relay TOYOTA CAMRY 1994 XV10 / 4.G Wiring Diagrams Owners Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1994, Model line: CAMRY, Model: TOYOTA CAMRY 1994 XV10 / 4.GPages: 307, PDF Size: 5.48 MB

Page 173 of 307

![TOYOTA CAMRY 1994 XV10 / 4.G Wiring Diagrams Owners Manual 173

HORN

10

11

G±B

G±W

G±W FROM POWER SOURCE SYSTEM(

SEE PAGE 64)

HORN SW

[COMB. SW]

HORN

LHHORN

RH C12

H5 H6

2G 52A3 10A

HORN

HORN

RELAY

13 2

HORN RELAY

2±3 : CLOSED WITH HORN SW ON

: PARTS LOCAT TOYOTA CAMRY 1994 XV10 / 4.G Wiring Diagrams Owners Manual 173

HORN

10

11

G±B

G±W

G±W FROM POWER SOURCE SYSTEM(

SEE PAGE 64)

HORN SW

[COMB. SW]

HORN

LHHORN

RH C12

H5 H6

2G 52A3 10A

HORN

HORN

RELAY

13 2

HORN RELAY

2±3 : CLOSED WITH HORN SW ON

: PARTS LOCAT](/img/14/6859/w960_6859-172.png)

173

HORN

10

11

G±B

G±W

G±W FROM POWER SOURCE SYSTEM(

SEE PAGE 64)

HORN SW

[COMB. SW]

HORN

LHHORN

RH C12

H5 H6

2G 52A3 10A

HORN

HORN

RELAY

13 2

HORN RELAY

2±3 : CLOSED WITH HORN SW ON

: PARTS LOCATION

CODESEE PAGECODESEE PAGECODESEE PAGE

C1232H 528 (1MZ±FE), 30 (5S±FE)H 628 (1MZ±FE), 30 (5S±FE)

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CODESEE PAGEJOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

2A22ENGINE ROOM MAIN WIRE AND J/B NO 2 (ENGINE COMPARTMENT LEFT)2E22ENGINE ROOM MAIN WIRE AND J/B NO. 2 (ENGINE COMPARTMENT LEFT)

1 BLACK BLACK C12 H 5, H 6

XXX

X

10

SERVICE HINTS

Page 184 of 307

184

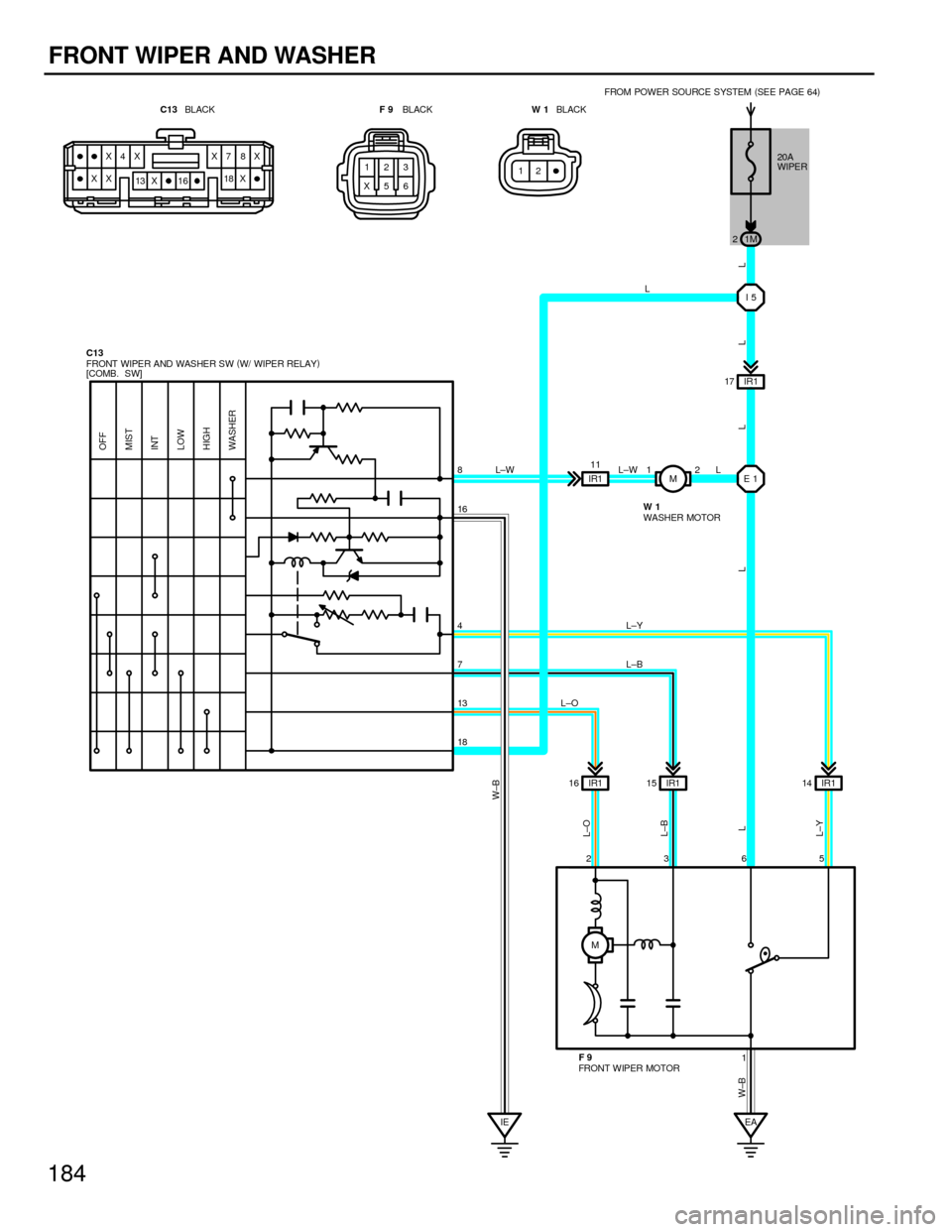

FRONT WIPER AND WASHER

M365 IR1 16 IR115 IR114

IEI5

OFF

MIST

INT

LOW

HIGH

WASHER

L

FROM POWER SOURCE SYSTEM(

SEEPAGE64)

8

4 16

13 7

18

L±O

L±B

L

L±YW±B

L±OL±B

L±Y FRONT WIPER AND WASHER SW(

W/ WIPER RELAY)

[COMB. SW]

