Brake SUZUKI SX4 2010 1.G Service Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2010, Model line: SX4, Model: SUZUKI SX4 2010 1.GPages: 297, PDF Size: 4.51 MB

Page 225 of 297

7-20

INSPECTION AND MAINTENANCE

80J23-03E

Continuously Variable

Transaxle (CVT) FluidSpecified FluidUse a CVT fluid SUZUKI CVT FLUID

GREEN-1 or Shell GREEN-1V.Fluid Level CheckYou must check the fluid level with the CVT

fluid at normal operating temperature.

To check the fluid level:

1) To warm up the transaxle fluid, drive the

vehicle or idle the engine until the tem-

perature gauge indicates normal oper-

ating temperature.

2) Then drive for ten more minutes.

NOTE:

Do not check the fluid level if you have just

driven the vehicle for a long time at high

speed, or if you have driven in city traffic inhot weather. Wait until the fluid cools down

(about 30 minutes), or the fluid level indica-

tion will not be correct.

3) Park your vehicle on level ground.

4) Apply the parking brake and then start

the engine in “P” (Park). Let it idle for

two minutes and keep it running during

the fluid level check.

5) With your foot on the brake pedal, move

the gearshift lever through each gear,

pausing for about three seconds in

each range. Then move it back to the

“P” (Park) position.

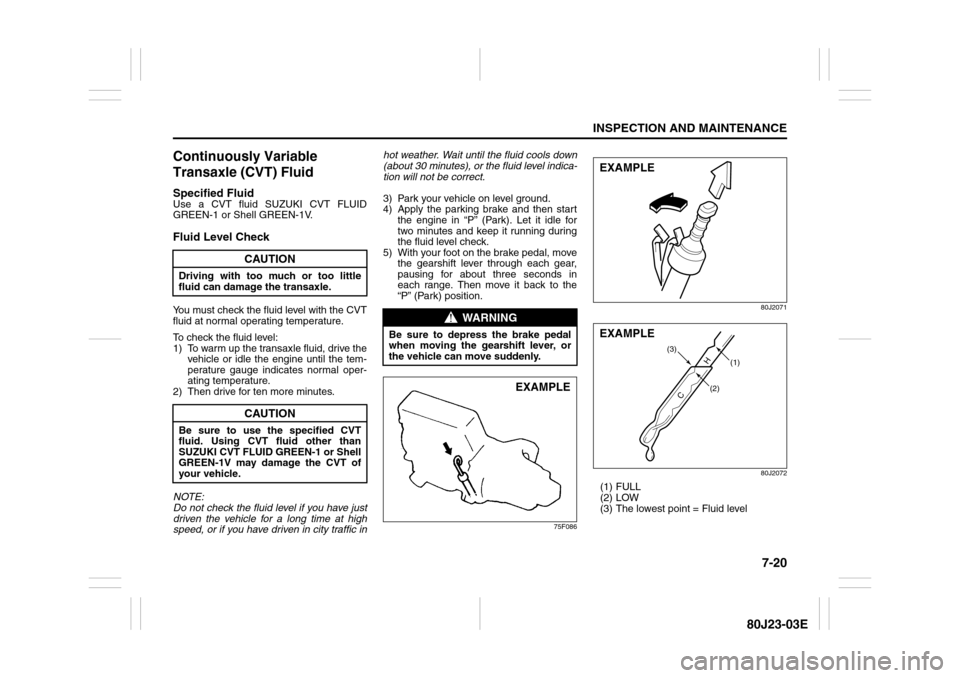

75F08680J2071

80J2072

(1) FULL

(2) LOW

(3) The lowest point = Fluid level

CAUTION

Driving with too much or too little

fluid can damage the transaxle.

CAUTION

Be sure to use the specified CVT

fluid. Using CVT fluid other than

SUZUKI CVT FLUID GREEN-1 or Shell

GREEN-1V may damage the CVT of

your vehicle.

WARNING

Be sure to depress the brake pedal

when moving the gearshift lever, or

the vehicle can move suddenly.

EXAMPLE

EXAMPLE

(2)H

C

(1) (3)

EXAMPLE

Page 226 of 297

7-21INSPECTION AND MAINTENANCE

80J23-03E

6) The handle of the CVT fluid dipstick is

colored red or orange for easy identifi-

cation.

Remove the dipstick, clean it and push

it back in until the cap seats. Pull out

the dipstick and read the fluid level.

The fluid level should be between the

two marks in the “HOT” range on the

dipstick.

