section 7 SUZUKI SX4 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2010, Model line: SX4, Model: SUZUKI SX4 2010 1.GPages: 297, PDF Size: 4.51 MB

Page 241 of 297

7-36

INSPECTION AND MAINTENANCE

80J23-03E

Your vehicle is equipped with a battery that

requires infrequent maintenance. You will

never have to add water. You should, how-

ever, periodically check the battery, battery

terminals and battery hold-down bracket

for corrosion. Remove corrosion using a

stiff brush and ammonia mixed with water,

or baking soda mixed with water. After

removing corrosion, rinse with clean water.

The test indicator on the top of the battery

provides information on the condition of

the battery.

If your vehicle is not going to be driven for

a month or longer, disconnect the cable

from the negative terminal of the battery to

help prevent discharge.

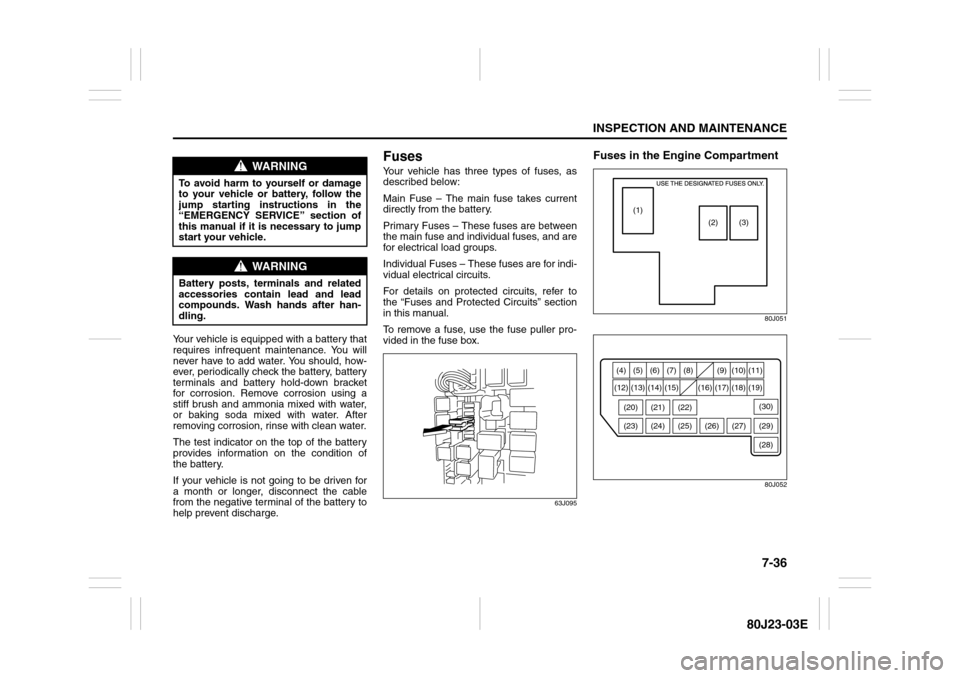

FusesYour vehicle has three types of fuses, as

described below:

Main Fuse – The main fuse takes current

directly from the battery.

Primary Fuses – These fuses are between

the main fuse and individual fuses, and are

for electrical load groups.

Individual Fuses – These fuses are for indi-

vidual electrical circuits.

For details on protected circuits, refer to

the “Fuses and Protected Circuits” section

in this manual.

To remove a fuse, use the fuse puller pro-

vided in the fuse box.

63J095

Fuses in the Engine Compartment

80J051

80J052

WARNING

To avoid harm to yourself or damage

to your vehicle or battery, follow the

jump starting instructions in the

“EMERGENCY SERVICE” section of

this manual if it is necessary to jump

start your vehicle.

WARNING

Battery posts, terminals and related

accessories contain lead and lead

compounds. Wash hands after han-

dling.

(1)

(2) (3)

(28) (27) (26) (25) (6) (7) (9) (11)

(15) (16) (17) (18) (19)

(24)

(8) (4) (5) (10)

(22) (21)

(23)(20)(12) (13) (14)

(30)

(29)

Page 261 of 297

8-4

EMERGENCY SERVICE

80J23-03E

Changing WheelsTo change a wheel, use the following pro-

cedure:

1) Remove the jack, tools and spare wheel

from the vehicle.

2) Loosen, but do not remove the wheel

nuts.