FRONT W IP ER MOTOR F9 C13

2IR111

M 12

E1

L L

L

L±W L

WASHER MOTOR W1 L±W

L

12 C13BLACKW1BLACK F9BLACK

IR1 17

EA 1

W±B

X78X

XX

1618 X 4X X

13 X123

6 5 X

1M 220A

WIPER

Page 185 of 307

185

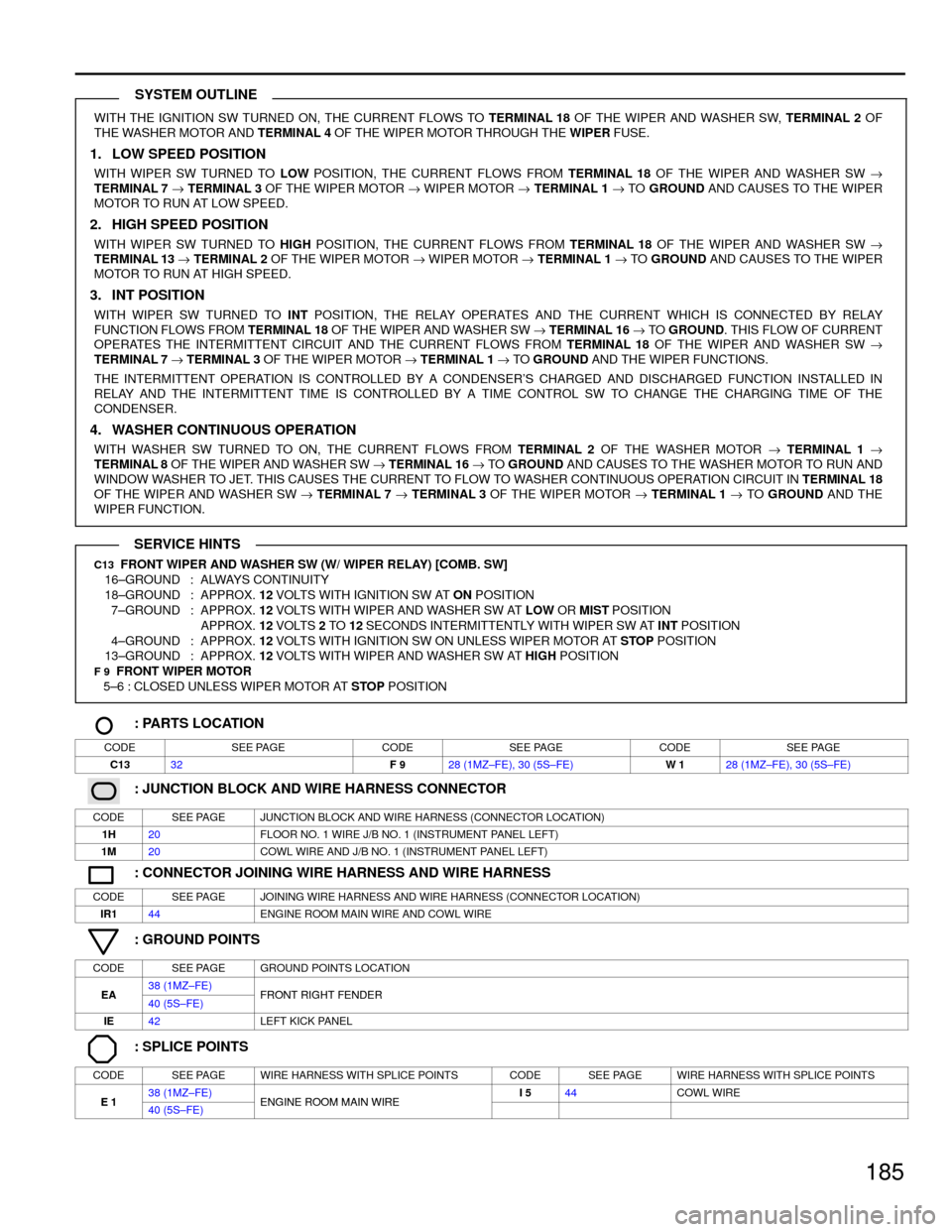

WITH THE IGNITION SW TURNED ON, THE CURRENT FLOWS TO TERMINAL 18 OF THE WIPER AND WASHER SW, TERMINAL 2 OF

THE WASHER MOTOR AND TERMINAL 4 OF THE WIPER MOTOR THROUGH THE WIPER FUSE.

1. LOW SPEED POSITION

WITH WIPER SW TURNED TO LOW POSITION, THE CURRENT FLOWS FROM TERMINAL 18 OF THE WIPER AND WASHER SW "

TERMINAL 7 " TERMINAL 3 OF THE WIPER MOTOR " WIPER MOTOR " TERMINAL 1 " TO GROUND AND CAUSES TO THE WIPER

MOTOR TO RUN AT LOW SPEED.

2. HIGH SPEED POSITION

WITH WIPER SW TURNED TO HIGH POSITION, THE CURRENT FLOWS FROM TERMINAL 18 OF THE WIPER AND WASHER SW "

TERMINAL 13 " TERMINAL 2 OF THE WIPER MOTOR " WIPER MOTOR " TERMINAL 1 " TO GROUND AND CAUSES TO THE WIPER

MOTOR TO RUN AT HIGH SPEED.

3. INT POSITION

WITH WIPER SW TURNED TO INT POSITION, THE RELAY OPERATES AND THE CURRENT WHICH IS CONNECTED BY RELAY

FUNCTION FLOWS FROM TERMINAL 18 OF THE WIPER AND WASHER SW " TERMINAL 16 " TO GROUND. THIS FLOW OF CURRENT

OPERATES THE INTERMITTENT CIRCUIT AND THE CURRENT FLOWS FROM TERMINAL 18 OF THE WIPER AND WASHER SW "

TERMINAL 7 " TERMINAL 3 OF THE WIPER MOTOR " TERMINAL 1 " TO GROUND AND THE WIPER FUNCTIONS.

THE INTERMITTENT OPERATION IS CONTROLLED BY A CONDENSER'S CHARGED AND DISCHARGED FUNCTION INSTALLED IN

RELAY AND THE INTERMITTENT TIME IS CONTROLLED BY A TIME CONTROL SW TO CHANGE THE CHARGING TIME OF THE

CONDENSER.

4. WASHER CONTINUOUS OPERATION

WITH WASHER SW TURNED TO ON, THE CURRENT FLOWS FROM TERMINAL 2 OF THE WASHER MOTOR " TERMINAL 1 "

TERMINAL 8 OF THE WIPER AND WASHER SW " TERMINAL 16 " TO GROUND AND CAUSES TO THE WASHER MOTOR TO RUN AND

WINDOW WASHER TO JET. THIS CAUSES THE CURRENT TO FLOW TO WASHER CONTINUOUS OPERATION CIRCUIT IN TERMINAL 18

OF THE WIPER AND WASHER SW " TERMINAL 7 " TERMINAL 3 OF THE WIPER MOTOR " TERMINAL 1 " TO GROUND AND THE

WIPER FUNCTION.

