check engine TOYOTA CAMRY 2000 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2000, Model line: CAMRY, Model: TOYOTA CAMRY 2000Pages: 4770, PDF Size: 86.41 MB

Page 424 of 4770

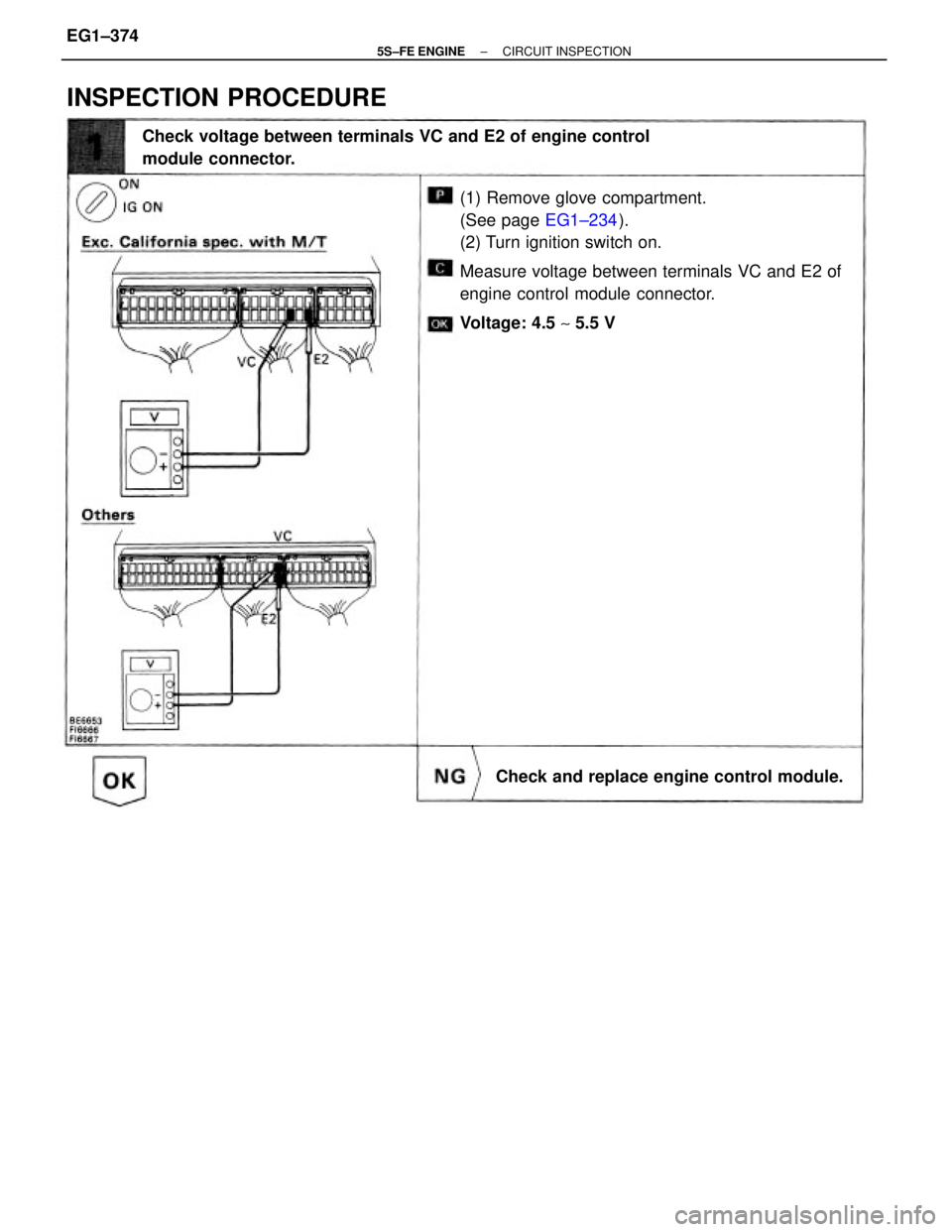

(1) Remove glove compartment.

(See page EG1±234).

(2) Turn ignition switch on.

Measure voltage between terminals VC and E2 of

engine control module connector.

Voltage: 4.5 ~ 5.5 V Check voltage between terminals VC and E2 of engine control

module connector.

Check and replace engine control module.

