wheel alignment TOYOTA CAMRY V20 1986 Service Information

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1986, Model line: CAMRY V20, Model: TOYOTA CAMRY V20 1986Pages: 2389, PDF Size: 84.44 MB

Page 985 of 2389

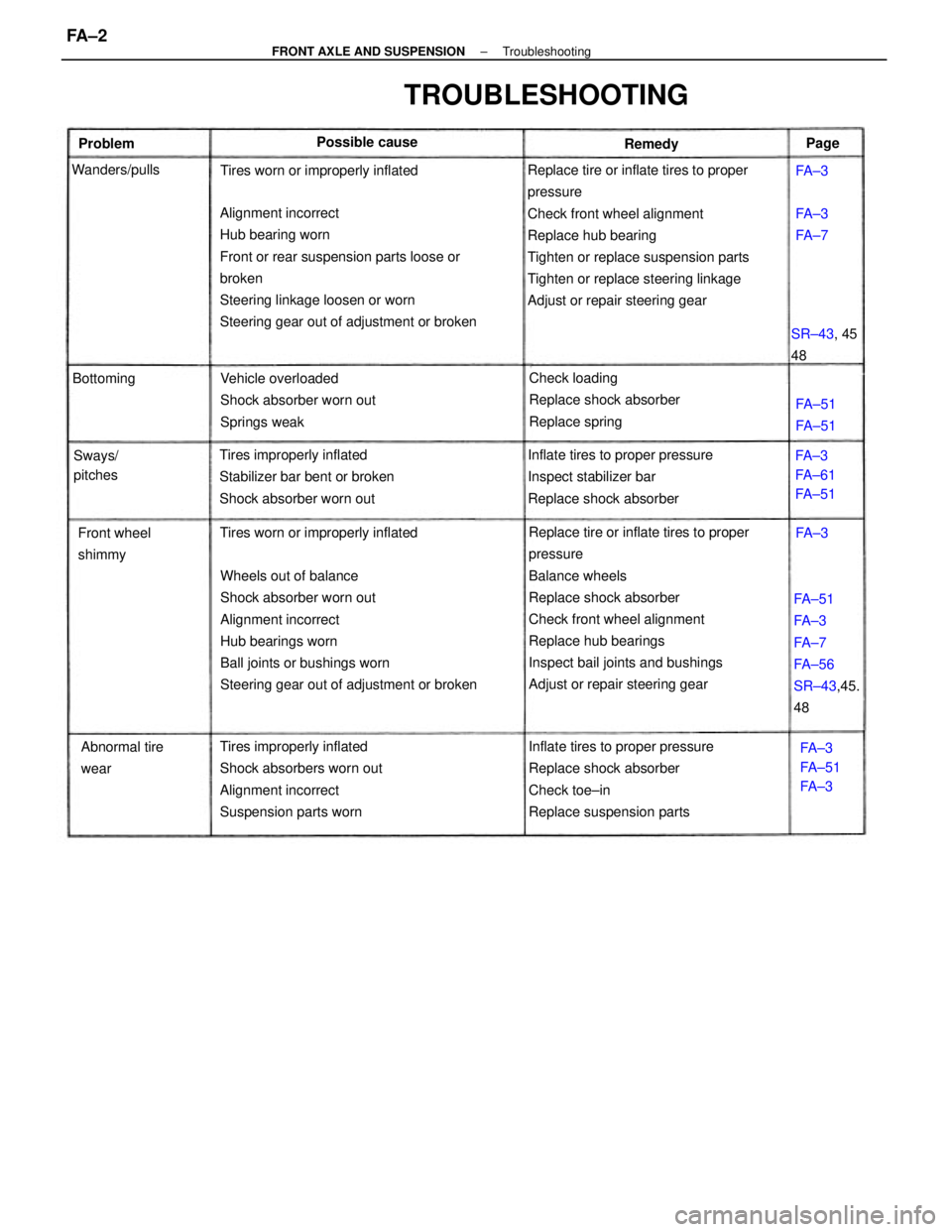

INSTALLATION OF CLUTCH UNIT

(See page CL±8)

1. INSTALL CLUTCH DISC AND COVER ON FLYWHEEL

(a) Insert SST in the clutch disc, and then set them and the cover

in position.

SST S51 Transaxle

09301±32010

E52, E56F5 Transaxle

09301±17010

(b) Align the matchmarks on the clutch cover and flywheel.

(e) Torque the bolts on the clutch cover in the order shown.