C13 FRONT WIPER AND WASHER SW (W/ WIPER RELAY) [COMB. SW]

16±GROUND : ALWAYS CONTINUITY

18±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION

7±GROUND : APPROX. 12 VOLTS WITH WIPER AND WASHER SW AT LOW OR MIST POSITION

APPROX. 12 VOLTS 2 TO 12 SECONDS INTERMITTENTLY WITH WIPER SW AT INT POSITION

4±GROUND : APPROX. 12 VOLTS WITH IGNITION SW ON UNLESS WIPER MOTOR AT STOP POSITION

13±GROUND : APPROX. 12 VOLTS WITH WIPER AND WASHER SW AT HIGH POSITION

F 9 FRONT WIPER MOTOR

5±6 : CLOSED UNLESS WIPER MOTOR AT STOP POSITION

: PARTS LOCATION

CODESEE PAGECODESEE PAGECODESEE PAGE

C1332F 928 (1MZ±FE), 30 (5S±FE)W 128 (1MZ±FE), 30 (5S±FE)

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODESEE PAGEJUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

1H20FLOOR NO. 1 WIRE J/B NO. 1 (INSTRUMENT PANEL LEFT)

1M20COWL WIRE AND J/B NO. 1 (INSTRUMENT PANEL LEFT)

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CODESEE PAGEJOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

IR144ENGINE ROOM MAIN WIRE AND COWL WIRE

: GROUND POINTS

CODESEE PAGEGROUND POINTS LOCATION

EA38 (1MZ±FE)FRONT RIGHT FENDEREA40 (5S±FE)FRONT RIGHT FENDER

IE42LEFT KICK PANEL

: SPLICE POINTS

CODESEE PAGEWIRE HARNESS WITH SPLICE POINTSCODESEE PAGEWIRE HARNESS WITH SPLICE POINTS

E138 (1MZ±FE)ENGINE ROOM MAIN WIREI 544COWL WIREE 140 (5S±FE)ENGINE ROOM MAIN WIRE

SYSTEM OUTLINE

SERVICE HINTS

Page 186 of 307

186

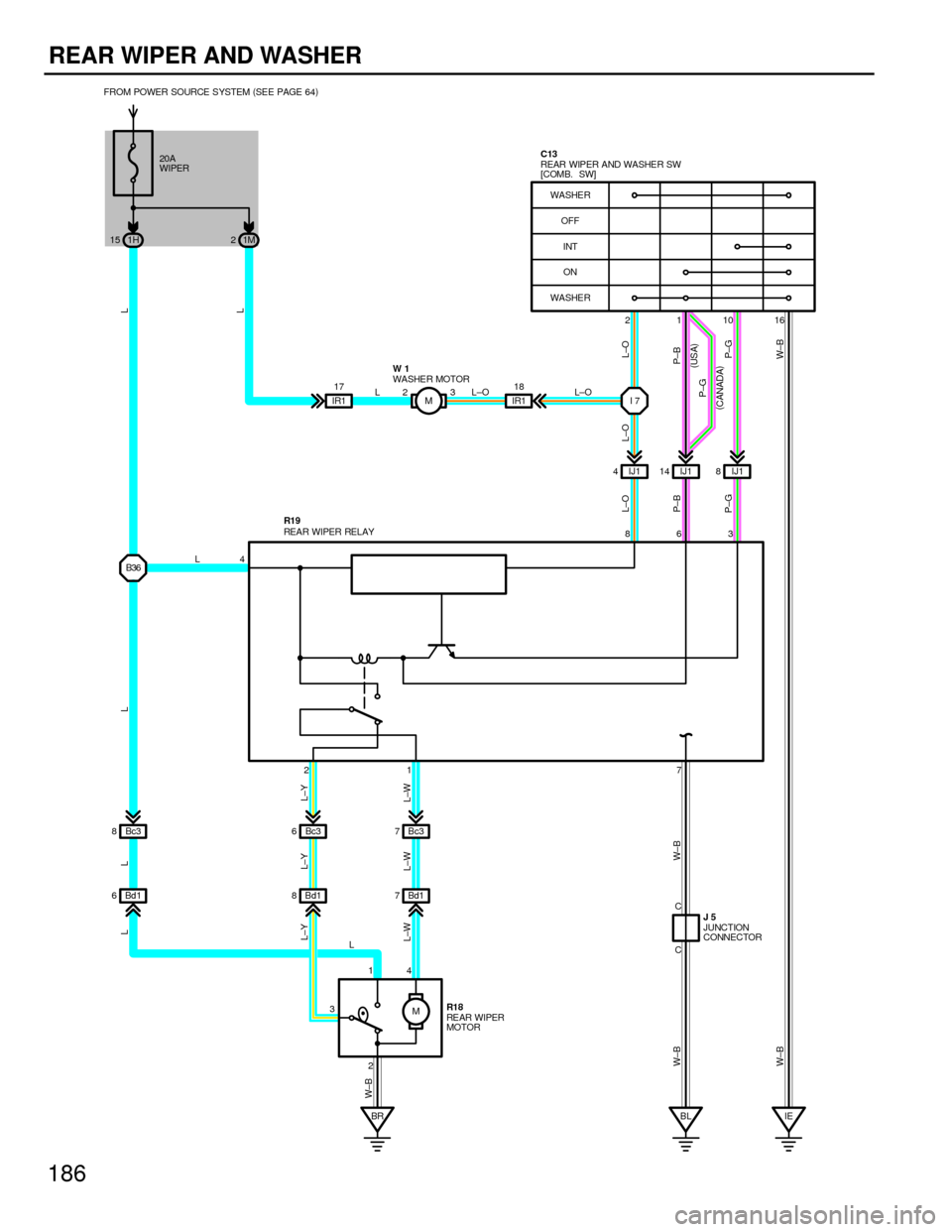

REAR WIPER AND WASHER

IR118

IR117

M 23

IJ1 4IJ114 IJ18

Bc3 8Bc36Bc37

Bd1 6Bd18Bd17I7

B36

M 14

BL IE L L±O L±O

L

L

L

L

L±O

P±B

P±G

W±B L±O L±O

P±B

P±G W±B W±B

W±BL±WL±Y

L±WL±Y

L±WL±YLL L

21 72 1 10 16

3 4

C 863

C FROM POWER SOURCE SYSTEM(

SEE PAGE 64)

JUNCTION

CONNECTOR J5

REAR WIPER

MOTOR R18 REA R WIPER RELAY R19WASHER MOTOR W1REAR WIPER AND WASHER SW

[COMB. SW] C13

OFF

INT

ON

WASHER WASHER

P±G

(

CANADA)

BR 2

W±B

(

US A)

