cable SUZUKI SX4 2006 1.G Service Manual PDF

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 418 of 1556

Downloaded from www.Manualslib.com manuals search engine 1J-4 Charging System:

Diagnostic Information and Procedures

Battery InspectionS6RW0D1A04001

Common Causes of Failure

A battery is not designed to last indefinitely; however,

with proper care, it will provide many years of service. If

the battery performs satisfactorily during test buy fails to

operate properly for no apparent reason, the following

are some factors that may point to the cause of trouble:

• Accessories left on overnight or for an extended

period without the generator operating.

• Slow average driving speed for short periods.

• Electrical load exceeding generator output particularly

with addition of aftermarket equipment.

• Defects in charging system such as high resistance,

slipping drive belt, loose generator output terminal,

faulty generator or voltage regulator. Refer to

“Generator Symptom Diagnosis”.

• Battery abuse, including failure to keep battery cable

terminals clean and tight or loose battery hold down.

• Mechanical problems in electrical system such as

shorted or pinched wires.

Visual Inspection

Check for obvious damage, such as cracked or broken

case or cover, that could permit loss of electrolyte. If

obvious damage is noted, replace battery. Determine

cause of damage and correct as needed.

Generator Symptom DiagnosisS6RW0D1A04002

CAUTION!

• Do not mistake polarities of “IG” terminal

and “L” terminal.

• Do not create short circuit between “IG”

and “L” terminals. Always connect these

terminals through a lamp.

• Do not connect any load between “L” and

“E” terminals.

• When connecting charger or booster

battery to vehicle battery, refer to “Jump

Starting in Case of Emergency”.

Trouble in charging system will show up as one or more

of the following conditions:

1) Faulty indicator lamp operation.

2) An undercharged battery as evidenced by slow

cranking or indicator dark.

3) An overcharged battery as evidenced by excessive

spewing of electrolyte from vents.

Noise from generator may be caused by loose drive

pulley, loose mounting bolts, worn or dirty bearings,

defective diode, or defective stator.

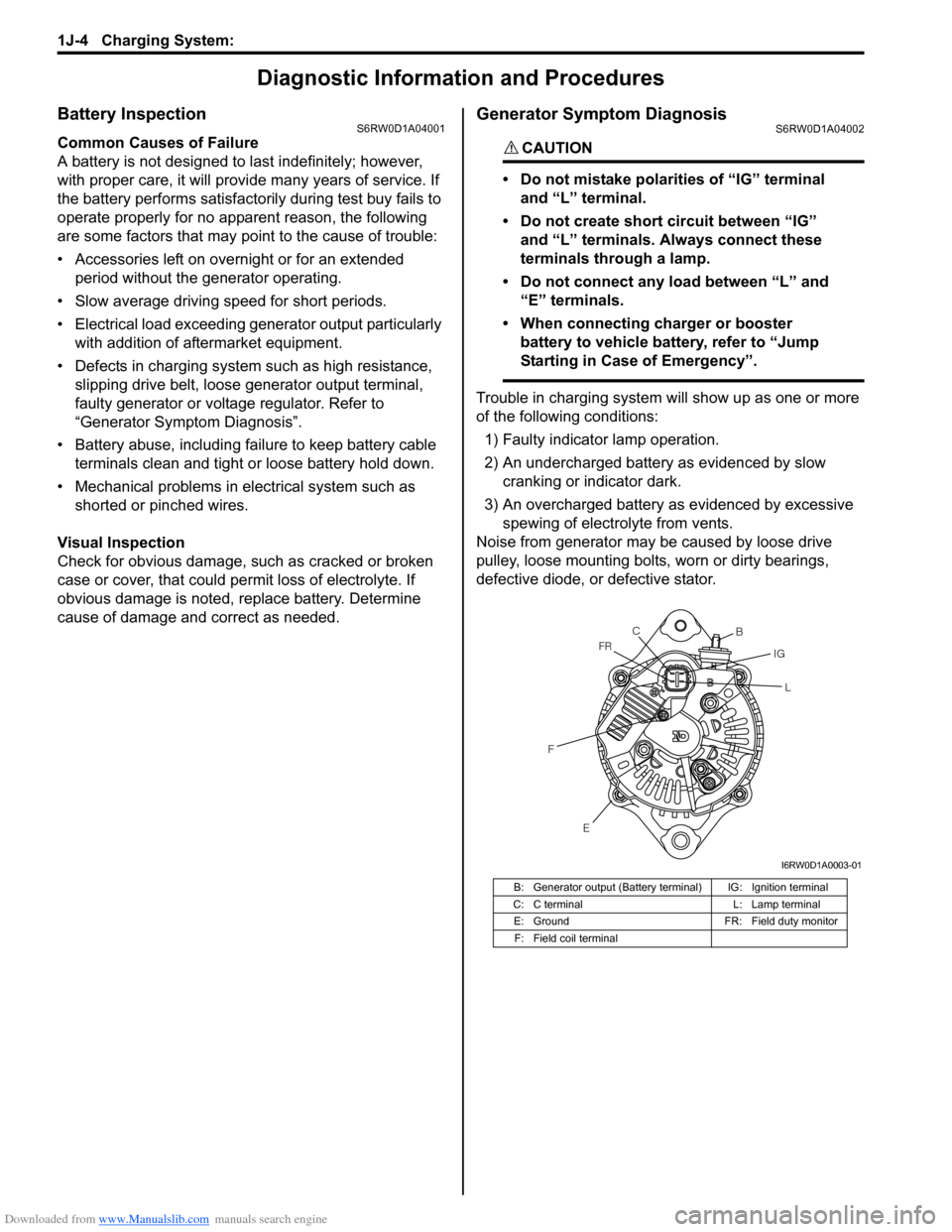

B: Generator output (Battery terminal) IG: Ignition terminal

C: C terminal L: Lamp terminal

E: Ground FR: Field duty monitor

F: Field coil terminal

E FFRC

B

IG

L

I6RW0D1A0003-01

Page 419 of 1556

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-5

Charging Indicator Lamp Operation

Generator Test (Undercharged Battery Check)S6RW0D1A04003

This condition, as evidenced by slow cranking or low

specific gravity can be caused by one or more of the

following conditions even though indicator lamp may be

operating normal. The following procedure also applies

to cars with voltmeter and ammeter.

• Make sure that undercharged condition has not been

caused by accessories left on for extended period of

time.

• Check drive belt for proper tension.

• If battery defect is suspected, refer to “Battery

Description”.

• Inspect wiring for defects. Check all connections for

tightness and cleanliness, battery cable connections

at battery, starting motor and ignition ground cable.

