service SUZUKI SX4 2008 1.G Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SX4, Model: SUZUKI SX4 2008 1.GPages: 278, PDF Size: 4.07 MB

Page 174 of 278

6-19OPERATING YOUR VEHICLE

80J21-03E

Catalytic Converter

54G236

The purpose of the catalytic converter is to

minimize the amount of harmful pollutants

in your vehicle’s exhaust. Use of leaded

fuel in vehicles equipped with catalytic

converters is prohibited by federal law,

because lead deactivates the pollutant-

reducing components of the catalyst sys-

tem.

The converter is designed to last the life of

the vehicle under normal usage and when

unleaded fuel is used. No special mainte-

nance is required on the converter. How-

ever, it is very important to keep the engine

properly tuned. Engine misfiring, which

can result from an improperly tuned

engine, may cause overheating of the cat-

alyst. This may result in permanent heat

damage to the catalyst and other vehicle

components.

54G584S

CAUTION

To minimize the possibility of catalyst

or other vehicle damage:

Maintain the engine in the proper

operating condition.

In the event of an engine malfunc-

tion, particularly one involving

engine misfire or other apparent

loss of performance, have the vehi-

cle serviced promptly.

Do not shut off the engine or inter-

rupt the ignition when the transaxle

is in gear and the vehicle is in

motion.

Do not try to start the engine by

pushing or towing the vehicle or

coasting down a hill.

Do not idle the engine with any

spark plug wires disconnected or

removed, such as during diagnos-

tic testing.

Do not idle the vehicle for pro-

longed periods if idling seems

rough or there are other malfunc-

tions.

Do not allow the fuel tank to get

near the empty level.

WARNING

Be careful where you park and drive;

the catalytic converter and other

exhaust components can get very

hot. As with any vehicle, do not park

or operate this vehicle in areas where

combustible materials such as dry

grass or leaves can come in contact

with a hot exhaust system.

Page 190 of 278

9-1INSPECTION AND MAINTENANCE

80J21-03E

60A187S

WARNING

You should take extreme care when

working on your vehicle to prevent

accidental injury. Here are a few pre-

cautions that you should be espe-

cially careful to observe:

To prevent damage or unintended

inflation of the air bag system, be

sure the battery is disconnected

and the ignition switch has been in

the “LOCK” position for at least 90

seconds before performing any

electrical service work on your

SUZUKI. Do not touch air bag sys-

tem components or wires. The

wires are wrapped with yellow tape

or yellow tubing, and the couplers

are yellow for easy identification.

(Continued)

WARNING

(Continued)

Do not leave the engine running in

garages or other confined areas.

When the engine is running, keep

hands, clothing, tools and other

objects away from the moving fan

and drive belt.

When it is necessary to do service

work with the engine running, make

sure that the parking brake is set

fully and the transaxle is in Neutral

(for manual transaxle vehicles) or

Park (for automatic transaxle vehi-

cles).

Do not touch ignition wires or other

ignition system parts when starting

the engine or when the engine is

running, or you could receive an

electric shock.

Be careful not to touch a hot

engine, exhaust manifold and

pipes, muffler, radiator and water

hoses.

Do not allow smoking, sparks or

flames around gasoline or the bat-

tery. Flammable fumes are present.

Do not get under your vehicle if it is

supported only with the portable

jack provided in your vehicle.

(Continued)

WARNING

(Continued)

Be careful not to cause accidental

short circuits between the positive

and negative battery terminals.

Keep used oil, engine coolant and

other fluids away from children and

pets. Dispose of used fluids prop-

erly; never pour them on the

ground, into sewers, etc.

Page 191 of 278

9-2

INSPECTION AND MAINTENANCE

80J21-03E

NOTICE (for U.S.A.)

Maintenance, replacement or repair of

the emission control devices and sys-

tems may be performed by any automo-

bile repair establishment or individual

using any part which has been certified

under the provisions in the Clean Air

Act sec. 207. (a) (2).

