suspension TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 741 of 2389

BODY DIMENSIONS

General Information

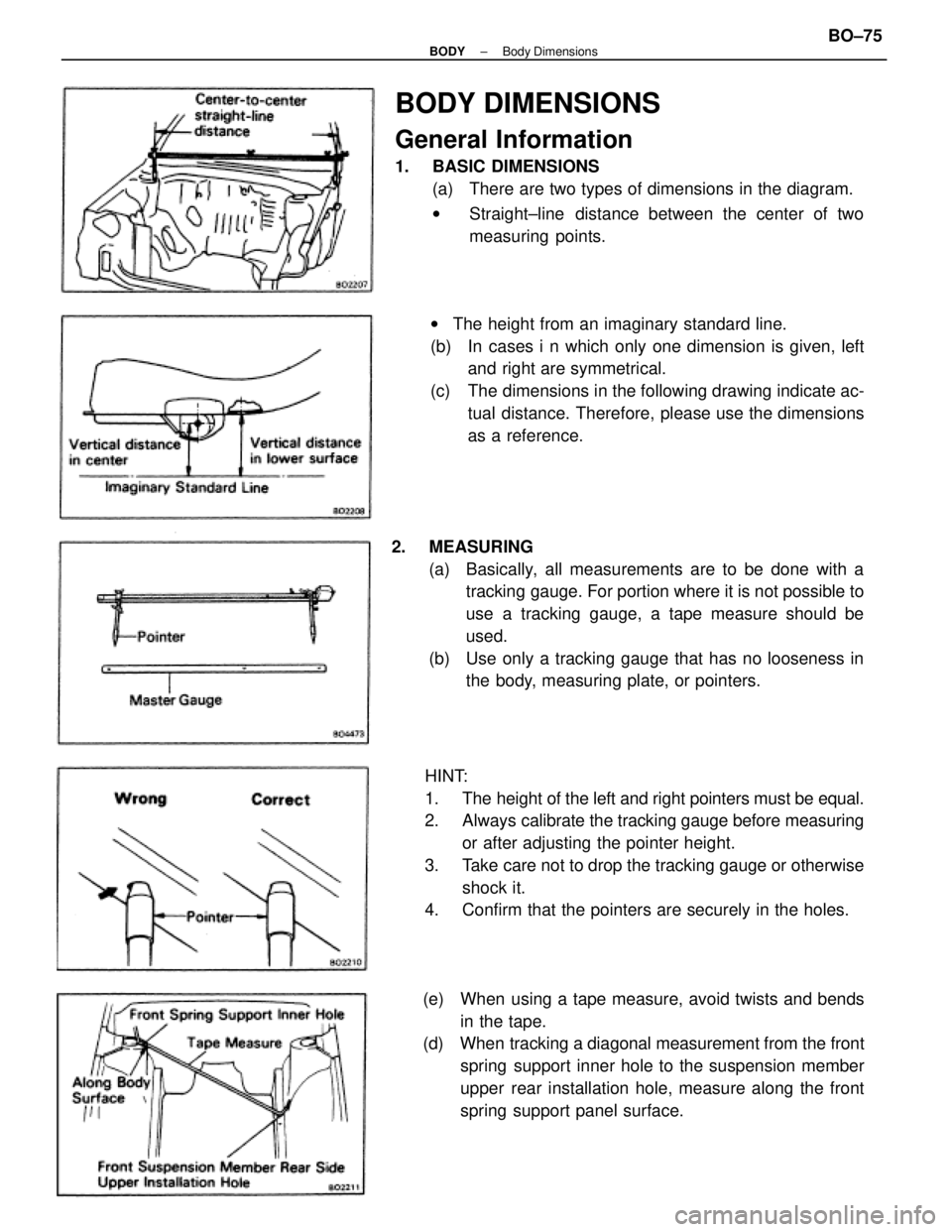

1. BASIC DIMENSIONS

(a) There are two types of dimensions in the diagram.

wStraight±line distance between the center of two

measuring points.

HINT:

1. The height of the left and right pointers must be equal.

2. Always calibrate the tracking gauge before measuring

or after adjusting the pointer height.

3. Take care not to drop the tracking gauge or otherwise

shock it.

4. Confirm that the pointers are securely in the holes. 2. MEASURING

(a) Basically, all measurements are to be done with a

tracking gauge. For portion where it is not possible to

use a tracking gauge, a tape measure should be

used.

(b) Use only a tracking gauge that has no looseness in

the body, measuring plate, or pointers. wThe height from an imaginary standard line.

(b) In cases i n which only one dimension is given, left

and right are symmetrical.

(c) The dimensions in the following drawing indicate ac-

tual distance. Therefore, please use the dimensions

as a reference.

(e) When using a tape measure, avoid twists and bends

in the tape.

(d) When tracking a diagonal measurement from the front

spring support inner hole to the suspension member

upper rear installation hole, measure along the front

spring support panel surface.

