system TOYOTA CAMRY 1994 XV10 / 4.G Wiring Diagrams Owner's Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1994, Model line: CAMRY, Model: TOYOTA CAMRY 1994 XV10 / 4.GPages: 307, PDF Size: 5.48 MB

Page 89 of 307

89

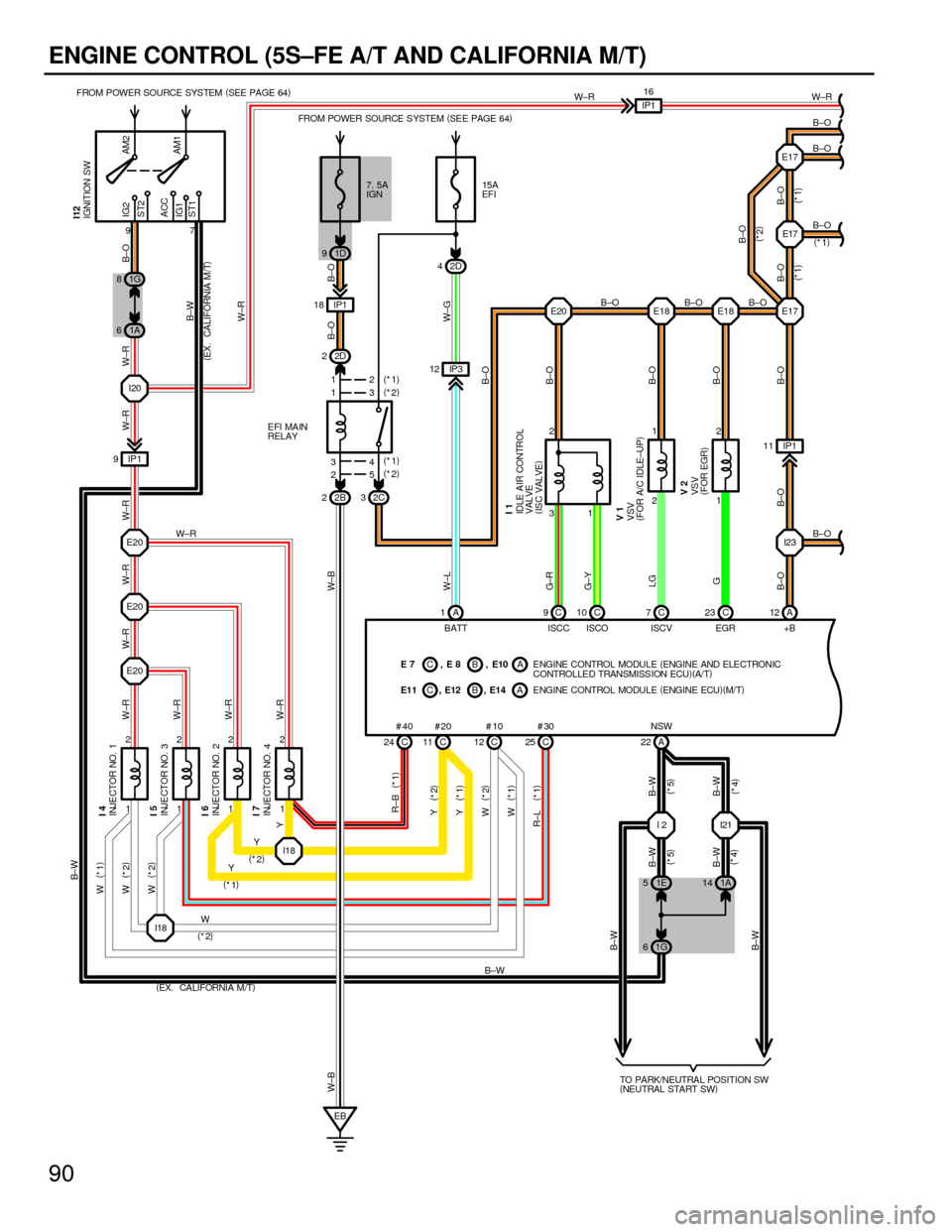

2. CONTROL SYSTEM

*MFI (MULTIPORT FUEL INJECTION (EFI)) SYSTEM

THE MFI (EFI) SYSTEM MONITORS THE ENGINE CONDITION THROUGH THE SIGNALS INPUT FROM EACH SENSOR (INPUT

SIGNALS FROM (1) TO (13) ETC.) TO THE ENGINE CONTROL MODULE (ECU). THE BEST FUEL INJECTION VOLUME IS DECIDED

BASED ON THIS DATA AND THE PROGRAM MEMORIZED BY THE ENGINE CONTROL MODULE (ECU), AND THE CONTROL SIGNAL

IS OUTPUT TO TERMINALS #10, #20, #30 AND #40 (CALIFORNIA), TERMINALS #10 AND #20 (EX. CALIFORNIA) OF THE ENGINE

CONTROL MODULE (ECU) TO OPERATE THE INJECTOR. (INJECT THE FUEL). THE MFI (EFI) SYSTEM PRODUCES CONTROL OF

FUEL INJECTION OPERATION BY THE ENGINE CONTROL MODULE (ECU) IN RESPONSE TO THE DRIVING CONDITIONS.

