steering wheel TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 2327 of 2389

Inflate tires to proper pressure

lubricate suspension and steering

linkage

Check front wheel alignment

Replace steering system joints

Replace lower arm ball joints

Inspect steering column

Adjust or repair steering gear

Adjust belt

Check reservoir

Check power steering unit

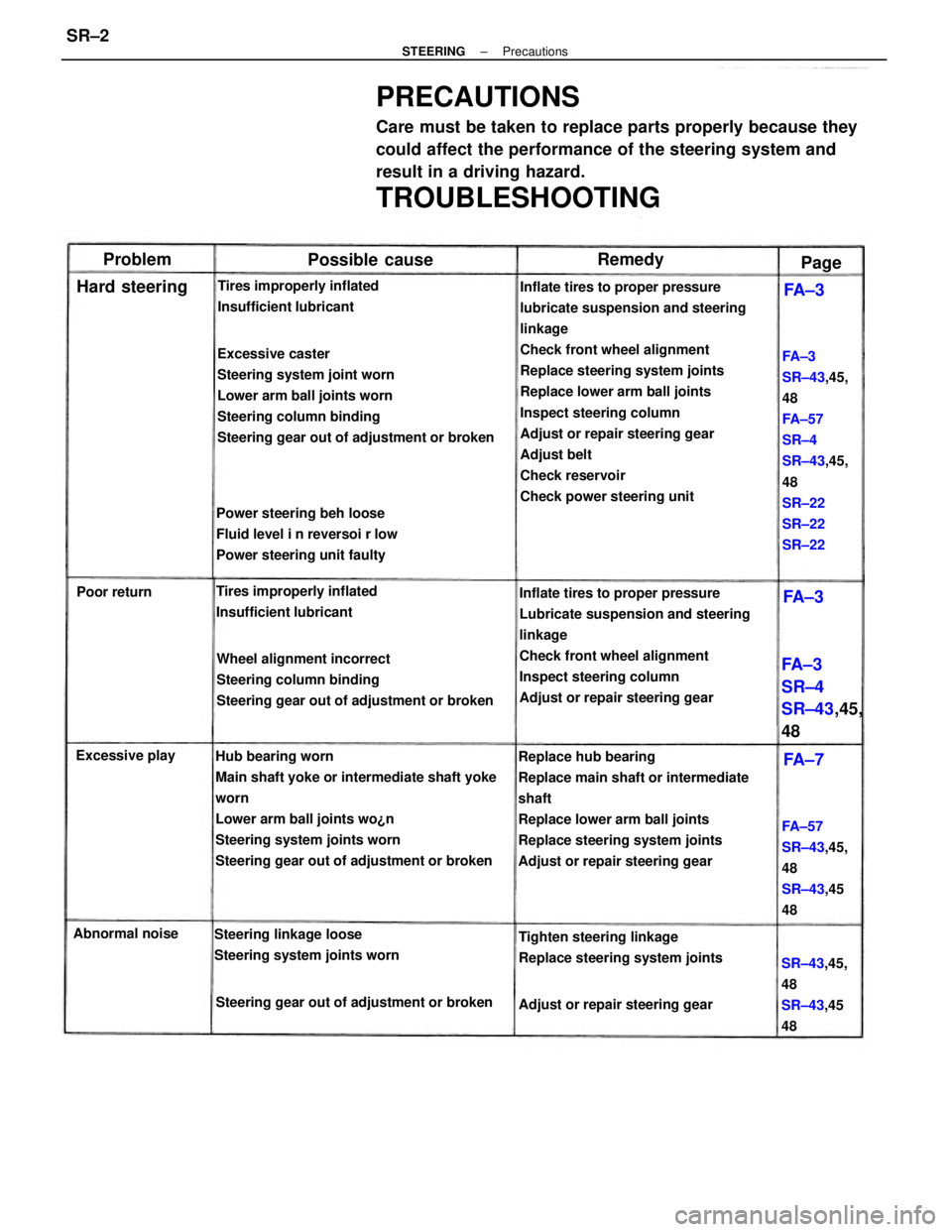

PRECAUTIONS

Care must be taken to replace parts properly because they

could affect the performance of the steering system and

result in a driving hazard.

