alternator belt TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 958 of 2389

PRECAUTIONS

1. Check that the battery cables are connected to the correct

terminals.

2. Disconnect the battery cables when the battery is given a

quick charge.

3. Do not perform tests with a high voltage insulation

resistance tester.

4. Never disconnect the battery when the engine is running.

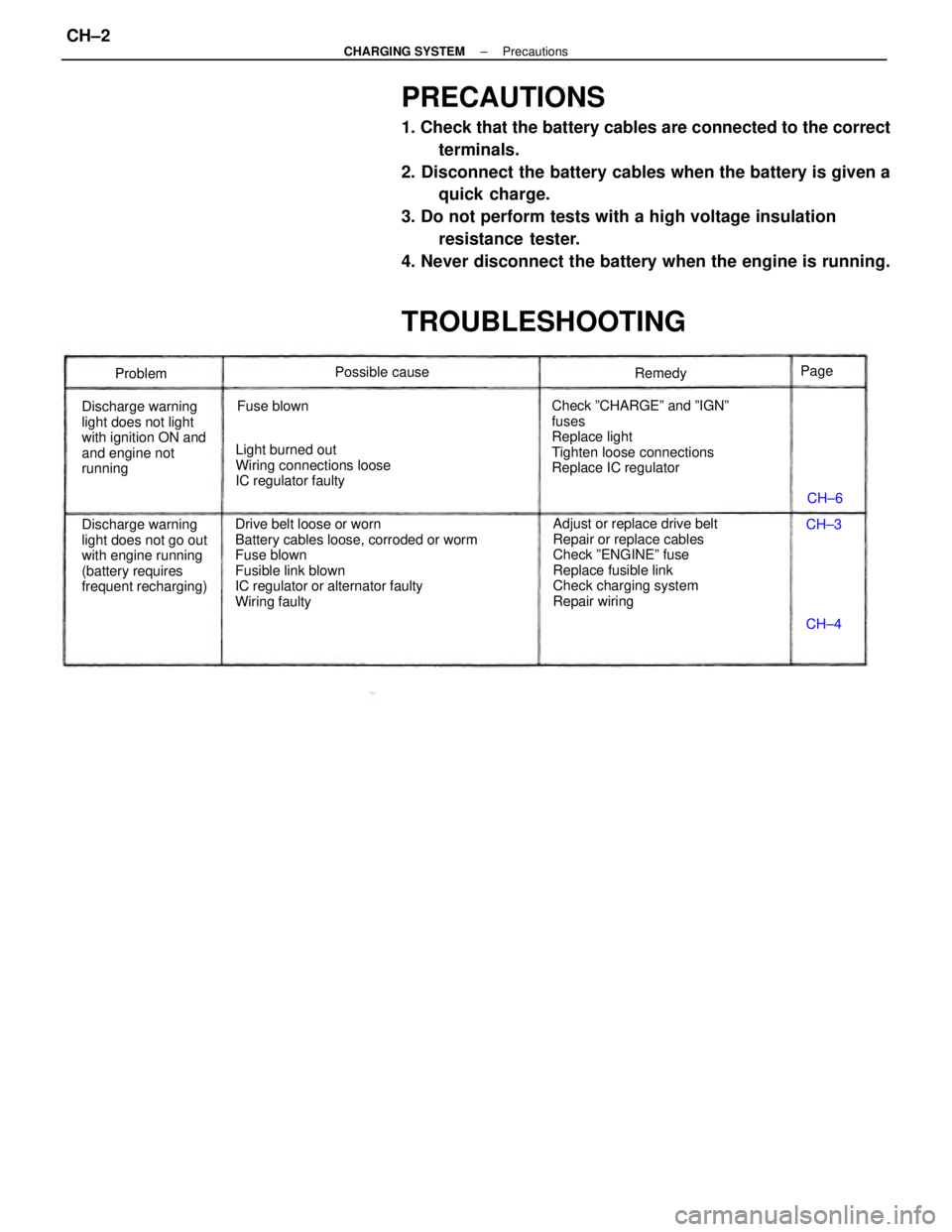

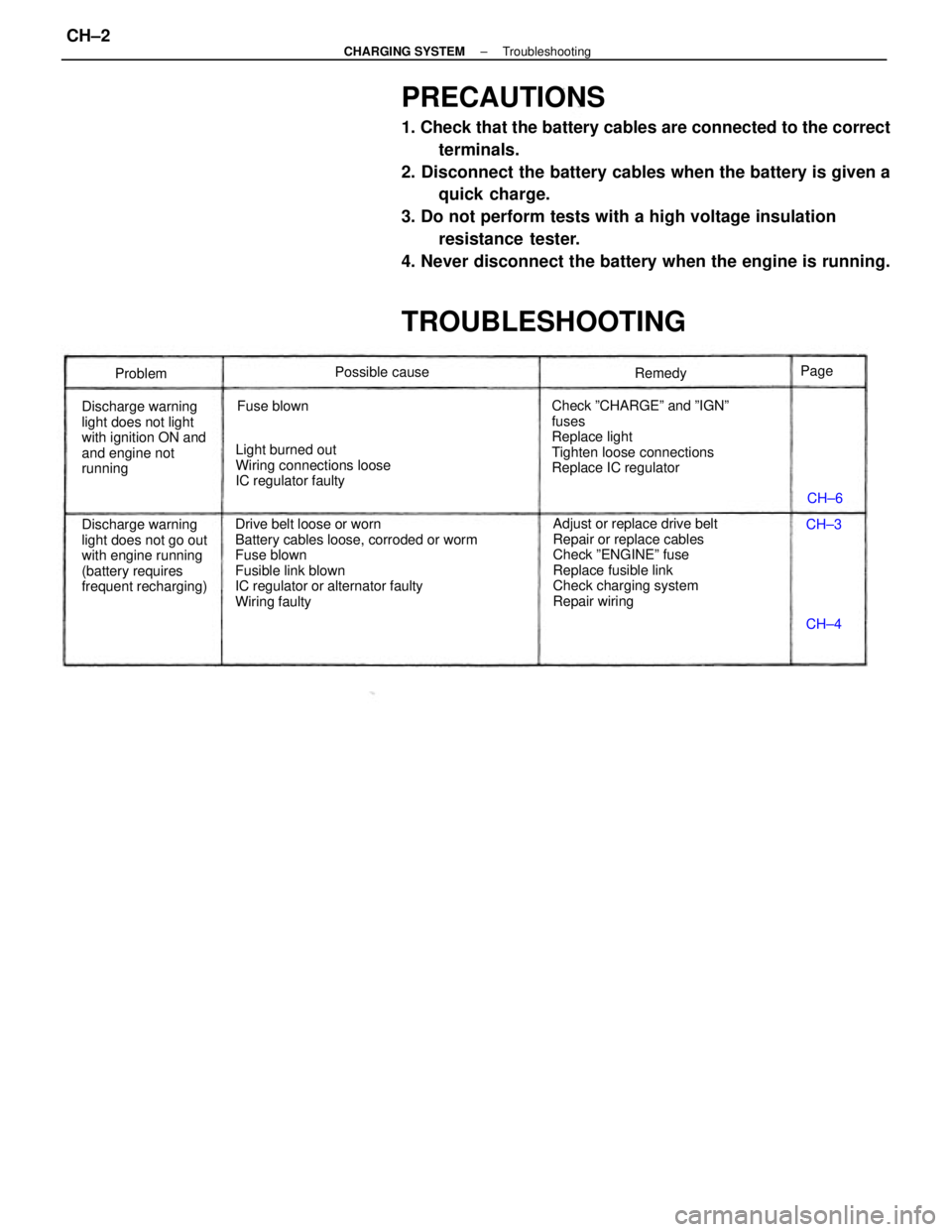

TROUBLESHOOTING

Drive belt loose or worn

Battery cables loose, corroded or worm

Fuse blown

Fusible link blown

IC regulator or alternator faulty

Wiring faultyAdjust or replace drive belt

Repair or replace cables

Check ºENGINEº fuse

Replace fusible link

Check charging system

Repair wiring Check ºCHARGEº and ºIGNº

fuses

Replace light

Tighten loose connections

Replace IC regulator

Discharge warning

light does not go out

with engine running

(battery requires

frequent recharging) Discharge warning

light does not light

with ignition ON and

and engine not

runningLight burned out

Wiring connections loose

IC regulator faultyPossible cause

Fuse blownRemedy

Problem

CH±6

CH±4 CH±3 Page

± CHARGING SYSTEMPrecautionsCH±2

Page 959 of 2389

PRECAUTIONS

1. Check that the battery cables are connected to the correct

terminals.

2. Disconnect the battery cables when the battery is given a

quick charge.

3. Do not perform tests with a high voltage insulation

resistance tester.