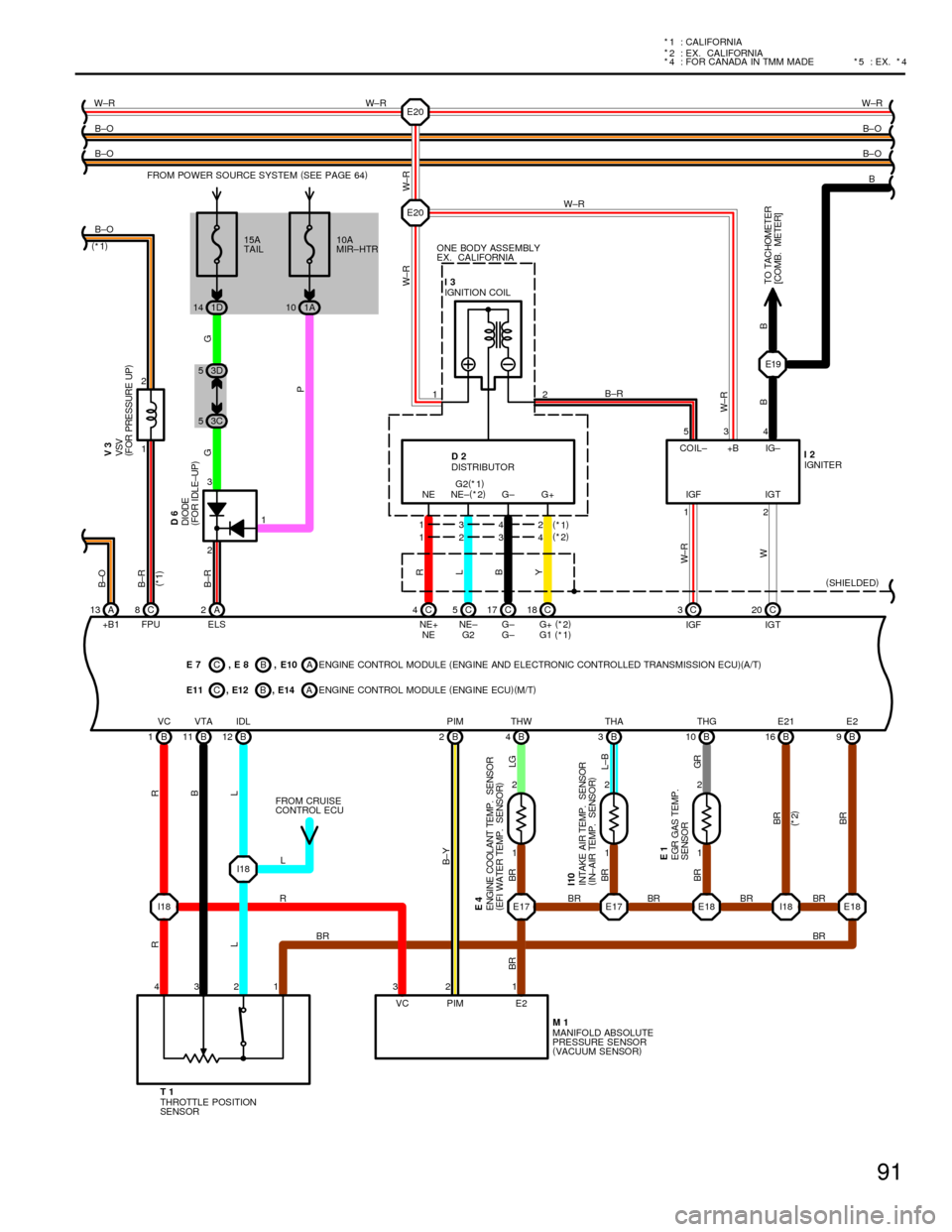

*ESA (ELECTRONIC SPARK ADVANCE) SYSTEM

THE ESA SYSTEM MONITORS THE ENGINE CONDITION THROUGH THE SIGNALS INPUT TO THE ENGINE CONTROL MODULE (ECU)

FROM EACH SENSOR (INPUT SIGNALS FROM (1), (2), (4) TO (12) ETC.) THE BEST IGNITION TIMING IS DETECTED ACCORDING TO

THIS DATA AND THE MEMORIZED DATA IN THE ENGINE CONTROL MODULE (ECU) AND THE CONTROL SIGNAL IS OUTPUT TO

TERMINAL IGT. THIS SIGNAL CONTROLS THE IGNITER TO PROVIDE THE BEST IGNITION TIMING FOR THE DRIVING CONDITIONS.

*IAC (IDLE AIR CONTROL (ISC)) SYSTEM

THE IAC (ISC) SYSTEM (ROTARY SOLENOID TYPE) INCREASES THE RPM AND PROVIDES IDLING STABILITY FOR FAST IDLE±UP

WHEN THE ENGINE IS COLD AND WHEN THE IDLE SPEED HAS DROPPED DUE TO ELECTRICAL LOAD, ETC. THE ENGINE

CONTROL MODULE (ECU) EVALUATES THE SIGNALS FROM EACH SENSOR (INPUT SIGNALS (1), (4) TO (8), (13) ETC.), OUTPUTS

CURRENT TO TERMINALS ISCO AND ISCC, AND CONTROLS THE IDLE AIR CONTROL VALVE (ISC VALVE).

*FUEL PUMP CONTROL SYSTEM

THE ENGINE CONTROL MODULE (ECU) OPERATION OUTPUTS TO TERMINAL FC AND CONTROLS THE CIRCUIT OPENING RELAY

AND THUS CONTROLS THE FUEL PUMP DRIVE SPEED IN RESPONSE TO CONDITIONS.

*A/C IDLE±UP SYSTEM

IN ORDER TO PREVENT THE ENGINE IDLING SPEED FROM DROPPING WHEN THE A/C IS OPERATING, THE A/C IDLE±UP SYSTEM

CONTROLS THE VSV (FOR A/C IDLE±UP) TO INCREASE THE ENGINE IDLING SPEED AND KEEP IT STABLE.

*EGR CONTROL SYSTEM

THE EGR CUT CONTROL SYSTEM CONTROLS THE VSV (FOR EGR) BY EVALUATING THE SIGNALS FROM EACH SENSOR INPUT TO

THE ENGINE CONTROL MODULE (ECU) (INPUT SIGNALS (1), (5), (6), (9) ETC.) AND BY SENDING OUTPUT TO TERMINAL THG OF

THE ENGINE CONTROL MODULE (ECU).

*A/C CUT CONTROL SYSTEM

WHEN THE VEHICLE SUDDENLY ACCELERATES FROM LOW ENGINE SPEED, THIS SYSTEM CUTS OFF AIR CONDITIONING

OPERATION FOR A FIXED PERIOD OF TIME IN RESPONSE TO THE VEHICLE SPEED AND THROTTLE VALVE OPENING ANGLE IN

ORDER TO MAINTAIN ACCELERATION PERFORMANCE.

THE ENGINE CONTROL MODULE (ECU) RECEIVES INPUT SIGNALS ((5), (6) ETC.), AND OUTPUTS SIGNALS TO TERMINAL ACT.