INSPECTION PROCEDURE

± 5S±FE ENGINECIRCUIT INSPECTIONEG1±374

Page 425 of 4770

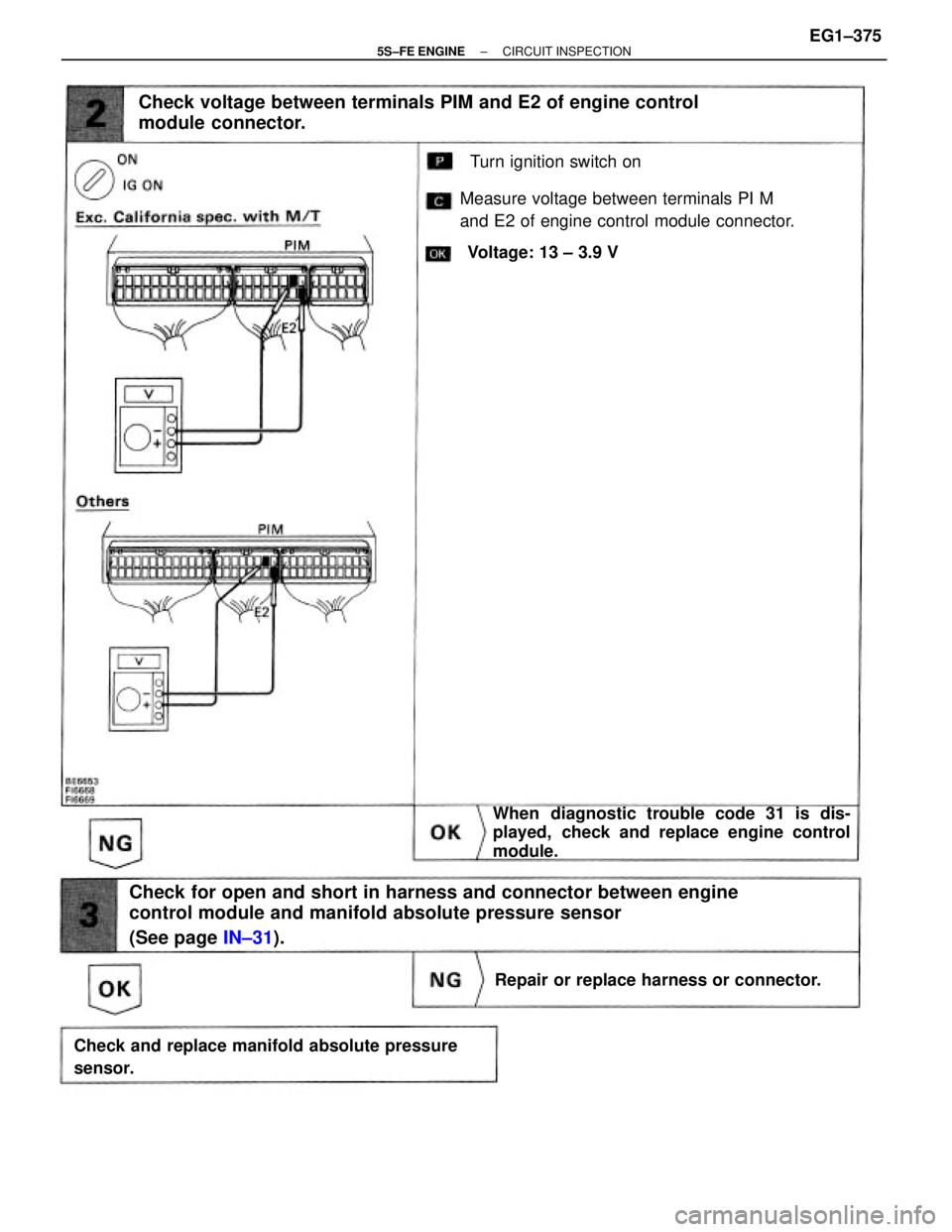

Check for open and short in harness and connector between engine

control module and manifold absolute pressure sensor

(See page IN±31).

Turn ignition switch on

Check voltage between terminals PIM and E2 of engine control

module connector.

Check and replace manifold absolute pressure

sensor.When diagnostic trouble code 31 is dis-

played, check and replace engine control

module.

Repair or replace harness or connector. Voltage: 13 ± 3.9 V Measure voltage between terminals PI M

and E2 of engine control module connector.