7) Add just enough specified fluid through

the dipstick hole to fill the transaxle to

the proper level. It takes only 0.6 liters

(1.27 US pt) for CVT to raise the level

from “LOW” to “FULL”.Deterioration Checking or Chang-

ing OilSince special procedures, materials and

tools are required to check the deteriora-

tion of CVT oil or change, it is recom-

mended that you trust this job to your

authorized SUZUKI dealer.

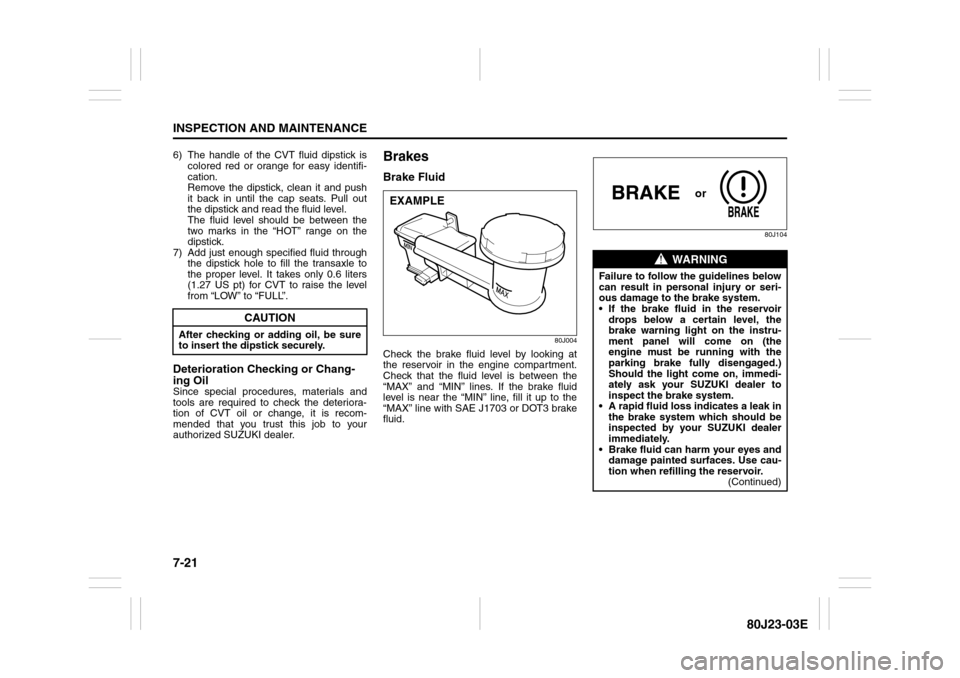

BrakesBrake Fluid

80J004

Check the brake fluid level by looking at

the reservoir in the engine compartment.

Check that the fluid level is between the

“MAX” and “MIN” lines. If the brake fluid

level is near the “MIN” line, fill it up to the

“MAX” line with SAE J1703 or DOT3 brake

fluid.

80J104

CAUTION

After checking or adding oil, be sure

to insert the dipstick securely.

EXAMPLE

WARNING

Failure to follow the guidelines below

can result in personal injury or seri-

ous damage to the brake system.

If the brake fluid in the reservoir

drops below a certain level, the

brake warning light on the instru-

ment panel will come on (the

engine must be running with the

parking brake fully disengaged.)

Should the light come on, immedi-

ately ask your SUZUKI dealer to

inspect the brake system.

A rapid fluid loss indicates a leak in

the brake system which should be

inspected by your SUZUKI dealer

immediately.

Brake fluid can harm your eyes and

damage painted surfaces. Use cau-

tion when refilling the reservoir.

(Continued)

or

Page 227 of 297

7-22

INSPECTION AND MAINTENANCE

80J23-03E

NOTE:

With disc brakes, the fluid level can be

expected to gradually fall as the brake

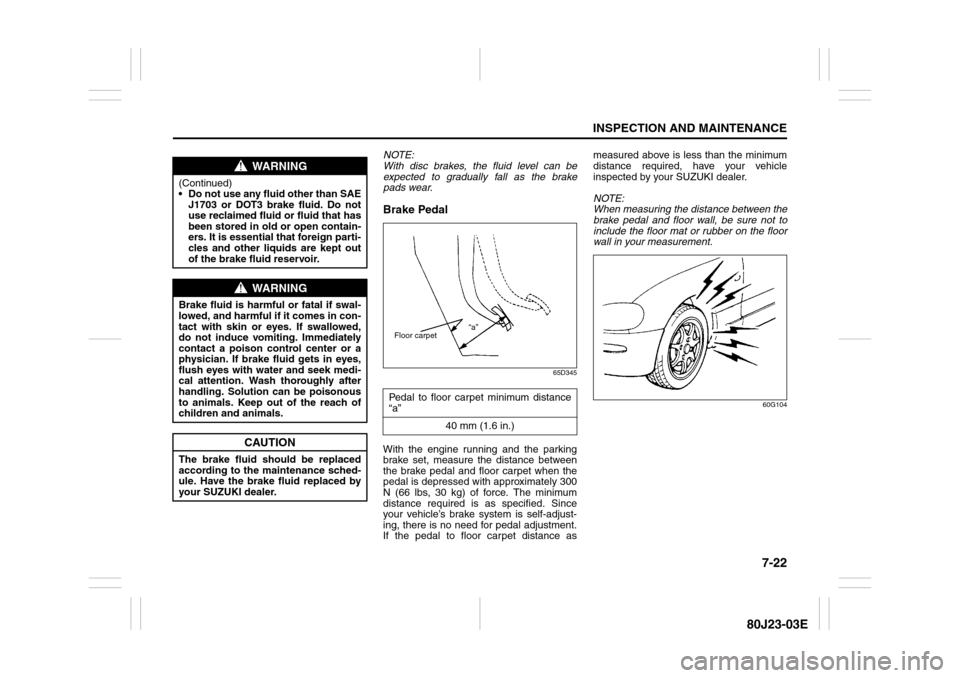

pads wear.Brake Pedal

65D345

With the engine running and the parking

brake set, measure the distance between

the brake pedal and floor carpet when the

pedal is depressed with approximately 300

N (66 lbs, 30 kg) of force. The minimum

distance required is as specified. Since

your vehicle’s brake system is self-adjust-

ing, there is no need for pedal adjustment.

If the pedal to floor carpet distance asmeasured above is less than the minimum

distance required, have your vehicle

inspected by your SUZUKI dealer.

NOTE:

When measuring the distance between the

brake pedal and floor wall, be sure not to

include the floor mat or rubber on the floor

wall in your measurement.

60G104

WARNING

(Continued)

Do not use any fluid other than SAE

J1703 or DOT3 brake fluid. Do not

use reclaimed fluid or fluid that has

been stored in old or open contain-

ers. It is essential that foreign parti-

cles and other liquids are kept out

of the brake fluid reservoir.

WARNING

Brake fluid is harmful or fatal if swal-

lowed, and harmful if it comes in con-

tact with skin or eyes. If swallowed,

do not induce vomiting. Immediately

contact a poison control center or a

physician. If brake fluid gets in eyes,

flush eyes with water and seek medi-

cal attention. Wash thoroughly after

handling. Solution can be poisonous

to animals. Keep out of the reach of

children and animals.

CAUTION

The brake fluid should be replaced

according to the maintenance sched-

ule. Have the brake fluid replaced by

your SUZUKI dealer.

Pedal to floor carpet minimum distance

“a”

40 mm (1.6 in.)

“a”

