TOYOTA 86 2022 Owners Manual

Manufacturer: TOYOTA, Model Year: 2022, Model line: 86, Model: TOYOTA 86 2022Pages: 449, PDF Size: 8.5 MB

Page 361 of 449

3617-2. Steps to take in an emergency

7

When trouble arises

gency tire puncture repair kit can

be used only once to temporarily

repair a single tire. If the sealant

has been used and needs to be

purchased, contact your Toyota

dealer. The compressor is reus-

able.

●The sealant can be used when the

outside temperature is from -22°F

(-30°C) to 140°F (60°C).

●The kit is exclusively designed for

size and type of tires originally

installed on your vehicle. Do not

use it for tires that a different size

than the original ones, or for any

other purposes.

●If the sealant gets on your clothes,

it may stain.

●If the sealant adheres to a wheel

or the surface of the vehicle body,

the stain may not be removable if

it is not cleaned at once. Immedi-

ately wipe away the sealant with a

wet cloth.

●During operation of the kit, a loud

operation noise is produced. This

does not indicate a malfunction.

●Do not use the emergency tire

puncture repair kit to check or to

adjust the tire pressure.

●In extremely low temperatures

-22°F to -4°F (-30°C to -20°C), the

viscosity of the sealant increases

and the sealant will flow more

slowly. In such temperatures,

bring the sealant into the vehicle

to warm it up before use.

■Note for checking the emer-

gency tire puncture repair kit

Check the sealant expiry date occa-

sionally.

The expiry date is shown on the bot-

tle. Do not use sealant whose expiry

date has already passed. Other-

wise, repairs conducted using the

emergency tire puncture repair kit

may not be performed properly.