4. Never disconnect the battery when the engine is running.

TROUBLESHOOTING

Drive belt loose or worn

Battery cables loose, corroded or worm

Fuse blown

Fusible link blown

IC regulator or alternator faulty

Wiring faultyAdjust or replace drive belt

Repair or replace cables

Check ºENGINEº fuse

Replace fusible link

Check charging system

Repair wiring Check ºCHARGEº and ºIGNº

fuses

Replace light

Tighten loose connections

Replace IC regulator

Discharge warning

light does not go out

with engine running

(battery requires

frequent recharging) Discharge warning

light does not light

with ignition ON and

and engine not

runningLight burned out

Wiring connections loose

IC regulator faultyPossible cause

Fuse blownRemedy

Problem

CH±6

CH±4 CH±3 Page

± CHARGING SYSTEMTroubleshootingCH±2

Page 961 of 2389

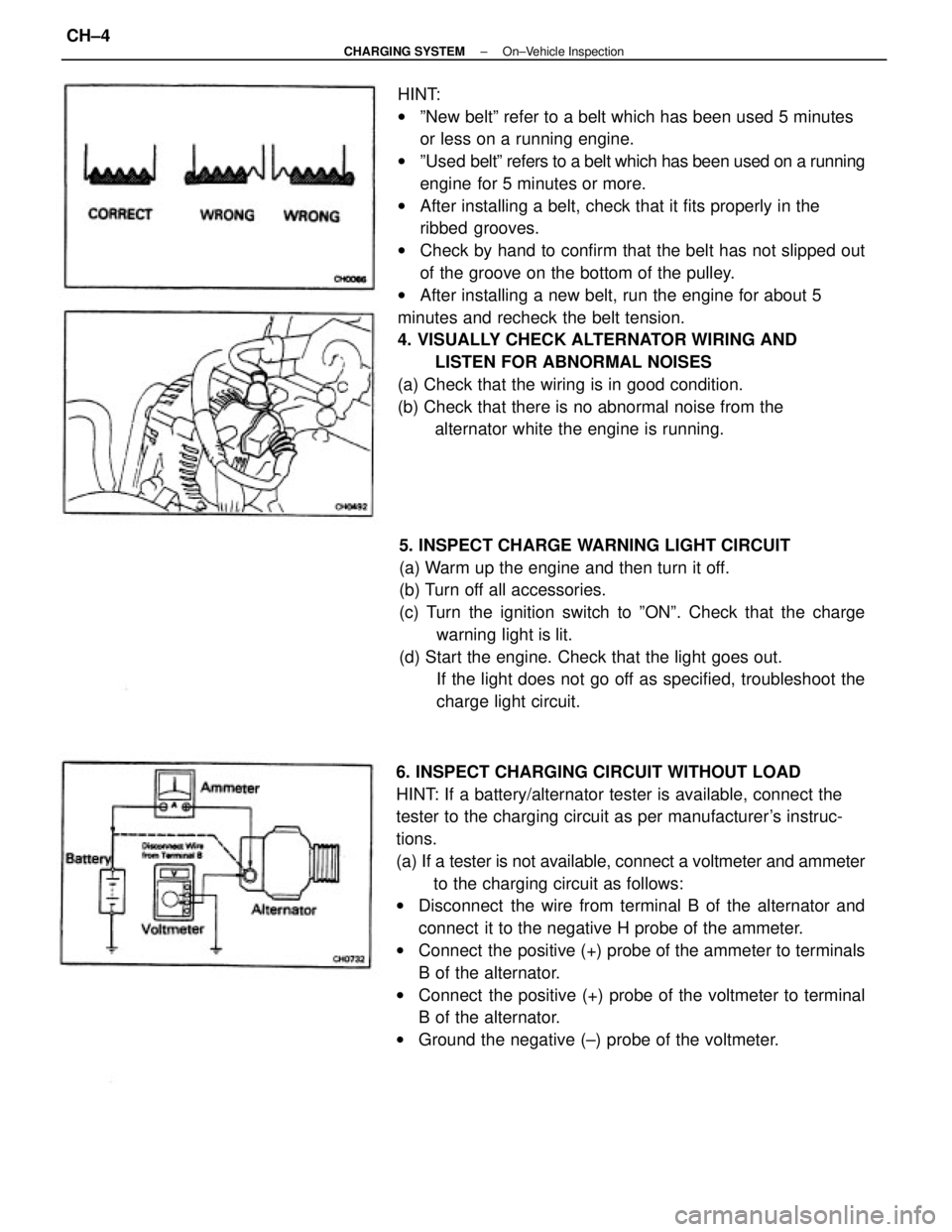

HINT:

wºNew beltº refer to a belt which has been used 5 minutes

or less on a running engine.

wºUsed beltº refers to a belt which has been used on a running

engine for 5 minutes or more.

wAfter installing a belt, check that it fits properly in the

ribbed grooves.

wCheck by hand to confirm that the belt has not slipped out

of the groove on the bottom of the pulley.

wAfter installing a new belt, run the engine for about 5

minutes and recheck the belt tension.

4. VISUALLY CHECK ALTERNATOR WIRING AND

LISTEN FOR ABNORMAL NOISES

(a) Check that the wiring is in good condition.

(b) Check that there is no abnormal noise from the

alternator white the engine is running.

6. INSPECT CHARGING CIRCUIT WITHOUT LOAD

HINT: If a battery/alternator tester is available, connect the

tester to the charging circuit as per manufacturer's instruc-

tions.

(a) If a tester is not available, connect a voltmeter and ammeter

to the charging circuit as follows:

wDisconnect the wire from terminal B of the alternator and

connect it to the negative H probe of the ammeter.

wConnect the positive (+) probe of the ammeter to terminals

B of the alternator.

wConnect the positive (+) probe of the voltmeter to terminal

B of the alternator.

wGround the negative (±) probe of the voltmeter. 5. INSPECT CHARGE WARNING LIGHT CIRCUIT

(a) Warm up the engine and then turn it off.

(b) Turn off all accessories.

(c) Turn the ignition switch to ºONº. Check that the charge

warning light is lit.

(d) Start the engine. Check that the light goes out.

If the light does not go off as specified, troubleshoot the

charge light circuit.

