light TOYOTA CAMRY 1994 XV10 / 4.G Wiring Diagrams Manual Online

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1994, Model line: CAMRY, Model: TOYOTA CAMRY 1994 XV10 / 4.GPages: 307, PDF Size: 5.48 MB

Page 192 of 307

192

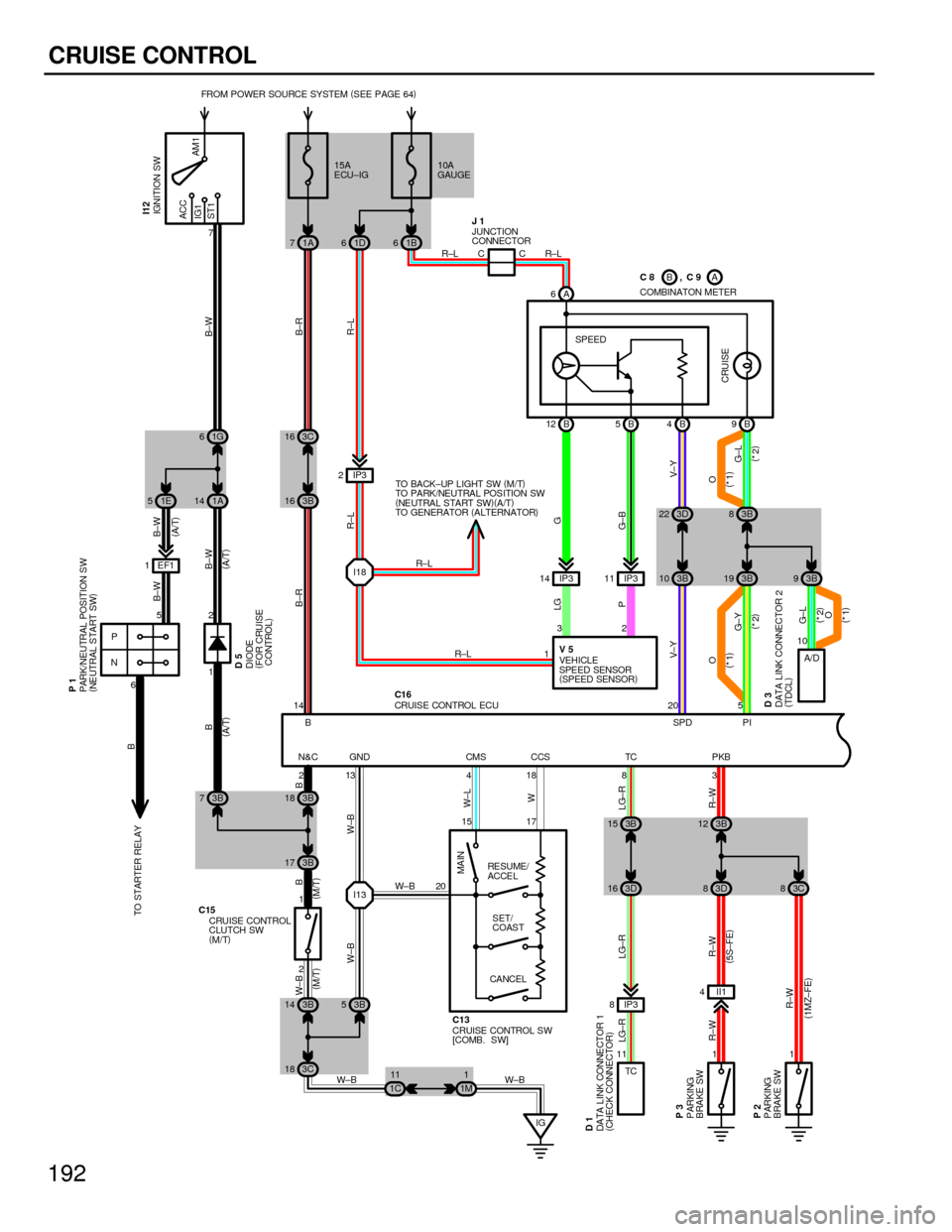

CRUISE CONTROL

B

ST1 IG1 ACC

AM1

7

IP3 8IP3 11

II1 4 2 1

1 1 213 41883

17 15

20 1420 510 2

13B 4 B 12 B5B9 A 6

1 2

IG CC

I13

11 R±L R±L

R±L

W±B

W±B W±B

B±R B±W

R±L B±W

B±R B

B

W±B

W±L

W

LG±R

R±W LG±R

R±W LG±R

R±W

R±WW±B

W±B

G±BG

V±Y

G±Y V±YP LG B

FROM POWER SOURCE SYSTEM(

SEEPAGE64)

10A

GAUGE

COMBINATON METER

DIODE

(

FOR CRUISE

CONTROL)VEHICLE

SPEED SENSOR

(

SPEED SENSOR)

DATA LINK CONNECTOR 2

(

TDCL)

A/D JUNCTION

CONNECTOR

CRUISE CONTROL

CLUTCH SW

(

M/T)

CRUISE CONTROL SW

[COMB. SW]

DA TA LINK CONNE CTOR 1

(

CHECK CONNECTOR)

PARKING

BRAKE SW

PARKING

BRAKE SWMAIN

CA NCELSET/

COAST RE SUME/

ACCEL N&C GND CMS CCS TC PKBBSPD PI

TC

IGNITION SW

P

N5

6EF1 1

B±W B±W

J1

P1

D5

C8 , C9

D3

V5A

PARK/NEUTRAL POSITION SW

(

NE UTRAL S TA RT SW)

(

A/T) B

TO STARTER RELAY

CRUIS E CONTROL ECU C16

C15

C13

D1

P3

P2

(

1MZ±FE)

SPEED

CRUISEI12

IP3 2

(

A/T)

(

5S±FE)IP3 14

(

A/T)

(

M/T) (

M/T)

R±L

TO BA CK ±UP LIGHT SW(

M/T)

TO PARK/NEUTRAL POSITION SW

(

NE UTRA L S TA RT SW)(

A/T)

TO GENERATOR(

ALTERNATOR)

R±L

I18

(

*2) O

(

*1)

G±L

(

*2) O

(

*1)

O

(

*1) G±L

(

*2)

1G 63C16

1A 14 3B16 1E 5

1A 71D61B6 15A

ECU±IG

3D 22 3B8

3B 10 3B19 3B9

3B 73B18

3B 17

3B 14 3B5

3C 18

1M1

1C11

3B 12

3D 83C83B 15

3D 16

Page 193 of 307

193

*

2:TMMMADE * 1 : TMC MADE

A

M 26 25 24 1211 23 22 9 1 15 16

3217 65A 17 B7

IP 3 17 IP15

IR1 9IR18IR17IR13IR12IR11

EB 4I23

10 FROM POWER SOURCE SYSTEM(

SEE PAGE 64)

VR3 VR2 VR1 MC MO

R±Y

W±B W±B IDL ECT OD STP+ BATT STP±

L

P±L L

V±R

Y±B

G±R

G±R G±R

G±W G±W G±W R±GR±BL L±B L±R L±R

L±B

L

R±B

R±G

R±Y

(

1MZ±FE)

(

5S±FE)

CRUISE CONTROL ECU

CRUIS E CONTROL ACTUATOR E NGINE CO NTROL MO DULE

(

ENGINE AND ELECTRONIC CONTROLLED

TRANSMISSION ECU)

A 32

C 12

C16

C2 IDL S2 OD1A 1B1

B

2B2

14 23 G±R

G±W

G±B

G±R

R±YG±B

NOISE FILTER

(

FOR STOP LIGHT)

STOP

LIGHT SW

N2 ,N3

S10

A

(

A/T) (

A/T)

(

A/T)L±W

(

1MZ±FE)

L

(

5S±FE)

B E7 ,E10

AC,E8(

A/T)

E14C(

M/T)

1A 12 1M3 15A

STOP

1A 151M 6

3B 133C 19

2E8

2B6

Page 196 of 307

196

CRUISE CONTROL

CURRENT IS APPLIED AT ALL TIMES THROUGH STOP FUSE TO TERMINAL 1 OF THE CRUISE CONTROL ECU AND TERMINAL 2 OF

STOP LIGHT SW, AND ALSO THROUGH THE STOP FUSE TO TERMINAL 15 OF CRUISE CONTROL ECU.

WITH THE IGNITION SW TURNED TO ON, THE CURRENT FLOWS THROUGH GAUGE FUSE TO TERMINAL (A) 6 OF COMBINATION

METER AND THE CURRENT THROUGH ECU±IG FUSE FLOWS TO TERMINAL 14 OF CRUISE CONTROL ECU.

WHEN THE IGNITION SW IS ON AND THE CRUISE CONTROL MAIN SW IS TURNED ON, A SIGNAL IS INPUT FROM TERMINAL 15 OF

CRUISE CONTROL MAIN SW TO TERMINAL 4 OF CRUISE CONTROL ECU. AS A RESULT, THE CRUISE CONTROL ECU FUNCTIONS

AND THE CURRENT TO TERMINAL 14 OF CRUISE CONTROL ECU TO TERMINAL 13 OF CRUISE CONTROL ECU " GROUND, AND

THE CRUISE CONTROL SYSTEM IS IN A CONDITION READY FOR OPERATION.