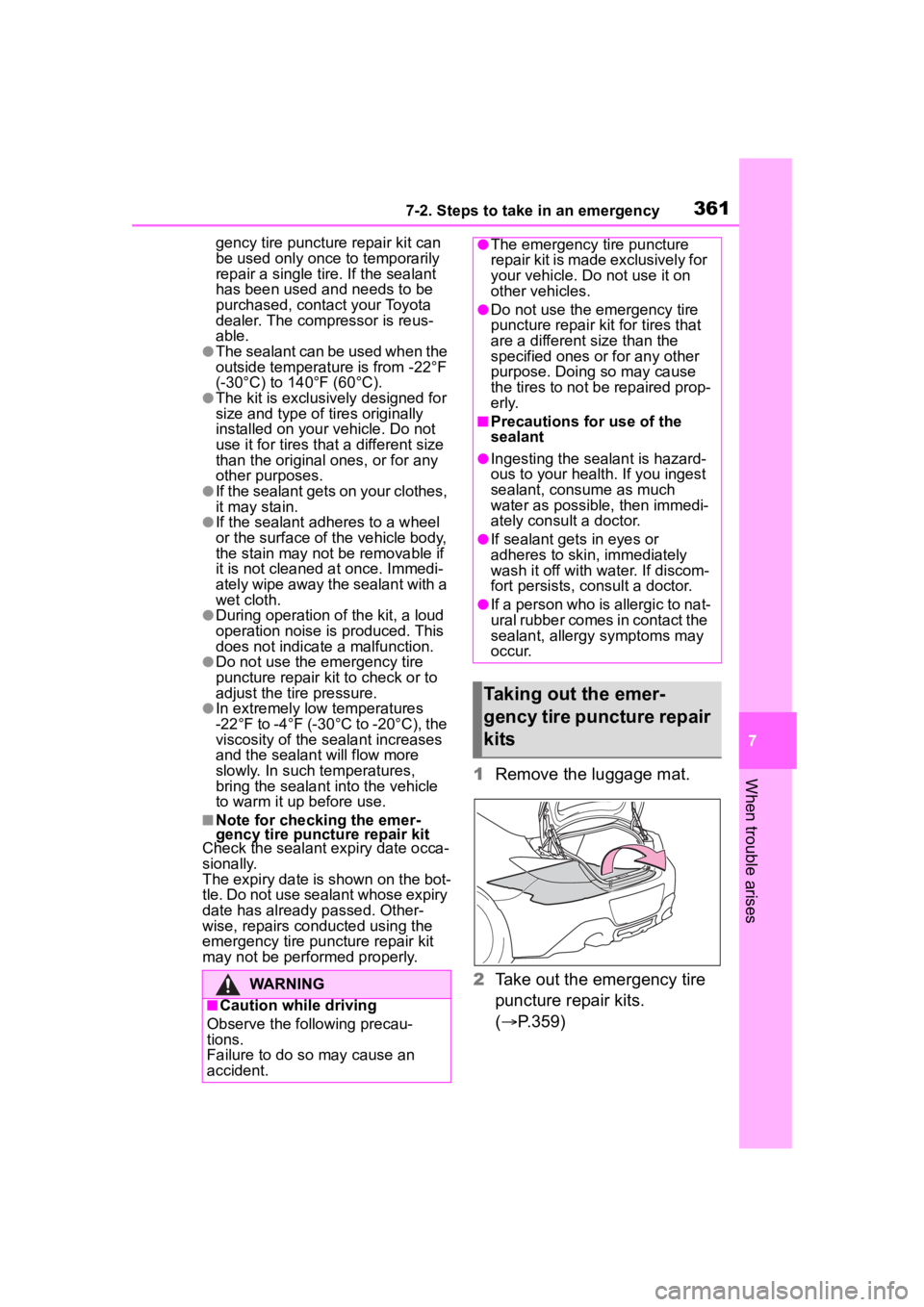

1 Remove the luggage mat.

2 Take out the emergency tire

puncture repair kits.

( P.359)

WARNING

■Caution while driving

Observe the following precau-

tions.

Failure to do so may cause an

accident.

●The emergency tire puncture

repair kit is made exclusively for

your vehicle. Do not use it on

other vehicles.

●Do not use the emergency tire

puncture repair kit for tires that

are a different size than the

specified ones or for any other

purpose. Doing so may cause

the tires to not be repaired prop-

erly.

■Precautions for use of the

sealant

●Ingesting the sealant is hazard-

ous to your health. If you ingest

sealant, consume as much

water as possible, then immedi-

ately consult a doctor.

●If sealant gets in eyes or

adheres to skin, immediately

wash it off with water. If discom-

fort persists, consult a doctor.

●If a person who is allergic to nat-

ural rubber comes in contact the

sealant, allergy symptoms may

occur.

