maintenance SUZUKI SX4 2008 1.G User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SX4, Model: SUZUKI SX4 2008 1.GPages: 278, PDF Size: 4.07 MB

Page 157 of 278

6-2

OPERATING YOUR VEHICLE

80J21-03E

12)Check all gauges.

13)Make sure that the BRAKE light turns

off when the parking brake is released.

Once a week, or each time you fill your fuel

tank, perform the following under-hood

checks:

1) Engine oil level

2) Coolant level

3) Brake fluid level

4) Power steering (if equipped) fluid level

5) Windshield washer fluid level

6) Hood latch operation

Pull the hood release handle inside the

vehicle. Make sure that you cannot

open the hood all the way without

releasing the secondary latch. Be sure

to close the hood securely after check-

ing for proper latch operation. See the

item “All latches, hinges and locks” of

“CHASSIS AND BODY” in the “Periodic

Maintenance Schedule” section in the

“INSPECTION AND MAINTENANCE”

section for lubrication schedule.

Starting the EngineBefore Starting the Engine1) Make sure the parking brake is set fully.

2) Manual Transaxle – Shift into “N” (Neu-

tral) and depress the clutch pedal all

the way to the floor.

Hold the clutch pedal while starting the

engine.

Automatic Transaxle – If the gearshift

lever is not in “P” (Park) position, shift

into “P”. (If you need to re-start the

engine while the vehicle is moving, shift

into “N”.)

NOTE:

The engine of manual transaxle vehicle will

not start unless the clutch pedal is

depressed.

NOTE:

Automatic transaxle vehicles have a starter

interlock device which is designed to keep

the starter from operating if the transaxle is

in any of the drive positions.

Starting a Cold EngineWith your foot off the accelerator pedal,

crank the engine by turning the ignition key

to “START”. Release the key when the

engine starts.

If the engine does not start after 15 sec-

onds of cranking, wait about 15 seconds,

then press down the accelerator pedal to

1/3 of its travel and try cranking the engine

again. Release the key and accelerator

pedal when the engine starts.

If the engine still does not start, try holding

the accelerator pedal all the way to the

floor while cranking. This should clear the

engine if it is flooded.

If you are unable to start the engine using

this procedure, consult your SUZUKI

dealer.Starting a Warm EngineUse the same procedure as for “Starting a

Cold Engine”.

WARNING

Make sure the hood is fully closed

and latched before driving. If it is not,

it can fly up unexpectedly during

driving, obstructing your view and

resulting in an accident.

WARNING

Make sure that the parking brake is

set fully and the transaxle is in Neu-

tral (or Park for vehicles with an auto-

matic transaxle) before attempting to

start the engine.

CAUTION

Stop turning the starter immedi-

ately after the engine has started or

the starter system can be dam-

aged.

Do not crank the engine for more

than 15 seconds at a time. If the

engine doesn’t start on the first try,

wait about 15 seconds before try-

ing again.

Daily Inspection Checklist: NO

Starting the Engine: 1

Page 164 of 278

6-9OPERATING YOUR VEHICLE

80J21-03E

Braking

60G165

The distance needed to bring any vehicle

to a halt increases with the speed of the

vehicle. The braking distance needed, for

example, at 60 km/h (37 mph) will be

approximately 4 times greater than the

braking distance needed at 30 km/h (19

mph). Start to brake the vehicle when there

is plenty of distance between your vehicle

and the stopping point, and slow down

gradually.

Power Assisted BrakesYour vehicle has power assisted brakes. If

power assistance is lost due to a stalled

engine or other failures, the system is still

fully operational on reserve power and you

can bring the vehicle to a complete stop by

pressing the brake pedal once and holding

it down. The reserve power is partly used

up when you depress the brake pedal and

reduces each time the pedal is pressed.

Apply smooth and even pressure to the

pedal. Do not pump the pedal.