1H 15 1M2 WIPER

20A

Page 187 of 307

187

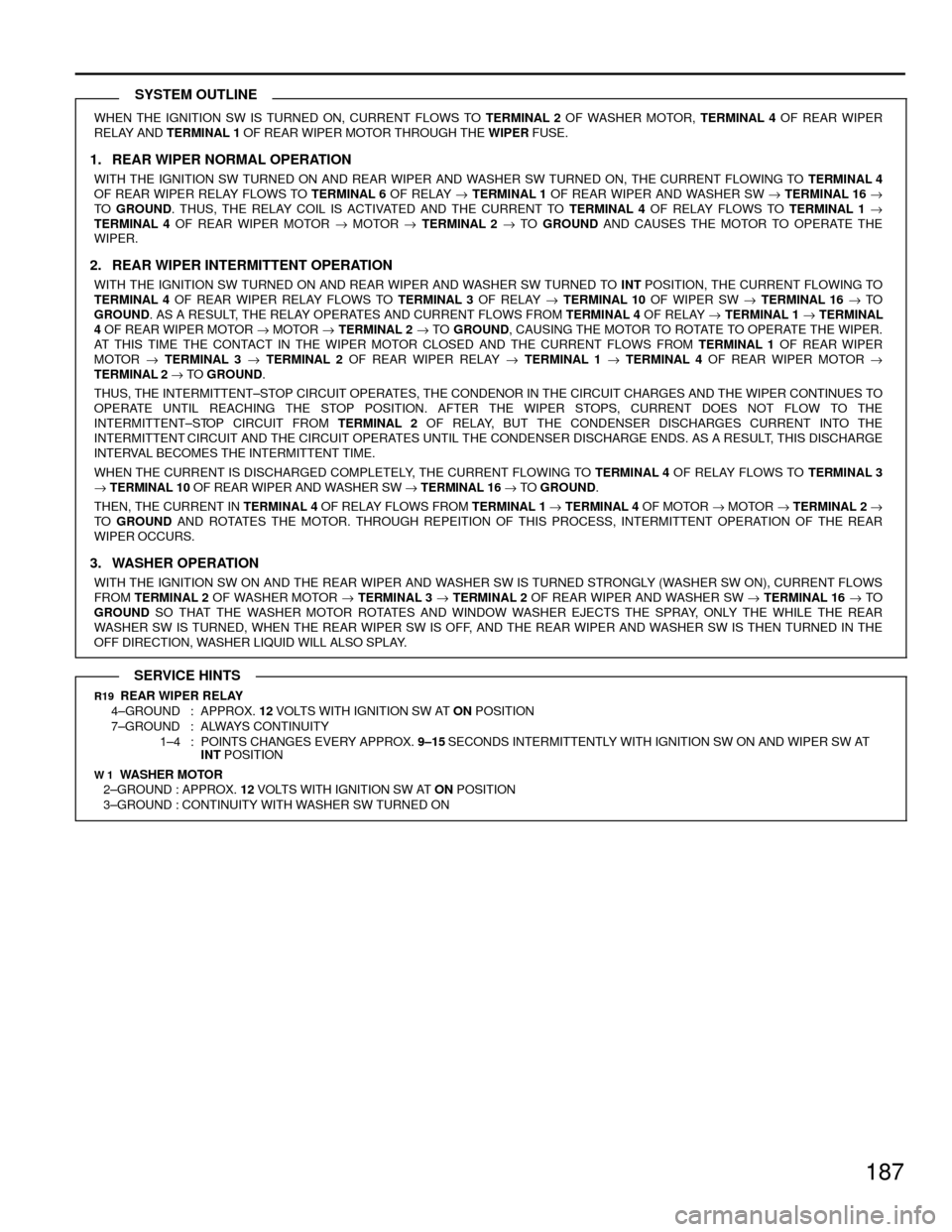

WHEN THE IGNITION SW IS TURNED ON, CURRENT FLOWS TO TERMINAL 2 OF WASHER MOTOR, TERMINAL 4 OF REAR WIPER

RELAY AND TERMINAL 1 OF REAR WIPER MOTOR THROUGH THE WIPER FUSE.

1. REAR WIPER NORMAL OPERATION

WITH THE IGNITION SW TURNED ON AND REAR WIPER AND WASHER SW TURNED ON, THE CURRENT FLOWING TO TERMINAL 4

OF REAR WIPER RELAY FLOWS TO TERMINAL 6 OF RELAY " TERMINAL 1 OF REAR WIPER AND WASHER SW " TERMINAL 16 "

TO GROUND. THUS, THE RELAY COIL IS ACTIVATED AND THE CURRENT TO TERMINAL 4 OF RELAY FLOWS TO TERMINAL 1 "

TERMINAL 4 OF REAR WIPER MOTOR " MOTOR " TERMINAL 2 " TO GROUND AND CAUSES THE MOTOR TO OPERATE THE

WIPER.

2. REAR WIPER INTERMITTENT OPERATION

WITH THE IGNITION SW TURNED ON AND REAR WIPER AND WASHER SW TURNED TO INT POSITION, THE CURRENT FLOWING TO

TERMINAL 4 OF REAR WIPER RELAY FLOWS TO TERMINAL 3 OF RELAY " TERMINAL 10 OF WIPER SW " TERMINAL 16 " TO

GROUND. AS A RESULT, THE RELAY OPERATES AND CURRENT FLOWS FROM TERMINAL 4 OF RELAY " TERMINAL 1 " TERMINAL

4 OF REAR WIPER MOTOR " MOTOR " TERMINAL 2 " TO GROUND, CAUSING THE MOTOR TO ROTATE TO OPERATE THE WIPER.

AT THIS TIME THE CONTACT IN THE WIPER MOTOR CLOSED AND THE CURRENT FLOWS FROM TERMINAL 1 OF REAR WIPER

MOTOR " TERMINAL 3 " TERMINAL 2 OF REAR WIPER RELAY " TERMINAL 1 " TERMINAL 4 OF REAR WIPER MOTOR "

TERMINAL 2 " TO GROUND.

THUS, THE INTERMITTENT±STOP CIRCUIT OPERATES, THE CONDENOR IN THE CIRCUIT CHARGES AND THE WIPER CONTINUES TO

OPERATE UNTIL REACHING THE STOP POSITION. AFTER THE WIPER STOPS, CURRENT DOES NOT FLOW TO THE

INTERMITTENT±STOP CIRCUIT FROM TERMINAL 2 OF RELAY, BUT THE CONDENSER DISCHARGES CURRENT INTO THE

INTERMITTENT CIRCUIT AND THE CIRCUIT OPERATES UNTIL THE CONDENSER DISCHARGE ENDS. AS A RESULT, THIS DISCHARGE

INTERVAL BECOMES THE INTERMITTENT TIME.

WHEN THE CURRENT IS DISCHARGED COMPLETELY, THE CURRENT FLOWING TO TERMINAL 4 OF RELAY FLOWS TO TERMINAL 3

" TERMINAL 10 OF REAR WIPER AND WASHER SW " TERMINAL 16 " TO GROUND.

THEN, THE CURRENT IN TERMINAL 4 OF RELAY FLOWS FROM TERMINAL 1 " TERMINAL 4 OF MOTOR " MOTOR " TERMINAL 2 "

TO GROUND AND ROTATES THE MOTOR. THROUGH REPEITION OF THIS PROCESS, INTERMITTENT OPERATION OF THE REAR

WIPER OCCURS.

3. WASHER OPERATION

WITH THE IGNITION SW ON AND THE REAR WIPER AND WASHER SW IS TURNED STRONGLY (WASHER SW ON), CURRENT FLOWS

FROM TERMINAL 2 OF WASHER MOTOR " TERMINAL 3 " TERMINAL 2 OF REAR WIPER AND WASHER SW " TERMINAL 16 " TO

GROUND SO THAT THE WASHER MOTOR ROTATES AND WINDOW WASHER EJECTS THE SPRAY, ONLY THE WHILE THE REAR

WASHER SW IS TURNED, WHEN THE REAR WIPER SW IS OFF, AND THE REAR WIPER AND WASHER SW IS THEN TURNED IN THE

OFF DIRECTION, WASHER LIQUID WILL ALSO SPLAY.