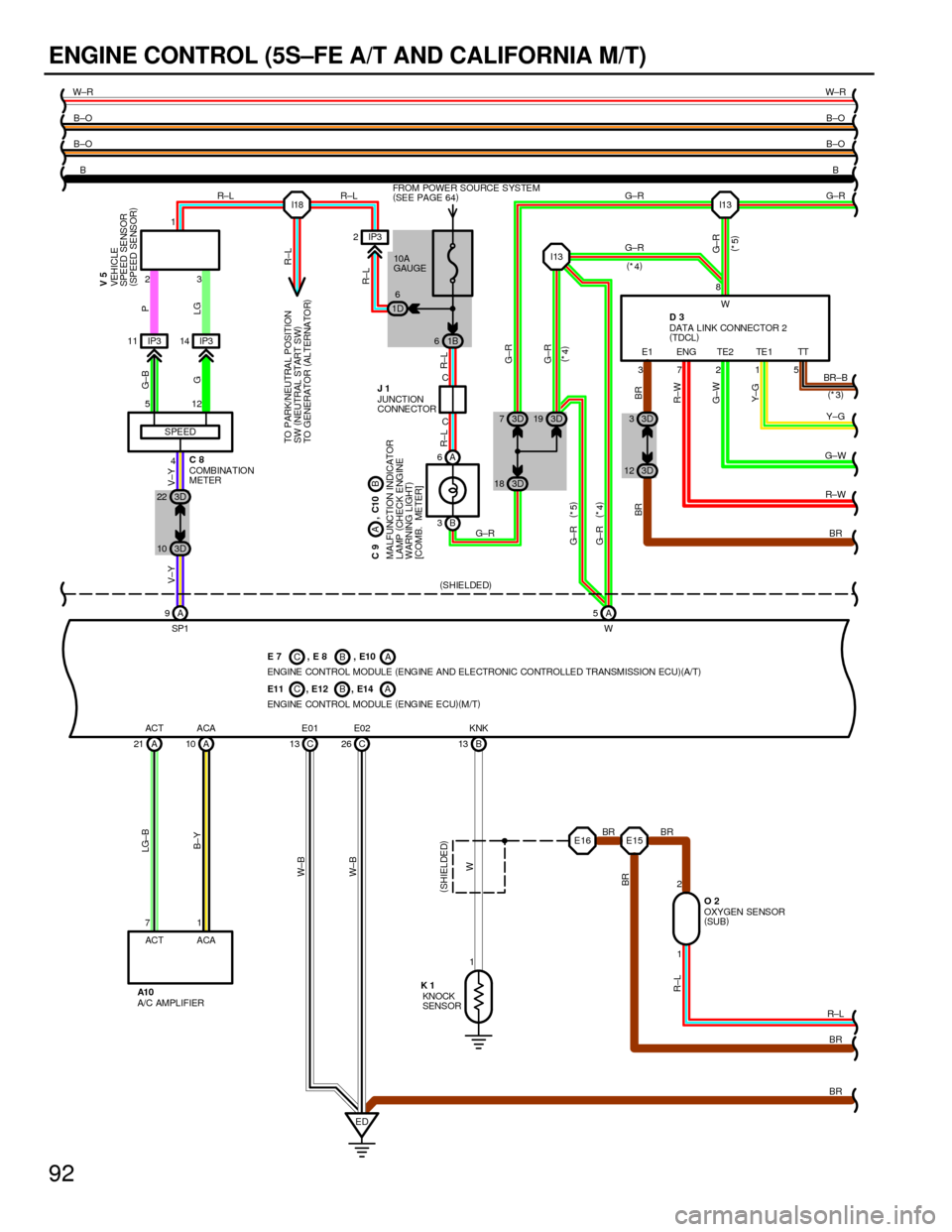

3. DIAGNOSIS SYSTEM

WITH THE DIAGNOSIS SYSTEM, WHEN THERE IS A MALFUNCTIONING IN THE ENGINE CONTROL MODULE (ECU) SIGNAL SYSTEM,

THE MALFUNCTION SYSTEM IS RECORDED IN THE MEMORY. THE MALFUNCTIONING SYSTEM CAN THEN BE FOUND BY READING

THE DISPLAY (CODE) OF THE MALFUNCTION INDICATOR LAMP (CHECK ENGINE WARNING LIGHT).

4. FAIL±SAFE SYSTEM

WHEN A MALFUNCTION OCCURS IN ANY SYSTEM, IF THERE IS A POSSIBILITY OF ENGINE TROUBLE BEING CAUSED BY

CONTINUED CONTROL BASED ON THE SIGNALS FROM THAT SYSTEM, THE FAIL±SAFE SYSTEM EITHER CONTROLS THE SYSTEM

BY USING DATA (STANDARD VALUES) RECORDED IN THE ENGINE CONTROL MODULE (ECU) MEMORY OR ELSE STOPS THE

ENGINE.

Page 90 of 307

90

ENGINE CONTROL (5S±FE A/T AND CALIFORNIA M/T)

CB

IG2

ACC

IG1 ST2AM2

AM1

ST1

7 9

1 2

1 2

1 2

1 2 E20

E20

E20I20

I23 E20 E18 E18 E17E17

I18

EBA 1A 12

A 22 C 11 C12A23 C 7 IP 3 12

1 2

2 1 2D 2

2B 22C3

W±B

B±W B±WY

B±W

Y WW±R

W±R

W±R

W±RW±R W±R W±R W±R B±O

B±W

B±O

W±G

B±O B±O

B±O B±O B±OLG

G W±L W±B B±W

W±R

B±O B±O B±O W±R

B±O B±O B±O

B±O

7. 5A

IGN

IP1 18

B±O

#20 #10 NSWBATT EGRISCV +B 15A

EFI

EFI MAIN

RELAY

VSV

(

FOR EGR) VSV

(

FOR A/C IDLE±UP)

E NGINE CONTROL MODULE(

ENGINE AND ELECTRONIC

CONTROLLED TRANSMISSION ECU)(

A/T)

INJE CTOR NO. 1

INJE CTOR NO. 3

INJE CTOR NO. 2

INJE CTOR NO. 4 I4

I5

I6

I7

E7 , E8 , E10C

V2 V1

W±R

I12

IGNITION SW

C 9C10 31 2

B±O

G±Y G±R

ISCC ISCO

IDLE AIR CONTROL

VALVE

(

ISC VALVE) I1

FROM POWER SOURCE SYSTEM(

SEE PAGE 64)

FROM POWER SOURCE SYSTEM(

SEE PAGE 64)

34 13

IP1 11

IP1 9

W±R

B±O (

*4) (

*5)

TO PARK/NEUTRAL POSITION SW

(

NEUTRAL STA RT SW) 2D 4IP116

W±R

I2 C 24#40

I18C 25#30

W W(

*1)

(

*2)

(

*2)

Y

(

*2)

Y

(

*1)

R±B(

*1)

(

*2)

Y(

*1)

W(

*2)

W(

*1)

R±L(

*1)

B±W

(

*5)

E17

B±O B±O

(

*2)

(

*1) (

*1)

B±O

(

*1)

12

25(

*1)

(

*2)

(

*1)

(

*2)

B±W

W

(

*2)

(

EX. CALIFORNIA M/T)

(

EX. CALIFORNIA M/T)B E11 , E12CA,E14E NGINE CONTROL MODULE(

ENGINE ECU)(

M/T)

I21

B±W

(

*4)

B±W

1A 61G 8

1D 9

1G 61E 51A14

Page 91 of 307

91

*

2 : EX. CALIFORNIA

* 4 : FOR CANADA IN TMM MADE * 1 : CALIFORNIA

* 5 : EX. * 4

B C

I18B 11 B 1B12

R

B

L R

VC VTA IDL

THROTTLE POSITION

SENSOR T11 2

1 2

1 2 E20

E20

E18 E17 E17 1234

2 3

32 112

A 13 A2C 18 C 17 C 5 C 4

B 2 A

4B3B10 B16 B9 PIM THW THA THG E21 E2 NE NE±(

*2)

G± G+B B± O W±R W±R

B±O

B± O

BR BR BR

B±Y

BR BR

BR

BR

BR

BRGR L±BLGB±R G G

W± R W±R

R

L

B

Y

B±O

D6

I3

D2

E7 ,E8 , E10 +B1 ELSW± R

NE+ NE± G± G+(

*2)

VC E2PIM

(

*2)

M1

E4

I10

E1

MANIFOLD ABSOLUTE

PRESSURE SENSOR

(

VACUUM SENSOR)

ENGINE COOLANT TEMP. SENSOR

(

EFI WATER TEMP. SENSOR)

INTAKE AIR TEMP. SENSOR

(

IN±AIR TEMP. SENSOR)

EGR GAS TEMP.

SENSOR

ENGINE CONTROL MODULE(

ENGINE AND ELECTRONIC CONTROLLED TRANSMISSION ECU)(

A/T)

B

DIODE

(

FOR IDLE±UP)

IGNITION COIL

DISTRIBUTOR FROM

I18 E18

4321BR

BR I18

L

L FROM CRUISE

CONTROL ECU 1

P

E19

C 3C20 534

12

W± R

WBW±R

B

W±R

(

SHIELDED)

IGF IGT COIL± +B IG±

IGF IGTIGNITER I2

TO TACHOMETER

[COMB. METER]

C 8

FPU 1 2 B±O

(

*1)

B±O

(

*1) B±RV3

VSV

(

FOR PRESSURE UP)

1342G2(

*1)

(

*1)

(

*2)

NE G2 G± G1(

*1)

B E11 , E12CA,E14ENGINE CONTROL MODULE(

ENGINE ECU)(

M/T) ONE BODY ASSEMBLY

EX. CALIFORNIA

R

BRB±R

1D 1415A

TAIL

1A 1010A

MIR±HTR

3C 53D 5

POWER SOURCESYSTEM(

SEE PAGE 64)

Page 92 of 307

92

ENGINE CONTROL (5S±FE A/T AND CALIFORNIA M/T)