Floor carpet

Page 228 of 297

7-23INSPECTION AND MAINTENANCE

80J23-03E

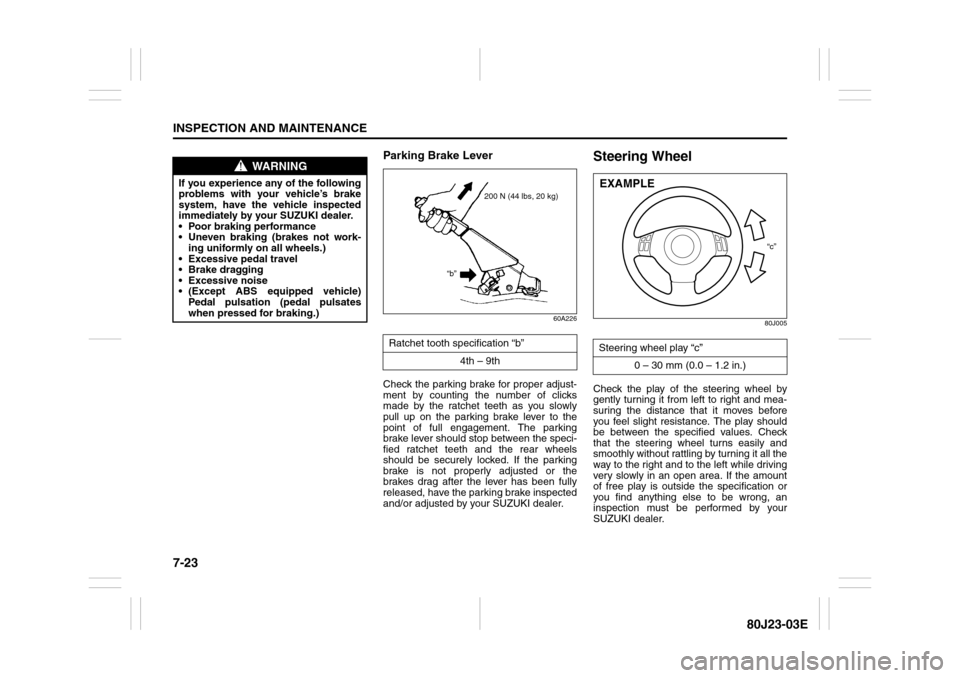

Parking Brake Lever

60A226

Check the parking brake for proper adjust-

ment by counting the number of clicks

made by the ratchet teeth as you slowly

pull up on the parking brake lever to the

point of full engagement. The parking

brake lever should stop between the speci-

fied ratchet teeth and the rear wheels

should be securely locked. If the parking

brake is not properly adjusted or the

brakes drag after the lever has been fully

released, have the parking brake inspected

and/or adjusted by your SUZUKI dealer.

Steering Wheel

80J005

Check the play of the steering wheel by

gently turning it from left to right and mea-

suring the distance that it moves before

you feel slight resistance. The play should

be between the specified values. Check

that the steering wheel turns easily and

smoothly without rattling by turning it all the

way to the right and to the left while driving

very slowly in an open area. If the amount

of free play is outside the specification or

you find anything else to be wrong, an

inspection must be performed by your

SUZUKI dealer.

WARNING

If you experience any of the following

problems with your vehicle’s brake

system, have the vehicle inspected

immediately by your SUZUKI dealer.

Poor braking performance

Uneven braking (brakes not work-

ing uniformly on all wheels.)

Excessive pedal travel

Brake dragging

Excessive noise

(Except ABS equipped vehicle)

Pedal pulsation (pedal pulsates

when pressed for braking.)

Ratchet tooth specification “b”

4th – 9th

200 N (44 lbs, 20 kg)

“b”

Steering wheel play “c”

0 – 30 mm (0.0 – 1.2 in.)

“c”

EXAMPLE

Page 237 of 297

7-32

INSPECTION AND MAINTENANCE

80J23-03E

Snow Tires

Your vehicle is equipped with all-sea-

son tires which are designed for use in

summer and most winter conditions.

For improved traction in severe winter

conditions, SUZUKI recommends

mounting radial snow tires on all four

wheels. Snow tires must be the same

size as the standard tires. Also be sure

to use the tires of the same type and

brand on all four wheels of your vehi-

cle.GLOSSARY OF TIRE TERMINOL-

OGY

Accessory Weight – the combined

weight (in excess of those standard

items which may be replaced) of CVT,

power steering, power brakes, power

windows, power seats, radio, and

heater, to the extent that these items

are available as factory-installed

equipment (whether installed or not).

Cold Tire Inflation Pressure – the pres-

sure in a tire that has been driven less

than 1 mile or has been standing for

three hours or more.

Curb Weight – the weight of a motor

vehicle with standard equipment

including the maximum capacity of

fuel, oil, and coolant, and, if so

equipped, air conditioning and addi-

tional weight optional engine.

Intended Outboard Sidewall – (1) the

sidewall that contains a whitewall,

bears white lettering or bears manu-

facturer, brand, and/or model name

molding that is higher or deeper than

the same molding on the other side-

wall of the tire, or (2) the outward fac-

ing sidewall of an asymmetrical tire

that has a particular side that must

always face outward when mounted

on a vehicle.Maximum Inflation Pressure – the max-

imum cold inflation pressure a tire is

designed to support in normal service.

Maximum Loaded Vehicle Weight –

the sum of curb weight, accessory

weight, vehicle capacity weight (total

load capacity), and production options

weight.

Normal Occupant Weight – 68 kilo-

grams times the number of occupants

specified in the second column of

Table 1 (shown below).

Occupant distribution – distribution of

occupants in a vehicle as specified in

the third column of Table 1 (shown

below).