TROUBLESHOOTING

Hub bearing worn

Main shaft yoke or intermediate shaft yoke

worn

Lower arm ball joints wo¿n

Steering system joints worn

Steering gear out of adjustment or brokenExcessive caster

Steering system joint worn

Lower arm ball joints worn

Steering column binding

Steering gear out of adjustment or broken

Replace hub bearing

Replace main shaft or intermediate

shaft

Replace lower arm ball joints

Replace steering system joints

Adjust or repair steering gearInflate tires to proper pressure

Lubricate suspension and steering

linkage

Check front wheel alignment

Inspect steering column

Adjust or repair steering gear Wheel alignment incorrect

Steering column binding

Steering gear out of adjustment or brokenFA±3

SR±43,45,

48

FA±57

SR±4

SR±43,45,

48

SR±22

SR±22

SR±22 Power steering beh loose

Fluid level i n reversoi r low

Power steering unit faulty

Tighten steering linkage

Replace steering system joints Steering linkage loose

Steering system joints wornFA±57

SR±43,45,

48

SR±43,45

48 Tires improperly inflated

Insufficient lubricantTires improperly inflated

Insufficient lubricant

Steering gear out of adjustment or broken

FA ± 3

SR±4

SR±43,45,

48

SR±43,45,

48

SR±43,45

48 Adjust or repair steering gear Abnormal noiseExcessive play

Possible cause

Hard steering

Poor return

Remedy Problem

Page

FA ± 7FA ± 3

FA ± 3

± STEERINGPrecautionsSR±2

Page 2328 of 2389

Inflate tires to proper pressure

lubricate suspension and steering

linkage

Check front wheel alignment

Replace steering system joints

Replace lower arm ball joints

Inspect steering column

Adjust or repair steering gear

Adjust belt

Check reservoir

Check power steering unit

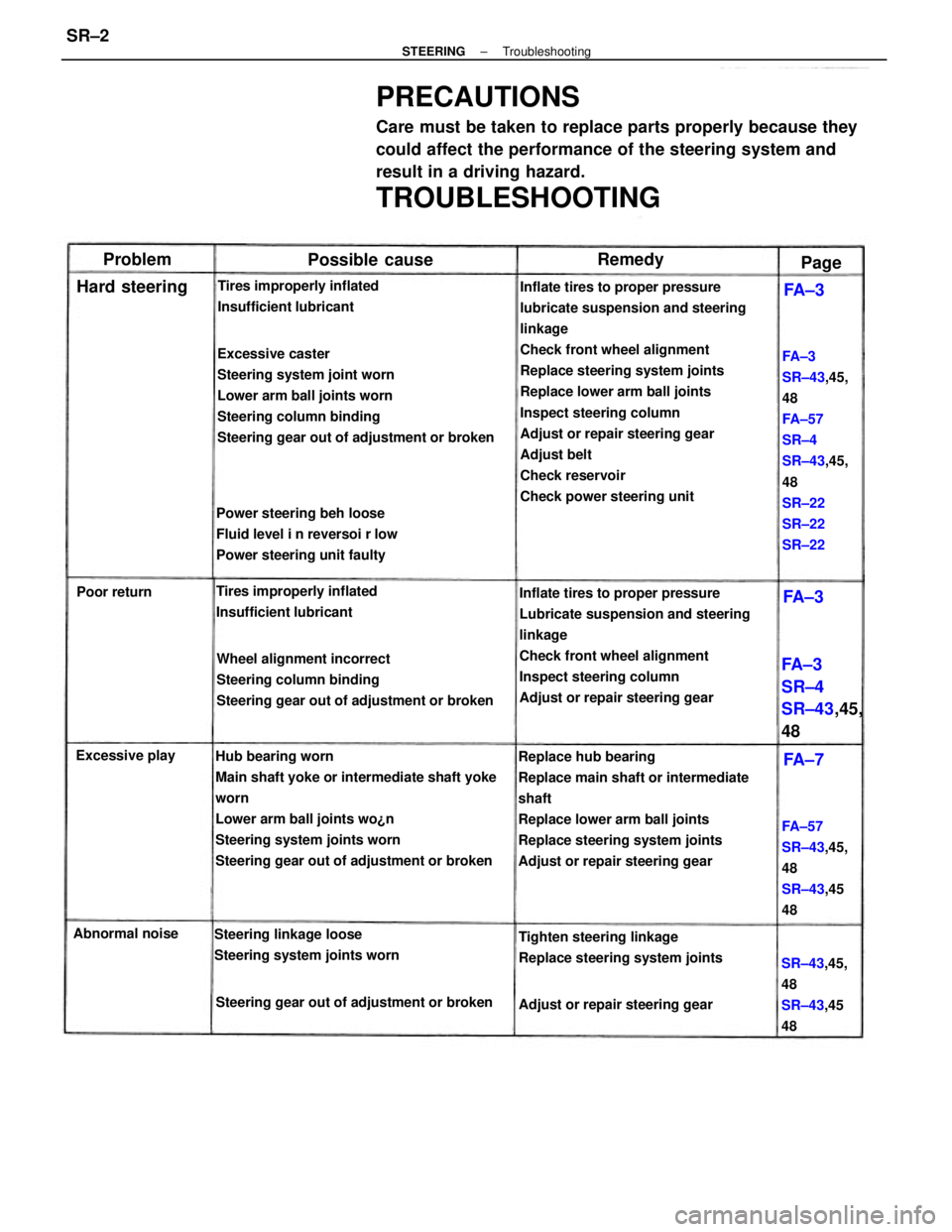

PRECAUTIONS

Care must be taken to replace parts properly because they

could affect the performance of the steering system and

result in a driving hazard.

