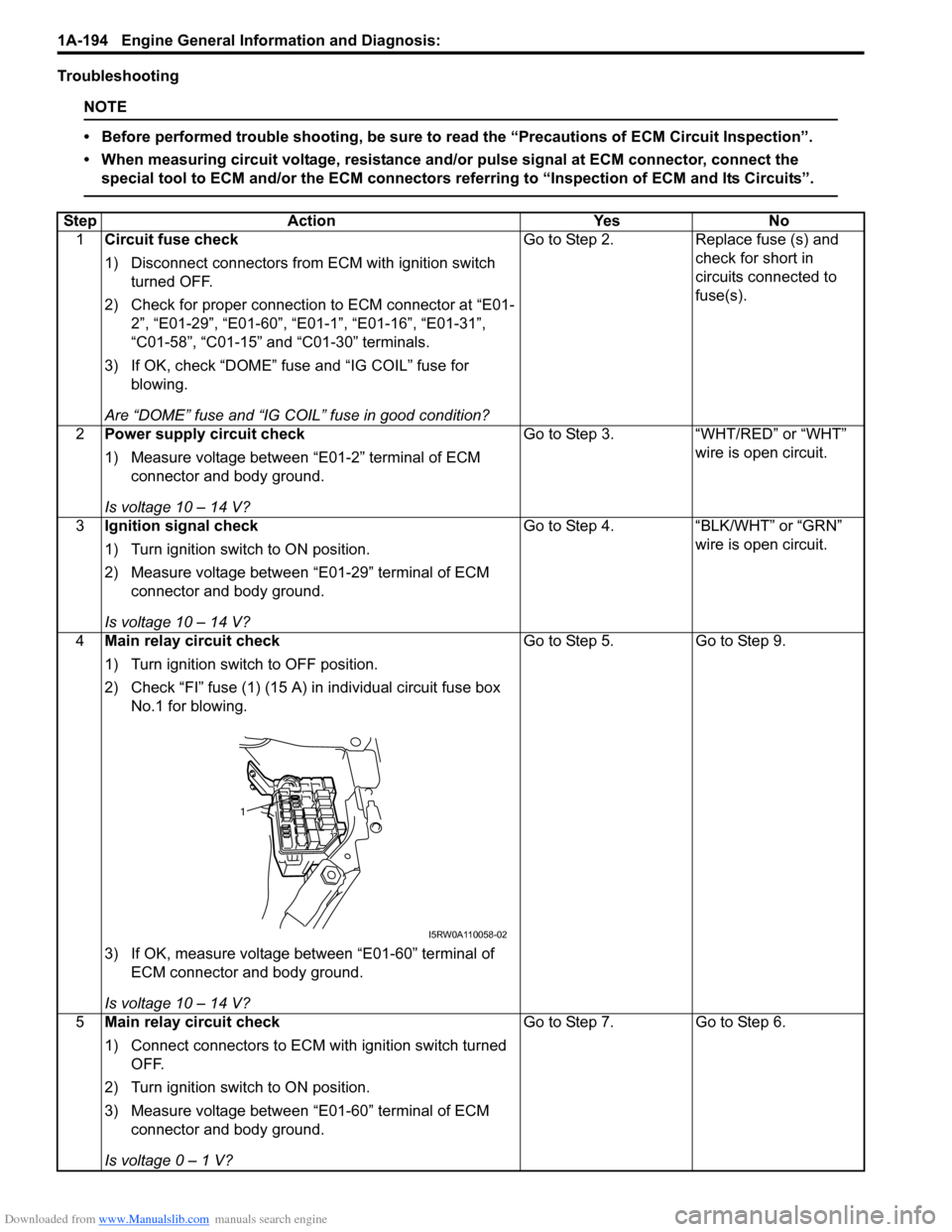

4Main relay circuit check

1) Turn ignition switch to OFF position.

2) Check “FI” fuse (1) (15 A) in individual circuit fuse box

No.1 for blowing.

3) If OK, measure voltage between “E01-60” terminal of

ECM connector and body ground.

Is voltage 10 – 14 V?Go to Step 5. Go to Step 9.

5Main relay circuit check

1) Connect connectors to ECM with ignition switch turned

OFF.

2) Turn ignition switch to ON position.

3) Measure voltage between “E01-60” terminal of ECM

connector and body ground.

Is voltage 0 – 1 V?Go to Step 7. Go to Step 6.

1

I5RW0A110058-02

Page 247 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-197

Troubleshooting

NOTE

• Before performed trouble shooting, be sure to read the “Precautions of ECM Circuit Inspection”.

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors referring to “Inspection of ECM and Its Circuits”.

Step Action Yes No

1Fuel injector check for operating sound

1) Using sound scope, check each injector for operating

sound at engine cranking.

Do all 4 injector make operating sound?Fuel injectors circuit is

in good condition.Go to Step 2.

