tire type TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 711 of 2389

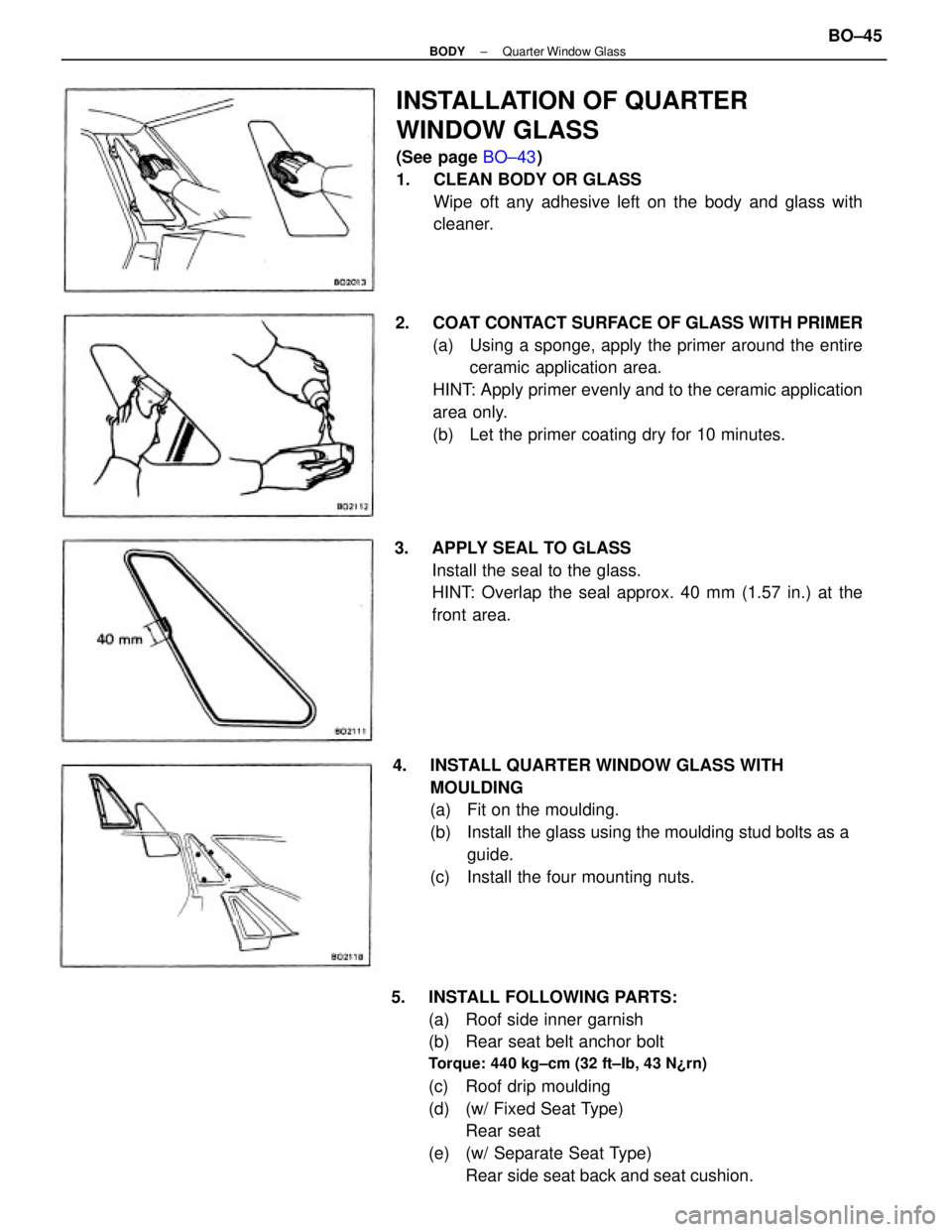

5. INSTALL FOLLOWING PARTS:

(a) Roof side inner garnish

(b) Rear seat belt anchor bolt

Torque: 440 kg±cm (32 ft±Ib, 43 N¿rn)

(c) Roof drip moulding

(d) (w/ Fixed Seat Type)

Rear seat

(e) (w/ Separate Seat Type)

Rear side seat back and seat cushion. 2. COAT CONTACT SURFACE OF GLASS WITH PRIMER

(a) Using a sponge, apply the primer around the entire

ceramic application area.

