wheel SUZUKI SX4 2008 1.G Service Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SX4, Model: SUZUKI SX4 2008 1.GPages: 278, PDF Size: 4.07 MB

Page 198 of 278

9-9INSPECTION AND MAINTENANCE

80J21-03E

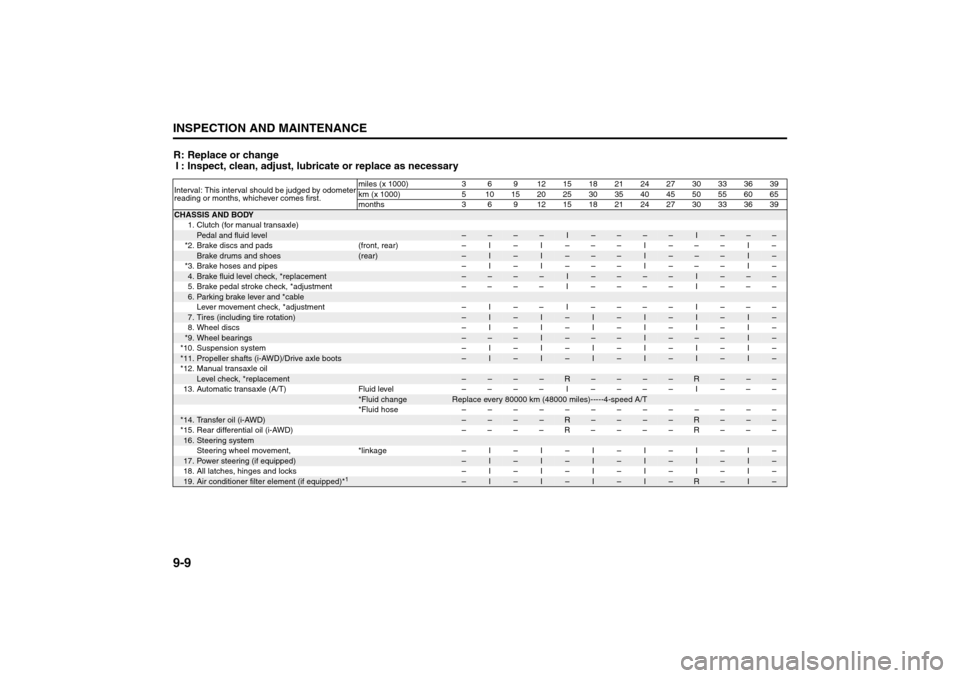

R: Replace or change

I : Inspect, clean, adjust, lubricate or replace as necessaryInterval: This interval should be judged by odometer

reading or months, whichever comes first.miles (x 1000) 3 6 9 12 15 18 21 24 27 30 33 36 39

km (x 1000) 5 101520253035404550556065

months 3 6 9 12 15 18 21 24 27 30 33 36 39CHASSIS AND BODY

1. Clutch (for manual transaxle)

Pedal and fluid level

–

–

–

–

I

–

–

–

–

I

–

–

–

*2. Brake discs and pads (front, rear) – I – I – – – I – – – I –

Brake drums and shoes

(rear)

–

I

–

I

–

–

–

I

–

–

–

I

–

*3. Brake hoses and pipes – I – I – – – I – – – I –

4.Brake fluid level check, *replacement

–

–

–

–

I

–

–

–

–

I

–

–

–

5.Brake pedal stroke check, *adjustment –––– I –––– I –––

6.Parking brake lever and *cableLever movement check, *adjustment – I –– I –––– I –––7.Tires (including tire rotation)

–

I

–

I

–

I

–

I

–

I

–

I

–

8. Wheel discs – I – I – I – I – I – I –

*9.

Wheel bearings

–

–

–

I

–

–

–

I

–

–

–

I

–

*10. Suspension system – I – I – I – I – I – I –

*11.

Propeller shafts (i-AWD)/Drive axle boots

–

I

–

I

–

I

–

I

–

I

–

I

–

*12. Manual transaxle oil

Level check, *replacement

–

–

–

–

R

–

–

–

–

R

–

–

–

13.Automatic transaxle (A/T) Fluid level –––– I –––– I –––

*Fluid change

Replace every 80000 km (48000 miles)-----4-speed A/T

*Fluid hose –––––––––––––

*14.

Transfer oil (i-AWD)

–

–

–

–

R

–

–

–

–

R

–

–

–

*15.Rear differential oil (i-AWD) ––––R––––R–––

16.

Steering systemSteering wheel movement, *linkage – I – I – I – I – I – I –

17.

Power steering (if equipped)

–

I

–

I

–

I

–

I

–

I

–

I

–

18. All latches, hinges and locks – I – I – I – I – I – I –

19.