± CHARGING SYSTEMOn±Vehicle InspectionCH±4

Page 964 of 2389

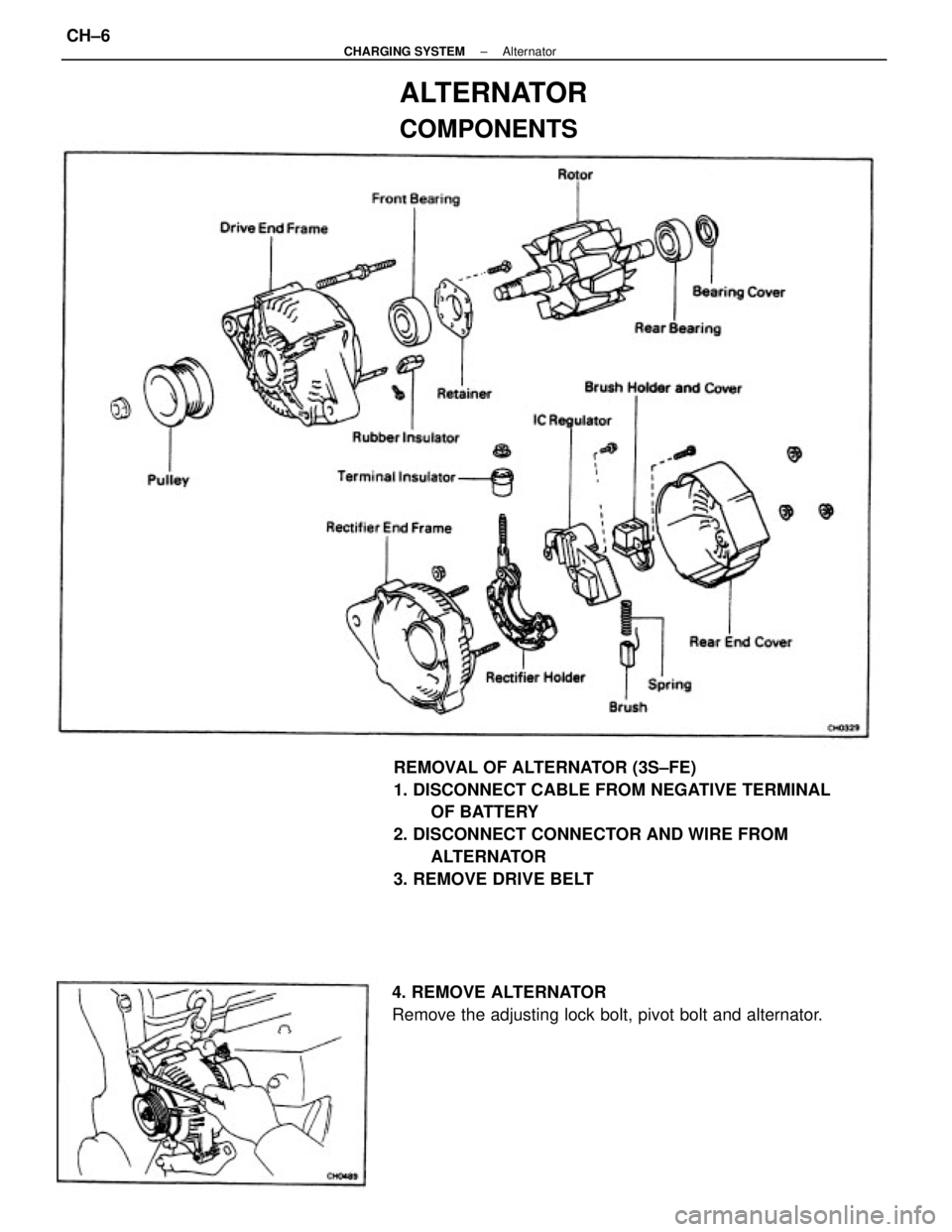

REMOVAL OF ALTERNATOR (3S±FE)

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL

OF BATTERY

2. DISCONNECT CONNECTOR AND WIRE FROM

ALTERNATOR

3. REMOVE DRIVE BELT

4. REMOVE ALTERNATOR

Remove the adjusting lock bolt, pivot bolt and alternator.