± 5S±FE ENGINECIRCUIT INSPECTIONEG1±375

Page 427 of 4770

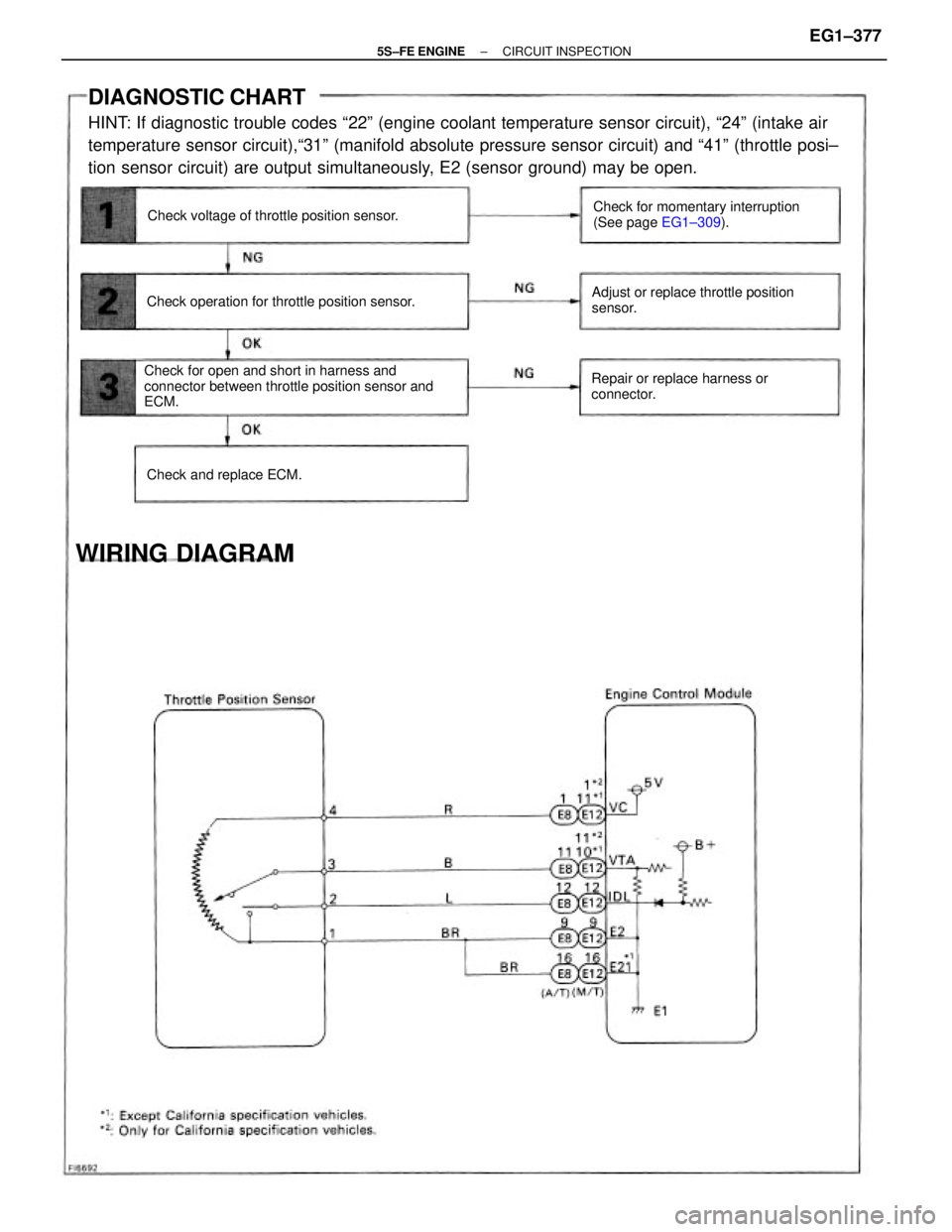

DIAGNOSTIC CHART

HINT: If diagnostic trouble codes ª22º (engine coolant temperature sensor circuit), ª24º (intake air

temperature sensor circuit),ª31º (manifold absolute pressure sensor circuit) and ª41º (throttle posi±

tion sensor circuit) are output simultaneously, E2 (sensor ground) may be open.

Check for open and short in harness and

connector between throttle position sensor and

ECM.Check for momentary interruption

(See page EG1±309).

Adjust or replace throttle position

sensor.

Repair or replace harness or

connector. Check operation for throttle position sensor.Check voltage of throttle position sensor.

WIRING DIAGRAM

Check and replace ECM.