± BODYBody DimensionsBO±75

Page 904 of 2389

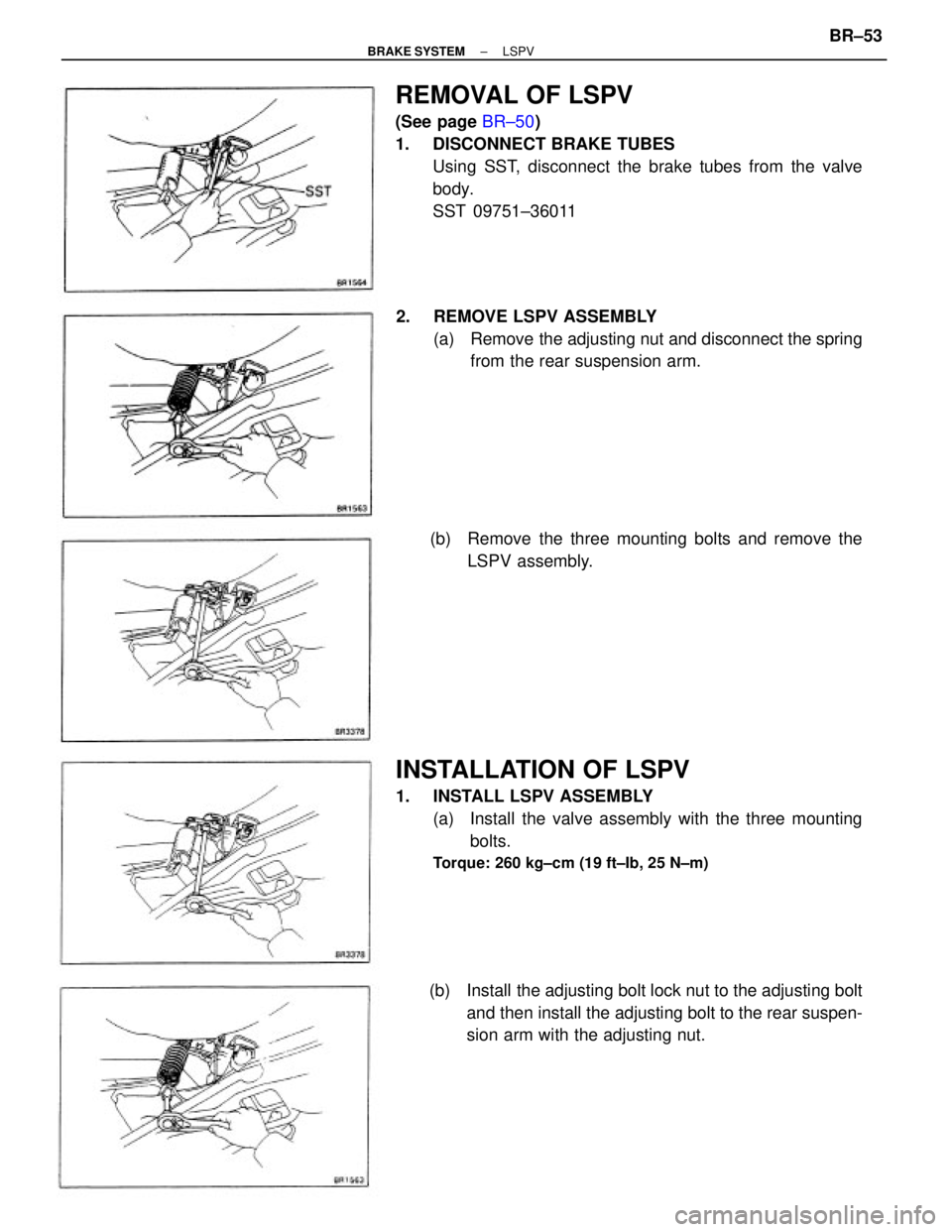

REMOVAL OF LSPV

(See page BR±50)

1. DISCONNECT BRAKE TUBES

Using SST, disconnect the brake tubes from the valve

body.

SST 09751±36011

INSTALLATION OF LSPV

1. INSTALL LSPV ASSEMBLY

(a) Install the valve assembly with the three mounting

bolts.

Torque: 260 kg±cm (19 ft±Ib, 25 N±m)

2. REMOVE LSPV ASSEMBLY

(a) Remove the adjusting nut and disconnect the spring

from the rear suspension arm.

(b) Install the adjusting bolt lock nut to the adjusting bolt

and then install the adjusting bolt to the rear suspen-

sion arm with the adjusting nut. (b) Remove the three mounting bolts and remove the

LSPV assembly.