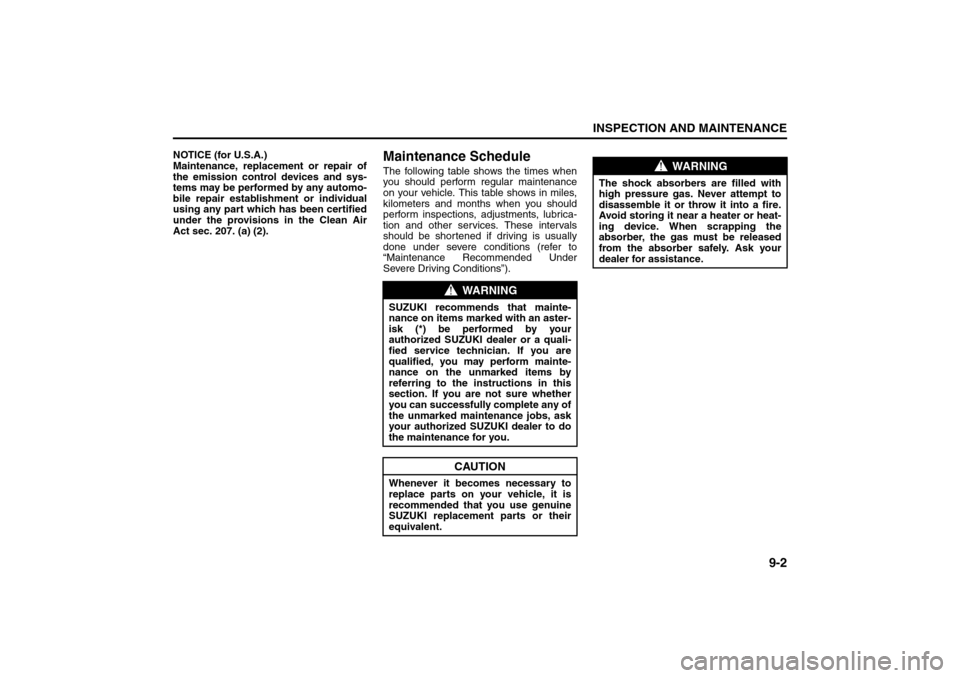

Maintenance ScheduleThe following table shows the times when

you should perform regular maintenance

on your vehicle. This table shows in miles,

kilometers and months when you should

perform inspections, adjustments, lubrica-

tion and other services. These intervals

should be shortened if driving is usually

done under severe conditions (refer to

“Maintenance Recommended Under

Severe Driving Conditions”).

WARNING

SUZUKI recommends that mainte-

nance on items marked with an aster-

isk (*) be performed by your

authorized SUZUKI dealer or a quali-

fied service technician. If you are

qualified, you may perform mainte-

nance on the unmarked items by

referring to the instructions in this

section. If you are not sure whether

you can successfully complete any of

the unmarked maintenance jobs, ask

your authorized SUZUKI dealer to do

the maintenance for you.

CAUTION

Whenever it becomes necessary to

replace parts on your vehicle, it is

recommended that you use genuine

SUZUKI replacement parts or their

equivalent.

WARNING

The shock absorbers are filled with

high pressure gas. Never attempt to

disassemble it or throw it into a fire.

Avoid storing it near a heater or heat-

ing device. When scrapping the

absorber, the gas must be released

from the absorber safely. Ask your

dealer for assistance.