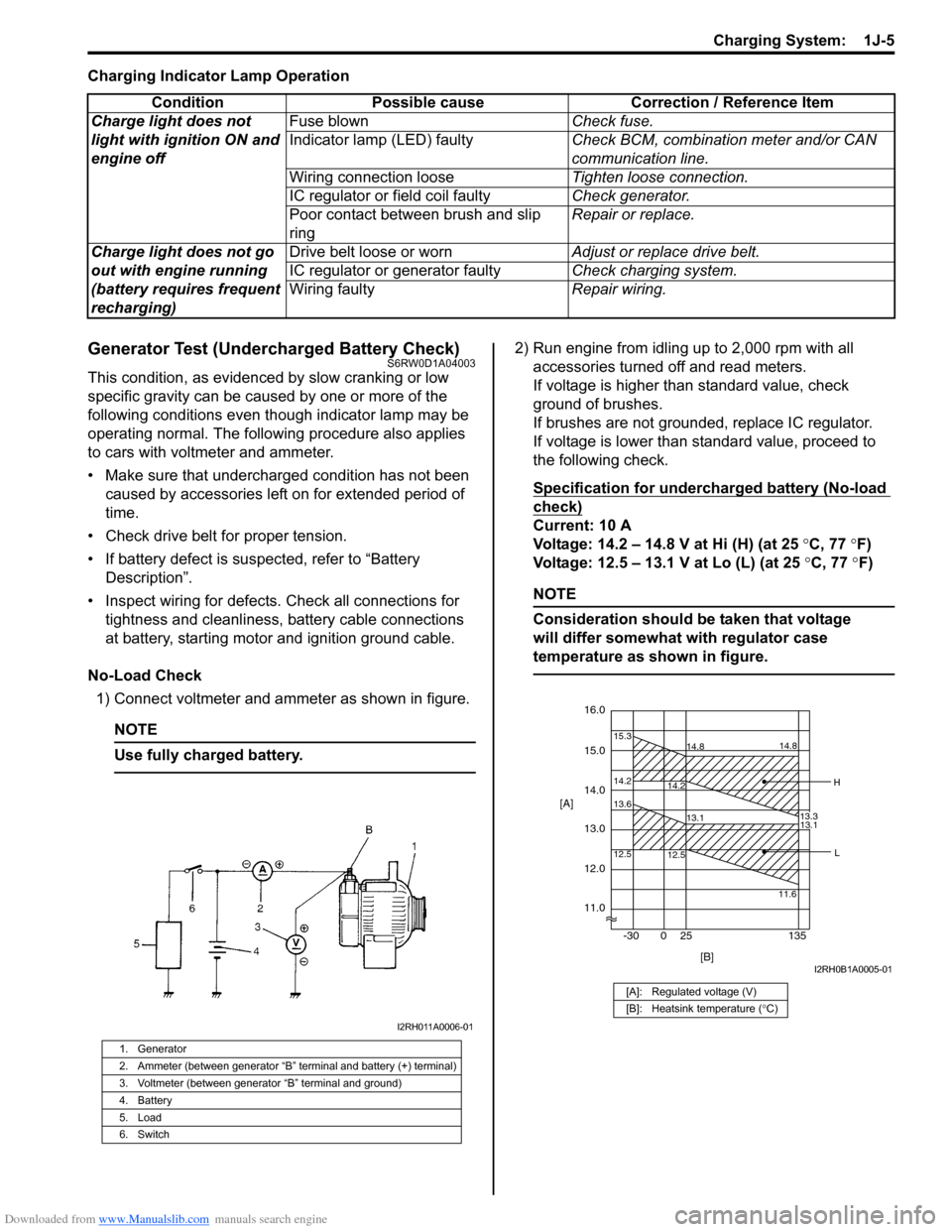

No-Load Check

1) Connect voltmeter and ammeter as shown in figure.

NOTE

Use fully charged battery.

2) Run engine from idling up to 2,000 rpm with all

accessories turned off and read meters.

If voltage is higher than standard value, check

ground of brushes.

If brushes are not grounded, replace IC regulator.

If voltage is lower than standard value, proceed to

the following check.

Specification for undercharged battery (No-load

check)

Current: 10 A

Voltage: 14.2 – 14.8 V at Hi (H) (at 25 °C, 77 °F)

Voltage: 12.5 – 13.1 V at Lo (L) (at 25 °C, 77 °F)

NOTE

Consideration should be taken that voltage

will differ somewhat with regulator case

temperature as shown in figure.

Condition Possible cause Correction / Reference Item

Charge light does not

light with ignition ON and

engine offFuse blownCheck fuse.

Indicator lamp (LED) faultyCheck BCM, combination meter and/or CAN

communication line.

Wiring connection looseTighten loose connection.

IC regulator or field coil faultyCheck generator.

Poor contact between brush and slip

ringRepair or replace.

Charge light does not go

out with engine running

(battery requires frequent

recharging)Drive belt loose or wornAdjust or replace drive belt.

IC regulator or generator faultyCheck charging system.

Wiring faultyRepair wiring.

1. Generator

2. Ammeter (between generator “B” terminal and battery (+) terminal)

3. Voltmeter (between generator “B” terminal and ground)

4. Battery

5. Load

6. Switch

I2RH011A0006-01

[A]: Regulated voltage (V)

[B]: Heatsink temperature (°C)

16.0

12.0

14.2 15.3

14.8

14.2

13.3 14.8

15.0

11.0 14.0

13.0 [A]

12.5 13.6

13.1

12.5

11.613.1

[B] -30 0 25 135

H

L

I2RH0B1A0005-01

Page 420 of 1556

Downloaded from www.Manualslib.com manuals search engine 1J-6 Charging System:

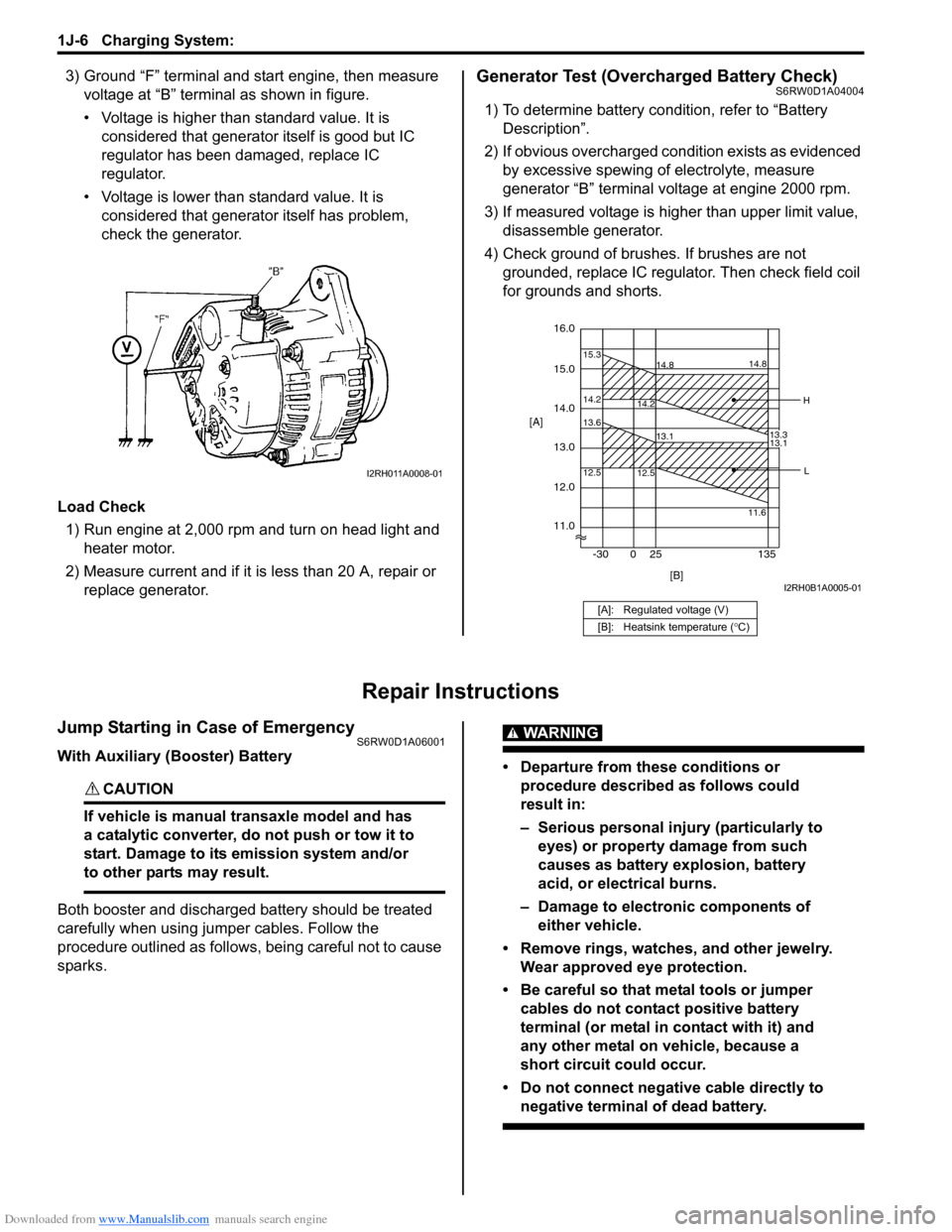

3) Ground “F” terminal and start engine, then measure

voltage at “B” terminal as shown in figure.

• Voltage is higher than standard value. It is

considered that generator itself is good but IC

regulator has been damaged, replace IC

regulator.

• Voltage is lower than standard value. It is

considered that generator itself has problem,

check the generator.

Load Check

1) Run engine at 2,000 rpm and turn on head light and

heater motor.

2) Measure current and if it is less than 20 A, repair or

replace generator.Generator Test (Overcharged Battery Check)S6RW0D1A04004

1) To determine battery condition, refer to “Battery

Description”.

2) If obvious overcharged condition exists as evidenced

by excessive spewing of electrolyte, measure

generator “B” terminal voltage at engine 2000 rpm.

3) If measured voltage is higher than upper limit value,

disassemble generator.

4) Check ground of brushes. If brushes are not

grounded, replace IC regulator. Then check field coil

for grounds and shorts.

Repair Instructions

Jump Starting in Case of EmergencyS6RW0D1A06001

With Auxiliary (Booster) Battery

CAUTION!

If vehicle is manual transaxle model and has

a catalytic converter, do not push or tow it to

start. Damage to its emission system and/or

to other parts may result.

Both booster and discharged battery should be treated

carefully when using jumper cables. Follow the

procedure outlined as follows, being careful not to cause

sparks.

WARNING!

• Departure from these conditions or

procedure described as follows could

result in:

– Serious personal injury (particularly to

eyes) or property damage from such

causes as battery explosion, battery

acid, or electrical burns.

– Damage to electronic components of

either vehicle.

• Remove rings, watches, and other jewelry.

Wear approved eye protection.

• Be careful so that metal tools or jumper

cables do not contact positive battery

terminal (or metal in contact with it) and

any other metal on vehicle, because a

short circuit could occur.

• Do not connect negative cable directly to

negative terminal of dead battery.

I2RH011A0008-01

[A]: Regulated voltage (V)

[B]: Heatsink temperature (°C)

16.0

12.0

14.2 15.3

14.8

14.2

13.3 14.8

15.0

11.0 14.0

13.0 [A]

12.5 13.6

13.1

12.5

11.613.1

[B] -30 0 25 135

H

L

I2RH0B1A0005-01

Page 421 of 1556

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-7

1) Set parking brake and place automatic transaxle in

PARK (NEUTRAL on manual transaxle). Turn off

ignition, turn off lights and all other electrical loads.

2) Check electrolyte level. If it is below low level line,

add distilled water.

3) Attach end of one jumper cable to positive terminal

of booster battery and the other end of the same

cable to positive terminal of discharged battery. (Use

12-volt battery only to jump start engine).

4) Attach one end of the remaining negative cable to

negative terminal of booster battery, and the other

end to a solid engine ground (such as exhaust

manifold) at least 45 cm (18 in.) away from battery of

vehicle being started.

5) Start engine of vehicle with booster battery and turn

off electrical accessories. Then start engine of the

vehicle with discharged battery.

6) Disconnect jumper cables in the exact reverse order.

With Charging Equipment

CAUTION!

When jump starting engine with charging

equipment, be sure equipment used is 12-

volt and negative ground. Do not use 24-volt

charging equipment. Using such equipment

can cause serious damage to electrical

system or electronic parts.