2Fuel injector resistance check

1) Disconnect connectors from fuel injectors with ignition

switch turned OFF.

2) Check for proper connection to fuel injector at each

terminals.

3) If OK, check all 4 fuel injectors for resistance referring to

“Fuel Injector On-Vehicle Inspection in Section 1G”.

Are all injectors in good condition?Go to Step 3. Faulty fuel injector.

3Fuel injector insulation resistance check

1) Check that there is insulation between each fuel injector

terminal and engine ground.

Is there insulation?Go to Step 4. Faulty fuel injector.

4Fuel injector power supply check

1) Measure voltage between each “BLK/RED” wire terminal

of fuel injector connector and engine ground with ignition

switch turned ON.

Is voltage 10 – 14 V?Go to Step 5. “BLK/RED” wire is open

or shorted to ground

circuit.

If it is in good condition,

go to “ECM Power and

Ground Circuit Check”.

5Wire circuit check

1) Turn OFF ignition switch.

2) Disconnect connectors from ECM.

3) Measure resistance between each “BLU/YEL”, “BLU/

WHT”, “BLU/RED”, “BLU/ORN” wire terminal of fuel

injector connector and vehicle body ground.

Is resistance infinity?Go to Step 6. “BLU/YEL”, “BLU/WHT”,

“BLU/RED” and/or

“BLU/ORN” wire(s) are

shorted to ground.

6Wire circuit check

1) Measure voltage between each “BLU/YEL”, “BLU/WHT”,

“BLU/RED”, “BLU/ORN” wire terminal of fuel injector

connector and vehicle body ground with ignition switch

turned ON.

Is voltage 0 V?Go to Step 7. “BLU/YEL”, “BLU/WHT”,

“BLU/RED” and/or

“BLU/ORN” wire(s) are

shorted to power supply

circuit.

7Fuel injector drive signal check

1) Connect connectors to each fuel injector and ECM with

ignition switch turned OFF.

2) Turn ON ignition switch.

3) Measure voltage between each “C01-1”, “C01-2”, “C01-

16”, “C01-17” terminal of ECM connector and vehicle

body ground.

Is voltage 10 – 14 V?Check fuel injector

referring to “Fuel

Injector Inspection in

Section 1G”.

If check result is

satisfactory, substitute a

known-good ECM and

recheck.“BLU/YEL”, “BLU/WHT”,

“BLU/RED” and/or

“BLU/ORN” wire(s) are

open circuit.

Page 249 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-199

Troubleshooting

NOTE

• Before performed trouble shooting, be sure to read the “Precautions of ECM Circuit Inspection”.

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors referring to “Inspection of ECM and Its Circuits”.

Step Action Yes No

1Fuel pump control system check for operation

Is fuel pump heard to operate 2 sec. after ignition switch is

turned ON?Fuel pump circuit is in

good condition.Go to Step 2.

2Fuel pump relay power supply check

1) Disconnect fuel pump relay from individual circuit fuse

box No.1 with ignition switch turned OFF.

2) Check for proper connection to fuel pump relay at each

terminal.

3) If OK, turn ON ignition switch, measure voltage between

“BLK/WHT” wire terminal of fuel pump relay connector

and engine ground.

Is voltage 10 – 14 V?Go to Step 3. “BLK/WHT” wire is open

or shorted to ground

circuit.

3Fuel pump relay power supply check

1) Turn ON ignition switch, measure voltage between “BLK/

RED” wire terminal of fuel pump relay connector and

engine ground.

Is voltage 10 – 14 V?Go to Step 4. “BLK/RED” wire is open

circuit.

4Fuel pump relay check

1) Check fuel pump relay referring to “Main Relay, Fuel

Pump Relay, Starting Motor Control Relay, Throttle

Actuator Control Relay and Radiator Cooling Fan Relay

Inspection in Section 1C”.

Is relay in good condition?Go to Step 5. Faulty relay.

5Fuel pump relay drive signal check

1) Connect fuel pump relay to individual circuit fuse box

No.1.

2) Connect voltmeter between “E01-15” terminal of ECM

connector and vehicle body ground.

3) Measure voltage 2 second after ignition switch is turned

ON.

Is voltage 10 – 14 V?Go to Step 6. “GRN/WHT” wire is

open circuit or shorted

to ground circuit.