ALTERNATOR

COMPONENTS

± CHARGING SYSTEMAlternatorCH±6

Page 965 of 2389

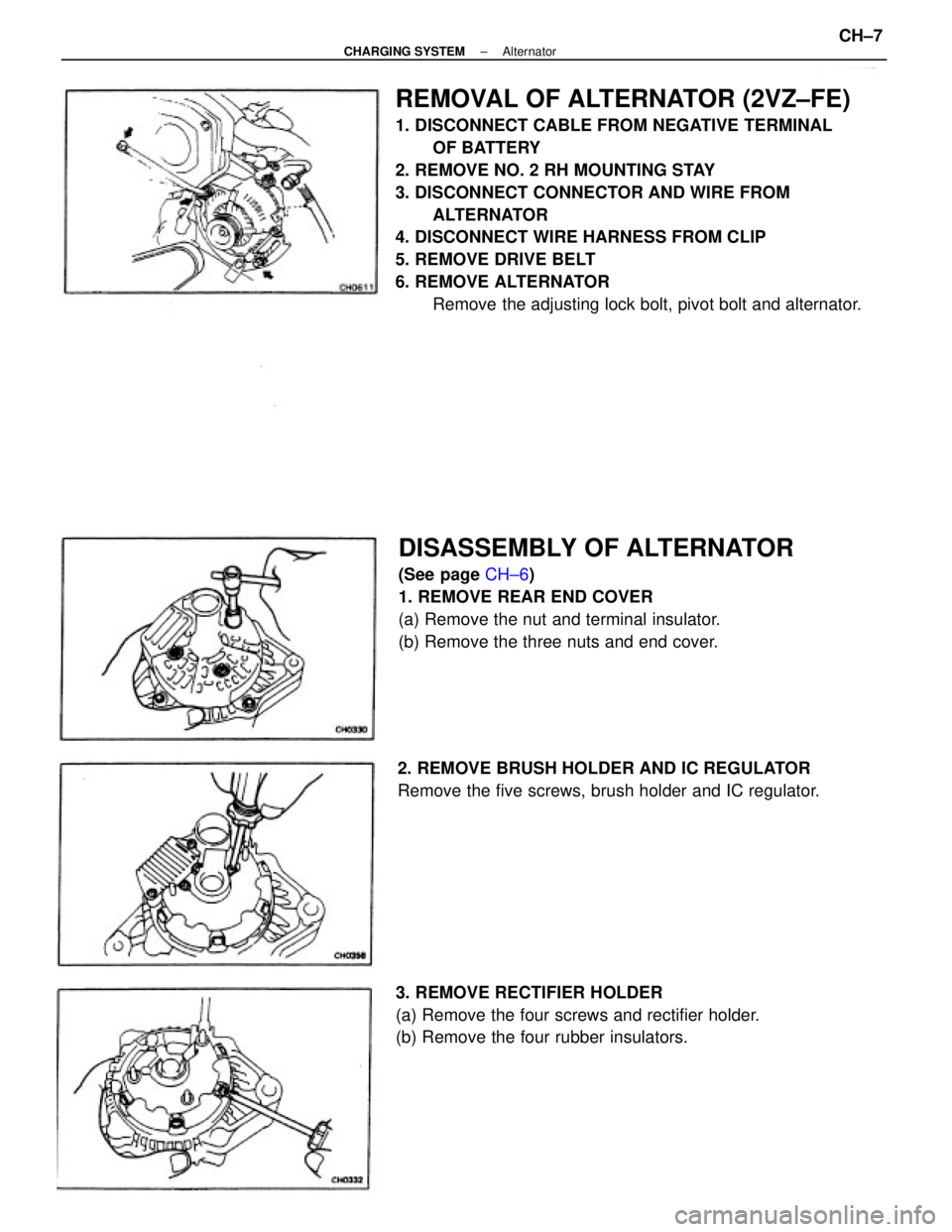

REMOVAL OF ALTERNATOR (2VZ±FE)

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL

OF BATTERY

2. REMOVE NO. 2 RH MOUNTING STAY

3. DISCONNECT CONNECTOR AND WIRE FROM

ALTERNATOR

4. DISCONNECT WIRE HARNESS FROM CLIP

5. REMOVE DRIVE BELT

6. REMOVE ALTERNATOR

Remove the adjusting lock bolt, pivot bolt and alternator.

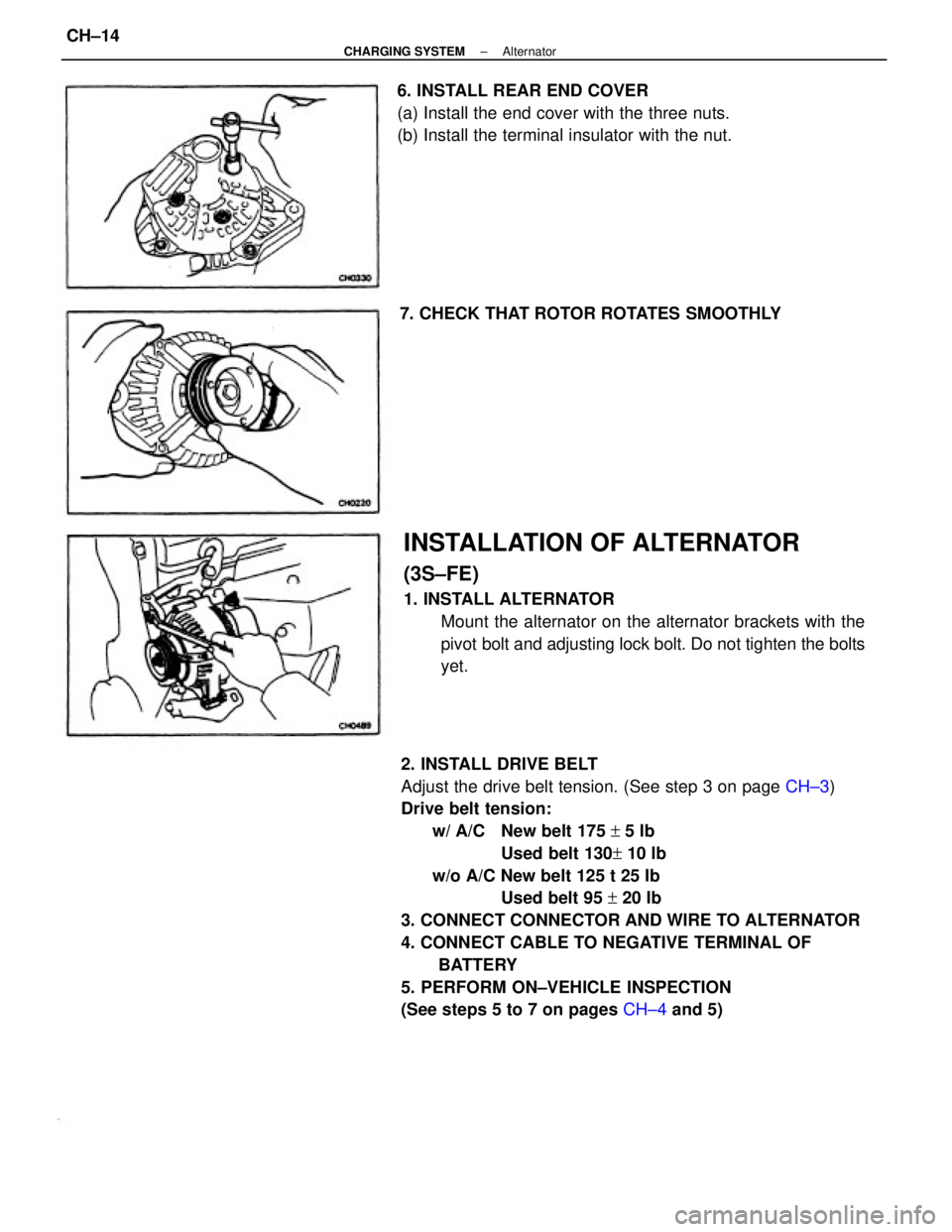

DISASSEMBLY OF ALTERNATOR

(See page CH±6)

1. REMOVE REAR END COVER

(a) Remove the nut and terminal insulator.

(b) Remove the three nuts and end cover.

3. REMOVE RECTIFIER HOLDER

(a) Remove the four screws and rectifier holder.

