SUZUKI XL7 2007 2.G Owners Manual

Manufacturer: SUZUKI, Model Year: 2007, Model line: XL7, Model: SUZUKI XL7 2007 2.GPages: 274, PDF Size: 6.12 MB

Page 251 of 274

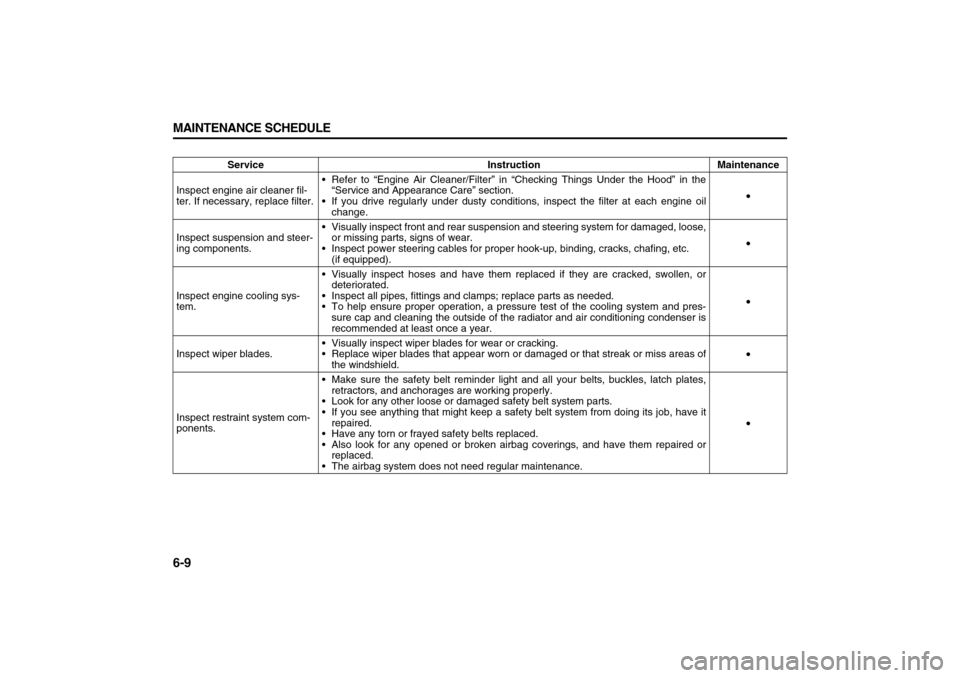

6-9 MAINTENANCE SCHEDULE

78J00-03E

Service Instruction Maintenance

Inspect engine air cleaner fil-

ter. If necessary, replace filter. Refer to “Engine Air Cleaner/Filter” in “Checking Things Under the Hood” in the

“Service and Appearance Care” section.

If you drive regularly under dusty conditions, inspect the filter at each engine oil

change.•

Inspect suspension and steer-

ing components. Visually inspect front and rear suspension and steering system for damaged, loose,

or missing parts, signs of wear.

Inspect power steering cables for proper hook-up, binding, cracks, chafing, etc.

(if equipped).•

Inspect engine cooling sys-

tem. Visually inspect hoses and have them replaced if they are cracked, swollen, or

deteriorated.

Inspect all pipes, fittings and clamps; replace parts as needed.

To help ensure proper operation, a pressure test of the cooling system and pres-

sure cap and cleaning the outside of the radiator and air conditioning condenser is

recommended at least once a year.•

Inspect wiper blades. Visually inspect wiper blades for wear or cracking.

Replace wiper blades that appear worn or damaged or that streak or miss areas of

the windshield.•

Inspect restraint system com-

ponents. Make sure the safety belt reminder light and all your belts, buckles, latch plates,

retractors, and anchorages are working properly.

Look for any other loose or damaged safety belt system parts.

If you see anything that might keep a safety belt system from doing its job, have it

repaired.

Have any torn or frayed safety belts replaced.

Also look for any opened or broken airbag coverings, and have them repaired or

replaced.

