condition TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 2300 of 2389

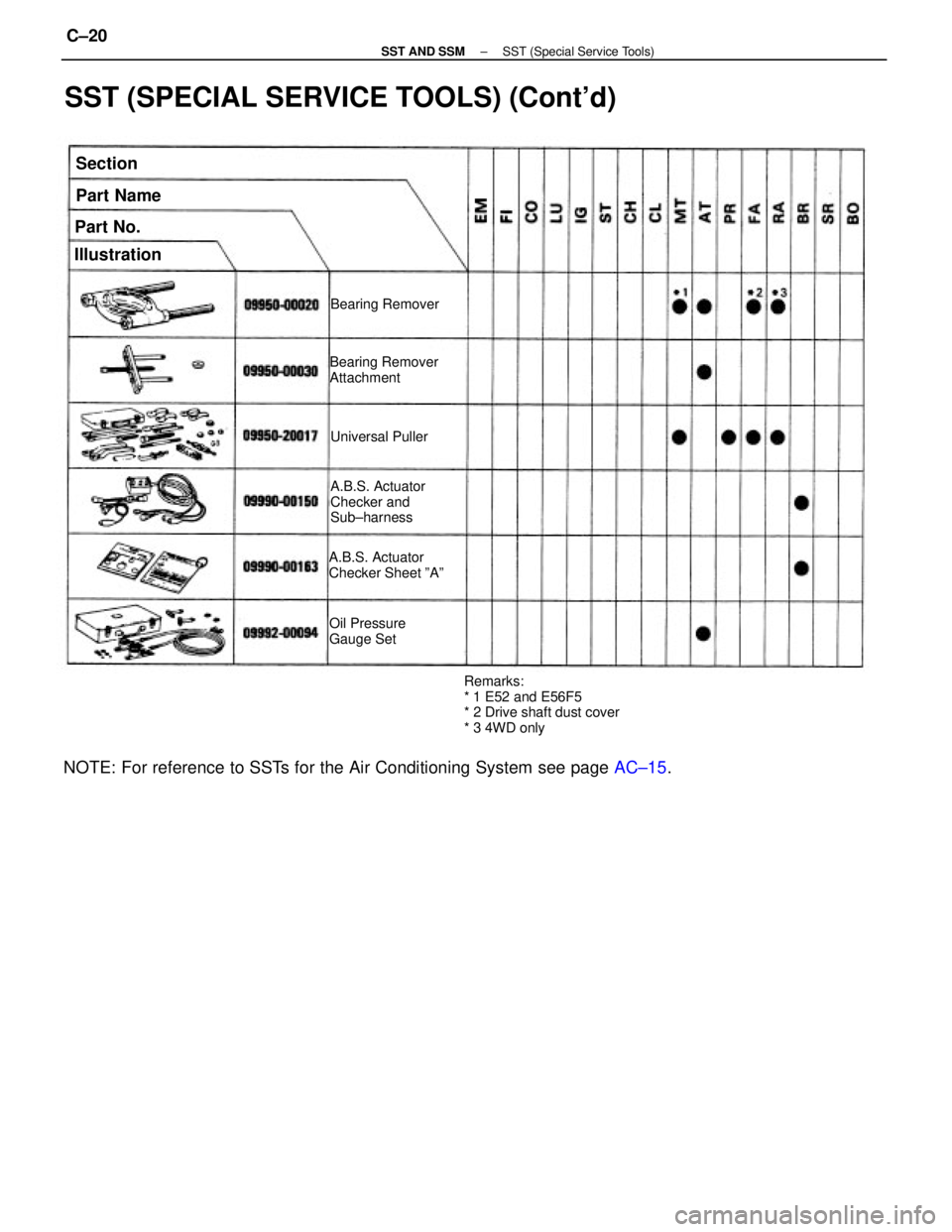

SST (SPECIAL SERVICE TOOLS) (Cont'd)

NOTE: For reference to SSTs for the Air Conditioning System see page AC±15.

