cruise control SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 98 of 1556

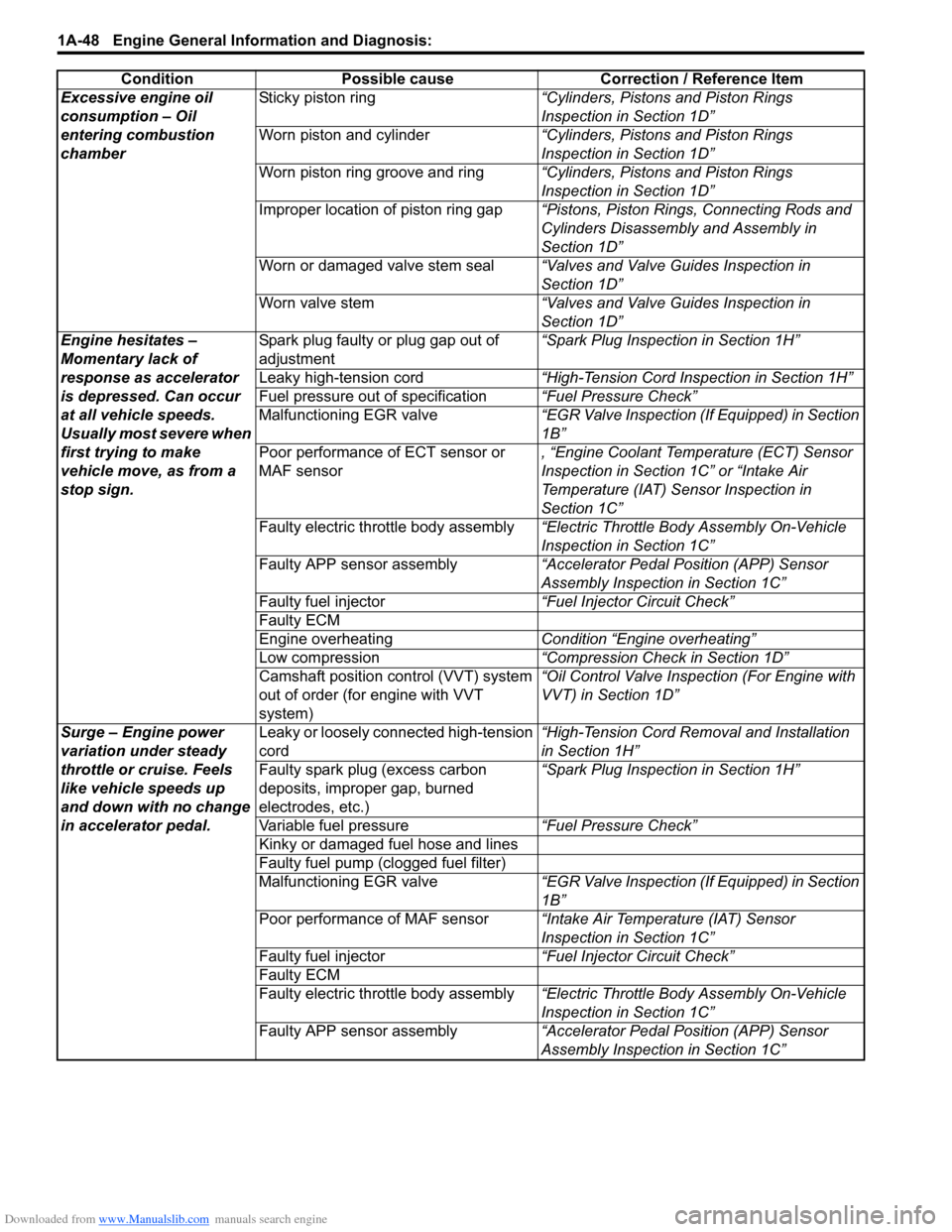

Downloaded from www.Manualslib.com manuals search engine 1A-48 Engine General Information and Diagnosis:

Excessive engine oil

consumption – Oil

entering combustion

chamberSticky piston ring“Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Worn piston and cylinder“Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Worn piston ring groove and ring“Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Improper location of piston ring gap“Pistons, Piston Rings, Connecting Rods and

Cylinders Disassembly and Assembly in

Section 1D”

Worn or damaged valve stem seal“Valves and Valve Guides Inspection in

Section 1D”

Worn valve stem“Valves and Valve Guides Inspection in

Section 1D”

Engine hesitates –

Momentary lack of

response as accelerator

is depressed. Can occur

at all vehicle speeds.