The airbag system does not need regular maintenance.•

Page 252 of 274

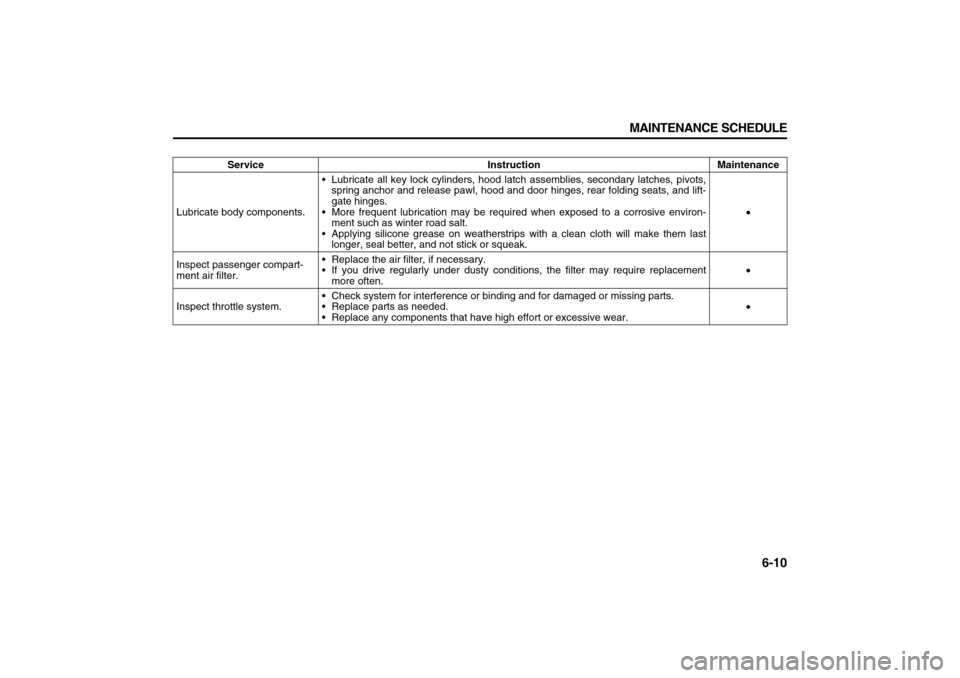

6-10 MAINTENANCE SCHEDULE

78J00-03E

Service Instruction Maintenance

Lubricate body components. Lubricate all key lock cylinders, hood latch assemblies, secondary latches, pivots,

spring anchor and release pawl, hood and door hinges, rear folding seats, and lift-

gate hinges.

More frequent lubrication may be required when exposed to a corrosive environ-

ment such as winter road salt.

Applying silicone grease on weatherstrips with a clean cloth will make them last

longer, seal better, and not stick or squeak.•

Inspect passenger compart-

ment air filter. Replace the air filter, if necessary.

If you drive regularly under dusty conditions, the filter may require replacement

more often.•

Inspect throttle system. Check system for interference or binding and for damaged or missing parts.

Replace parts as needed.