TROUBLESHOOTING

Hub bearing worn

Main shaft yoke or intermediate shaft yoke

worn

Lower arm ball joints wo¿n

Steering system joints worn

Steering gear out of adjustment or brokenExcessive caster

Steering system joint worn

Lower arm ball joints worn

Steering column binding

Steering gear out of adjustment or broken

Replace hub bearing

Replace main shaft or intermediate

shaft

Replace lower arm ball joints

Replace steering system joints

Adjust or repair steering gearInflate tires to proper pressure

Lubricate suspension and steering

linkage

Check front wheel alignment

Inspect steering column

Adjust or repair steering gear Wheel alignment incorrect

Steering column binding

Steering gear out of adjustment or brokenFA±3

SR±43,45,

48

FA±57

SR±4

SR±43,45,

48

SR±22

SR±22

SR±22 Power steering beh loose

Fluid level i n reversoi r low

Power steering unit faulty

Tighten steering linkage

Replace steering system joints Steering linkage loose

Steering system joints wornFA±57

SR±43,45,

48

SR±43,45

48 Tires improperly inflated

Insufficient lubricantTires improperly inflated

Insufficient lubricant

Steering gear out of adjustment or broken

FA ± 3

SR±4

SR±43,45,

48

SR±43,45,

48

SR±43,45

48 Adjust or repair steering gear Abnormal noiseExcessive play

Possible cause

Hard steering

Poor return

Remedy Problem

Page

FA ± 7FA ± 3

FA ± 3

± STEERINGTroubleshootingSR±2

Page 2329 of 2389

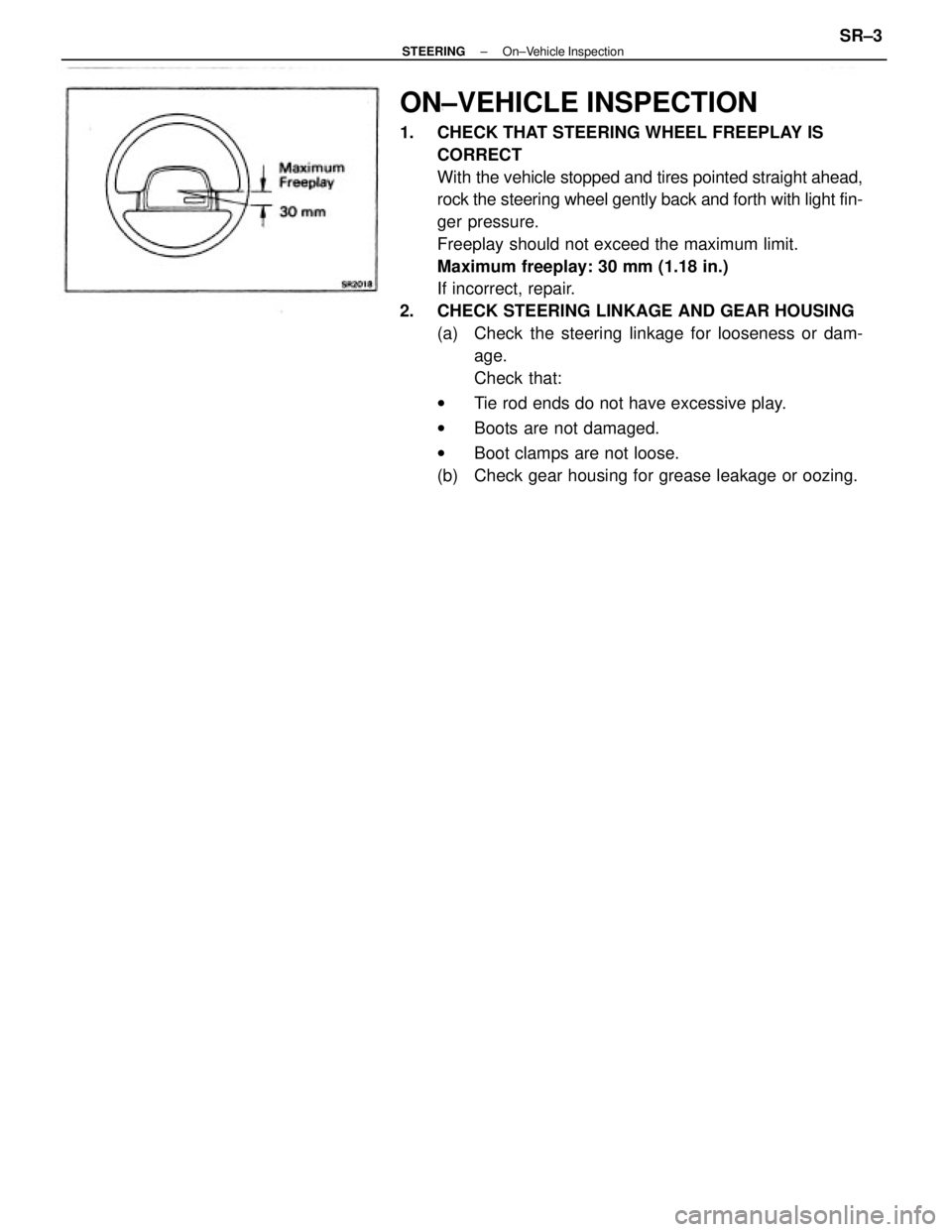

ON±VEHICLE INSPECTION

1. CHECK THAT STEERING WHEEL FREEPLAY IS

CORRECT

With the vehicle stopped and tires pointed straight ahead,

rock the steering wheel gently back and forth with light fin-

ger pressure.

Freeplay should not exceed the maximum limit.

Maximum freeplay: 30 mm (1.18 in.)

If incorrect, repair.

2. CHECK STEERING LINKAGE AND GEAR HOUSING

(a) Check the steering linkage for looseness or dam-

age.

Check that:

wTie rod ends do not have excessive play.

wBoots are not damaged.

wBoot clamps are not loose.

(b) Check gear housing for grease leakage or oozing.

± STEERINGOn±Vehicle InspectionSR±3

Page 2330 of 2389

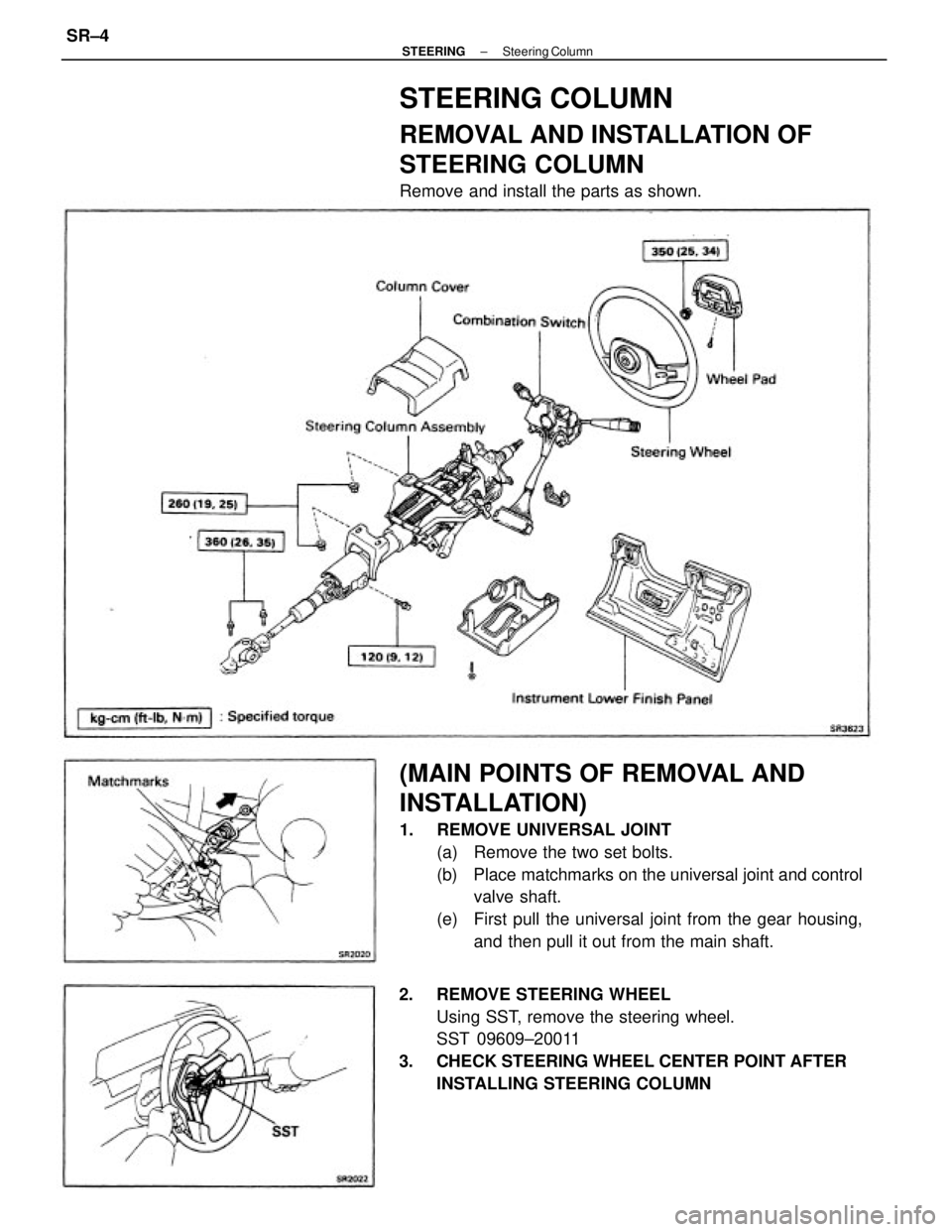

(MAIN POINTS OF REMOVAL AND

INSTALLATION)

1. REMOVE UNIVERSAL JOINT

(a) Remove the two set bolts.