Remarks:

* 1 E52 and E56F5

* 2 Drive shaft dust cover

* 3 4WD only A.B.S. Actuator

Checker and

Sub±harness

A.B.S. Actuator

Checker Sheet ºAºBearing Remover

Attachment

Oil Pressure

Gauge SetBearing Remover

IllustrationPart Name

Universal Puller

Part No.Section

± SST AND SSMSST (Special Service Tools)C±20

Page 2302 of 2389

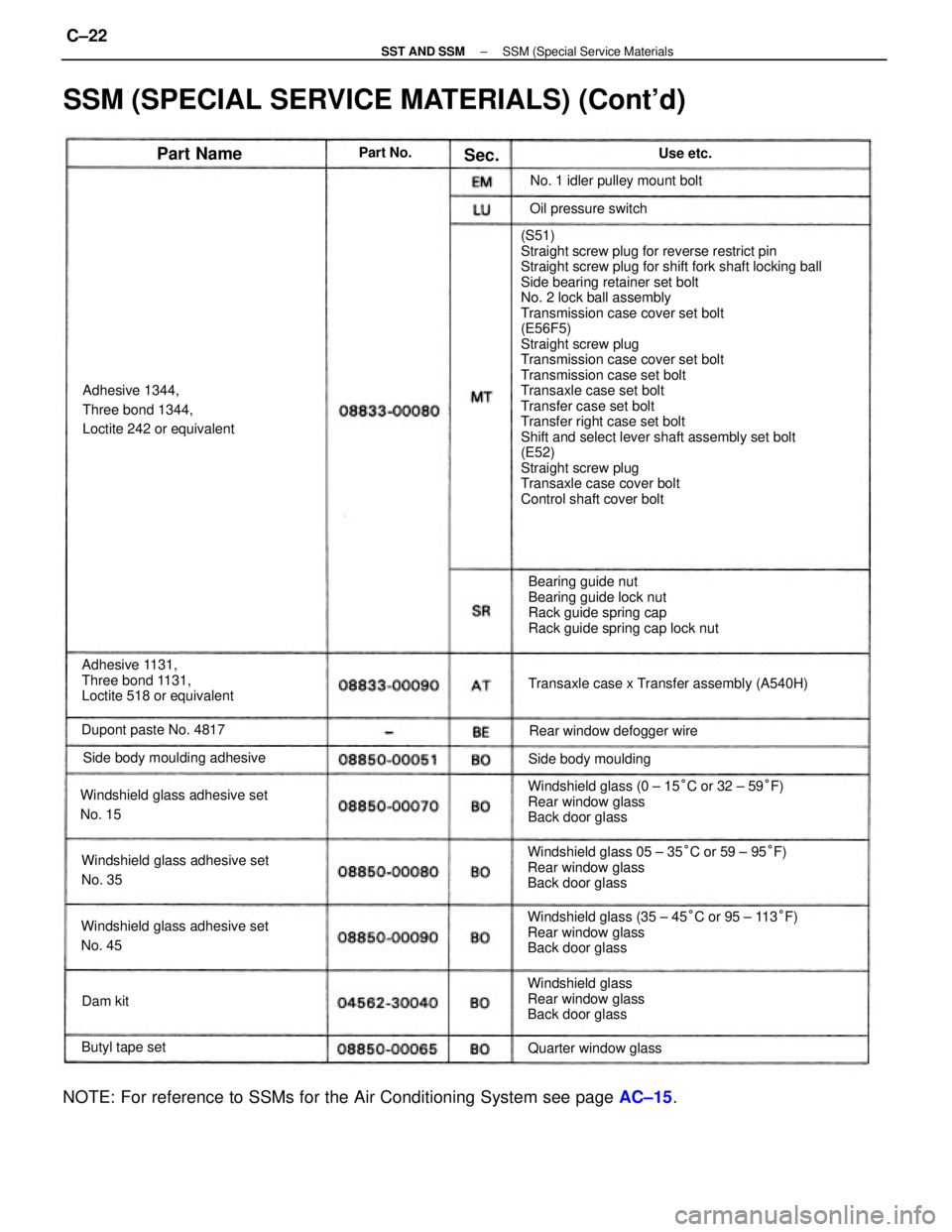

(S51)

Straight screw plug for reverse restrict pin

Straight screw plug for shift fork shaft locking ball

Side bearing retainer set bolt

No. 2 lock ball assembly

Transmission case cover set bolt

(E56F5)