Usually most severe when

first trying to make

vehicle move, as from a

stop sign.Spark plug faulty or plug gap out of

adjustment“Spark Plug Inspection in Section 1H”

Leaky high-tension cord“High-Tension Cord Inspection in Section 1H”

Fuel pressure out of specification“Fuel Pressure Check”

Malfunctioning EGR valve“EGR Valve Inspection (If Equipped) in Section

1B”

Poor performance of ECT sensor or

MAF sensor, “Engine Coolant Temperature (ECT) Sensor

Inspection in Section 1C” or “Intake Air

Temperature (IAT) Sensor Inspection in

Section 1C”

Faulty electric throttle body assembly“Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly“Accelerator Pedal Position (APP) Sensor

Assembly Inspection in Section 1C”

Faulty fuel injector“Fuel Injector Circuit Check”

Faulty ECM

Engine overheatingCondition “Engine overheating”

Low compression“Compression Check in Section 1D”

Camshaft position control (VVT) system

out of order (for engine with VVT

system)“Oil Control Valve Inspection (For Engine with

VVT) in Section 1D”

Surge – Engine power

variation under steady

throttle or cruise. Feels

like vehicle speeds up

and down with no change

in accelerator pedal.Leaky or loosely connected high-tension

cord“High-Tension Cord Removal and Installation

in Section 1H”

Faulty spark plug (excess carbon

deposits, improper gap, burned

electrodes, etc.)“Spark Plug Inspection in Section 1H”

Variable fuel pressure“Fuel Pressure Check”

Kinky or damaged fuel hose and lines

Faulty fuel pump (clogged fuel filter)

Malfunctioning EGR valve“EGR Valve Inspection (If Equipped) in Section

1B”

Poor performance of MAF sensor“Intake Air Temperature (IAT) Sensor

Inspection in Section 1C”

Faulty fuel injector“Fuel Injector Circuit Check”

Faulty ECM

Faulty electric throttle body assembly“Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly“Accelerator Pedal Position (APP) Sensor

Assembly Inspection in Section 1C” Condition Possible cause Correction / Reference Item

