height TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 14 of 2389

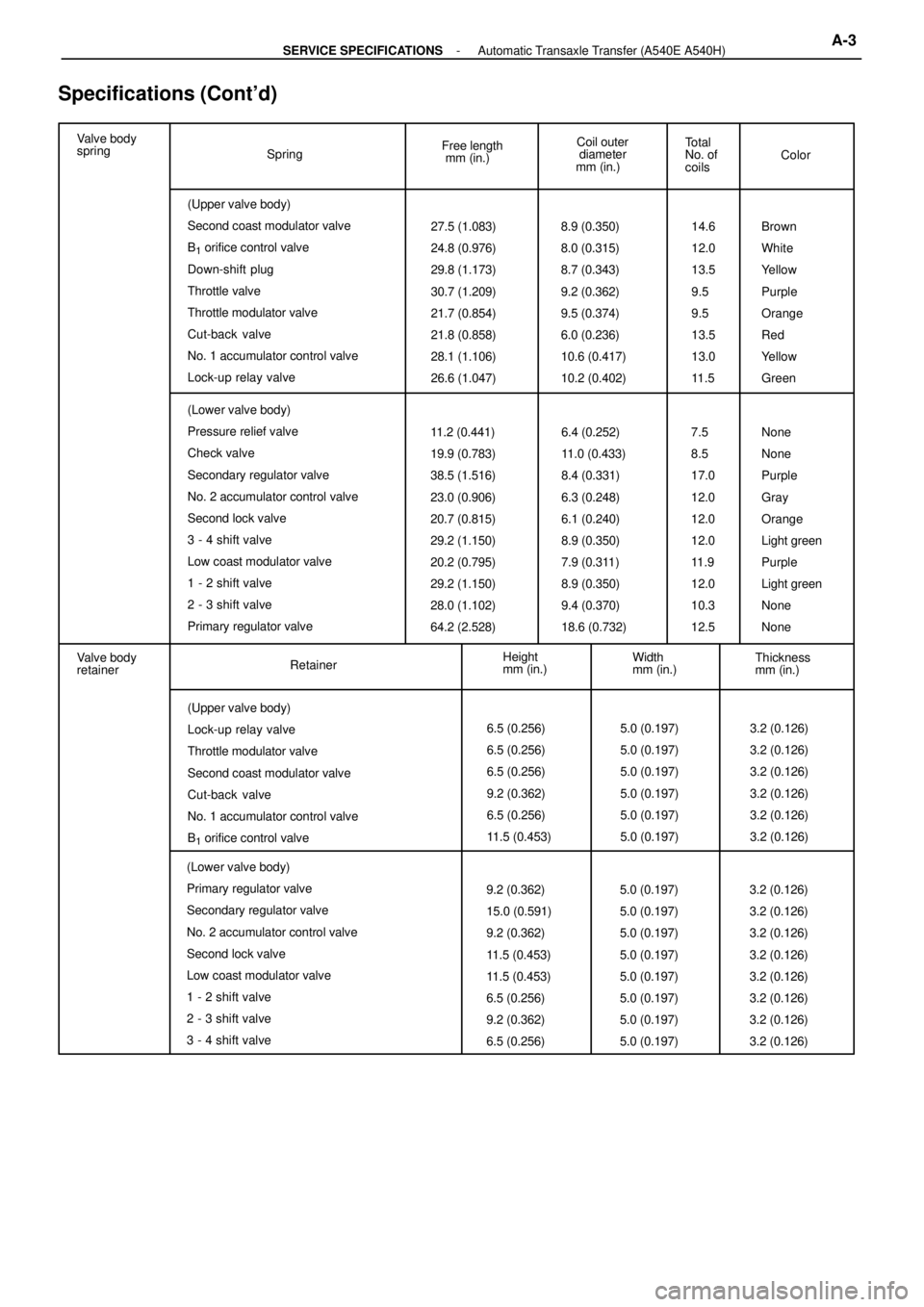

Valve body

spring

SpringFree length

mm (in.)Coil outer

diameter

mm (in.)Total

No. of

coilsColor

(Upper valve body)

Second coast modulator valve

B

1 orifice control valve

Down-shift plug

Throttle valve

Throttle modulator valve

Cut-back valve

No. 1 accumulator control valve

Lock-up relay valve27.5 (1.083)

24.8 (0.976)

29.8 (1.173)

30.7 (1.209)

21.7 (0.854)

21.8 (0.858)

28.1 (1.106)

26.6 (1.047)8.9 (0.350)

8.0 (0.315)

8.7 (0.343)

9.2 (0.362)

9.5 (0.374)

6.0 (0.236)

10.6 (0.417)

10.2 (0.402)14.6

12.0

13.5

9.5

9.5

13.5

13.0

11.5Brown

White

Yellow

Purple

Orange

Red

Yellow

Green

(Lower valve body)

Pressure relief valve

Check valve

Secondary regulator valve

No. 2 accumulator control valve

Second lock valve

3 - 4 shift valve

Low coast modulator valve

1 - 2 shift valve

2 - 3 shift valve

Primary regulator valve11.2 (0.441)

19.9 (0.783)

38.5 (1.516)

23.0 (0.906)

20.7 (0.815)

29.2 (1.150)

20.2 (0.795)

29.2 (1.150)

28.0 (1.102)

64.2 (2.528)6.4 (0.252)

11.0 (0.433)

8.4 (0.331)

6.3 (0.248)

6.1 (0.240)

8.9 (0.350)

7.9 (0.311)

8.9 (0.350)

9.4 (0.370)

18.6 (0.732)7.5

8.5

17.0

12.0

12.0

12.0

11.9

12.0

10.3

12.5None

None

Purple

Gray

Orange

Light green

Purple

Light green

None

None

Valve body

retainerRetainerHeight

mm (in.)Width

mm (in.)Thickness

mm (in.)