Taking out the emer-

gency tire puncture repair

kits

Page 362 of 449

3627-2. Steps to take in an emergency

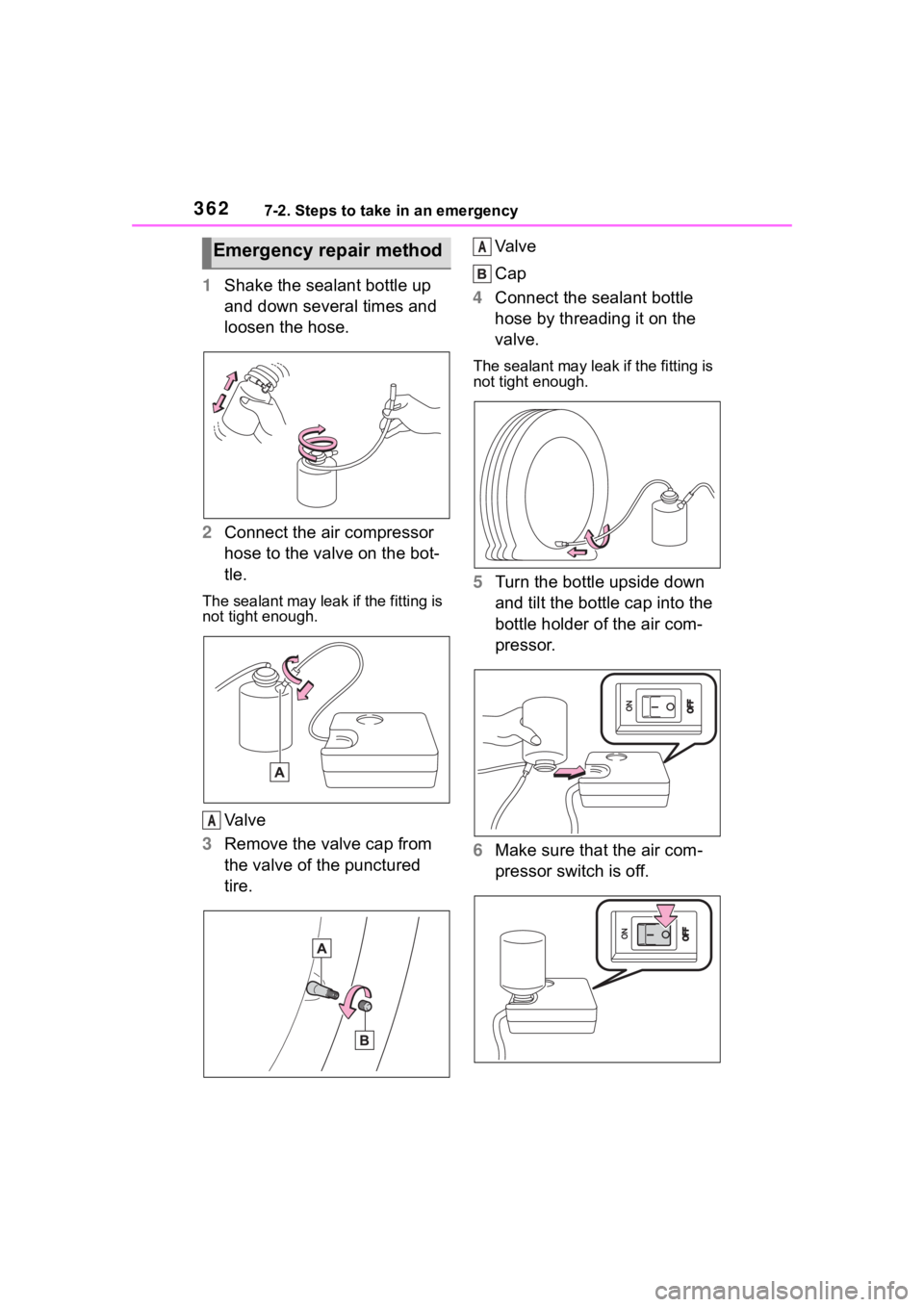

1Shake the sealant bottle up

and down several times and

loosen the hose.

2 Connect the air compressor

hose to the valve on the bot-

tle.

The sealant may leak if the fitting is

not tight enough.

Va l v e

3 Remove the valve cap from

the valve of the punctured

tire. Va l v e

Cap

4 Connect the sealant bottle

hose by threading it on the

valve.

The sealant may leak if the fitting is

not tight enough.

5Turn the bottle upside down

and tilt the bottle cap into the

bottle holder of the air com-

pressor.

6 Make sure that the air com-

pressor switch is off.

Emergency repair method

A

A

Page 363 of 449

3637-2. Steps to take in an emergency

7

When trouble arises

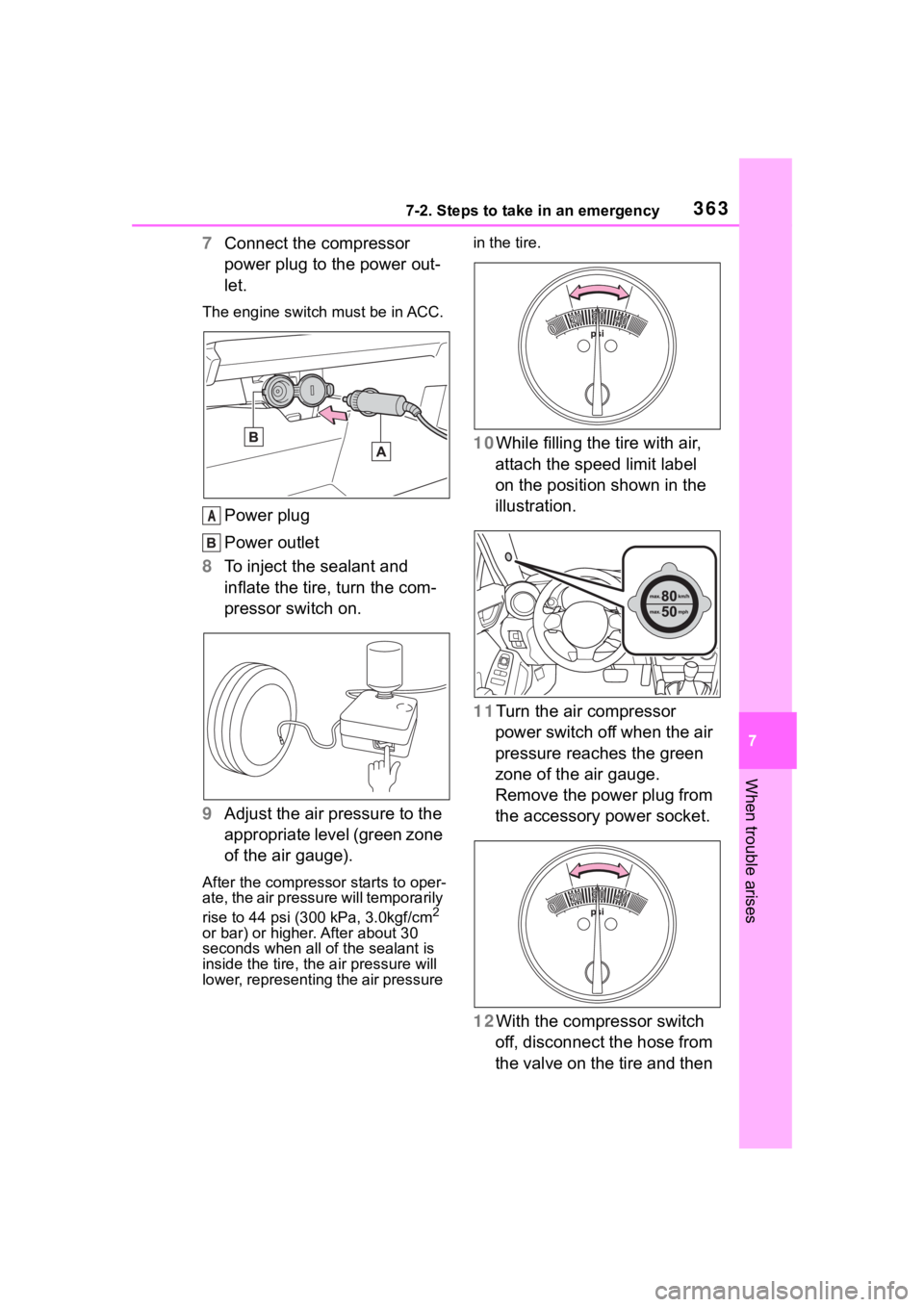

7Connect the compressor

power plug to the power out-

let.