Straight screw plug

Transmission case cover set bolt

Transmission case set bolt

Transaxle case set bolt

Transfer case set bolt

Transfer right case set bolt

Shift and select lever shaft assembly set bolt

(E52)

Straight screw plug

Transaxle case cover bolt

Control shaft cover bolt

SSM (SPECIAL SERVICE MATERIALS) (Cont'd)

Windshield glass (35 ± 45°C or 95 ± 113°F)

Rear window glass

Back door glass Windshield glass 05 ± 35°C or 59 ± 95°F)

Rear window glass

Back door glassWindshield glass (0 ± 15°C or 32 ± 59°F)

Rear window glass

Back door glass

NOTE: For reference to SSMs for the Air Conditioning System see page AC±15.

Bearing guide nut

Bearing guide lock nut

Rack guide spring cap

Rack guide spring cap lock nut

Adhesive 1131,

Three bond 1131,

Loctite 518 or equivalentAdhesive 1344,

Three bond 1344,

Loctite 242 or equivalent

Windshield glass adhesive set

No. 15

Windshield glass adhesive set

No. 45Windshield glass adhesive set

No. 35Transaxle case x Transfer assembly (A540H)

Windshield glass

Rear window glass

Back door glass Side body moulding adhesiveNo. 1 idler pulley mount bolt

Rear window defogger wire Dupont paste No. 4817

Quarter window glassSide body mouldingOil pressure switch

Butyl tape set

Part NameUse etc. Part No.

Dam kitSec.