(b) Remove the four rubber insulators.2. REMOVE BRUSH HOLDER AND IC REGULATOR

Remove the five screws, brush holder and IC regulator.

± CHARGING SYSTEMAlternatorCH±7

Page 972 of 2389

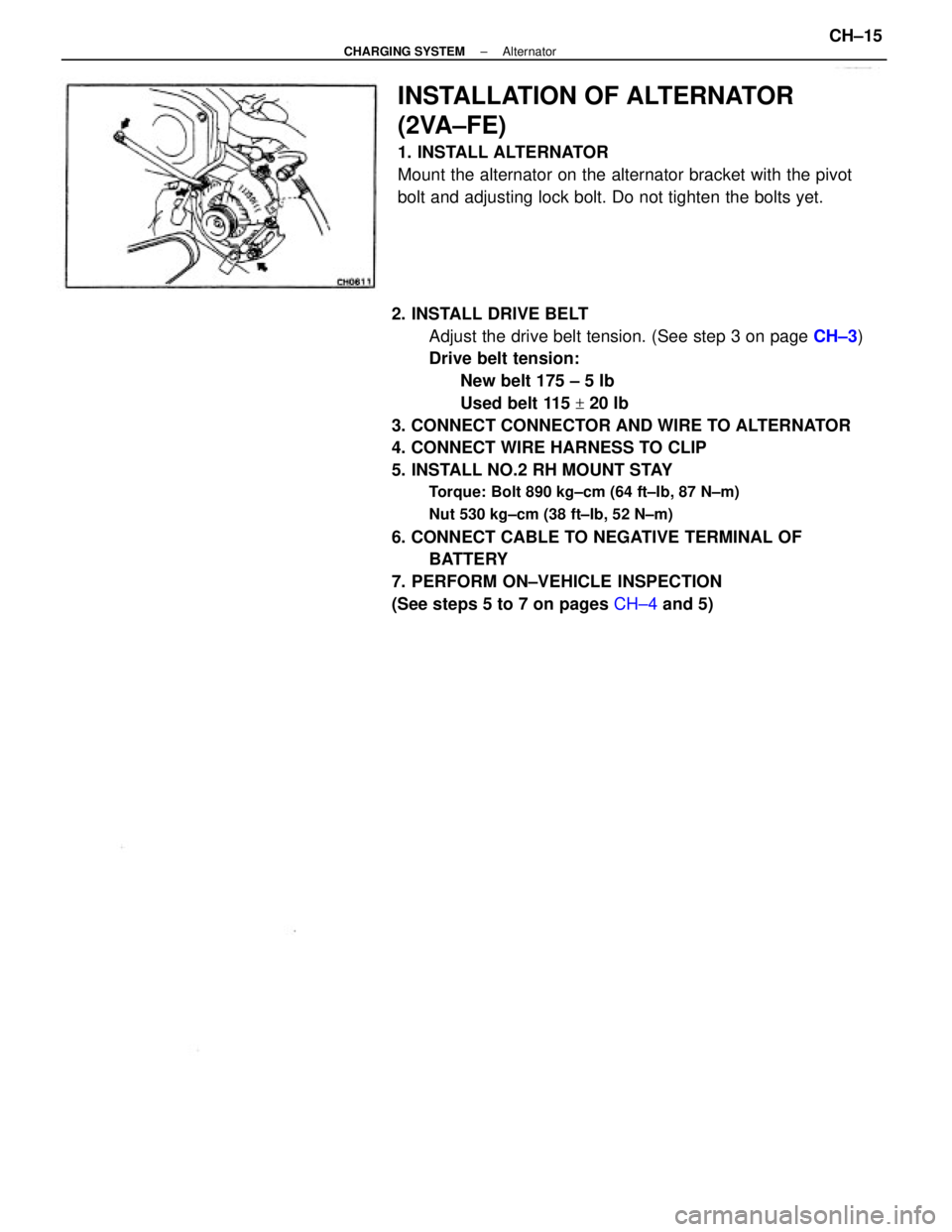

2. INSTALL DRIVE BELT

Adjust the drive belt tension. (See step 3 on page CH±3)

Drive belt tension:

w/ A/C New belt 175 + 5 lb

Used belt 130+ 10 lb

w/o A/C New belt 125 t 25 Ib

Used belt 95 + 20 Ib

3. CONNECT CONNECTOR AND WIRE TO ALTERNATOR

4. CONNECT CABLE TO NEGATIVE TERMINAL OF

BATTERY

5. PERFORM ON±VEHICLE INSPECTION

(See steps 5 to 7 on pages CH±4 and 5)

INSTALLATION OF ALTERNATOR

(3S±FE)

1. INSTALL ALTERNATOR

Mount the alternator on the alternator brackets with the

pivot bolt and adjusting lock bolt. Do not tighten the bolts

yet. 6. INSTALL REAR END COVER

(a) Install the end cover with the three nuts.

(b) Install the terminal insulator with the nut.

7. CHECK THAT ROTOR ROTATES SMOOTHLY

± CHARGING SYSTEMAlternatorCH±14

Page 973 of 2389

2. INSTALL DRIVE BELT

Adjust the drive belt tension. (See step 3 on page CH±3)

Drive belt tension:

New belt 175 ± 5 Ib

Used belt 115

+ 20 Ib

3. CONNECT CONNECTOR AND WIRE TO ALTERNATOR

4. CONNECT WIRE HARNESS TO CLIP

5. INSTALL NO.2 RH MOUNT STAY

Torque: Bolt 890 kg±cm (64 ft±Ib, 87 N±m)

Nut 530 kg±cm (38 ft±Ib, 52 N±m)

6. CONNECT CABLE TO NEGATIVE TERMINAL OF

BATTERY

7. PERFORM ON±VEHICLE INSPECTION

(See steps 5 to 7 on pages CH±4 and 5)

INSTALLATION OF ALTERNATOR

(2VA±FE)

1. INSTALL ALTERNATOR

Mount the alternator on the alternator bracket with the pivot

bolt and adjusting lock bolt. Do not tighten the bolts yet.