3) Jack up the vehicle (follow the jacking

instructions in this section).

4) Remove the wheel nuts and wheel.

5) Before installing the new wheel, clean

any mud or dirt off from the surface of

the wheel and hub with a clean cloth.

Clean the hub carefully; it may be hot

from driving.

6) Install the new wheel and replace the

wheel nuts with their cone shaped end

facing the wheel. Tighten each nut

snugly by hand until the wheel is

securely seated on the hub.

81A057

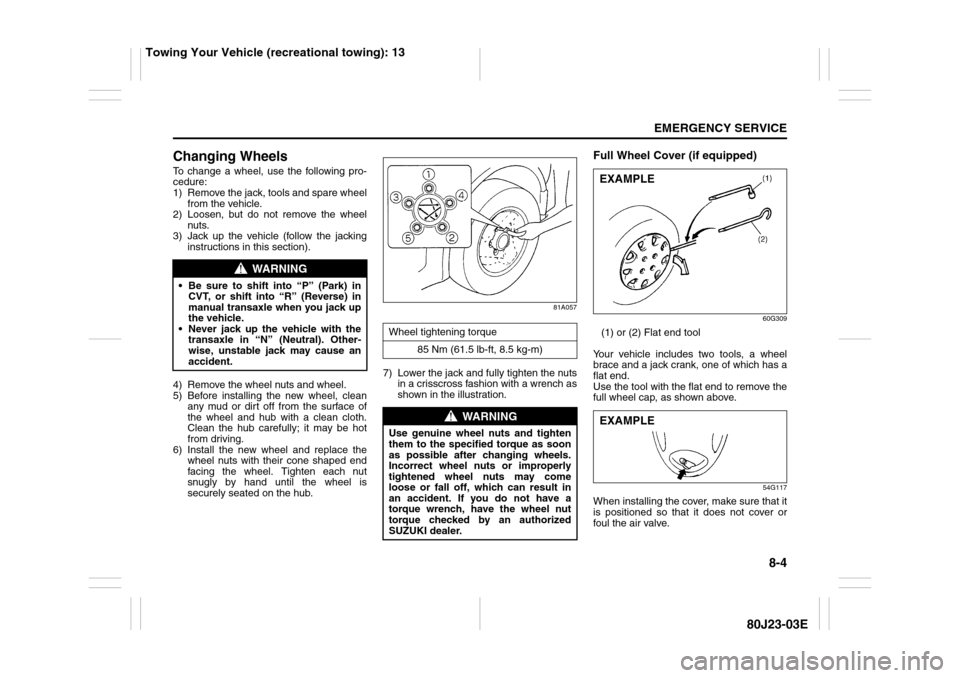

7) Lower the jack and fully tighten the nuts

in a crisscross fashion with a wrench as

shown in the illustration.

Full Wheel Cover (if equipped)

60G309

(1) or (2) Flat end tool

Your vehicle includes two tools, a wheel

brace and a jack crank, one of which has a

flat end.

Use the tool with the flat end to remove the

full wheel cap, as shown above.

54G117

When installing the cover, make sure that it

is positioned so that it does not cover or

foul the air valve.

WARNING

Be sure to shift into “P” (Park) in

CVT, or shift into “R” (Reverse) in

manual transaxle when you jack up

the vehicle.

Never jack up the vehicle with the

transaxle in “N” (Neutral). Other-

wise, unstable jack may cause an

accident.

Wheel tightening torque

85 Nm (61.5 lb-ft, 8.5 kg-m)

WARNING

Use genuine wheel nuts and tighten

them to the specified torque as soon

as possible after changing wheels.

Incorrect wheel nuts or improperly

tightened wheel nuts may come

loose or fall off, which can result in

an accident. If you do not have a

torque wrench, have the wheel nut

torque checked by an authorized

SUZUKI dealer.

EXAMPLEEXAMPLE

Towing Your Vehicle (recreational towing): 13

Page 263 of 297

8-6

EMERGENCY SERVICE

80J23-03E

4) If the booster battery you are using is

installed on another vehicle, start the

engine of the vehicle with the booster

battery. Run the engine at moderate

speed.

5) Start the engine of the vehicle with the

discharged battery.

6) Remove the jumper cables in the exact

reverse order in which you connected

them.