CAUTION

Unevenly worn tires can cause prob-

lems in the operation of the 2WD/i-

AWD switch. Be sure to rotate the

tires according to the maintenance

schedule. Refer to “Tires” and “Main-

tenance Schedule” in the “INSPEC-

TION AND MAINTENANCE” section

for proper tire rotation procedures.

WARNING

If water gets into the brake drums,

brake performance may become poor

and unpredictable.

After driving through water or wash-

ing the underside of the vehicle, test

the brakes while driving at a slow

speed to see if they have maintained

their normal effectiveness. If the

brakes are less effective than normal,

dry them by repeatedly applying the

brakes while driving slowly until the

brakes have regained their normal

effectiveness.

Braking: 6

Break-In: 6

Catalytic Converter: NO

Page 170 of 278

6-15OPERATING YOUR VEHICLE

80J21-03E

Low Tire Pressure Warning Light

52D305

WARNING

Each tire, including the spare (if pro-

vided), should be checked monthly

when cold and inflated to the inflation

pressure recommended by the vehi-

cle manufacturer on the vehicle plac-

ard or tire inflation pressure label. (If

your vehicle has tires of a different

size than the size indicated on the

vehicle placard or tire inflation pres-

sure label, you should determine the

proper tire inflation pressure for

those tires.)

As an added safety feature, your

vehicle has been equipped with a tire

pressure monitoring system (TPMS)

that illuminates a low tire pressure

telltale when one or more of your

tires is significantly under-inflated.

Accordingly, when the low tire pres-

sure telltale illuminates, you should

stop and check your tires as soon as

possible, and inflate them to the

proper pressure.

(Continued)

WARNING

(Continued)

Driving on a significantly under-

inflated tire causes the tire to over-

heat and can lead to tire failure.

Under-inflation also reduces fuel effi-

ciency and tire tread life, and may

affect the vehicle’s handling and

stopping ability.

Please note that the TPMS is not a

substitute for proper tire mainte-

nance, and it is the driver’s responsi-

bility to maintain correct tire

pressure, even if under-inflation has

not reached the level to trigger illumi-

nation of the TPMS low tire pressure

telltale.

WARNING

The tire pressure monitoring system

is not a substitute for regular tire

pressure inspections. Check tire

inflation pressures monthly when

cold and set to the recommended

inflation pressure as specified on the

vehicle’s tire information placard and

in the owner’s manual. Refer to

“Tires” in the “INSPECTION AND

MAINTENANCE” section.

WARNING

If the low tire pressure warning light

does not come on when the ignition

is turned to the “ON” position, or

comes on and blinks while driving

there may be a problem with the tire

pressure monitoring system. Have

your vehicle inspected by an autho-

rized SUZUKI dealer. Even if the light

turns off after blinking, indicating

that the monitoring system has

recovered, make sure to have an

authorized SUZUKI dealer check the

system.

WARNING

The load rating of your tires is

reduced at lower inflation pressures.

If your tires become even moderately

under-inflated, the vehicle load may

exceed the load rating of the tires,

which can lead to tire failure. The low

tire pressure warning light will not

alert you of this condition. The warn-

ing light will only come on when one

or more of your tires become signifi-

cantly under-inflated. Check and

adjust your tire inflation pressure at

least once a month. Refer to “Tires”

in the “INSPECTION AND MAINTE-

NANCE” section.

Page 171 of 278

6-16

OPERATING YOUR VEHICLE

80J21-03E

The low tire pressure warning light can

come on due to normal causes such as

natural air leaks and pressure changes

caused by changes in temperature or

atmospheric pressure. Adjusting the air

pressure in the tires to the pressure shownon the tire information placard should

cause the low tire pressure warning light to

turn off.

If the light turns on again shortly after

adjusting the pressure in your tires, you

may have a flat tire. If you have a flat tire,

replace it with the spare tire. Refer to

“Jacking Instructions” in the “EMER-

GENCY SERVICE” section. Refer to

“Replacing Tires and/or Wheels” for

instructions on how to restore normal oper-

ation of the tire pressure monitoring sys-

tem after you have had a flat tire.