Page 1127 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-88

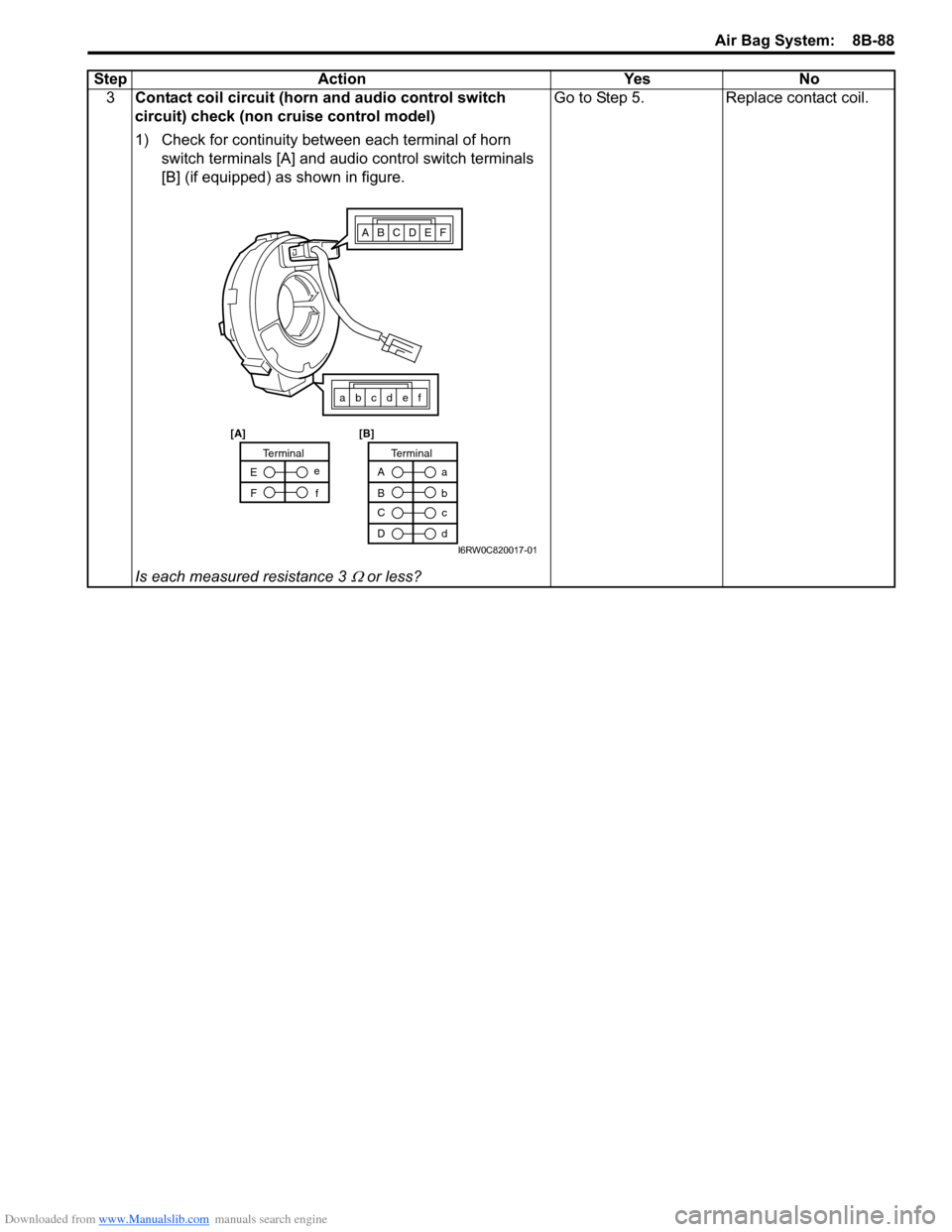

3Contact coil circuit (horn and audio control switch

circuit) check (non cruise control model)

1) Check for continuity between each terminal of horn

switch terminals [A] and audio control switch terminals

[B] (if equipped) as shown in figure.

Is each measured resistance 3

Ω or less?Go to Step 5. Replace contact coil. Step Action Yes No

ABCDEF

abcdef

A

Ba

b

TerminalTerminal

C

Dc

d E

Fe

f

[A] [B]

I6RW0C820017-01

Page 1128 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-89 Air Bag System:

Inspection of Intermittent and Poor

Connections

S6RW0D8204047

Most intermittents are caused by faulty electrical

connections or wiring. When a check for proper

connection is requested in a diagnostic flow, perform

careful check of suspect circuits.

If any abnormality is found, repair or replace as a wire

harness assembly.

• Poor mating of connector halves, or terminals not fully

seated in the connector body (backed out).• Dirt or corrosion on the terminals. The terminals must

be clean and free of any foreign material which could

impede proper terminal contact.

However, cleaning the terminal with a sand paper or

the like is prohibited.