± 5S±FE ENGINECIRCUIT INSPECTIONEG1±377

Page 428 of 4770

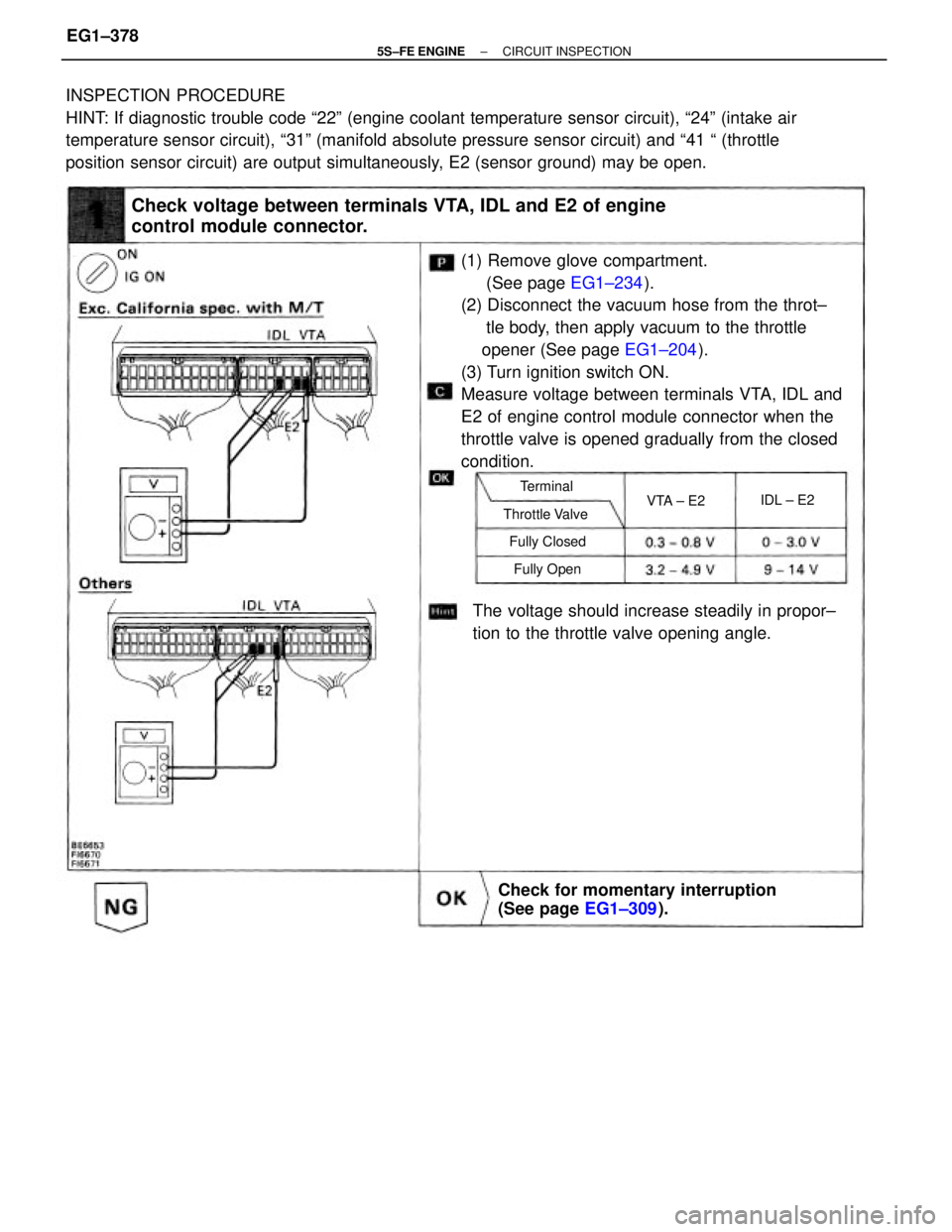

INSPECTION PROCEDURE

HINT: If diagnostic trouble code ª22º (engine coolant temperature sensor circuit), ª24º (intake air

temperature sensor circuit), ª31º (manifold absolute pressure sensor circuit) and ª41 ª (throttle

position sensor circuit) are output simultaneously, E2 (sensor ground) may be open.

(1) Remove glove compartment.

(See page EG1±234).

(2) Disconnect the vacuum hose from the throt±

tle body, then apply vacuum to the throttle

opener (See page EG1±204).

(3) Turn ignition switch ON.

Measure voltage between terminals VTA, IDL and

E2 of engine control module connector when the

throttle valve is opened gradually from the closed

condition.

Check voltage between terminals VTA, IDL and E2 of engine

control module connector.

The voltage should increase steadily in propor±

tion to the throttle valve opening angle.

Check for momentary interruption

(See page EG1±309).

Throttle Valve

Fully Closed

Fully OpenVTA ± E2 Terminal

IDL ± E2

± 5S±FE ENGINECIRCUIT INSPECTIONEG1±378

Page 429 of 4770

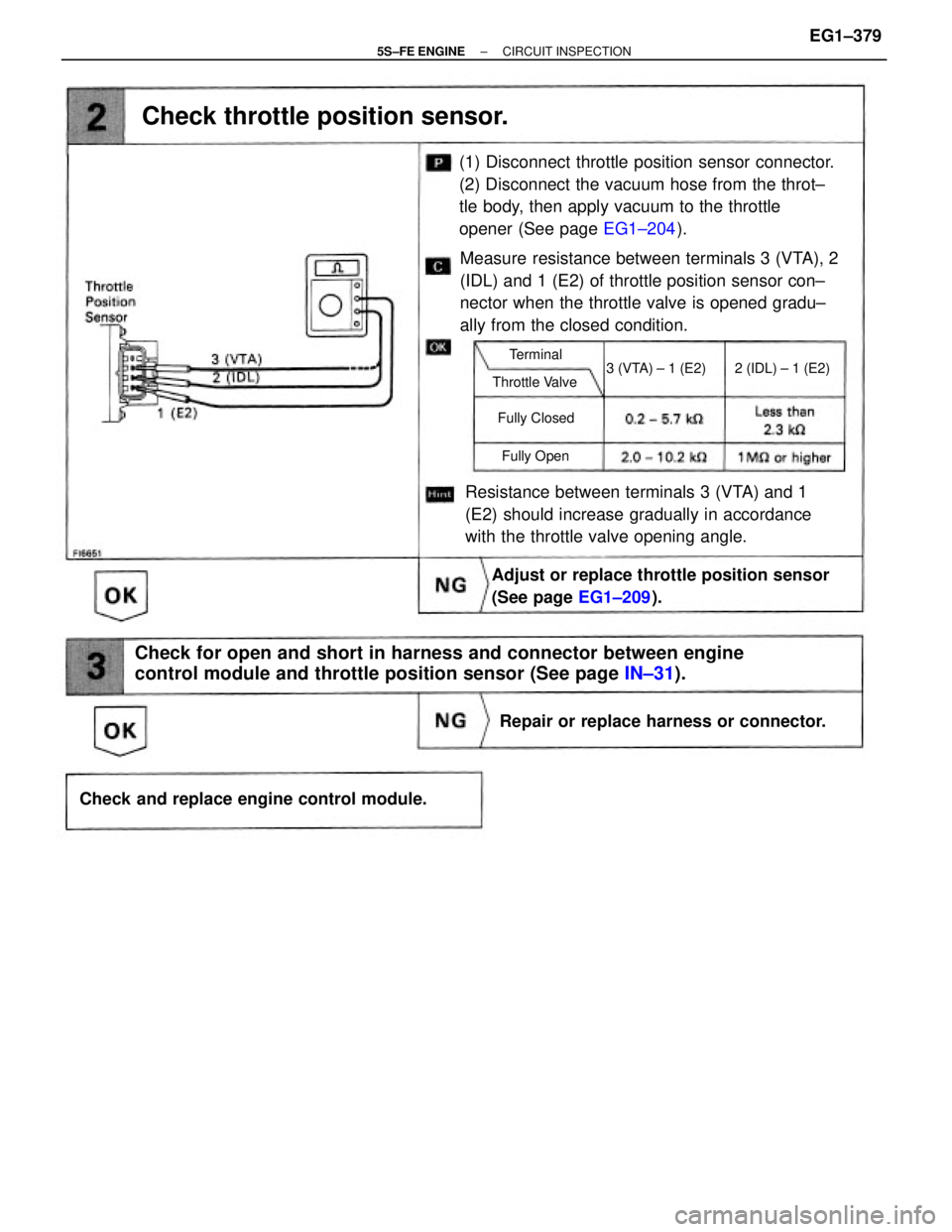

(1) Disconnect throttle position sensor connector.