R19 REAR WIPER RELAY

4±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION

7±GROUND : ALWAYS CONTINUITY

1±4 : POINTS CHANGES EVERY APPROX. 9±15 SECONDS INTERMITTENTLY WITH IGNITION SW ON AND WIPER SW AT

INT POSITION

W 1 WASHER MOTOR

2±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION

3±GROUND : CONTINUITY WITH WASHER SW TURNED ON

SYSTEM OUTLINE

SERVICE HINTS

Page 191 of 307

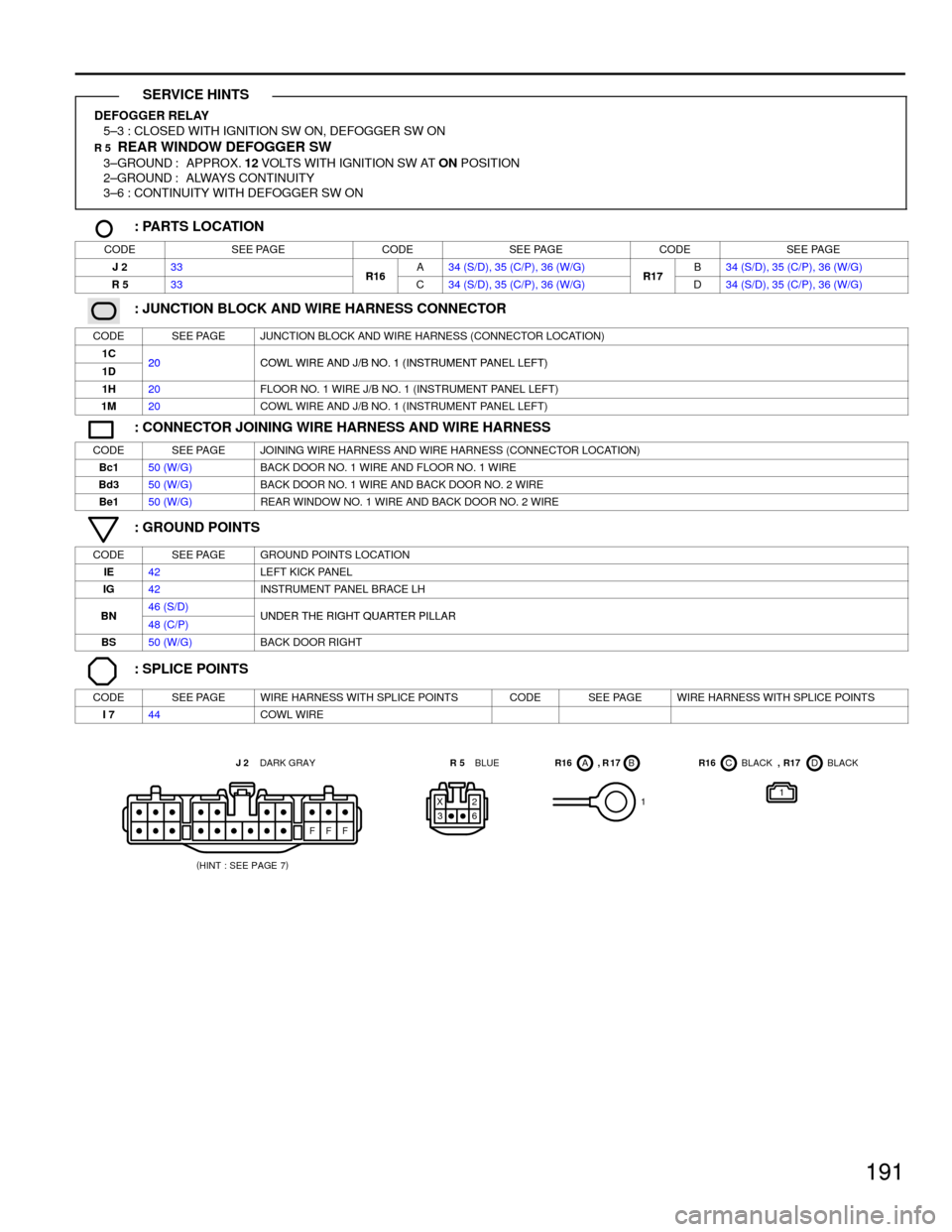

191

DEFOGGER RELAY

5±3 : CLOSED WITH IGNITION SW ON, DEFOGGER SW ON

R 5 REAR WINDOW DEFOGGER SW

3±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION

2±GROUND : ALWAYS CONTINUITY

3±6 : CONTINUITY WITH DEFOGGER SW ON

: PARTS LOCATION

CODESEE PAGECODESEE PAGECODESEE PAGE

J 233R16A34 (S/D), 35 (C/P), 36 (W/G)R17B34 (S/D), 35 (C/P), 36 (W/G)

R 533R16C34 (S/D), 35 (C/P), 36 (W/G)R17D34 (S/D), 35 (C/P), 36 (W/G)

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODESEE PAGEJUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

1C20COWL WIRE AND J/B NO 1 (INSTRUMENT PANEL LEFT)1D20COWL WIRE AND J/B NO. 1 (INSTRUMENT PANEL LEFT)

1H20FLOOR NO. 1 WIRE J/B NO. 1 (INSTRUMENT PANEL LEFT)

1M20COWL WIRE AND J/B NO. 1 (INSTRUMENT PANEL LEFT)

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CODESEE PAGEJOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