HINT: Apply primer evenly and to the ceramic application

area only.

(b) Let the primer coating dry for 10 minutes.

4. INSTALL QUARTER WINDOW GLASS WITH

MOULDING

(a) Fit on the moulding.

(b) Install the glass using the moulding stud bolts as a

guide.

(c) Install the four mounting nuts.

INSTALLATION OF QUARTER

WINDOW GLASS

(See page BO±43)

1. CLEAN BODY OR GLASS

Wipe oft any adhesive left on the body and glass with

cleaner.

3. APPLY SEAL TO GLASS

Install the seal to the glass.

HINT: Overlap the seal approx. 40 mm (1.57 in.) at the

front area.

± BODYQuarter Window GlassBO±45

Page 1864 of 2389

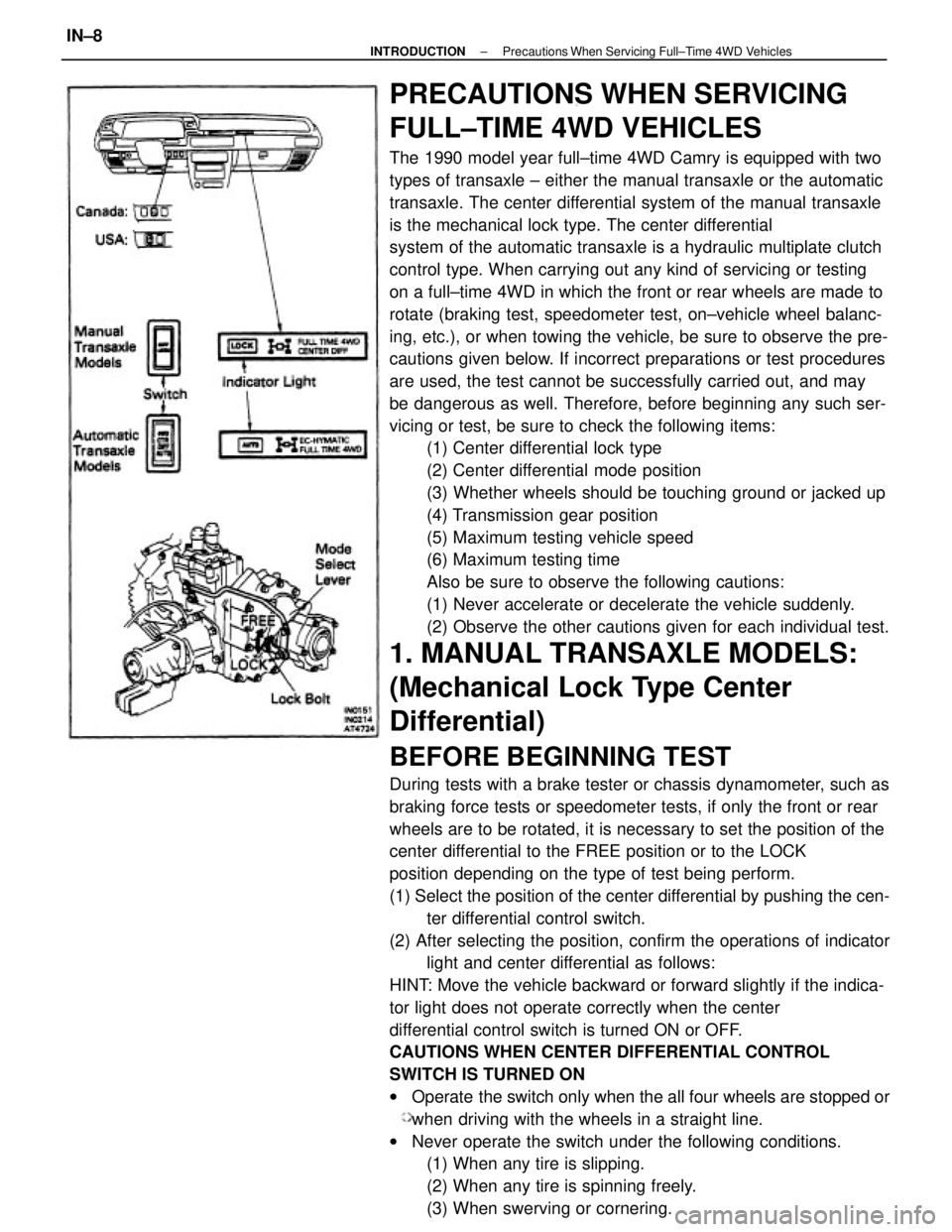

PRECAUTIONS WHEN SERVICING

FULL±TIME 4WD VEHICLES

The 1990 model year full±time 4WD Camry is equipped with two

types of transaxle ± either the manual transaxle or the automatic

transaxle. The center differential system of the manual transaxle

is the mechanical lock type. The center differential

system of the automatic transaxle is a hydraulic multiplate clutch

control type. When carrying out any kind of servicing or testing

on a full±time 4WD in which the front or rear wheels are made to

rotate (braking test, speedometer test, on±vehicle wheel balanc-

ing, etc.), or when towing the vehicle, be sure to observe the pre-

cautions given below. If incorrect preparations or test procedures

are used, the test cannot be successfully carried out, and may

be dangerous as well. Therefore, before beginning any such ser-

vicing or test, be sure to check the following items:

(1) Center differential lock type

(2) Center differential mode position

(3) Whether wheels should be touching ground or jacked up

(4) Transmission gear position

(5) Maximum testing vehicle speed

(6) Maximum testing time

Also be sure to observe the following cautions:

(1) Never accelerate or decelerate the vehicle suddenly.

(2) Observe the other cautions given for each individual test.

1. MANUAL TRANSAXLE MODELS:

(Mechanical Lock Type Center

Differential)

BEFORE BEGINNING TEST