CB

A

321

C

1 78

C

A 6

B 3

A 21 A10 C13 C26 B13A 5

EDI13G±R R±L R±L

G±R

G±R

Y±G G±WBR LG±B

B±Y

W W±B W±B

W±R

B±O

B±O

B

G±R B±O B±O W±R

R±W G±WY±G G±R

E1 TE2 TE1

WW

DATA LINK CONNECTOR 2

(

TDCL) FROM CE SYSTEM

(

SEE P

JUNCTION

CONNECTOR

MALFUNCTION INDICATOR

LAMP(

CHECK E NG INE

WARNING LIGHT)

[COMB. METER]

ACT ACA E01 E02 KNKENGINE CONTROL MODULE(

ENGINE AND ELECTRONIC CONTROLLED TRANSMISSION ECU)(

A/T)

ACT ACA

KNOCK

SENSOR A/C AMPLIFIER A1 0K1 E7 ,E8 ,E10

A

C9 , C10

J1D3

B

(

SHIELDED)

(

SHIELDED)

E16

O2

OXYGEN SENSOR

(

SUB)

1E15BR

BR

5TT

BR±B IP3 11 IP314

A 9 23

4 1

512IP3 2

SPEED

LGP G±B

G V±Y V±Y

R±L

R±L

SP1COMBINATION

METER C8

VEHICLE

SPEED SENSOR

(

SPEED SENSOR) V5

B

BR I13

G±R

G±R(

*5)

(

*4)

R±L

BR BR

1 2BR 7

R±W

ENG

BR

R±L

I18

R±L TO PARK/NEUTRAL POSITION

SW(

NEUTRAL START SW)

TO GENERATOR(

ALTERNATOR)

R±L

G±R(

*5)(

*4)

(

*3)

B E11 , E12CA,E14

ENGINE CONTROL MODULE(

ENGINE ECU)(

M/T) G±R

(

*

4)

1B 6 10A

GAUGE

1D6

3D 73D19

3D 18

3D 22

3D 10

3D 3

3D 12

POWER SOUR

AGE 64)

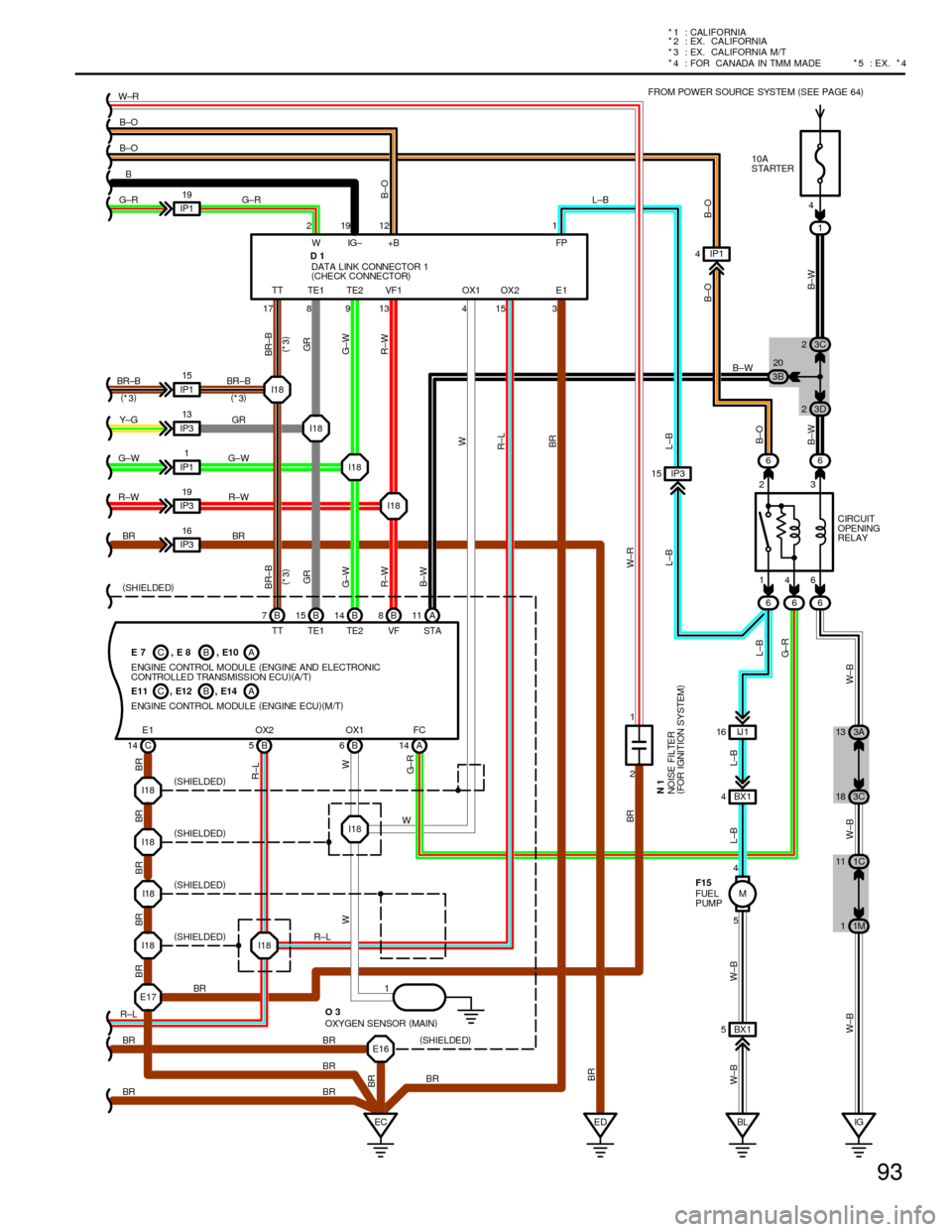

Page 93 of 307

93

* 1 : CALIFORNIA

*

2 : EX. CALIFORNIA

* 3 : EX. CALIFORNIA M/T

*

5 : EX.*

4 *

4 : FOR CANADA IN TMM MADE

CB

17 8 9 13 4 15

146 212 1

23 IP119

IP115

IP313

IP11

IP3196 61

666

M

5 4

E17I18 I18 I18

I18

I18I18 I18 I18 I18

IP3 15IP1 4

BX1 4IJ 1 16

BX1 5

BL IG 2 1

EC B 7B15 B14 B8A11

A

14 B5B6A143

BR±B

GR

G±W

R±W B±O

B±W B±WB±O L±B

G±R

W±B W±B W±BW±B W±B L±B L±BBRR±W G±WGR BR±B

L±BBR R±LW

B±O W

R±L

BRR±LBR BR BR BR

W

G±R

L±B

W±R

B±O

B±O

G±R

BR±B

Y±G

G±W

R±W

(

SHIELDED)G±RL±B

R±LW

BR BR±B

GR

G±W

R±WTT TE1 TE2 VF1 OX1 OX2 E1

B±O B±W

B±W

(

SHIELDED) BR (

SHIELDED) (

SHIELDED) (

SHIELDED)

W±R

D1

E1 OX2 OX1 FCTT TE1 TE2 VF STAW+B FP

E7 ,E8 ,E10

N1

F15

O3FROM POWER SOURCE SYSTEM(

SEE PAGE 64)

10A

STARTER

DATA LINK CONNECTOR 1

(

CHE CK CONNE CTOR)

CIRCUIT

OPENING

RELAY

NOISE FILTER

(

FOR IGNITION SYSTEM)