Bc150 (W/G)BACK DOOR NO. 1 WIRE AND FLOOR NO. 1 WIRE

Bd350 (W/G)BACK DOOR NO. 1 WIRE AND BACK DOOR NO. 2 WIRE

Be150 (W/G)REAR WINDOW NO. 1 WIRE AND BACK DOOR NO. 2 WIRE

: GROUND POINTS

CODESEE PAGEGROUND POINTS LOCATION

IE42LEFT KICK PANEL

IG42INSTRUMENT PANEL BRACE LH

BN46 (S/D)UNDER THE RIGHT QUARTER PILLARBN48 (C/P)UNDER THE RIGHT QUARTER PILLAR

BS50 (W/G)BACK DOOR RIGHT

: SPLICE POINTS

CODESEE PAGEWIRE HARNESS WITH SPLICE POINTSCODESEE PAGEWIRE HARNESS WITH SPLICE POINTS

I 744COWL WIRE

A

F F FX2

36 J2 R 5 R16 ,R17B DARK GRAYBLACK BLUE

(

HINT : SEE PAGE 7)11D R16 , R17CBLACK

SERVICE HINTS

Page 192 of 307

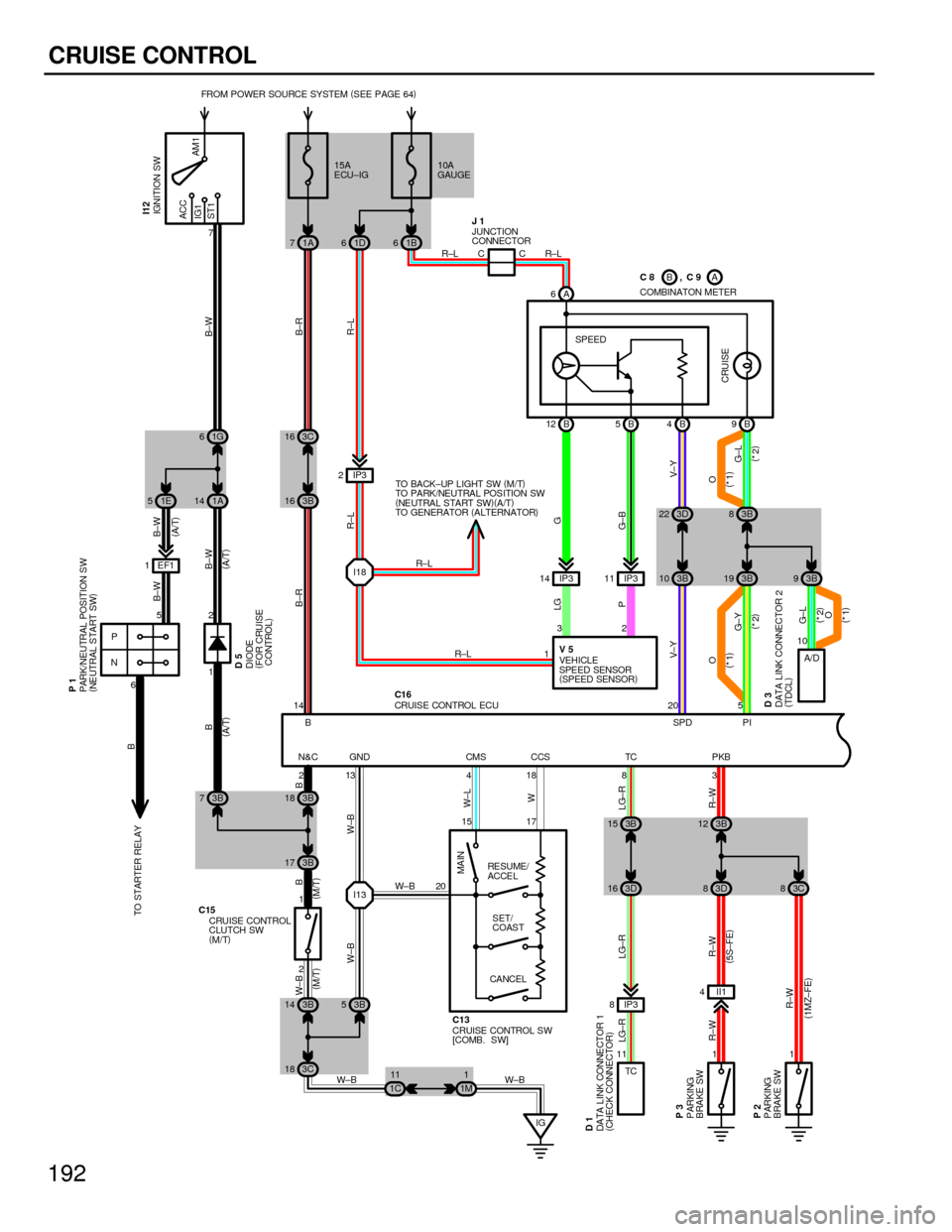

192

CRUISE CONTROL

B

ST1 IG1 ACC

AM1

7

IP3 8IP3 11

II1 4 2 1

1 1 213 41883

17 15

20 1420 510 2

13B 4 B 12 B5B9 A 6

1 2

IG CC

I13

11 R±L R±L

R±L

W±B

W±B W±B

B±R B±W

R±L B±W

B±R B

B

W±B

W±L

W

LG±R

R±W LG±R

R±W LG±R

R±W

R±WW±B

W±B

G±BG

V±Y

G±Y V±YP LG B

FROM POWER SOURCE SYSTEM(

SEEPAGE64)

10A

GAUGE

COMBINATON METER

DIODE

(

FOR CRUISE

CONTROL)VEHICLE

SPEED SENSOR

(

SPEED SENSOR)

DATA LINK CONNECTOR 2

(

TDCL)

A/D JUNCTION

CONNECTOR

CRUISE CONTROL

CLUTCH SW

(

M/T)

CRUISE CONTROL SW

[COMB. SW]

DA TA LINK CONNE CTOR 1

(

CHECK CONNECTOR)

PARKING

BRAKE SW

PARKING

BRAKE SWMAIN

CA NCELSET/

COAST RE SUME/

ACCEL N&C GND CMS CCS TC PKBBSPD PI

TC

IGNITION SW

P

N5

6EF1 1

B±W B±W

J1

P1

D5

C8 , C9

D3

V5A

PARK/NEUTRAL POSITION SW

(

NE UTRAL S TA RT SW)

(

A/T) B

TO STARTER RELAY

CRUIS E CONTROL ECU C16

C15

C13

D1

P3

P2

(

1MZ±FE)

SPEED

CRUISEI12

IP3 2

(

A/T)

(

5S±FE)IP3 14

(

A/T)

(

M/T) (

M/T)

R±L

TO BA CK ±UP LIGHT SW(

M/T)

TO PARK/NEUTRAL POSITION SW

(

NE UTRA L S TA RT SW)(

A/T)

TO GENERATOR(

ALTERNATOR)

R±L

I18

(

*2) O

(

*1)

G±L

(

*2) O

(

*1)

O

(

*1) G±L

(

*2)