Maintenance Schedule: 1, 2, 3, 4, 5, 6, 9, 10

Page 193 of 278

9-4

INSPECTION AND MAINTENANCE

80J21-03E

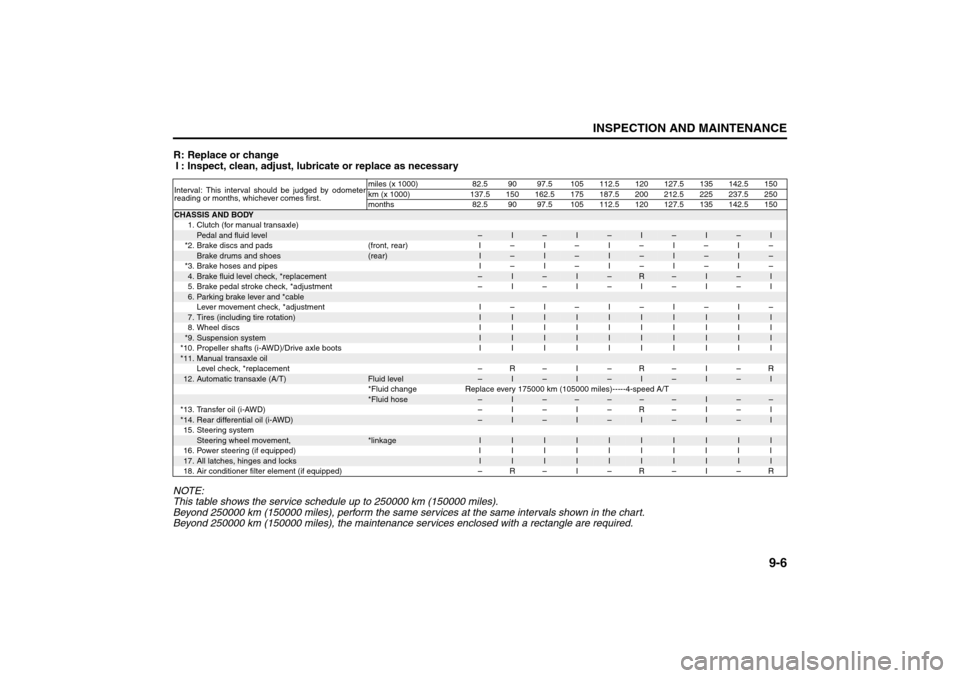

R: Replace or change

I : Inspect, clean, adjust, lubricate or replace as necessary

#1: Inspect at 250000 km (150000 miles) or 180 months.

NOTE:

The maintenance services enclosed with rectangle are recommended maintenance items.Interval: This interval should be judged by odometer

reading or months, whichever comes first.miles (x 1000) 82.5 90 97.5 105 112.5 120 127.5 135 142.5 150

km (x 1000) 137.5 150 162.5 175 187.5 200 212.5 225 237.5 250

months 82.5 90 97.5 105 112.5 120 127.5 135 142.5 150ENGINE & EMISSION CONTROL

1. Drive belt

*Tension check, *adjustment, *replacement

–

I

–

–

–

I

–

–

–

I

*2. Valve lash (clearance) – I – – – I – – – I3.Engine oil and oil filter

R

R

R

R

R

R

R

R

R

R

*4. Cooling system hoses and connections – I – – – I – – – I5.Engine coolant

–

R

–

–

–

R

–

–

–

R

*6. Exhaust pipes and mountings – I – – – I – – – I*7.

EVAP canister

Replace every 250000 km (150000 miles) or 180 months

*8. Emission-related hoses & tubes – – – – – I – – – I9.Spark plugs

–

–

–

–

–

R

–

–

–

–

*10. Ignition coil (plug cap) – I – – – I – – – I*11.

Fuel tank & cap

–

I

–

I

–

I

–

I

–

I (#1)

12. Air cleaner filter element (paved road) – R – – – R – – – R*13.

Fuel filter

–

–

–

–

–

–

–

–

–

R

*14. Fuel lines and connections – I – – – I – – – I (#1)*15.

Canister air suction filter

Replace every 250000 km (150000 miles) or 180 months

The U.S. Environmental Protection Agency or the California Air Resources Board has determined that the failure to perform recom-

mended maintenance items enclosed with a rectangle will not nullify the emission warranty or limit recall liability prior to the completion

of the vehicle’s useful life. SUZUKI, however, urges that all recommended maintenance services be performed at the indicated inter-

vals and the maintenance recorded.

Periodic Maintenance Schedule: 1, 2, 3, 4, 5, 6, 9, 10

Page 195 of 278

9-6

INSPECTION AND MAINTENANCE

80J21-03E

R: Replace or change

I : Inspect, clean, adjust, lubricate or replace as necessary

NOTE:

This table shows the service schedule up to 250000 km (150000 miles).

Beyond 250000 km (150000 miles), perform the same services at the same intervals shown in the chart.

