Steering angle SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 437 of 1556

Downloaded from www.Manualslib.com manuals search engine Suspension General Diagnosis: 2A-3

Specifications

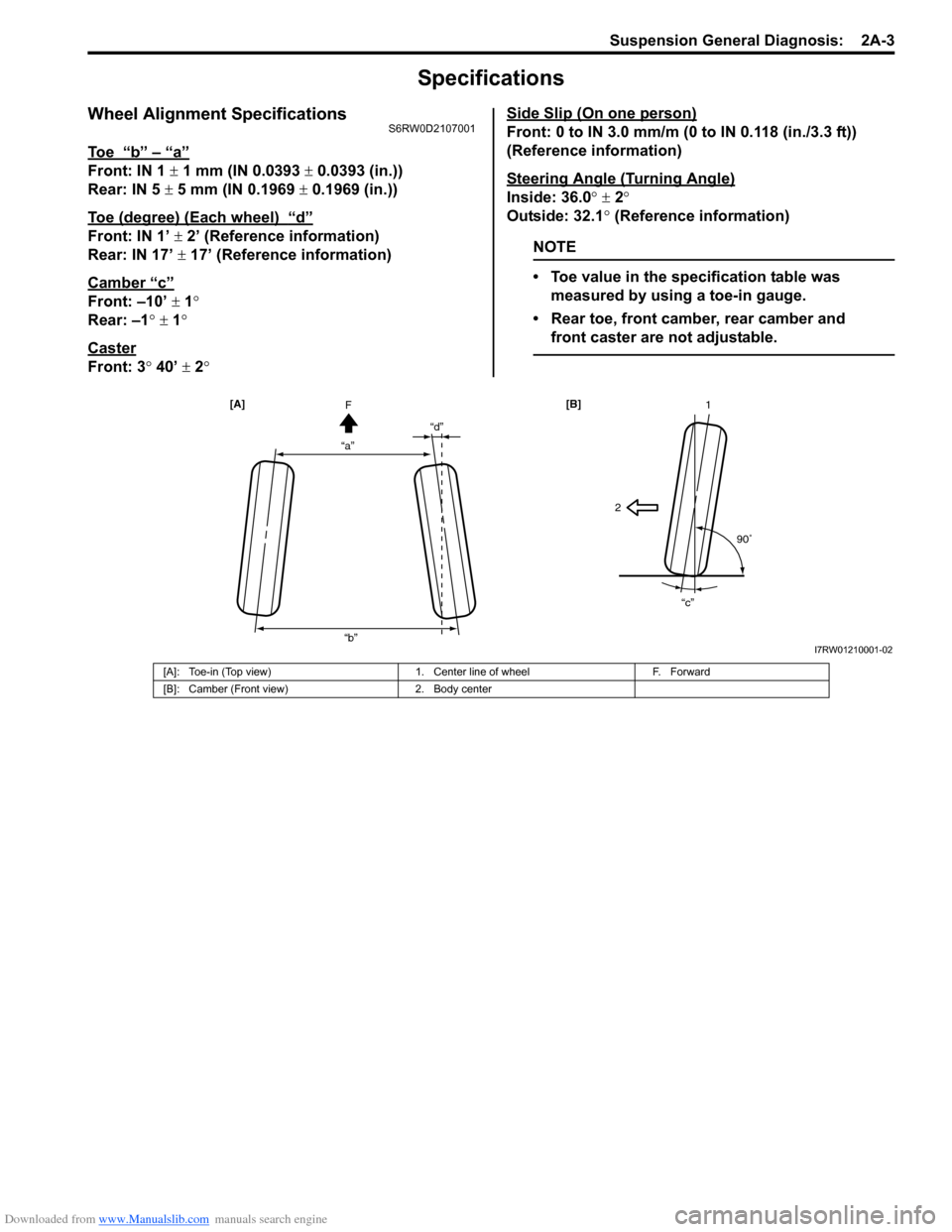

Wheel Alignment SpecificationsS6RW0D2107001

To e “b” – “a”

Front: IN 1 ± 1 mm (IN 0.0393 ± 0.0393 (in.))

Rear: IN 5 ± 5 mm (IN 0.1969 ± 0.1969 (in.))

Toe (degree) (Each wheel)

“d”

Front: IN 1’ ± 2’ (Reference information)

Rear: IN 17’ ± 17’ (Reference information)

Camber

“c”

Front: –10’ ± 1°

Rear: –1° ± 1°

Caster

Front: 3° 40’ ± 2°Side Slip (On one person)

Front: 0 to IN 3.0 mm/m (0 to IN 0.118 (in./3.3 ft))

(Reference information)

Steering Angle (Turning Angle)

Inside: 36.0° ± 2°

Outside: 32.1° (Reference information)

NOTE

• Toe value in the specification table was

measured by using a toe-in gauge.