AT THE SAME TIME, THE CURRENT THROUGH THE GAUGE FUSE FLOWS FROM TERMINAL (A) 6 OF CRUISE CONTROL INDICATOR

LIGHT " TERMINAL (B) 9 " TERMINAL 5 OF CRUISE CONTROL ECU " TERMINAL 13 " TO GROUND, CAUSING THE CRUISE

CONTROL INDICATOR LIGHT TO LIGHT UP, INDICATING THAT THE CRUISE CONTROL IS READY FOR OPERATION.

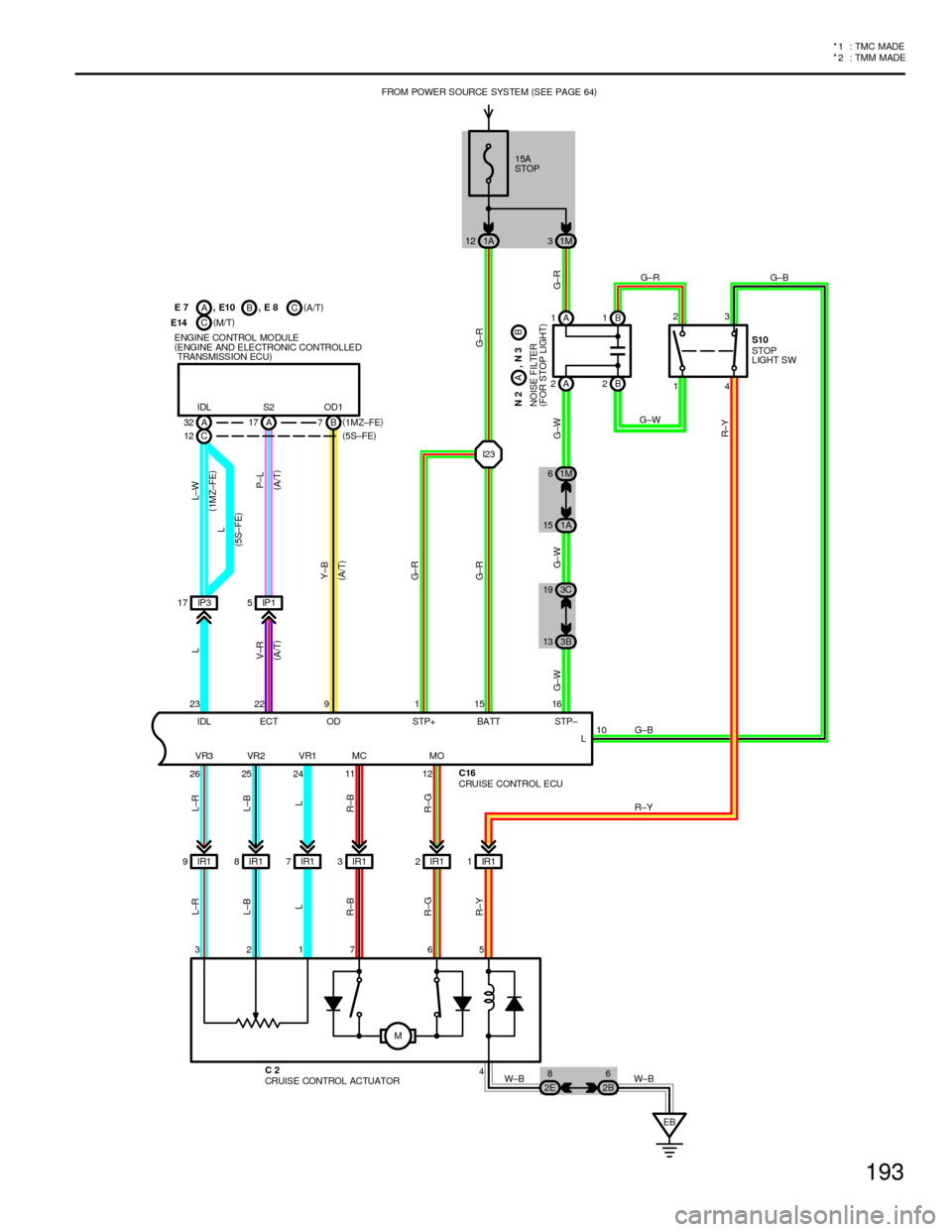

1. SET OPERATION

WHEN THE CRUISE CONTROL MAIN SW IS TURNED ON AND THE SET SW IS TURNED ON WITH THE VEHICLE SPEED WITHIN THE

SET LIMIT (APPROX. 40 KM/H, 25 MPH TO 200 KM/H, 124 MPH), A SIGNAL IS INPUT TO TERMINAL 18 OF THE CRUISE CONTROL ECU

AND THE VEHICLE SPEED AT THE TIME THE SET SW IS RELEASED IS MEMORIZED IN THE ECU AS THE SET SPEED.

2. SET SPEED CONTROL

DURING CRUISE CONTROL DRIVING, THE ECU COMPARES THE SET SPEED MEMORIZED IN THE ECU WITH THE ACTUAL VEHICLE

SPEED INPUT INTO TERMINAL 20 OF THE CRUISE CONTROL ECU FROM THE VEHICLE SPEED SENSOR (SPEED SENSOR), AND

CONTROLS THE CRUISE CONTROL ACTUATOR TO MAINTAIN THE SET SPEED.

WHEN THE ACTUAL SPEED IS LOWER THAN THE SET SPEED, THE ECU CAUSES THE CURRENT TO THE CRUISE CONTROL

ACTUATOR TO FLOW FROM TERMINAL 12" TERMINAL 6 OF CRUISE CONTROL ACTUATOR "TERMINAL 7 "TERMINAL 11 OF

CRUISE CONTROL ECU. AS A RESULT, THE MOTOR IN THE CRUISE CONTROL ACTUATOR IS ROTATED TO OPEN THE THROTTLE

VALVE AND THE THROTTLE CABLE IS PULLED TO INCREASE THE VEHICLE SPEED. WHEN THE ACTUAL DRIVING SPEED IS HIGHER

THAN THE SET SPEED, THE CURRENT TO CRUISE CONTROL ACTUATOR FLOWS FROM TERMINAL 11 OF ECU "TERMINAL 7 OF

CRUISE CONTROL ACTUATOR "TERMINAL 6 "TERMINAL 12 OF CRUISE CONTROL ECU.

THIS CAUSES THE MOTOR IN THE CRUISE CONTROL ACTUATOR TO ROTATE TO CLOSE THE THROTTLE VALVE AND RETURN THE

THROTTLE CABLE TO DECREASE THE VEHICLE SPEED.

3. COAST CONTROL

DURING THE CRUISE CONTROL DRIVING, WHILE THE COAST SW IS ON, THE CRUISE CONTROL ACTUATOR RETURNS THE

THROTTLE CABLE TO CLOSE THE THROTTLE VALVE AND DECREASE THE DRIVING SPEED. THE VEHICLE SPEED WHEN THE COAST

SW IS TURNED OFF IS MEMORIZED AND THE VEHICLE CONTINUES AT THE NEW SET SPEED.

4. ACCEL CONTROL

DURING CRUISE CONTROL DRIVING, WHILE THE ACCEL SW IS TURNED ON, THE CRUISE CONTROL ACTUATOR PULLS THE

THROTTLE CABLE TO OPEN THE THROTTLE VALVE AND INCREASE THE DRIVING SPEED.

THE VEHICLE SPEED WHEN THE ACCEL SW IS TURNED OFF IS MEMORIZED AND THE VEHICLE CONTINUES AT THE NEW SET

SPEED.

5. RESUME CONTROL

UNLESS THE VEHICLE SPEED FALLS BELOW THE MINIMUM SPEED LIMIT (APPROX. 40 KM/H, 25 MPH) AFTER CANCELING THE SET

SPEED BY THE CANCEL SW, PUSHING THE RESUME SW WILL CAUSE THE VEHICLE TO RESUME THE SPEED SET BEFORE

CANCELLATION.

6. MANUAL CANCEL MECHANISM

IF ANY OF THE FOLLOWING OPERATIONS OCCURS DURING CRUISE CONTROL OPERATION, CURRENT FLOW TO MAGNETIC

CLUTCH OF THE ACTUATOR IS CUT TURNS OFF AND THE MOTOR ROTATES TO CLOSE THE THROTTLE VALVE AND THE CRUISE

CONTROL IS RELEASED.