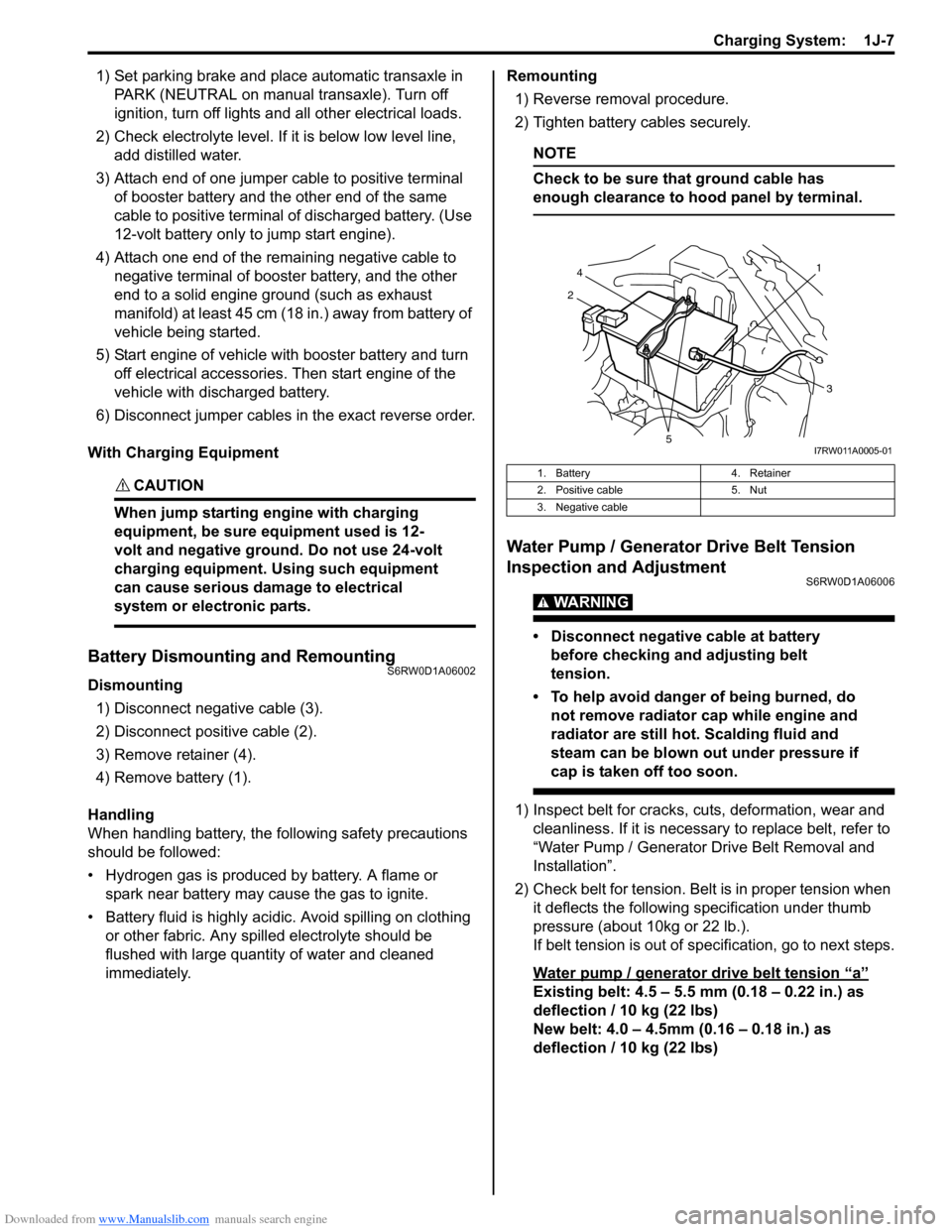

Battery Dismounting and RemountingS6RW0D1A06002

Dismounting

1) Disconnect negative cable (3).

2) Disconnect positive cable (2).

3) Remove retainer (4).

4) Remove battery (1).

Handling

When handling battery, the following safety precautions

should be followed:

• Hydrogen gas is produced by battery. A flame or

spark near battery may cause the gas to ignite.

• Battery fluid is highly acidic. Avoid spilling on clothing

or other fabric. Any spilled electrolyte should be

flushed with large quantity of water and cleaned

immediately.Remounting

1) Reverse removal procedure.

2) Tighten battery cables securely.

NOTE

Check to be sure that ground cable has

enough clearance to hood panel by terminal.

Water Pump / Generator Drive Belt Tension

Inspection and Adjustment

S6RW0D1A06006

WARNING!

• Disconnect negative cable at battery

before checking and adjusting belt

tension.

• To help avoid danger of being burned, do

not remove radiator cap while engine and

radiator are still hot. Scalding fluid and

steam can be blown out under pressure if

cap is taken off too soon.

1) Inspect belt for cracks, cuts, deformation, wear and

cleanliness. If it is necessary to replace belt, refer to

“Water Pump / Generator Drive Belt Removal and

Installation”.

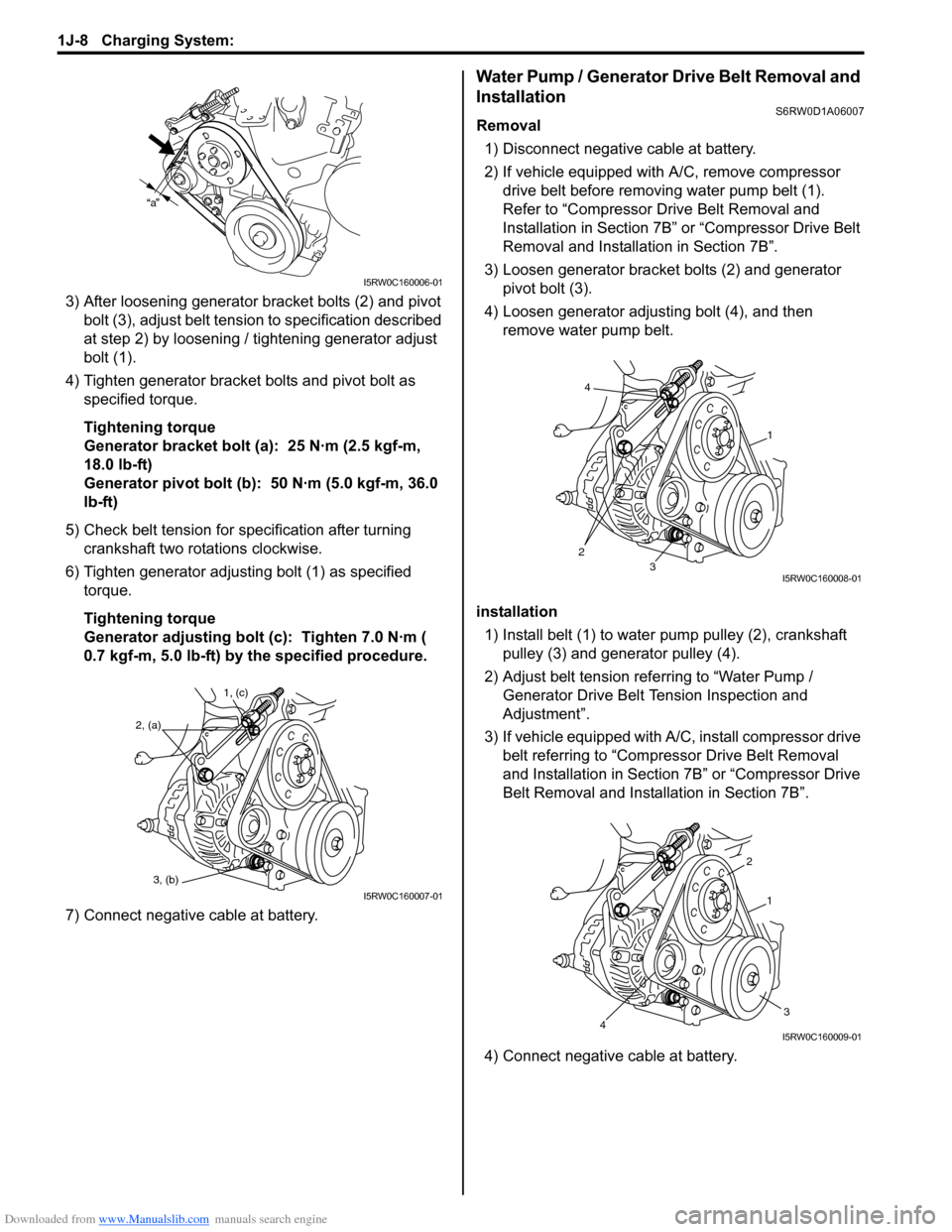

2) Check belt for tension. Belt is in proper tension when

it deflects the following specification under thumb

pressure (about 10kg or 22 lb.).

If belt tension is out of specification, go to next steps.