Production Options Weight – the com-

bined weight of those installed regular

production options weighing over 2.3

kilograms in excess of those standard

items which they replace, not previ-

ously considered in curb weight or

accessory weight, including heavy

duty brakes, ride levelers, roof rack,

heavy duty battery, and special trim.

Recommended Inflation Pressure –

the cold tire inflation pressure recom-

mended by a manufacturer.

Rim – metal support for a tire or tire

and tube assembly upon which the tire

beads are seated.

Page 243 of 297

7-38

INSPECTION AND MAINTENANCE

80J23-03E

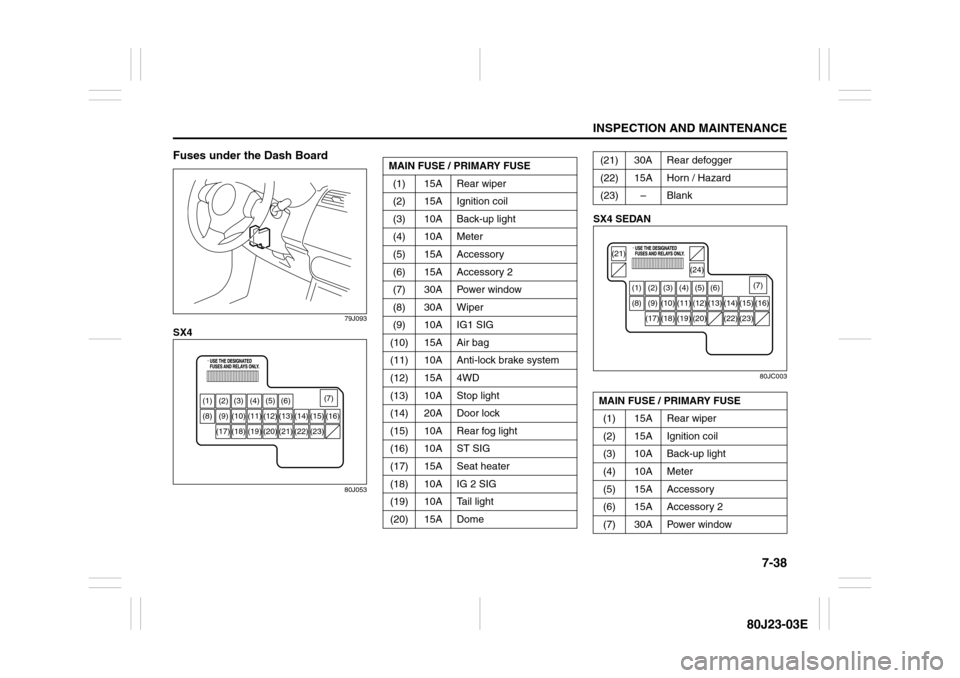

Fuses under the Dash Board

79J093

SX4

80J053

SX4 SEDAN

80JC003

(1) (2) (3) (4) (5) (6)

(8) (9) (10) (11) (12) (13) (14) (15) (16)

(18) (17) (19) (20) (21) (22) (23)(7)

MAIN FUSE / PRIMARY FUSE

(1) 15A Rear wiper

(2) 15A Ignition coil

(3) 10A Back-up light

(4) 10A Meter

(5) 15A Accessory

(6) 15A Accessory 2

(7) 30A Power window

(8) 30A Wiper

(9) 10A IG1 SIG

(10) 15A Air bag

(11) 10A Anti-lock brake system

(12) 15A 4WD

(13) 10A Stop light

(14) 20A Door lock

(15) 10A Rear fog light

(16) 10A ST SIG

(17) 15A Seat heater

(18) 10A IG 2 SIG

(19) 10A Tail light

(20) 15A Dome

(21) 30A Rear defogger

(22) 15A Horn / Hazard

(23) – Blank

MAIN FUSE / PRIMARY FUSE

(1) 15A Rear wiper

(2) 15A Ignition coil

(3) 10A Back-up light

(4) 10A Meter

(5) 15A Accessory

(6) 15A Accessory 2

(7) 30A Power window

(1) (2) (3) (4) (5) (6)

(8) (9) (10) (11) (12) (13)

(21)

(24)

(14) (15) (16)

(18) (17) (19) (20) (22) (23)(7)

Page 244 of 297

7-39INSPECTION AND MAINTENANCE

80J23-03E

The fuses are also located under the

driver’s side of the dashboard. Remove the

fuse box cover by pulling it off. The amper-

age of each fuse is shown on the top of the

fuse box cover.