± SST AND SSMSSM (Special Service MaterialsC±22

Page 2333 of 2389

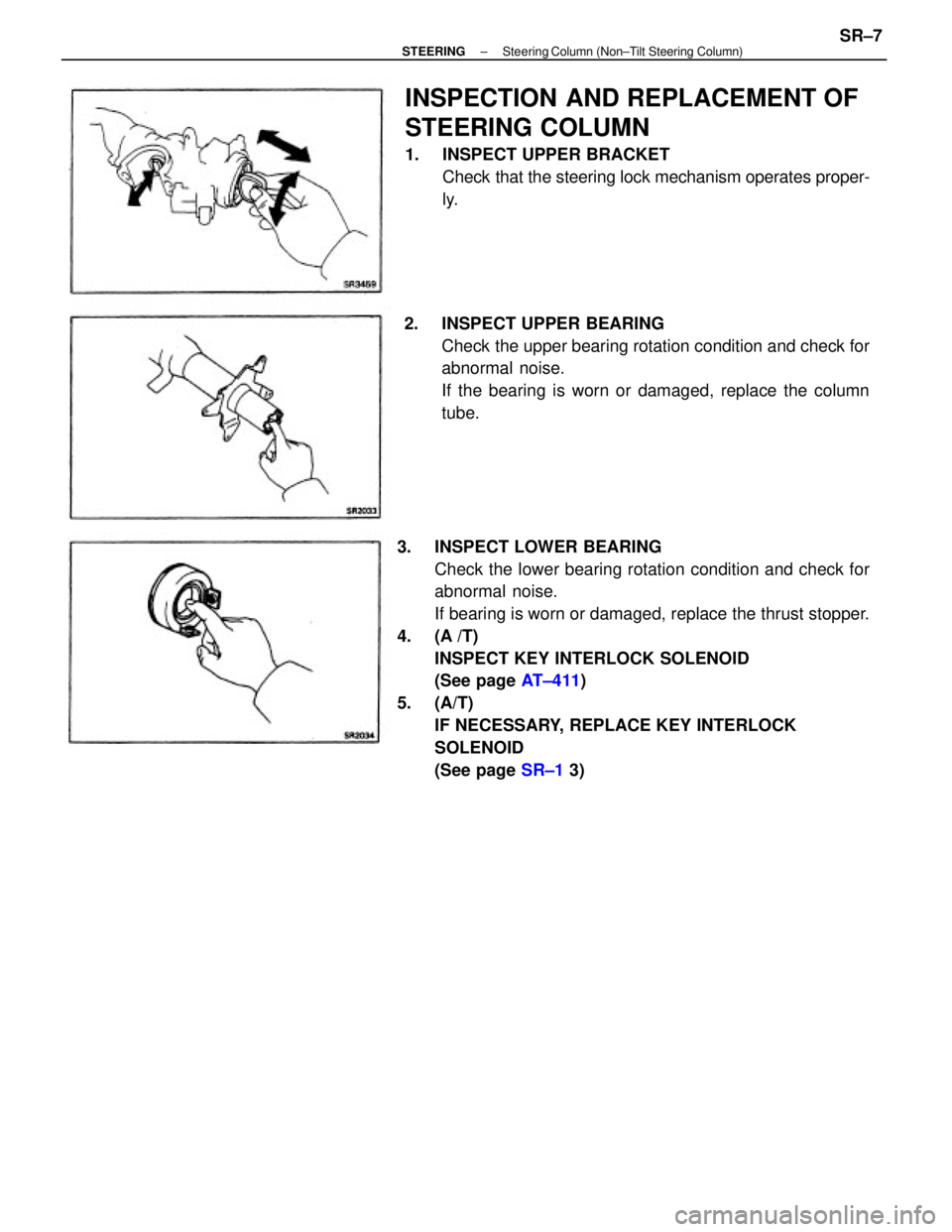

3. INSPECT LOWER BEARING

Check the lower bearing rotation condition and check for

abnormal noise.

If bearing is worn or damaged, replace the thrust stopper.

4. (A /T)

INSPECT KEY INTERLOCK SOLENOID

(See page AT±411)

5. (A/T)

IF NECESSARY, REPLACE KEY INTERLOCK

SOLENOID

(See page SR±1 3)

INSPECTION AND REPLACEMENT OF

STEERING COLUMN

1. INSPECT UPPER BRACKET

Check that the steering lock mechanism operates proper-

ly.

2. INSPECT UPPER BEARING

Check the upper bearing rotation condition and check for

abnormal noise.

If the bearing is worn or damaged, replace the column

tube.