± CHARGING SYSTEMAlternatorCH±15

Page 996 of 2389

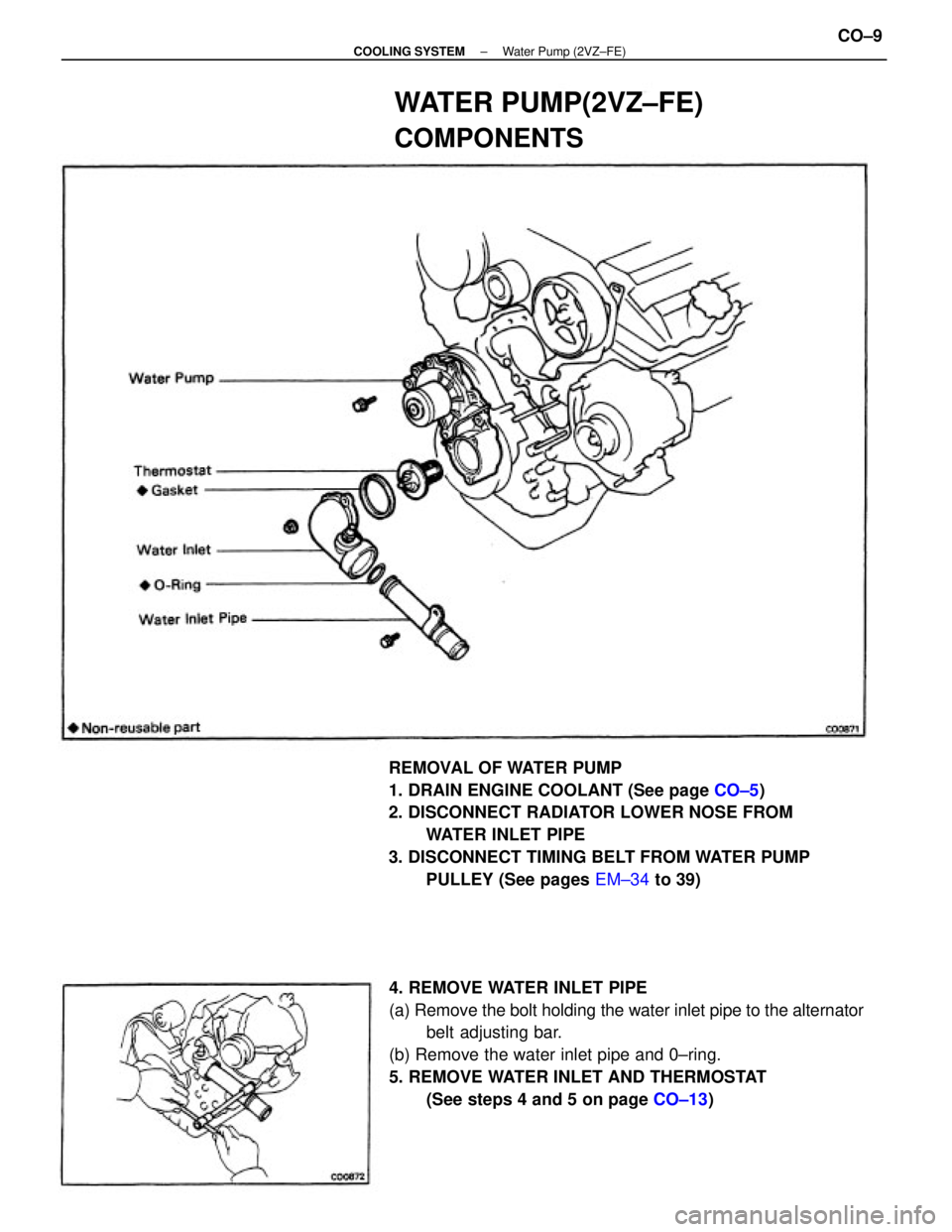

REMOVAL OF WATER PUMP

1. DRAIN ENGINE COOLANT (See page CO±5)

2. DISCONNECT RADIATOR LOWER NOSE FROM

WATER INLET PIPE

3. DISCONNECT TIMING BELT FROM WATER PUMP

PULLEY (See pages EM±34 to 39)

4. REMOVE WATER INLET PIPE

(a) Remove the bolt holding the water inlet pipe to the alternator

belt adjusting bar.

(b) Remove the water inlet pipe and 0±ring.