The engine switch must be in ACC.

Power plug

Power outlet

8 To inject the sealant and

inflate the tire, turn the com-

pressor switch on.

9 Adjust the air pressure to the

appropriate level (green zone

of the air gauge).

After the compressor starts to oper-

ate, the air pressure will temporarily

rise to 44 psi (300 kPa, 3.0kgf/cm

2

or bar) or higher. After about 30

seconds when all of the sealant is

inside the tire, th e air pressure will

lower, representing the air pressure in the tire.

10While filling the tire with air,

attach the speed limit label

on the position shown in the

illustration.

11Turn the air compressor power switch off when the air

pressure reaches the green

zone of the air gauge.

Remove the power plug from

the accessory power socket.

12With the compressor switch off, disconnect the hose from

the valve on the tire and then

A

Page 364 of 449

3647-2. Steps to take in an emergency

pull out the power plug from

the power outlet socket.

Some sealant may leak when the

hose is removed.

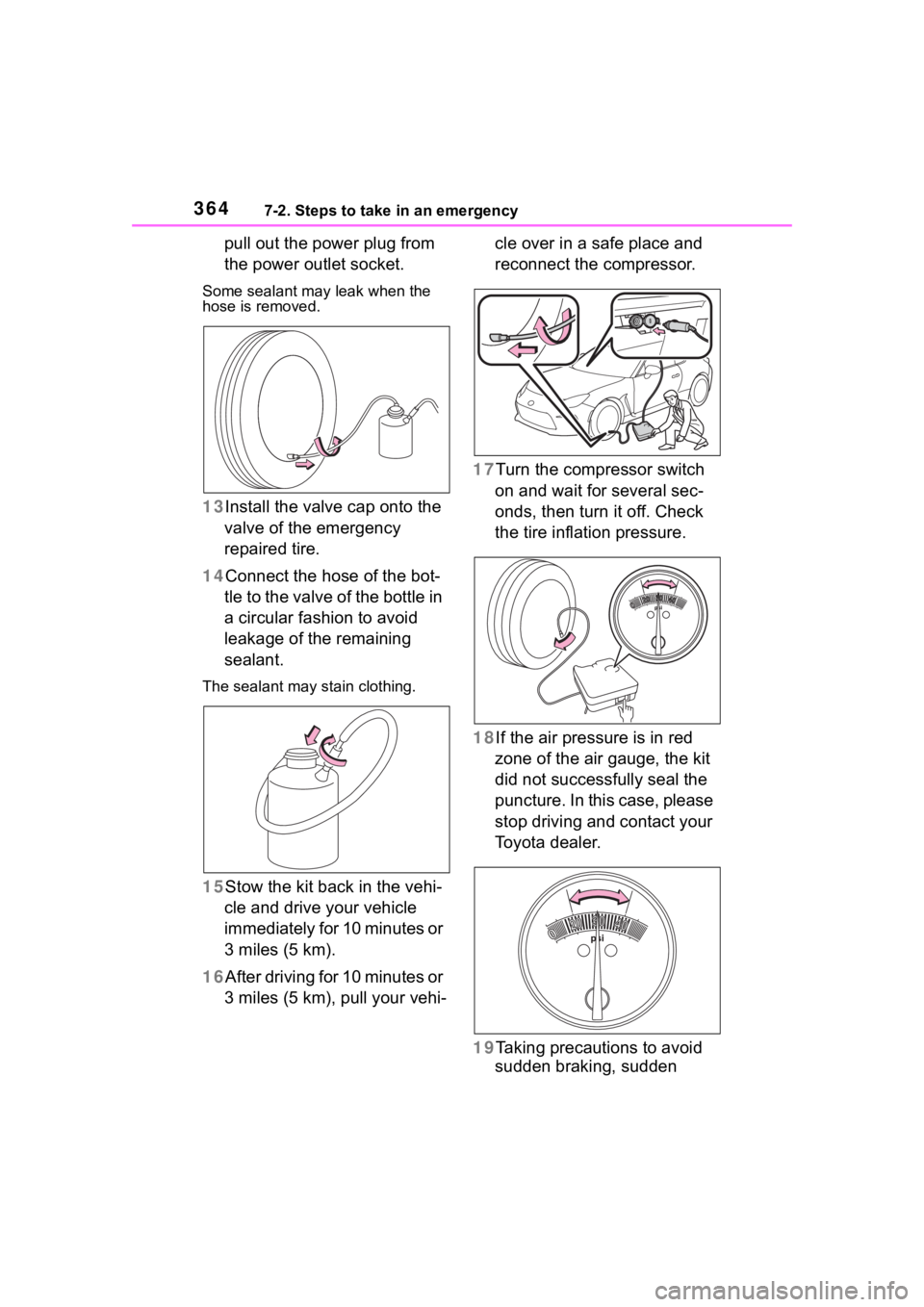

13Install the valve cap onto the

valve of the emergency

repaired tire.

14 Connect the hose of the bot-

tle to the valve of the bottle in

a circular fashion to avoid

leakage of the remaining

sealant.

The sealant may s tain clothing.

15Stow the kit back in the vehi-

cle and drive your vehicle

immediately for 10 minutes or

3 miles (5 km).

16 After driving for 10 minutes or

3 miles (5 km), pull your vehi- cle over in a safe place and

reconnect the compressor.

17Turn the compressor switch on and wait for several sec-

onds, then turn it off. Check

the tire inflation pressure.

18If the air pressure is in red zone of the air gauge, the kit

did not successfully seal the

puncture. In this case, please

stop driving and contact your

Toyota dealer.

19Taking precautions to avoid sudden braking, sudden

Page 365 of 449

3657-2. Steps to take in an emergency

7

When trouble arises

acceleration and sharp turns,

drive carefully at under 50

mph (80 km/h) to the nearest

Toyota dealer that is less

than 124 miles (200 km)

away for tire repair or

replacement.

■After a tire is repaired with the

emergency tire puncture repair

kit

●The tire pressure warning valve

and transmitter should be

replaced.

●Even if the tire inflation pressure is

at the recommended level, the tire

pressure warning light may come

on/flash.

WARNING

■Do not drive the vehicle with

a flat tire

Do not continue driving with a flat

tire.

Driving even a short distance with

a flat tire can damage the tire and

the wheel beyond repair. Driving

with a flat tire may cause a cir-

cumferential groove on the side

wall. In such a case, the tire may

explode when using a repair kit.

■When fixing the flat tire