I2RH01110132-01

Page 256 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-206 Engine General Information and Diagnosis:

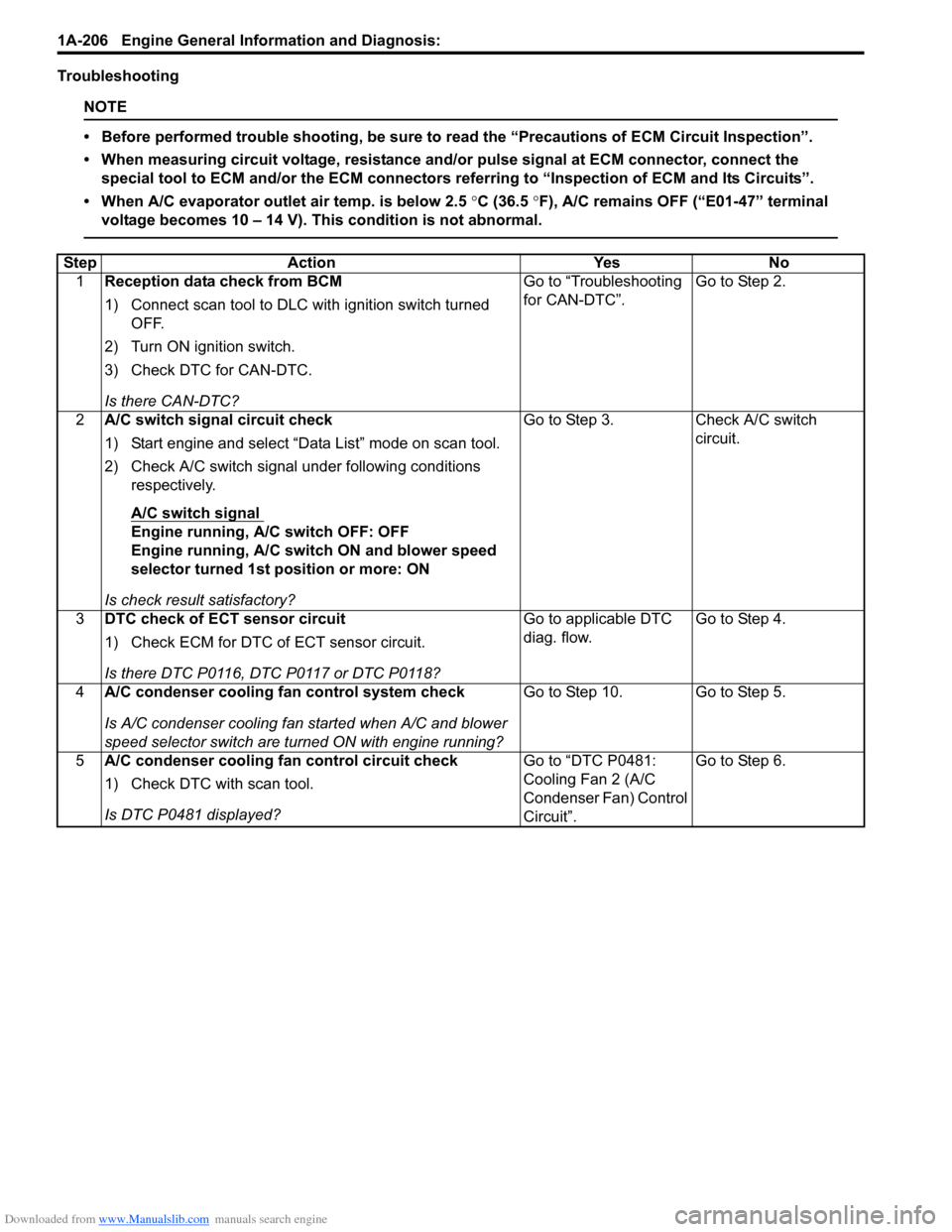

Troubleshooting

NOTE

• Before performed trouble shooting, be sure to read the “Precautions of ECM Circuit Inspection”.

• When measuring circuit voltage, resistance and/or pulse signal at ECM connector, connect the

special tool to ECM and/or the ECM connectors referring to “Inspection of ECM and Its Circuits”.

• When A/C evaporator outlet air temp. is below 2.5 °C (36.5 °F), A/C remains OFF (“E01-47” terminal

voltage becomes 10 – 14 V). This condition is not abnormal.

Step Action Yes No

1Reception data check from BCM

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch.

3) Check DTC for CAN-DTC.

Is there CAN-DTC?Go to “Troubleshooting

for CAN-DTC”.Go to Step 2.

2A/C switch signal circuit check

1) Start engine and select “Data List” mode on scan tool.

2) Check A/C switch signal under following conditions

respectively.

A/C switch signal

Engine running, A/C switch OFF: OFF

Engine running, A/C switch ON and blower speed

selector turned 1st position or more: ON

Is check result satisfactory?Go to Step 3. Check A/C switch

circuit.

3DTC check of ECT sensor circuit

1) Check ECM for DTC of ECT sensor circuit.

Is there DTC P0116, DTC P0117 or DTC P0118?Go to applicable DTC

diag. flow.Go to Step 4.

4A/C condenser cooling fan control system check

Is A/C condenser cooling fan started when A/C and blower

speed selector switch are turned ON with engine running?Go to Step 10. Go to Step 5.

5A/C condenser cooling fan control circuit check

1) Check DTC with scan tool.

Is DTC P0481 displayed?Go to “DTC P0481:

Cooling Fan 2 (A/C

Condenser Fan) Control

Circuit”.Go to Step 6.