Beyond 250000 km (150000 miles), the maintenance services enclosed with a rectangle are required.Interval: This interval should be judged by odometer

reading or months, whichever comes first.miles (x 1000) 82.5 90 97.5 105 112.5 120 127.5 135 142.5 150

km (x 1000) 137.5 150 162.5 175 187.5 200 212.5 225 237.5 250

months 82.5 90 97.5 105 112.5 120 127.5 135 142.5 150CHASSIS AND BODY

1. Clutch (for manual transaxle)

Pedal and fluid level

–

I

–

I

–

I

–

I

–

I

*2. Brake discs and pads (front, rear) I – I – I – I – I –

Brake drums and shoes

(rear)

I

–

I

–

I

–

I

–

I

–

*3. Brake hoses and pipes I – I – I – I – I –

4.Brake fluid level check, *replacement

–

I

–

I

–

R

–

I

–

I

5. Brake pedal stroke check, *adjustment – I – I – I – I – I

6.Parking brake lever and *cableLever movement check, *adjustment I – I – I – I – I –7.Tires (including tire rotation)

I

I

I

I

I

I

I

I

I

I

8. Wheel discs I I I I I I I I I I

*9.

Suspension system

I

I

I

I

I

I

I

I

I

I

*10. Propeller shafts (i-AWD)/Drive axle boots I I I I I I I I I I

*11.

Manual transaxle oilLevel check, *replacement – R – I – R – I – R

12.

Automatic transaxle (A/T)

Fluid level

–

I

–

I

–

I

–

I

–

I

*Fluid change Replace every 175000 km (105000 miles)-----4-speed A/T

*Fluid hose

–

I

–

–

–

–

–

I

–

–

*13. Transfer oil (i-AWD) – I – I – R – I – I

*14.

Rear differential oil (i-AWD)

–

I

–

I

–

I

–

I

–

I

15. Steering system

Steering wheel movement,

*linkage

I

I

I

I

I

I

I

I

I

I

16. Power steering (if equipped) I I I I I I I I I I

17.

All latches, hinges and locks

I

I

I

I

I

I

I

I

I

I

18. Air conditioner filter element (if equipped) – R – I – R – I – R

Maintenance Recommended under Severe Driving Condi-

tions: 1, 2, 3, 4, 5, 6, 9, 10

Page 196 of 278

9-7INSPECTION AND MAINTENANCE

80J21-03E

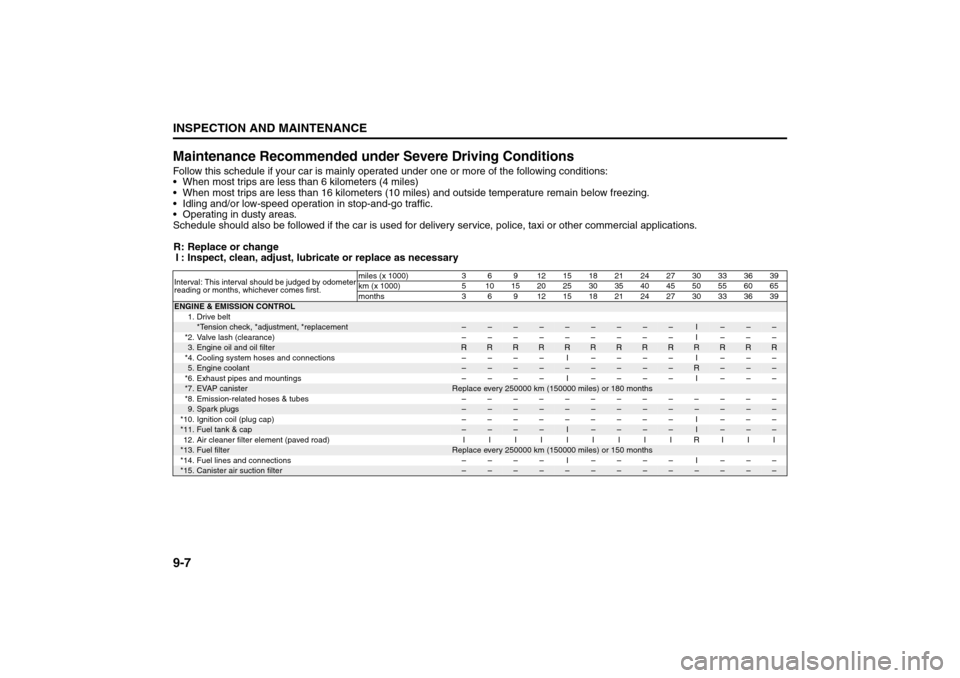

Maintenance Recommended under Severe Driving ConditionsFollow this schedule if your car is mainly operated under one or more of the following conditions:

When most trips are less than 6 kilometers (4 miles)

When most trips are less than 16 kilometers (10 miles) and outside temperature remain below freezing.