*PLACING THE SHIFT LEVER IN ªNº POSITION (PARK/NEUTRAL POSITION SW (NEUTRAL START SW ON). ªSIGNAL INPUT TO

TERMINAL 2 OF ECUº (A/T)

*DEPRESSING THE CLUTCH PEDAL (CLUCH SW ON). ªSIGNAL INPUT TO TERMINAL 2 OF THE ECUº (M/T)

*DEPRESSING THE BRAKE PEDAL (STOP LIGHT SW ON). ªSIGNAL INPUT TO TERMINAL 16 OF ECUº

*PUSH THE CANCEL SW (CANCEL SW ON). ªSIGNAL INPUT TO TERMINAL 18 OF ECUº

*DEPRESSING THE PARKING BRAKE PEDAL (PARKING BRAKE SW ON). ªSIGNAL INPUT TO TERMINAL 3 OF ECUº (3VZ±FE)

*PULLING THE PARKING BRAKE LEVER (PARKING BRAKE SW ON). ªSIGNAL INPUT TO TERMINAL 3 OF THE ECUº (5S±FE)

SYSTEM OUTLINE

Page 198 of 307

198

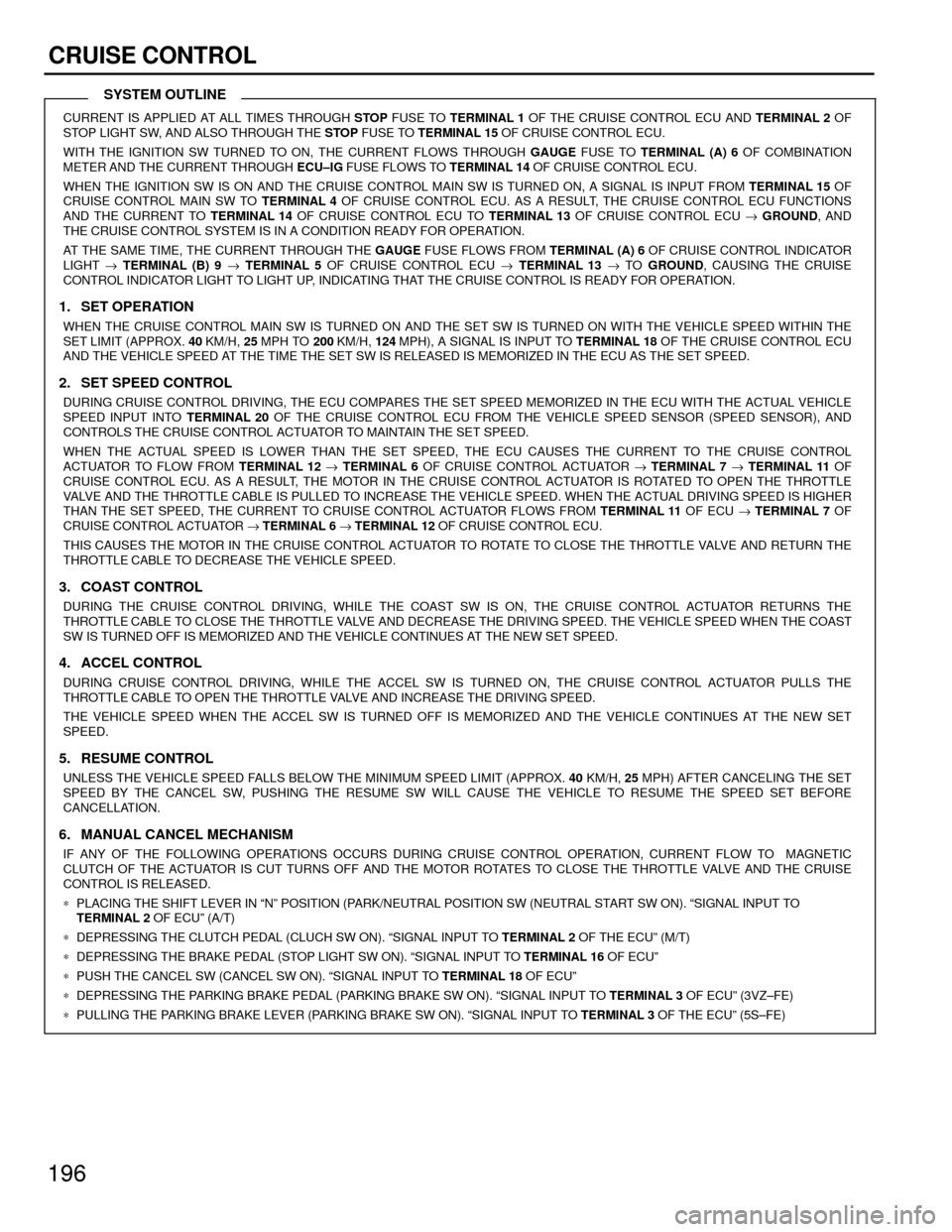

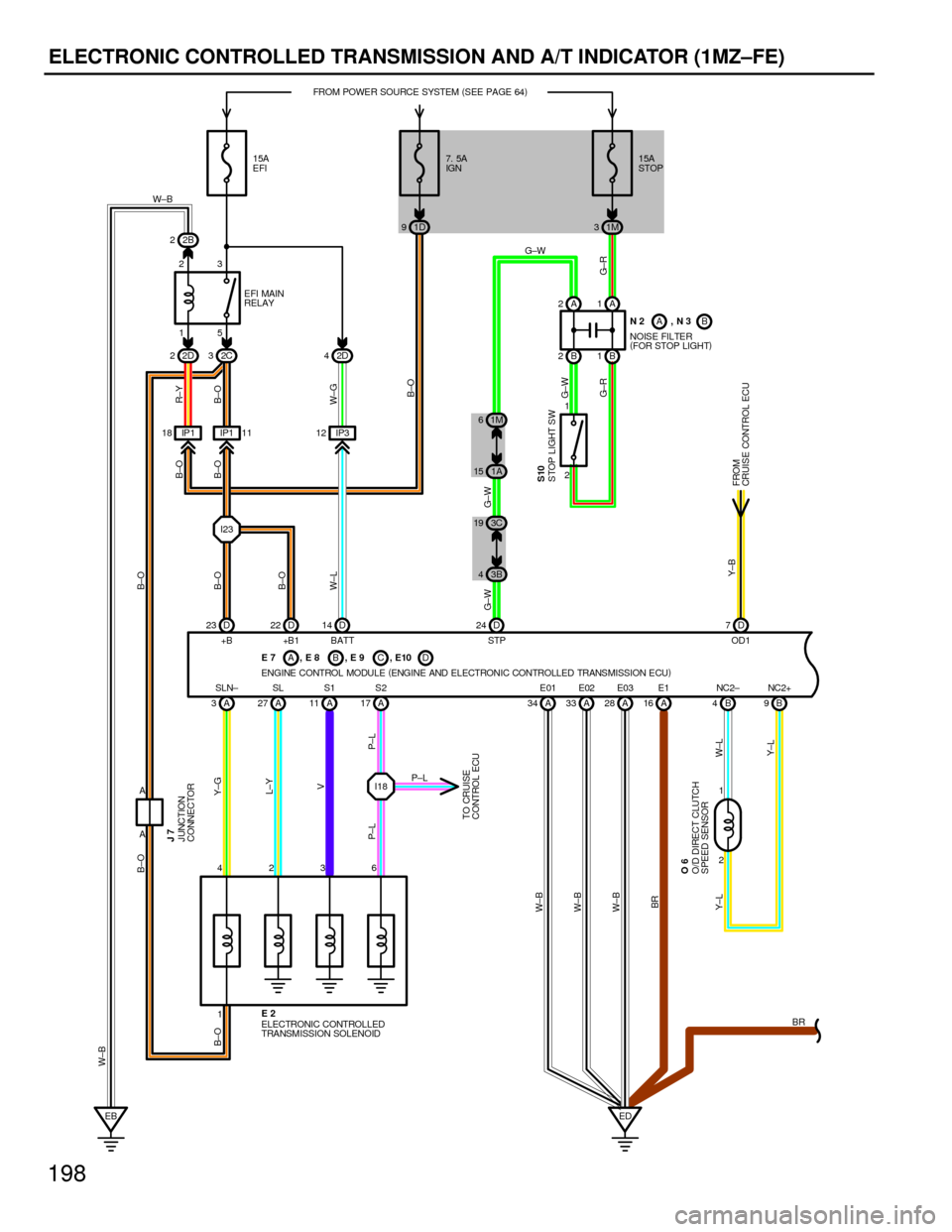

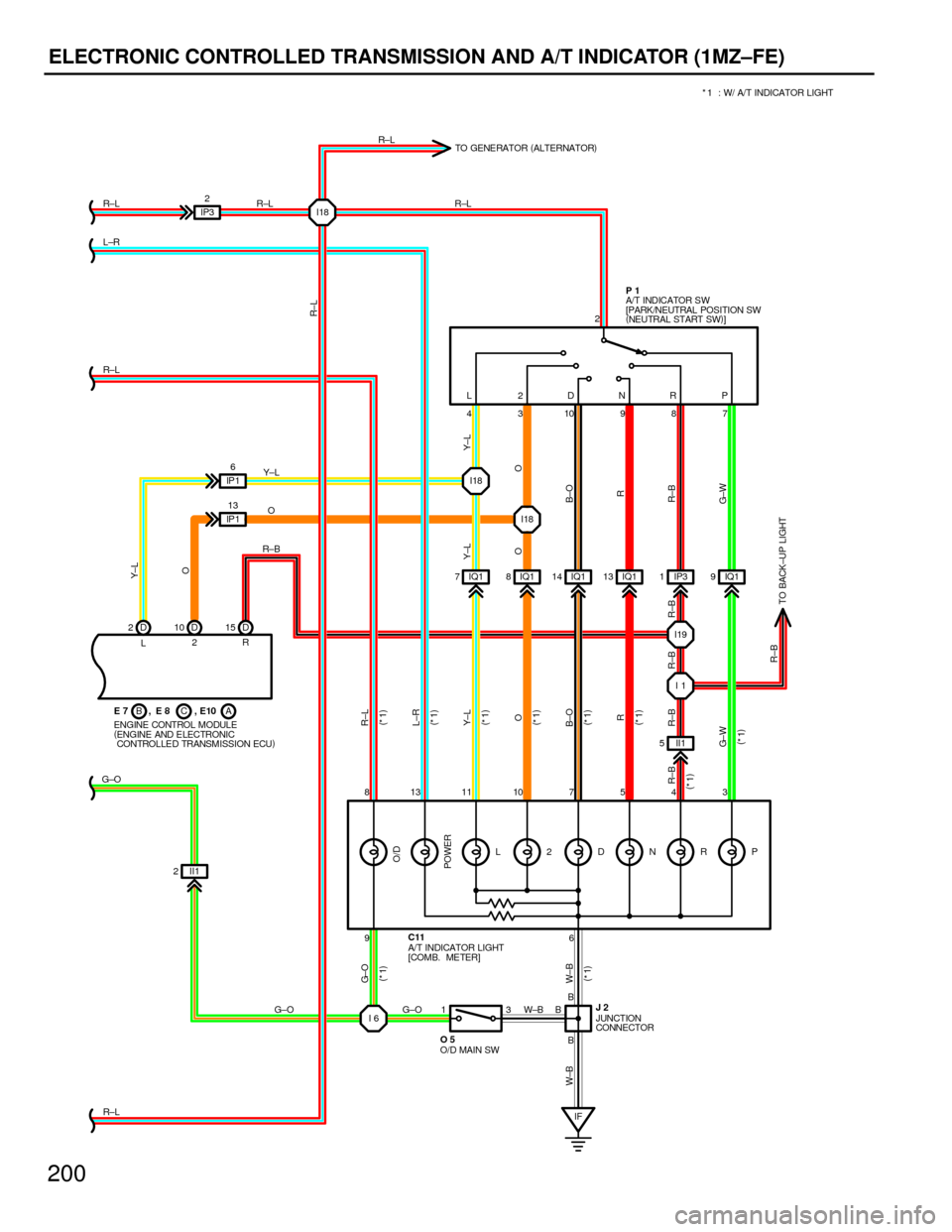

ELECTRONIC CONTROLLED TRANSMISSION AND A/T INDICATOR (1MZ±FE)

A

2D 22C32D4 2B 2

I23

I18

2 1

EBED IP 1 18 IP1 11 IP312

D 7 D 24 D 14 D 22 D 23

A 27 A11 A17 A33 B4

26FROM POWER SOURCE SYSTEM(

SEE PAGE 64)

P±L P±LV L±Y W±B

B±O

B±OB±O

W±L

G±W G±W

Y±BW±GB±OR±Y

W±L Y±L W±BB±O

15A

EFI

SL S1 S2 E02 NC2± +B +B1 BATT STP OD1EFI MAIN

RELAY

FROM

CRUIS E CONTROL ECU

BR P±L

TO CRUISE

CONTROL ECU

15 23

O/D DIRECT CLUTCH

SPEED SENSOR O6STOP LIGHT SW

G±R

G±W

2 1

S10

B 1 A 2

B 2B1NOISE FILTER

(

FOR STOP LIGHT) N2 ,N3 A

G±W

G±R

B E7 ,E8AC,E9

ENGINE CONTROL MODULE(

ENGINE AND ELECTRONIC CONTROLLED TRANSMISSION ECU)

B±O

D ,E10

A

3

ELECTRONIC CONTROLLED

TRANSMISSION SOLENOID E2 4 A