± BRAKE SYSTEMLSPVBR±53

Page 949 of 2389

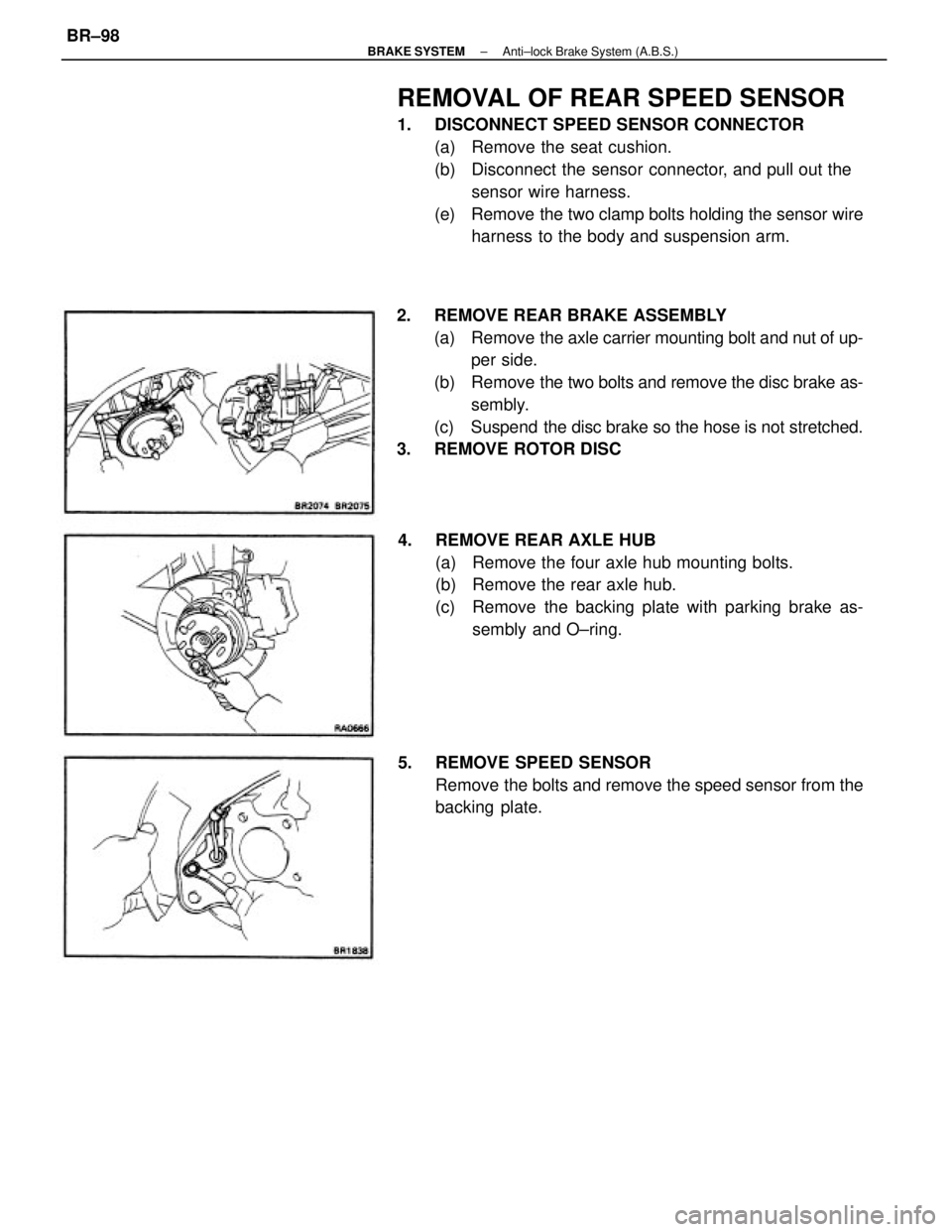

REMOVAL OF REAR SPEED SENSOR

1. DISCONNECT SPEED SENSOR CONNECTOR

(a) Remove the seat cushion.

(b) Disconnect the sensor connector, and pull out the

sensor wire harness.

(e) Remove the two clamp bolts holding the sensor wire

harness to the body and suspension arm.

2. REMOVE REAR BRAKE ASSEMBLY

(a) Remove the axle carrier mounting bolt and nut of up-

per side.

(b) Remove the two bolts and remove the disc brake as-

sembly.

(c) Suspend the disc brake so the hose is not stretched.

3. REMOVE ROTOR DISC

4. REMOVE REAR AXLE HUB

(a) Remove the four axle hub mounting bolts.

(b) Remove the rear axle hub.

(c) Remove the backing plate with parking brake as-

sembly and O±ring.

5. REMOVE SPEED SENSOR

Remove the bolts and remove the speed sensor from the

backing plate.

± BRAKE SYSTEMAnti±lock Brake System (A.B.S.)BR±98

Page 1163 of 2389

INSPECTION OF EXHAUST PIPE

ASSEMBLY

CHECK CONNECTIONS FOR LOOSENESS OR DAMAGE

REPLACEMENT OF CATALYTIC

CONVERTERS

1. REMOVE CONVERTERS

(a) Jack up the vehicle.

(b) Check that the converter is cool.

(e) Remove the suspension lower crossmember.

(See page EM±44)

(d) Remove the front exhaust pipe (Sub±converter).

wLoosen the bolt, and disconnect the clamp the

exhaust pipe bracket.

wRemove the three nuts, and remove the exhaust pipe. Remove

the three nuts, and remove the exhaust pipe. Remove the gas-

ket.

(e) Remove the two bolts, two nuts and two converter stays.

(f) Remove the three bolts, two nuts, gasket, retainer, cushion and

main converter.

(g) Remove the eight bolts and two heat insulators from the main

converter.