OXYGEN SENSOR(

MAIN)FUEL

PUMP ENGINE CONTROL MODULE(

ENGINE AND ELECTRONIC

CONTROLLED TRANSMISSION ECU)(

A/T)

C

E16 BR1 B

BR BRBR 19

IG±

BR BR

IP316

BR

BR

ED4

I18

BR(

SHIELDED) (

*3)(

*3)

(

*3) (

*3)

B E11 , E12CA,E14

ENGINE CONTROL MODULE(

ENGINE ECU)(

M/T)

3D 2

3C 2

3B20

3A 13

1C 113C 18

1M 1

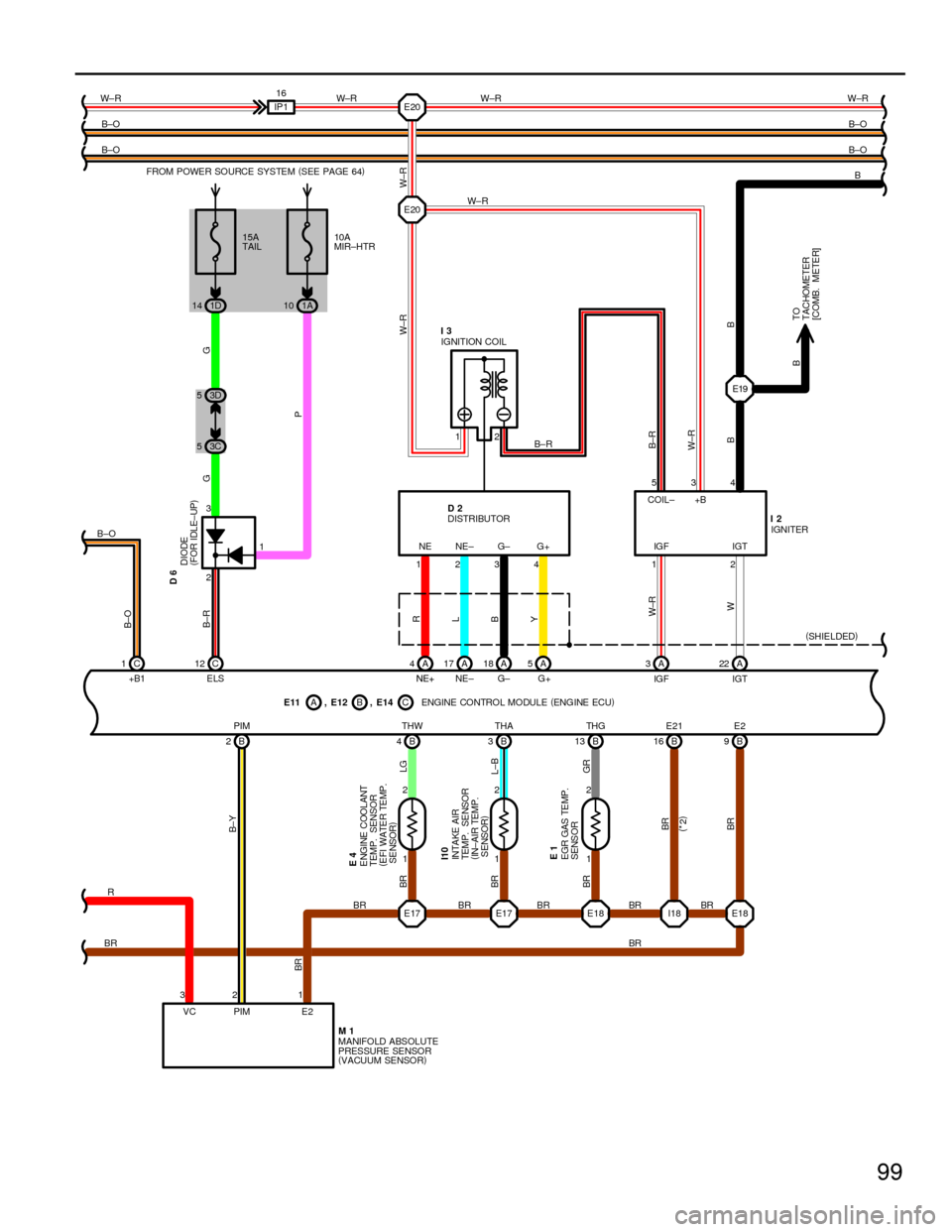

Page 99 of 307

99

AB

1 2

1 2

1 2 E20

E20

E18 E17 E171234

32 112

C 1A 5 A 18 A 17 A 4

B 2C

4B3B13 B9 B 16 IP116

PIM THW THA THG E2E21 NE NE± G± G+

(

SHIELDED) B B±O W±R W± R

B±O

B±O

R

BRBR BR BR BR

B±Y

BR

BR

BR

BR

BRGR L±BLGW±R W±R

R

L

B

Y

B±O

D6

I3

D2

E11 , E12 , E14 +B1W±R

NE+ NE± G± G+

VC E2PIM

M1

E4

I10

E1

MANIFOLD ABSOLUTE

PRESSURE SENSOR

(

VACUUM SENSOR)

ENGINE COOLANT

TEMP. SENSOR

(

EFI WATER TEMP.

SENSOR)

INTAKE AIR

TEM P. SE NSOR

(

IN±AIR TEMP.

SENSOR)

EGR GAS TEMP.

SENSOR

ENGINE CONTROL MODULE(

ENGINE ECU)

B

DIODE

(

FOR IDLE±UP)

IGNITION COIL

DISTRIBUTOR

I18 E18

BR

BRBR 2 3

C 12

B±R G G

ELS FRO E 64)

1

P

E19

A 3A22

W±R

WB±R

W±R

BB

B

W± R

B± R

12 534

COIL± +B

IG F IGT

IG F IGTIGNITER I2

TO

TACHOMETER

[COMB. METER]