1

J UNCTION

CONNECTOR J7

A 3SLN±

Y±GB±O

B±OB±O

W±B

W±B

BR

A 34E01

A 28E03

A 16E1

B 9NC2+

Y±L

W±B

1D 91M3 7. 5A

IGN15A

STOP

1A 15

3B 43C 191M 6

Page 200 of 307

200

ELECTRONIC CONTROLLED TRANSMISSION AND A/T INDICATOR (1MZ±FE)

BC

L 2DNR P

43109872

I6I18

I18

IQ1 7IQ18IQ114 IQ113 IP31IQ19

II1 5

3 1 II1 2

B B 81311107543 D 2D10 D15

6

B

IF 9 R±L

L±R

R±L

G±O

G±O G±O W±B R±BO Y±LR±L

W±B W±BG± O

R±B R±B

G± WR B±OO Y±L L±R

R±L

Y±L

OY±L

O

B±O

R

R±B

G±W

L2R

ENGINE CONTROL MODULE

(

ENGINE AND ELECTRONIC

CONTROLLED TRANSMISSION ECU)A/T INDICATOR SW

[PARK/NEUTRAL POSITION SW

(

NEUTRAL START SW)

]

JUNCTION

CONNECTOR

O/DMAINSW A/T INDICATOR LIGHT

[COMB. METER]

O/D

POWERL2DNRP I18 IP32

R±L

E7 , E8 ,E10AP1

C11

O5J2

R±L

R±L

(

*1) (

*1)

I1

R±B

TO BACK±UP LIGHT R±B (

*1) (

*1) (

*1) (

*1) (

*1) (

*1)

(

*1) (

*1)

* 1 : W/ A/T INDICATOR LIGHT

R±L

TO GENE RATOR(

ALTERNATOR)

IP 16

O Y±L

I19

R±B

IP 113

Page 201 of 307

201

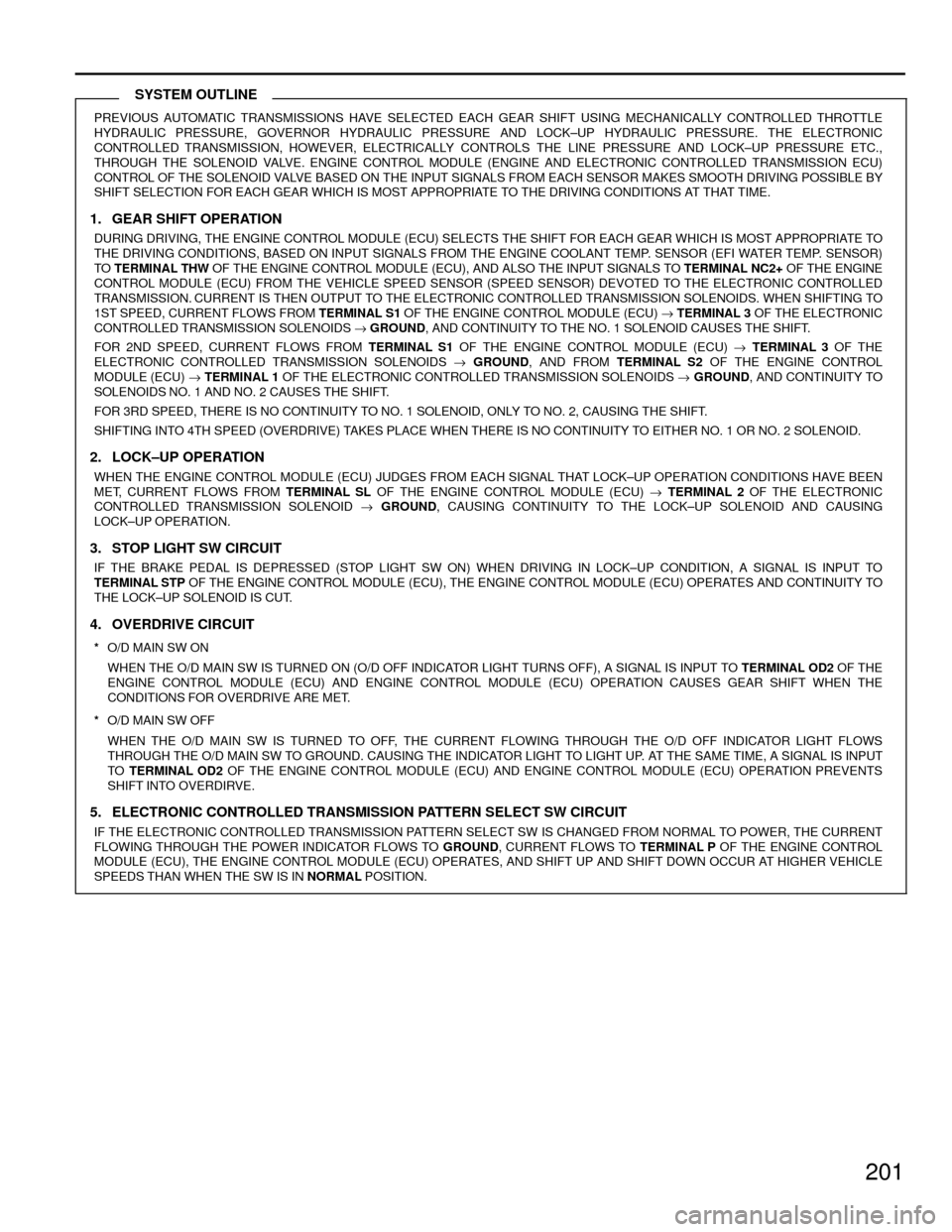

PREVIOUS AUTOMATIC TRANSMISSIONS HAVE SELECTED EACH GEAR SHIFT USING MECHANICALLY CONTROLLED THROTTLE

HYDRAULIC PRESSURE, GOVERNOR HYDRAULIC PRESSURE AND LOCK±UP HYDRAULIC PRESSURE. THE ELECTRONIC

CONTROLLED TRANSMISSION, HOWEVER, ELECTRICALLY CONTROLS THE LINE PRESSURE AND LOCK±UP PRESSURE ETC.,

THROUGH THE SOLENOID VALVE. ENGINE CONTROL MODULE (ENGINE AND ELECTRONIC CONTROLLED TRANSMISSION ECU)