65D046

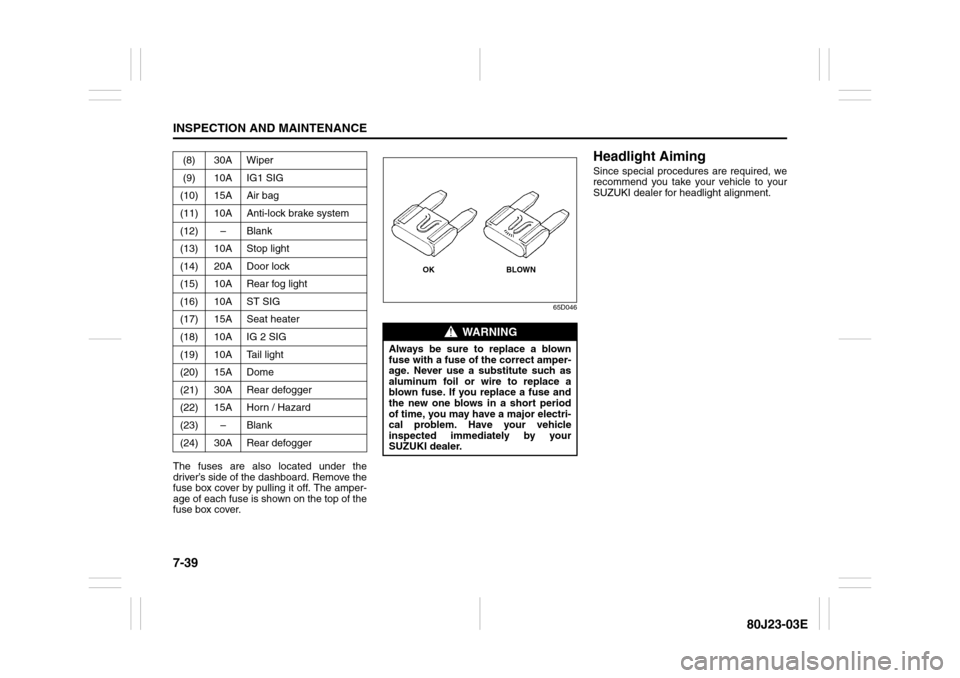

Headlight AimingSince special procedures are required, we

recommend you take your vehicle to your

SUZUKI dealer for headlight alignment. (8) 30A Wiper

(9) 10A IG1 SIG

(10) 15A Air bag

(11) 10A Anti-lock brake system

(12) – Blank

(13) 10A Stop light

(14) 20A Door lock

(15) 10A Rear fog light

(16) 10A ST SIG

(17) 15A Seat heater

(18) 10A IG 2 SIG

(19) 10A Tail light

(20) 15A Dome

(21) 30A Rear defogger

(22) 15A Horn / Hazard

(23) – Blank

(24) 30A Rear defogger

WARNING

Always be sure to replace a blown

fuse with a fuse of the correct amper-

age. Never use a substitute such as

aluminum foil or wire to replace a

blown fuse. If you replace a fuse and

the new one blows in a short period

of time, you may have a major electri-

cal problem. Have your vehicle

inspected immediately by your

SUZUKI dealer.