(b) Place matchmarks on the universal joint and control

valve shaft.

(e) First pull the universal joint from the gear housing,

and then pull it out from the main shaft.

STEERING COLUMN

REMOVAL AND INSTALLATION OF

STEERING COLUMN

Remove and install the parts as shown.

2. REMOVE STEERING WHEEL

Using SST, remove the steering wheel.

SST 09609±20011

3. CHECK STEERING WHEEL CENTER POINT AFTER

INSTALLING STEERING COLUMN

± STEERINGSteering ColumnSR±4

Page 2336 of 2389

SERVICE HINT

Troubles with the power steering system are usually

concerned with hard steering due to the fact that

there is no assist. In such cases, before attempting

to make repairs, it is necessary to determine wheth-

er the trouble lies with the pump or with the gear

housing. To do this, an on±vehicle inspection can be

made by using a pressure gauge.

ON±VEHICLE INSPECTION

Power steering is a hydraulic device and problems

are normally due to insufficient fluid pressure acting

on the piston. This could be caused by either the

pump not producing the specified fluid pressure or

the control valve in the gear housing not functioning

properly so that the proper fluid pressure can not be

obtained.

If the fault lies with the pump, the same symptoms

will generally occur whether the steering wheel is

turned fully to the right or left. On the other hand, if

the fault lies with the control valve, there will gener-

ally be difference between the amount of assist

when the steering wheel is turned to the left and

right, causing harder steering. However, if the piston

seal of the power cylinder is worn, there will be a

loss of fluid pressure whether the steering wheel is

turned to the right or left and the symptoms will be

the same for both.

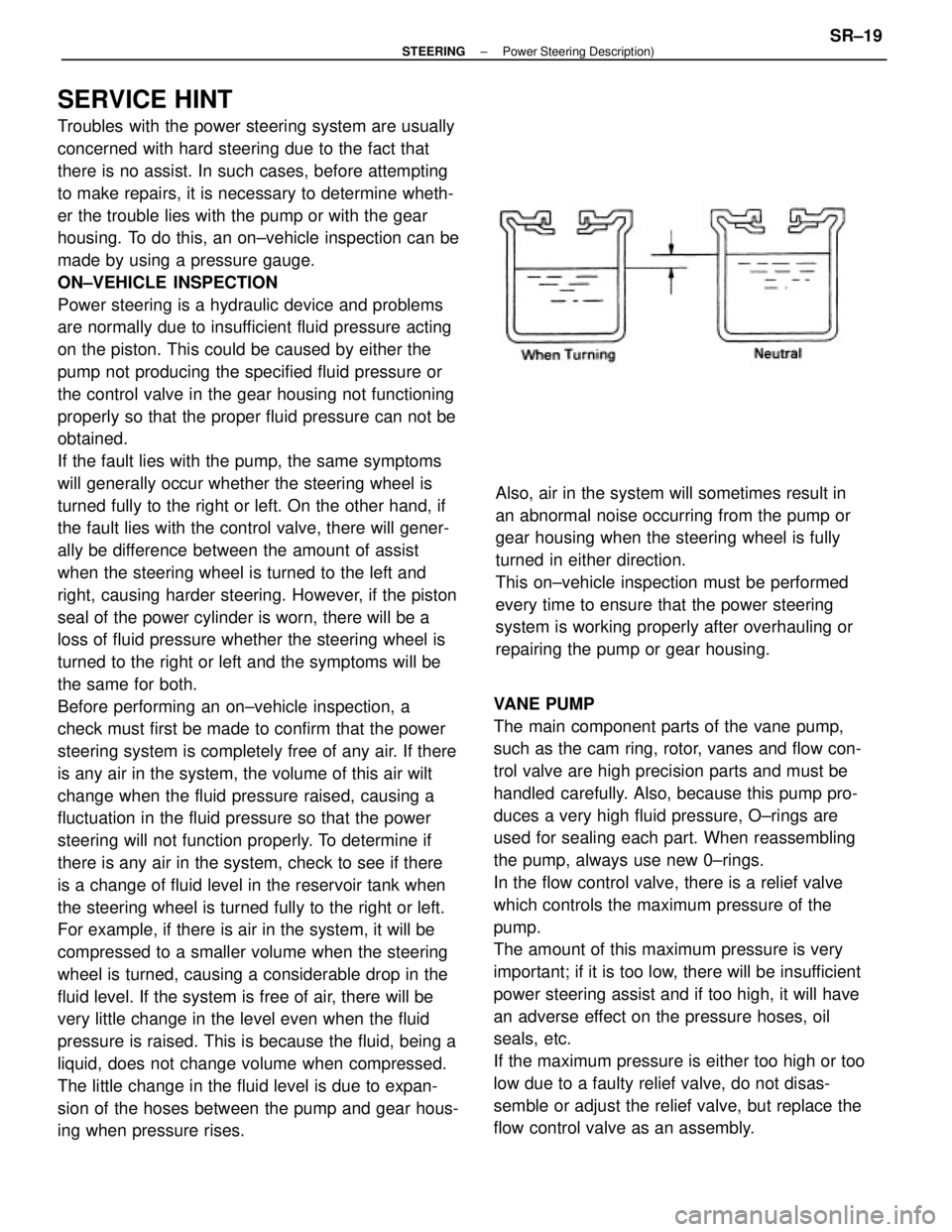

Before performing an on±vehicle inspection, a

check must first be made to confirm that the power

steering system is completely free of any air. If there

is any air in the system, the volume of this air wilt

change when the fluid pressure raised, causing a

fluctuation in the fluid pressure so that the power

steering will not function properly. To determine if

there is any air in the system, check to see if there

is a change of fluid level in the reservoir tank when

the steering wheel is turned fully to the right or left.

For example, if there is air in the system, it will be

compressed to a smaller volume when the steering

wheel is turned, causing a considerable drop in the

fluid level. If the system is free of air, there will be

very little change in the level even when the fluid

pressure is raised. This is because the fluid, being a

liquid, does not change volume when compressed.

The little change in the fluid level is due to expan-

sion of the hoses between the pump and gear hous-

ing when pressure rises.VANE PUMP

The main component parts of the vane pump,

such as the cam ring, rotor, vanes and flow con-

trol valve are high precision parts and must be

handled carefully. Also, because this pump pro-

duces a very high fluid pressure, O±rings are

used for sealing each part. When reassembling

the pump, always use new 0±rings.