NOTE:

When the tire inflation pressure is

adjusted in high altitude areas, the low

tire pressure light may not turn off even

after tire inflation pressure adjustment.

In this case, adjust the inflation pressure

to a slightly higher pressure than is

shown on the tire information placard.

The low tire pressure warning light may

turn off temporarily after coming on. This

could be due to surface temperature

increases after long distance driving or

traveling to a high temperature area.

Even if the tire pressure warning light

turns off after coming on, make sure to

check the inflation pressure of all tires.

To reduce the chance that the low tire

pressure warning light will come on due

to normal changes in temperature and

atmospheric pressure, it is important to

check and adjust the tire pressureswhen the tires are cold. Tires that

appear to be at the specified pressure

when checked after driving, when the

tires are warm, could have pressure

below the specification when the tires

cool down. Also, tires that are inflated to

the specified pressure in a warm garage

may have pressure below the specifica-

tion when the vehicle is driven outside in

very cold temperature. If you adjust the

tire pressure in a garage that is warmer

than the outside temperature, you

should add 1 psi to the recommended

cold tire inflation pressure for every 10°F

difference between garage temperature

and outside temperature.

For tire inflation pressure information, refer

to “Tire Inflation Pressure” in the “INSPEC-

TION AND MAINTENANCE” section.

WARNING

If the low tire pressure warning light

comes on and stays on, reduce your

speed and avoid abrupt steering and

braking. Stop in a safe place as soon

as possible and check your tires.

If you have a flat tire, replace it with

the spare tire. Refer to “Jacking

Instructions” in the “EMERGENCY

SERVICE” section. Refer to

“Replacing Tires and/or Wheels”

for instructions on how to restore

normal operation of the tire pres-

sure monitoring system after you

have had a flat tire.

If one or more of your tires is

under-inflated adjust the inflation

pressure in all of your tires to the

recommended inflation pressure as

soon as possible.

Be aware that driving on a signifi-

cantly under-inflated tire can cause

the tire to overheat and can lead to

tire failure, and may affect steering

control and brake effectiveness. This

could lead to an accident, resulting in

severe injury or death.

Page 173 of 278

6-18

OPERATING YOUR VEHICLE

80J21-03E

When the TPMS sensor’s electronic sig-

nal is disturbed in one of the following

ways:

– Electric devices or facilities using simi-

lar radio wave frequencies are nearby.

– A lot of snow or ice covers the vehicle,

in particular, around the wheels or

wheel housings.

– Snow tires or tire chains are used.

When you use non-genuine SUZUKI

wheels or tires.Replacing Tires and/or WheelsIf you get a flat tire, Suzuki recommends

that you have an authorized SUZUKI

dealer mount a new tire on the wheel that

had the flat tire, and reinstall this tire on the

vehicle in place of the spare. The TPMS is

already set up to recognize the ID code of

the original wheel, and normal TPMS oper-

ation will be restored.

If you need to replace original wheels on

your vehicle, your dealer must make sure

that TPMS sensors are installed in the new

wheels and must set up the TPMS to rec-

ognize the new sensors.

NOTE:

A TPMS sensor is not installed in the spare

tire. You should use the spare tire only in

an emergency situation, and should

replace the spare tire as soon as possible

to restore normal TPMS operation.

For Vehicles Sold in U.S.A.This device complies with Part 15 of the

FCC Rules.

Operation is subject to the following two

conditions:

1) This device may not cause harmful

interference.

2) This device must accept any interfer-

ence received, including interference

that may cause undesired operation.

NOTE:

Changes or modifications not expressly

approved by the party responsible for com-

pliance could void the user’s authority to

operate the equipment.Traveling to CANADAPlease note that service for the tire pres-

sure monitoring system may not be avail-

able in CANADA should there be any

problems or malfunctions in the system.