BLOWN OK

Page 259 of 297

8-2

EMERGENCY SERVICE

80J23-03E

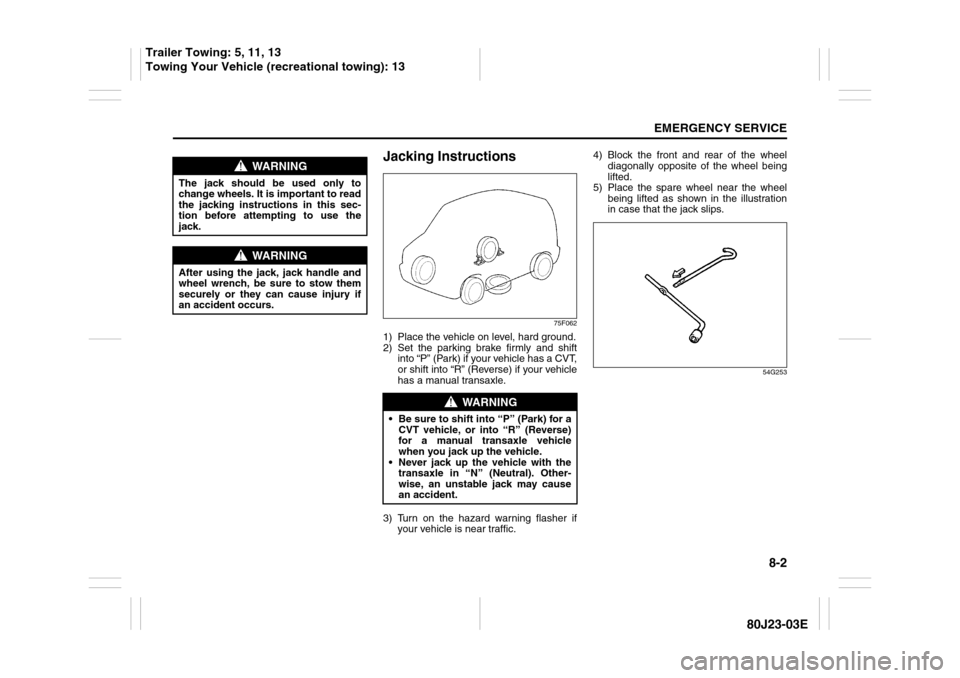

Jacking Instructions

75F062

1) Place the vehicle on level, hard ground.

2) Set the parking brake firmly and shift

into “P” (Park) if your vehicle has a CVT,

or shift into “R” (Reverse) if your vehicle

has a manual transaxle.

3) Turn on the hazard warning flasher if

your vehicle is near traffic.4) Block the front and rear of the wheel

diagonally opposite of the wheel being

lifted.

5) Place the spare wheel near the wheel

being lifted as shown in the illustration

in case that the jack slips.

54G253

WARNING

The jack should be used only to

change wheels. It is important to read

the jacking instructions in this sec-

tion before attempting to use the

jack.

WARNING

After using the jack, jack handle and

wheel wrench, be sure to stow them

securely or they can cause injury if

an accident occurs.

WARNING

Be sure to shift into “P” (Park) for a

CVT vehicle, or into “R” (Reverse)

for a manual transaxle vehicle

when you jack up the vehicle.

Never jack up the vehicle with the

transaxle in “N” (Neutral). Other-

wise, an unstable jack may cause

an accident.

Trailer Towing: 5, 11, 13

Towing Your Vehicle (recreational towing): 13

Page 262 of 297

8-5EMERGENCY SERVICE

80J23-03E

Jump Starting Instructions

When jump starting your vehicle, use

the following procedure:

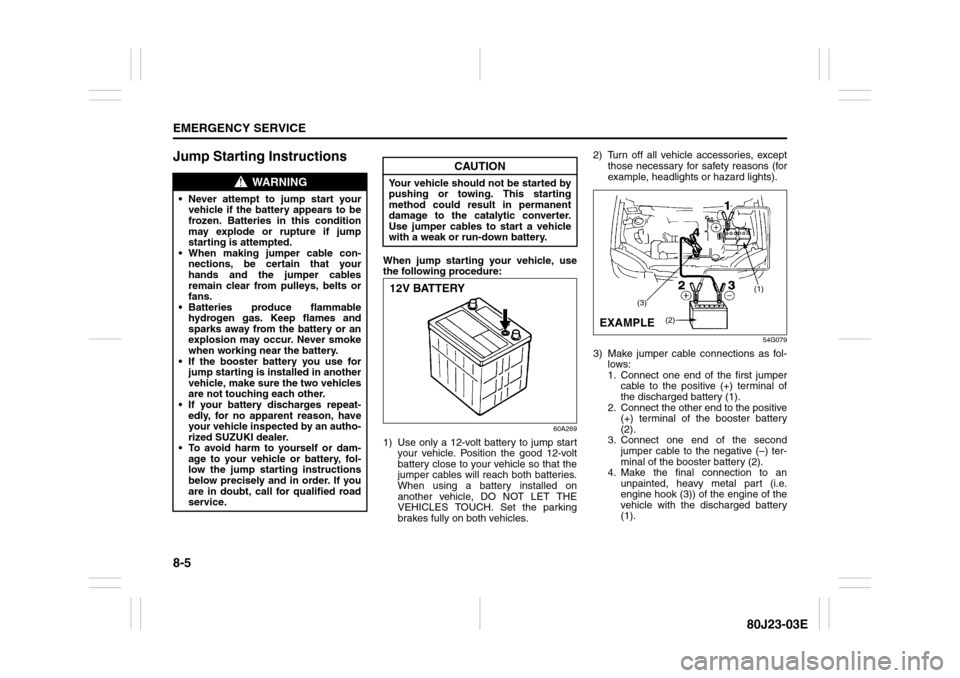

60A269

1) Use only a 12-volt battery to jump start

your vehicle. Position the good 12-volt

battery close to your vehicle so that the

jumper cables will reach both batteries.