In the flow control valve, there is a relief valve

which controls the maximum pressure of the

pump.

The amount of this maximum pressure is very

important; if it is too low, there will be insufficient

power steering assist and if too high, it will have

an adverse effect on the pressure hoses, oil

seals, etc.

If the maximum pressure is either too high or too

low due to a faulty relief valve, do not disas-

semble or adjust the relief valve, but replace the

flow control valve as an assembly.Also, air in the system will sometimes result in

an abnormal noise occurring from the pump or

gear housing when the steering wheel is fully

turned in either direction.

This on±vehicle inspection must be performed

every time to ensure that the power steering

system is working properly after overhauling or

repairing the pump or gear housing.

± STEERINGPower Steering Description)SR±19

Page 2338 of 2389

IDLE±UP DEVICE

The pump produces the maximum fluid pressure

when the steering wheel is turned fully to the

right or left and, at this time, there is a maximum

load on

the pump which causes a decrease in engine

idle rpm. To solve this problem, vehicles are

equipped with an idle±up device which acts to

raise the engine idle rpm whenever there is a

heavy load on

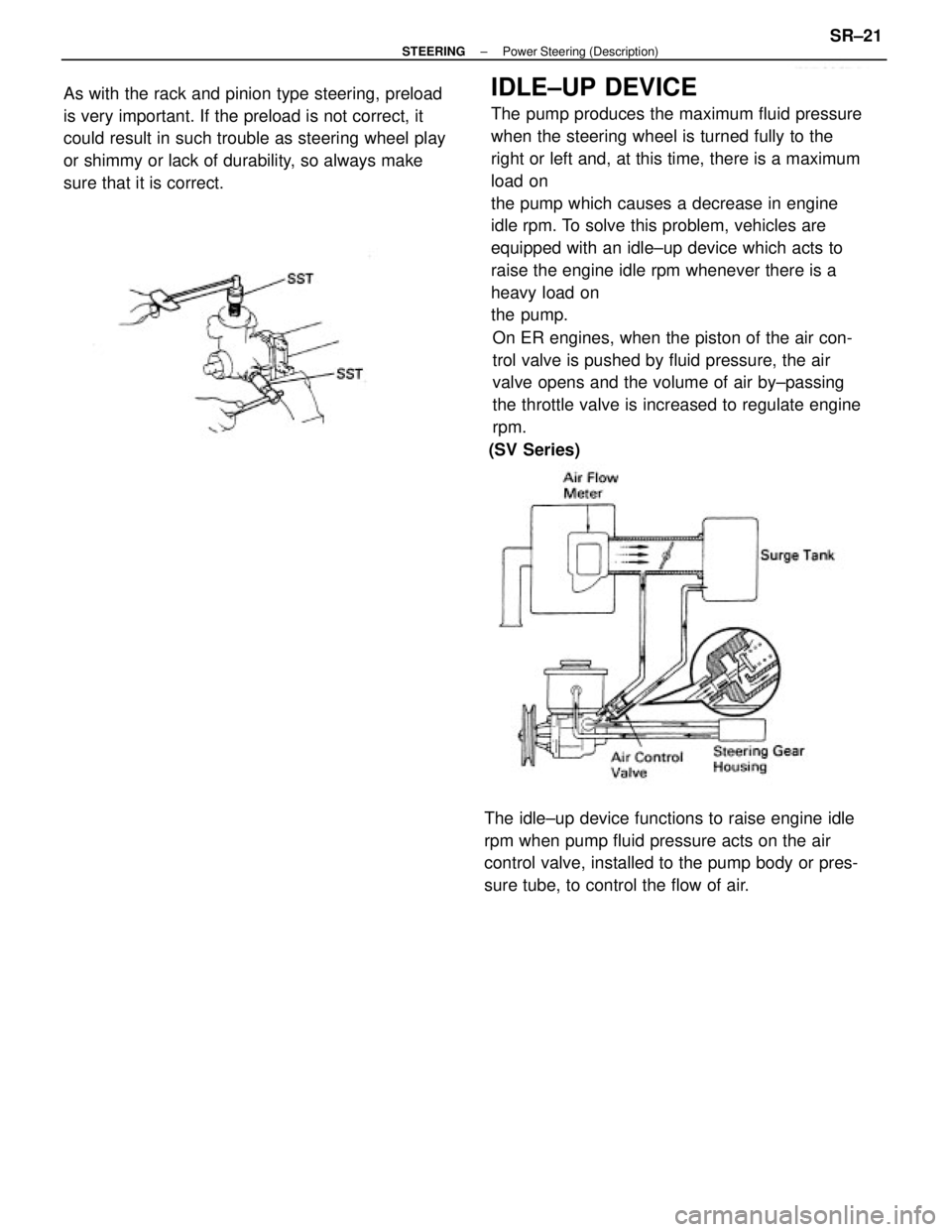

the pump. As with the rack and pinion type steering, preload

is very important. If the preload is not correct, it

could result in such trouble as steering wheel play

or shimmy or lack of durability, so always make

sure that it is correct.

On ER engines, when the piston of the air con-

trol valve is pushed by fluid pressure, the air

valve opens and the volume of air by±passing

the throttle valve is increased to regulate engine

rpm.

The idle±up device functions to raise engine idle

rpm when pump fluid pressure acts on the air

control valve, installed to the pump body or pres-

sure tube, to control the flow of air.(SV Series)