●Stop your vehicle in a safe and

flat area.

●Do not touch the wheels or the

area around the brakes immedi-

ately after the vehicle has been

driven.

After the vehicle has been

driven, the wheels and the area

around the brakes may be

extremely hot. Touching these

areas with hands , feet or other

body parts may result in burns.

●Connect the valve and hose

securely with the tire installed

on the vehicle.

●If the hose is not properly con-

nected to the valve, air leakage

may occur or sealant may be

sprayed out.

●If the hose comes off the valve

while inflating the tire, there is a

risk that the hose will move

abruptly due to air pressure.

●After inflation of the tire has

completed, the sealant may

splatter when the hose is dis-

connected or some air is let out

of the tire.

●Follow the operation procedure

to repair the tire. If the proce-

dure is not followed, the sealant

may spray out.

●Keep back from the tire while it

is being repaired, as there is a

chance of it bursting while the

repair operation is being per-

formed. If you notice any cracks

or deformation of the tire, turn

off the compressor switch and

stop the repair operation imme-

diately.

●The kit may overheat if operated

for a long period of time. Do not

operate the compressor contin-

uously for more than 10 min-

utes.

●Parts of the kit become hot

during operation. Be careful

handling the kit during and after

operation. Do not touch the

metal part around the connect-

ing area between the bottle and

compressor. It will be extremely

hot.

●Do not attach the vehicle speed

warning sticker to an area other

than the one indicated. If the

sticker is attached to an area

where an SRS airbag is located,

such as the pad of the steering

wheel, it may prevent the SRS

airbag from operating properly.

Page 366 of 449

3667-2. Steps to take in an emergency

WARNING

■Driving to spread the liquid

sealant evenly

Observe the following precautions

to reduce the risk of accidents.

Failing to do so may result in a

loss of vehicle control and cause

death or serious injury.

●Drive the vehicle carefully at a

low speed. Be especially careful

when turning and cornering.

●If the vehicle d oes not drive

straight or you feel a pull

through the steering wheel, stop

the vehicle and check the tire.

The tire may have separated

from the wheel.

NOTICE

■When performing an emer-

gency repair

●Perform the emergency repair

without removing the nail or

screw that has punctured the

tread of the tire. If the object

that has punctur ed the tire is

removed, repair by the emer-

gency tire puncture repair kit

may not be possible.

●The kit is not waterproof. Make

sure that the kit is not exposed

to water, such as when it is

being used in the rain.