Idling and/or low-speed operation in stop-and-go traffic.

Operating in dusty areas.

Schedule should also be followed if the car is used for delivery service, police, taxi or other commercial applications.

R: Replace or change

I : Inspect, clean, adjust, lubricate or replace as necessaryInterval: This interval should be judged by odometer

reading or months, whichever comes first.miles (x 1000) 3 6 9 12 15 18 21 24 27 30 33 36 39

km (x 1000) 5 101520253035404550556065

months 3 6 9 12 15 18 21 24 27 30 33 36 39ENGINE & EMISSION CONTROL

1. Drive belt

*Tension check, *adjustment, *replacement

–

–

–

–

–

–

–

–

–

I

–

–

–

*2.Valve lash (clearance) ––––––––– I –––

3.Engine oil and oil filter

R

R

R

R

R

R

R

R

R

R

R

R

R

*4. Cooling system hoses and connections–––– I –––– I –––

5.Engine coolant

–

–

–

–

–

–

–

–

–

R

–

–

–

*6. Exhaust pipes and mountings–––– I –––– I –––

*7.

EVAP canister

Replace every 250000 km (150000 miles) or 180 months

*8.Emission-related hoses & tubes –––––––––––––

9.Spark plugs

–

–

–

–

–

–

–

–

–

–

–

–

–

*10.Ignition coil (plug cap) ––––––––– I –––

*11.

Fuel tank & cap

–

–

–

–

I

–

–

–

–

I

–

–

–

12. Air cleaner filter element (paved road)IIIIIIIIIRIII

*13.

Fuel filter

Replace every 250000 km (150000 miles) or 150 months

*14. Fuel lines and connections–––– I –––– I –––

*15.

Canister air suction filter

–

–

–

–

–

–

–

–

–

–

–

–

–

Engine Oil and Filter: 1, 2

Page 199 of 278

9-10

INSPECTION AND MAINTENANCE

80J21-03E

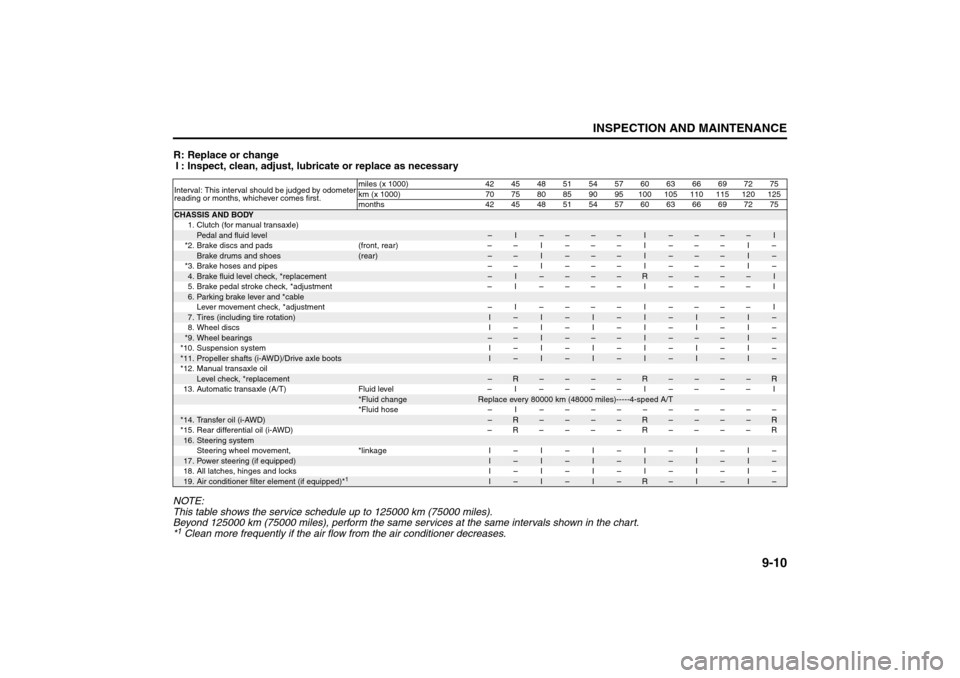

R: Replace or change

I : Inspect, clean, adjust, lubricate or replace as necessary

NOTE:

This table shows the service schedule up to 125000 km (75000 miles).