± STEERINGPower Steering (Description)SR±21

Page 2348 of 2389

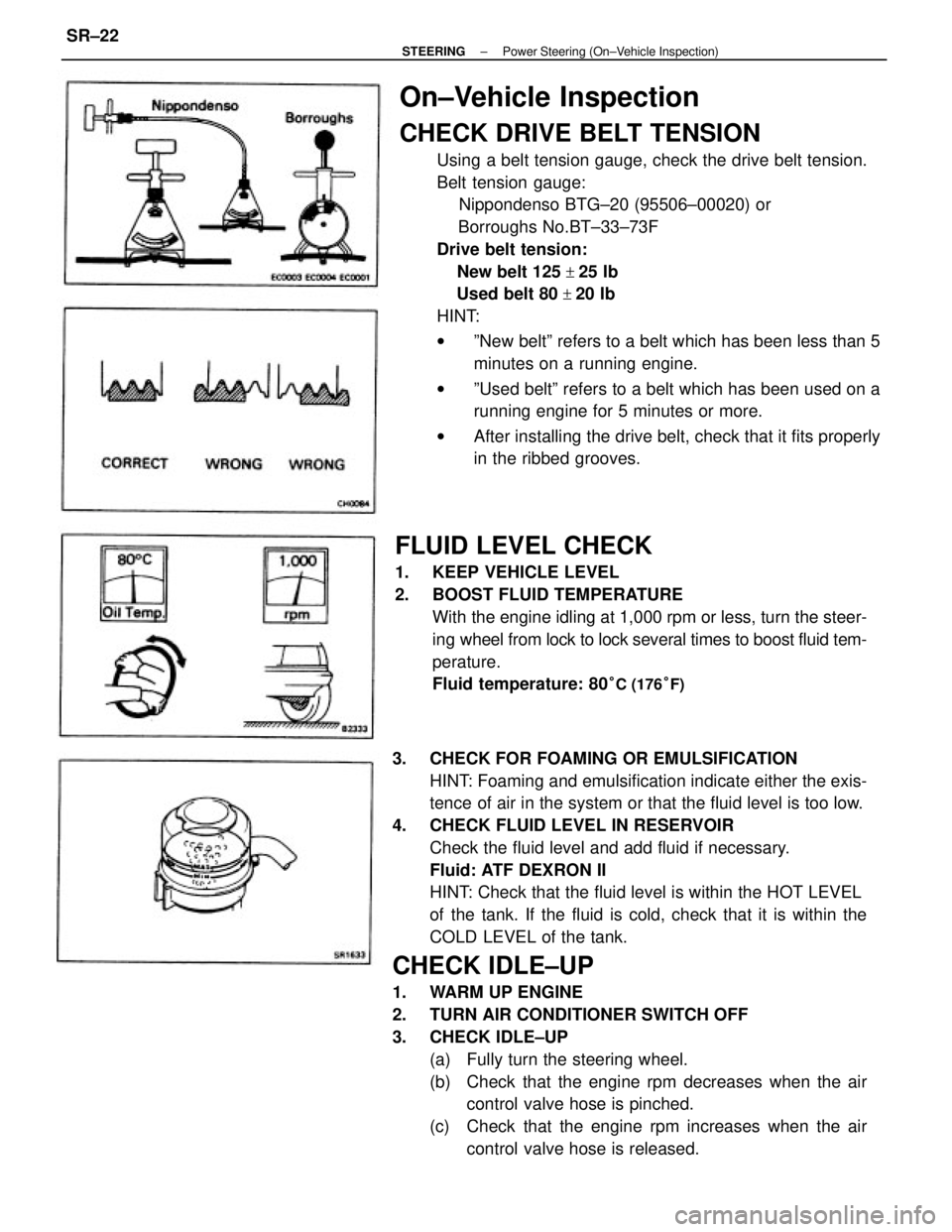

3. CHECK FOR FOAMING OR EMULSIFICATION

HINT: Foaming and emulsification indicate either the exis-

tence of air in the system or that the fluid level is too low.

4. CHECK FLUID LEVEL IN RESERVOIR

Check the fluid level and add fluid if necessary.

Fluid: ATF DEXRON II

HINT: Check that the fluid level is within the HOT LEVEL

of the tank. If the fluid is cold, check that it is within the

COLD LEVEL of the tank.

CHECK IDLE±UP

1. WARM UP ENGINE

2. TURN AIR CONDITIONER SWITCH OFF

3. CHECK IDLE±UP

(a) Fully turn the steering wheel.

(b) Check that the engine rpm decreases when the air

control valve hose is pinched.

(c) Check that the engine rpm increases when the air

control valve hose is released.

On±Vehicle Inspection

CHECK DRIVE BELT TENSION

Using a belt tension gauge, check the drive belt tension.

Belt tension gauge:

Nippondenso BTG±20 (95506±00020) or

Borroughs No.BT±33±73F

Drive belt tension:

New belt 125

+25 Ib

Used belt 80

+20 Ib

HINT:

wºNew beltº refers to a belt which has been less than 5

minutes on a running engine.

wºUsed beltº refers to a belt which has been used on a

running engine for 5 minutes or more.

wAfter installing the drive belt, check that it fits properly

in the ribbed grooves.

FLUID LEVEL CHECK

1. KEEP VEHICLE LEVEL

2. BOOST FLUID TEMPERATURE

With the engine idling at 1,000 rpm or less, turn the steer-

ing wheel from lock to lock several times to boost fluid tem-

perature.

Fluid temperature: 80

°C (176°F)