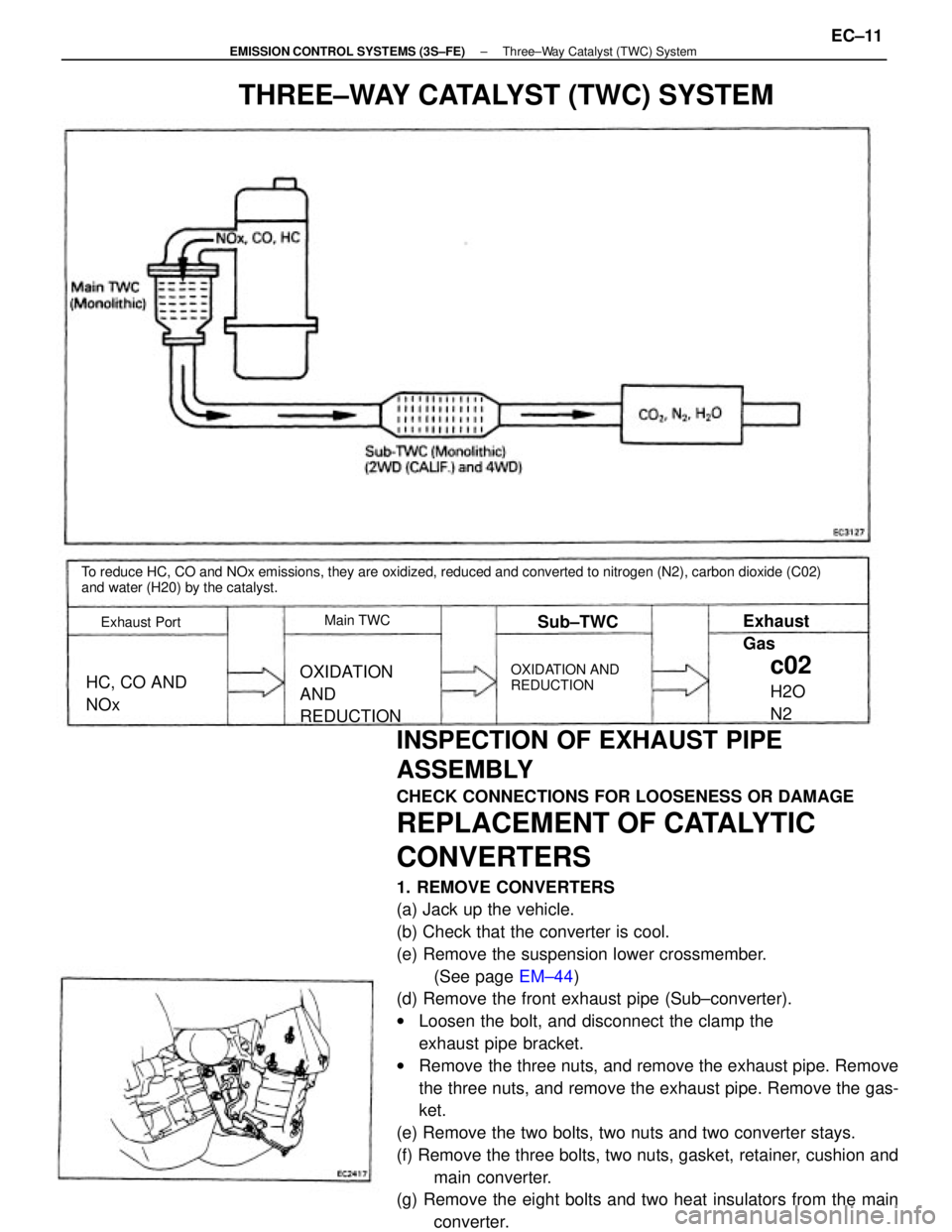

To reduce HC, CO and NOx emissions, they are oxidized, reduced and converted to nitrogen (N2), carbon dioxide (C02)

and water (H20) by the catalyst.