• Rear toe, front camber, rear camber and

front caster are not adjustable.

“a”“d”

“b”F [A]

21

90�

“c” [B]

I7RW01210001-02

[A]: Toe-in (Top view) 1. Center line of wheel F. Forward

[B]: Camber (Front view) 2. Body center

Page 440 of 1556

Downloaded from www.Manualslib.com manuals search engine 2B-3 Front Suspension:

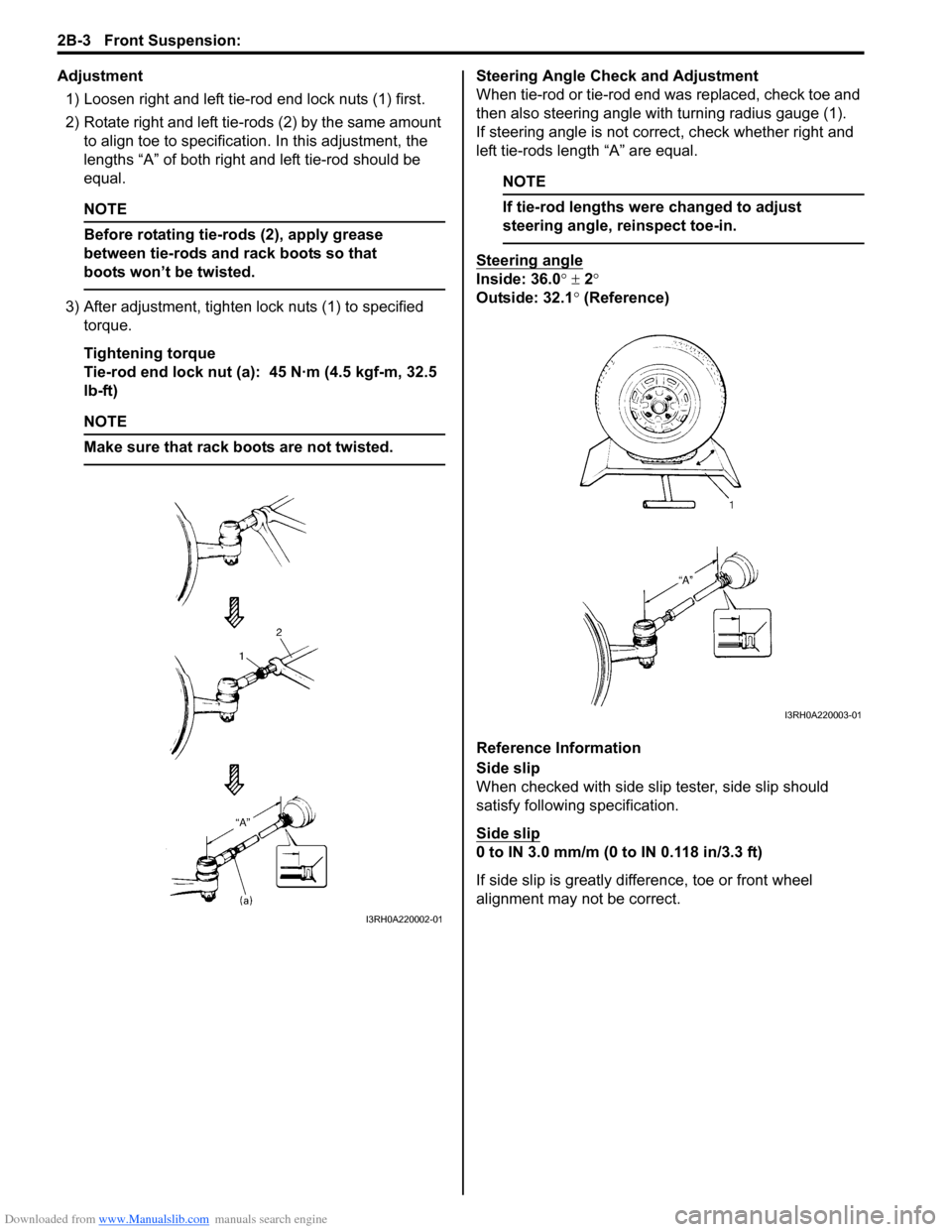

Adjustment

1) Loosen right and left tie-rod end lock nuts (1) first.