Replace any components that have high effort or excessive wear.•

Page 253 of 274

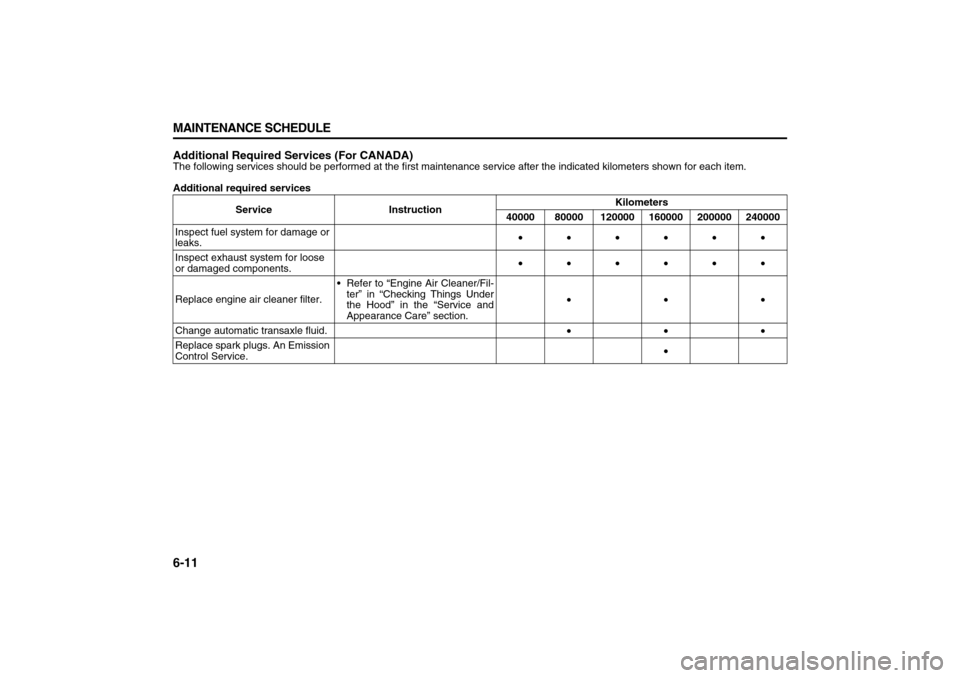

6-11 MAINTENANCE SCHEDULE

78J00-03E

Additional Required Services (For CANADA)The following services should be performed at the first maintenance service after the indicated kilometers shown for each item.

Additional required services

Service InstructionKilometers

40000 80000 120000 160000 200000 240000

Inspect fuel system for damage or

leaks.••••••

Inspect exhaust system for loose

or damaged components.••••••

Replace engine air cleaner filter. Refer to “Engine Air Cleaner/Fil-

ter” in “Checking Things Under

the Hood” in the “Service and

Appearance Care” section.•••

Change automatic transaxle fluid. •••

Replace spark plugs. An Emission

Control Service.•

Page 254 of 274

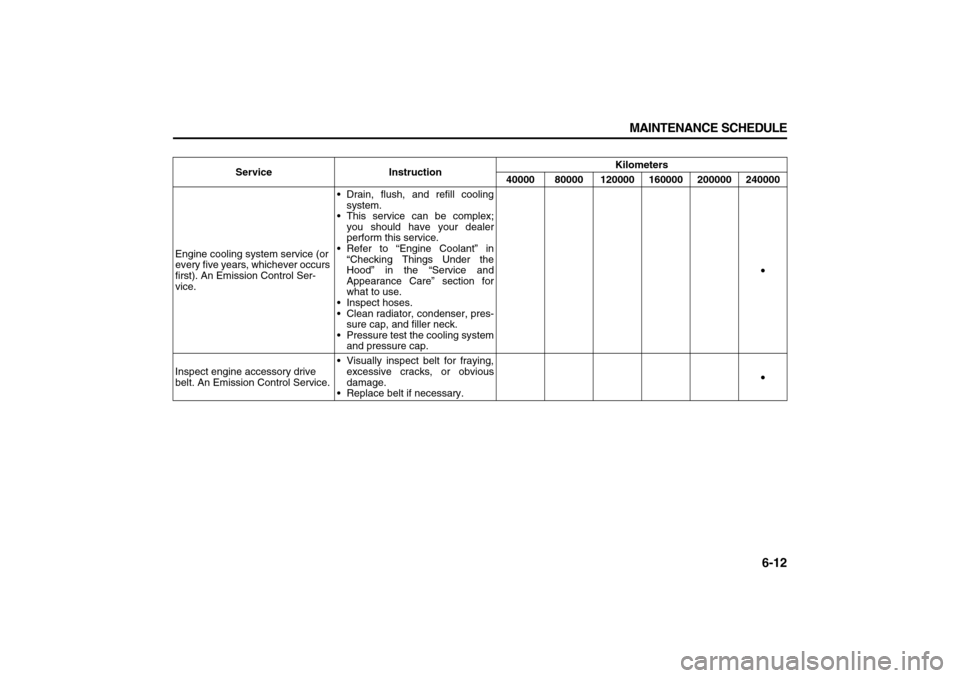

6-12 MAINTENANCE SCHEDULE

78J00-03E

Service InstructionKilometers

40000 80000 120000 160000 200000 240000

Engine cooling system service (or

every five years, whichever occurs

first). An Emission Control Ser-

vice. Drain, flush, and refill cooling

system.