(Upper valve body)

Lock-up relay valve

Throttle modulator valve

Second coast modulator valve

Cut-back valve

No. 1 accumulator control valve

B

1 orifice control valve6.5 (0.256)

6.5 (0.256)

6.5 (0.256)

9.2 (0.362)

6.5 (0.256)

11.5 (0.453)5.0 (0.197)

5.0 (0.197)

5.0 (0.197)

5.0 (0.197)

5.0 (0.197)

5.0 (0.197)3.2 (0.126)

3.2 (0.126)

3.2 (0.126)

3.2 (0.126)

3.2 (0.126)

3.2 (0.126)

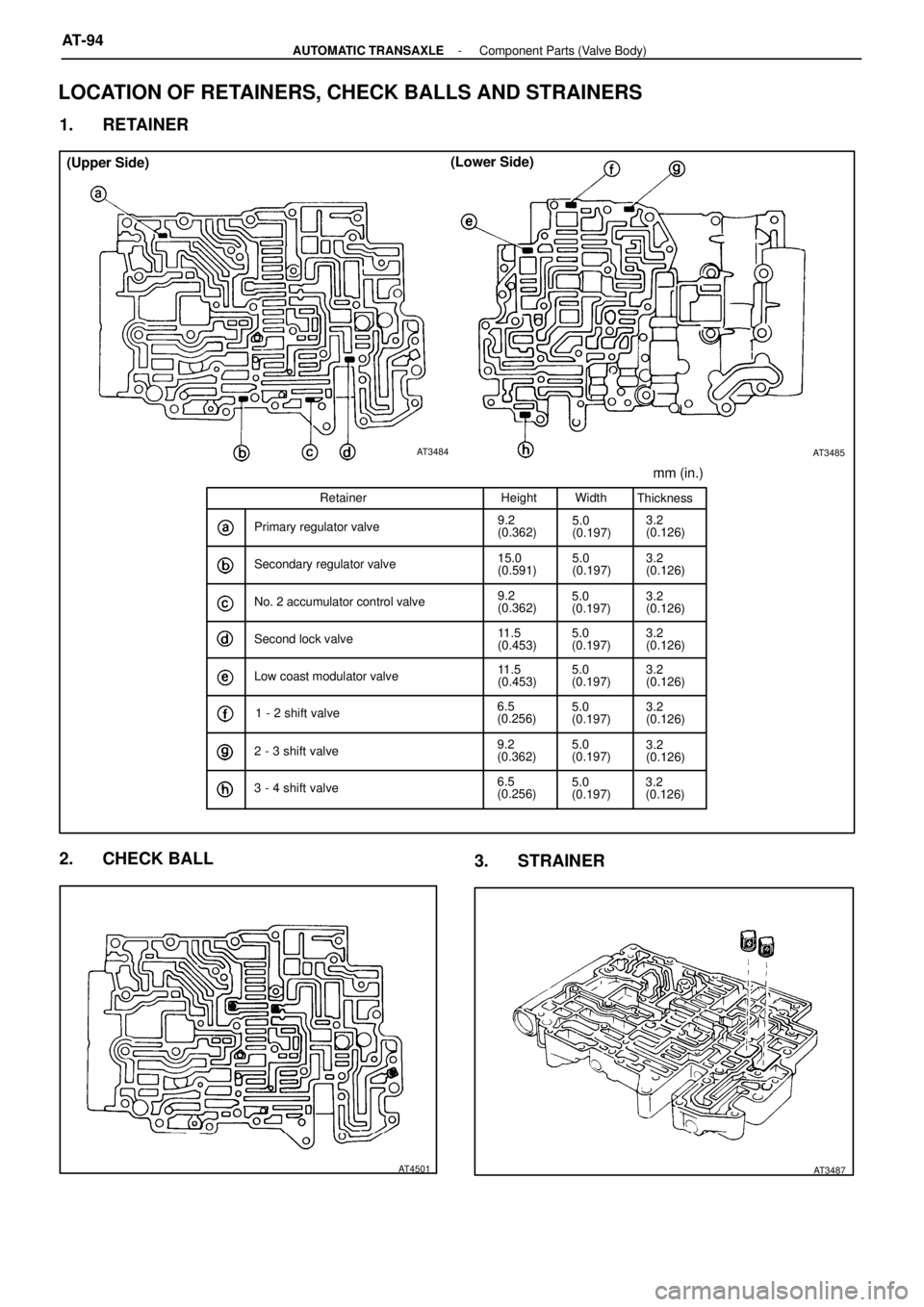

(Lower valve body)

Primary regulator valve

Secondary regulator valve

No. 2 accumulator control valve

Second lock valve

Low coast modulator valve

1 - 2 shift valve

2 - 3 shift valve

3 - 4 shift valve9.2 (0.362)

15.0 (0.591)

9.2 (0.362)

11.5 (0.453)

11.5 (0.453)

6.5 (0.256)

9.2 (0.362)

6.5 (0.256)5.0 (0.197)

5.0 (0.197)

5.0 (0.197)

5.0 (0.197)

5.0 (0.197)

5.0 (0.197)

5.0 (0.197)

5.0 (0.197)3.2 (0.126)

3.2 (0.126)

3.2 (0.126)

3.2 (0.126)

3.2 (0.126)

3.2 (0.126)

3.2 (0.126)

3.2 (0.126)

Specifications (Cont'd)