THREE±WAY CATALYST (TWC) SYSTEM

OXIDATION

AND

REDUCTIONOXIDATION AND

REDUCTIONHC, CO AND

NOx

Exhaust Port

c02

H2O

N2 Exhaust

Gas

Main TWCSub±TWC

± EMISSION CONTROL SYSTEMS (3S±FE)Three±Way Catalyst (TWC) SystemEC±11

Page 1164 of 2389

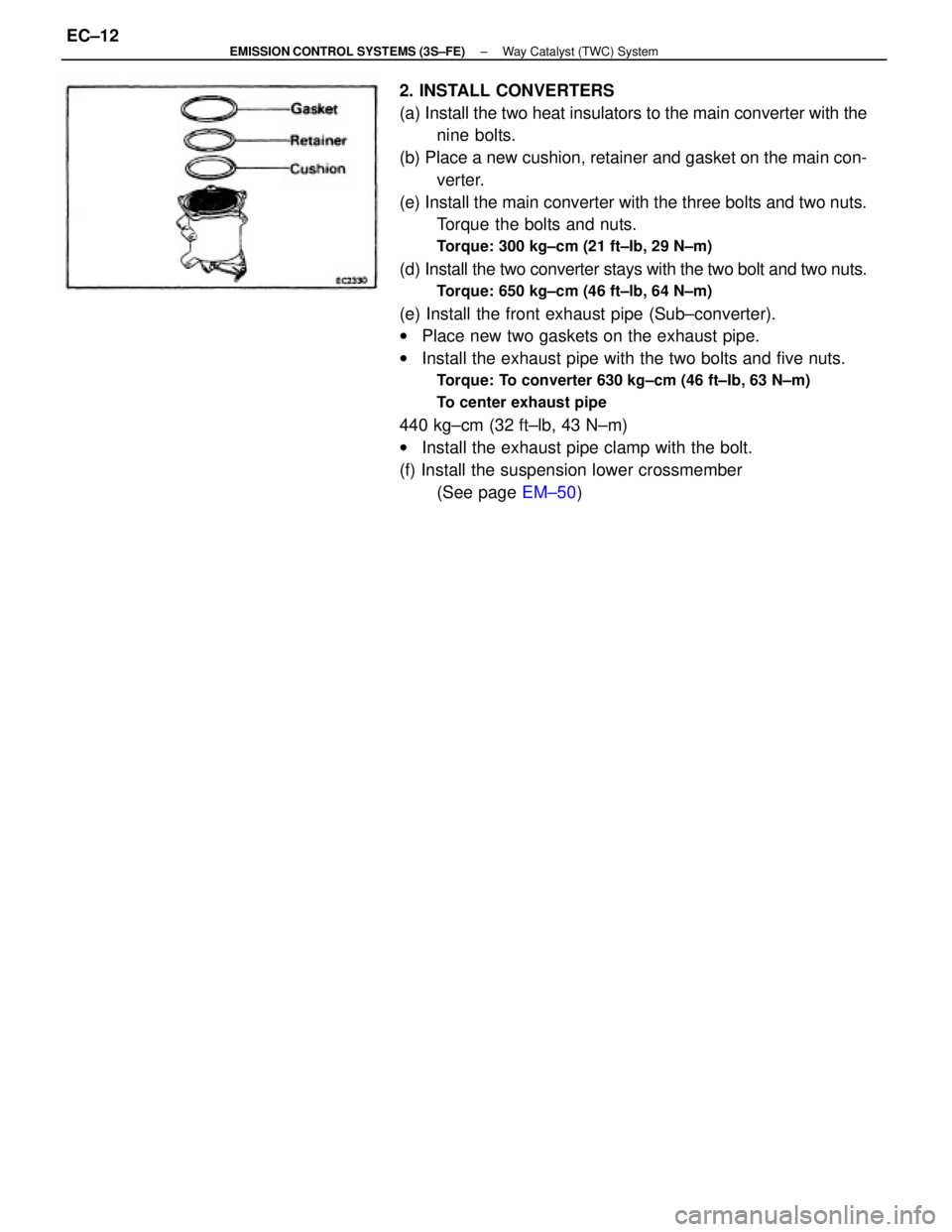

2. INSTALL CONVERTERS

(a) Install the two heat insulators to the main converter with the

nine bolts.

(b) Place a new cushion, retainer and gasket on the main con-

verter.

(e) Install the main converter with the three bolts and two nuts.

Torque the bolts and nuts.

Torque: 300 kg±cm (21 ft±Ib, 29 N±m)

(d) Install the two converter stays with the two bolt and two nuts.

Torque: 650 kg±cm (46 ft±lb, 64 N±m)

(e) Install the front exhaust pipe (Sub±converter).

wPlace new two gaskets on the exhaust pipe.

wInstall the exhaust pipe with the two bolts and five nuts.

Torque: To converter 630 kg±cm (46 ft±Ib, 63 N±m)

To center exhaust pipe

440 kg±cm (32 ft±lb, 43 N±m)

wInstall the exhaust pipe clamp with the bolt.

(f) Install the suspension lower crossmember

(See page EM±50)

± EMISSION CONTROL SYSTEMS (3S±FE)Way Catalyst (TWC) SystemEC±12

Page 1226 of 2389

REMOVAL OF CYLINDER HEAD

(See page EM±48)

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL

OF BATTERY

2. DRAIN ENGINE COOLANT (See page CO±4)

3. (A/T)

DISCONNECT THROTTLE CABLE AND BRACKET FROM

THROTTLE BODY

4. DISCONNECT ACCELERATOR CABLE AND BRACKET

FROM THROTTLE BODY AND AIR INTAKE CHAMBER

5. REMOVE CRUISE CONTROL ACTUATOR

(See step 9 on page EM±108)

6. REMOVE AIR CLEANER HOSE

7. REMOVE ALTERNATOR (See page CH±6)

8. REMOVE OIL PRESSURE SWITCH, ENGINE HANGERS

AND ALTERNATOR UPPER BRACKET

9. RAISE VEHICLE

NOTICE: Be sure the vehicle is securely supported.

10. REMOVE RH FRONT WHEEL

11. REMOVE ENGINE RH UNDER COVER

12. REMOVE SUSPENSION LOWER CROSSMEMBER

(See step 20 on page EM±109)

13. DISCONNECT FRONT EXHAUST PIPE FROM

CATALYTIC CONVERTER

(See step 25 on page EM±110)