Beyond 125000 km (75000 miles), perform the same services at the same intervals shown in the chart.

*1 Clean more frequently if the air flow from the air conditioner decreases.Interval: This interval should be judged by odometer

reading or months, whichever comes first.miles (x 1000) 42 45 48 51 54 57 60 63 66 69 72 75

km (x 1000) 70 75 80 85 90 95 100 105 110 115 120 125

months 42 45 48 51 54 57 60 63 66 69 72 75CHASSIS AND BODY

1. Clutch (for manual transaxle)

Pedal and fluid level

–

I

–

–

–

–

I

–

–

–

–

I

*2. Brake discs and pads (front, rear) – – I – – – I – – – I –

Brake drums and shoes

(rear)

–

–

I

–

–

–

I

–

–

–

I

–

*3. Brake hoses and pipes – – I – – – I – – – I –

4.Brake fluid level check, *replacement

–

I

–

–

–

–

R

–

–

–

–

I

5.Brake pedal stroke check, *adjustment – I –––– I –––– I

6.Parking brake lever and *cableLever movement check, *adjustment – I –––– I –––– I7.Tires (including tire rotation)

I

–

I

–

I

–

I

–

I

–

I

–

8.Wheel discs I–I–I–I–I–I–

*9.

Wheel bearings

–

–

I

–

–

–

I

–

–

–

I

–

*10. Suspension system I – I – I – I – I – I –

*11.

Propeller shafts (i-AWD)/Drive axle boots

I

–

I

–

I

–

I

–

I

–

I

–

*12. Manual transaxle oil

Level check, *replacement

–

R

–

–

–

–

R

–

–

–

–

R

13.Automatic transaxle (A/T) Fluid level – I –––– I –––– I

*Fluid change

Replace every 80000 km (48000 miles)-----4-speed A/T

*Fluid hose – I ––––––––––

*14.

Transfer oil (i-AWD)

–

R

–

–

–

–

R

–

–

–

–

R

*15.Rear differential oil (i-AWD) –R––––R––––R

16.

Steering systemSteering wheel movement, *linkage I – I – I – I – I – I –

17.

Power steering (if equipped)

I

–

I

–

I

–

I

–

I

–

I

–

18. All latches, hinges and locks I – I – I – I – I – I –

19.