- SERVICE SPECIFICATIONSAutomatic Transaxle Transfer (A540E A540H)A-3

Page 18 of 2389

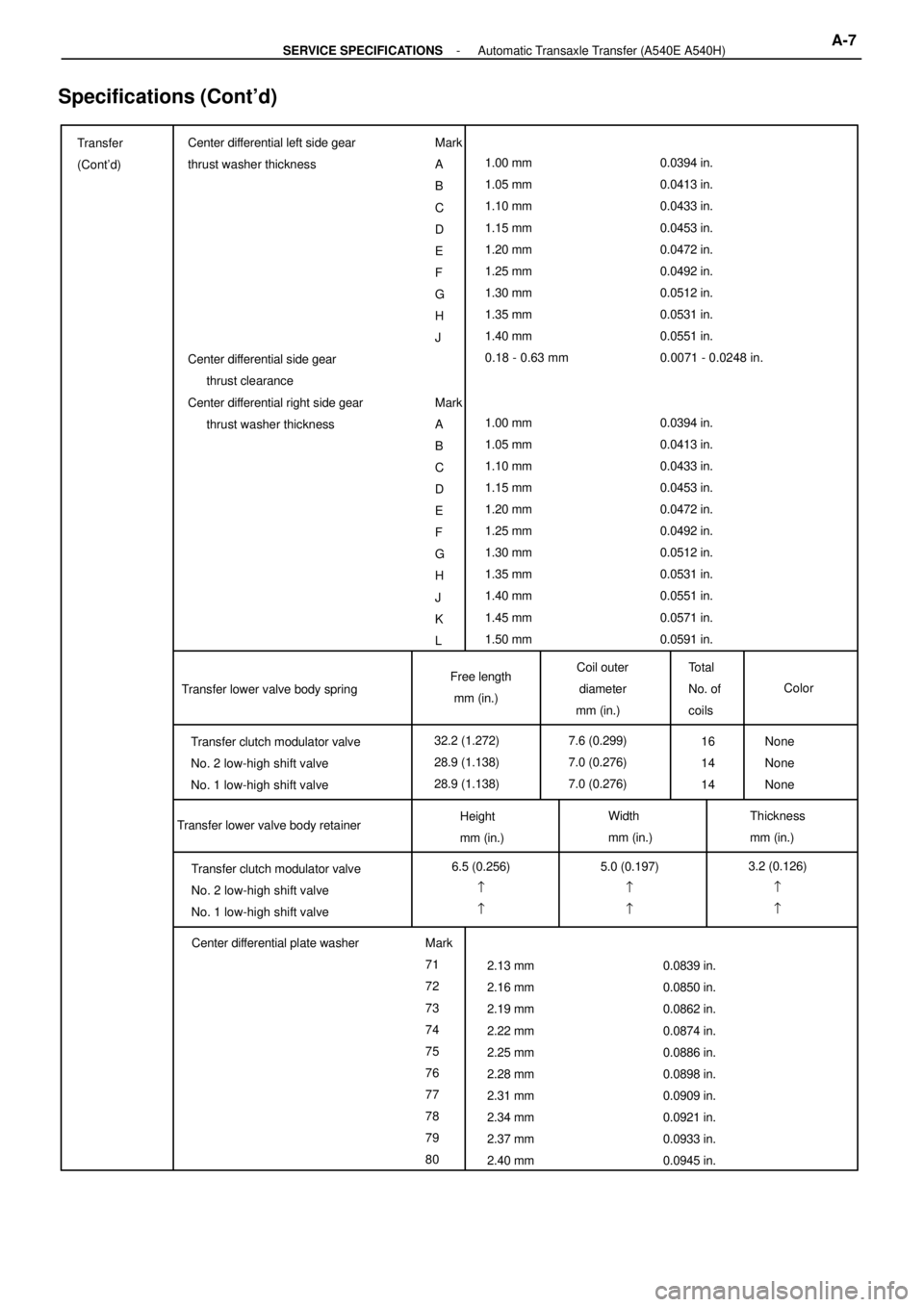

Transfer

(Cont'd)Center differential left side gear

thrust washer thickness

Center differential side gear

thrust clearance

Center differential right side gear

thrust washer thickness 0.0394 in.

0.0413 in.

0.0433 in.

0.0453 in.

0.0472 in.

0.0492 in.

0.0512 in.

0.0531 in.

0.0551 in.

0.0071 - 0.0248 in.

0.0394 in.

0.0413 in.

0.0433 in.

0.0453 in.

0.0472 in.

0.0492 in.

0.0512 in.

0.0531 in.

0.0551 in.

0.0571 in.

0.0591 in. 1.00 mm

1.05 mm

1.10 mm

1.15 mm

1.20 mm

1.25 mm

1.30 mm

1.35 mm

1.40 mm

0.18 - 0.63 mm

1.00 mm

1.05 mm

1.10 mm

1.15 mm

1.20 mm

1.25 mm

1.30 mm

1.35 mm

1.40 mm

1.45 mm

1.50 mm

Transfer lower valve body springFree length

mm (in.)Coil outer

diameter

mm (in.)Total

No. of

coilsColor

Transfer clutch modulator valve

No. 2 low-high shift valve

No. 1 low-high shift valve32.2 (1.272)

28.9 (1.138)

28.9 (1.138)7.6 (0.299)

7.0 (0.276)

7.0 (0.276)16

14

14None

None

None

Transfer lower valve body retainerHeight

mm (in.)Width

mm (in.)Thickness

mm (in.)

Transfer clutch modulator valve

No. 2 low-high shift valve

No. 1 low-high shift valve6.5 (0.256)

=

=5.0 (0.197)

=

=3.2 (0.126)

=

=

Center differential plate washer

2.13 mm

2.16 mm

2.19 mm

2.22 mm

2.25 mm

2.28 mm

2.31 mm

2.34 mm

2.37 mm

2.40 mm0.0839 in.

0.0850 in.

0.0862 in.

0.0874 in.

0.0886 in.

0.0898 in.

0.0909 in.

0.0921 in.

0.0933 in.

0.0945 in.

Specifications (Cont'd)