This service can be complex;

you should have your dealer

perform this service.

Refer to “Engine Coolant” in

“Checking Things Under the

Hood” in the “Service and

Appearance Care” section for

what to use.

Inspect hoses.

Clean radiator, condenser, pres-

sure cap, and filler neck.

Pressure test the cooling system

and pressure cap.•

Inspect engine accessory drive

belt. An Emission Control Service. Visually inspect belt for fraying,

excessive cracks, or obvious

damage.

Replace belt if necessary.•

Page 255 of 274

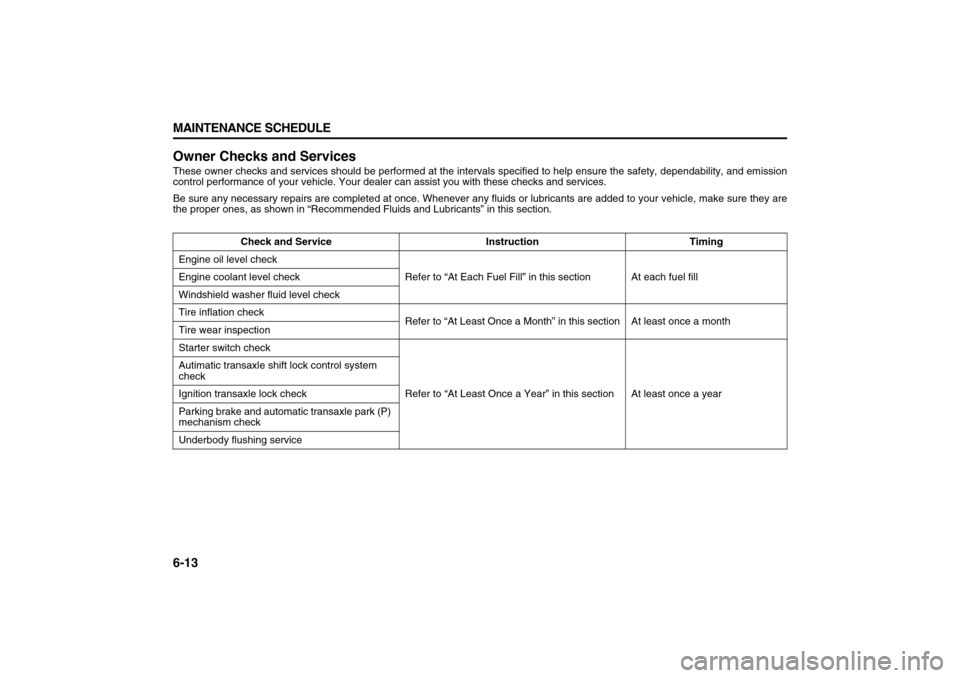

6-13 MAINTENANCE SCHEDULE

78J00-03E

Owner Checks and ServicesThese owner checks and services should be performed at the intervals specified to help ensure the safety, dependability, and emission

control performance of your vehicle. Your dealer can assist you with these checks and services.

Be sure any necessary repairs are completed at once. Whenever any fluids or lubricants are added to your vehicle, make sure they are

the proper ones, as shown in “Recommended Fluids and Lubricants” in this section.