Break-In

WARNING

Only use tires and wheels recom-

mended by SUZUKI as standard or

optional equipment for your vehicle.

Use of tires or wheels not recom-

mended by SUZUKI can result in

TPMS failure. Refer to “Tires” in the

“INSPECTION AND MAINTENANCE”

section for additional information.

CAUTION

The future performance and reliabil-

ity of the engine depends on the care

and restraint exercised during its

early life. It is especially important to

observe the following precautions

during the initial 960 km (600 miles)

of vehicle operation.

After starting, do not race the

engine. Warm it up gradually.

Avoid prolonged vehicle operation

at a constant speed. Moving parts

will break in better if you vary your

speed.

Start off from a stop slowly. Avoid

full throttle starts.

Avoid hard stopping, especially

during the first 320 km (200 miles)

of driving.

Do not drive slowly with the tran-

saxle in a high gear.

Drive the vehicle at moderate

engine speeds.

Page 180 of 278

7-3DRIVING TIPS

80J21-03E

Tire ChainsTire chains should only be used if they are

needed to increase traction or are required

by law. Make sure that the chains you use

are small-link chains or cable-type chains

and are the correct size for your vehicle’s

tires. Also make sure that there is enough

clearance between the fenders and the

chains as installed on the tires.

Install the chains on the front tires tightly,

according to the chain manufacturer’s

instructions. Retighten the chains after

driving about 1.0 km (1/2 mile) if neces-

sary. With the chains installed, drive slowly.Do not drive through deep or rushing

water

Driving in deep or rushing water can be

hazardous. You could lose control of the

vehicle and the occupants could drown.

Also, your vehicle could be seriously dam-

aged. To avoid these risks, observe the fol-

lowing instructions and precautions.

Do not drive through deep or rushing

water. Deep or rushing water, such as

fast-moving streams or floodwaters,

could carry your vehicle away from your

intended path. The water is too deep if it

covers your wheel hubs, axles or

exhaust tailpipe. Know the depth of the

water before you attempt to drive

through it.

If water blocks the tailpipe, the engine

may not start or run. If the water is deep

enough to get drawn into the engine

intake system, the engine will be badly

damaged.

Submerged brakes will have poor brak-

ing performance. Drive slowly and care-

fully. Driving slowly will also help avoid

water splashing onto the ignition system,

which could cause the engine to stall.

Even when driving through shallow or

still waters, drive carefully since the

water may be hiding ground hazards

such as holes, ditches or bumps.

54G638S

CAUTION

Do not continue rocking the vehicle

for more than a few minutes. Pro-

longed rocking can cause engine

overheating, transaxle or transfer

case damage or tire damage.

CAUTION

If you hear the chains hitting against

the vehicle body while driving, stop

and tighten them.

If your vehicle is equipped with full

wheel caps, remove the wheel caps

before installing the chains or the

wheel caps can be damaged by the

chain bands.

WARNING

In addition to following the driving

tips in this section, it is important to

observe the following precautions.

Make sure your tires are in good

condition and always maintain the

specified tire pressure. Refer to

“Tires” in the “INSPECTION AND

MAINTENANCE” section for

details.

Do not use tires other than those

specified by SUZUKI. Never use dif-

ferent sizes or types of tires on the

front and rear wheels. For informa-

tion regarding the specified tires,

refer to the Tire Information Label

located on the driver’s side door

pillar.

(Continued)

Driving on Slippery Roads: NO

Page 189 of 278

INSPECTION AND MAINTENANCE

9

80J21-03E

60G410

INSPECTION AND MAINTENANCEMaintenance Schedule ....................................................... 9-2

Periodic Maintenance Schedule ........................................ 9-3

Maintenance Recommended under Severe Driving

Conditions ........................................................................... 9-7

Engine Oil and Filter ........................................................... 9-11

Gear Oil ................................................................................ 9-14

Automatic Transaxle Fluid ................................................. 9-16

Engine Coolant .................................................................... 9-17