(2) Disconnect the vacuum hose from the throt±

tle body, then apply vacuum to the throttle

opener (See page EG1±204).

Check for open and short in harness and connector between engine

control module and throttle position sensor (See page IN±31).

Resistance between terminals 3 (VTA) and 1

(E2) should increase gradually in accordance

with the throttle valve opening angle.

Adjust or replace throttle position sensor

(See page EG1±209).

Check throttle position sensor.

Check and replace engine control module.Repair or replace harness or connector.

3 (VTA) ± 1 (E2) 2 (IDL) ± 1 (E2)

Throttle Valve

Fully Closed

Fully OpenTerminal

Measure resistance between terminals 3 (VTA), 2

(IDL) and 1 (E2) of throttle position sensor con±

nector when the throttle valve is opened gradu±

ally from the closed condition.

± 5S±FE ENGINECIRCUIT INSPECTIONEG1±379

Page 431 of 4770

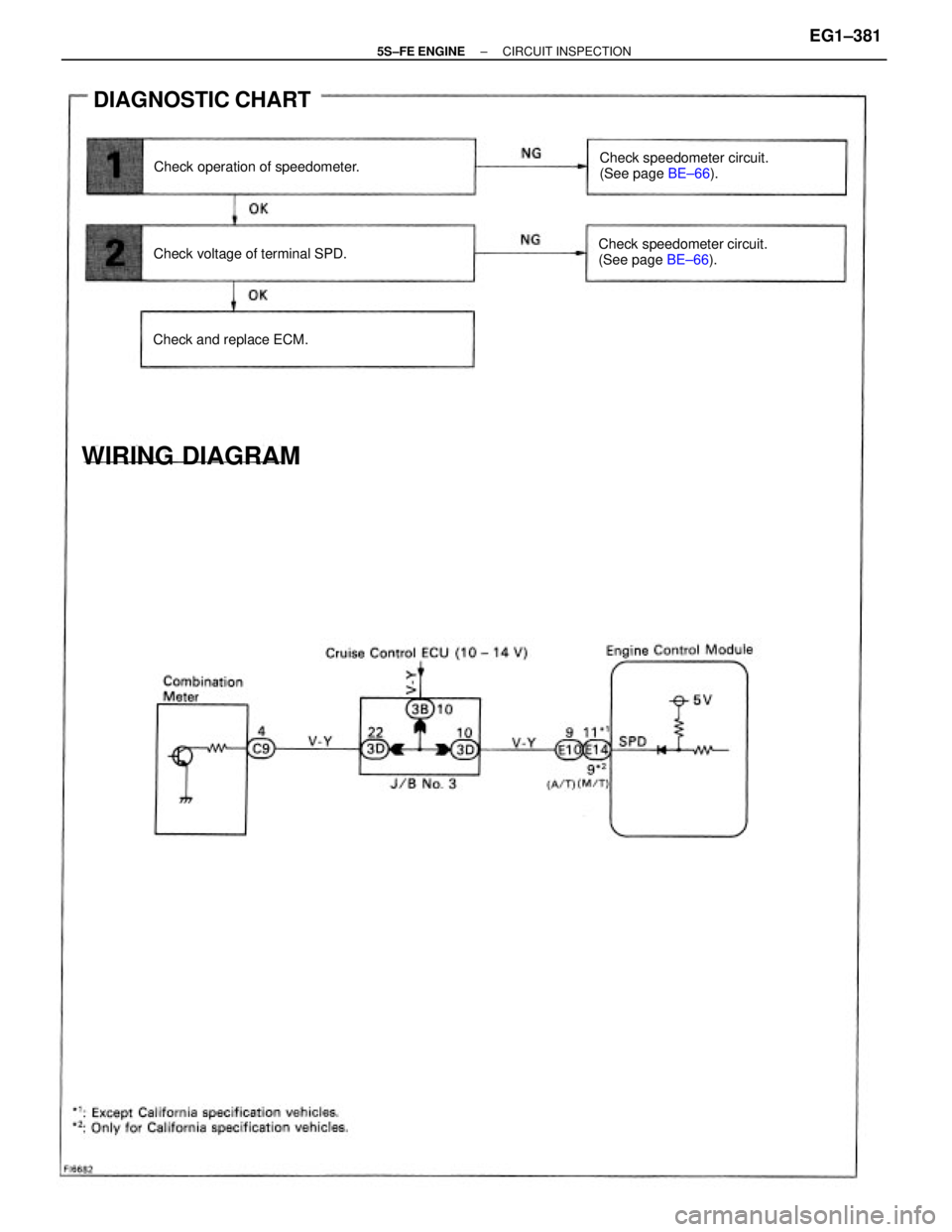

Check speedometer circuit.

(See page BE±66). Check speedometer circuit.

(See page BE±66).