Check and Service Instruction Timing

Engine oil level check

Refer to “At Each Fuel Fill” in this section At each fuel fill Engine coolant level check

Windshield washer fluid level check

Tire inflation check

Refer to “At Least Once a Month” in this section At least once a month

Tire wear inspection

Starter switch check

Refer to “At Least Once a Year” in this section At least once a year Autimatic transaxle shift lock control system

check

Ignition transaxle lock check

Parking brake and automatic transaxle park (P)

mechanism check

Underbody flushing service

Page 256 of 274

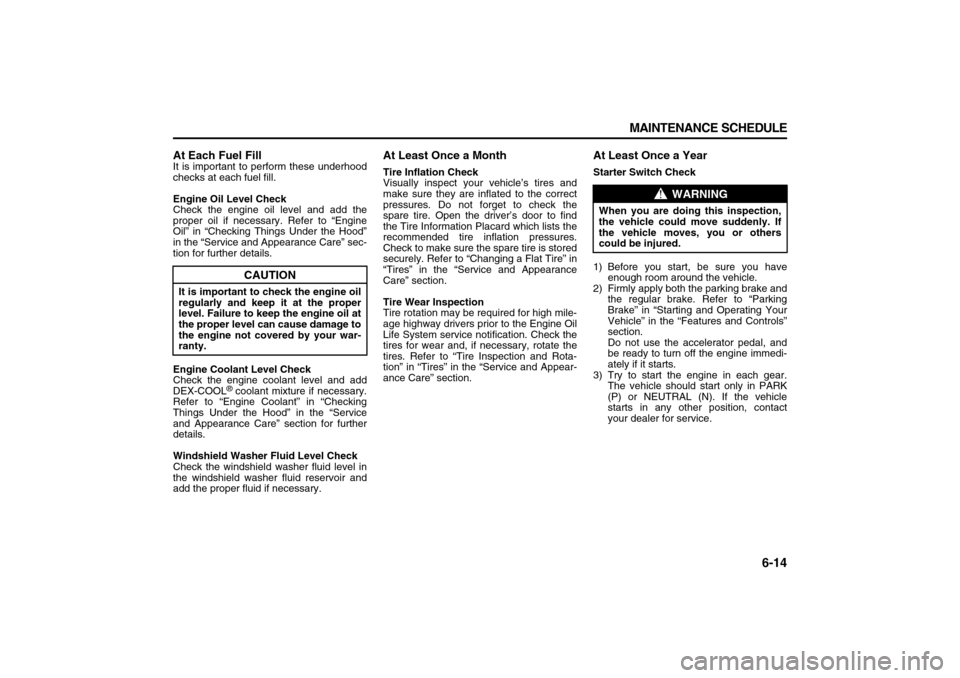

6-14 MAINTENANCE SCHEDULE

78J00-03E

At Each Fuel FillIt is important to perform these underhood

checks at each fuel fill.

Engine Oil Level Check

Check the engine oil level and add the

proper oil if necessary. Refer to “Engine

Oil” in “Checking Things Under the Hood”

in the “Service and Appearance Care” sec-

tion for further details.

Engine Coolant Level Check

Check the engine coolant level and add

DEX-COOL

® coolant mixture if necessary.

Refer to “Engine Coolant” in “Checking

Things Under the Hood” in the “Service

and Appearance Care” section for further

details.

Windshield Washer Fluid Level Check

Check the windshield washer fluid level in

the windshield washer fluid reservoir and

add the proper fluid if necessary.

At Least Once a MonthTire Inflation Check

Visually inspect your vehicle’s tires and

make sure they are inflated to the correct

pressures. Do not forget to check the

spare tire. Open the driver’s door to find

the Tire Information Placard which lists the

recommended tire inflation pressures.

Check to make sure the spare tire is stored

securely. Refer to “Changing a Flat Tire” in

“Tires” in the “Service and Appearance

Care” section.

Tire Wear Inspection

Tire rotation may be required for high mile-

age highway drivers prior to the Engine Oil

Life System service notification. Check the

tires for wear and, if necessary, rotate the

tires. Refer to “Tire Inspection and Rota-

tion” in “Tires” in the “Service and Appear-

ance Care” section.

At Least Once a YearStarter Switch Check

1) Before you start, be sure you have

enough room around the vehicle.