± STEERINGPower Steering (On±Vehicle Inspection)SR±22

Page 2349 of 2389

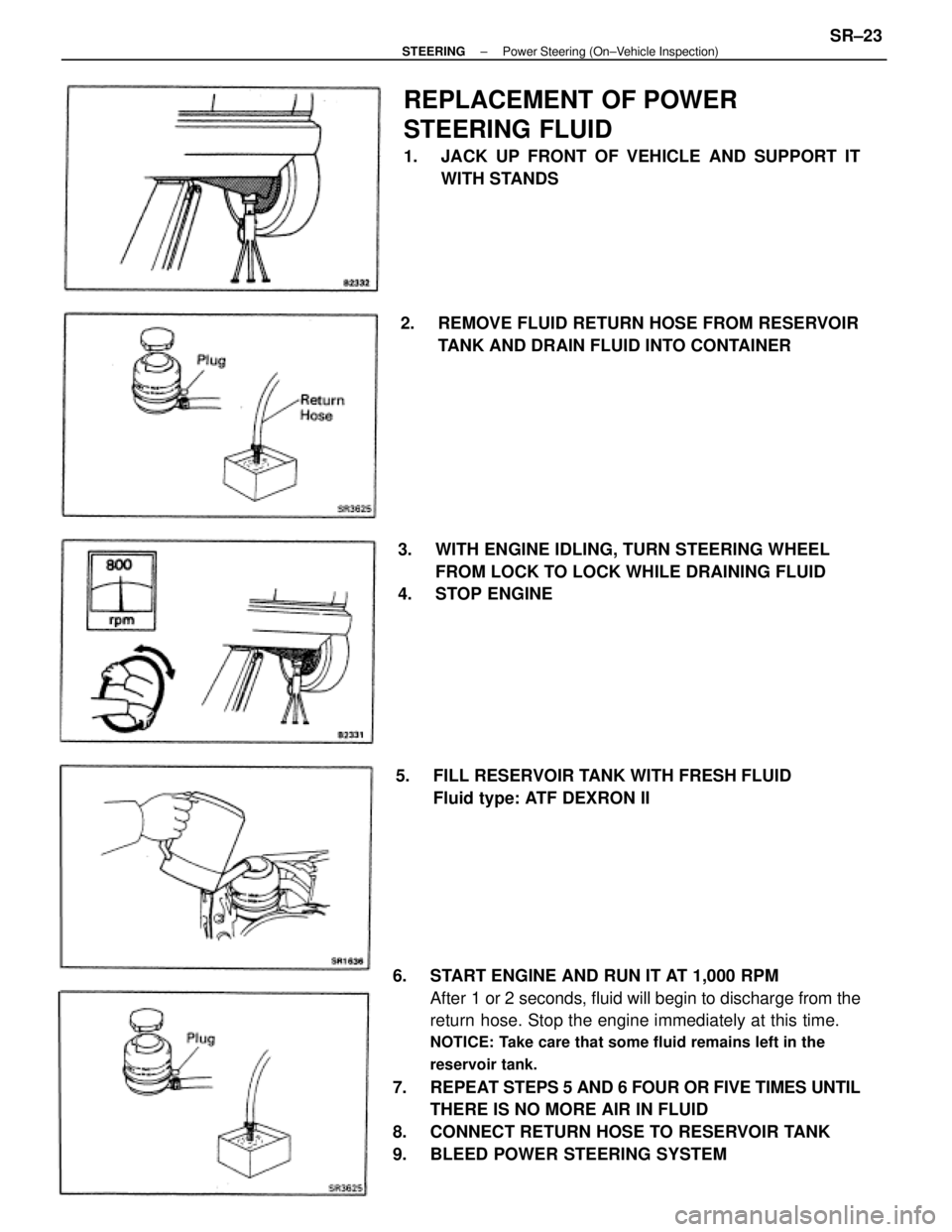

6. START ENGINE AND RUN IT AT 1,000 RPM

After 1 or 2 seconds, fluid will begin to discharge from the

return hose. Stop the engine immediately at this time.

NOTICE: Take care that some fluid remains left in the

reservoir tank.

7. REPEAT STEPS 5 AND 6 FOUR OR FIVE TIMES UNTIL

THERE IS NO MORE AIR IN FLUID

8. CONNECT RETURN HOSE TO RESERVOIR TANK

9. BLEED POWER STEERING SYSTEM

REPLACEMENT OF POWER

STEERING FLUID

1. JACK UP FRONT OF VEHICLE AND SUPPORT IT

WITH STANDS

3. WITH ENGINE IDLING, TURN STEERING WHEEL

FROM LOCK TO LOCK WHILE DRAINING FLUID

4. STOP ENGINE2. REMOVE FLUID RETURN HOSE FROM RESERVOIR

TANK AND DRAIN FLUID INTO CONTAINER

5. FILL RESERVOIR TANK WITH FRESH FLUID

Fluid type: ATF DEXRON II

± STEERINGPower Steering (On±Vehicle Inspection)SR±23

Page 2350 of 2389

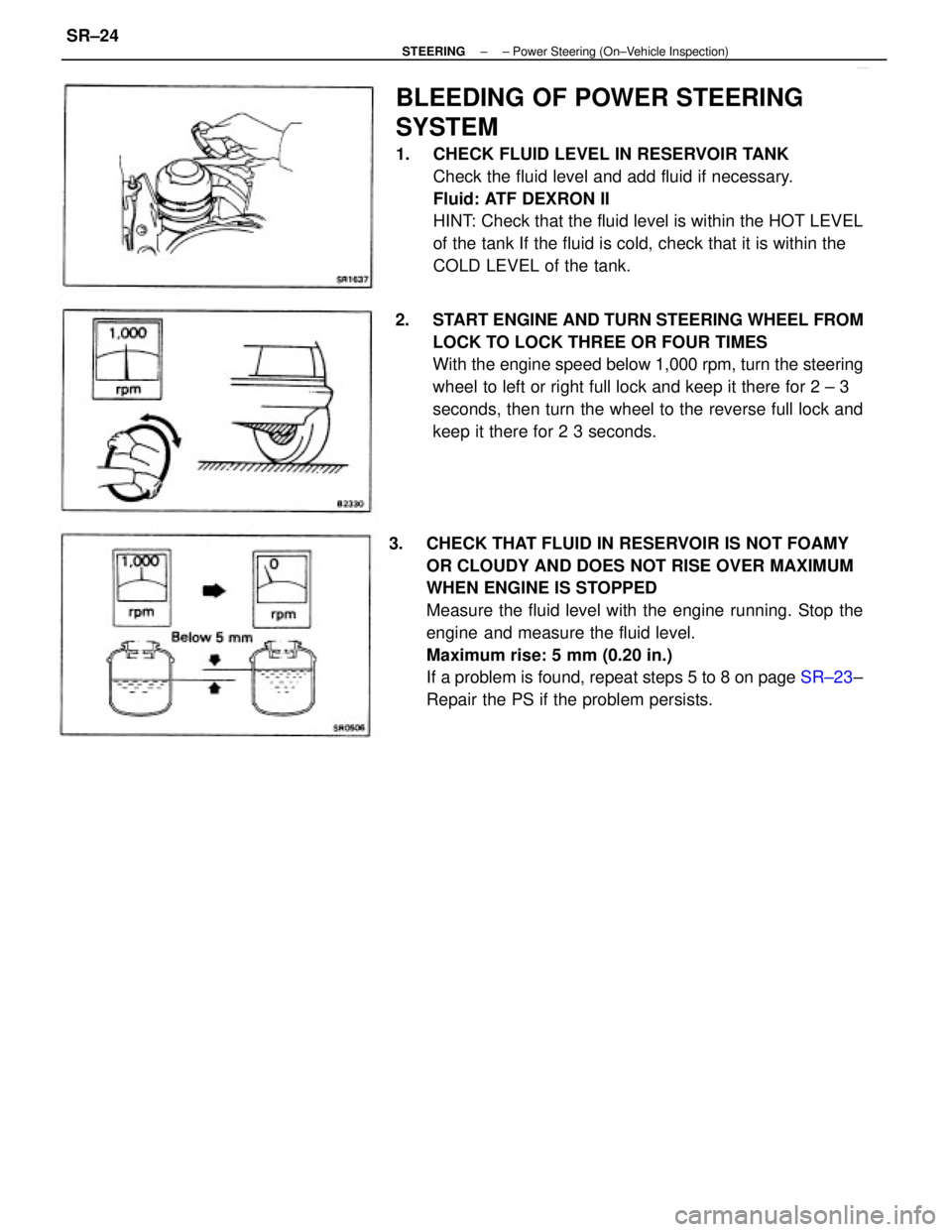

3. CHECK THAT FLUID IN RESERVOIR IS NOT FOAMY

OR CLOUDY AND DOES NOT RISE OVER MAXIMUM

WHEN ENGINE IS STOPPED

Measure the fluid level with the engine running. Stop the

engine and measure the fluid level.