●Do not put the kit directly onto

dusty ground such as sand at

the side of the road. If the kit

vacuums up dus t etc., a mal-

function may occur.

●Make sure to stand the kit with

the bottle vertical. The kit can-

not work properly if it is laid on

its side.

■Handling the emergency tire

puncture repair kit

●The compressor power source

should be 12 V DC suitable for

vehicle use. Do not connect the

compressor to any other

source.

●If gasoline splatters on the kit,

the kit may deteriorate. Take

care not to allow gasoline to

contact it.

●Store the emergency tire punc-

ture repair kit in the trunk. The

kit may be thrown around during

sudden braking and so forth,

damaging the kit.

Place the repair kit in a storage to

prevent it from being exposed to

dirt or water.

●Store the kit in its assigned

place out of reach of children.

●Do not disassemble or modify

the kit. Do not subject parts

such as the air pressure indica-

tor to impacts. This may cause a

malfunction.

■To avoid damage to the tire

pressure warning valves and

transmitters

When a tire is repa ired with liquid

sealants, the tire pressure warn-

ing valve and transmitter may not

operate properly. If a liquid seal-

ant is used, contact your Toyota

dealer as soon as possible. After

use of liquid sealant, make sure to

replace the tire p ressure warning

valve and transmitter when repair-

ing or replaci ng the tire. (P.316)

Page 367 of 449

3677-2. Steps to take in an emergency

7

When trouble arises

One of the following may be the

cause of the problem:

There may not be sufficient

fuel in the vehicle’s tank.

Refuel the vehicle.

The engine may be flooded.

Try to restart the engine again

following correct starting pro-

cedures. ( P.145)

There may be a malfunction

in the engine immobilizer sys-

tem. ( P. 7 9 )

One of the following may be the

cause of the problem:

The battery may be dis-

charged. ( P.371)

The battery terminal connec-

tions may be loose or cor-

roded. ( P.309)

The engine starting system may

be malfunctioning due to an

electrical problem such as elec-

tronic key battery depletion or a

blown fuse. However, an interim

measure is available to start the

engine. ( P.367)

One of the following may be the

cause of the problem:

One or both of the battery ter-

minals may be disconnected.

( P.309)

The battery may be dis-

charged. ( P.371)

There may be a malfunction

in the steering lock system.

Contact your Toyota dealer if the

problem cannot be repaired, or if

repair procedures are unknown.

When the engine does not start,

the following steps can be used

as an interim measure to start

If the engine will not

start

If the engine will not start

even though correct starting

procedures are being fol-

lowed ( P.145), consider

each of the following points:

The engine wil l not start

even though the starter

motor operates normally.

The starter motor turns

over slowly, the interior

lights and headlights are

dim, or the horn does not

sound or sounds at a low

volume.

The starter motor does

not turn over

The starter motor does

not turn over, the interior

lights and headlights do

not turn on, or the horn

does not sound.

Emergency start function

Page 368 of 449

3687-2. Steps to take in an emergency

the engine if the engine switch is

functioning normally:

1Set the parking brake.

2 Shift the shift lever to P (auto-

matic transmission) or N

(manual transmission).

3 Turn the engine switch to

ACC.

4 Press and hold the engine

switch for about 15 seconds

while depressing the brake

pedal firmly.

Even if the engine can be

started using the above steps,

the system may be malfunction-

ing. Have the vehicle inspected

by your Toyota dealer.If you lose your keys

New genuine mechanical

keys can be made by your

Toyota dealer using another

mechanical key and the key

number stamped on your

key number plate.

Keep the plate in a safe

place such as your wallet,

not in the vehicle.

NOTICE

■When an electronic key is lost

If the electronic key remains lost,

the risk of vehicle theft increases

significantly. Visit your Toyota

dealer immediately with all

remaining electronic keys that

were provided with your vehicle.