Water pump / generator drive belt tension

“a”

Existing belt: 4.5 – 5.5 mm (0.18 – 0.22 in.) as

deflection / 10 kg (22 lbs)

New belt: 4.0 – 4.5mm (0.16 – 0.18 in.) as

deflection / 10 kg (22 lbs)

1. Battery 4. Retainer

2. Positive cable 5. Nut

3. Negative cable

21

4

3

5I7RW011A0005-01

Page 422 of 1556

Downloaded from www.Manualslib.com manuals search engine 1J-8 Charging System:

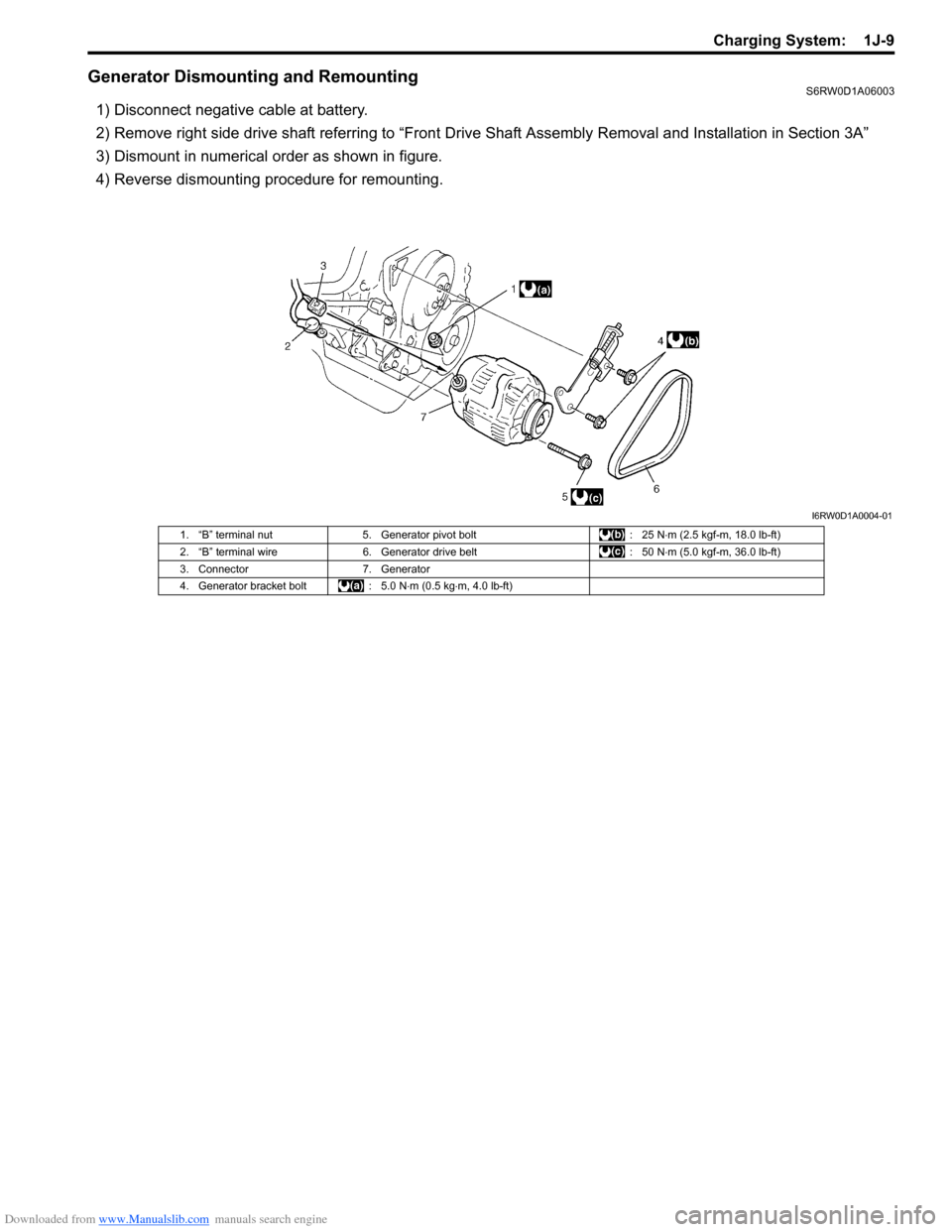

3) After loosening generator bracket bolts (2) and pivot

bolt (3), adjust belt tension to specification described

at step 2) by loosening / tightening generator adjust

bolt (1).

4) Tighten generator bracket bolts and pivot bolt as

specified torque.

Tightening torque

Generator bracket bolt (a): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

Generator pivot bolt (b): 50 N·m (5.0 kgf-m, 36.0

lb-ft)

5) Check belt tension for specification after turning

crankshaft two rotations clockwise.

6) Tighten generator adjusting bolt (1) as specified

torque.

Tightening torque

Generator adjusting bolt (c): Tighten 7.0 N·m (

0.7 kgf-m, 5.0 lb-ft) by the specified procedure.

7) Connect negative cable at battery.