1G 63C16

1A 14 3B16 1E 5

1A 71D61B6 15A

ECU±IG

3D 22 3B8

3B 10 3B19 3B9

3B 73B18

3B 17

3B 14 3B5

3C 18

1M1

1C11

3B 12

3D 83C83B 15

3D 16

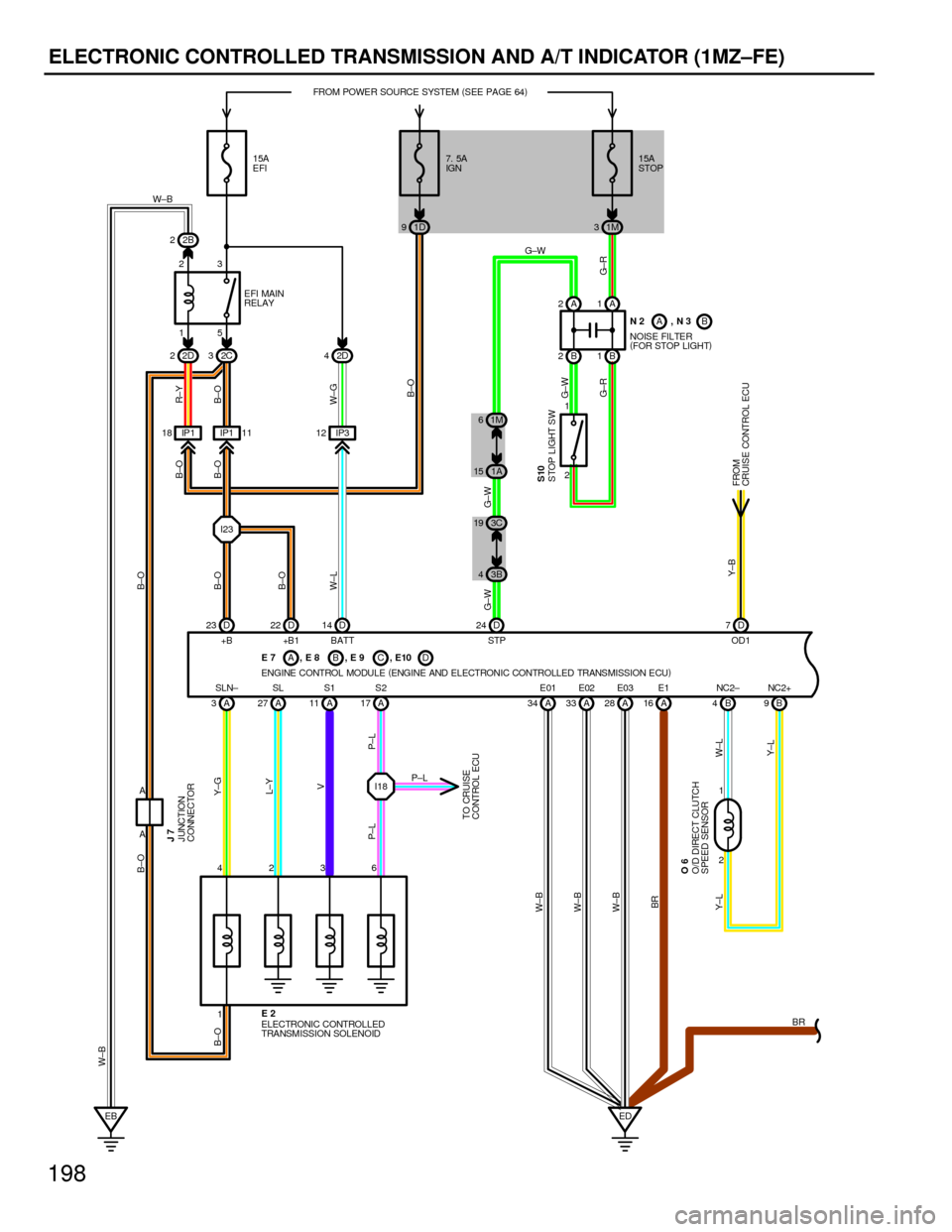

Page 198 of 307

198

ELECTRONIC CONTROLLED TRANSMISSION AND A/T INDICATOR (1MZ±FE)

A

2D 22C32D4 2B 2

I23

I18

2 1

EBED IP 1 18 IP1 11 IP312

D 7 D 24 D 14 D 22 D 23

A 27 A11 A17 A33 B4

26FROM POWER SOURCE SYSTEM(

SEE PAGE 64)

P±L P±LV L±Y W±B

B±O

B±OB±O

W±L

G±W G±W

Y±BW±GB±OR±Y

W±L Y±L W±BB±O

15A

EFI

SL S1 S2 E02 NC2± +B +B1 BATT STP OD1EFI MAIN

RELAY

FROM

CRUIS E CONTROL ECU

BR P±L

TO CRUISE

CONTROL ECU

15 23

O/D DIRECT CLUTCH

SPEED SENSOR O6STOP LIGHT SW

G±R

G±W

2 1

S10

B 1 A 2

B 2B1NOISE FILTER

(

FOR STOP LIGHT) N2 ,N3 A

G±W

G±R

B E7 ,E8AC,E9

ENGINE CONTROL MODULE(

ENGINE AND ELECTRONIC CONTROLLED TRANSMISSION ECU)