Air conditioner filter element (if equipped)*

1

–

I

–

I

–

I

–

I

–

R

–

I

–

Engine Oil and Filter: 1, 2

Page 199 of 278

9-10

INSPECTION AND MAINTENANCE

80J21-03E

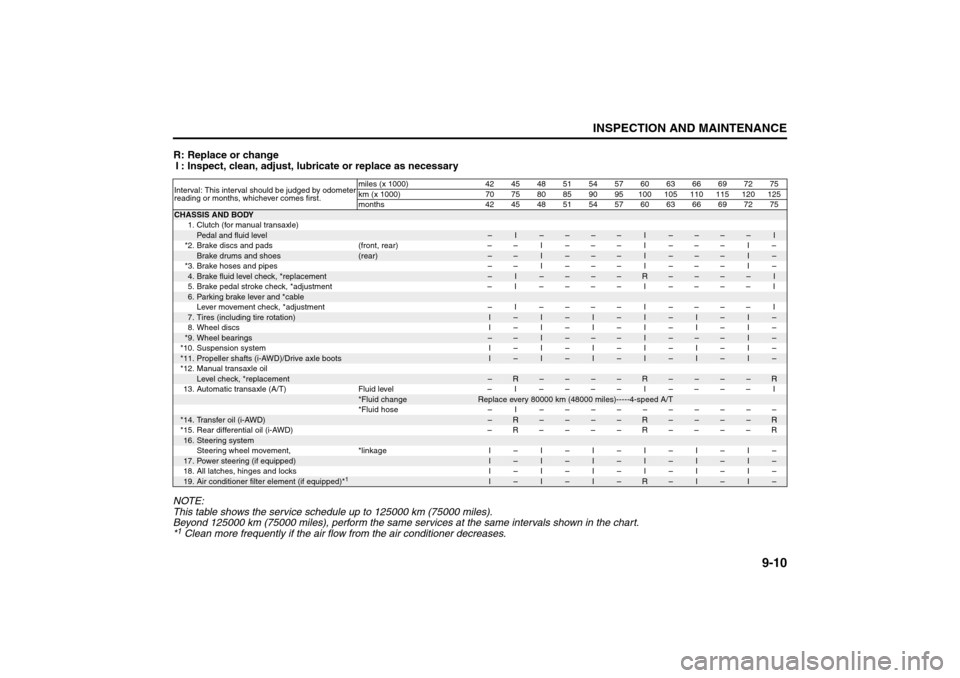

R: Replace or change

I : Inspect, clean, adjust, lubricate or replace as necessary

NOTE:

This table shows the service schedule up to 125000 km (75000 miles).

Beyond 125000 km (75000 miles), perform the same services at the same intervals shown in the chart.

*1 Clean more frequently if the air flow from the air conditioner decreases.Interval: This interval should be judged by odometer

reading or months, whichever comes first.miles (x 1000) 42 45 48 51 54 57 60 63 66 69 72 75

km (x 1000) 70 75 80 85 90 95 100 105 110 115 120 125

months 42 45 48 51 54 57 60 63 66 69 72 75CHASSIS AND BODY

1. Clutch (for manual transaxle)

Pedal and fluid level

–

I

–

–

–

–

I

–

–

–

–

I

*2. Brake discs and pads (front, rear) – – I – – – I – – – I –

Brake drums and shoes

(rear)

–

–

I

–

–

–

I

–

–

–

I

–

*3. Brake hoses and pipes – – I – – – I – – – I –

4.Brake fluid level check, *replacement

–

I

–

–

–

–

R

–

–

–

–

I

5.Brake pedal stroke check, *adjustment – I –––– I –––– I

6.Parking brake lever and *cableLever movement check, *adjustment – I –––– I –––– I7.Tires (including tire rotation)

I

–

I

–

I

–

I

–

I

–

I

–

8.Wheel discs I–I–I–I–I–I–

*9.

Wheel bearings

–

–

I

–

–

–

I

–

–

–

I

–

*10. Suspension system I – I – I – I – I – I –

*11.

Propeller shafts (i-AWD)/Drive axle boots

I

–

I

–

I

–

I

–

I

–

I

–

*12. Manual transaxle oil

Level check, *replacement

–

R

–

–

–

–

R

–

–

–

–

R

13.Automatic transaxle (A/T) Fluid level – I –––– I –––– I

*Fluid change

Replace every 80000 km (48000 miles)-----4-speed A/T

*Fluid hose – I ––––––––––

*14.

Transfer oil (i-AWD)

–

R

–

–

–

–

R

–

–

–

–

R

*15.Rear differential oil (i-AWD) –R––––R––––R

16.

Steering systemSteering wheel movement, *linkage I – I – I – I – I – I –

17.

Power steering (if equipped)

I

–

I

–

I

–

I

–

I

–

I

–

18. All latches, hinges and locks I – I – I – I – I – I –

19.