± STEERINGSteering Column (Non±Tilt Steering Column)SR±7

Page 2343 of 2389

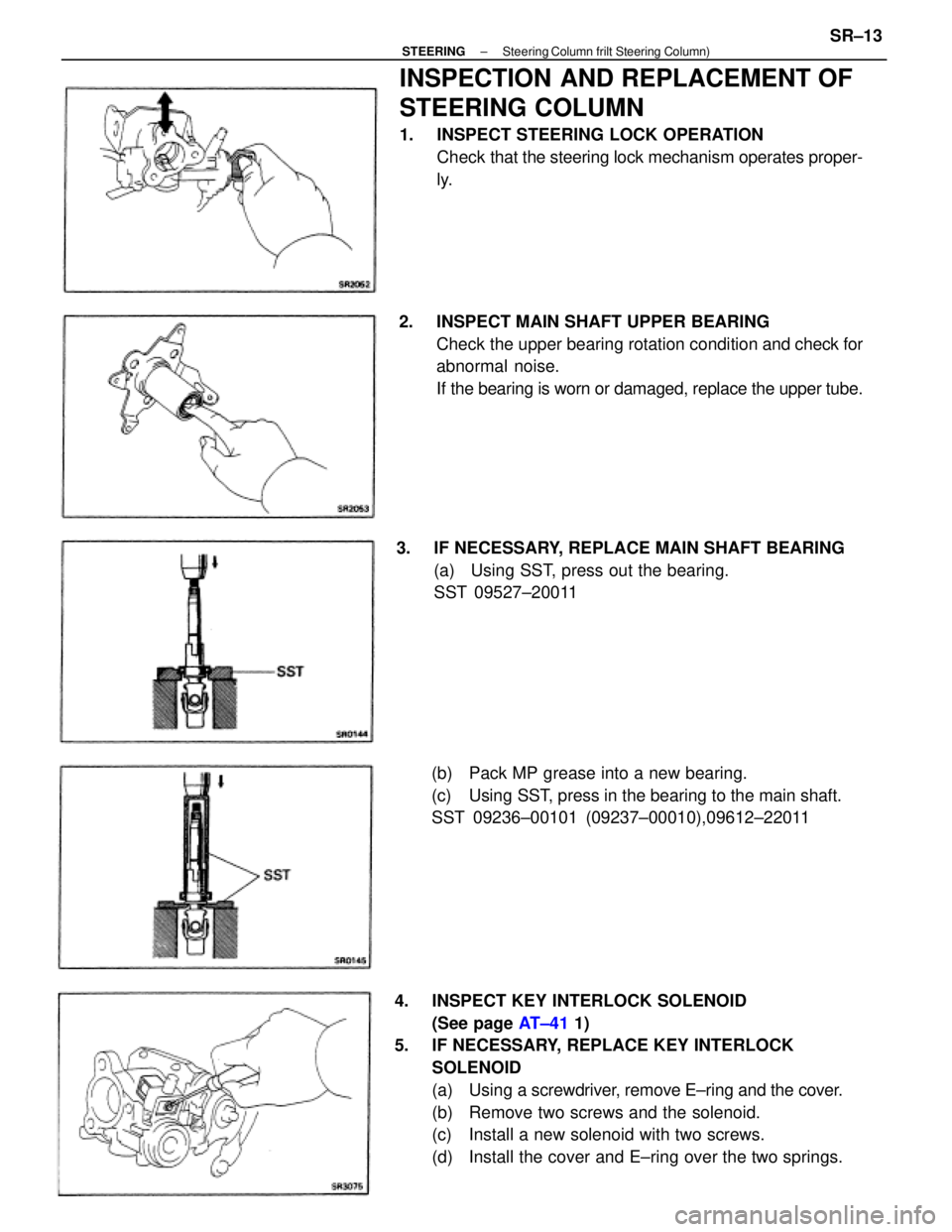

4. INSPECT KEY INTERLOCK SOLENOID

(See page AT±41 1)

5. IF NECESSARY, REPLACE KEY INTERLOCK

SOLENOID

(a) Using a screwdriver, remove E±ring and the cover.

(b) Remove two screws and the solenoid.

(c) Install a new solenoid with two screws.

(d) Install the cover and E±ring over the two springs.

INSPECTION AND REPLACEMENT OF

STEERING COLUMN

1. INSPECT STEERING LOCK OPERATION

Check that the steering lock mechanism operates proper-

ly.

2. INSPECT MAIN SHAFT UPPER BEARING

Check the upper bearing rotation condition and check for

abnormal noise.

If the bearing is worn or damaged, replace the upper tube.

3. IF NECESSARY, REPLACE MAIN SHAFT BEARING

(a) Using SST, press out the bearing.

SST 09527±20011

(b) Pack MP grease into a new bearing.

(c) Using SST, press in the bearing to the main shaft.

SST 09236±00101 (09237±00010),09612±22011

± STEERINGSteering Column frilt Steering Column)SR±13

Page 2348 of 2389

3. CHECK FOR FOAMING OR EMULSIFICATION

HINT: Foaming and emulsification indicate either the exis-

tence of air in the system or that the fluid level is too low.

4. CHECK FLUID LEVEL IN RESERVOIR

Check the fluid level and add fluid if necessary.

Fluid: ATF DEXRON II

HINT: Check that the fluid level is within the HOT LEVEL

of the tank. If the fluid is cold, check that it is within the

COLD LEVEL of the tank.

CHECK IDLE±UP

1. WARM UP ENGINE

2. TURN AIR CONDITIONER SWITCH OFF

3. CHECK IDLE±UP

(a) Fully turn the steering wheel.

(b) Check that the engine rpm decreases when the air

control valve hose is pinched.

(c) Check that the engine rpm increases when the air

control valve hose is released.