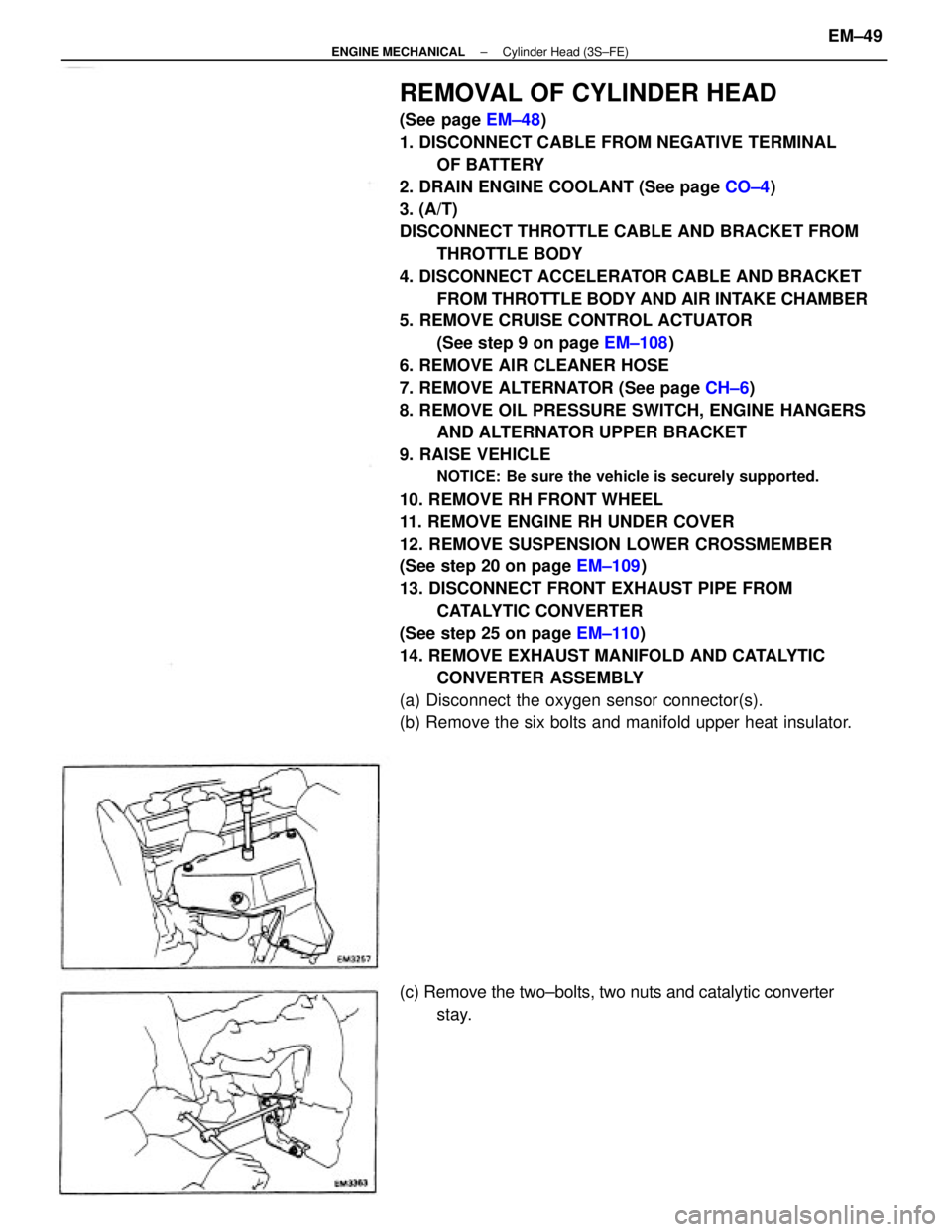

14. REMOVE EXHAUST MANIFOLD AND CATALYTIC

CONVERTER ASSEMBLY

(a) Disconnect the oxygen sensor connector(s).

(b) Remove the six bolts and manifold upper heat insulator.

(c) Remove the two±bolts, two nuts and catalytic converter

stay.

± ENGINE MECHANICALCylinder Head (3S±FE)EM±49

Page 1250 of 2389

21. CONNECT FRONT EXHAUST PIPE TO CATALYTIC

CONVERTER

(See step 12 on page EM±136)

22. INSTALL SUSPENSION LOWER CROSSMEMBER

(See step 17 on page EM±136)