2) Rotate right and left tie-rods (2) by the same amount

to align toe to specification. In this adjustment, the

lengths “A” of both right and left tie-rod should be

equal.

NOTE

Before rotating tie-rods (2), apply grease

between tie-rods and rack boots so that

boots won’t be twisted.

3) After adjustment, tighten lock nuts (1) to specified

torque.

Tightening torque

Tie-rod end lock nut (a): 45 N·m (4.5 kgf-m, 32.5

lb-ft)

NOTE

Make sure that rack boots are not twisted.

Steering Angle Check and Adjustment

When tie-rod or tie-rod end was replaced, check toe and

then also steering angle with turning radius gauge (1).

If steering angle is not correct, check whether right and

left tie-rods length “A” are equal.

NOTE

If tie-rod lengths were changed to adjust

steering angle, reinspect toe-in.

Steering angle

Inside: 36.0° ± 2°

Outside: 32.1° (Reference)

Reference Information

Side slip

When checked with side slip tester, side slip should

satisfy following specification.

Side slip

0 to IN 3.0 mm/m (0 to IN 0.118 in/3.3 ft)

If side slip is greatly difference, toe or front wheel

alignment may not be correct.

I3RH0A220002-01

I3RH0A220003-01

Page 511 of 1556

Downloaded from www.Manualslib.com manuals search engine Differential: 3B-14

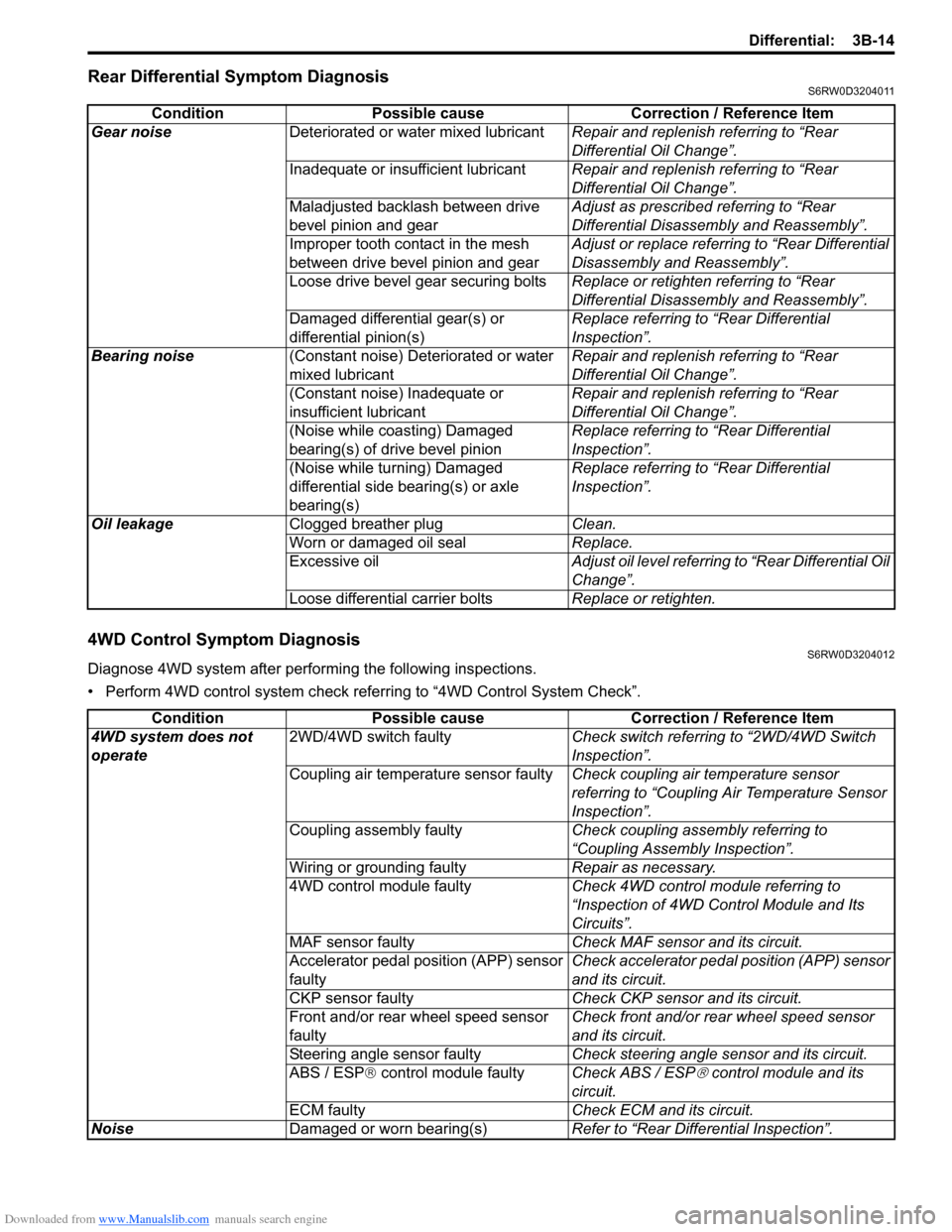

Rear Differential Symptom DiagnosisS6RW0D3204011

4WD Control Symptom DiagnosisS6RW0D3204012

Diagnose 4WD system after performing the following inspections.