• Damaged connector body, exposing the terminals to

moisture and dirt, as well as not maintaining proper

terminal orientation with the component or mating

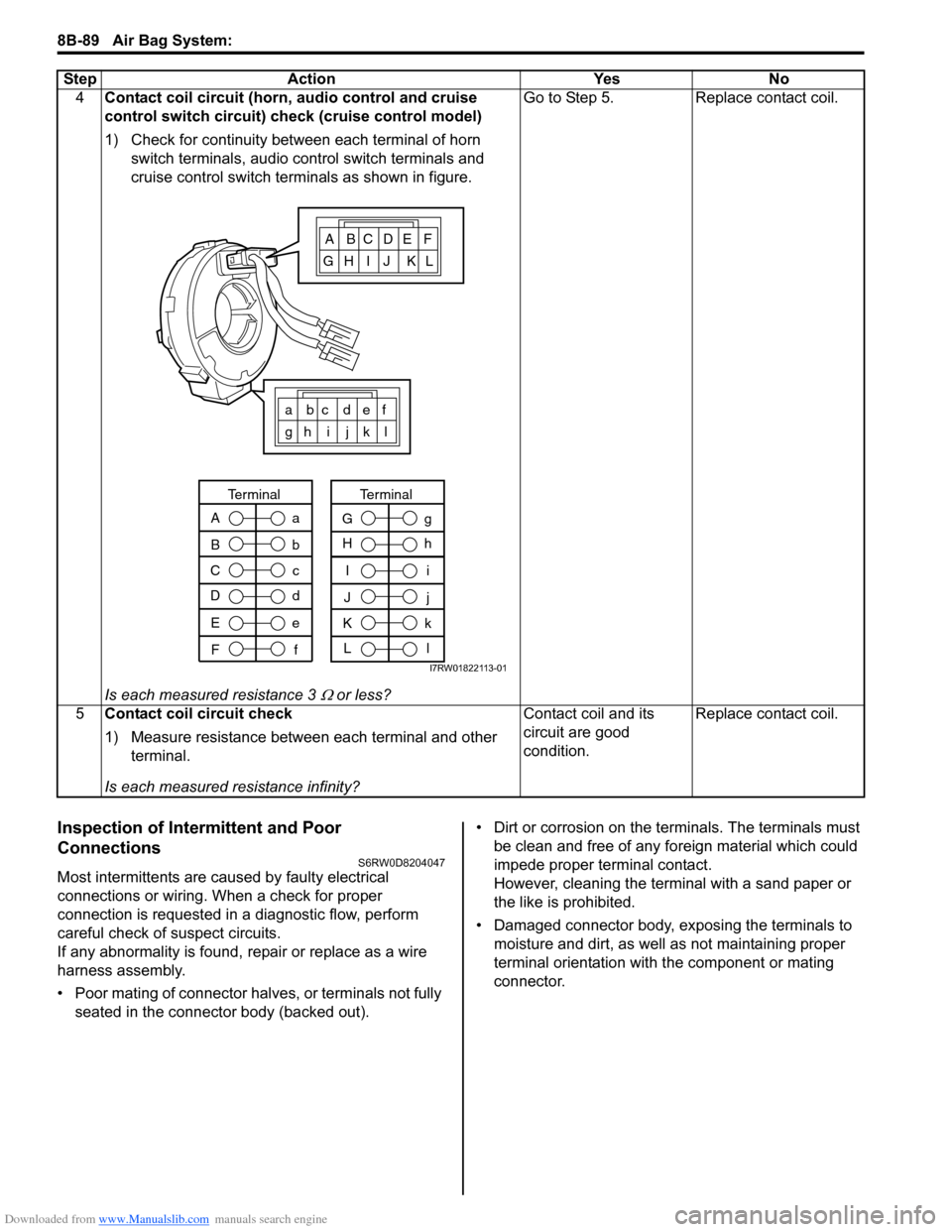

connector. 4Contact coil circuit (horn, audio control and cruise

control switch circuit) check (cruise control model)

1) Check for continuity between each terminal of horn

switch terminals, audio control switch terminals and

cruise control switch terminals as shown in figure.

Is each measured resistance 3

Ω or less?Go to Step 5. Replace contact coil.

5Contact coil circuit check

1) Measure resistance between each terminal and other

terminal.