Mark

A

B

C

D

E

F

G

H

J

Mark

A

B

C

D

E

F

G

H

J

K

L

Mark

71

72

73

74

75

76

77

78

79

80

- SERVICE SPECIFICATIONSAutomatic Transaxle Transfer (A540E A540H)A-7

Page 99 of 2389

AT7731

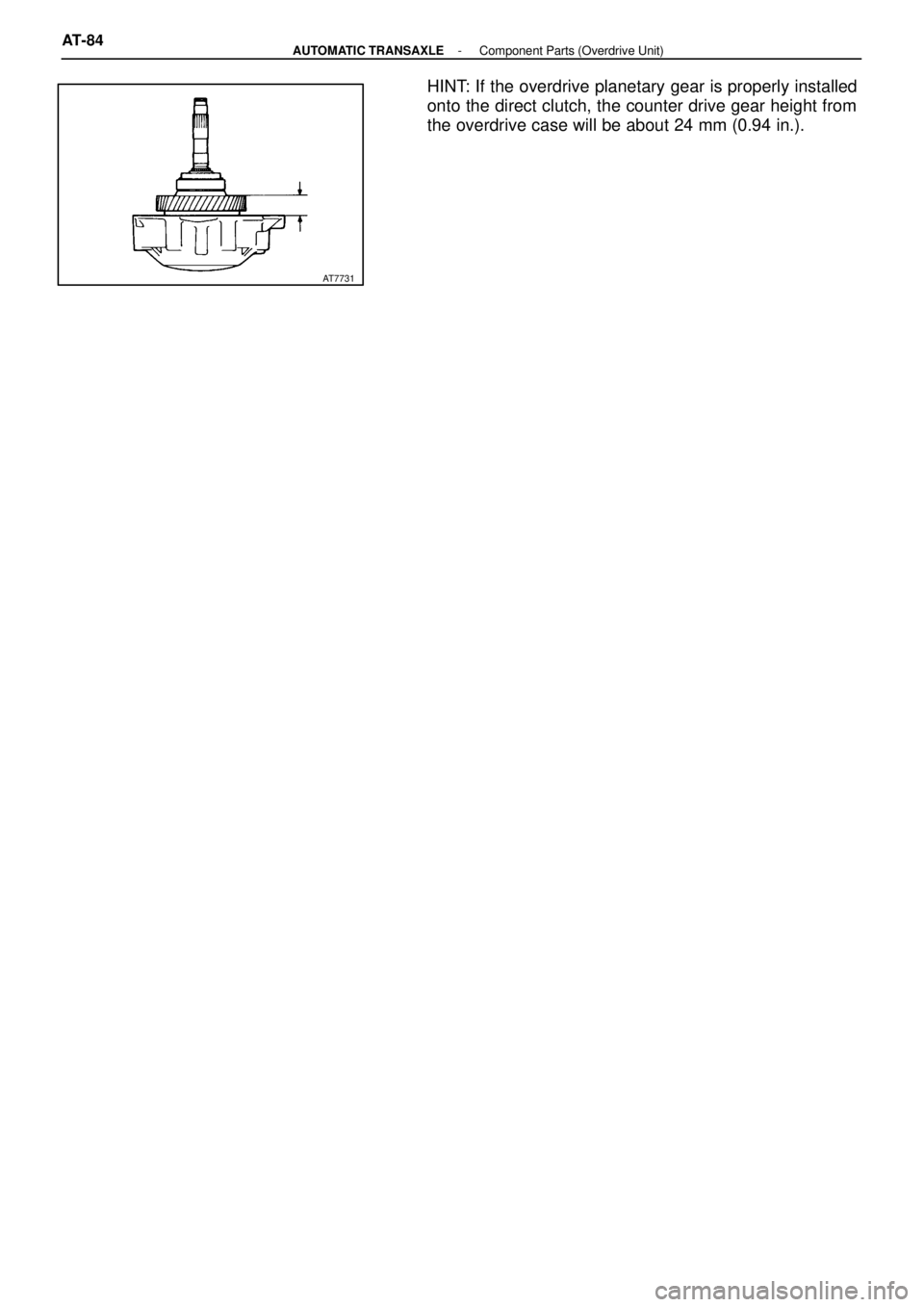

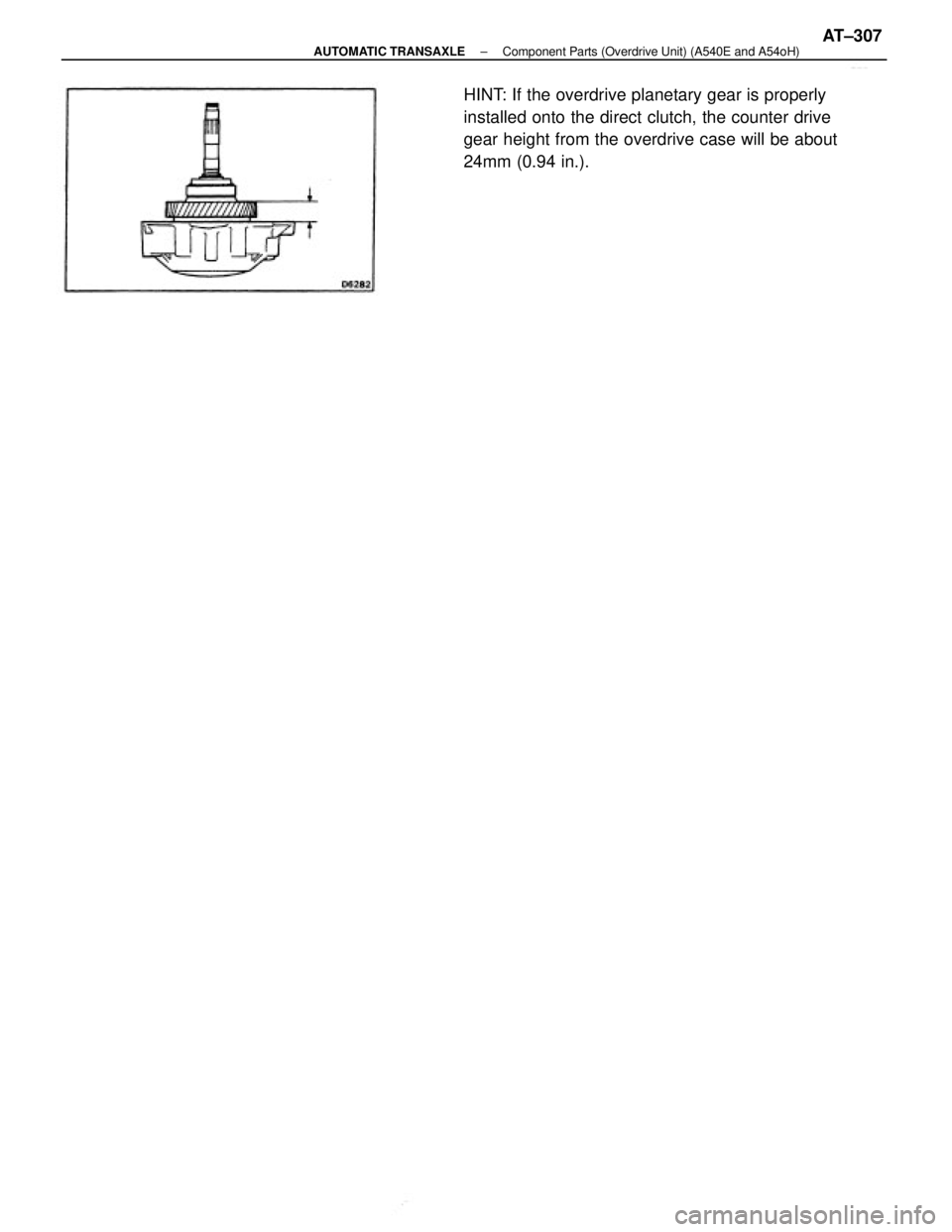

HINT: If the overdrive planetary gear is properly installed

onto the direct clutch, the counter drive gear height from

the overdrive case will be about 24 mm (0.94 in.).