• Perform 4WD control system check referring to “4WD Control System Check”. Condition Possible cause Correction / Reference Item

Gear noiseDeteriorated or water mixed lubricantRepair and replenish referring to “Rear

Differential Oil Change”.

Inadequate or insufficient lubricantRepair and replenish referring to “Rear

Differential Oil Change”.

Maladjusted backlash between drive

bevel pinion and gearAdjust as prescribed referring to “Rear

Differential Disassembly and Reassembly”.

Improper tooth contact in the mesh

between drive bevel pinion and gearAdjust or replace referring to “Rear Differential

Disassembly and Reassembly”.

Loose drive bevel gear securing boltsReplace or retighten referring to “Rear

Differential Disassembly and Reassembly”.

Damaged differential gear(s) or

differential pinion(s)Replace referring to “Rear Differential

Inspection”.

Bearing noise(Constant noise) Deteriorated or water

mixed lubricantRepair and replenish referring to “Rear

Differential Oil Change”.

(Constant noise) Inadequate or

insufficient lubricantRepair and replenish referring to “Rear

Differential Oil Change”.

(Noise while coasting) Damaged

bearing(s) of drive bevel pinionReplace referring to “Rear Differential

Inspection”.

(Noise while turning) Damaged

differential side bearing(s) or axle

bearing(s)Replace referring to “Rear Differential

Inspection”.

Oil leakageClogged breather plugClean.

Worn or damaged oil sealReplace.

Excessive oilAdjust oil level referring to “Rear Differential Oil

Change”.

Loose differential carrier boltsReplace or retighten.

Condition Possible cause Correction / Reference Item

4WD system does not

operate2WD/4WD switch faultyCheck switch referring to “2WD/4WD Switch

Inspection”.

Coupling air temperature sensor faultyCheck coupling air temperature sensor

referring to “Coupling Air Temperature Sensor

Inspection”.

Coupling assembly faultyCheck coupling assembly referring to

“Coupling Assembly Inspection”.

Wiring or grounding faultyRepair as necessary.

4WD control module faultyCheck 4WD control module referring to

“Inspection of 4WD Control Module and Its

Circuits”.

MAF sensor faultyCheck MAF sensor and its circuit.

Accelerator pedal position (APP) sensor

faultyCheck accelerator pedal position (APP) sensor

and its circuit.

CKP sensor faultyCheck CKP sensor and its circuit.

Front and/or rear wheel speed sensor

faultyCheck front and/or rear wheel speed sensor

and its circuit.

Steering angle sensor faultyCheck steering angle sensor and its circuit.

ABS / ESP® control module faultyCheck ABS / ESP

® control module and its

circuit.

ECM faultyCheck ECM and its circuit.

NoiseDamaged or worn bearing(s)Refer to “Rear Differential Inspection”.