Air conditioner filter element (if equipped)*

1

I

–

I

–

I

–

R

–

I

–

I

–

Engine Oil and Filter: 1, 2

Gear Oil: 6, 10

Page 209 of 278

9-20

INSPECTION AND MAINTENANCE

80J21-03E

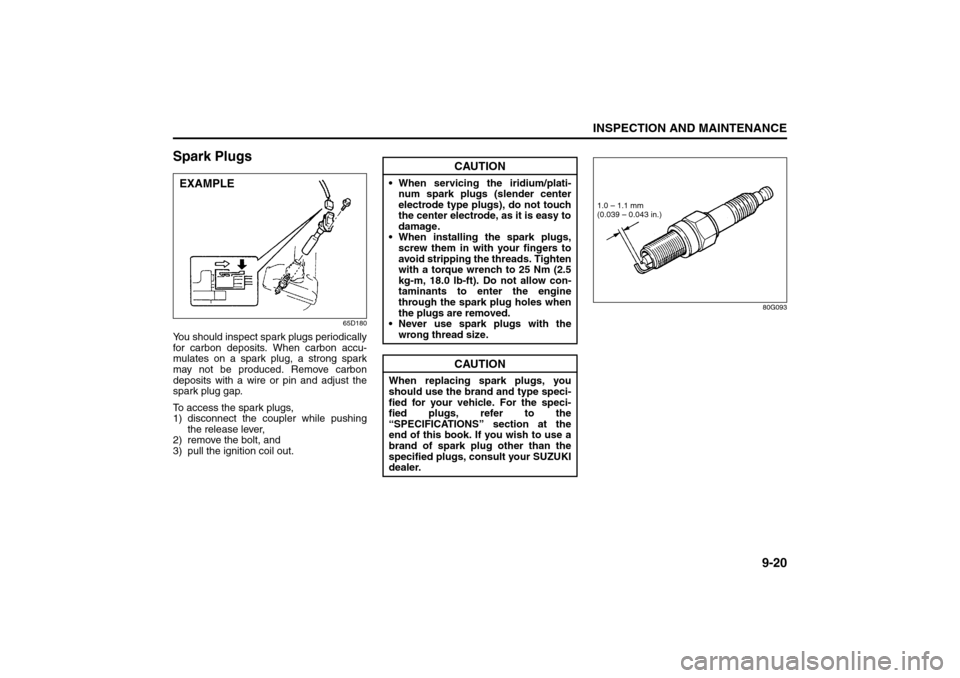

Spark Plugs

65D180

You should inspect spark plugs periodically

for carbon deposits. When carbon accu-

mulates on a spark plug, a strong spark

may not be produced. Remove carbon

deposits with a wire or pin and adjust the

spark plug gap.

To access the spark plugs,

1) disconnect the coupler while pushing

the release lever,

2) remove the bolt, and

3) pull the ignition coil out.

80G093

EXAMPLE

CAUTION

When servicing the iridium/plati-

num spark plugs (slender center

electrode type plugs), do not touch

the center electrode, as it is easy to

damage.

When installing the spark plugs,

screw them in with your fingers to

avoid stripping the threads. Tighten

with a torque wrench to 25 Nm (2.5

kg-m, 18.0 lb-ft). Do not allow con-

taminants to enter the engine

through the spark plug holes when

the plugs are removed.

Never use spark plugs with the

wrong thread size.

CAUTION

When replacing spark plugs, you

should use the brand and type speci-

fied for your vehicle. For the speci-

fied plugs, refer to the

“SPECIFICATIONS” section at the

end of this book. If you wish to use a

brand of spark plug other than the

specified plugs, consult your SUZUKI

dealer.

1.0 – 1.1 mm

(0.039 – 0.043 in.)

Brakes: 6

Steering Wheel: 6

Page 211 of 278

9-22

INSPECTION AND MAINTENANCE

80J21-03E

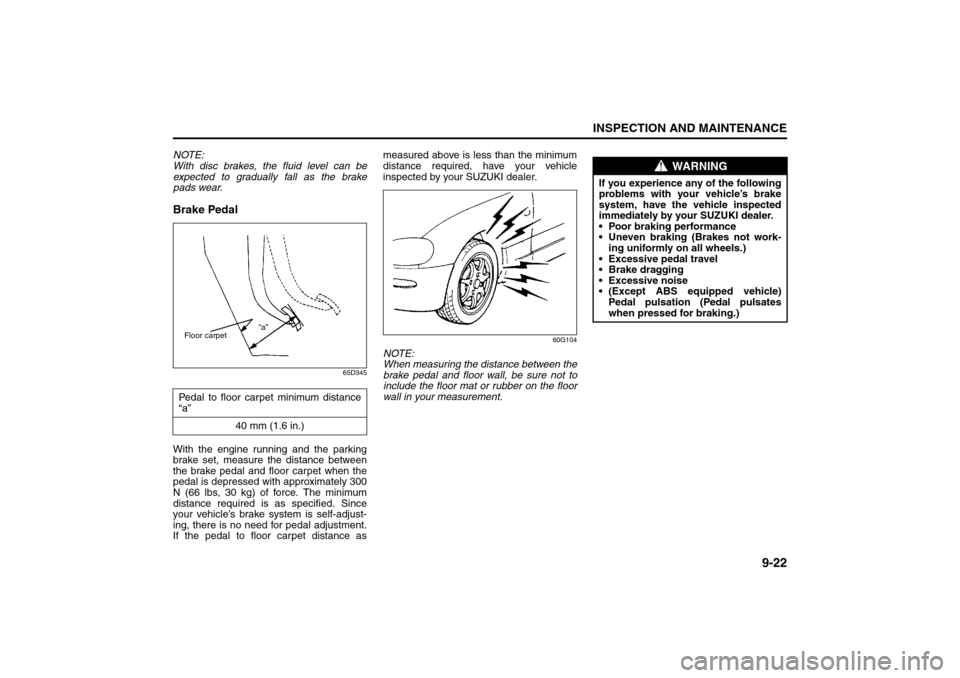

NOTE:

With disc brakes, the fluid level can be

expected to gradually fall as the brake

pads wear.Brake Pedal

65D345

With the engine running and the parking

brake set, measure the distance between

the brake pedal and floor carpet when the

pedal is depressed with approximately 300

N (66 lbs, 30 kg) of force. The minimum

distance required is as specified. Since

your vehicle’s brake system is self-adjust-

ing, there is no need for pedal adjustment.

If the pedal to floor carpet distance asmeasured above is less than the minimum

distance required, have your vehicle

inspected by your SUZUKI dealer.

60G104

NOTE:

When measuring the distance between the

brake pedal and floor wall, be sure not to

include the floor mat or rubber on the floor

wall in your measurement.

Pedal to floor carpet minimum distance

“a”

40 mm (1.6 in.)

“a”

Floor carpet

WARNING

If you experience any of the following

problems with your vehicle’s brake

system, have the vehicle inspected

immediately by your SUZUKI dealer.

Poor braking performance

Uneven braking (Brakes not work-

ing uniformly on all wheels.)

Excessive pedal travel

Brake dragging

Excessive noise

(Except ABS equipped vehicle)

Pedal pulsation (Pedal pulsates

when pressed for braking.)

Tires: 6

Page 212 of 278

9-23INSPECTION AND MAINTENANCE

80J21-03E

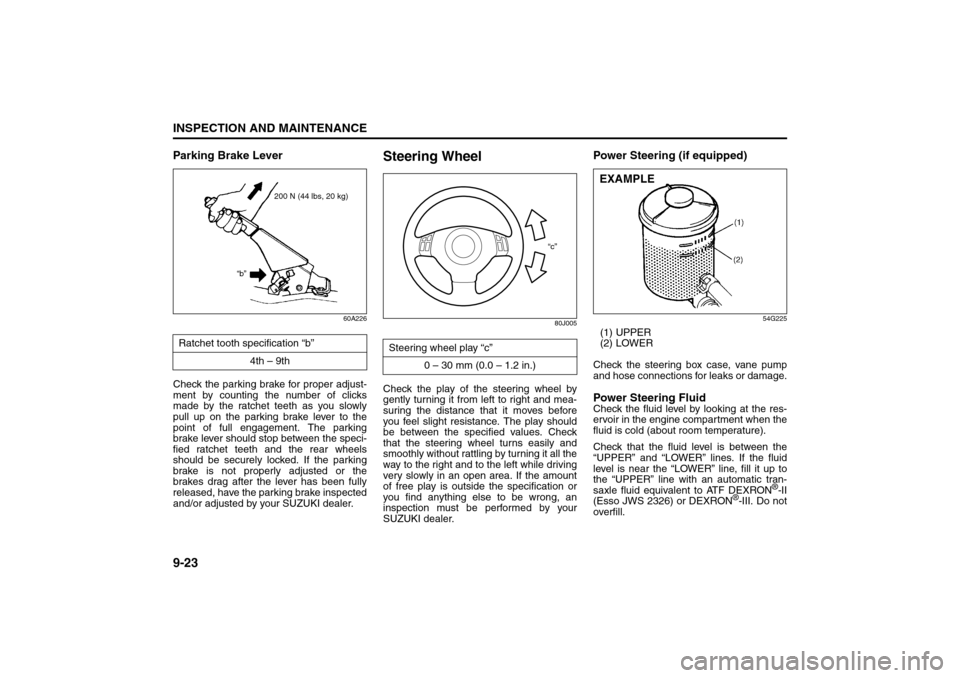

Parking Brake Lever

60A226

Check the parking brake for proper adjust-

ment by counting the number of clicks

made by the ratchet teeth as you slowly

pull up on the parking brake lever to the

point of full engagement. The parking

brake lever should stop between the speci-

fied ratchet teeth and the rear wheels

should be securely locked. If the parking

brake is not properly adjusted or the

brakes drag after the lever has been fully

released, have the parking brake inspected

and/or adjusted by your SUZUKI dealer.

Steering Wheel

80J005

Check the play of the steering wheel by

gently turning it from left to right and mea-

suring the distance that it moves before

you feel slight resistance. The play should

be between the specified values. Check

that the steering wheel turns easily and

smoothly without rattling by turning it all the

way to the right and to the left while driving

very slowly in an open area. If the amount

of free play is outside the specification or

you find anything else to be wrong, an

inspection must be performed by your

SUZUKI dealer.