CONTROL OF THE SOLENOID VALVE BASED ON THE INPUT SIGNALS FROM EACH SENSOR MAKES SMOOTH DRIVING POSSIBLE BY

SHIFT SELECTION FOR EACH GEAR WHICH IS MOST APPROPRIATE TO THE DRIVING CONDITIONS AT THAT TIME.

1. GEAR SHIFT OPERATION

DURING DRIVING, THE ENGINE CONTROL MODULE (ECU) SELECTS THE SHIFT FOR EACH GEAR WHICH IS MOST APPROPRIATE TO

THE DRIVING CONDITIONS, BASED ON INPUT SIGNALS FROM THE ENGINE COOLANT TEMP. SENSOR (EFI WATER TEMP. SENSOR)

TO TERMINAL THW OF THE ENGINE CONTROL MODULE (ECU), AND ALSO THE INPUT SIGNALS TO TERMINAL NC2+ OF THE ENGINE

CONTROL MODULE (ECU) FROM THE VEHICLE SPEED SENSOR (SPEED SENSOR) DEVOTED TO THE ELECTRONIC CONTROLLED

TRANSMISSION. CURRENT IS THEN OUTPUT TO THE ELECTRONIC CONTROLLED TRANSMISSION SOLENOIDS. WHEN SHIFTING TO

1ST SPEED, CURRENT FLOWS FROM TERMINAL S1 OF THE ENGINE CONTROL MODULE (ECU) " TERMINAL 3 OF THE ELECTRONIC

CONTROLLED TRANSMISSION SOLENOIDS " GROUND, AND CONTINUITY TO THE NO. 1 SOLENOID CAUSES THE SHIFT.

FOR 2ND SPEED, CURRENT FLOWS FROM TERMINAL S1 OF THE ENGINE CONTROL MODULE (ECU) " TERMINAL 3 OF THE

ELECTRONIC CONTROLLED TRANSMISSION SOLENOIDS " GROUND, AND FROM TERMINAL S2 OF THE ENGINE CONTROL

MODULE (ECU) " TERMINAL 1 OF THE ELECTRONIC CONTROLLED TRANSMISSION SOLENOIDS " GROUND, AND CONTINUITY TO

SOLENOIDS NO. 1 AND NO. 2 CAUSES THE SHIFT.

FOR 3RD SPEED, THERE IS NO CONTINUITY TO NO. 1 SOLENOID, ONLY TO NO. 2, CAUSING THE SHIFT.

SHIFTING INTO 4TH SPEED (OVERDRIVE) TAKES PLACE WHEN THERE IS NO CONTINUITY TO EITHER NO. 1 OR NO. 2 SOLENOID.

2. LOCK±UP OPERATION

WHEN THE ENGINE CONTROL MODULE (ECU) JUDGES FROM EACH SIGNAL THAT LOCK±UP OPERATION CONDITIONS HAVE BEEN

MET, CURRENT FLOWS FROM TERMINAL SL OF THE ENGINE CONTROL MODULE (ECU) " TERMINAL 2 OF THE ELECTRONIC

CONTROLLED TRANSMISSION SOLENOID " GROUND, CAUSING CONTINUITY TO THE LOCK±UP SOLENOID AND CAUSING

LOCK±UP OPERATION.

3. STOP LIGHT SW CIRCUIT

IF THE BRAKE PEDAL IS DEPRESSED (STOP LIGHT SW ON) WHEN DRIVING IN LOCK±UP CONDITION, A SIGNAL IS INPUT TO

TERMINAL STP OF THE ENGINE CONTROL MODULE (ECU), THE ENGINE CONTROL MODULE (ECU) OPERATES AND CONTINUITY TO

THE LOCK±UP SOLENOID IS CUT.

4. OVERDRIVE CIRCUIT

*O/D MAIN SW ON

WHEN THE O/D MAIN SW IS TURNED ON (O/D OFF INDICATOR LIGHT TURNS OFF), A SIGNAL IS INPUT TO TERMINAL OD2 OF THE

ENGINE CONTROL MODULE (ECU) AND ENGINE CONTROL MODULE (ECU) OPERATION CAUSES GEAR SHIFT WHEN THE

CONDITIONS FOR OVERDRIVE ARE MET.

*O/D MAIN SW OFF

WHEN THE O/D MAIN SW IS TURNED TO OFF, THE CURRENT FLOWING THROUGH THE O/D OFF INDICATOR LIGHT FLOWS

THROUGH THE O/D MAIN SW TO GROUND. CAUSING THE INDICATOR LIGHT TO LIGHT UP. AT THE SAME TIME, A SIGNAL IS INPUT

TO TERMINAL OD2 OF THE ENGINE CONTROL MODULE (ECU) AND ENGINE CONTROL MODULE (ECU) OPERATION PREVENTS

SHIFT INTO OVERDIRVE.

5. ELECTRONIC CONTROLLED TRANSMISSION PATTERN SELECT SW CIRCUIT

IF THE ELECTRONIC CONTROLLED TRANSMISSION PATTERN SELECT SW IS CHANGED FROM NORMAL TO POWER, THE CURRENT

FLOWING THROUGH THE POWER INDICATOR FLOWS TO GROUND, CURRENT FLOWS TO TERMINAL P OF THE ENGINE CONTROL

MODULE (ECU), THE ENGINE CONTROL MODULE (ECU) OPERATES, AND SHIFT UP AND SHIFT DOWN OCCUR AT HIGHER VEHICLE

SPEEDS THAN WHEN THE SW IS IN NORMAL POSITION.