Is each measured resistance infinity?Contact coil and its

circuit are good

condition.Replace contact coil. Step Action Yes No

ABCDEF

GH I J KL

a bc def

gh i j k l

A

B

C

Da

b

c

d

Terminal

E

Fe

f

I

J

K

Li

j

k

l

Terminal

G

Hg

h

I7RW01822113-01

Page 1189 of 1556

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-22

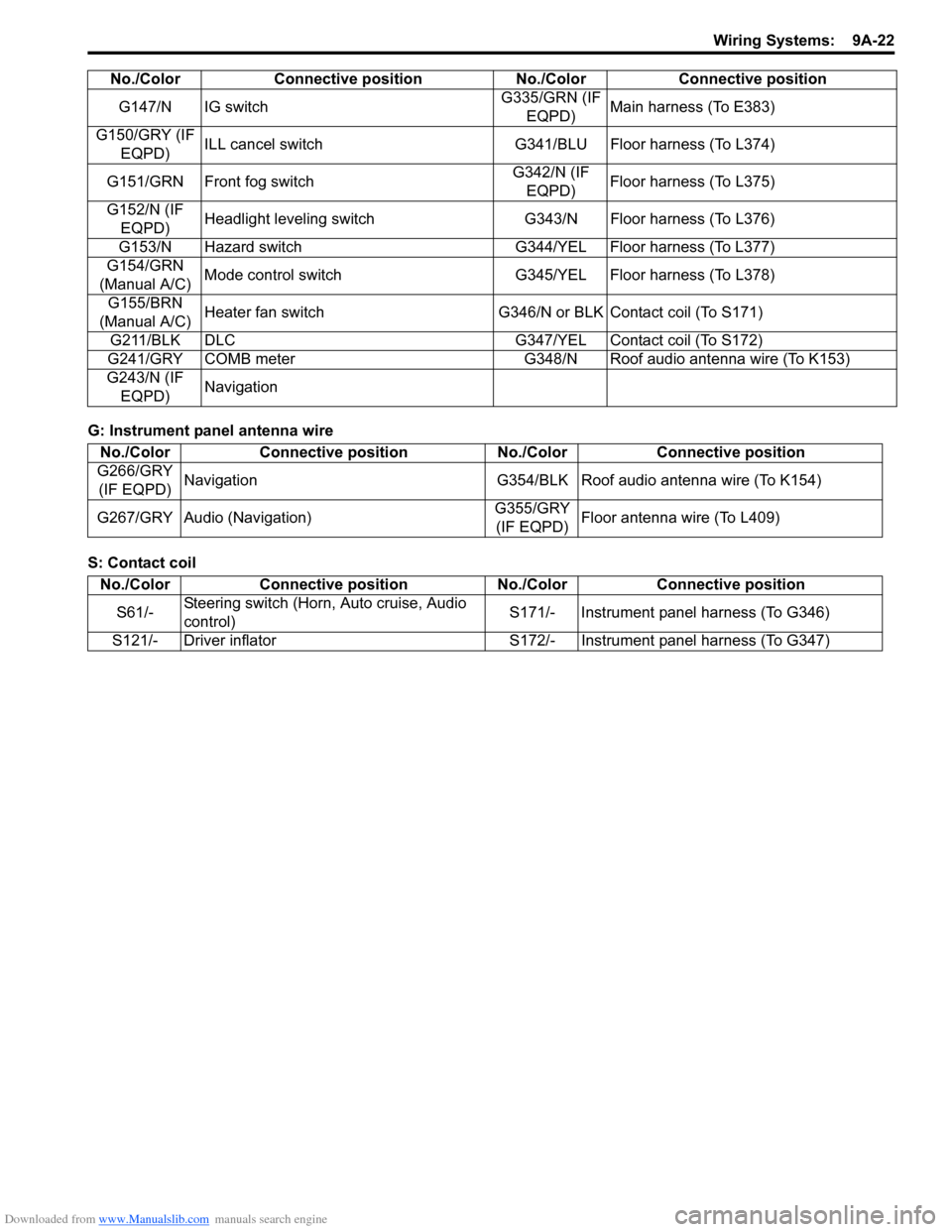

G: Instrument panel antenna wire

S: Contact coilG147/N IG switchG335/GRN (IF

EQPD)Main harness (To E383)

G150/GRY (IF

EQPD)ILL cancel switch G341/BLU Floor harness (To L374)

G151/GRN Front fog switchG342/N (IF

EQPD)Floor harness (To L375)

G152/N (IF

EQPD)Headlight leveling switch G343/N Floor harness (To L376)

G153/N Hazard switch G344/YEL Floor harness (To L377)

G154/GRN

(Manual A/C)Mode control switch G345/YEL Floor harness (To L378)

G155/BRN

(Manual A/C)Heater fan switch G346/N or BLK Contact coil (To S171)

G211/BLK DLC G347/YEL Contact coil (To S172)

G241/GRY COMB meter G348/N Roof audio antenna wire (To K153)

G243/N (IF

EQPD)Navigation No./Color Connective position No./Color Connective position

No./Color Connective position No./Color Connective position

G266/GRY

(IF EQPD)Navigation G354/BLK Roof audio antenna wire (To K154)

G267/GRY Audio (Navigation)G355/GRY

(IF EQPD)Floor antenna wire (To L409)

No./Color Connective position No./Color Connective position

S61/-Steering switch (Horn, Auto cruise, Audio

control)S171/- Instrument panel harness (To G346)

S121/- Driver inflator S172/- Instrument panel harness (To G347)

Page 1241 of 1556

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-74

G333

E381S171

G346161514

GWGY

J/B

2

15ASTOP

30

15ADOME

37

E0120

GRN/WHT

GRN/WHT

GRN

12

10AIG1 SIG

26

LT GRN/BLK

8

GRN/YEL

622RED/WHTLT GRN21BLK/YEL

RED/WHT

RED/BLK

LT GRNBLK/YEL

RB

E325 E323 E325 E3234

15AIG COIL

20

5

E181

3 4Brake

light

switch

MAIN RESUME/

ACCEL SET/

COAST CANCEL

1 2

S61

12

Steering

switch

(Auto

cruise

switch)