Air conditioner filter element (if equipped)*

1

I

–

I

–

I

–

R

–

I

–

I

–

Engine Oil and Filter: 1, 2

Gear Oil: 6, 10

Page 213 of 278

9-24

INSPECTION AND MAINTENANCE

80J21-03E

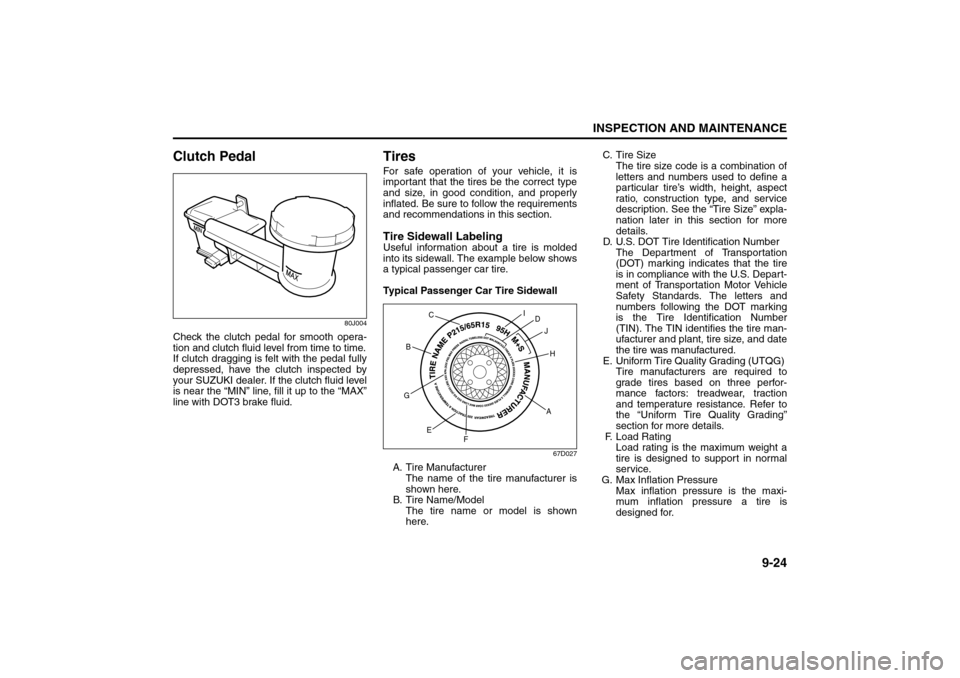

Clutch Pedal

80J004

Check the clutch pedal for smooth opera-

tion and clutch fluid level from time to time.

If clutch dragging is felt with the pedal fully

depressed, have the clutch inspected by

your SUZUKI dealer. If the clutch fluid level

is near the “MIN” line, fill it up to the “MAX”

line with DOT3 brake fluid.

TiresFor safe operation of your vehicle, it is

important that the tires be the correct type

and size, in good condition, and properly

inflated. Be sure to follow the requirements

and recommendations in this section.Tire Sidewall LabelingUseful information about a tire is molded

into its sidewall. The example below shows

a typical passenger car tire.

Typical Passenger Car Tire Sidewall

67D027

A. Tire Manufacturer

The name of the tire manufacturer is

shown here.

B. Tire Name/Model

The tire name or model is shown

here.C. Tire Size

The tire size code is a combination of

letters and numbers used to define a

particular tire’s width, height, aspect

ratio, construction type, and service

description. See the “Tire Size” expla-

nation later in this section for more

details.

D. U.S. DOT Tire Identification Number

The Department of Transportation

(DOT) marking indicates that the tire

is in compliance with the U.S. Depart-

ment of Transportation Motor Vehicle

Safety Standards. The letters and

numbers following the DOT marking

is the Tire Identification Number

(TIN). The TIN identifies the tire man-

ufacturer and plant, tire size, and date

the tire was manufactured.

E. Uniform Tire Quality Grading (UTQG)

Tire manufacturers are required to

grade tires based on three perfor-

mance factors: treadwear, traction

and temperature resistance. Refer to

the “Uniform Tire Quality Grading”

section for more details.

F. Load Rating

Load rating is the maximum weight a

tire is designed to support in normal

service.

G. Max Inflation Pressure

Max inflation pressure is the maxi-

mum inflation pressure a tire is

designed for.

AH B

G

E

FD

J I

C

Tires: 6

Page 215 of 278

9-26

INSPECTION AND MAINTENANCE

80J21-03E

Tire Inflation PressureTire inflation pressure should be checked

when the tire is cold. “Cold tire inflation

pressure” is the pressure in a tire that has

been driven less than 1 mile (1.6 km) or

has been standing for three hours or more.

80JS025

The front and rear tire pressure specifica-

tions for your vehicle are shown below and

are listed on the Tire and Loading Informa-

tion Label, which is located on the driver’s

door lock pillar. The Tire and Loading Infor-

mation Label contains the following infor-

mation:

Seating Capacity

Maximum Allowed Combined Weight of

Occupants and Cargo

Original Tire Size

Recommended Cold Tire Inflation Pres-

sure of Original Tires

Size of Compact Spare Tire Recommended Cold Tire Inflation Pres-

sure of Compact Spare Tire

NOTE:

The tire inflation pressure will change due

to changes in atmospheric pressure, tem-

perature or tire temperature when driving.