Maximum rise: 5 mm (0.20 in.)

If a problem is found, repeat steps 5 to 8 on page SR±23±

Repair the PS if the problem persists.

BLEEDING OF POWER STEERING

SYSTEM

1. CHECK FLUID LEVEL IN RESERVOIR TANK

Check the fluid level and add fluid if necessary.

Fluid: ATF DEXRON II

HINT: Check that the fluid level is within the HOT LEVEL

of the tank If the fluid is cold, check that it is within the

COLD LEVEL of the tank.

2. START ENGINE AND TURN STEERING WHEEL FROM

LOCK TO LOCK THREE OR FOUR TIMES

With the engine speed below 1,000 rpm, turn the steering

wheel to left or right full lock and keep it there for 2 ± 3

seconds, then turn the wheel to the reverse full lock and

keep it there for 2 3 seconds.

± STEERING± Power Steering (On±Vehicle Inspection)SR±24

Page 2351 of 2389

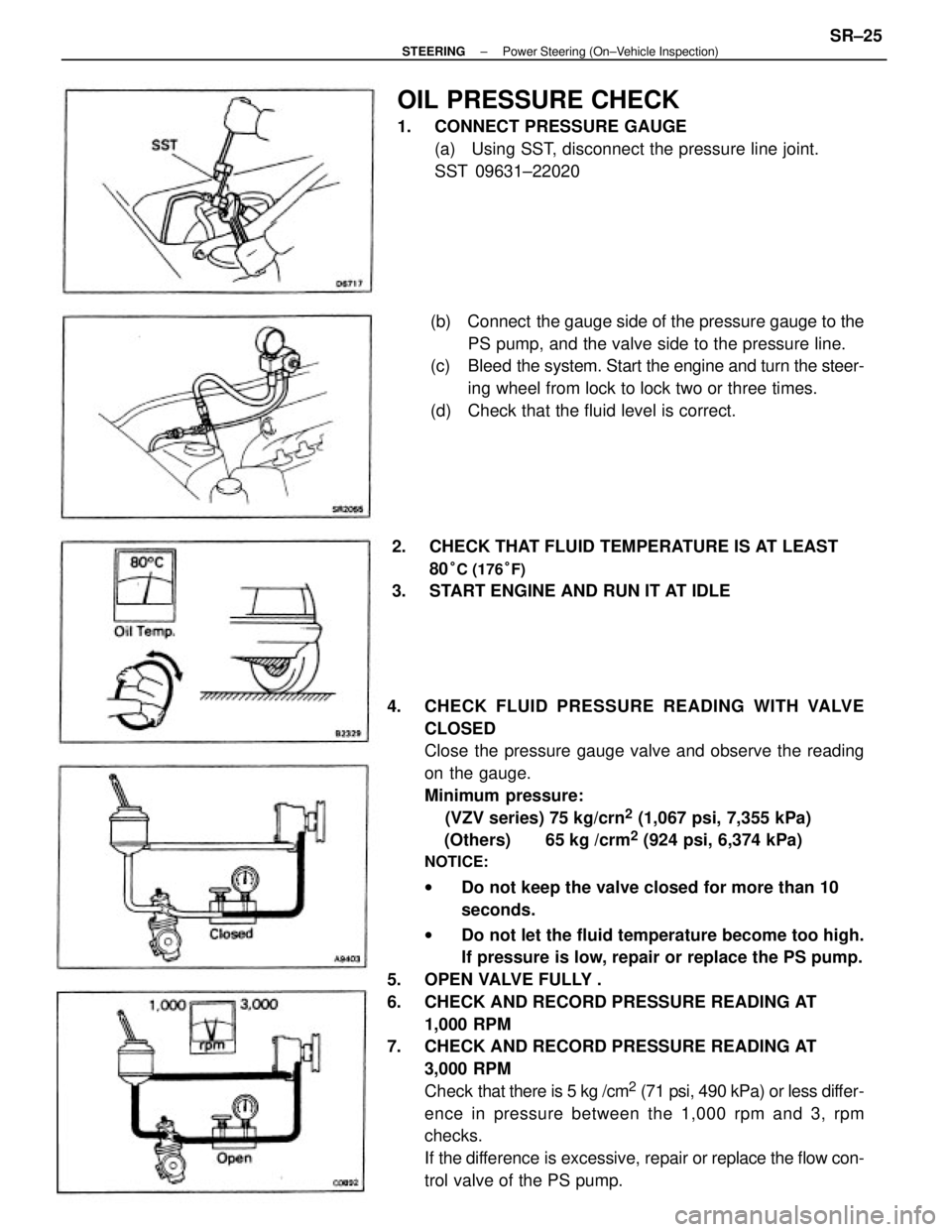

4. CHECK FLUID PRESSURE READING WITH VALVE

CLOSED

Close the pressure gauge valve and observe the reading

on the gauge.

Minimum pressure:

(VZV series) 75 kg/crn

2 (1,067 psi, 7,355 kPa)

(Others) 65 kg /crm

2 (924 psi, 6,374 kPa)

NOTICE:

wDo not keep the valve closed for more than 10

seconds.

wDo not let the fluid temperature become too high.

If pressure is low, repair or replace the PS pump.

5. OPEN VALVE FULLY .

6. CHECK AND RECORD PRESSURE READING AT

1,000 RPM

7. CHECK AND RECORD PRESSURE READING AT

3,000 RPM

Check that there is 5 kg /cm

2 (71 psi, 490 kPa) or less differ-

ence in pressure between the 1,000 rpm and 3, rpm

checks.

If the difference is excessive, repair or replace the flow con-

trol valve of the PS pump.(b) Connect the gauge side of the pressure gauge to the

PS pump, and the valve side to the pressure line.

(c) Bleed the system. Start the engine and turn the steer-

ing wheel from lock to lock two or three times.

(d) Check that the fluid level is correct.

OIL PRESSURE CHECK

1. CONNECT PRESSURE GAUGE

(a) Using SST, disconnect the pressure line joint.

SST 09631±22020

2. CHECK THAT FLUID TEMPERATURE IS AT LEAST

80

°C (176°F)

3. START ENGINE AND RUN IT AT IDLE

± STEERINGPower Steering (On±Vehicle Inspection)SR±25