During tests with a brake tester or chassis dynamometer, such as

braking force tests or speedometer tests, if only the front or rear

wheels are to be rotated, it is necessary to set the position of the

center differential to the FREE position or to the LOCK

position depending on the type of test being perform.

(1) Select the position of the center differential by pushing the cen-

ter differential control switch.

(2) After selecting the position, confirm the operations of indicator

light and center differential as follows:

HINT: Move the vehicle backward or forward slightly if the indica-

tor light does not operate correctly when the center

differential control switch is turned ON or OFF.

CAUTIONS WHEN CENTER DIFFERENTIAL CONTROL

SWITCH IS TURNED ON

wOperate the switch only when the all four wheels are stopped or

when driving with the wheels in a straight line.

wNever operate the switch under the following conditions.

(1) When any tire is slipping.

(2) When any tire is spinning freely.

(3) When swerving or cornering.

± INTRODUCTIONPrecautions When Servicing Full±Time 4WD VehiclesIN±8

Page 1865 of 2389

PRECAUTIONS WHEN SERVICING

FULL±TIME 4WD VEHICLES

The 1990 model year full±time 4WD Camry is equipped with two

types of transaxle ± either the manual transaxle or the automatic

transaxle. The center differential system of the manual transaxle

is the mechanical lock type. The center differential

system of the automatic transaxle is a hydraulic multiplate clutch

control type. When carrying out any kind of servicing or testing

on a full±time 4WD in which the front or rear wheels are made to

rotate (braking test, speedometer test, on±vehicle wheel balanc-

ing, etc.), or when towing the vehicle, be sure to observe the pre-

cautions given below. If incorrect preparations or test procedures

are used, the test cannot be successfully carried out, and may

be dangerous as well. Therefore, before beginning any such ser-

vicing or test, be sure to check the following items:

(1) Center differential lock type

(2) Center differential mode position

(3) Whether wheels should be touching ground or jacked up

(4) Transmission gear position

(5) Maximum testing vehicle speed

(6) Maximum testing time

Also be sure to observe the following cautions:

(1) Never accelerate or decelerate the vehicle suddenly.

(2) Observe the other cautions given for each individual test.

1. MANUAL TRANSAXLE MODELS:

(Mechanical Lock Type Center

Differential)

BEFORE BEGINNING TEST

During tests with a brake tester or chassis dynamometer, such as

braking force tests or speedometer tests, if only the front or rear

wheels are to be rotated, it is necessary to set the position of the

center differential to the FREE position or to the LOCK

position depending on the type of test being perform.

(1) Select the position of the center differential by pushing the cen-

ter differential control switch.

(2) After selecting the position, confirm the operations of indicator

light and center differential as follows:

HINT: Move the vehicle backward or forward slightly if the indica-

tor light does not operate correctly when the center

differential control switch is turned ON or OFF.

CAUTIONS WHEN CENTER DIFFERENTIAL CONTROL

SWITCH IS TURNED ON

wOperate the switch only when the all four wheels are stopped or

when driving with the wheels in a straight line.

wNever operate the switch under the following conditions.

(1) When any tire is slipping.

(2) When any tire is spinning freely.

(3) When swerving or cornering.