Towing a Disabled VehicleEmergency TowingIf your vehicle is disabled, it may be towed

by a tow truck using one of the following

methods:

1) Tow the vehicle with two wheels lifted

by the tow truck and the other two

wheels on a towing dolly.

2) Use the appropriate towing method

specified for your vehicle in the “Towing

Your Vehicle (recreational towing)” sec-

tion, but with the wheels lifted by the

tow truck instead of on a towing dolly.

Be sure to carefully follow the specific

instructions provided in the “Towing

Your Vehicle (recreational towing)” sec-

tion.

If the Starter Does Not

Operate1) Try turning the ignition switch to the

“START” position with the headlights

turned on to determine the battery con-

dition. If the headlights go excessively

dim or go off, it usually means that

either the battery has run down or bat-

tery terminal contact is poor. Recharge

the battery or correct battery terminal

contact if necessary.

2) If the headlights remain bright, check

the fuses. If the reason for failure of the

starter is not obvious, there may be a

major electrical problem. Have the vehi-

cle inspected by your authorized

SUZUKI dealer.

WARNING

Never connect the jumper cable

directly to the negative (–) terminal of

the discharged battery, or an explo-

sion may occur.

CAUTION

If vehicle damage (such as steering

or drivetrain damage, etc.) prevents

normal use of the towing procedures

for your vehicle described in the

“Towing Your Vehicle (recreational

towing)” section, have your vehicle

towed with two wheels lifted by the

tow truck and the other two wheels

on a towing dolly.

Page 264 of 297

8-7EMERGENCY SERVICE

80J23-03E

If the Engine is FloodedIf the engine is flooded with gasoline, it

may be hard to start. If this happens, press

the accelerator pedal all the way to the

floor and hold it there while cranking the

engine. (Do not operate the starter motor

for more than 15 seconds).

If the Engine OverheatsThe engine could overheat temporarily

under severe driving conditions. If the

engine coolant temperature gauge indi-

cates overheating during driving:

1) Turn off the air conditioner, if equipped.

2) Take the vehicle to a safe place and

park.

3) Let the engine run at normal idle speed

for a few minutes until the indicator is

within the normal, acceptable tempera-

ture range shown by the white band

between “H” and “C”.If the temperature indication does not

come down to within the normal, accept-

able range:

1) Turn off the engine and check that the

water pump belt and pulleys are not

damaged or slipping. If any abnormality

is found, correct it.

2) Check the coolant level in the reservoir.

If it is found to be lower than the “LOW”

line, look for leaks at the radiator, water

pump and radiator and heater hoses. If

you locate any leaks that may have

caused the overheating, do not run the

engine until these problems have been

corrected.

3) If you do not find a leak, carefully add

coolant to the reservoir and then the

radiator, if necessary. (Refer to “Engine

Coolant” in the “INSPECTION AND

MAINTENANCE” section.)

WARNING

If you see or hear escaping steam,

stop the vehicle in a safe place and

immediately turn off the engine to let

it cool. Do not open the hood when

steam is present. When the steam

can no longer be seen or heard, open

the hood to see if the coolant is still

boiling. If it is, you must wait until it

stops boiling before you proceed.

Also, be careful not to touch hot

engine parts (radiator, water hoses,

engine etc.).

Page 268 of 297

9-1APPEARANCE CARE

80J23-03E

Corrosion PreventionIt is important to take good care of your

vehicle to protect it from corrosion.

Listed below are instructions for how to

maintain your vehicle to prevent corrosion.

Please read and follow these instructions

carefully.Important Information About

CorrosionCommon causes of corrosion

1) Accumulation of road salt, dirt, moisture

or chemicals in hard-to-reach areas of

the vehicle underbody or frame.

2) Chipping, scratches and any damage to

treated or painted metal surfaces

resulting from minor accidents or

impact from stones and gravel.

Environmental conditions which accel-

erate corrosion

1) Road salt, dust control chemicals, sea

air or industrial pollution will all acceler-

ate the corrosion of metal.

2) High humidity will increase the rate of

corrosion particularly when the temper-

ature range is just above the freezing

point.

3) Moisture in certain areas of a vehicle

for an extended period of time may pro-

mote corrosion even though other body

sections may be completely dry.

4) High temperatures will cause an accel-

erated rate of corrosion to parts of thevehicle which are not well ventilated to

permit quick drying.