Torque: 195 kg±cm (14 ft±Ib, 19 N±m)

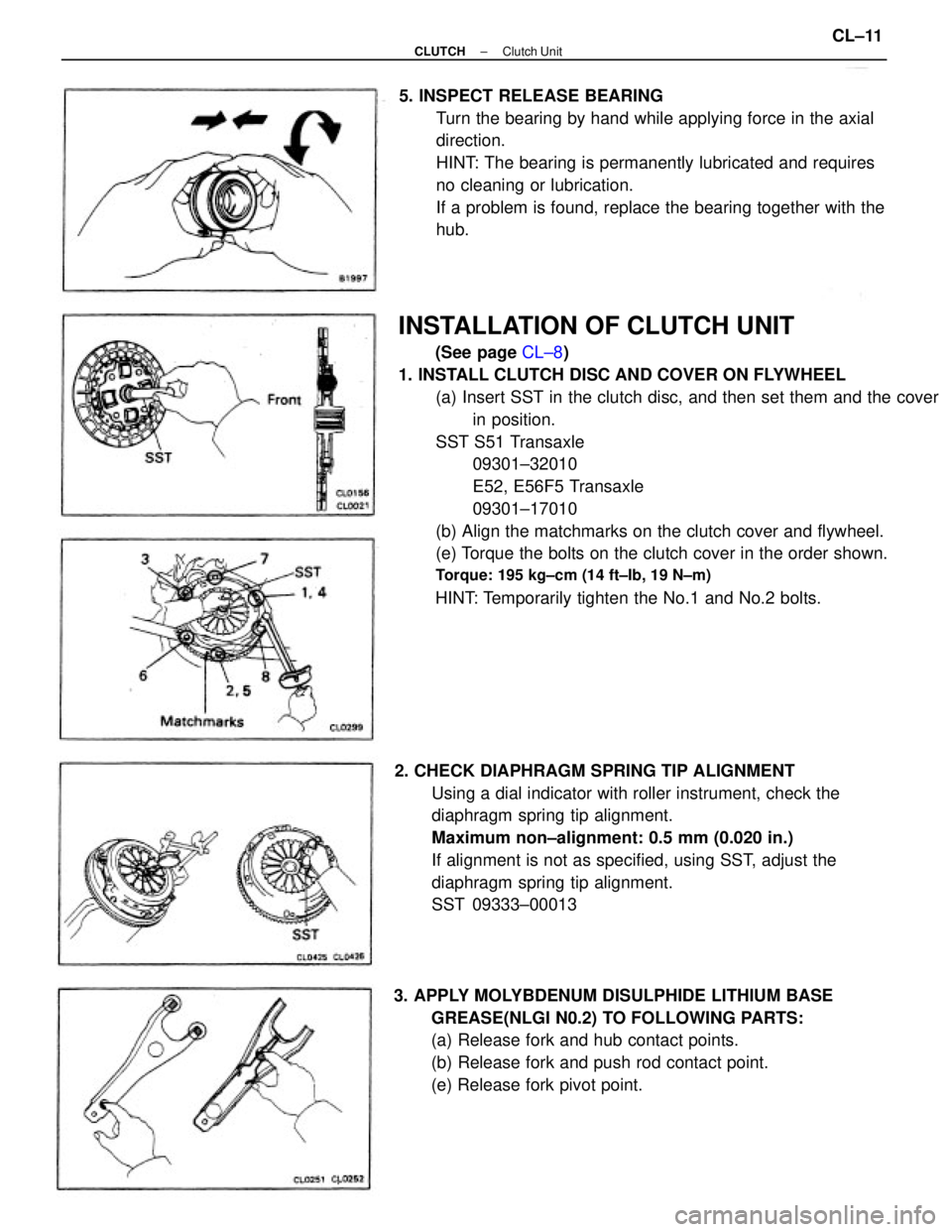

HINT: Temporarily tighten the No.1 and No.2 bolts. 5. INSPECT RELEASE BEARING

Turn the bearing by hand while applying force in the axial

direction.

HINT: The bearing is permanently lubricated and requires

no cleaning or lubrication.

If a problem is found, replace the bearing together with the

hub.

2. CHECK DIAPHRAGM SPRING TIP ALIGNMENT

Using a dial indicator with roller instrument, check the

diaphragm spring tip alignment.

Maximum non±alignment: 0.5 mm (0.020 in.)

If alignment is not as specified, using SST, adjust the

diaphragm spring tip alignment.

SST 09333±00013

3. APPLY MOLYBDENUM DISULPHIDE LITHIUM BASE

GREASE(NLGI N0.2) TO FOLLOWING PARTS:

(a) Release fork and hub contact points.

(b) Release fork and push rod contact point.

(e) Release fork pivot point.

± CLUTCHClutch UnitCL±11

Page 1359 of 2389

Replace tire or inflate tires to proper

pressure

Check front wheel alignment

Replace hub bearing

Tighten or replace suspension parts

Tighten or replace steering linkage

Adjust or repair steering gear

Replace tire or inflate tires to proper

pressure

Balance wheels

Replace shock absorber

Check front wheel alignment

Replace hub bearings

Inspect bail joints and bushings

Adjust or repair steering gear Wheels out of balance

Shock absorber worn out

Alignment incorrect

Hub bearings worn

Ball joints or bushings worn

Steering gear out of adjustment or broken Alignment incorrect

Hub bearing worn

Front or rear suspension parts loose or

broken

Steering linkage loosen or worn

Steering gear out of adjustment or broken

Inflate tires to proper pressure

Replace shock absorber

Check toe±in

Replace suspension parts Tires improperly inflated

Shock absorbers worn out

Alignment incorrect

Suspension parts wornInflate tires to proper pressure

Inspect stabilizer bar

Replace shock absorber Tires improperly inflated

Stabilizer bar bent or broken

Shock absorber worn outVehicle overloaded

Shock absorber worn out

Springs weakCheck loading

Replace shock absorber

Replace spring

FA±51

FA±3

FA±7

FA±56

SR±43,45.