2) Firmly apply both the parking brake and

the regular brake. Refer to “Parking

Brake” in “Starting and Operating Your

Vehicle” in the “Features and Controls”

section.

Do not use the accelerator pedal, and

be ready to turn off the engine immedi-

ately if it starts.

3) Try to start the engine in each gear.

The vehicle should start only in PARK

(P) or NEUTRAL (N). If the vehicle

starts in any other position, contact

your dealer for service.

CAUTION

It is important to check the engine oil

regularly and keep it at the proper

level. Failure to keep the engine oil at

the proper level can cause damage to

the engine not covered by your war-

ranty.

WARNING

When you are doing this inspection,

the vehicle could move suddenly. If

the vehicle moves, you or others

could be injured.

Page 257 of 274

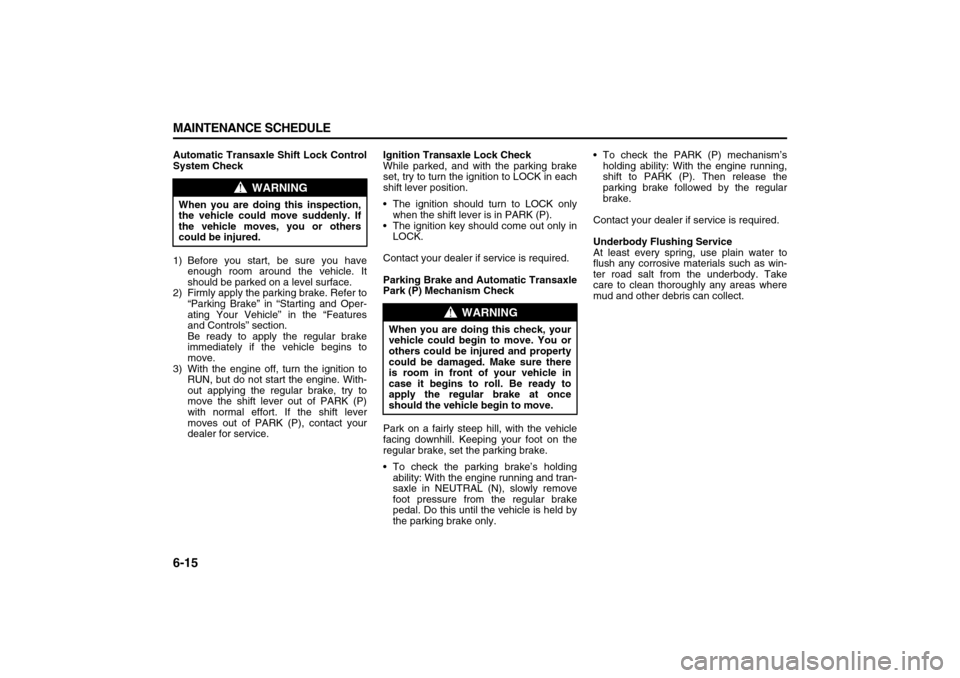

6-15 MAINTENANCE SCHEDULE

78J00-03E

Automatic Transaxle Shift Lock Control

System Check

1) Before you start, be sure you have

enough room around the vehicle. It

should be parked on a level surface.

2) Firmly apply the parking brake. Refer to

“Parking Brake” in “Starting and Oper-

ating Your Vehicle” in the “Features

and Controls” section.

Be ready to apply the regular brake

immediately if the vehicle begins to

move.

3) With the engine off, turn the ignition to

RUN, but do not start the engine. With-

out applying the regular brake, try to

move the shift lever out of PARK (P)

with normal effort. If the shift lever

moves out of PARK (P), contact your

dealer for service.Ignition Transaxle Lock Check

While parked, and with the parking brake

set, try to turn the ignition to LOCK in each

shift lever position.

The ignition should turn to LOCK only

when the shift lever is in PARK (P).

The ignition key should come out only in

LOCK.

Contact your dealer if service is required.

Parking Brake and Automatic Transaxle

Park (P) Mechanism Check

Park on a fairly steep hill, with the vehicle

facing downhill. Keeping your foot on the

regular brake, set the parking brake.