Windshield Washer Fluid ................................................... 9-19

Air Cleaner ........................................................................... 9-19

Spark Plugs ......................................................................... 9-20

Brakes .................................................................................. 9-21

Steering Wheel .................................................................... 9-23

Clutch Pedal ........................................................................ 9-24

Tires ...................................................................................... 9-24

Battery .................................................................................. 9-35

Fuses .................................................................................... 9-35

Headlight Aiming ................................................................. 9-39

Bulb Replacement ............................................................... 9-39

Wiper Blades ....................................................................... 9-44

Air Conditioning System .................................................... 9-48

Page 190 of 278

9-1INSPECTION AND MAINTENANCE

80J21-03E

60A187S

WARNING

You should take extreme care when

working on your vehicle to prevent

accidental injury. Here are a few pre-

cautions that you should be espe-

cially careful to observe:

To prevent damage or unintended

inflation of the air bag system, be

sure the battery is disconnected

and the ignition switch has been in

the “LOCK” position for at least 90

seconds before performing any

electrical service work on your

SUZUKI. Do not touch air bag sys-

tem components or wires. The

wires are wrapped with yellow tape

or yellow tubing, and the couplers

are yellow for easy identification.

(Continued)

WARNING

(Continued)

Do not leave the engine running in

garages or other confined areas.

When the engine is running, keep

hands, clothing, tools and other

objects away from the moving fan

and drive belt.

When it is necessary to do service

work with the engine running, make

sure that the parking brake is set

fully and the transaxle is in Neutral

(for manual transaxle vehicles) or

Park (for automatic transaxle vehi-

cles).

Do not touch ignition wires or other

ignition system parts when starting

the engine or when the engine is

running, or you could receive an

electric shock.

Be careful not to touch a hot

engine, exhaust manifold and

pipes, muffler, radiator and water

hoses.

Do not allow smoking, sparks or

flames around gasoline or the bat-

tery. Flammable fumes are present.

Do not get under your vehicle if it is

supported only with the portable

jack provided in your vehicle.

(Continued)

WARNING

(Continued)

Be careful not to cause accidental

short circuits between the positive

and negative battery terminals.

Keep used oil, engine coolant and

other fluids away from children and

pets. Dispose of used fluids prop-

erly; never pour them on the

ground, into sewers, etc.

Page 191 of 278

9-2

INSPECTION AND MAINTENANCE

80J21-03E

NOTICE (for U.S.A.)

Maintenance, replacement or repair of

the emission control devices and sys-

tems may be performed by any automo-

bile repair establishment or individual

using any part which has been certified

under the provisions in the Clean Air

Act sec. 207. (a) (2).

Maintenance ScheduleThe following table shows the times when

you should perform regular maintenance

on your vehicle. This table shows in miles,

kilometers and months when you should

perform inspections, adjustments, lubrica-

tion and other services. These intervals

should be shortened if driving is usually

done under severe conditions (refer to

“Maintenance Recommended Under

Severe Driving Conditions”).

WARNING

SUZUKI recommends that mainte-

nance on items marked with an aster-

isk (*) be performed by your

authorized SUZUKI dealer or a quali-

fied service technician. If you are

qualified, you may perform mainte-

nance on the unmarked items by

referring to the instructions in this

section. If you are not sure whether

you can successfully complete any of

the unmarked maintenance jobs, ask

your authorized SUZUKI dealer to do

the maintenance for you.

CAUTION

Whenever it becomes necessary to

replace parts on your vehicle, it is

recommended that you use genuine

SUZUKI replacement parts or their

equivalent.

WARNING

The shock absorbers are filled with

high pressure gas. Never attempt to

disassemble it or throw it into a fire.

Avoid storing it near a heater or heat-

ing device. When scrapping the

absorber, the gas must be released

from the absorber safely. Ask your

dealer for assistance.