AT-84- AUTOMATIC TRANSAXLEComponent Parts (Overdrive Unit)

Page 106 of 2389

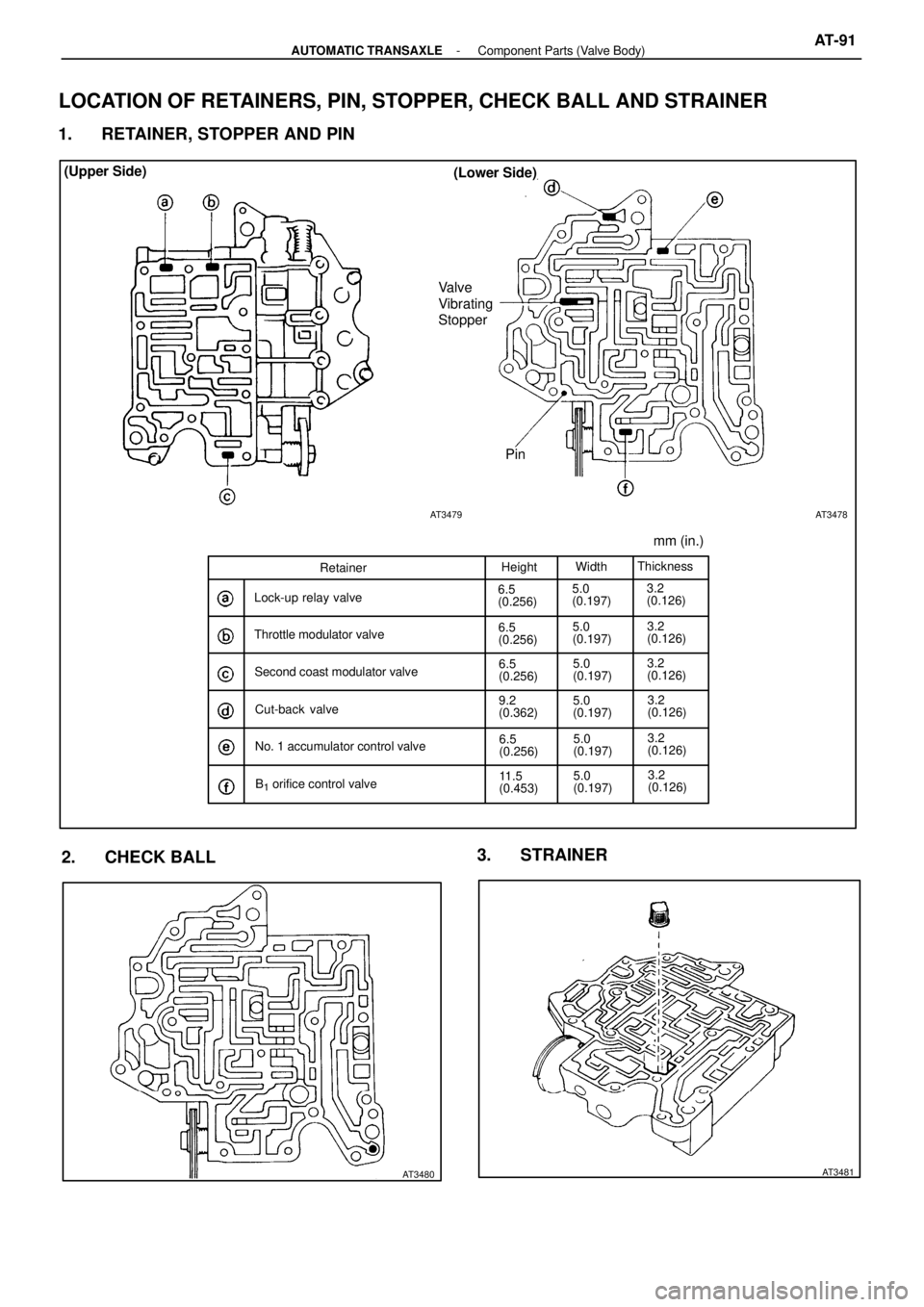

11.5

(0.453)5.0

(0.197)3.2

(0.126) B1 orifice control valve6.5

(0.256)5.0

(0.197)3.2

(0.126) No. 1 accumulator control valve9.2

(0.362)5.0

(0.197)3.2

(0.126) Cut-back valve5.0

(0.197)3.2

(0.126) 6.5

(0.256) Second coast modulator valve6.5

(0.256)5.0

(0.197)3.2

(0.126) Throttle modulator valve6.5

(0.256)5.0

(0.197)3.2

(0.126) Lock-up relay valveRetainerHeightWidthThickness

mm (in.)

AT3478 AT3479

Pin Valve

Vibrating

Stopper (Upper Side)

(Lower Side)

AT3480AT3481

LOCATION OF RETAINERS, PIN, STOPPER, CHECK BALL AND STRAINER

1. RETAINER, STOPPER AND PIN

3. STRAINER

2. CHECK BALL

- AUTOMATIC TRANSAXLEComponent Parts (Valve Body)AT-91

Page 109 of 2389

6.5

(0.256)5.0

(0.197)3.2

(0.126) 3 - 4 shift valve5.0

(0.197) 9.2

(0.362)3.2

(0.126) 2 - 3 shift valve6.5

(0.256)5.0

(0.197)3.2

(0.126) 1 - 2 shift valve3.2

(0.126) 11.5

(0.453)5.0

(0.197) Low coast modulator valve11.5

(0.453)5.0

(0.197)3.2

(0.126) Second lock valve9.2

(0.362)5.0

(0.197)3.2

(0.126) No. 2 accumulator control valve3.2

(0.126) 15.0

(0.591)5.0

(0.197) Secondary regulator valve5.0

(0.197)3.2

(0.126) 9.2

(0.362) Primary regulator valveHeight Width

Thickness Retainer

mm (in.)

AT3485 AT3484

(Lower Side)

(Upper Side)

AT4501

AT3487

LOCATION OF RETAINERS, CHECK BALLS AND STRAINERS

1. RETAINER

2. CHECK BALL

3. STRAINER

AT-94- AUTOMATIC TRANSAXLEComponent Parts (Valve Body)