SYSTEM OUTLINE

Page 204 of 307

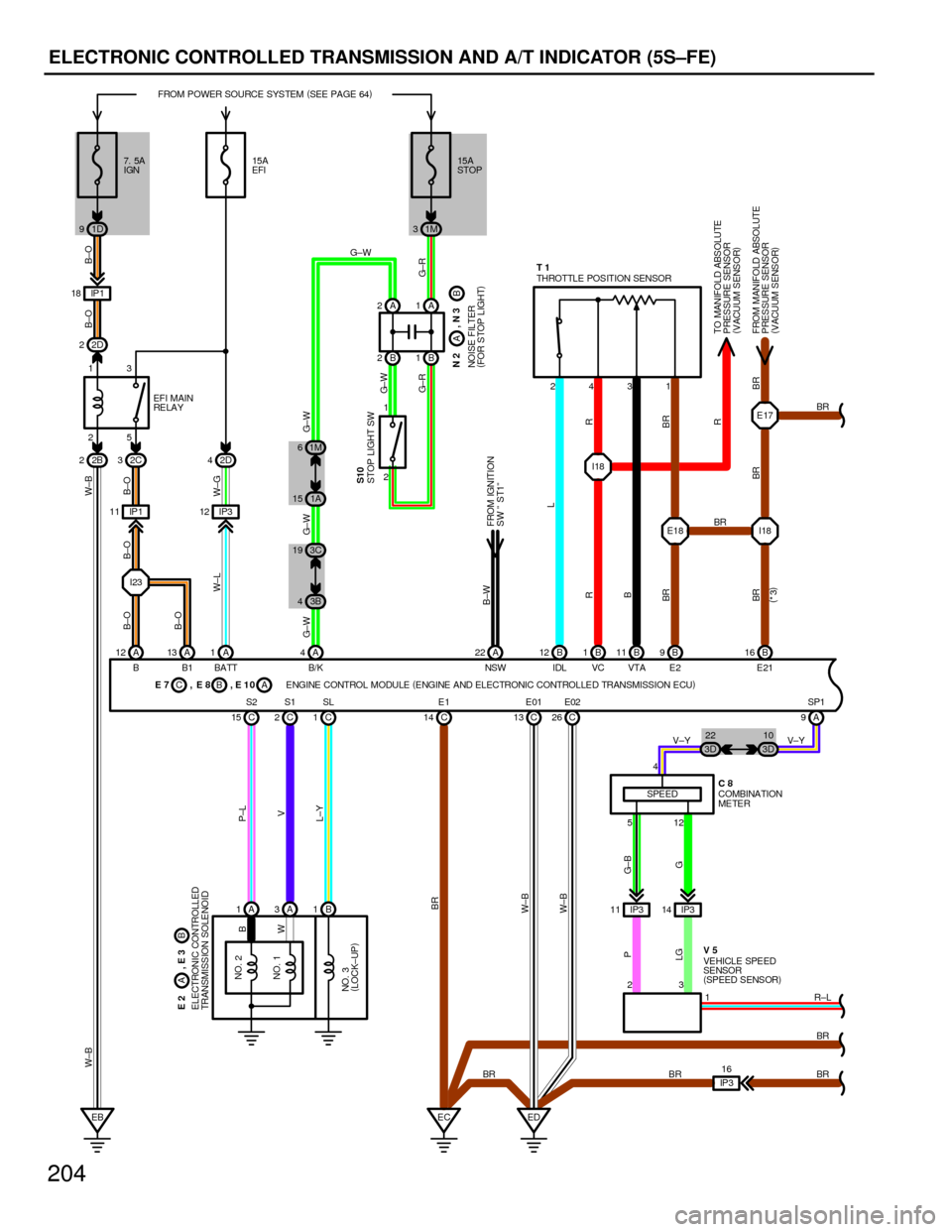

204

ELECTRONIC CONTROLLED TRANSMISSION AND A/T INDICATOR (5S±FE)

A

C,B

A2D 2

2B 22C32D4

IP 1 11 IP312 IP 1 18

I23

A 1A3B1 A 12

BA 13

B1A 1

BATTA 4

B/KA 22

NSWB 12

IDLB 1

VCB 11

VTAB 9

E2

C 15S2

C 2S1

C 1SL

C 14E1

C 13E01

C 26E02

EBEC EDE21 2431

I18

E18 I18BRBR

BR

B±O B±O

G±W

R

BR

R

BR BRR B±W G±W G±WW±B

B±O

W±G B±O B±O

B±O

W±L

V

L±Y P±L

W±B

W±BBR W±B

L

B

FROM POWER SOURCE SYSTEM(

SEE PAGE 64)

15A

EFI

EFI MAIN

RE LA YTHROTTLE POSITION SENSOR

ELECTRONIC CONTROLLED

TRANSMISSION SOLENOID

FROM IGNITION

SW º ST1º

IP 316

BR

E2 ,E3

E7 E8 ,E10T1

A

B

WB

B 16E17

25 13

A 9

SPEED

IP3 11 IP314 5124

G±B

G

23

1 VEHICLE SPEED

SENSOR

(

SPEED SENSOR)

LGP

R±L SP1

COMBINATION

METER

V5C8V±Y V±Y

BR BR FROM MANIFOLD ABSOLUTE

PRESSURE SENSOR

(

V ACUUM S ENS OR) TO MANIFOLD ABSOLUTE

PRESSURE SENSOR

(

V ACUUM S ENS OR)

BR

BR

STOP LIGHT SW

G±R

G±W

2 1

S10

B

1 A 2

B 2B1

NOISE FILTER

(

FOR S TOP L IGHT) N2 ,N3

A

G± W

G±R NO. 3

(

LOCK±UP) NO. 1 NO. 2

E NGINE CONTROL MODULE(

ENGINE AND ELECTRONIC CONTROLLED TRANSMISSION ECU)

(

*3)

1A 15

3B 43C 191M 6

1D 97. 5A

IGN1M 315A

STOP

3D22

3D10

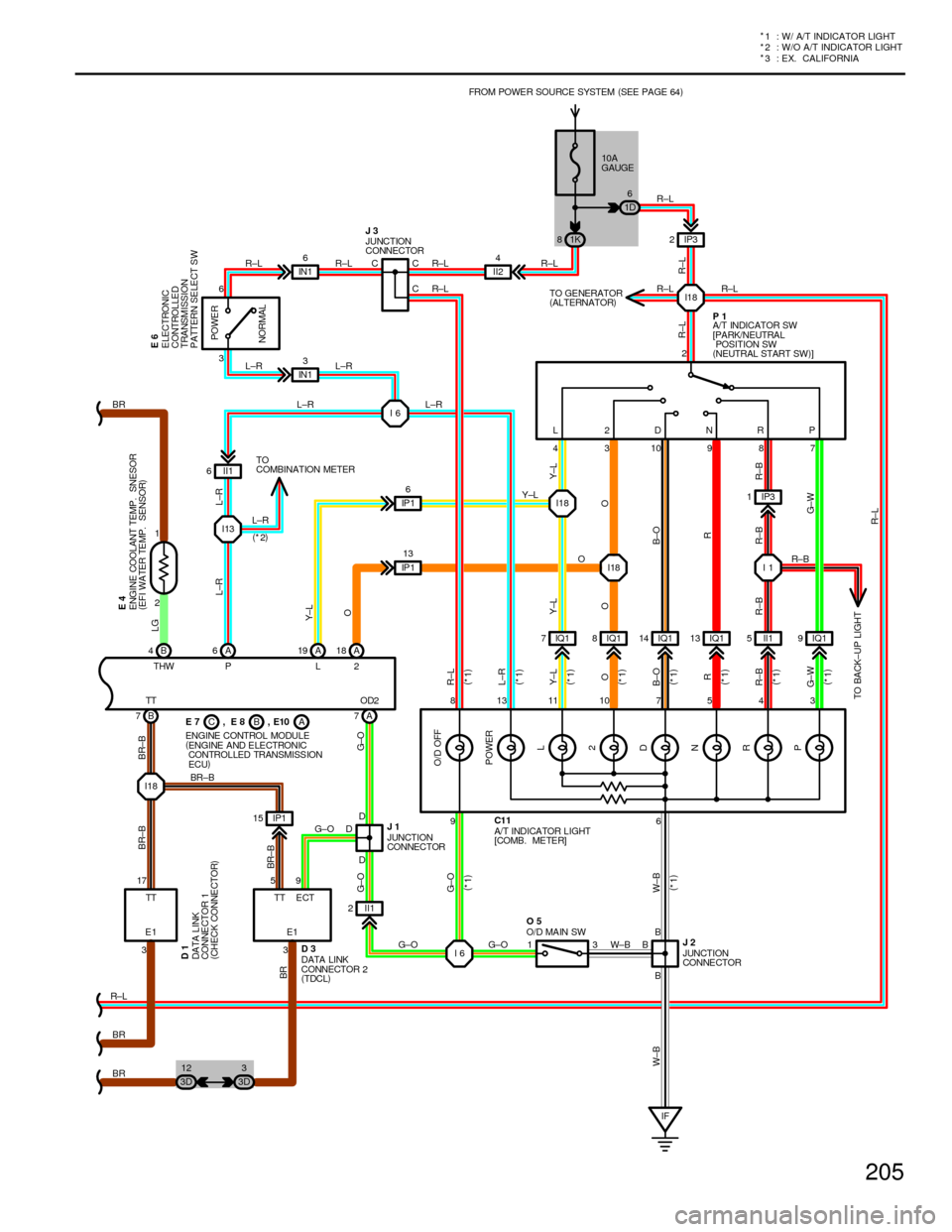

Page 205 of 307

205

* 2 : W/O A/T INDICATOR LIGHT *

1 : W/ A/T INDICATOR LIGHT

*

3 : EX. CALIFORNIA

CB

II1 6

IQ1 7IQ18IQ114 IQ113 II15IQ19 IP3 1 L2DNRP

43109872

I18

I6 I6

I13

I18 II24

B 7TT

A 7OD2 B 4

THWA 6

PA 19

LA 18

2

IF 96 3

3

B DC

B 17 5 9DD 6C

8131110 7 5 4 3 C

2 1R±L R±L R±L

L±R

BR

BR±B

G±O

BRW±B G±OR±L

L±R

L±R

L±R LG

L±R

Y±L

O

R±L

L±R

Y±L

O

B±O

R

R±B

G±W G±WR±BR B±OOY±L Y±L

O

R±L W±BG±O BR±B BR±B

G±O

G±O

BR

W±B

FROM POWER SOURCE SYSTEM(

SEE PAGE 64)

POWER

NORMAL ENGINE COOLANT TEMP. SNESOR

(

EFI WATER TEMP. SENSOR)

JUNCTION

CONNECTOR

JUNCTION

CONNE CTOR O/D MAIN SW A/T INDICATOR LIGHT

[COMB. METER]A/T INDICATOR SW

[PA RK/NEUTRA L

POSITION SW

(

NEUTRAL START SW)

] JUNCTION

CONNECTOR

DA TA LINK

CONNE CTOR 1

(

CHECK CONNE CTOR)DATA LINK

CONNECTOR 2

(

TDCL) TT ECT

E1 TT

ELECTRONIC

CONTROLLE D

TRANSMISSION

PATTERN SELECT SW

R±B

ENGINE CONTROL MODULE

(

ENGINE A ND E LE CTRONIC

CONTROLLED TRANSMISSION

ECU)

