torque TOYOTA 4RUNNER 1997 Owners Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1997, Model line: 4RUNNER, Model: TOYOTA 4RUNNER 1997Pages: 223, PDF Size: 4.66 MB

Page 49 of 223

52

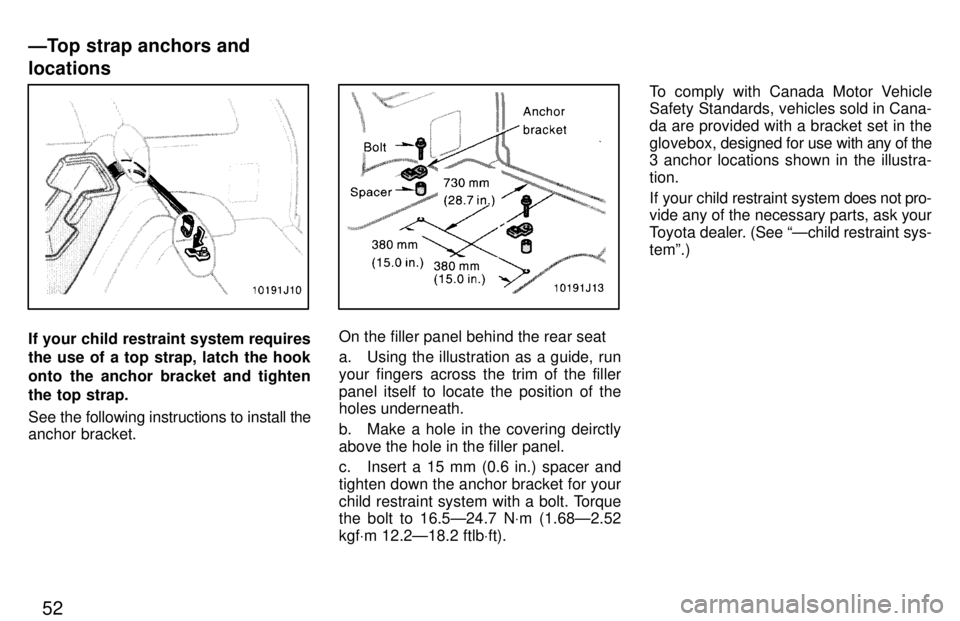

If your child restraint system requires

the use of a top strap, latch the hook

onto the anchor bracket and tighten

the top strap.

See the following instructions to install the

anchor bracket.On the filler panel behind the rear seat

a. Using the illustration as a guide, run

your fingers across the trim of the fillerpanel itself to locate the position of the

holes underneath.

b. Make a hole in the covering deirctly

above the hole in the filler panel.

c. Insert a 15 mm (0.6 in.) spacer and tighten down the anchor bracket for your

child restraint system with a bolt. Torque the bolt to 16.5Ð24.7 NVm (1.68Ð2.52

kgf Vm 12.2Ð18.2 ftlb Vft). To comply with Canada Motor Vehicle

Safety Standards, vehicles sold in Cana-

da are provided with a bracket set in the

glovebox,

designed for use with any of the

3 anchor locations shown in the illustra-tion.

If your child restraint system does not pro-

vide any of the necessary parts, ask your

Toyota dealer. (See Ðchild restraint sys-

temº.)

ÐTop strap anchors and locations

Page 168 of 223

171

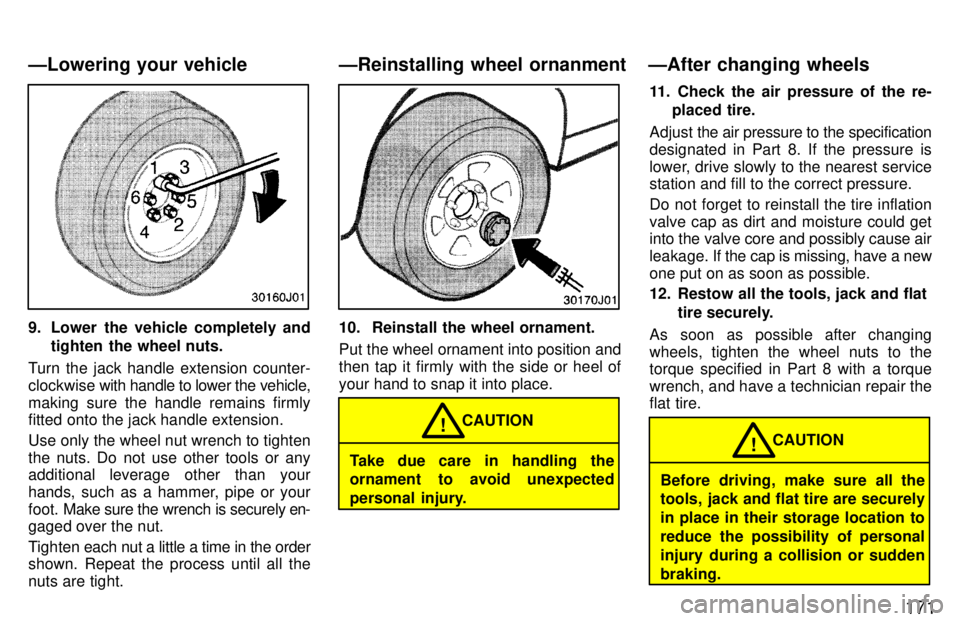

9. Lower the vehicle completely andtighten the wheel nuts.

Turn the jack handle extension counter-

clockwise with handle to lower the vehicle,

making sure the handle remains firmly

fitted onto the jack handle extension. Use only the wheel nut wrench to tighten the nuts. Do not use other tools or any

additional leverage other than your

hands, such as a hammer, pipe or your

foot. Make sure the wrench is securely en-

gaged over the nut.