To check the parking brake’s holding

ability: With the engine running and tran-

saxle in NEUTRAL (N), slowly remove

foot pressure from the regular brake

pedal. Do this until the vehicle is held by

the parking brake only. To check the PARK (P) mechanism’s

holding ability: With the engine running,

shift to PARK (P). Then release the

parking brake followed by the regular

brake.

Contact your dealer if service is required.

Underbody Flushing Service

At least every spring, use plain water to

flush any corrosive materials such as win-

ter road salt from the underbody. Take

care to clean thoroughly any areas where

mud and other debris can collect.

WARNING

When you are doing this inspection,

the vehicle could move suddenly. If

the vehicle moves, you or others

could be injured.

WARNING

When you are doing this check, your

vehicle could begin to move. You or

others could be injured and property

could be damaged. Make sure there

is room in front of your vehicle in

case it begins to roll. Be ready to

apply the regular brake at once

should the vehicle begin to move.

Page 258 of 274

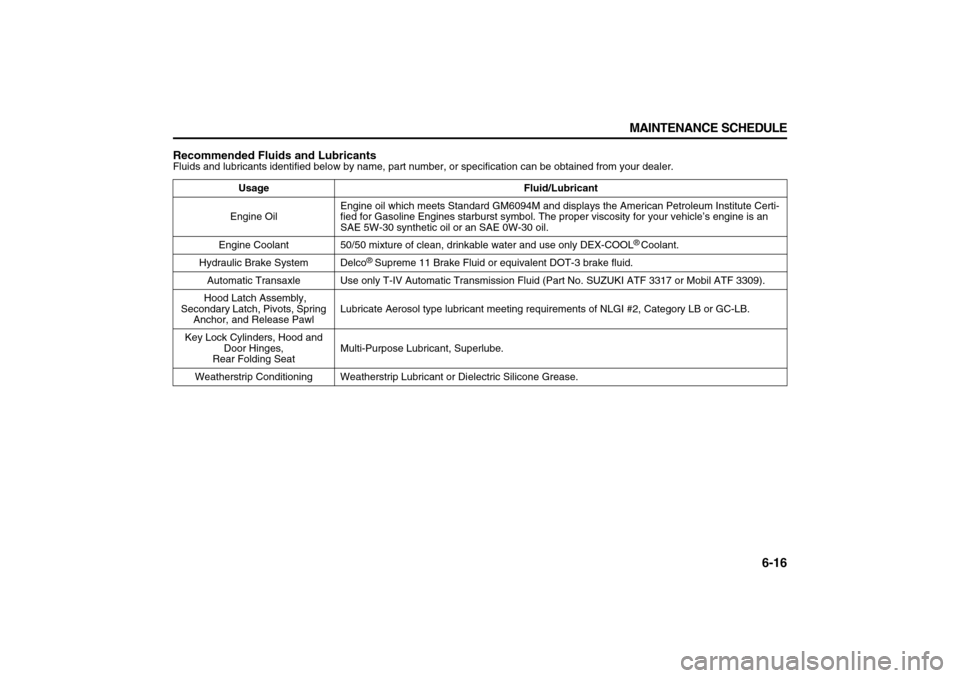

6-16 MAINTENANCE SCHEDULE

78J00-03E

Recommended Fluids and LubricantsFluids and lubricants identified below by name, part number, or specification can be obtained from your dealer.

Usage Fluid/Lubricant

Engine OilEngine oil which meets Standard GM6094M and displays the American Petroleum Institute Certi-

fied for Gasoline Engines starburst symbol. The proper viscosity for your vehicle’s engine is an

SAE 5W-30 synthetic oil or an SAE 0W-30 oil.

Engine Coolant 50/50 mixture of clean, drinkable water and use only DEX-COOL

® Coolant.

Hydraulic Brake System Delco

® Supreme 11 Brake Fluid or equivalent DOT-3 brake fluid.