C11

O5

J2

D1D3J1 E7 , E8 ,E10

E4

P1

E6

J3

A

3 1 IP1 15

BR±B

I18 IP3 2

R±LR±L

R±L

R±L

R±L

O Y±L

P R

N

D2 L POWER O/D OFF

B

BR3E1II1 2

G±O

(

*1)

(

*1)(

*1)

(

*1)

(

*1)

(

*1)

(

*1)

(

*1)

(

*1)

(

*1)

I1

R±B

R±B

TO BA CK± UP LI GHT

I18 TO

COMBINATION METER

L±RIN16

R±L

IN13

L±R

(

*2)TO GENERATOR

(

ALTERNATOR)R±L

IP 16

IP 113

1K 8GE

1D6

10A

GAU

3D12

3D3

Page 206 of 307

206

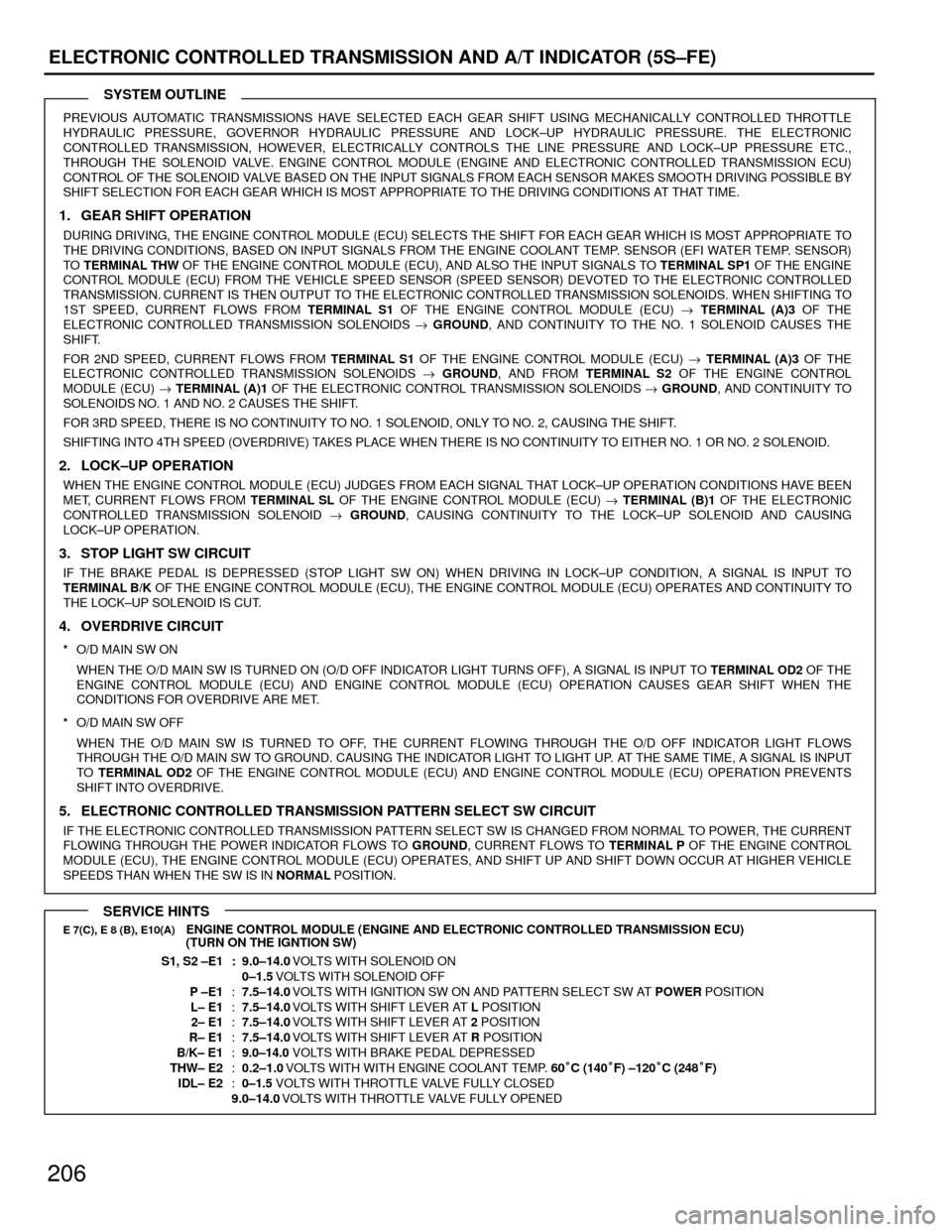

ELECTRONIC CONTROLLED TRANSMISSION AND A/T INDICATOR (5S±FE)

PREVIOUS AUTOMATIC TRANSMISSIONS HAVE SELECTED EACH GEAR SHIFT USING MECHANICALLY CONTROLLED THROTTLE

HYDRAULIC PRESSURE, GOVERNOR HYDRAULIC PRESSURE AND LOCK±UP HYDRAULIC PRESSURE. THE ELECTRONIC

CONTROLLED TRANSMISSION, HOWEVER, ELECTRICALLY CONTROLS THE LINE PRESSURE AND LOCK±UP PRESSURE ETC.,

THROUGH THE SOLENOID VALVE. ENGINE CONTROL MODULE (ENGINE AND ELECTRONIC CONTROLLED TRANSMISSION ECU)

CONTROL OF THE SOLENOID VALVE BASED ON THE INPUT SIGNALS FROM EACH SENSOR MAKES SMOOTH DRIVING POSSIBLE BY

SHIFT SELECTION FOR EACH GEAR WHICH IS MOST APPROPRIATE TO THE DRIVING CONDITIONS AT THAT TIME.

1. GEAR SHIFT OPERATION

DURING DRIVING, THE ENGINE CONTROL MODULE (ECU) SELECTS THE SHIFT FOR EACH GEAR WHICH IS MOST APPROPRIATE TO

THE DRIVING CONDITIONS, BASED ON INPUT SIGNALS FROM THE ENGINE COOLANT TEMP. SENSOR (EFI WATER TEMP. SENSOR)

TO TERMINAL THW OF THE ENGINE CONTROL MODULE (ECU), AND ALSO THE INPUT SIGNALS TO TERMINAL SP1 OF THE ENGINE

CONTROL MODULE (ECU) FROM THE VEHICLE SPEED SENSOR (SPEED SENSOR) DEVOTED TO THE ELECTRONIC CONTROLLED

TRANSMISSION. CURRENT IS THEN OUTPUT TO THE ELECTRONIC CONTROLLED TRANSMISSION SOLENOIDS. WHEN SHIFTING TO

1ST SPEED, CURRENT FLOWS FROM TERMINAL S1 OF THE ENGINE CONTROL MODULE (ECU) " TERMINAL (A)3 OF THE

ELECTRONIC CONTROLLED TRANSMISSION SOLENOIDS " GROUND, AND CONTINUITY TO THE NO. 1 SOLENOID CAUSES THE

SHIFT.

FOR 2ND SPEED, CURRENT FLOWS FROM TERMINAL S1 OF THE ENGINE CONTROL MODULE (ECU) " TERMINAL (A)3 OF THE

ELECTRONIC CONTROLLED TRANSMISSION SOLENOIDS " GROUND, AND FROM TERMINAL S2 OF THE ENGINE CONTROL

MODULE (ECU) " TERMINAL (A)1 OF THE ELECTRONIC CONTROL TRANSMISSION SOLENOIDS " GROUND, AND CONTINUITY TO

SOLENOIDS NO. 1 AND NO. 2 CAUSES THE SHIFT.

FOR 3RD SPEED, THERE IS NO CONTINUITY TO NO. 1 SOLENOID, ONLY TO NO. 2, CAUSING THE SHIFT.

SHIFTING INTO 4TH SPEED (OVERDRIVE) TAKES PLACE WHEN THERE IS NO CONTINUITY TO EITHER NO. 1 OR NO. 2 SOLENOID.

2. LOCK±UP OPERATION

WHEN THE ENGINE CONTROL MODULE (ECU) JUDGES FROM EACH SIGNAL THAT LOCK±UP OPERATION CONDITIONS HAVE BEEN

MET, CURRENT FLOWS FROM TERMINAL SL OF THE ENGINE CONTROL MODULE (ECU) " TERMINAL (B)1 OF THE ELECTRONIC

CONTROLLED TRANSMISSION SOLENOID " GROUND, CAUSING CONTINUITY TO THE LOCK±UP SOLENOID AND CAUSING

LOCK±UP OPERATION.

3. STOP LIGHT SW CIRCUIT

IF THE BRAKE PEDAL IS DEPRESSED (STOP LIGHT SW ON) WHEN DRIVING IN LOCK±UP CONDITION, A SIGNAL IS INPUT TO

TERMINAL B/K OF THE ENGINE CONTROL MODULE (ECU), THE ENGINE CONTROL MODULE (ECU) OPERATES AND CONTINUITY TO

THE LOCK±UP SOLENOID IS CUT.