Page 188 of 2389

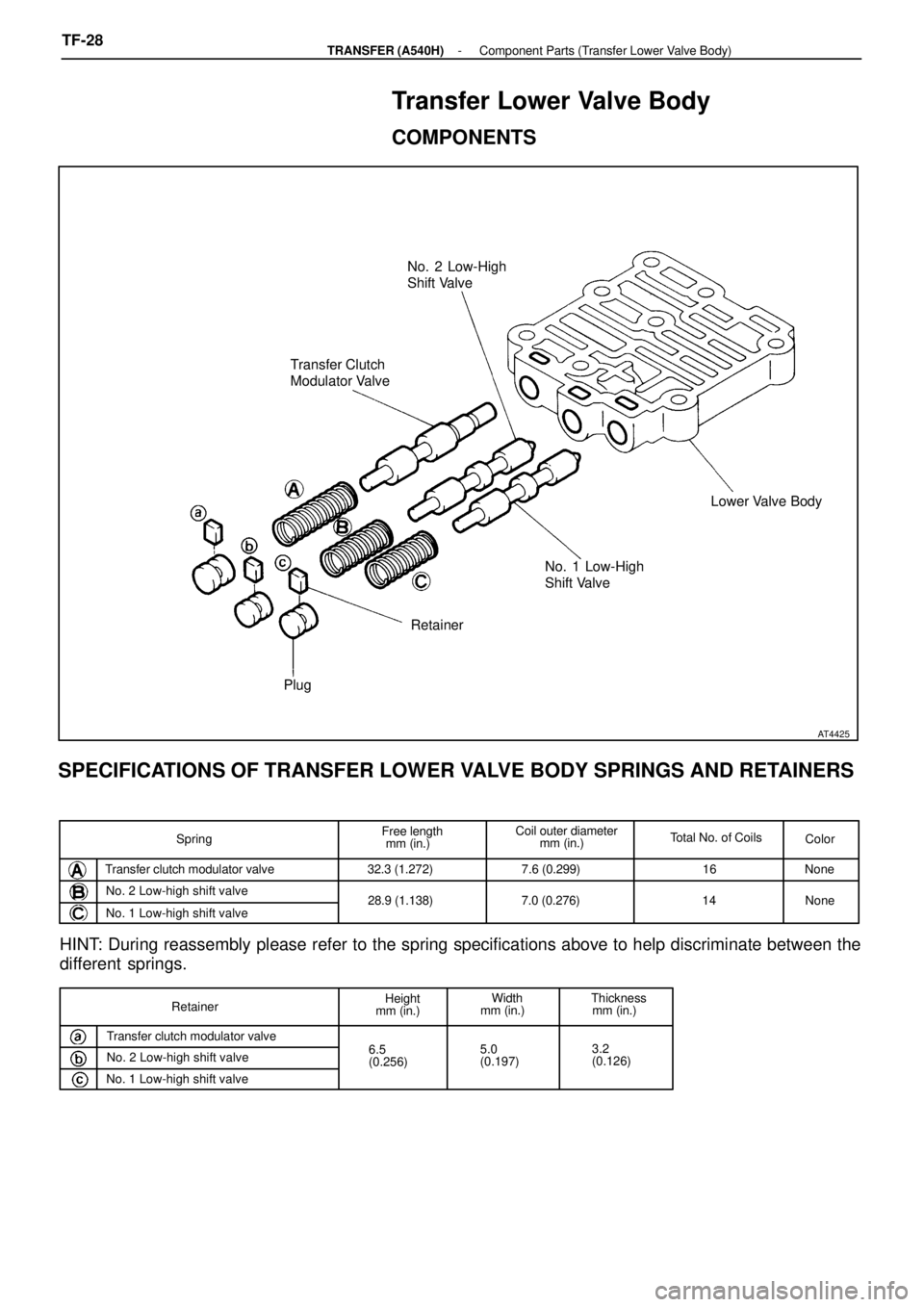

SpringFree length

mm (in.)Coil outer diameter

mm (in.)Total No. of Coils

Color

Transfer clutch modulator valve 32.3 (1.272) 7.6 (0.299) 16None

No. 2 Low-high shift valve

28.9 (1.138) 7.0 (0.276) 14None

No. 1 Low-high shift valve

RetainerHeight

mm (in.)Width

mm (in.)Thickness

mm (in.)

Transfer clutch modulator valve

6.5

(0.256)5.0

(0.197)3.2

(0.126) No. 2 Low-high shift valve

No. 1 Low-high shift valve

AT4425

PlugRetainerNo. 1 Low-High

Shift ValveLower Valve Body Transfer Clutch

Modulator ValveNo. 2 Low-High

Shift Valve

Transfer Lower Valve Body

COMPONENTS

SPECIFICATIONS OF TRANSFER LOWER VALVE BODY SPRINGS AND RETAINERS

HINT: During reassembly please refer to the spring specifications above to help discriminate between the

different springs.

TF-28- TRANSFER (A540H)Component Parts (Transfer Lower Valve Body)

Page 562 of 2389

HINT: If the overdrive planetary gear is properly

installed onto the direct clutch, the counter drive

gear height from the overdrive case will be about

24mm (0.94 in.).