Power Steering (if equipped)

54G225

(1) UPPER

(2) LOWER

Check the steering box case, vane pump

and hose connections for leaks or damage.Power Steering FluidCheck the fluid level by looking at the res-

ervoir in the engine compartment when the

fluid is cold (about room temperature).

Check that the fluid level is between the

“UPPER” and “LOWER” lines. If the fluid

level is near the “LOWER” line, fill it up to

the “UPPER” line with an automatic tran-

saxle fluid equivalent to ATF DEXRON

®-II

(Esso JWS 2326) or DEXRON

®-III. Do not

overfill. Ratchet tooth specification “b”

4th – 9th

200 N (44 lbs, 20 kg)

“b”

Steering wheel play “c”

0 – 30 mm (0.0 – 1.2 in.)

“c”

EXAMPLE

Tires: 6

Page 214 of 278

9-25INSPECTION AND MAINTENANCE

80J21-03E

H. Tire Ply Material

These tire markings describe the type

of cord and number of plies in the

sidewall and under the tread.

I. Load Index and Speed Rating

The two- or three-digit number is the

tire’s load index, the maximum load a

tire can carry at the speed indicated

by its speed symbol at the maximum

inflation pressure. The higher the

number is, the greater the load carry-

ing capacity. The letter symbol

denotes the speed at which a tire is

designed to be driven for extended

periods of time. (Ratings are listed

below.)

*The letters ZR may be used on tires with a

maximum speed capability over 149 mphand will always be used on tires with a

maximum speed capability over 186 mph.

J. M+S Marking

This marking indicates the tire has

some mud and snow capabilities and

is designed for all-season use.

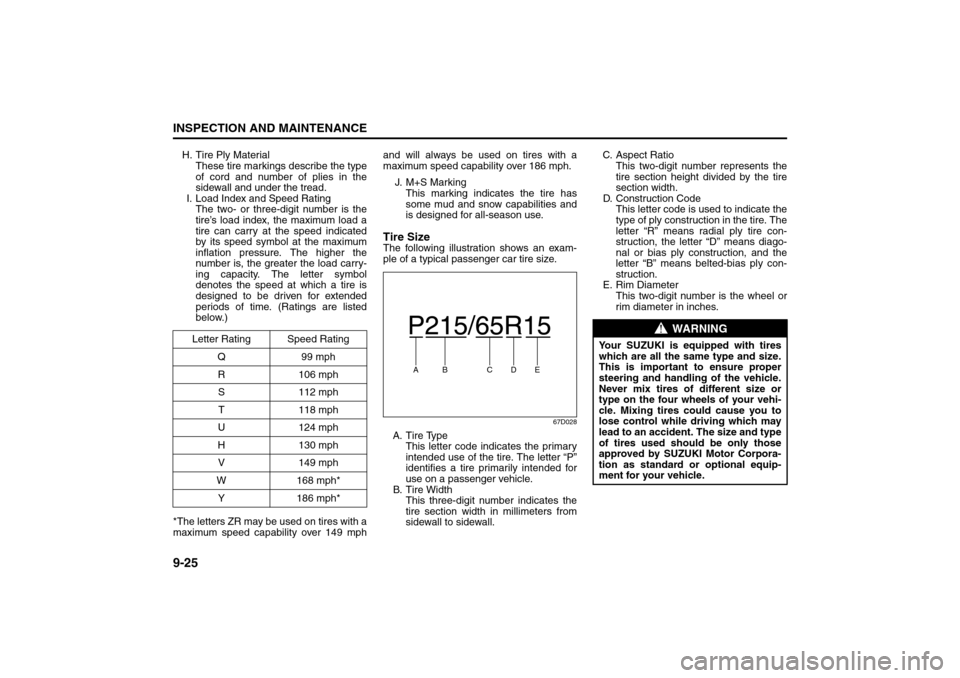

Tire SizeThe following illustration shows an exam-

ple of a typical passenger car tire size.

67D028

A. Tire Type

This letter code indicates the primary

intended use of the tire. The letter “P”

identifies a tire primarily intended for

use on a passenger vehicle.

B. Tire Width

This three-digit number indicates the

tire section width in millimeters from

sidewall to sidewall.C. Aspect Ratio

This two-digit number represents the

tire section height divided by the tire

section width.

D. Construction Code

This letter code is used to indicate the

type of ply construction in the tire. The

letter “R” means radial ply tire con-

struction, the letter “D” means diago-

nal or bias ply construction, and the

letter “B” means belted-bias ply con-

struction.

E. Rim Diameter

This two-digit number is the wheel or

rim diameter in inches.

Letter Rating Speed Rating

Q 99 mph

R106 mph

S112 mph

T118 mph

U124 mph

H130 mph

V149 mph

W 168 mph*

Y 186 mph*

A

B

C

D

E

WARNING

Your SUZUKI is equipped with tires

which are all the same type and size.

This is important to ensure proper

steering and handling of the vehicle.