23. INSTALL ENGINE RH UNDER COVER

24. INSTALL RH FRONT WHEEL

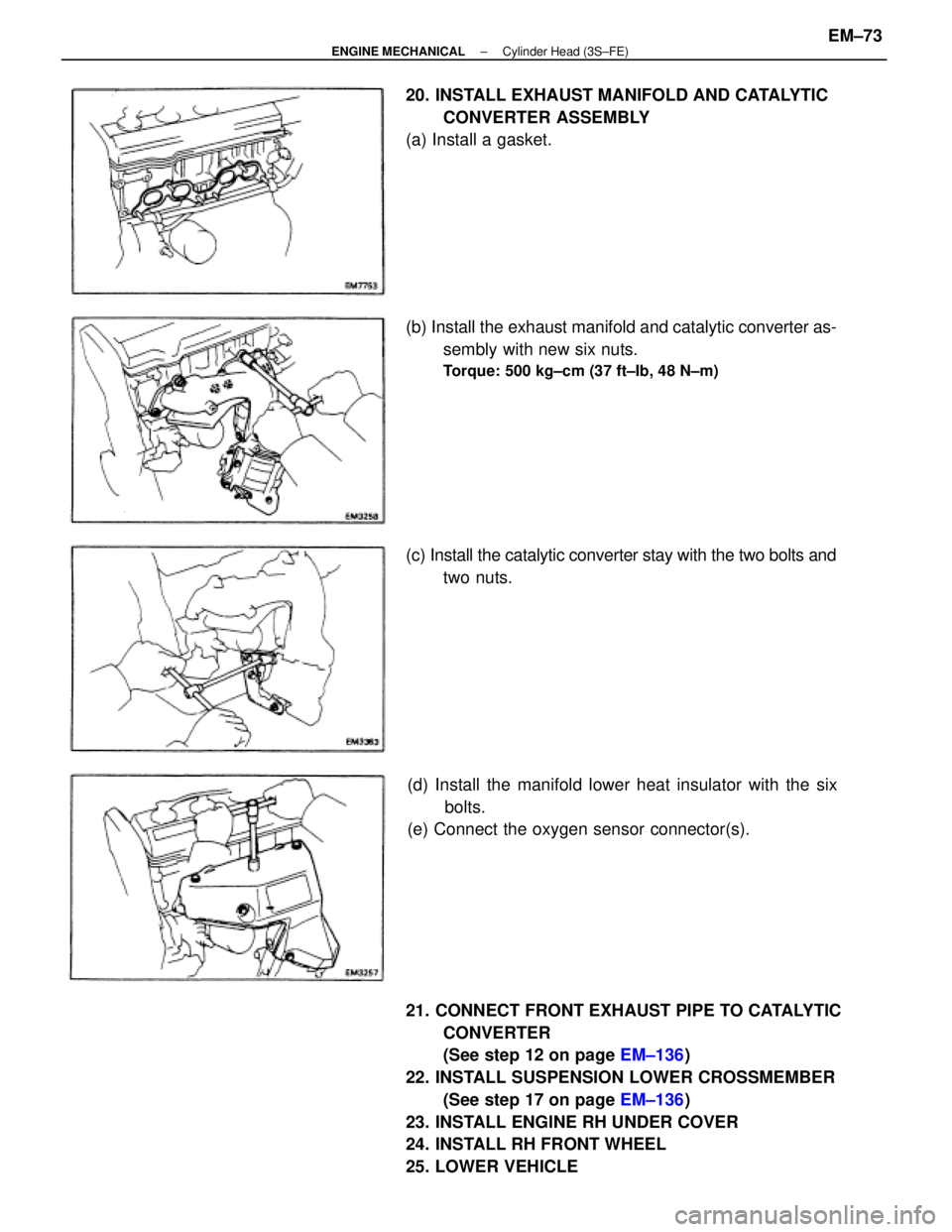

25. LOWER VEHICLE(d) Install the manifold lower heat insulator with the six

bolts.

(e) Connect the oxygen sensor connector(s). (b) Install the exhaust manifold and catalytic converter as-

sembly with new six nuts.

Torque: 500 kg±cm (37 ft±Ib, 48 N±m)

20. INSTALL EXHAUST MANIFOLD AND CATALYTIC

CONVERTER ASSEMBLY

(a) Install a gasket.

(c) Install the catalytic converter stay with the two bolts and

two nuts.

± ENGINE MECHANICALCylinder Head (3S±FE)EM±73

Page 1253 of 2389

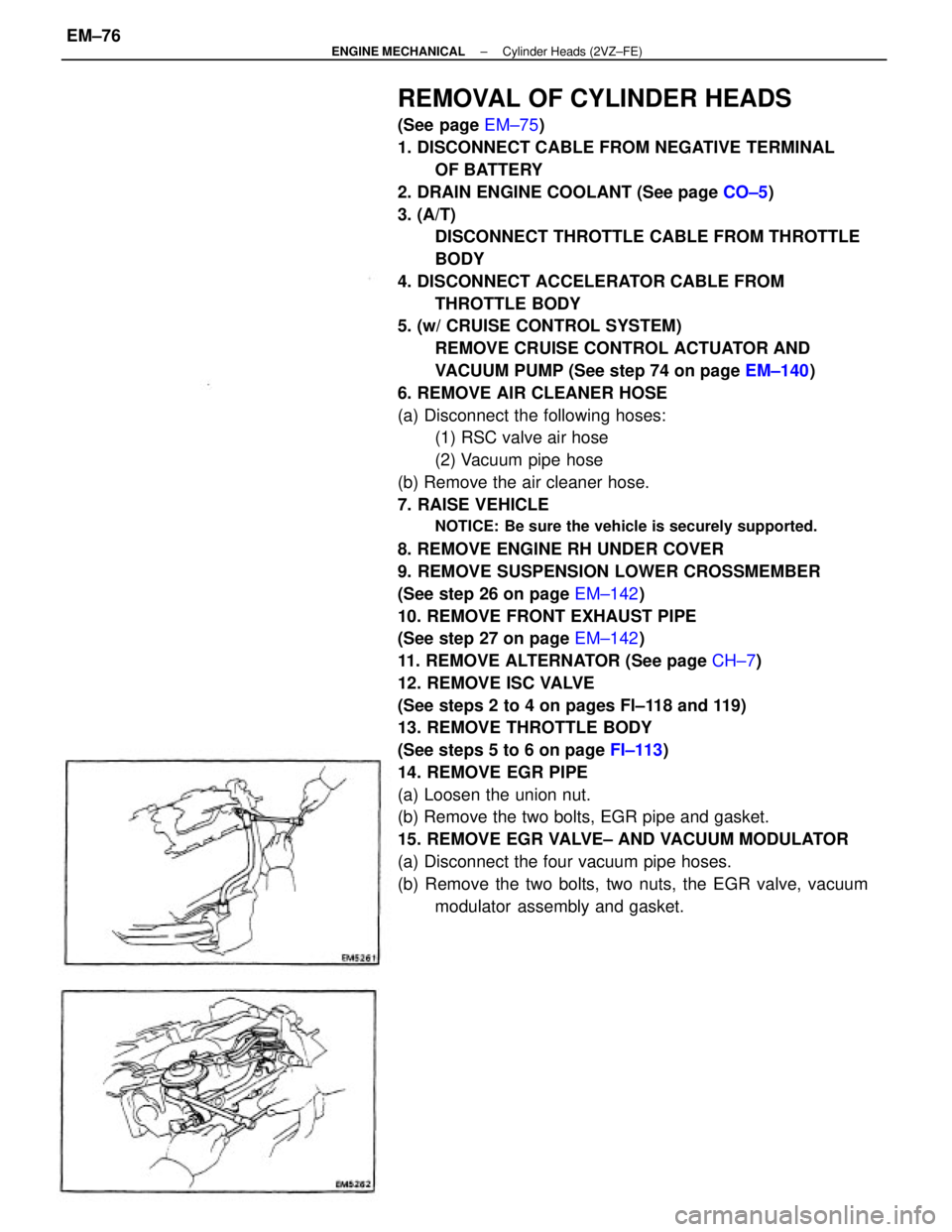

REMOVAL OF CYLINDER HEADS

(See page EM±75)