Water Pump / Generator Drive Belt Removal and

Installation

S6RW0D1A06007

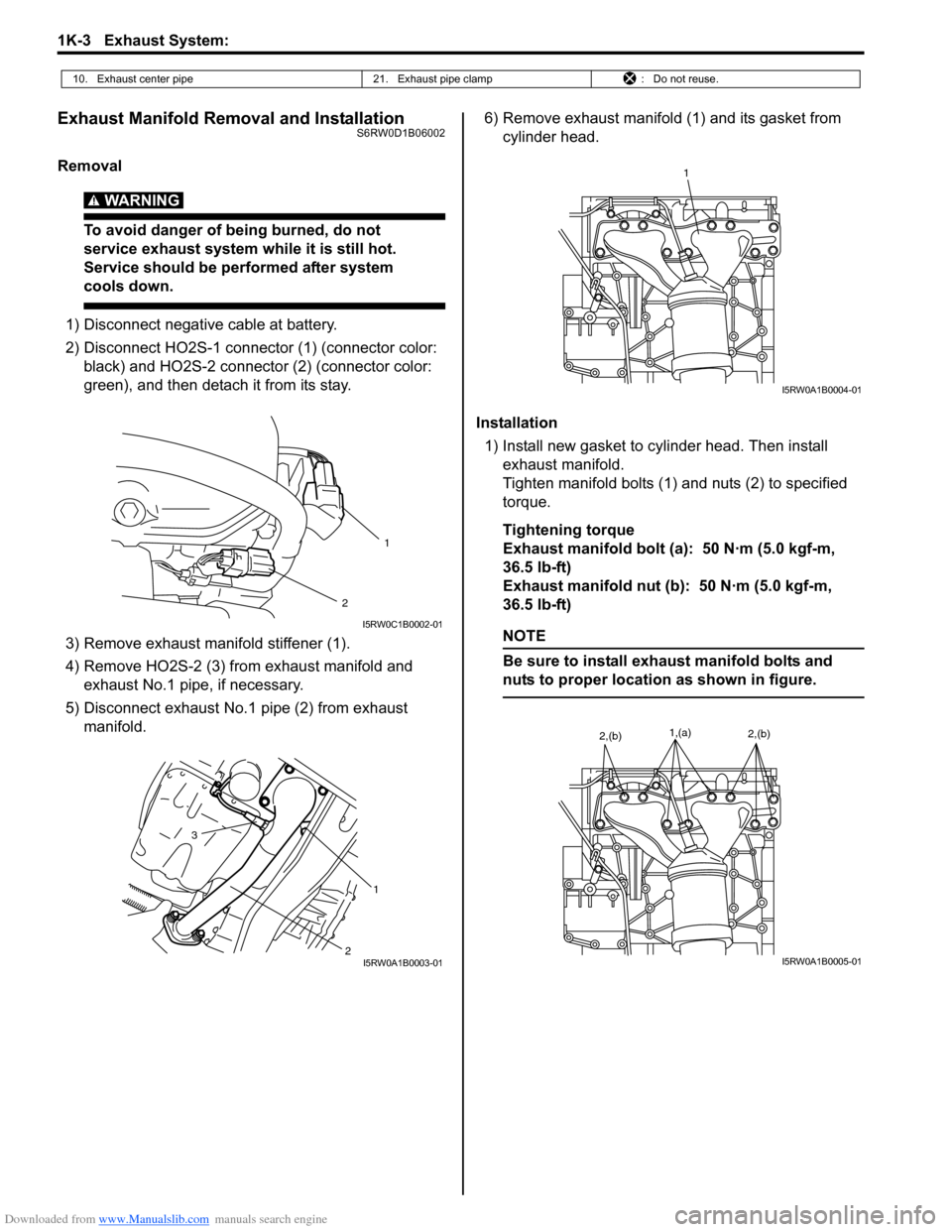

Removal

1) Disconnect negative cable at battery.

2) If vehicle equipped with A/C, remove compressor

drive belt before removing water pump belt (1).

Refer to “Compressor Drive Belt Removal and

Installation in Section 7B” or “Compressor Drive Belt

Removal and Installation in Section 7B”.

3) Loosen generator bracket bolts (2) and generator

pivot bolt (3).

4) Loosen generator adjusting bolt (4), and then

remove water pump belt.

installation

1) Install belt (1) to water pump pulley (2), crankshaft

pulley (3) and generator pulley (4).

2) Adjust belt tension referring to “Water Pump /

Generator Drive Belt Tension Inspection and

Adjustment”.

3) If vehicle equipped with A/C, install compressor drive

belt referring to “Compressor Drive Belt Removal

and Installation in Section 7B” or “Compressor Drive

Belt Removal and Installation in Section 7B”.

4) Connect negative cable at battery.

a

I5RW0C160006-01

1, (c)

2, (a)

3, (b)

I5RW0C160007-01

4

23

1

I5RW0C160008-01

2

1

34I5RW0C160009-01

Page 423 of 1556

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-9

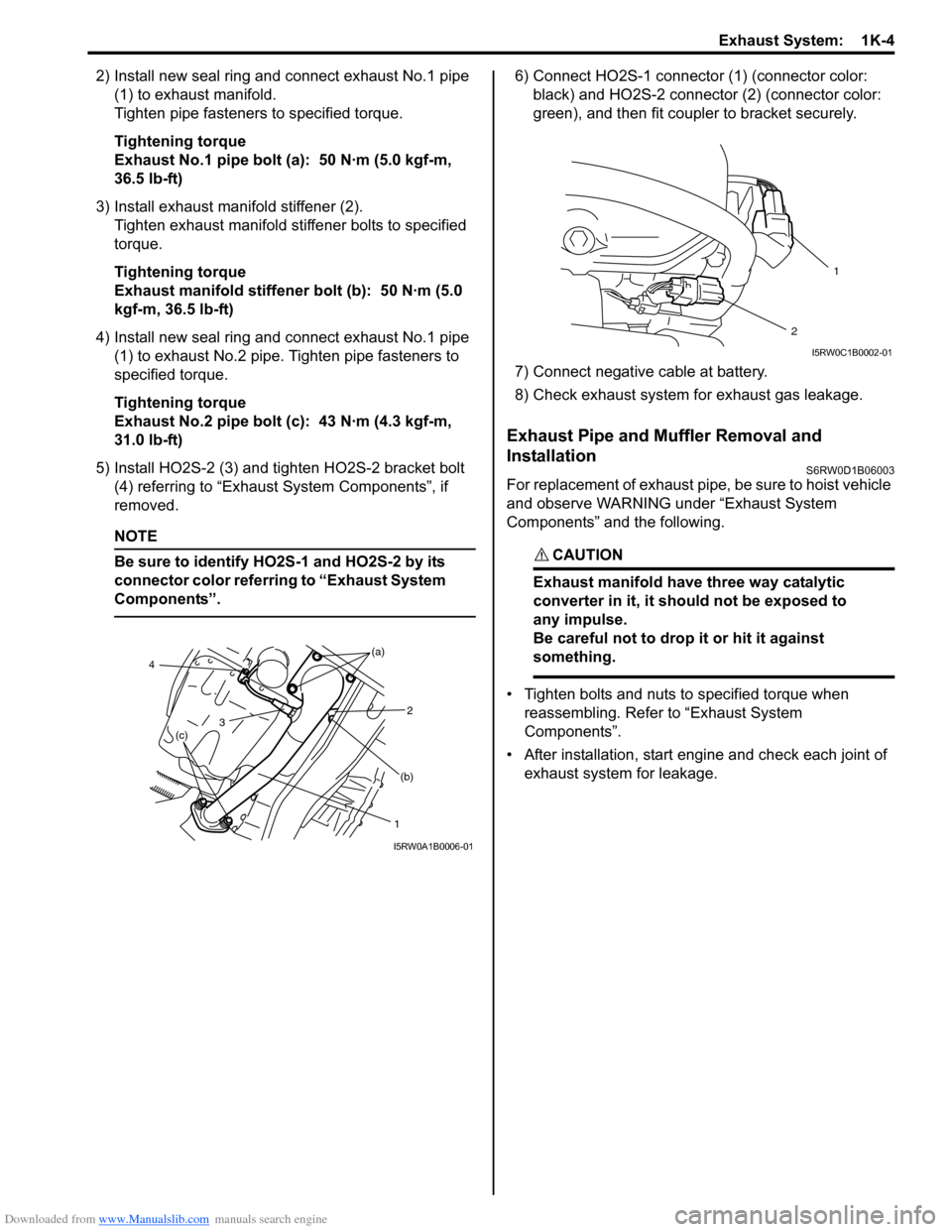

Generator Dismounting and RemountingS6RW0D1A06003

1) Disconnect negative cable at battery.

2) Remove right side drive shaft referring to “Front Drive Shaft Assembly Removal and Installation in Section 3A”

3) Dismount in numerical order as shown in figure.

4) Reverse dismounting procedure for remounting.

I6RW0D1A0004-01

1. “B” terminal nut 5. Generator pivot bolt : 25 N⋅m (2.5 kgf-m, 18.0 lb-ft)

2. “B” terminal wire 6. Generator drive belt : 50 N⋅m (5.0 kgf-m, 36.0 lb-ft)

3. Connector 7. Generator

4. Generator bracket bolt : 5.0 N⋅m (0.5 kg⋅m, 4.0 lb-ft)

Page 430 of 1556

Downloaded from www.Manualslib.com manuals search engine 1K-3 Exhaust System:

Exhaust Manifold Removal and InstallationS6RW0D1B06002

Removal

WARNING!

To avoid danger of being burned, do not

service exhaust system while it is still hot.