Never mix tires of different size or

type on the four wheels of your vehi-

cle. Mixing tires could cause you to

lose control while driving which may

lead to an accident. The size and type

of tires used should be only those

approved by SUZUKI Motor Corpora-

tion as standard or optional equip-

ment for your vehicle.

Tires: 6

Page 216 of 278

9-27INSPECTION AND MAINTENANCE

80J21-03E

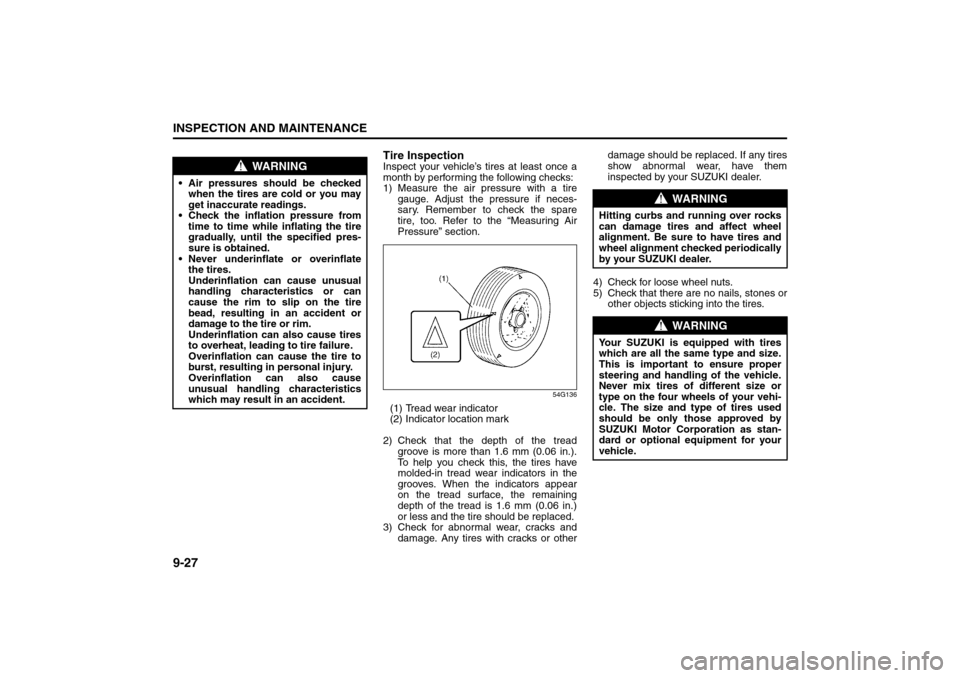

Tire InspectionInspect your vehicle’s tires at least once a

month by performing the following checks:

1) Measure the air pressure with a tire

gauge. Adjust the pressure if neces-

sary. Remember to check the spare

tire, too. Refer to the “Measuring Air

Pressure” section.

54G136

(1) Tread wear indicator

(2) Indicator location mark

2) Check that the depth of the tread

groove is more than 1.6 mm (0.06 in.).

To help you check this, the tires have

molded-in tread wear indicators in the

grooves. When the indicators appear

on the tread surface, the remaining

depth of the tread is 1.6 mm (0.06 in.)

or less and the tire should be replaced.

3) Check for abnormal wear, cracks and

damage. Any tires with cracks or otherdamage should be replaced. If any tires

show abnormal wear, have them

inspected by your SUZUKI dealer.

4) Check for loose wheel nuts.

5) Check that there are no nails, stones or

other objects sticking into the tires.

WARNING

Air pressures should be checked

when the tires are cold or you may

get inaccurate readings.

Check the inflation pressure from

time to time while inflating the tire

gradually, until the specified pres-

sure is obtained.

Never underinflate or overinflate

the tires.

Underinflation can cause unusual

handling characteristics or can

cause the rim to slip on the tire

bead, resulting in an accident or

damage to the tire or rim.

Underinflation can also cause tires

to overheat, leading to tire failure.

Overinflation can cause the tire to

burst, resulting in personal injury.

Overinflation can also cause

unusual handling characteristics

which may result in an accident.

WARNING

Hitting curbs and running over rocks

can damage tires and affect wheel

alignment. Be sure to have tires and

wheel alignment checked periodically

by your SUZUKI dealer.

WARNING

Your SUZUKI is equipped with tires

which are all the same type and size.

This is important to ensure proper

steering and handling of the vehicle.

Never mix tires of different size or

type on the four wheels of your vehi-

cle. The size and type of tires used

should be only those approved by

SUZUKI Motor Corporation as stan-

dard or optional equipment for your

vehicle.

Tires: 6

Page 217 of 278

9-28

INSPECTION AND MAINTENANCE

80J21-03E

Uniform Tire Quality GradingThe U.S. National Highway Traffic Safety

Administration has developed a grading

system for evaluating the performance of

passenger car tires. The following informa-

tion will help you understand the grading

system, which applies to vehicles sold in

the U.S. Consult your SUZUKI dealer or

tire retailer for help in choosing the correct

replacement tires for your vehicle.