Contact

coilContact

coil

11 610

121110

6

Cruise control (IF EQPD)

ECM

2

CMP

sensor

C01

BLK

34

1529 3031

3C32

52C01 E0122302813

RED/YEL

PNK/BLUBLKBLKBLKBLK

BLK/RED

12

J/B

E3251

2

"C-2"

G346

S171

YG

YEL/GRNYEL/BLKWHT/REDWHTYEL/RED

Starting

motor

relay Starting

motor

relay

"A-1"ICM

"A-7"YBYR

2

W"A-1"

E01

LT GRN/BLK

BLK

BLKBLK

7C019

CPP

cut

switch

E1921

2

79

BLK/ORNBLK/ORN

BLK/ORN

Current

sensor

C461

23

Weld

splice

C312

BLK/WHT

I6RW0C910946-04

Page 1290 of 1556

Downloaded from www.Manualslib.com manuals search engine 9A-123 Wiring Systems:

D-7 Brake Light System Circuit DiagramS6RW0D910E028

Brake

light

switch

Shift lock

relay

(R)

Brake light

GRNLT GRN/BLK

BLK

(L)

E181

L134

GRN/WHT

GRN/WHT

GRN/WHTGRN/WHT

5

L315

E325

J/B

"F-2"

ABS

Cont.M

GRN/WHT

2 2 1

"A-5"

ECM

21

GW

GW

GRN/YEL

"A-5"

ECM

GY

GW

42

31

J/B

L1332

52

1

GRN/WHT

"A-6"

GW

O92

High mounted

stop light

201918

BLKBLK

BLKBLKBLK

23

BLK

BLK

2

GRN/WHTGRN/WHTGRN/WHT

E3232

L393

L2331

O233

L3932

L390

O2312 15A

30STOP

E32512 10A

26IG1 SIG

Cruise control

(IF EQPD)