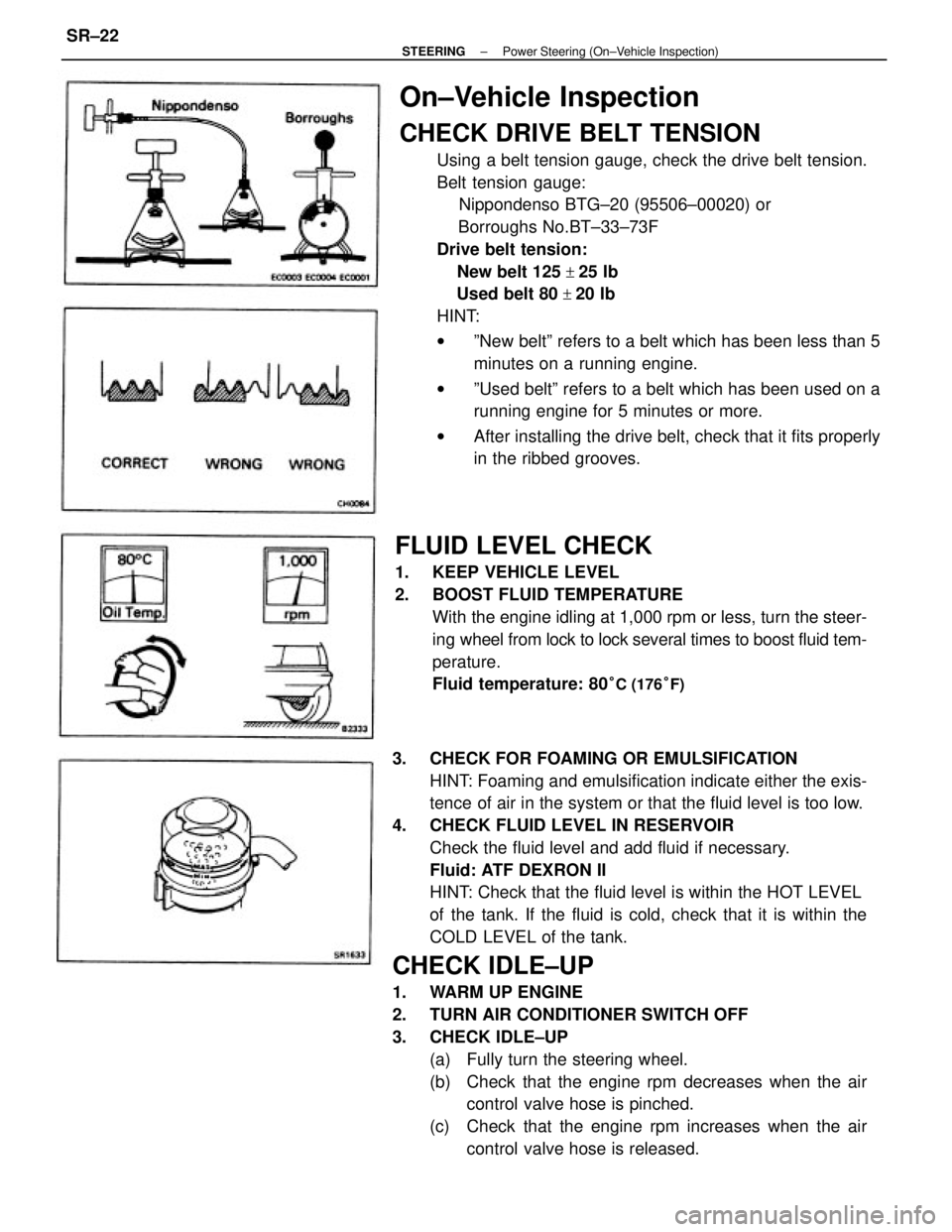

On±Vehicle Inspection

CHECK DRIVE BELT TENSION

Using a belt tension gauge, check the drive belt tension.

Belt tension gauge:

Nippondenso BTG±20 (95506±00020) or

Borroughs No.BT±33±73F

Drive belt tension:

New belt 125

+25 Ib

Used belt 80

+20 Ib

HINT:

wºNew beltº refers to a belt which has been less than 5

minutes on a running engine.

wºUsed beltº refers to a belt which has been used on a

running engine for 5 minutes or more.

wAfter installing the drive belt, check that it fits properly

in the ribbed grooves.

FLUID LEVEL CHECK

1. KEEP VEHICLE LEVEL

2. BOOST FLUID TEMPERATURE

With the engine idling at 1,000 rpm or less, turn the steer-

ing wheel from lock to lock several times to boost fluid tem-

perature.

Fluid temperature: 80

°C (176°F)

± STEERINGPower Steering (On±Vehicle Inspection)SR±22