Quality grades can be found where appli-

cable on the tire sidewall between tread

shoulder and maximum section width. For

example:

Treadwear 200 Traction AA Temperature ADOT Quality Grades

Treadwear

Traction AA A B C

Temperature A B CAll Passenger Car Tires Must Conform To

Federal Safety Requirements in Addition

To These GradesTreadwear

The treadwear grade is a comparative rat-

ing based on the wear rate of the tire when

tested under controlled conditions on a

specified government test course. For

example, a tire graded 150 would wear one

and one-half (1 1/2) times as well on the

government course as a tire graded 100.

The relative performance of tires depends

upon the actual conditions of their use,

however and may depart significantly from

the norm due to variations in driving habits,

service practices and differences in road

characteristics and climate.

Traction – AA, A, B, C

The traction grades, from highest to low-

est, are AA, A, B and C. Those grades rep-

resent the tire’s ability to stop on wet

pavement as measured under controlled

conditions on specified government test

surfaces of asphalt and concrete. A tire

marked C may have poor traction perfor-

mance.

CAUTION

For intelligent All Wheel Drive (i-

AWD) models, replacing a tire with

one of a different size, or using differ-

ent brands among the four tires can

result in damage to the drive train.

WARNING

Replacing the wheels and tires

equipped on your vehicle with certain

combinations of aftermarket wheels

and tires can significantly change the

steering and handling characteris-

tics of your vehicle. Oversized tires

may also rub against the fender over

bumps, causing vehicle damage or

tire failure. Therefore, use only those

wheel and tire combinations

approved by SUZUKI Motor Corpora-

tion as standard or optional equip-

ment for your vehicle. For

information regarding the specified

tires, refer to the Tire Information

Label located on the driver’s side

door pillar or the “SPECIFICATIONS”

section.

CAUTION

Replacing the original tires with tires

of a different size may result in false

speedometer or odometer readings.

Check with your SUZUKI dealer

before purchasing replacement tires

that differ in size from the original

tires.

WARNING

The traction grade assigned to this

tire is based on straight-ahead brak-

ing traction tests, and does not

include acceleration, cornering,

hydroplaning or peak traction charac-

teristics.

Tires: 6

Page 218 of 278

9-29INSPECTION AND MAINTENANCE

80J21-03E

Temperature – A, B, C

The temperature grades are A (the high-

est), B and C, representing the tire’s resis-

tance to the generation of heat and its

ability to dissipate heat when tested under

controlled conditions on a specified indoor

laboratory test wheel. Sustained high tem-

perature can cause the material of the tire

to degenerate and reduce tire life, and

excessive temperature can lead to sudden

tire failure. The grade C corresponds to a

level of performance which all passenger

car tires must meet under the Federal

Motor Vehicle Safety Standard No. 109.

Grades B and A represent higher levels of

performance on the laboratory test wheel

than the minimum required by law.

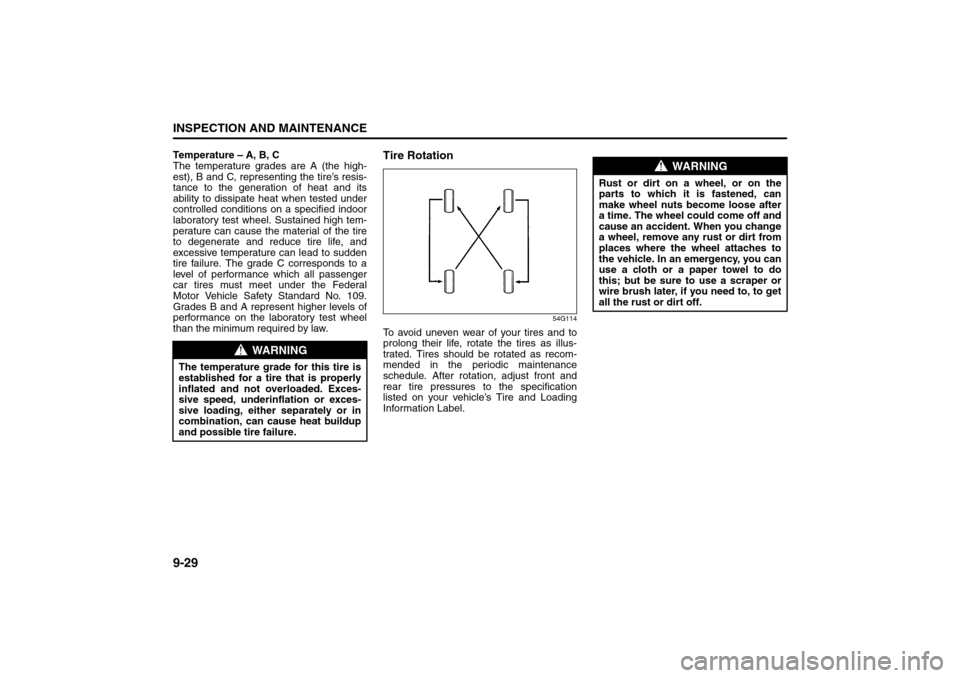

Tire Rotation

54G114

To avoid uneven wear of your tires and to

prolong their life, rotate the tires as illus-

trated. Tires should be rotated as recom-

mended in the periodic maintenance

schedule. After rotation, adjust front and

rear tire pressures to the specification

listed on your vehicle’s Tire and Loading

Information Label.