± INTRODUCTIONPrecautions When Servicing Full±Time 4WD VehiclesIN±8

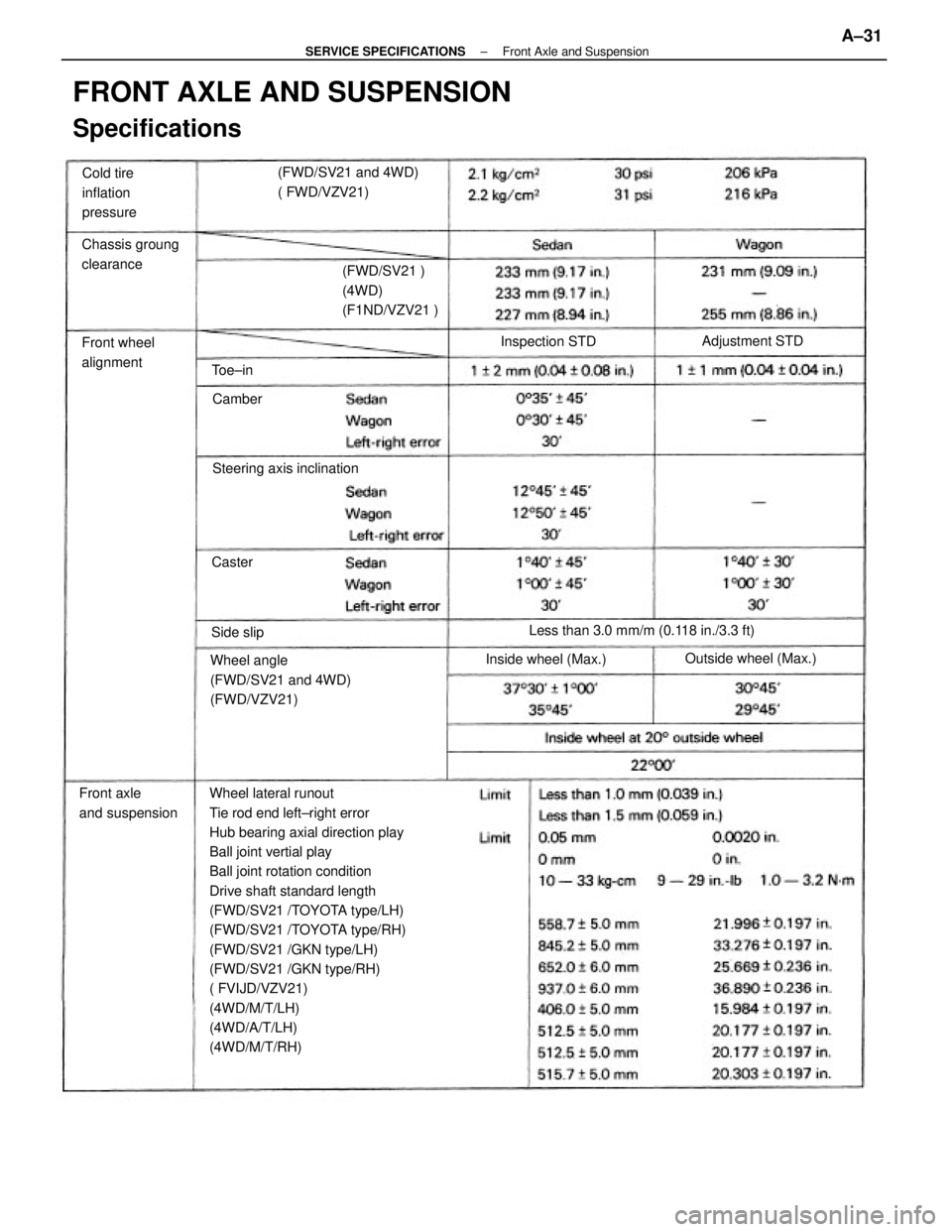

Page 2269 of 2389

Wheel lateral runout

Tie rod end left±right error

Hub bearing axial direction play

Ball joint vertial play

Ball joint rotation condition

Drive shaft standard length

(FWD/SV21 /TOYOTA type/LH)

(FWD/SV21 /TOYOTA type/RH)

(FWD/SV21 /GKN type/LH)

(FWD/SV21 /GKN type/RH)

( FVIJD/VZV21)

(4WD/M/T/LH)

(4WD/A/T/LH)

(4WD/M/T/RH)

FRONT AXLE AND SUSPENSION

Specifications

Wheel angle

(FWD/SV21 and 4WD)

(FWD/VZV21)(FWD/SV21 and 4WD)

( FWD/VZV21)

Less than 3.0 mm/m (0.118 in./3.3 ft) (FWD/SV21 )

(4WD)

(F1ND/VZV21 )

Front axle

and suspensionChassis groung

clearance

Steering axis inclination Cold tire

inflation

pressure

Front wheel

alignment

Outside wheel (Max.)