I6RW0C910A15-01

Page 1306 of 1556

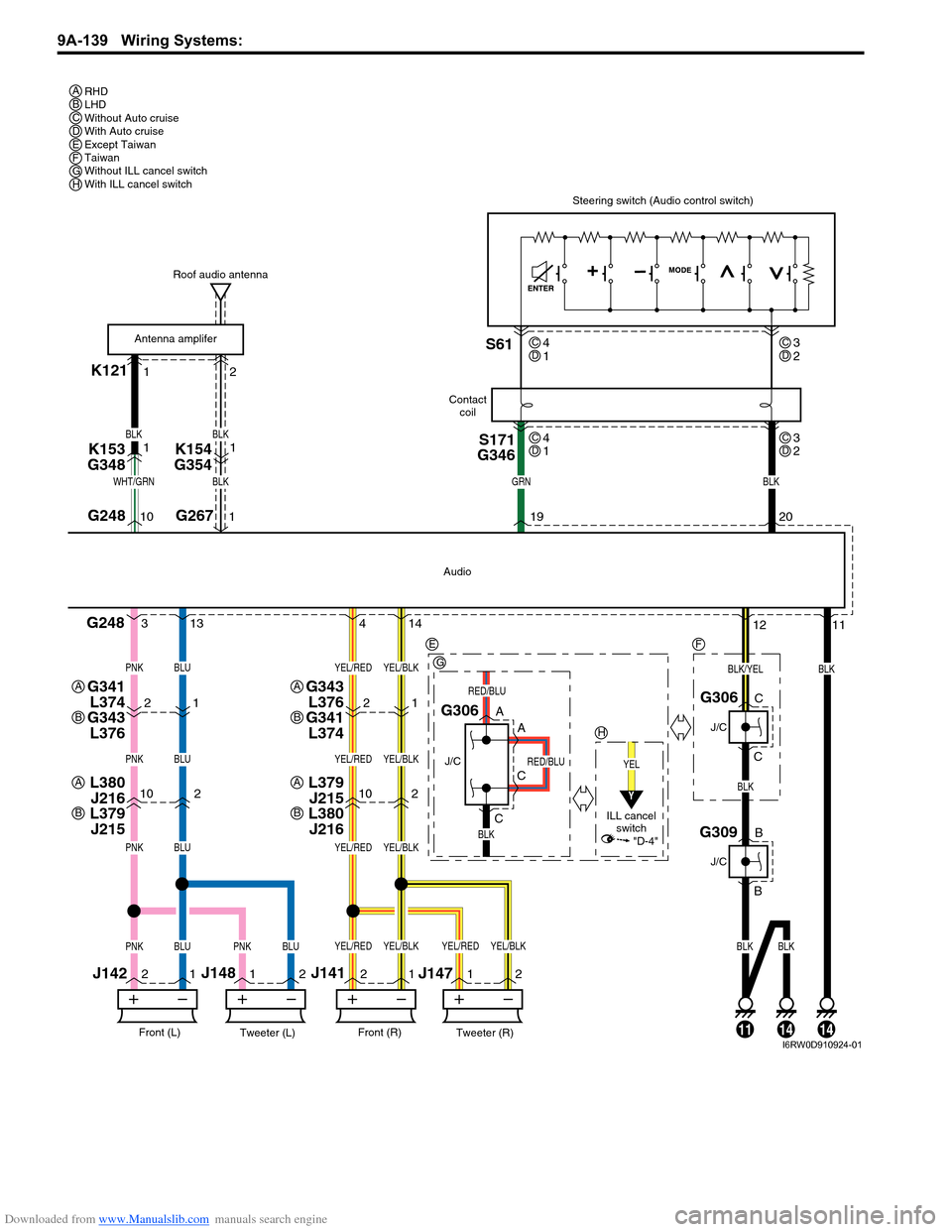

Downloaded from www.Manualslib.com manuals search engine 9A-139 Wiring Systems:

K12112

102102

2

11

22

11

211

G248

G248

BLK

Tweeter (L)Front (L)

J142J148

Tweeter (R)Front (R)

J141

J147

BLK

YEL

BLK

Audio

G306

J/C

ILL cancel

switch

A

A

C

C

G306

J/C

C

C

Steering switch (Audio control switch)

19G26710 120

BLKGRNWHT/GRN

BLK

BLUPNK

BLUPNK

BLUPNK

BLUBLKBLKBLUPNKPNK

YEL/BLKYEL/RED

YEL/BLKYEL/RED

YEL/BLKYEL/RED

YEL/BLKYEL/BLKYEL/REDYEL/RED

S171

G346S61

Roof audio antenna

Contact

coil

Antenna amplifer

4 313 14

K153

G3481

BLK

BLK

K154

G3541

21

G343

L376

G341

L3742112

BLK/YEL

RED/BLU

RED/BLU

G309

J/C

B

B

141114

RHD

LHD

Without Auto cruise

With Auto cruise

Except Taiwan

Taiwan

Without ILL cancel switch

With ILL cancel switch A

E

G

H

A

B

G341

L374

G343

L376A

B

L379

J215

L380

J216A

B

L380

J216

L379

J215A

B

F

BCDEFGH

4

1CD3

2CD

4

1CD3

2CD

Y

"D-4"

I6RW0D910924-01

Page 1374 of 1556

Downloaded from www.Manualslib.com manuals search engine 9C-22 Instrumentation / Driver Info. / Horn:

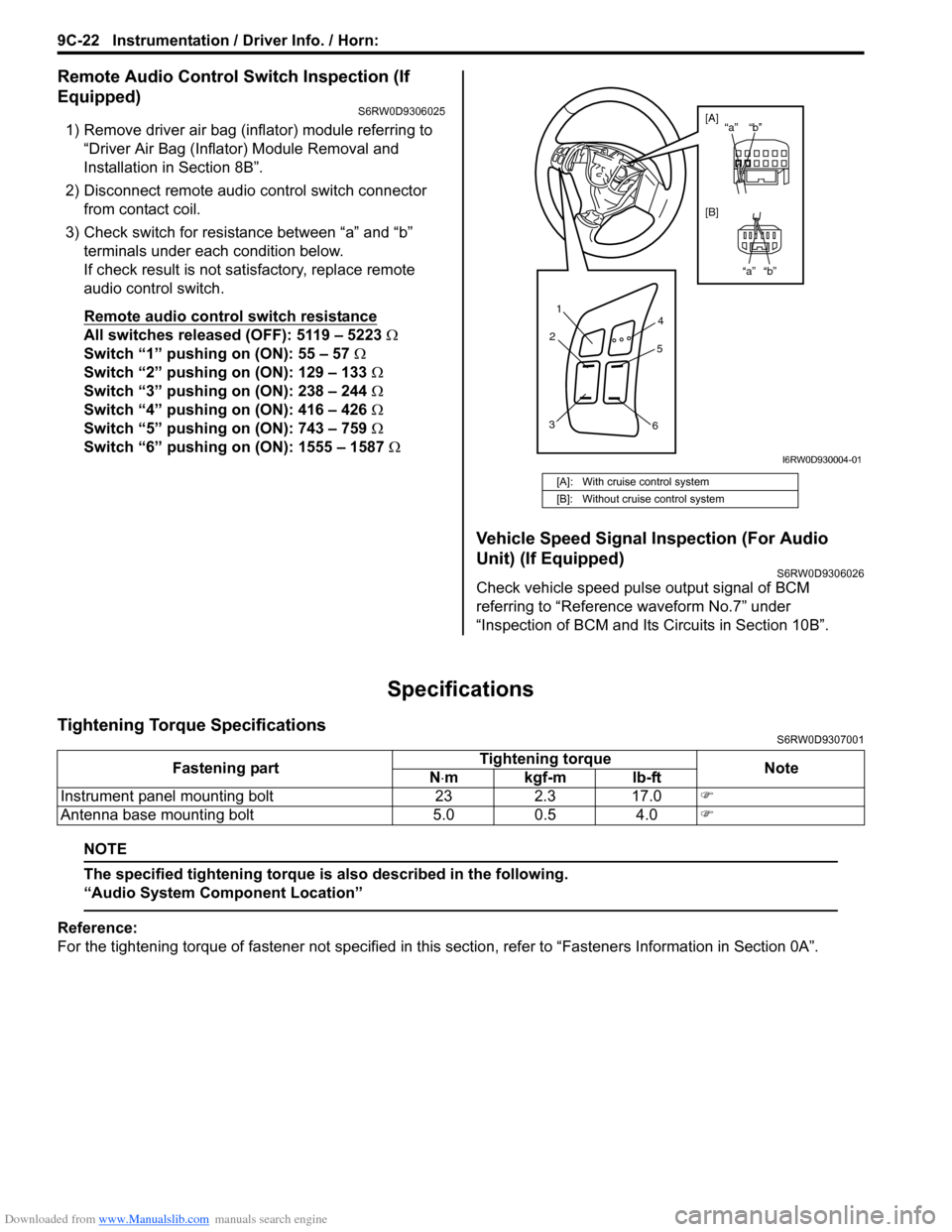

Remote Audio Control Switch Inspection (If

Equipped)

S6RW0D9306025

1) Remove driver air bag (inflator) module referring to

“Driver Air Bag (Inflator) Module Removal and

Installation in Section 8B”.

2) Disconnect remote audio control switch connector

from contact coil.

3) Check switch for resistance between “a” and “b”

terminals under each condition below.

If check result is not satisfactory, replace remote

audio control switch.

Remote audio control switch resistance

All switches released (OFF): 5119 – 5223 Ω

Switch “1” pushing on (ON): 55 – 57 Ω

Switch “2” pushing on (ON): 129 – 133 Ω

Switch “3” pushing on (ON): 238 – 244 Ω

Switch “4” pushing on (ON): 416 – 426 Ω

Switch “5” pushing on (ON): 743 – 759 Ω

Switch “6” pushing on (ON): 1555 – 1587 Ω

Vehicle Speed Signal Inspection (For Audio

Unit) (If Equipped)

S6RW0D9306026

Check vehicle speed pulse output signal of BCM

referring to “Reference waveform No.7” under

“Inspection of BCM and Its Circuits in Section 10B”.

Specifications

Tightening Torque SpecificationsS6RW0D9307001

NOTE

The specified tightening torque is also described in the following.

“Audio System Component Location”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

[A]: With cruise control system

[B]: Without cruise control system

1

2

34

5

6

“b” “a”

“b” “a” [A]

[B]

I6RW0D930004-01

Fastening partTightening torque

Note

N⋅mkgf-mlb-ft

Instrument panel mounting bolt 23 2.3 17.0�)

Antenna base mounting bolt 5.0 0.5 4.0�)