W±R

(

*

2)B±O

B±O

NE+

1D 1415A

TAIL

1A 1010A

MIR±HTR

3C 53D 5

M POWER SOURCE SYSTEM(

SEE PAG

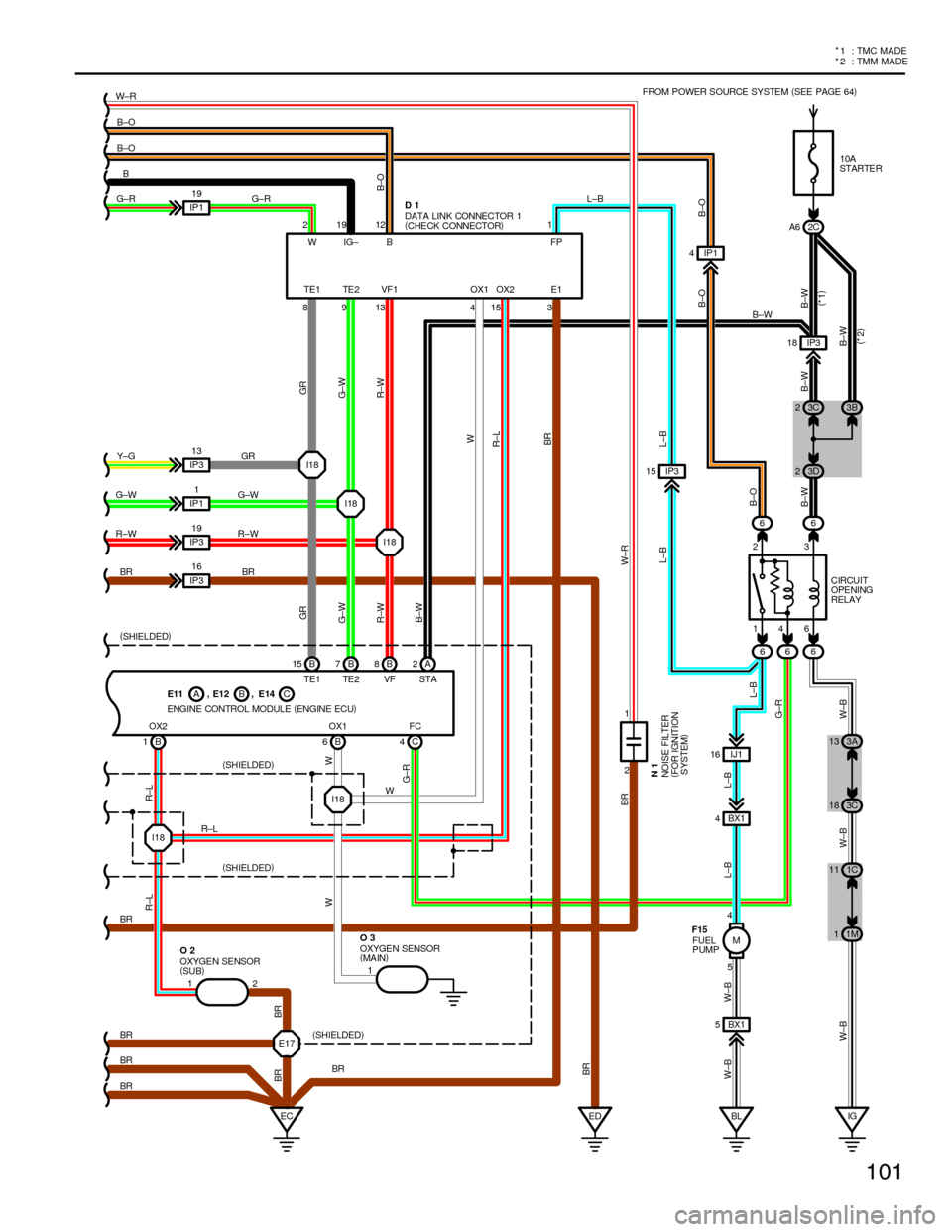

Page 101 of 307

101

* 2 : TMM MADE *

1:TMCMADE

AB

8913 415

146 212 1

23 IP313

IP11

IP3196 62C A6

666

M

5 4 I18

I18I18 I18 I18

IP3 15IP1 4

BX1 4IJ1 16IP3 18

BX1 5

BL IG 2 1

ECB 15 B7B8A2

C

B 1B6C43

GR

G±W

R±W B±O

B±W B±W B±WB±O L±B

G±R

W±B W±B W±BW±B W±B L±B L±BBRR±W G±WGR

L±BBR R±LW

B±O W BRR±L

W

G±R

L±B

W±R

B±O

B±O

G±R

Y±G

G±W

R±W

(

SHIELDED)G±RL±B

R±LW

BR

BR GR

G±W

R±WTE1 TE2 VF1 OX1 OX2 E1

B±O B±W

W±RD1

OX2 OX1 FCTE1 TE2 VF STAWB FP

E11 , E12 , E14

N1

F15

O3

O2FROM POWER SOURCE SYSTEM(

SEE PAGE 64)

10A

STARTER

DATA LINK CONNECTOR 1

(

CHECK CONNECTOR)

CIRCUIT

OPENING

RELAY

NOISE FILTER

(

FOR I GNITI ON

SYSTEM)

OXYGEN SENSOR

(

SUB)OXYGEN SENSOR

(

MAIN)FUEL

PUMP ENGINE CONTROL MODULE(

ENGINE ECU) IG± 19 B

BR(

SHIELDED) IP119

ED 2 11 IP316

BR BR(

SHIELDED)

(

SHIELDED)

R±L

BR BR

BR

BR

B±W

(

*2)(

*1)

B±W

E17

3C 2

3D 23B

3A 13

3C 18

1C 11

1M 1

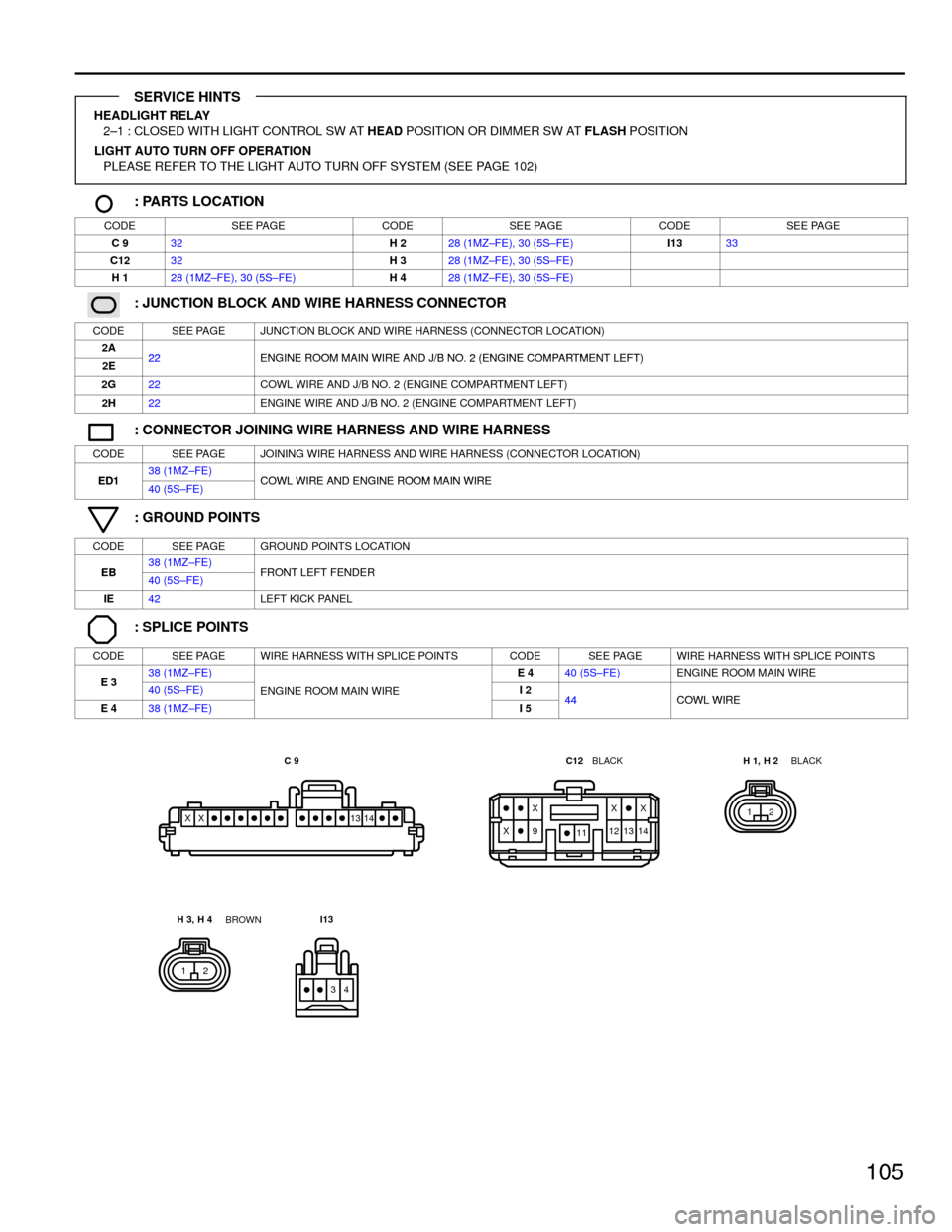

Page 105 of 307

105

HEADLIGHT RELAY

2±1 : CLOSED WITH LIGHT CONTROL SW AT HEAD POSITION OR DIMMER SW AT FLASH POSITION

LIGHT AUTO TURN OFF OPERATION

PLEASE REFER TO THE LIGHT AUTO TURN OFF SYSTEM (SEE PAGE 102)