Automatic Transaxle Use only T-IV Automatic Transmission Fluid (Part No. SUZUKI ATF 3317 or Mobil ATF 3309).

Hood Latch Assembly,

Secondary Latch, Pivots, Spring

Anchor, and Release PawlLubricate Aerosol type lubricant meeting requirements of NLGI #2, Category LB or GC-LB.

Key Lock Cylinders, Hood and

Door Hinges,

Rear Folding SeatMulti-Purpose Lubricant, Superlube.

Weatherstrip Conditioning Weatherstrip Lubricant or Dielectric Silicone Grease.

Page 259 of 274

6-17 MAINTENANCE SCHEDULE

78J00-03E

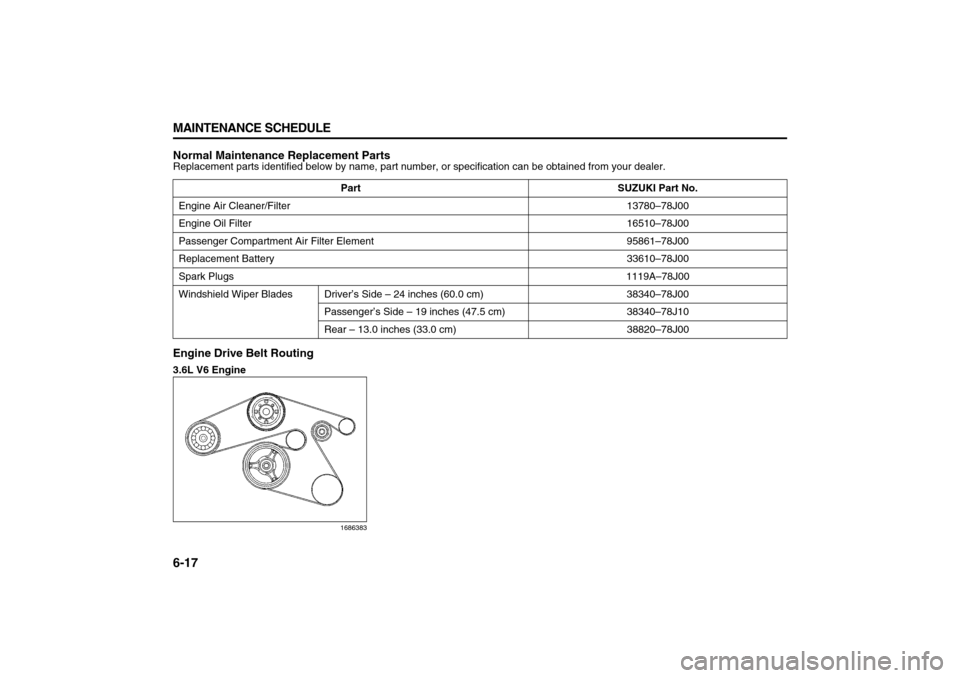

Normal Maintenance Replacement PartsReplacement parts identified below by name, part number, or specification can be obtained from your dealer.Engine Drive Belt Routing3.6L V6 Engine

1686383Part SUZUKI Part No.

Engine Air Cleaner/Filter13780–78J00

Engine Oil Filter16510–78J00

Passenger Compartment Air Filter Element 95861–78J00

Replacement Battery33610–78J00

Spark Plugs1119A–78J00

Windshield Wiper Blades Driver’s Side – 24 inches (60.0 cm) 38340–78J00

Passenger’s Side – 19 inches (47.5 cm) 38340–78J10

Rear – 13.0 inches (33.0 cm) 38820–78J00

Page 260 of 274

6-18 MAINTENANCE SCHEDULE

78J00-03E

Maintenance Record except CANADAAfter the scheduled services are performed, record the date, odometer reading, who performed the service, and the type of services per-

formed in the boxes provided. Refer to “Maintenance Requirements” in this section. Any additional information from “Owner Checks and

Services” in this section can be added on the following record pages. You should retain all maintenance receipts.

Maintenance record

DateOdometer

ReadingServiced ByMaintenance I or

Maintenance IIServices Performed