DIAGNOSTIC CHART

Check operation of speedometer.

WIRING DIAGRAM

Check voltage of terminal SPD.

Check and replace ECM.

± 5S±FE ENGINECIRCUIT INSPECTIONEG1±381

Page 432 of 4770

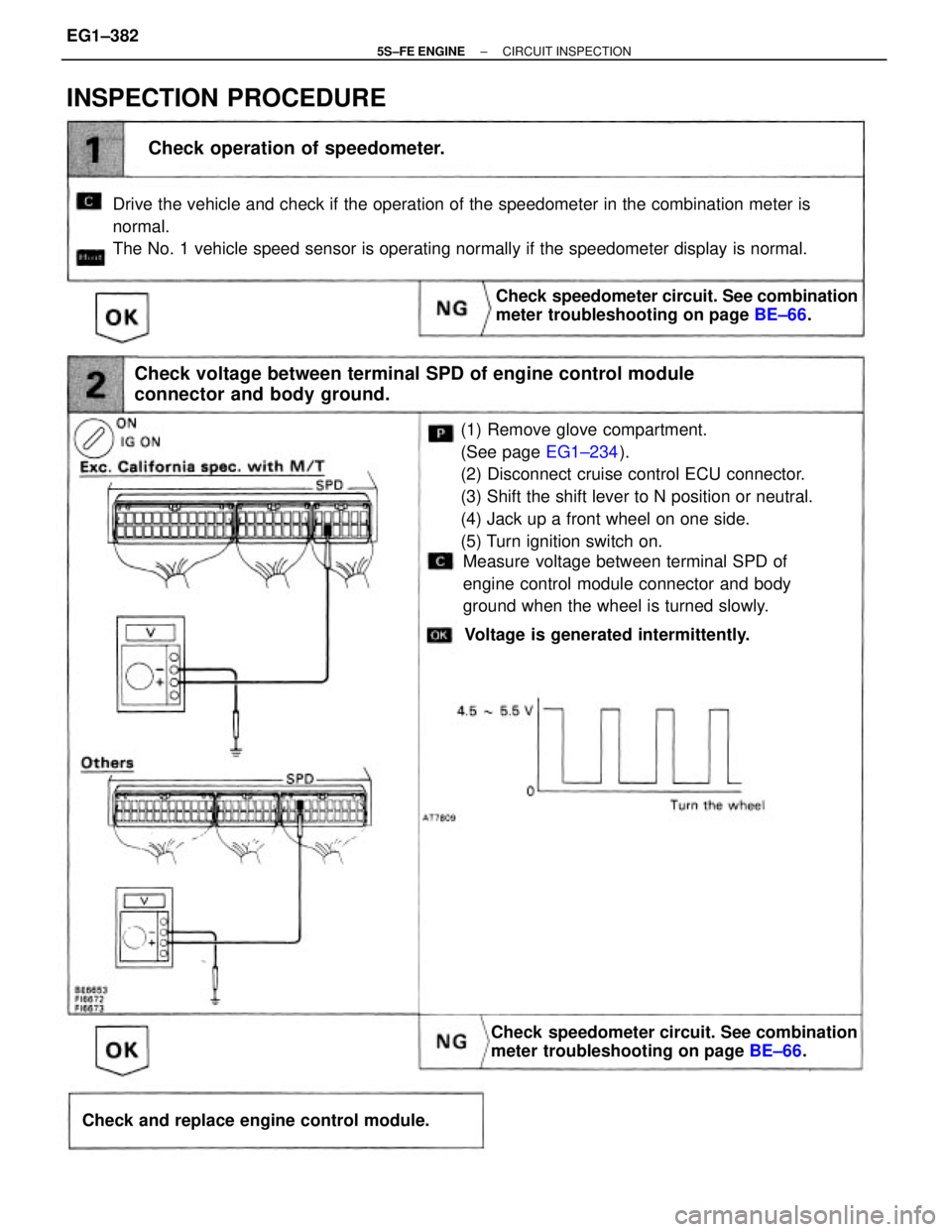

(1) Remove glove compartment.

(See page EG1±234).

(2) Disconnect cruise control ECU connector.

(3) Shift the shift lever to N position or neutral.

(4) Jack up a front wheel on one side.

(5) Turn ignition switch on. Drive the vehicle and check if the operation of the speedometer in the combination meter is

normal.

The No. 1 vehicle speed sensor is operating normally if the speedometer display is normal.

Check voltage between terminal SPD of engine control module

connector and body ground.

Check speedometer circuit. See combination

meter troubleshooting on page BE±66.

Check speedometer circuit. See combination

meter troubleshooting on page BE±66.

Check operation of speedometer.

Check and replace engine control module.

INSPECTION PROCEDURE

Measure voltage between terminal SPD of

engine control module connector and body

ground when the wheel is turned slowly.

Voltage is generated intermittently.