: PARTS LOCATION

CODESEE PAGECODESEE PAGECODESEE PAGE

C 932H 228 (1MZ±FE), 30 (5S±FE)I1333

C1232H 328 (1MZ±FE), 30 (5S±FE)

H 128 (1MZ±FE), 30 (5S±FE)H 428 (1MZ±FE), 30 (5S±FE)

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODESEE PAGEJUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

2A22ENGINE ROOM MAIN WIRE AND J/B NO 2 (ENGINE COMPARTMENT LEFT)2E22ENGINE ROOM MAIN WIRE AND J/B NO. 2 (ENGINE COMPARTMENT LEFT)

2G22COWL WIRE AND J/B NO. 2 (ENGINE COMPARTMENT LEFT)

2H22ENGINE WIRE AND J/B NO. 2 (ENGINE COMPARTMENT LEFT)

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CODESEE PAGEJOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

ED138 (1MZ±FE)COWL WIRE AND ENGINE ROOM MAIN WIREED140 (5S±FE)COWL WIRE AND ENGINE ROOM MAIN WIRE

: GROUND POINTS

CODESEE PAGEGROUND POINTS LOCATION

EB38 (1MZ±FE)FRONT LEFT FENDEREB40 (5S±FE)FRONT LEFT FENDER

IE42LEFT KICK PANEL

: SPLICE POINTS

CODESEE PAGEWIRE HARNESS WITH SPLICE POINTSCODESEE PAGEWIRE HARNESS WITH SPLICE POINTS

E338 (1MZ±FE)E 440 (5S±FE)ENGINE ROOM MAIN WIREE 340 (5S±FE)ENGINE ROOM MAIN WIREI 244COWL WIREE 438 (1MZ±FE)

ENGINE ROOM MAIN WIRE

I 544COWL WIRE

X X131412

12

34 C9 C12 H1,H2

H3,H4 I13BLACK BLACK

BROWNXXX

X9

1112 13 14

SERVICE HINTS

Page 107 of 307

107

55 5

IG 11ED1 8

II1 4A 11 8 18 1332

2171

AEC16

DA YTIME

RUNNING LIGHT

RE LA Y NO. 2 W

B

WB

WBR±LW

W±B

R±LR R± R±L

G±R

R Y

R±W R±W

R±W R±W

R±Y R±Y

W±B W±B W±BTO GE NE RATOR

(

ALTERNATOR)

ºLº

FROM

COMBINATION METER

DAYTIME RUNNING

LIGHT RELAY(

MAIN)

JUNCTION

CONNE CTOR

PARKING

BRAKE SW PARKING

BRAKE SW

(

1MZ±FE)

D4

P3 P2

J1 (

5S±FE)

G±R

W±B

1B 81E 4

TA I LL I GHT

RE LA Y

23 151B 710A

GAUGE

L

3A 183A 17

3C 8 3D 83A 103C 18

1M 13A 12

1C 11

FROM POWER SOURCE

SYSTEM(

SEEPAGE64)

Page 109 of 307

109

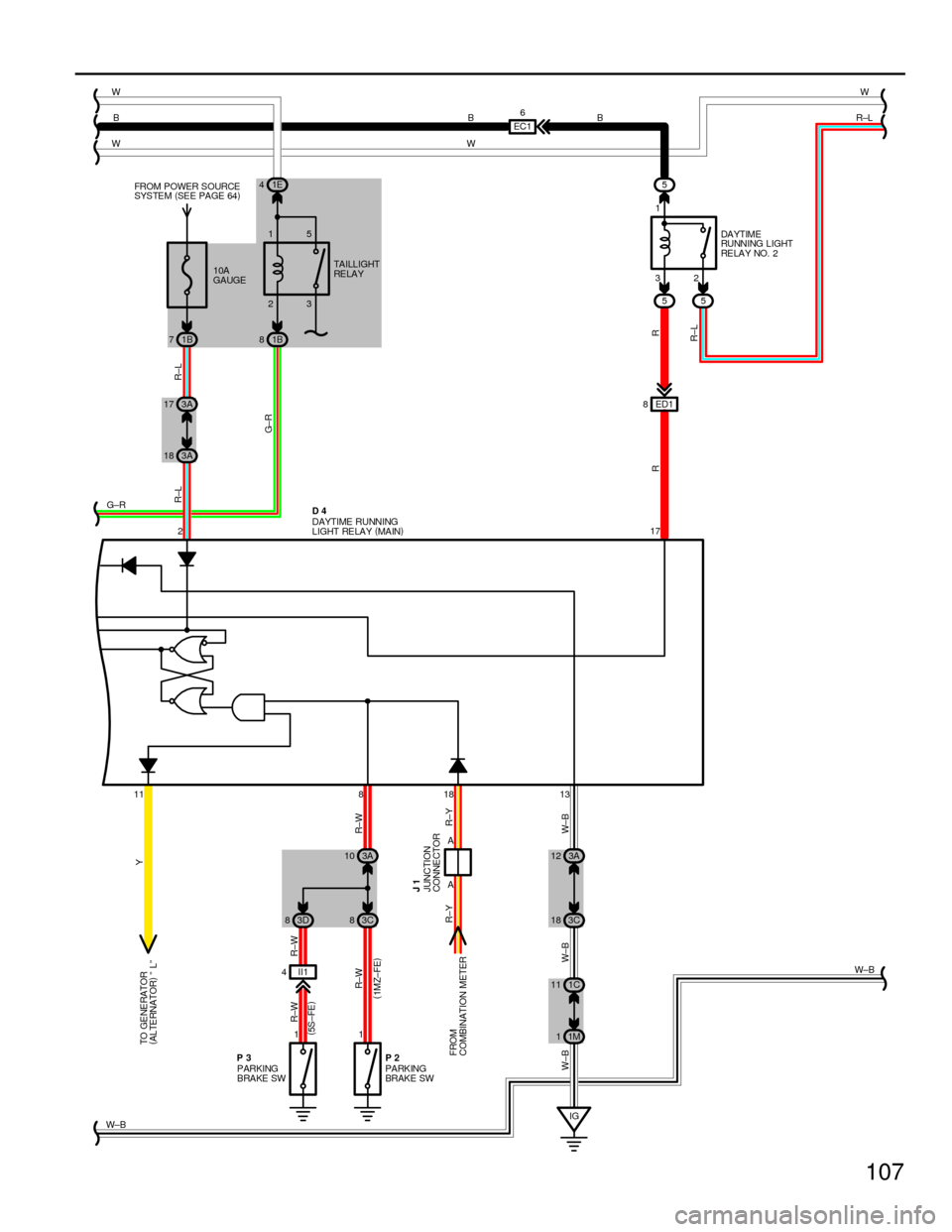

CURRENT FROM THE BATTERY IS ALWAYS FLOWING FROM THE FL MAIN " HEADLIGHT RELAY (COIL SIDE) " TERMINAL 5 OF THE

DAYTIME RUNNING LIGHT RELAY (MAIN) AND TERMINAL 14 OF THE DIMMER SW, HEADLIGHT RELAY (COIL SIDE) " TERMINAL 3 OF

THE INTEGRATION RELAY " TERMINAL 4 " TERMINAL 13 OF THE LIGHT CONTROL SW, FL MAIN " DAYTIME RUNNING LIGHT

RELAY NO. 2 (COIL SIDE) " TERMINAL 17 OF THE DAYTIME RUNNING LIGHT RELAY.