Service should be performed after system

cools down.

1) Disconnect negative cable at battery.

2) Disconnect HO2S-1 connector (1) (connector color:

black) and HO2S-2 connector (2) (connector color:

green), and then detach it from its stay.

3) Remove exhaust manifold stiffener (1).

4) Remove HO2S-2 (3) from exhaust manifold and

exhaust No.1 pipe, if necessary.

5) Disconnect exhaust No.1 pipe (2) from exhaust

manifold.6) Remove exhaust manifold (1) and its gasket from

cylinder head.

Installation

1) Install new gasket to cylinder head. Then install

exhaust manifold.

Tighten manifold bolts (1) and nuts (2) to specified

torque.

Tightening torque

Exhaust manifold bolt (a): 50 N·m (5.0 kgf-m,

36.5 lb-ft)

Exhaust manifold nut (b): 50 N·m (5.0 kgf-m,

36.5 lb-ft)

NOTE

Be sure to install exhaust manifold bolts and

nuts to proper location as shown in figure.

10. Exhaust center pipe 21. Exhaust pipe clamp : Do not reuse.

2

1

I5RW0C1B0002-01

2 3

1

I5RW0A1B0003-01

1

I5RW0A1B0004-01

1,(a)2,(b)2,(b)

I5RW0A1B0005-01

Page 431 of 1556

Downloaded from www.Manualslib.com manuals search engine Exhaust System: 1K-4

2) Install new seal ring and connect exhaust No.1 pipe

(1) to exhaust manifold.

Tighten pipe fasteners to specified torque.

Tightening torque

Exhaust No.1 pipe bolt (a): 50 N·m (5.0 kgf-m,

36.5 lb-ft)

3) Install exhaust manifold stiffener (2).

Tighten exhaust manifold stiffener bolts to specified

torque.

Tightening torque

Exhaust manifold stiffener bolt (b): 50 N·m (5.0

kgf-m, 36.5 lb-ft)

4) Install new seal ring and connect exhaust No.1 pipe

(1) to exhaust No.2 pipe. Tighten pipe fasteners to

specified torque.

Tightening torque

Exhaust No.2 pipe bolt (c): 43 N·m (4.3 kgf-m,

31.0 lb-ft)

5) Install HO2S-2 (3) and tighten HO2S-2 bracket bolt

(4) referring to “Exhaust System Components”, if

removed.

NOTE

Be sure to identify HO2S-1 and HO2S-2 by its

connector color referring to “Exhaust System

Components”.

6) Connect HO2S-1 connector (1) (connector color:

black) and HO2S-2 connector (2) (connector color:

green), and then fit coupler to bracket securely.

7) Connect negative cable at battery.

8) Check exhaust system for exhaust gas leakage.

Exhaust Pipe and Muffler Removal and

Installation

S6RW0D1B06003

For replacement of exhaust pipe, be sure to hoist vehicle

and observe WARNING under “Exhaust System

Components” and the following.

CAUTION!

Exhaust manifold have three way catalytic

converter in it, it should not be exposed to

any impulse.

Be careful not to drop it or hit it against

something.

• Tighten bolts and nuts to specified torque when

reassembling. Refer to “Exhaust System

Components”.

• After installation, start engine and check each joint of

exhaust system for leakage.

1 (c)3 4

(a)

(b)

2

I5RW0A1B0006-01

2

1

I5RW0C1B0002-01

Page 455 of 1556

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-18

Front Suspension Frame, Stabilizer Bar and/or

Bushing Removal and Installation

S6RW0D2206015

WARNING!

When supporting and installing front

suspension frame, be sure to apply some

supporting equipment (such as mission jack)

at well-balanced position in the center

section of front suspension frame so as to

prevent from its drop. Otherwise drop and

injure.

CAUTION!

When removal and installing suspension

control arm, be careful not to damage dust

boots of suspension control arm joint by

drive shaft dust cover and brake dust cover.

Removal

1) Disconnect negative (–) cable at battery.

2) Remove air cleaner assembly referring to “Air

Cleaner Assembly Removal and Installation in

Section 1D”.

3) Remove hood referring to “Hood Removal and

Installation in Section 9J”.

4) Hoist vehicle and remove front wheels.

5) Remove exhaust No.1, No.2 and center pipes

referring to “Exhaust System Components in Section

1K”.

6) Remove steering gear case mounting bolt referring

to “Steering Gear Case Assembly Components in

Section 6C”.

7) Fix steering gear case to body with rope to avoid the

steering gear case fall off when front suspension

frame is lowered.

8) Remove suspension control arms and disconnect

stabilizer joints.

9) Support engine assembly by using chain hoist (1).10) Remove engine rear mounting nut and mounting

member nut referring to “Engine Mountings

Components in Section 1D”.