Page 369 of 449

3697-2. Steps to take in an emergency

7

When trouble arises

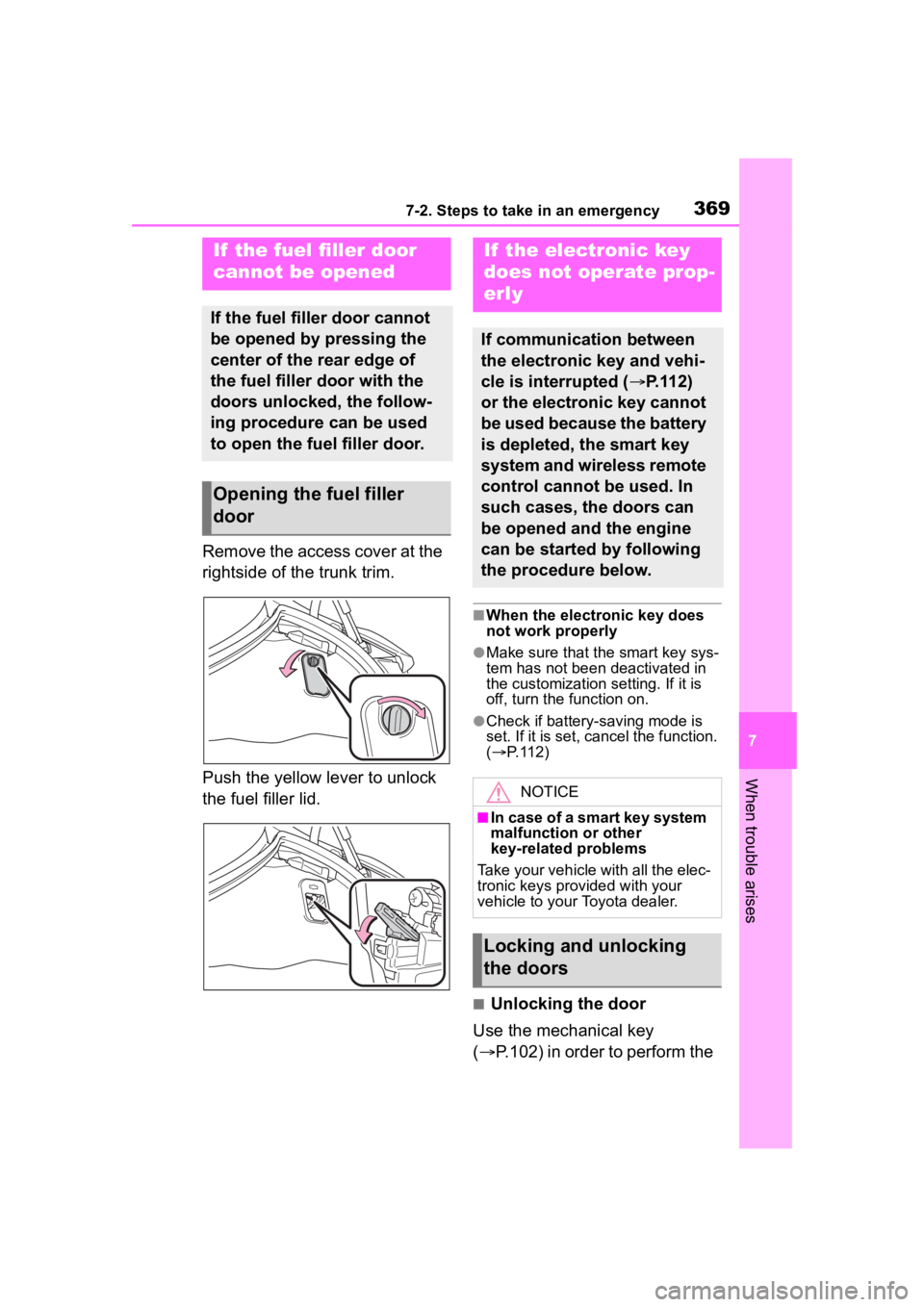

Remove the access cover at the

rightside of the trunk trim.

Push the yellow lever to unlock

the fuel filler lid.

■When the electronic key does

not work properly

●Make sure that the smart key sys-

tem has not been deactivated in

the customization setting. If it is

off, turn the function on.

●Check if battery-saving mode is

set. If it is set, cancel the function.

( P. 1 1 2 )

■Unlocking the door

Use the mechanical key

( P.102) in order to perform the

If the fuel filler door

cannot be opened

If the fuel filler door cannot

be opened by pressing the

center of the rear edge of

the fuel filler door with the

doors unlocked, the follow-

ing procedure can be used

to open the fuel filler door.

Opening the fuel filler

door

If the electronic key

does not operate prop-

erly

If communication between

the electronic key and vehi-

cle is interrupted ( P.112)

or the electronic key cannot

be used because the battery

is depleted, the smart key

system and wireless remote

control cannot be used. In

such cases, the doors can

be opened and the engine

can be started by following

the procedure below.

NOTICE

■In case of a smart key system

malfunction or other

key-related problems

Take your vehicle with all the elec-

tronic keys provided with your

vehicle to your Toyota dealer.