When using a battery installed on

another vehicle, DO NOT LET THE

VEHICLES TOUCH. Set the parking

brakes fully on both vehicles.2) Turn off all vehicle accessories, except

those necessary for safety reasons (for

example, headlights or hazard lights).

54G079

3) Make jumper cable connections as fol-

lows:

1. Connect one end of the first jumper

cable to the positive (+) terminal of

the discharged battery (1).

2. Connect the other end to the positive

(+) terminal of the booster battery

(2).

3. Connect one end of the second

jumper cable to the negative (–) ter-

minal of the booster battery (2).

4. Make the final connection to an

unpainted, heavy metal part (i.e.

engine hook (3)) of the engine of the

vehicle with the discharged battery

(1).

WARNING

Never attempt to jump start your

vehicle if the battery appears to be

frozen. Batteries in this condition

may explode or rupture if jump

starting is attempted.

When making jumper cable con-

nections, be certain that your

hands and the jumper cables

remain clear from pulleys, belts or

fans.

Batteries produce flammable

hydrogen gas. Keep flames and

sparks away from the battery or an

explosion may occur. Never smoke

when working near the battery.

If the booster battery you use for

jump starting is installed in another

vehicle, make sure the two vehicles

are not touching each other.

If your battery discharges repeat-

edly, for no apparent reason, have

your vehicle inspected by an autho-

rized SUZUKI dealer.

To avoid harm to yourself or dam-

age to your vehicle or battery, fol-

low the jump starting instructions

below precisely and in order. If you

are in doubt, call for qualified road

service.

CAUTION

Your vehicle should not be started by

pushing or towing. This starting

method could result in permanent

damage to the catalytic converter.

Use jumper cables to start a vehicle

with a weak or run-down battery.12V BATTERY

(1)

(3)

(2)

EXAMPLE

Page 271 of 297

9-4

APPEARANCE CARE

80J23-03E

WashingWhen washing the vehicle, follow the

instructions below:

1) Flush the underside of body and wheel

housings with pressurized water to

remove mud and debris. Use plenty of

water.2) Rinse the body to loosen the dirt.

Remove dirt and mud from the body

exterior with running water. You may

use a soft sponge or brush. Do not use

hard materials which can scratch the

paint or plastic. Remember that the

headlight covers or lenses are made of

plastic in many cases.

3) Wash the entire exterior with a mild

detergent or car wash soap using a

sponge or soft cloth. The sponge or

cloth should be frequently soaked in the

soap solution.

4) Once the dirt has been completely

removed, rinse off the detergent with

running water.

5) After rinsing, wipe off the vehicle body

with a wet chamois or cloth and allow it

to dry in the shade.6) Check carefully for damage to painted

surfaces. If there is any damage,

“touch-up” the damage following the

procedure below:

1. Clean all damaged spots and allow

them to dry.

2. Stir the paint and “touch-up” the

damaged spots lightly using a small

brush.

3. Allow the paint to dry completely.

WARNING

Never attempt to wash and wax

your vehicle with the engine run-

ning.

When cleaning the underside of the

body and fender, where there may

be sharp-edged parts, you should

wear gloves and a long-sleeved

shirt to protect your hands and

arms from being cut.

After washing your vehicle, care-

fully test the brakes before driving

to make sure they have maintained

their normal effectiveness.

CAUTION

When washing the vehicle, avoid

directing steam or hot water of

more than 80°C (176°F) on plastic

parts.

To avoid damaging engine compo-

nents, do not use pressurized

water in the engine compartment.

CAUTION

To avoid damage to the paint or plas-

tic surface, do not wipe the dirt off

without ample water. Be sure to fol-

low above procedure.

CAUTION

When using a commercial car wash

product, observe the cautions speci-

fied by the manufacturer. Never use

strong household detergents or

soaps.

CAUTION

If you use an automatic car wash,

make sure that your vehicle’s body

parts, such as spoilers, cannot be

damaged. If you are in doubt, consult

the car wash operator for advice.

Periodic Maintenance Schedule: 1, 2, 3, 4, 5, 6, 9, 10