5. REMOVE WATER INLET AND THERMOSTAT

(See steps 4 and 5 on page CO±13)

WATER PUMP(2VZ±FE)

COMPONENTS

± COOLING SYSTEMWater Pump (2VZ±FE)CO±9

Page 998 of 2389

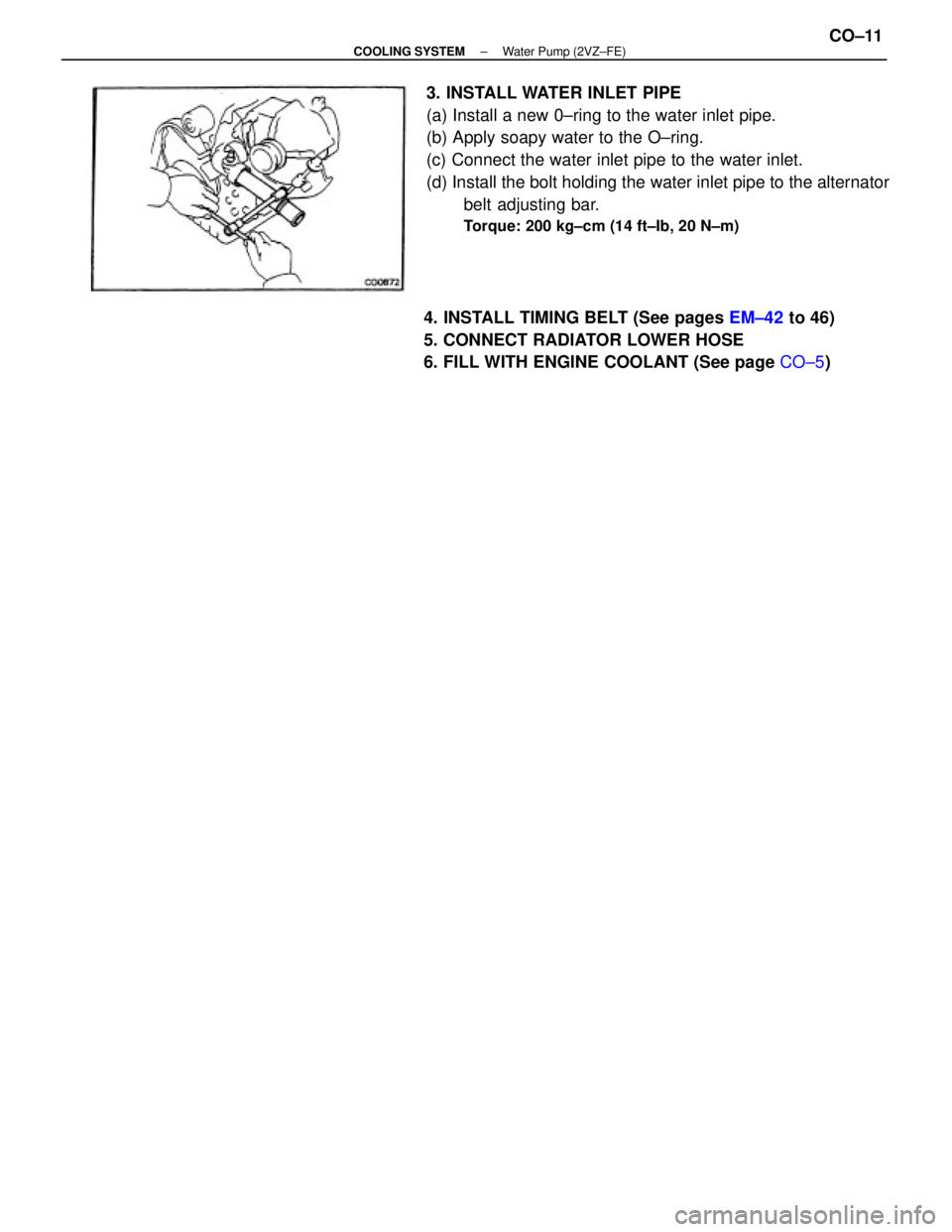

3. INSTALL WATER INLET PIPE

(a) Install a new 0±ring to the water inlet pipe.

(b) Apply soapy water to the O±ring.

(c) Connect the water inlet pipe to the water inlet.

(d) Install the bolt holding the water inlet pipe to the alternator

belt adjusting bar.

Torque: 200 kg±cm (14 ft±Ib, 20 N±m)

4. INSTALL TIMING BELT (See pages EM±42 to 46)

5. CONNECT RADIATOR LOWER HOSE

6. FILL WITH ENGINE COOLANT (See page CO±5)

± COOLING SYSTEMWater Pump (2VZ±FE)CO±11

Page 1187 of 2389

ENGINE TUNE±UP

INSPECTION OF ENGINE COOLANT

(See steps 1 and 2 on page CO±4)

INSPECTION OF ENGINE OIL

(See steps 1 and 2 on page LU±6)

INSPECTION OF BATTERY

(See steps 1 and 2 on page CH±3)

Standard specific gravity:

1.25 ±1.27 when fully charged at 2O°C (68°F)

INSPECTION OF AIR FILTER

(See step 3 on page MA±5)

INSPECTION OF HIGH±TENSION CORDS

(See page IG±6 or 10)

Maximum resistance: 25 kW per cord

INSPECTION OF SPARK PLUGS (3S±FE)

(See page IG±6)

Correct electrode gap: 1.1 mm (0.043 in.)

Recommended spark plugs:

ND Q16R±U11

NGK BCPR5EY11

INSPECTION OF SPARK PLUGS (2VZ±FE)

(See page IG±10)

Correct electrode gap of new plug:

1.1 mm (0.043 in.)

Maximum electrode gap: 1.3 mm (0.051 in.)

Recommended spark plugs:

ND P020R

NGK BCPR6EP11

INSPECTION OF ALTERNATOR DRIVE BELT

(See step 3 on page CH±3)

Drive belt tension:

3S±FE w/ A/C New belt 175 +5 Ib

Used belt 130 +10 Ib

w/o A/C New belt 125 +25 Ib

Used belt 95 +20 Ib

2VZ±FE New belt 175 +5 Ib

Used belt 115 +20 Ib

± ENGINE MECHANICALEngine Tune±UpEM±10