WARNING

The temperature grade for this tire is

established for a tire that is properly

inflated and not overloaded. Exces-

sive speed, underinflation or exces-

sive loading, either separately or in

combination, can cause heat buildup

and possible tire failure.

WARNING

Rust or dirt on a wheel, or on the

parts to which it is fastened, can

make wheel nuts become loose after

a time. The wheel could come off and

cause an accident. When you change

a wheel, remove any rust or dirt from

places where the wheel attaches to

the vehicle. In an emergency, you can

use a cloth or a paper towel to do

this; but be sure to use a scraper or

wire brush later, if you need to, to get

all the rust or dirt off.

Tires: 6

Page 219 of 278

9-30

INSPECTION AND MAINTENANCE

80J21-03E

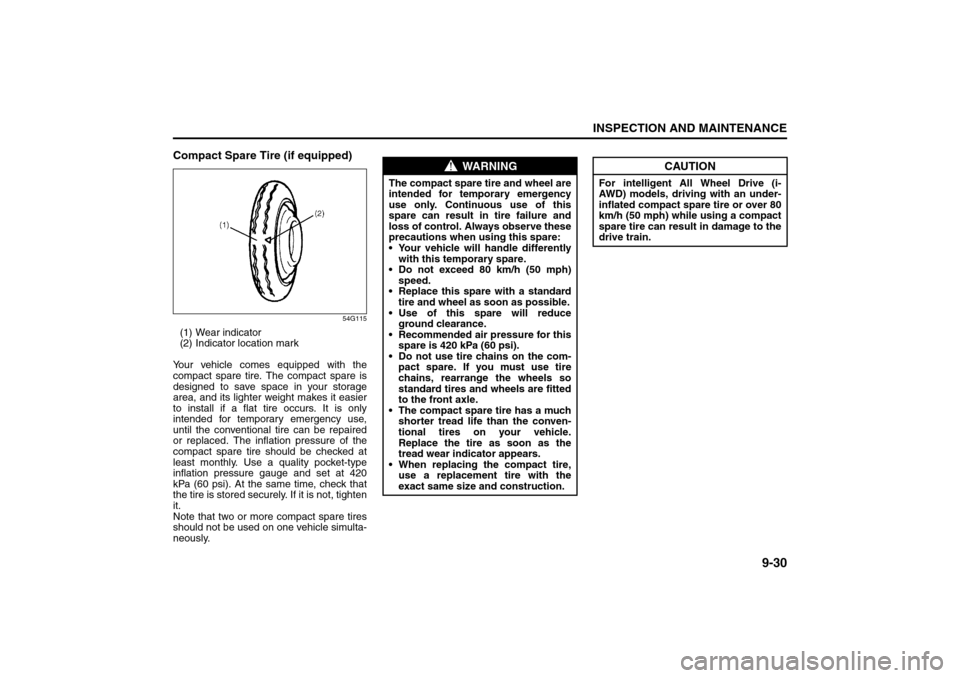

Compact Spare Tire (if equipped)

54G115

(1) Wear indicator

(2) Indicator location mark

Your vehicle comes equipped with the

compact spare tire. The compact spare is

designed to save space in your storage

area, and its lighter weight makes it easier

to install if a flat tire occurs. It is only

intended for temporary emergency use,

until the conventional tire can be repaired

or replaced. The inflation pressure of the

compact spare tire should be checked at

least monthly. Use a quality pocket-type

inflation pressure gauge and set at 420

kPa (60 psi). At the same time, check that

the tire is stored securely. If it is not, tighten

it.

Note that two or more compact spare tires

should not be used on one vehicle simulta-

neously.

WARNING

The compact spare tire and wheel are

intended for temporary emergency

use only. Continuous use of this

spare can result in tire failure and

loss of control. Always observe these

precautions when using this spare:

Your vehicle will handle differently

with this temporary spare.

Do not exceed 80 km/h (50 mph)

speed.

Replace this spare with a standard

tire and wheel as soon as possible.

Use of this spare will reduce

ground clearance.

Recommended air pressure for this

spare is 420 kPa (60 psi).

Do not use tire chains on the com-

pact spare. If you must use tire

chains, rearrange the wheels so

standard tires and wheels are fitted

to the front axle.

The compact spare tire has a much

shorter tread life than the conven-

tional tires on your vehicle.

Replace the tire as soon as the

tread wear indicator appears.

When replacing the compact tire,

use a replacement tire with the

exact same size and construction.

CAUTION

For intelligent All Wheel Drive (i-

AWD) models, driving with an under-

inflated compact spare tire or over 80

km/h (50 mph) while using a compact

spare tire can result in damage to the

drive train.

Tires: 6