± 5S±FE ENGINECIRCUIT INSPECTIONEG1±382

Page 433 of 4770

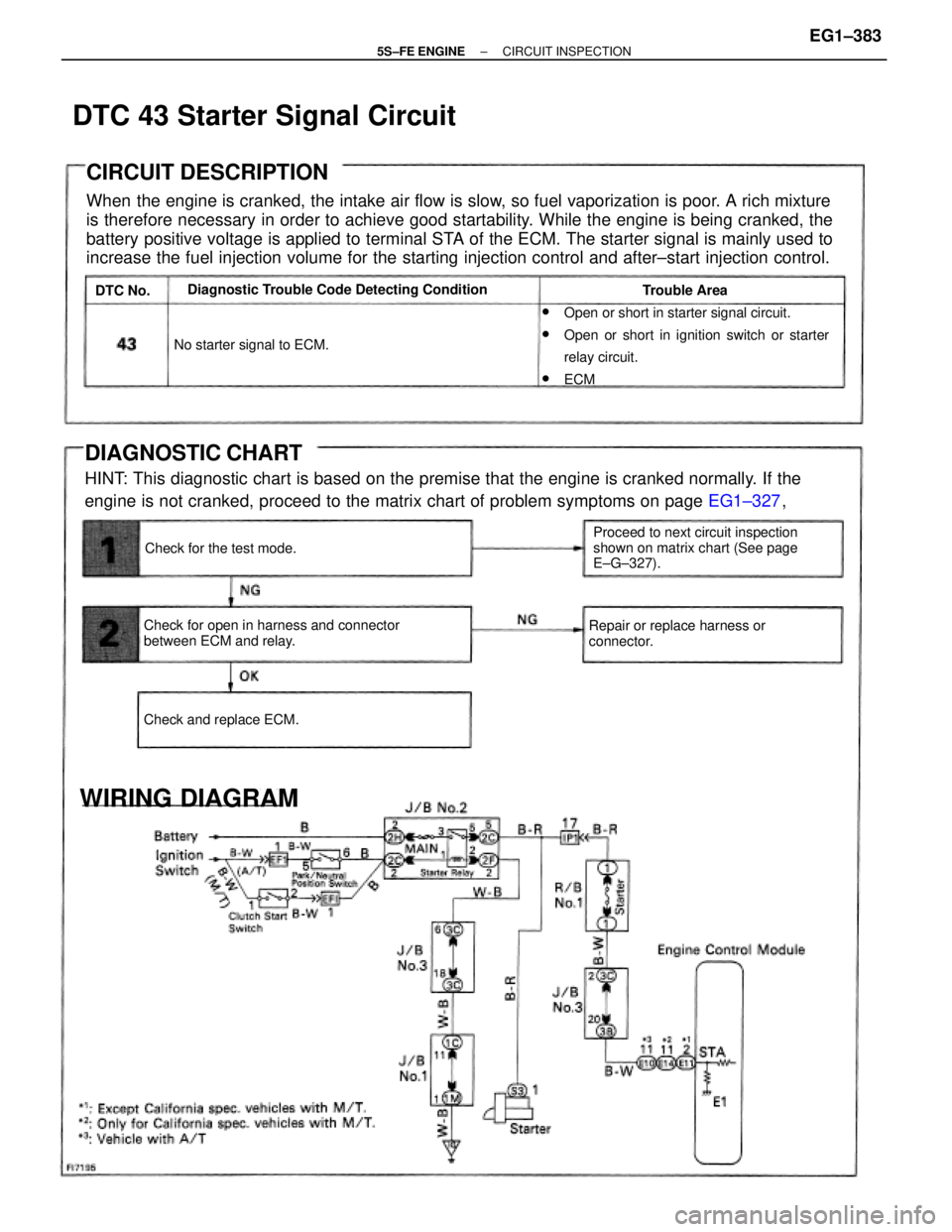

CIRCUIT DESCRIPTION

When the engine is cranked, the intake air flow is slow, so fuel vaporization is poor. A rich mixture

is therefore necessary in order to achieve good startability. While the engine is being cranked, the

battery positive voltage is applied to terminal STA of the ECM. The starter signal is mainly used to

increase the fuel injection volume for the starting injection control and after±start injection control.

DIAGNOSTIC CHART

HINT: This diagnostic chart is based on the premise that the engine is cranked normally. If the

engine is not cranked, proceed to the matrix chart of problem symptoms on page EG1±327, w

Open or short in starter signal circuit.

wOpen or short in ignition switch or starter

relay circuit.

wECM

Check for open in harness and connector

between ECM and relay.Proceed to next circuit inspection

shown on matrix chart (See page

E±G±327). Diagnostic Trouble Code Detecting Condition

Repair or replace harness or

connector.

WIRING DIAGRAM

No starter signal to ECM.

Check and replace ECM.Check for the test mode.Trouble Area

DTC 43 Starter Signal Circuit

DTC No.

± 5S±FE ENGINECIRCUIT INSPECTIONEG1±383

Page 434 of 4770

Setting the test mode.

(1) Turn ignition switch OFF.

(2) Connect terminals TE2 and E1 of DLC2.

(3) Turn ignition switch ON.

(Don't start the engine)

(4) Connect terminals TE1 and E1 of DLC2.

Check for open in harness and connector between engine control

module and starter relay (See page IN±31). Check output condition of diagnostic trouble code 43.

Proceed to next circuit inspection shown on

matrix chart (See page EG1±327).

Check and replace engine control module.Repair or replace harness or connector.

INSPECTION PROCEDURE

Check if code ª43º is output by the malfunc-

tion indicator lamp.

Code ª43º is output.

Start the engine.

Check if the code ª43º disappear.

Code ª43º is not output.

± 5S±FE ENGINECIRCUIT INSPECTIONEG1±384

Page 435 of 4770

If the ECM detects the above diagnosis conditions, it operates the fail safe function in which the

corrective retard angle value is set to the maximum value.