Locking and unlocking

the doors

Page 370 of 449

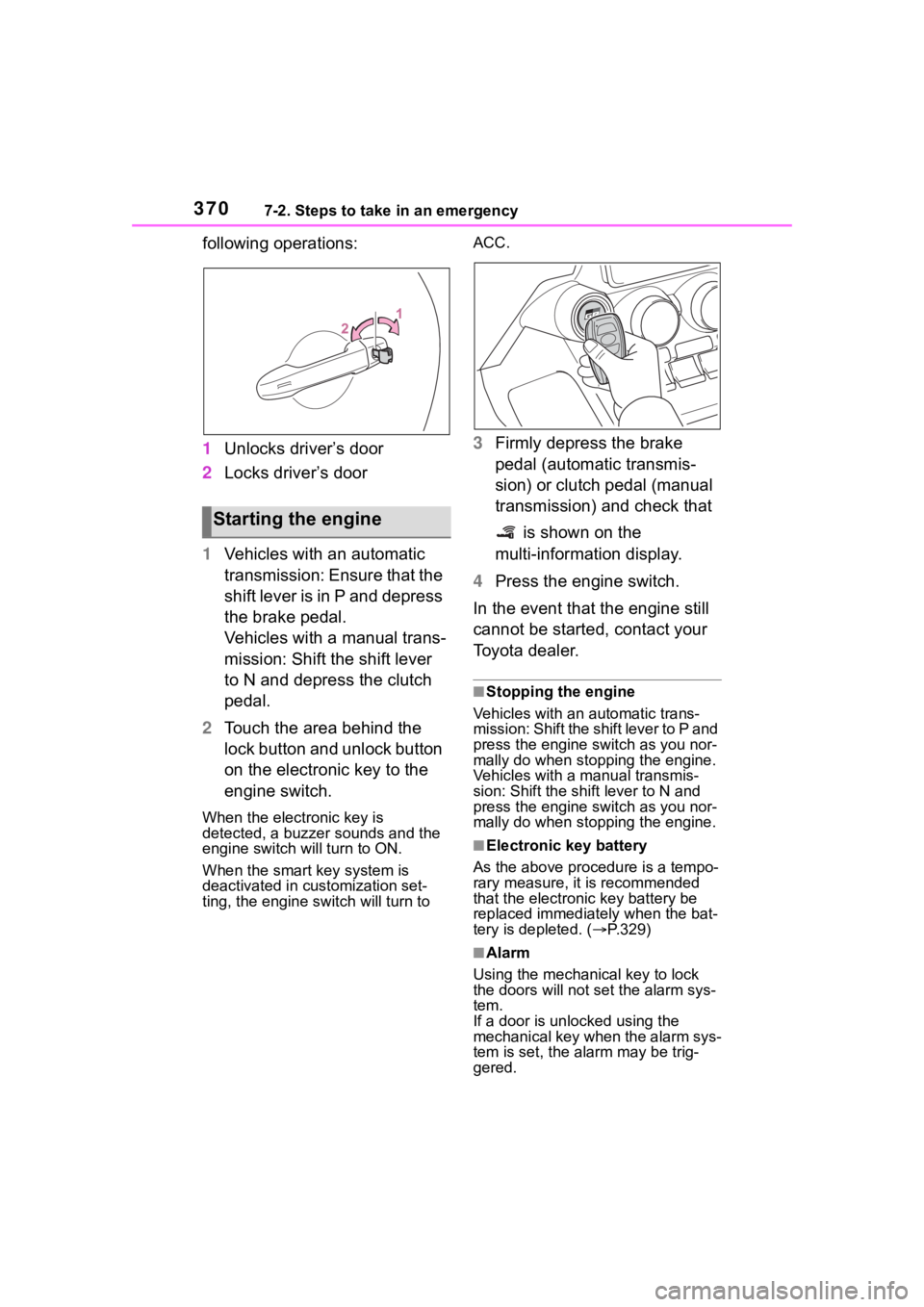

3707-2. Steps to take in an emergency

following operations:

1Unlocks driver’s door

2 Locks driver’s door

1 Vehicles with an automatic

transmission: Ensure that the

shift lever is in P and depress

the brake pedal.

Vehicles with a manual trans-

mission: Shift the shift lever

to N and depress the clutch

pedal.

2 Touch the area behind the

lock button and unlock button

on the electronic key to the

engine switch.

When the electronic key is

detected, a buzzer sounds and the

engine switch will turn to ON.

When the smart key system is

deactivated in customization set-

ting, the engine switch will turn to ACC.

3

Firmly depress the brake

pedal (automatic transmis-

sion) or clutch pedal (manual

transmission) and check that

is shown on the

multi-information display.

4 Press the engine switch.

In the event that the engine still

cannot be started, contact your

Toyota dealer.

■Stopping the engine

Vehicles with an automatic trans-

mission: Shift the shift lever to P and

press the engine switch as you nor-

mally do when stopping the engine.

Vehicles with a manual transmis-

sion: Shift the shift lever to N and

press the engine switch as you nor-

mally do when stopping the engine.

■Electronic key battery

As the above proce dure is a tempo-

rary measure, it is recommended

that the electronic key battery be

replaced immediatel y when the bat-

tery is depleted. ( P.329)

■Alarm

Using the mechanical key to lock

the doors will not set the alarm sys-

tem.

If a door is unl ocked using the

mechanical key when the alarm sys-

tem is set, the alarm may be trig-

gered.

Starting the engine