Inside wheel (Max.)Adjustment STD

Inspection STD

Side slipCamber

Caster Toe±in

± SERVICE SPECIFICATIONSFront Axle and SuspensionA±31

Page 2352 of 2389

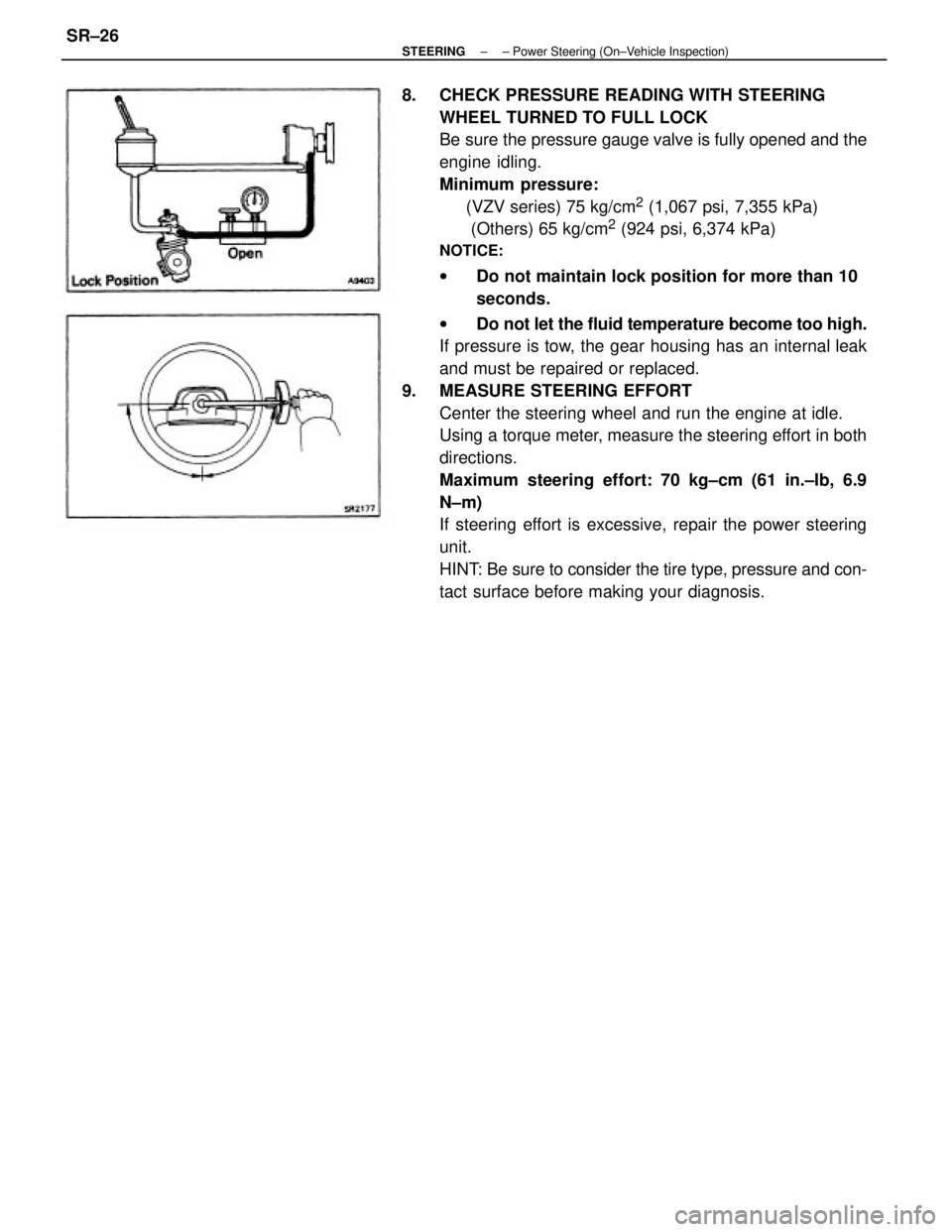

8. CHECK PRESSURE READING WITH STEERING

WHEEL TURNED TO FULL LOCK

Be sure the pressure gauge valve is fully opened and the

engine idling.

Minimum pressure:

(VZV series) 75 kg/cm

2 (1,067 psi, 7,355 kPa)

(Others) 65 kg/cm

2 (924 psi, 6,374 kPa)

NOTICE:

wDo not maintain lock position for more than 10

seconds.

wDo not let the fluid temperature become too high.

If pressure is tow, the gear housing has an internal leak

and must be repaired or replaced.

9. MEASURE STEERING EFFORT

Center the steering wheel and run the engine at idle.

Using a torque meter, measure the steering effort in both

directions.

Maximum steering effort: 70 kg±cm (61 in.±Ib, 6.9

N±m)

If steering effort is excessive, repair the power steering

unit.

HINT: Be sure to consider the tire type, pressure and con-

tact surface before making your diagnosis.

± STEERING± Power Steering (On±Vehicle Inspection)SR±26