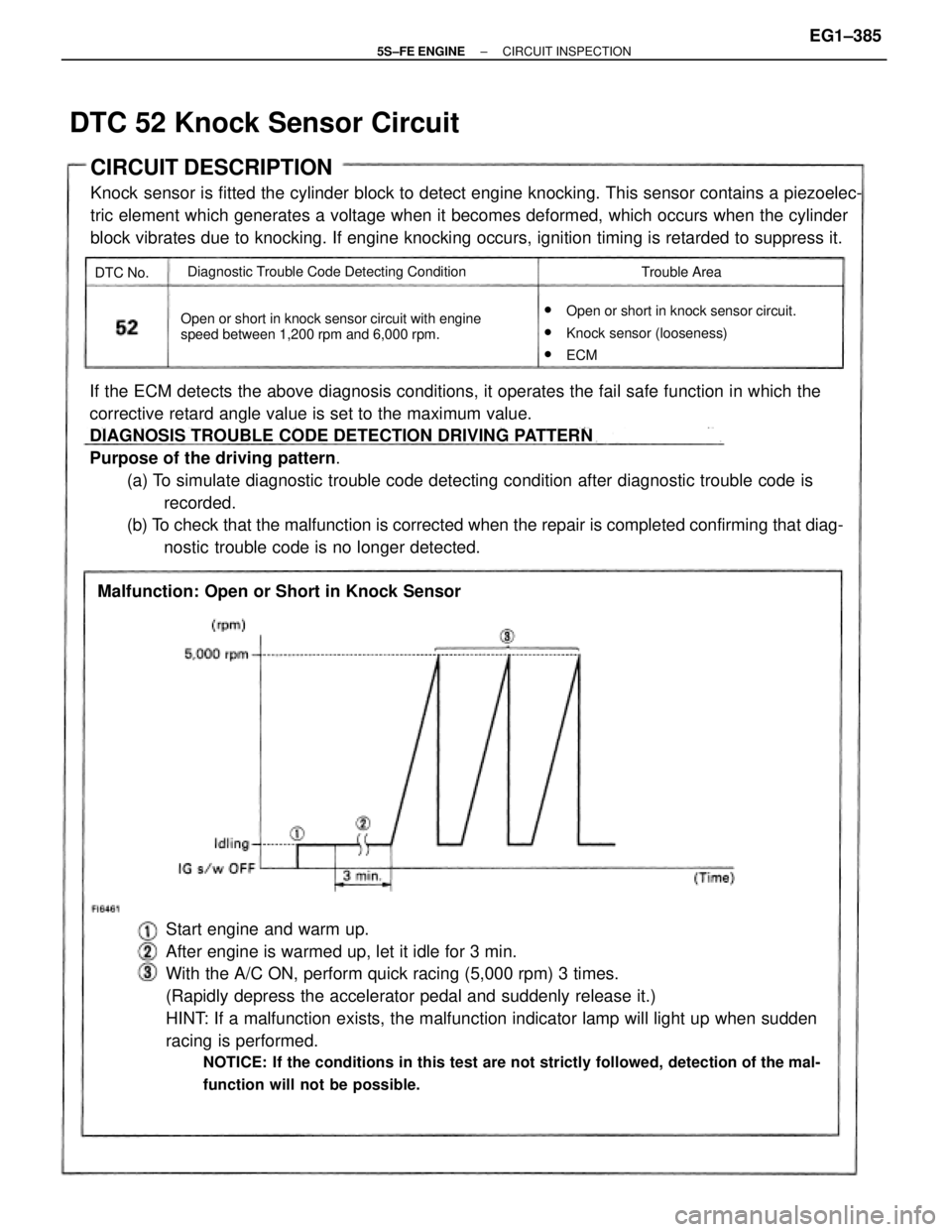

DIAGNOSIS TROUBLE CODE DETECTION DRIVING PATTERN

Purpose of the driving pattern.

(a) To simulate diagnostic trouble code detecting condition after diagnostic trouble code is

recorded.

(b) To check that the malfunction is corrected when the repair is completed confirming that diag-

nostic trouble code is no longer detected.

Start engine and warm up.

After engine is warmed up, let it idle for 3 min.

With the A/C ON, perform quick racing (5,000 rpm) 3 times.

(Rapidly depress the accelerator pedal and suddenly release it.)

HINT: If a malfunction exists, the malfunction indicator lamp will light up when sudden

racing is performed.

NOTICE: If the conditions in this test are not strictly followed, detection of the mal-

function will not be possible.

CIRCUIT DESCRIPTION

Knock sensor is fitted the cylinder block to detect engine knocking. This sensor contains a piezoelec-

tric element which generates a voltage when it becomes deformed, which occurs when the cylinder

block vibrates due to knocking. If engine knocking occurs, ignition timing is retarded to suppress it.

w

Open or short in knock sensor circuit.

wKnock sensor (looseness)

wECM Open or short in knock sensor circuit with engine

speed between 1,200 rpm and 6,000 rpm.

Malfunction: Open or Short in Knock Sensor

Diagnostic Trouble Code Detecting Condition

Trouble Area

DTC 52 Knock Sensor Circuit

DTC No.

± 5S±FE ENGINECIRCUIT INSPECTIONEG1±385