± AUTOMATIC TRANSAXLEComponent Parts (Overdrive Unit) (A540E and A54oH)AT±307

Page 625 of 2389

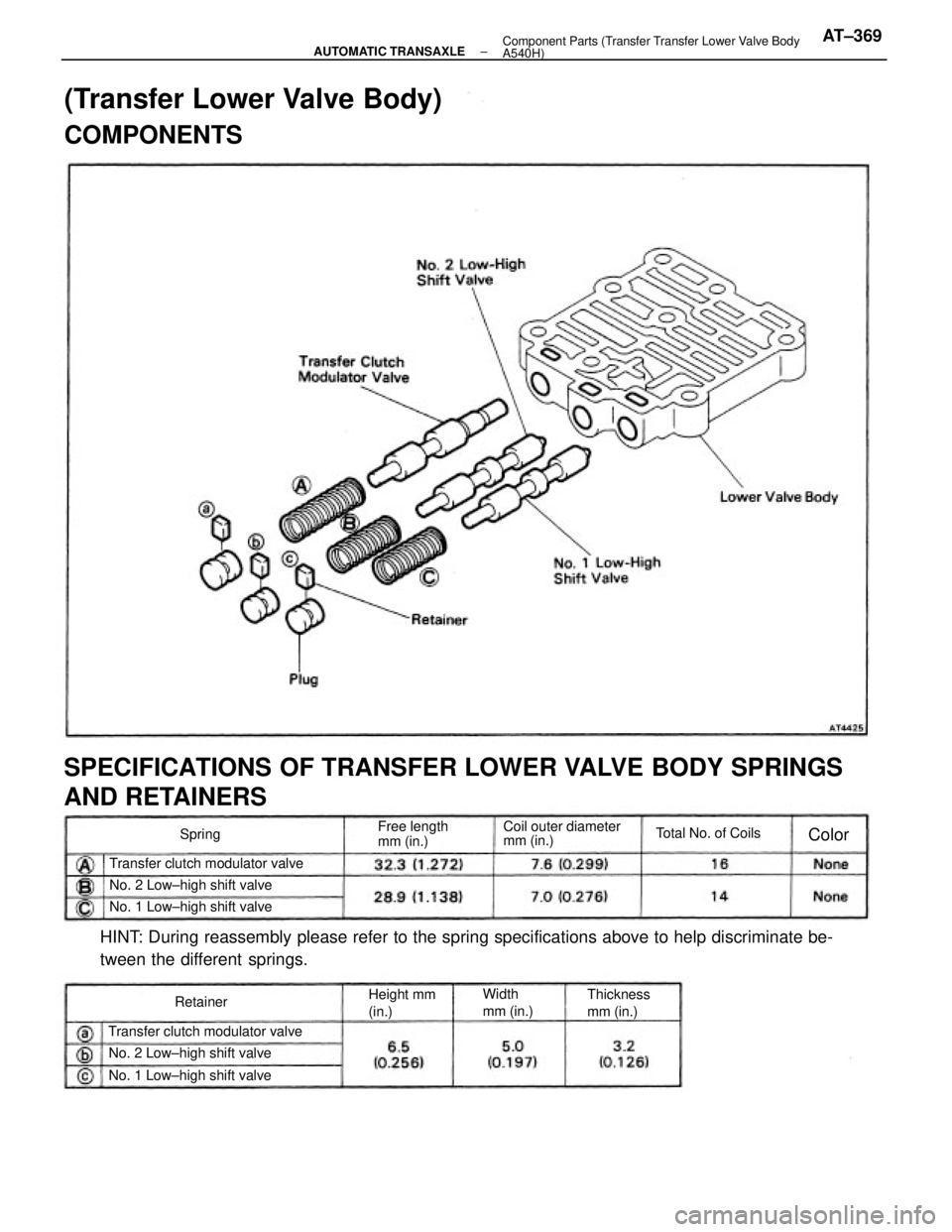

HINT: During reassembly please refer to the spring specifications above to help discriminate be-

tween the different springs.

SPECIFICATIONS OF TRANSFER LOWER VALVE BODY SPRINGS

AND RETAINERS

(Transfer Lower Valve Body)

COMPONENTS

Transfer clutch modulator valveTransfer clutch modulator valveCoil outer diameter

mm (in.)

No. 2 Low±high shift valveNo. 2 Low±high shift valve

No. 1 Low±high shift valveNo. 1 Low±high shift valveFree length

mm (in.)Total No. of Coils

Thickness

mm (in.) Height mm

(in.)Width

mm (in.) RetainerSpring

Color

± AUTOMATIC TRANSAXLEComponent Parts (Transfer Transfer Lower Valve Body

A540H)AT±369

Page 708 of 2389

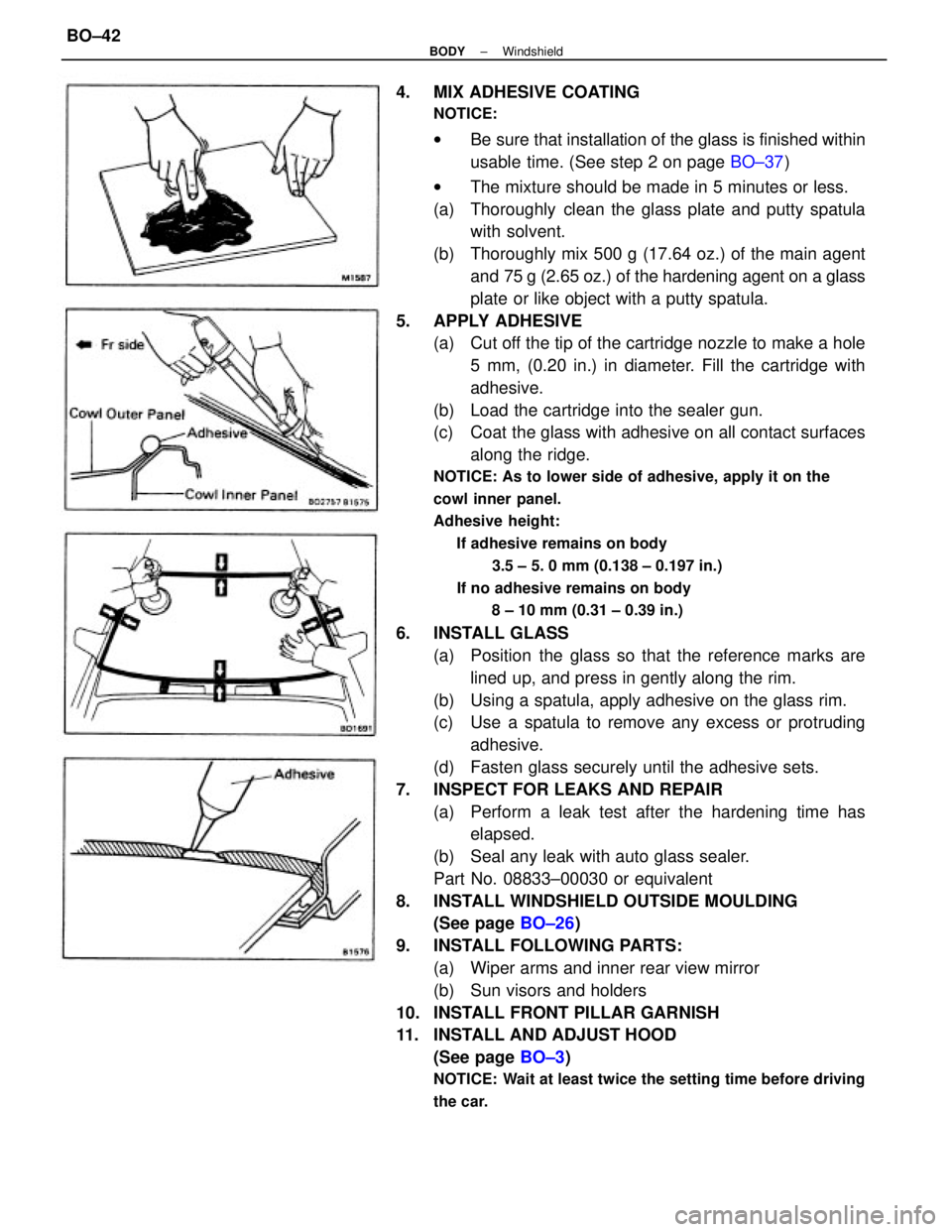

4. MIX ADHESIVE COATING

NOTICE:

wBe sure that installation of the glass is finished within

usable time. (See step 2 on page BO±37)

wThe mixture should be made in 5 minutes or less.

(a) Thoroughly clean the glass plate and putty spatula

with solvent.

(b) Thoroughly mix 500 g (17.64 oz.) of the main agent

and 75 g (2.65 oz.) of the hardening agent on a glass

plate or like object with a putty spatula.