To reduce the chance that the low tire

pressure warning light will come on due to

normal changes in temperature and atmo-

spheric pressure, it is important to check

and adjust the tire pressures when the

tires are cold. Tires that appear to be at the

specified pressure when checked after

driving, when the tires are warm, could

have pressure below the specification

when the tires cool down. Also, tires that

are inflated to the specified pressure in a

warm garage may have pressure below the

specification when the vehicle is driven

outside in very cold temperature. If you

adjust the tire pressure in a garage that is

warmer than the outside temperature, you

should add 1 psi to the recommended cold

tire inflation pressure for every 10°F differ-ence between garage temperature and

outside temperature.

Measuring Air Pressure

Use the following steps to achieve proper

tire inflation:

1) Identify the recommended tire pressure

on the vehicle’s Tire and Loading Infor-

mation Label or in the owner’s manual.

2) Remove the valve cap from the tire

valve stem.

3) Using a reliable pressure gauge, mea-

sure the tire inflation pressure by press-

ing the tire gauge firmly onto the valve

to get a pressure measurement.

Remember that inflation pressures

should be checked when the tires are

“cold”, meaning before they have been

driven one mile or after sitting for three

hours or more allowing the tire to cool

to ambient air temperature.

4) If the air pressure is too high, slowly

release the air by pressing on the tire

valve stem with the edge of the tire

gauge until you reach the correct pres-

sure.

5) If the air pressure is too low, fill the tire

with air at a service station until it

reaches the recommended pressure.

6) Make sure all tires have the same air

pressure (unless the owner’s manual

indicates otherwise).

Recommended Cold Tire Inflation

Pressures

Fr on t T ir es230 kPa

33 psi

Rear Tires230 kPa

33 psi

Compact Spare Tire420 kPa

60 psi

Tires: 6

Page 217 of 278

9-28

INSPECTION AND MAINTENANCE

80J21-03E

Uniform Tire Quality GradingThe U.S. National Highway Traffic Safety

Administration has developed a grading

system for evaluating the performance of

passenger car tires. The following informa-

tion will help you understand the grading

system, which applies to vehicles sold in

the U.S. Consult your SUZUKI dealer or

tire retailer for help in choosing the correct

replacement tires for your vehicle.

Quality grades can be found where appli-

cable on the tire sidewall between tread

shoulder and maximum section width. For

example:

Treadwear 200 Traction AA Temperature ADOT Quality Grades

Treadwear

Traction AA A B C

Temperature A B CAll Passenger Car Tires Must Conform To

Federal Safety Requirements in Addition

To These GradesTreadwear

The treadwear grade is a comparative rat-

ing based on the wear rate of the tire when

tested under controlled conditions on a

specified government test course. For

example, a tire graded 150 would wear one

and one-half (1 1/2) times as well on the

government course as a tire graded 100.

The relative performance of tires depends

upon the actual conditions of their use,

however and may depart significantly from

the norm due to variations in driving habits,

service practices and differences in road

characteristics and climate.

Traction – AA, A, B, C

The traction grades, from highest to low-

est, are AA, A, B and C. Those grades rep-

resent the tire’s ability to stop on wet

pavement as measured under controlled

conditions on specified government test

surfaces of asphalt and concrete. A tire

marked C may have poor traction perfor-

mance.

CAUTION

For intelligent All Wheel Drive (i-

AWD) models, replacing a tire with

one of a different size, or using differ-

ent brands among the four tires can

result in damage to the drive train.

WARNING

Replacing the wheels and tires

equipped on your vehicle with certain

combinations of aftermarket wheels

and tires can significantly change the

steering and handling characteris-

tics of your vehicle. Oversized tires

may also rub against the fender over

bumps, causing vehicle damage or

tire failure. Therefore, use only those

wheel and tire combinations

approved by SUZUKI Motor Corpora-

tion as standard or optional equip-

ment for your vehicle. For

information regarding the specified

tires, refer to the Tire Information

Label located on the driver’s side

door pillar or the “SPECIFICATIONS”

section.

CAUTION

Replacing the original tires with tires

of a different size may result in false

speedometer or odometer readings.

Check with your SUZUKI dealer

before purchasing replacement tires

that differ in size from the original

tires.

WARNING

The traction grade assigned to this

tire is based on straight-ahead brak-

ing traction tests, and does not

include acceleration, cornering,

hydroplaning or peak traction charac-

teristics.

Tires: 6