Maintenance Schedule: 1, 2, 3, 4, 5, 6, 9, 10

Page 192 of 278

9-3INSPECTION AND MAINTENANCE

80J21-03E

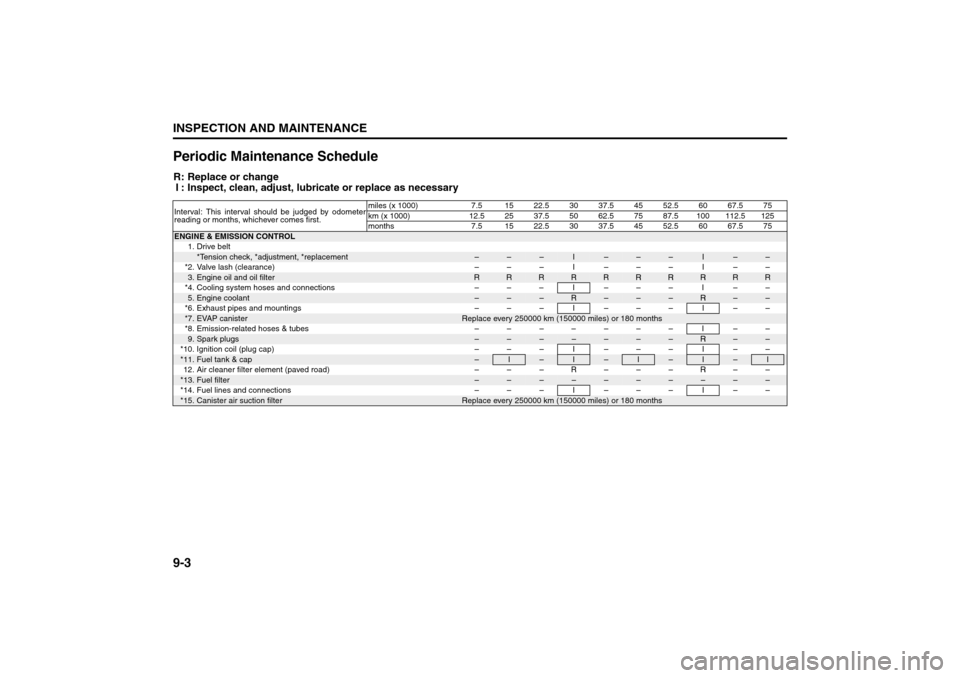

Periodic Maintenance ScheduleR: Replace or change

I : Inspect, clean, adjust, lubricate or replace as necessaryInterval: This interval should be judged by odometer

reading or months, whichever comes first.miles (x 1000) 7.5 15 22.5 30 37.5 45 52.5 60 67.5 75

km (x 1000) 12.5 25 37.5 50 62.5 75 87.5 100 112.5 125

months 7.5 1522.53037.54552.56067.575ENGINE & EMISSION CONTROL

1. Drive belt

*Tension check, *adjustment, *replacement

–

–

–

I

–

–

–

I

–

–

*2. Valve lash (clearance) – – – I – – – I – –3.Engine oil and oil filter

R

R

R

R

R

R

R

R

R

R

*4. Cooling system hoses and connections – – – I – – – I – –5.Engine coolant

–

–

–

R

–

–

–

R

–

–

*6. Exhaust pipes and mountings – – – I – – – I – –*7.

EVAP canister

Replace every 250000 km (150000 miles) or 180 months

*8. Emission-related hoses & tubes – – – – – – – I – –9.Spark plugs

–

–

–

–

–

–

–

R

–

–

*10. Ignition coil (plug cap) – – – I – – – I – –*11.

Fuel tank & cap

–

I

–

I

–

I

–

I

–

I

12. Air cleaner filter element (paved road) – – – R – – – R – –*13.

Fuel filter

–

–

–

–

–

–

–

–

–

–

*14. Fuel lines and connections – – – I – – – I – –*15.

Canister air suction filter

Replace every 250000 km (150000 miles) or 180 months

Periodic Maintenance Schedule: 1, 2, 3, 4, 5, 6, 9, 10