Tighten each nut a little a time in the order

shown. Repeat the process until all the

nuts are tight.10. Reinstall the wheel ornament.

Put the wheel ornament into position and

then tap it firmly with the side or heel ofyour hand to snap it into place.

Take due care in handling the

ornament to avoid unexpected

personal injury. CAUTION

! 11. Check the air pressure of the re-

placed tire.

Adjust the air pressure to the specification

designated in Part 8. If the pressure is

lower, drive slowly to the nearest service station and fill to the correct pressure.

Do not forget to reinstall the tire inflation valve cap as dirt and moisture could get into the valve core and possibly cause air

leakage. If the cap is missing, have a new

one put on as soon as possible.

12. Restow all the tools, jack and flat

tire securely.

As soon as possible after changing

wheels, tighten the wheel nuts to the torque specified in Part 8 with a torque wrench, and have a technician repair the flat tire.

Before driving, make sure all the

tools, jack and flat tire are securely in place in their storage location to

reduce the possibility of personal

injury during a collision or suddenbraking. CAUTION

!

ÐLowering your vehicle ÐReinstalling wheel ornanment ÐAfter changing wheels

Page 218 of 223

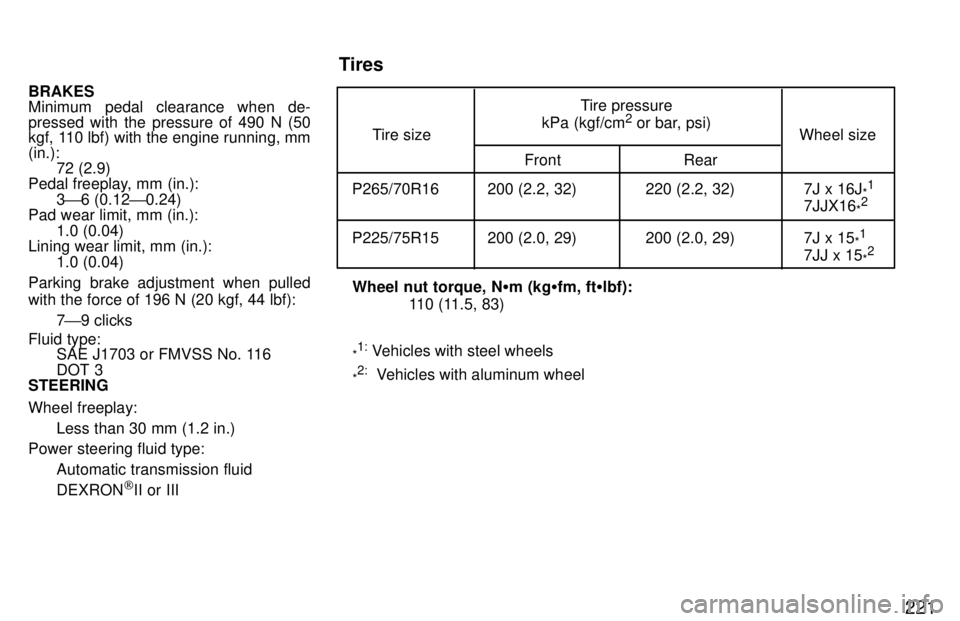

P265/70R16 200 (2.2, 32) 220 (2.2, 32) 7J x 16J*1

7JJX16 *2

P225/75R15 200 (2.0, 29) 200 (2.0, 29) 7J x 15 *1

7JJ x 15 *2

Tire size

Tire pressure

kPa (kgf/cm 2

or bar, psi)

Front Rear Wheel size

Wheel nut torque, N

�m (kg �fm, ft �lbf):

110 (11.5, 83)

* 1:

Vehicles with steel wheels

* 2:

Vehicles with aluminum wheel

221

BRAKES Minimum pedal clearance when de-pressed with the pressure of 490 N (50

kgf, 110 lbf) with the engine running, mm (in.):

72 (2.9)

Pedal freeplay, mm (in.):

3' 6 (0.12 '0.24)

Pad wear limit, mm (in.):

1.0 (0.04)

Lining wear limit, mm (in.):

1.0 (0.04)

Parking brake adjustment when pulled with the force of 196 N (20 kgf, 44 lbf): 7' 9 clicks

Fluid type: SAE J1703 or FMVSS No. 116 DOT 3

STEERING Wheel freeplay:

Less than 30 mm (1.2 in.)

Power steering fluid type:

Automatic transmission fluid DEXRON [

II or III Tires