B±O

D ,E10

A

3

ELECTRONIC CONTROLLED

TRANSMISSION SOLENOID E2 4 A

1

J UNCTION

CONNECTOR J7

A 3SLN±

Y±GB±O

B±OB±O

W±B

W±B

BR

A 34E01

A 28E03

A 16E1

B 9NC2+

Y±L

W±B

1D 91M3 7. 5A

IGN15A

STOP

1A 15

3B 43C 191M 6

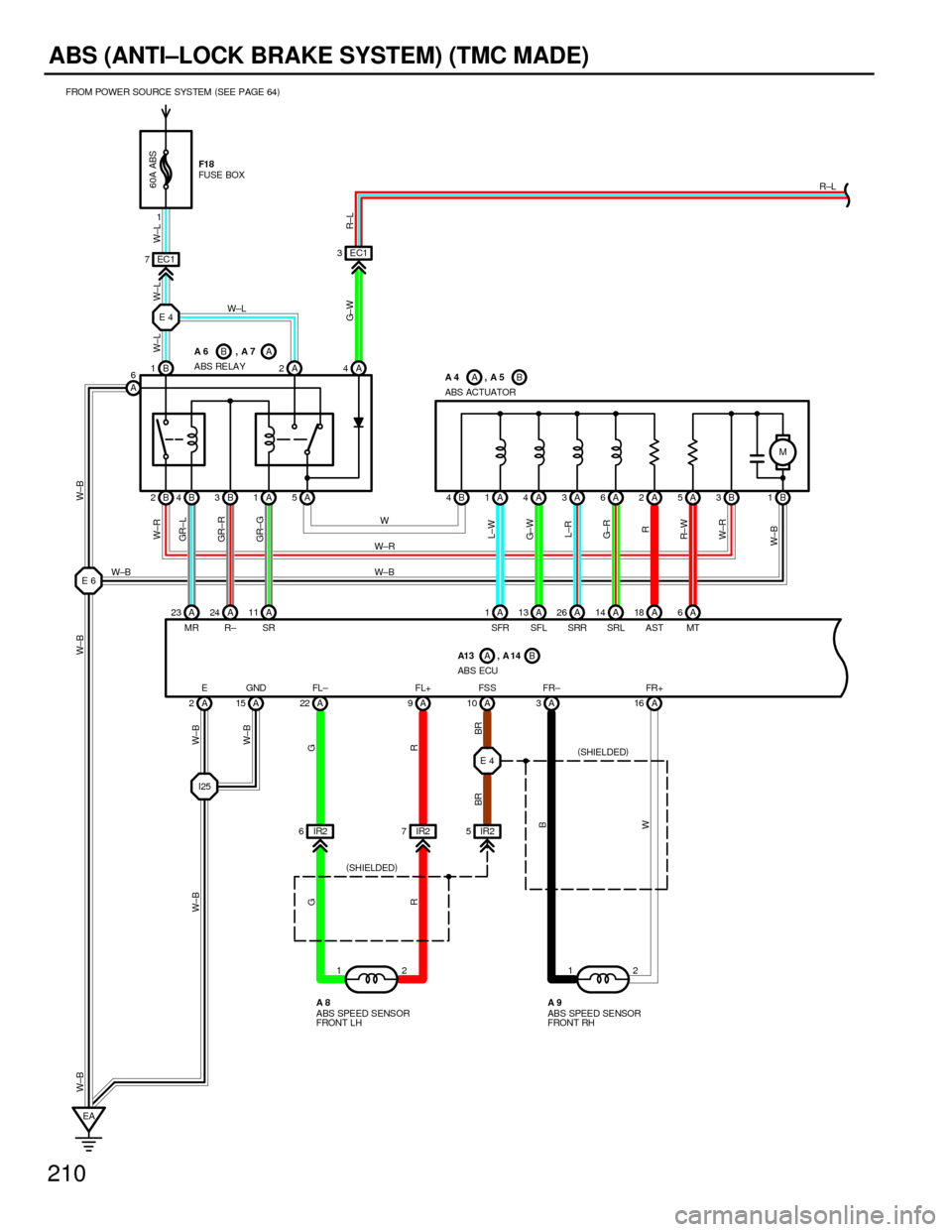

Page 210 of 307

210

ABS (ANTI±LOCK BRAKE SYSTEM) (TMC MADE)

A B

A

E4

E6

I25E4 EC1 7EC1 3

IR2 6IR27IR25M

2 1 A 23 A24 A11 A1A13 A26 A14 A18 A6 B 4A1A4A3A6A2A5B1 A 5 A 1 B 4 B 2B3

A 2A15 A22 A10 A3A16B 3

B 1A2A4

A6

A 9

2 1

EAR±L

FR+ FR± FS S FL+ FL ± GND E

W±L W±L W±L

W±LG± W W±R

GR±L

GR±R

GR±G

L±W

G±W

L±R

G±R

R

R±W

W±R

W±BW±B

W±B W±B

W±B

BR BR R G W±B

B

W

W

W±B1FUSE BOX

60A ABS

ABS RELAY

ABS ACTUATOR

R±L

R± SR MR SFR SFL SRR SRL AST MT

ABS SPEED SENSOR

FRONT LHABS SPEED SENSOR

FRONT RH

W±B

(

SHIELDED)(

SHIELDED) ABS ECU FROM POWER SOURCE SYSTEM(

SEE PAGE 64)

A1 3 , A 1 4 BA A6 , A7

B A4 , A5

A8 A9 F1 8

W±R

W±B

G

R

Page 212 of 307

212

ABS (ANTI±LOCK BRAKE SYSTEM) (TMC MADE)

THIS SYSTEM CONTROLS THE RESPECTIVE BRAKE FLUID PRESSURES ACTING ON THE DISC BRAKE CYLINDERS OF THE RIGHT

FRONT WHEEL, LEFT FRONT WHEEL AND REAR WHEELS WHEN THE BRAKES ARE APPLIED IN A PANIC STOP SO THAT THE

WHEELS DO NOT LOCK. THIS RESULTS IN IMPROVED DIRECTIONAL STABILITY AND STEERABILITY DURING PANIC BRAKEING.

1. INPUT SIGNALS

(1) SPEED SENSOR SIGNAL

THE SPEED OF THE WHEELS IS DETECTED AND INPUT TO TERMINALS FL+, FR+, RL+ AND RR+ OF THE ABS ECU.

(2) STOP LIGHT SW SIGNAL

A SIGNAL IS INPUT TO TERMINAL STP OF THE ABS ECU WHEN BRAKE PEDAL IS OPERATED.

(3) PARKING BRAKE SW SIGNAL

A SIGNAL IS INPUT TO TERMINAL PKB OF THE ABS ECU WHEN THE PARKING BRAKE IS OPERATED.

2. SYSTEM OPERATION

DURING SUDDEN BRAKEING THE ABS ECU, WHICH HAS SIGNALS INPUT FROM EACH SENSOR, CONTROLS THE CURRENT

FLOWING TO THE SOLENOID INSIDE THE ACTUATOR AND LETS THE HYDRAULIC PRESSURE ACTING ON EACH WHEEL CYLINDER

ESCAPE TO THE RESERVOIR. THE PUMP INSIDE THE ACTUATOR IS ALSO OPERATING AT THIS TIME AND IT RETURNS THE BRAKE

FLUID FROM THE RESERVOIR TO THE MASTER CYLINDER, THUS PREVENTING LOCKING OF THE VEHICLE WHEELS.

IF THE ECU JUDGES THAT THE HYDRAULIC PRESSURE ACTING ON THE WHEEL CYLINDER IS INSUFFICIENT, THE CURRENT

ACTING ON THE SOLENOID IS CONTROLLED AND THE HYDRAULIC PRESSURE IS INCREASED. HOLDING OF THE HYDRAULIC

PRESSURE IS ALSO CONTROLLED BY THE ECU, BY THE SAME METHOD AS ABOVE. BY REPEATED PRESSURE REDUCTION,

HOLDING AND INCREASE ARE REPLATED TO MAINTAIN VEHICLE STABILITY AND TO IMPROVE STEERBILITY DURING SUDDEN

BRAKING.

A 4(A), A 5(B) ABS ACTUATOR

(A)1, (A)3, (A)4, (A)6 ± (A)2 : APPROX. 6 W

(A)2±GROUND : APPROX. 5 W

A 6(B), A 7(A) ABS RELAY

(A)1±(B) 3 : 60 W±100 W

(A)4±(B) 3 : 60 W±100 W

(A)1, (B) 2±GROUND : APPROX. 12 VOLTS

(A)6±GROUND : APPROX. 12 VOLTS

A 8, A 9 ABS SPEED SENSOR FRONT LH, RH

1±2 : 0.8 K±1.3 KW

A19, A20 ABS SPEED SENSOR REAR LH, RH

1±2 : 1.1 K±1.5 KW

A13(A), A14(B) ABS ECU

(CONNECT THE ECU CONNECTORS)

(A) 5±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION AND DATA LINK CONNECTOR 1 (CHECK CONNECTOR)

TS±EI NOT CONNECTED

(B)15±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION AND DATA LINK CONNECTOR 1 (CHECK CONNECTOR)

TS±EI NOT CONNECTED

(A) 1±GROUND, (A) 13±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION AND ABS WARNING LIGHT GOES OFF

(A)14±GROUND, (A) 1±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION AND ABS WARNING LIGHT GOES OFF

(A)26±GROUND, (A) 18±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION AND ABS WARNING LIGHT GOES OFF

(A) 2±GROUND : ALWAYS CONTINUITY

(A)15±GROUND : ALWAYS CONTINUITY

(A)12±GROUND : APPROX. 12 VOLTS WITH IGNITION SW AT ON POSITION

(B) 6±GROUND : APPROX. 12 VOLTS WITH BRAKE PEDAL DEPRESSED

(A)25±GROUND : ALWAYS APPROX. 12 VOLTS

SYSTEM OUTLINE

SERVICE HINTS