1. DISCONNECT CABLE FROM NEGATIVE TERMINAL

OF BATTERY

2. DRAIN ENGINE COOLANT (See page CO±5)

3. (A/T)

DISCONNECT THROTTLE CABLE FROM THROTTLE

BODY

4. DISCONNECT ACCELERATOR CABLE FROM

THROTTLE BODY

5. (w/ CRUISE CONTROL SYSTEM)

REMOVE CRUISE CONTROL ACTUATOR AND

VACUUM PUMP (See step 74 on page EM±140)

6. REMOVE AIR CLEANER HOSE

(a) Disconnect the following hoses:

(1) RSC valve air hose

(2) Vacuum pipe hose

(b) Remove the air cleaner hose.

7. RAISE VEHICLE

NOTICE: Be sure the vehicle is securely supported.

8. REMOVE ENGINE RH UNDER COVER

9. REMOVE SUSPENSION LOWER CROSSMEMBER

(See step 26 on page EM±142)

10. REMOVE FRONT EXHAUST PIPE

(See step 27 on page EM±142)

11. REMOVE ALTERNATOR (See page CH±7)

12. REMOVE ISC VALVE

(See steps 2 to 4 on pages Fl±118 and 119)

13. REMOVE THROTTLE BODY

(See steps 5 to 6 on page FI±113)

14. REMOVE EGR PIPE

(a) Loosen the union nut.

(b) Remove the two bolts, EGR pipe and gasket.

15. REMOVE EGR VALVE± AND VACUUM MODULATOR

(a) Disconnect the four vacuum pipe hoses.

(b) Remove the two bolts, two nuts, the EGR valve, vacuum

modulator assembly and gasket.

± ENGINE MECHANICALCylinder Heads (2VZ±FE)EM±76

Page 1286 of 2389

15. DISCONNECT HOSES

(a) Two heater water by±pass hoses

(b) Two fuel hoses

NOTICE: Catch leaking fuel in a container.

(c) Brake booster vacuum hose

(d) A/C control valve vacuum hoses

(e) Charcoal canister vacuum hose

16. DISCONNECT WIRES AND CONNECTORS

(a) Check connector

(b) Ground straps from LH fender apron

(e) Connectors from relay box

(d) Engine room wire connector

17. RAISE VEHICLE

NOTICE: Be sure the vehicle is securely supported.

18. REMOVE ENGINE UNDER COVERS

19. DRAIN ENGINE OIL (See page LU±7)

20. REMOVE SUSPENSION LOWER CROSSMEMBER

Remove the four bolts, two nuts and crossmember.

21. REMOVE DRIVE SHAFTS

22. (4WD) .

REMOVE PROPELLER SHAFT

23. (4WD)

REMOVE DEFECTOR FROM TRANSFER EXTENSION

HOUSING

24. REMOVE PS PUMP WITHOUT DISCONNECTING

HOSES

HINT: Put aside the pump and suspend it to the cowl with a

string.14. (w/ A/C)

REMOVE A/C COMPRESSOR WITHOUT

DISCONNECTING HOSES

(a) Disconnect the two connectors.

(b) Remove the four compressor bolts.

HINT: Put aside the compressor, and suspend it to the radia-

tor support with a string.

± ENGINE MECHANICALCylinder Block (3S±FE)EM±109

Page 1313 of 2389

(c) Install the clamp with the bolt.

13. INSTALL PS PUMP

14. (4WD)

INSTALL DEFLECTOR TO TRANSFER EXTENSION

HOUSING

15. (411VD)

INSTALL PROPELLER SHAFT

16. INSTALL DRIVE SHAFTS

17. INSTALL SUSPENSION LOWER CROSSMEMBER

(a) Install the crossmember with the two bolts and two nuts.

Torque the bolts and nuts.

Torque: 2,100 kg±cm (153 ft±lb, 207 N±m)

(b) Install the two bolts holding the crossmember to the center

member. Torque the bolts.

Torque: 400 kg±cm (29 ft±Ib, 39 N±m)

18. INSTALL ENGINE UNDER COVERS

19. CONNECT WIRES AND CONNECTORS

(a) Check connector

(b) Ground straps from LH fender apron

(c) Connectors from relay box

(d) Engine room wire connector

20. CONNECT HOSES

(a) Two heater water by±pass hoses

(b) Two fuel hoses

(c) Brake booster vacuum hoses

(d) A/C idle±up vacuum hoses

(e) Charcoal canister vacuum hose

21. (w/ A/C)

INSTALL A/C COMPRESSOR

(a) Install the compressor with the four bolts.

(b) Connect the two connectors.

22. CONNECT TRANSAXLE CONTROL CABLE

23. CONNECT SPEEDOMETER CABLE 12. INSTALL FRONT EXHAUST PIPE

(a) Place two new gaskets on the front and rear of the front pipe.

(b) Install the front pipe with the two bolts and new five nuts.

Torque the nuts.

Torque:

To manifold: 830 kg±cm (46ft±Ib, 62 N±m)

To converter: 440 kg±cm (32ft±lb, 43 N±m)

± ENGINE MECHANICALCylinder Block (3S±FE)EM±136