1. DAYTIME RUNNING LIGHT OPERATION

WHEN THE ENGINE IS STARTED, VOLTAGE GENERATED AT TERMINAL L OF THE GENERATOR (ALTERNATOR) IS APPLIED TO

TERMINAL 11 OF THE DAYTIME RUNNING LIGHT RELAY (MAIN).

IF THE PARKING BRAKE LEVER IS PULLED UP (PARKING BRAKE SW ON) AT THIS TIME, THE RELAY IS NOT ENERGIZED, SO THE

DAYTIME RUNNING LIGHT SYSTEM DOES NOT OPERATE. IF THE PARKING BRAKE LEVER IS RELEASED (PARKING BRAKE LEVER

SW OFF), THE SIGNAL IS INPUT TO TERMINAL 8 OF THE RELAY. THIS ACTIVATES THE RELAY ALSO, CURRENT FROM FL MAIN

FLOWES TO DAYTIME RUNNING LIGHT RELAY NO. 2 (POINT SIDE) " HEAD (UPR±LH) FUSE " TERMINAL 1 OF THE HEAD LH±HI "

TERMINAL 2 " TERMINAL 2 OF THE HEAD RH±HI " TERMINAL 1 " TERMINAL 4 OF THE DAYTIME RUNNING LIGHT RELAY NO. 3 "

TERMINAL 2 " TO GROUND, SO BOTH TAIL AND HEADLIGHT UP.

THIS IS HOW THE DAYTIME RUNNING LIGHT SYSTEM OPERATES. ONCE THE DAYTIME RUNNING LIGHT SYSTEM OPERATES AND

HEAD HAVE LIGHT UP, HEAD REMAIN ON EVEN IF THE PARKING BRAKE LEVER IS PULLED UP (PARKING BRAKE SW ON).

EVEN IF THE ENGINE STALLS WITH THE IGNITION SW ON AND THERE IS NO VOLTAGE FROM TERMINAL L OF THE GENERATOR

(ALTERNATOR), HEAD REMAIN ON. IF THE IGNITION SW IS THEN TURNED OFF, AND HEAD ARE TURNED OFF.

IF THE ENGINE IS STARTED WHILE THE PARKING BRAKE LEVER IS RELEASED (PARKING BRAKE SW OFF), THE DAYTIME RUNNING

LIGHT SYSTEM OPERATES AND TAIL, HEADLIGHT UP AS THE ENGINE STARTS.

2. HEADLIGHT OPERATION

*(WHEN THE LIGHT CONTROL SW AT THE HEAD POSITION)

WHEN THE LIGHT CONTROL SW IS SET TO HEAD POSITION, THE CURRENT FLOWING TO THE HEADLIGHT RELAY (COIL SIDE)

FLOWS TO TERMINAL 3 OF THE INTEGRATION RELAY " TERMINAL 4 " TERMINAL 13 OF THE LIGHT CONTROL SW " TERMINAL 11

" GROUND, TURNING THE HEADLIGHT RELAY ON.

THIS CAUSES THE CURRENT FLOWING TO THE HEADLIGHT RELAY (POINT SIDE) " DRL FUSE " DAYTIME RUNNING LIGHT RELAY

NO. 3 (COIL SIDE) AND DAYTIME RUNNING LIGHT RELAY NO. 4 (COIL SIDE) " GROUND, TURNING THE DAYTIME RUNNING LIGHT

RELAY NO. 3 AND NO. 4 ON. ALSO, CURRENT FROM THE HEADLIGHT RELAY (POINT SIDE) TO HEAD (LWR) FUSES " TERMINAL 1

OF THE HEADLIGHTS (LO) " TERMINAL 2 " GROUND, SO THE HEADLIGHTS (LO) LIGHT UP.

*(DIMMER SW AT FLASH POSITION)

WHEN THE DIMMER SW IS SET TO FLASH POSITION, CURRENT FLOWS FROM HEADLIGHT RELAY (COIL SIDE) " TERMINAL 14 OF

THE DIMMER SW " TERMINAL 9 " GROUND, TURNING THE HEADLIGHT RELAY ON. AT THE SAME TIME, SIGNALS ARE OUTPUT

FROM TERMINAL 12 AND TERMINAL 14 OF THE DIMMER SW TO TERMINAL 16 AND TERMINAL 5 OF THE DAYTIME RUNNING LIGHT

RELAY (MAIN), ACTIVATING THE DAYTIME RUNNING LIGHT RELAY (MAIN) AND ALSO THE DAYTIME RUNNING LIGHT RELAY NO. 2.

WHEN THE HEADLIGHT RELAY AND DAYTIME RUNNING LIGHT RELAY (MAIN) ARE ACTIVATED, THE HEADLIGHTS (LO AND HI) THEN

LIGHT UP.

*(DIMMER SW AT HIGH POSITION)

WHEN THE LIGHT CONTROL SW IS SET TO HEAD POSITION, A SIGNAL IS OUTPUT FROM TERMINAL 13 OF THE LIGHT CONTROL SW

" TERMINAL 4 OF THE INTEGRATION RELAY " TERMINAL 3 " TERMINAL 5 OF THE DAYTIME RUNNING LIGHT RELAY (MAIN).

WHEN THE DIMMER SW IS SET TO HIGH POSITION, A SIGNAL IS OUTPUT FROM TERMINAL 12 OF THE DIMMER SW TO TERMINAL 16

OF THE DAYTIME RUNNING LIGHT RELAY (MAIN). THESE SIGNALS ACTIVATE DAYTIME RUNNING LIGHT RELAY NO. 2, SO CURRENT

FLOWS FROM DAYTIME RUNNING LIGHT RELAY NO. 2 (POINT SIDE) " HEAD (UPR±LH) FUSE " TERMINAL 1 OF THE HEADLIGHT

LH±HI " TERMINAL 2 " DAYTIME RUNNING LIGHT RELAY NO. 4 (POINT SIDE) " GROUND, AND CURRENT ALSO SIMUTANEOUSLY

FLOWS FROM HEAD (UPR±RH) FUSE " DAYTIME RUNNING LIGHT RELAY NO. 3 (POINT SIDE) " TERMINAL 1 OF THE HEADLIGHT

RH±HI " TERMINAL 2 " DAYTIME RUNNING LIGHT RELAY NO. 4 (POINT SIDE), CAUSING THE HEADLIGHTS (HI SIDE) TO LIGHT UP.

D 4 DAYTIME RUNNING LIGHT RELAY (MAIN)

2±GROUND : APPROX. 12 VOLTS WITH THE IGNITION SW AT ON POSITION

15±GROUND : ALWAYS APPROX. 12 VOLTS

8±GROUND : CONTINUITY WITH THE PARKING BRAKE LEVER PULLED UP (PARKING BRAKE SW ON)

13±GROUND : ALWAYS CONTINUITY

SYSTEM OUTLINE

SERVICE HINTS