52D151

This information illustrates the necessity of

keeping your vehicle (particularly the

underbody) as clean and dry as possible. It

is equally important to repair any damage

to the paint or protective coatings as soon

as possible.How to Help Prevent CorrosionWash your vehicle frequently

The best way to preserve the finish on your

vehicle and to help avoid corrosion is to

keep it clean with frequent washing.

Wash your vehicle at least once during the

winter and once immediately after the win-

ter. Keep your vehicle, particularly the

underside, as clean and dry as possible.If you frequently drive on salted roads, your

vehicle should be washed at least once a

month during the winter. If you live near the

ocean, your vehicle should be washed at

least once a month throughout the year.

For washing instructions, refer to the “Vehi-

cle Cleaning” section.

Remove foreign material deposits

Foreign material such as salts, chemicals,

road oil or tar, tree sap, bird droppings and

industrial fall-out may damage the finish of

your vehicle if it is left on painted surfaces.

Remove these types of deposits as quickly

as possible. If these deposits are difficult to

wash off, an additional cleaner may be

required. Be sure that any cleaner you use

is not harmful to painted surfaces and is

specifically intended for your purposes.

Follow the manufacturer’s directions when

using these special cleaners.

Repair finish damage

Carefully examine your vehicle for damage

to the painted surfaces, especially if it is

used off-road. Should you find any chips or

scratches in the paint, touch them up

immediately to prevent corrosion from

starting. If the chips or scratches have

gone through to the bare metal, have a

qualified body shop make the repair.

Page 288 of 297

12-2SPECIFICATIONS

80J23-03E

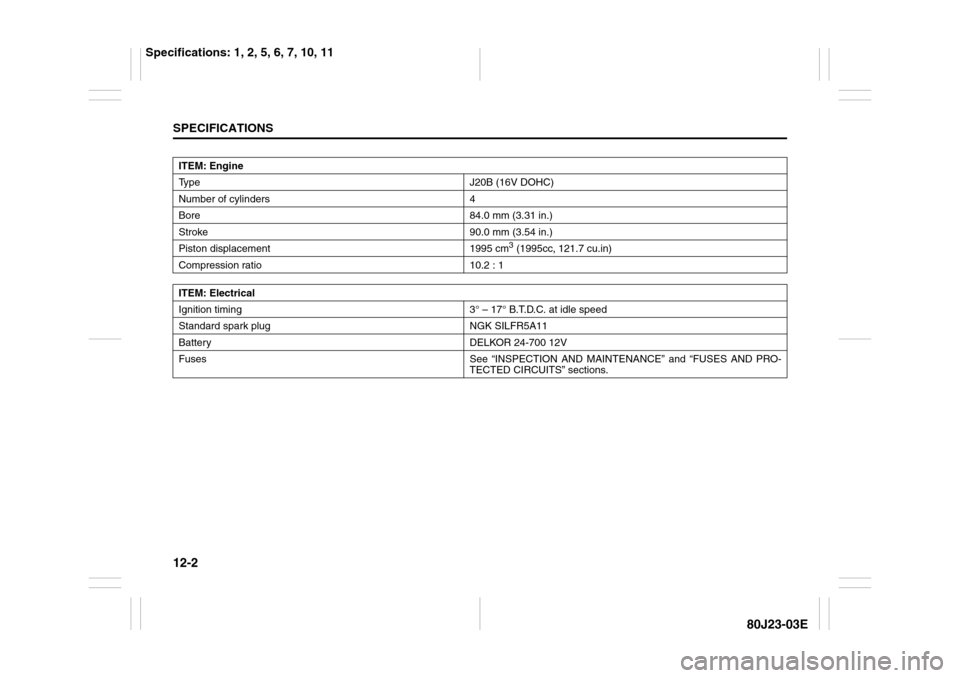

ITEM: Engine

Type J20B (16V DOHC)

Number of cylinders 4

Bore 84.0 mm (3.31 in.)

Stroke 90.0 mm (3.54 in.)

Piston displacement 1995 cm

3 (1995cc, 121.7 cu.in)

Compression ratio 10.2 : 1

ITEM: Electrical

Ignition timing 3° – 17° B.T.D.C. at idle speed

Standard spark plug NGK SILFR5A11

Battery DELKOR 24-700 12V

Fuses See “INSPECTION AND MAINTENANCE” and “FUSES AND PRO-

TECTED CIRCUITS” sections.

Specifications: 1, 2, 5, 6, 7, 10, 11