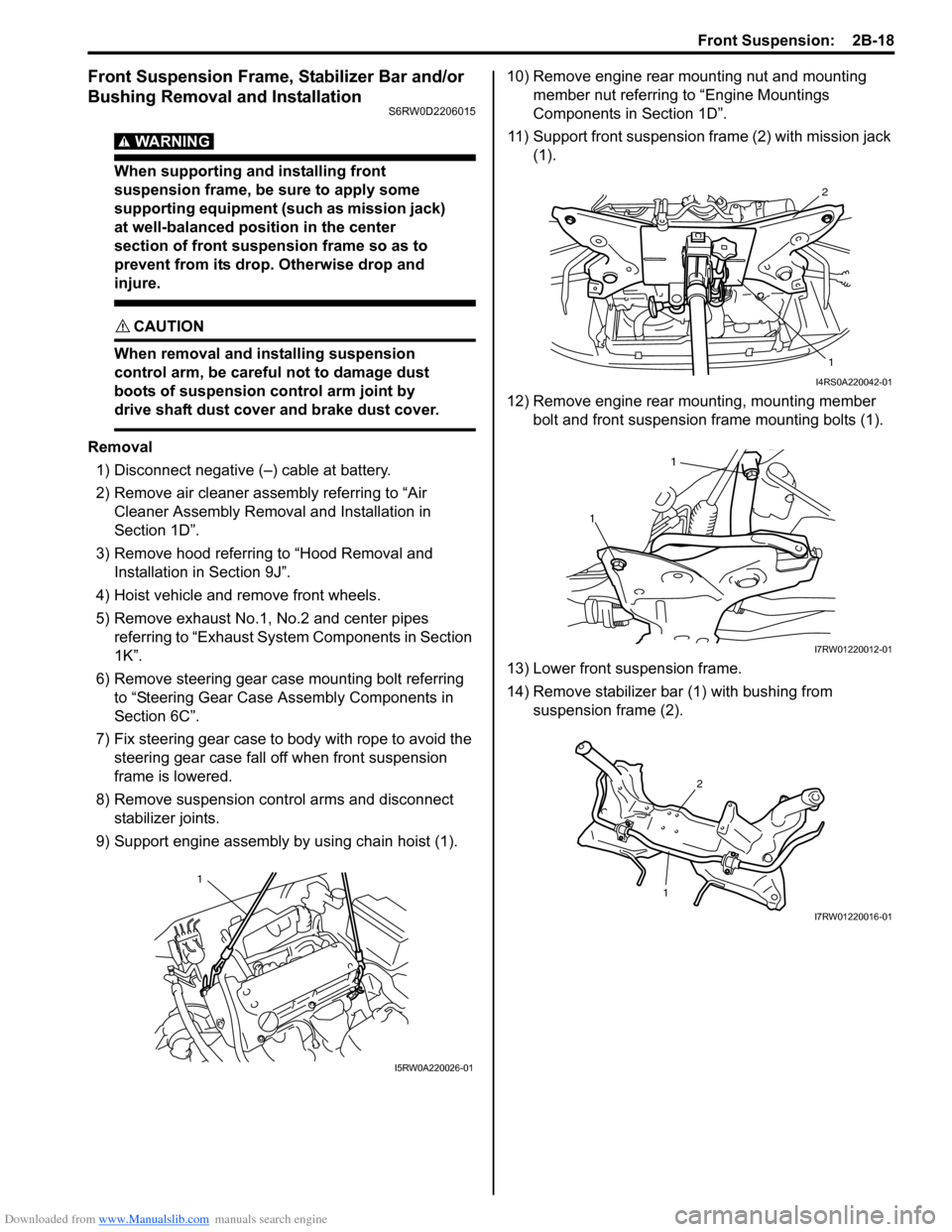

11) Support front suspension frame (2) with mission jack

(1).

12) Remove engine rear mounting, mounting member

bolt and front suspension frame mounting bolts (1).

13) Lower front suspension frame.

14) Remove stabilizer bar (1) with bushing from

suspension frame (2).

1

I5RW0A220026-01

2

1

I4RS0A220042-01

1

1

I7RW01220012-01

12

I7RW01220016-01

Page 457 of 1556

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-20

12) Install exhaust No.1, No.2 and center pipe referring

to “Exhaust System Components in Section 1K”.

13) Install wheel and tighten nut to specified torque.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

14) Install air cleaner assembly referring to “Air Cleaner

Assembly Removal and Installation in Section 1D”.

15) Install hood referring to “Hood Removal and

Installation in Section 9J”.

16) Lower hoist and vehicle in unloaded condition,

tighten suspension control arm bolts to specified

torque.

Tightening torque

Suspension control arm bolt: 95 N·m (9.5 kgf-m,

69.0 lb-ft)

17) Connect negative (–) cable at battery.

18) Confirm front wheel alignment referring to “Front

Wheel Alignment Inspection and Adjustment”.

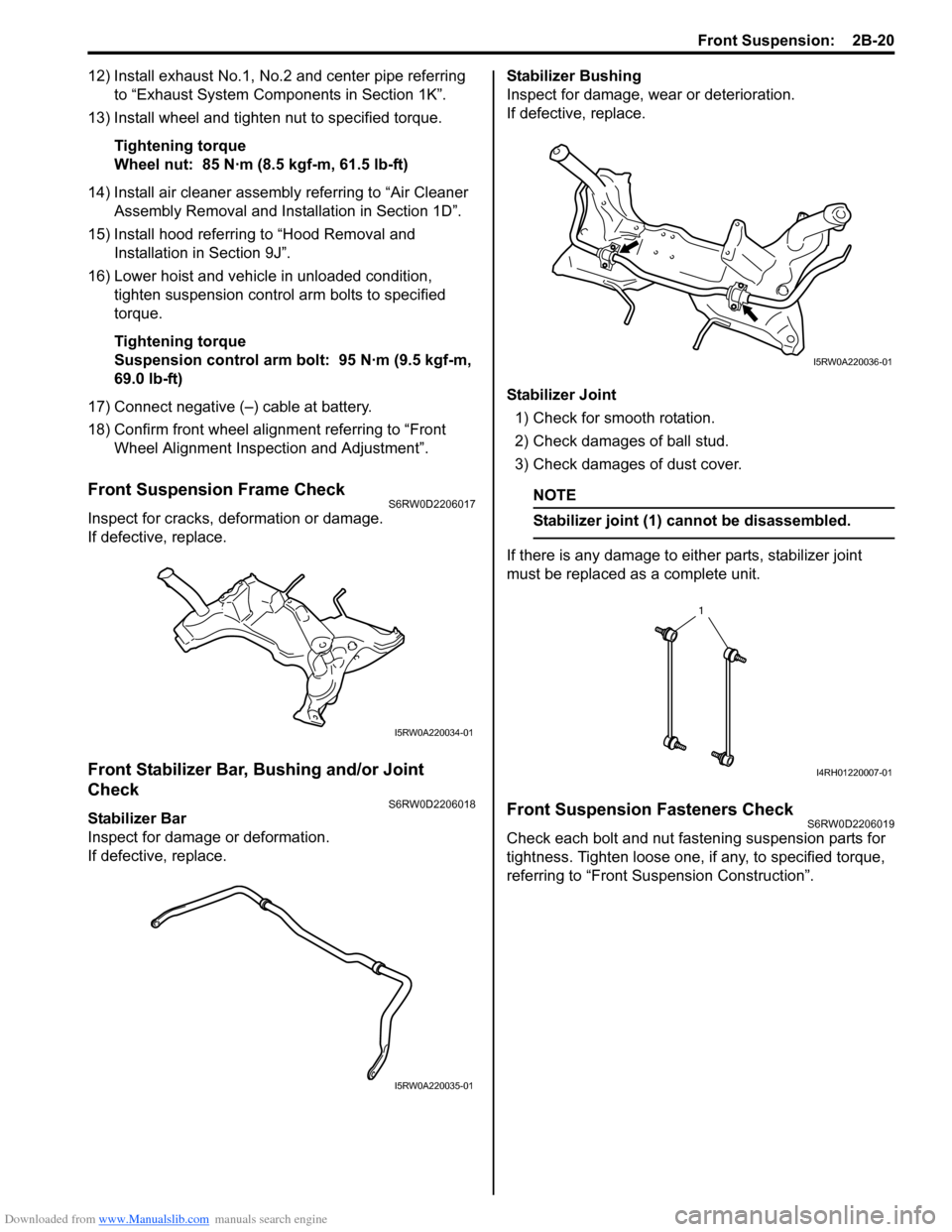

Front Suspension Frame CheckS6RW0D2206017

Inspect for cracks, deformation or damage.

If defective, replace.

Front Stabilizer Bar, Bushing and/or Joint

Check

S6RW0D2206018

Stabilizer Bar

Inspect for damage or deformation.

If defective, replace.Stabilizer Bushing

Inspect for damage, wear or deterioration.

If defective, replace.

Stabilizer Joint

1) Check for smooth rotation.

2) Check damages of ball stud.

3) Check damages of dust cover.

NOTE

Stabilizer joint (1) cannot be disassembled.

If there is any damage to either parts, stabilizer joint

must be replaced as a complete unit.

Front Suspension Fasteners CheckS6RW0D2206019

Check each bolt and nut fastening suspension parts for

tightness. Tighten loose one, if any, to specified torque,

referring to “Front Suspension Construction”.

I5RW0A220034-01

I5RW0A220035-01

I5RW0A220036-01

1

I4RH01220007-01