4. OVERDRIVE CIRCUIT

*O/D MAIN SW ON

WHEN THE O/D MAIN SW IS TURNED ON (O/D OFF INDICATOR LIGHT TURNS OFF), A SIGNAL IS INPUT TO TERMINAL OD2 OF THE

ENGINE CONTROL MODULE (ECU) AND ENGINE CONTROL MODULE (ECU) OPERATION CAUSES GEAR SHIFT WHEN THE

CONDITIONS FOR OVERDRIVE ARE MET.

*O/D MAIN SW OFF

WHEN THE O/D MAIN SW IS TURNED TO OFF, THE CURRENT FLOWING THROUGH THE O/D OFF INDICATOR LIGHT FLOWS

THROUGH THE O/D MAIN SW TO GROUND. CAUSING THE INDICATOR LIGHT TO LIGHT UP. AT THE SAME TIME, A SIGNAL IS INPUT

TO TERMINAL OD2 OF THE ENGINE CONTROL MODULE (ECU) AND ENGINE CONTROL MODULE (ECU) OPERATION PREVENTS

SHIFT INTO OVERDRIVE.

5. ELECTRONIC CONTROLLED TRANSMISSION PATTERN SELECT SW CIRCUIT

IF THE ELECTRONIC CONTROLLED TRANSMISSION PATTERN SELECT SW IS CHANGED FROM NORMAL TO POWER, THE CURRENT

FLOWING THROUGH THE POWER INDICATOR FLOWS TO GROUND, CURRENT FLOWS TO TERMINAL P OF THE ENGINE CONTROL

MODULE (ECU), THE ENGINE CONTROL MODULE (ECU) OPERATES, AND SHIFT UP AND SHIFT DOWN OCCUR AT HIGHER VEHICLE

SPEEDS THAN WHEN THE SW IS IN NORMAL POSITION.

E 7(C), E 8 (B), E10(A)ENGINE CONTROL MODULE (ENGINE AND ELECTRONIC CONTROLLED TRANSMISSION ECU)

(TURN ON THE IGNTION SW)

S1, S2 ±E1 :9.0±14.0 VOLTS WITH SOLENOID ON

0±1.5 VOLTS WITH SOLENOID OFF

P ±E1:7.5±14.0 VOLTS WITH IGNITION SW ON AND PATTERN SELECT SW AT POWER POSITION

L± E1:7.5±14.0 VOLTS WITH SHIFT LEVER AT L POSITION

2± E1:7.5±14.0 VOLTS WITH SHIFT LEVER AT 2 POSITION

R± E1:7.5±14.0 VOLTS WITH SHIFT LEVER AT R POSITION

B/K± E1:9.0±14.0 VOLTS WITH BRAKE PEDAL DEPRESSED

THW± E2:0.2±1.0 VOLTS WITH WITH ENGINE COOLANT TEMP. 60°C (140°F) ±120°C (248°F)

IDL± E2:0±1.5 VOLTS WITH THROTTLE VALVE FULLY CLOSED

9.0±14.0 VOLTS WITH THROTTLE VALVE FULLY OPENED

SYSTEM OUTLINE

SERVICE HINTS

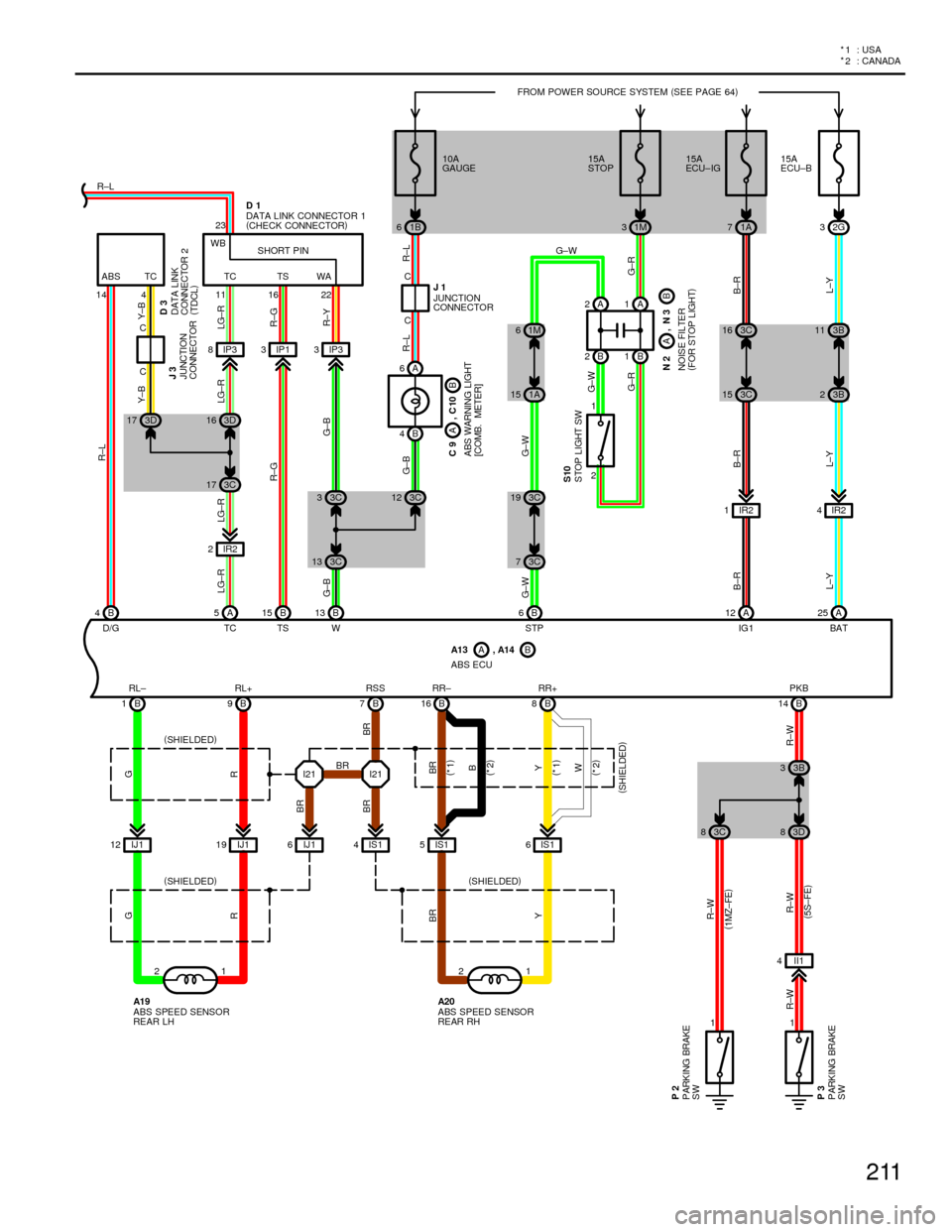

Page 211 of 307

211

*

2 : CANADA *1 : USA

A

A

A

2G

II1 4 IR2 2IR2 1IR24

IS1 6 IS1 5 IS1 4 IJ1 6 IJ1 19 IJ1 12

1 2 1 2I21 I21 B 1B9B7B

16 B8B14A 25 A 12 B 6 B 13 A 5 B 4A 6

B

4

11 IP3 8IP33

B 15

RL± RL+ RSS RR± RR+ PKB

BR ABS TC TC TS WA R±LFROM POWER SOURCE SYSTEM(

SEE PAGE 64)

R±L

B±R

L±Y B±R

L±Y B±R

L±Y G±W G±WG±BR±G LG±RR±L

LG±R

G±BG±BY±B

LG±R LG±R

R±G

R±YY±B G

R R G

BR

YBR

Y

R±W R±W R±WR±W

11 16 22 4 1423

D/G TC TS W STP IG1 BATWB

DATA LINK

CONNECTOR 2

(

TDCL)

DATA LINK CONNECTOR 1

(

CHECK CONNECTOR)

C C

ABS WARNING LIGHT

[COMB. METER]

ABS SPEED SENSOR

REAR LH(

SHIELDED)

(

SHIELDED)

ABS SPEED SENSOR

REAR RH

PARKING BRAKE

SW

PARKING BRAKE

SW(

1MZ±FE)

ABS ECU

JUNCTION

CONNECTOR

R±LC CJ1

JUNCTION

CONNECTORJ3

C9 ,C10

B

A13 , A14

B

BR BR

BR

A19 A20

P2

P3(

5S±FE)

D1

D3

SHORT PIN

STOP LIGHT SW

G±R

G±W

2 1

S10

B

1 A 2

B 2B1

NOISE FILTER

(

FOR STOP LIGHT) N2 , N3

A

G±W

G±R

IP1 3

(

*1)

(

*

1) B

(

*2)

W

(

*2)

(

SHIELDED)

(

SHIELDED)

1A 151M 6

1B 61M31A73 10A

GAUGE15A

ECU±B 15A

ECU±IG 15A

STOP

3C 73C 19

3D 17

3C 173D 16

3C 133C 33C12

3C 15 3B23B 11 3C 16

3B 3

3D 8 3C 8