5. APPLY ADHESIVE

(a) Cut off the tip of the cartridge nozzle to make a hole

5 mm, (0.20 in.) in diameter. Fill the cartridge with

adhesive.

(b) Load the cartridge into the sealer gun.

(c) Coat the glass with adhesive on all contact surfaces

along the ridge.

NOTICE: As to lower side of adhesive, apply it on the

cowl inner panel.

Adhesive height:

If adhesive remains on body

3.5 ± 5. 0 mm (0.138 ± 0.197 in.)

If no adhesive remains on body

8 ± 10 mm (0.31 ± 0.39 in.)

6. INSTALL GLASS

(a) Position the glass so that the reference marks are

lined up, and press in gently along the rim.

(b) Using a spatula, apply adhesive on the glass rim.

(c) Use a spatula to remove any excess or protruding

adhesive.

(d) Fasten glass securely until the adhesive sets.

7. INSPECT FOR LEAKS AND REPAIR

(a) Perform a leak test after the hardening time has

elapsed.

(b) Seal any leak with auto glass sealer.

Part No. 08833±00030 or equivalent

8. INSTALL WINDSHIELD OUTSIDE MOULDING

(See page BO±26)

9. INSTALL FOLLOWING PARTS:

(a) Wiper arms and inner rear view mirror

(b) Sun visors and holders

10. INSTALL FRONT PILLAR GARNISH

11. INSTALL AND ADJUST HOOD

(See page BO±3)

NOTICE: Wait at least twice the setting time before driving

the car.

± BODYWindshieldBO±42

Page 741 of 2389

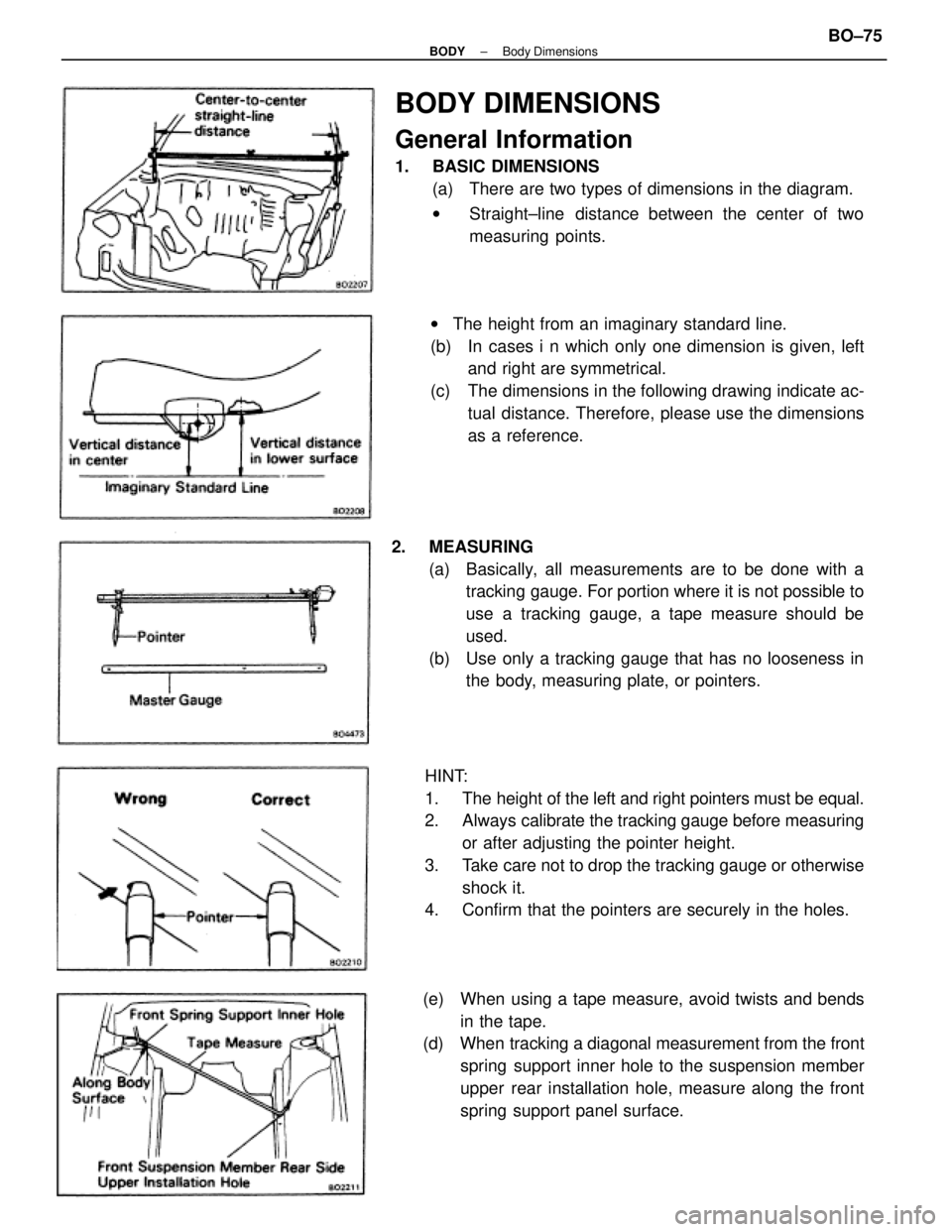

BODY DIMENSIONS

General Information

1. BASIC DIMENSIONS

(a) There are two types of dimensions in the diagram.

wStraight±line distance between the center of two

measuring points.

HINT:

1. The height of the left and right pointers must be equal.

2. Always calibrate the tracking gauge before measuring

or after adjusting the pointer height.

3. Take care not to drop the tracking gauge or otherwise

shock it.

4. Confirm that the pointers are securely in the holes. 2. MEASURING

(a) Basically, all measurements are to be done with a

tracking gauge. For portion where it is not possible to

use a tracking gauge, a tape measure should be

used.

(b) Use only a tracking gauge that has no looseness in

the body, measuring plate, or pointers. wThe height from an imaginary standard line.

(b) In cases i n which only one dimension is given, left

and right are symmetrical.

(c) The dimensions in the following drawing indicate ac-

tual distance. Therefore, please use the dimensions

as a reference.

(e) When using a tape measure, avoid twists and bends

in the tape.

(d) When tracking a diagonal measurement from the front

spring support inner hole to the suspension member

upper rear installation hole, measure along the front

spring support panel surface.

± BODYBody DimensionsBO±75