Page 919 of 1556

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-39

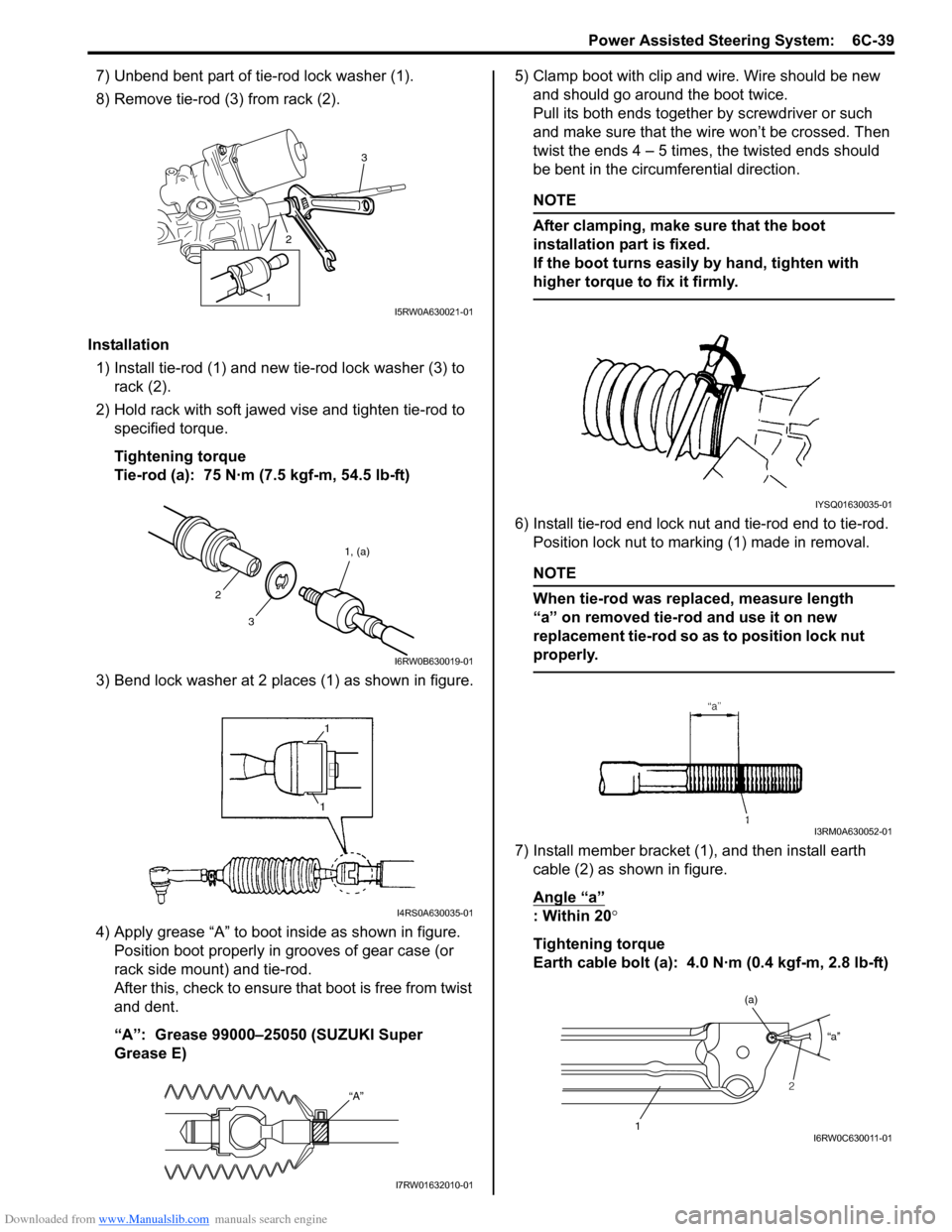

7) Unbend bent part of tie-rod lock washer (1).

8) Remove tie-rod (3) from rack (2).

Installation

1) Install tie-rod (1) and new tie-rod lock washer (3) to

rack (2).

2) Hold rack with soft jawed vise and tighten tie-rod to

specified torque.

Tightening torque

Tie-rod (a): 75 N·m (7.5 kgf-m, 54.5 lb-ft)

3) Bend lock washer at 2 places (1) as shown in figure.

4) Apply grease “A” to boot inside as shown in figure.

Position boot properly in grooves of gear case (or

rack side mount) and tie-rod.

After this, check to ensure that boot is free from twist

and dent.

“A”: Grease 99000–25050 (SUZUKI Super

Grease E) 5) Clamp boot with clip and wire. Wire should be new

and should go around the boot twice.

Pull its both ends together by screwdriver or such

and make sure that the wire won’t be crossed. Then

twist the ends 4 – 5 times, the twisted ends should

be bent in the circumferential direction.

NOTE

After clamping, make sure that the boot

installation part is fixed.

If the boot turns easily by hand, tighten with

higher torque to fix it firmly.

6) Install tie-rod end lock nut and tie-rod end to tie-rod.

Position lock nut to marking (1) made in removal.

NOTE

When tie-rod was replaced, measure length

“a” on removed tie-rod and use it on new

replacement tie-rod so as to position lock nut

properly.

7) Install member bracket (1), and then install earth

cable (2) as shown in figure.

Angle “a”

: Within 20°

Tightening torque

Earth cable bolt (a): 4.0 N·m (0.4 kgf-m, 2.8 lb-ft)

3

2

1I5RW0A630021-01

31, (a)

2

I6RW0B630019-01

I4RS0A630035-01

“A”

I7RW01632010-01

IYSQ01630035-01

I3RM0A630052-01

“a”

1

(a)

2

I6RW0C630011-01