48

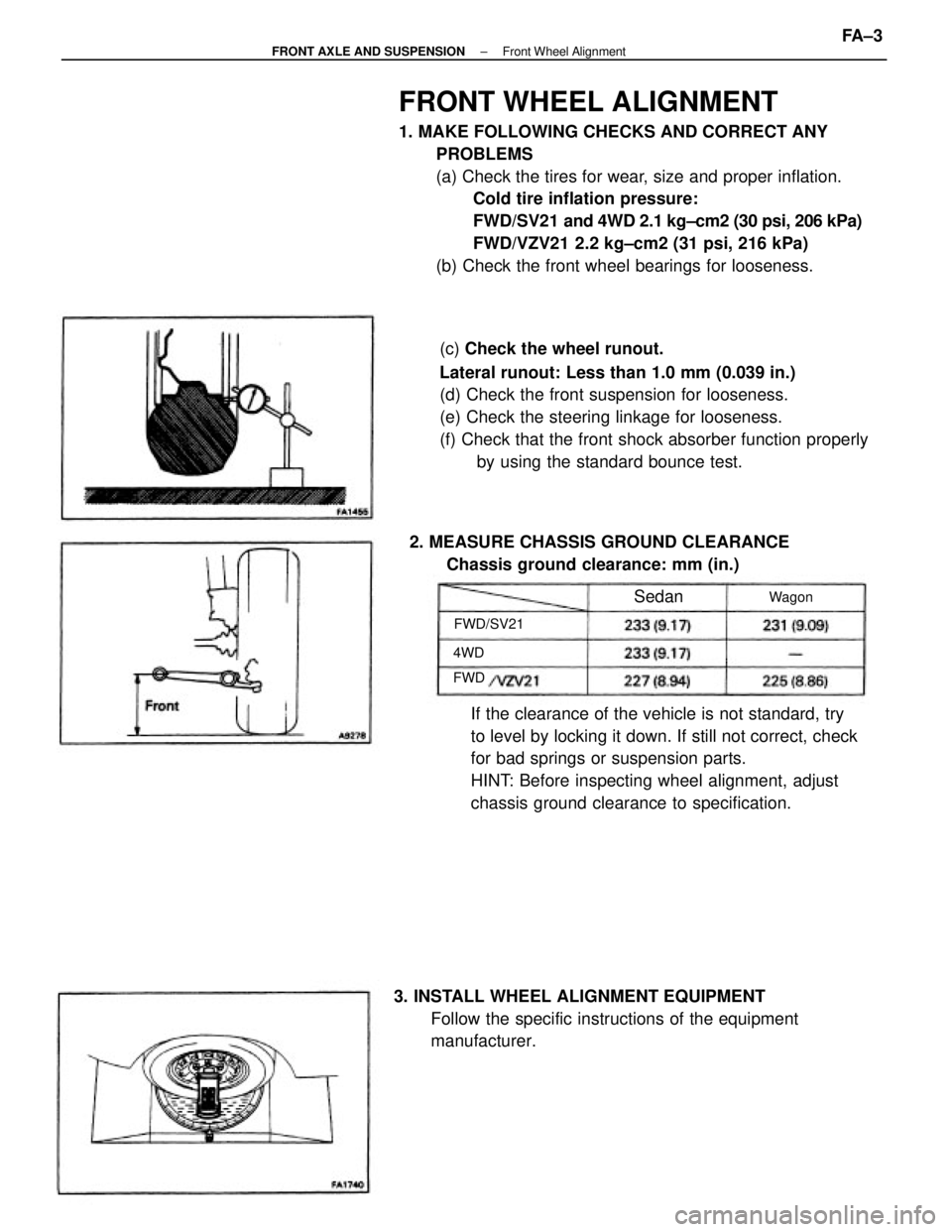

TROUBLESHOOTING

Tires worn or improperly inflatedTires worn or improperly inflated

Abnormal tire

wear Front wheel

shimmyFA±3

FA±61

FA±51

FA±3

FA±51

FA±3 SR±43, 45

48 Possible cause

Sways/

pitches Wanders/pulls

FA±51

FA±51 BottomingFA±3

FA±7 Problem

RemedyPage

FA±3

FA±3

± FRONT AXLE AND SUSPENSIONTroubleshootingFA ± 2

Page 1360 of 2389

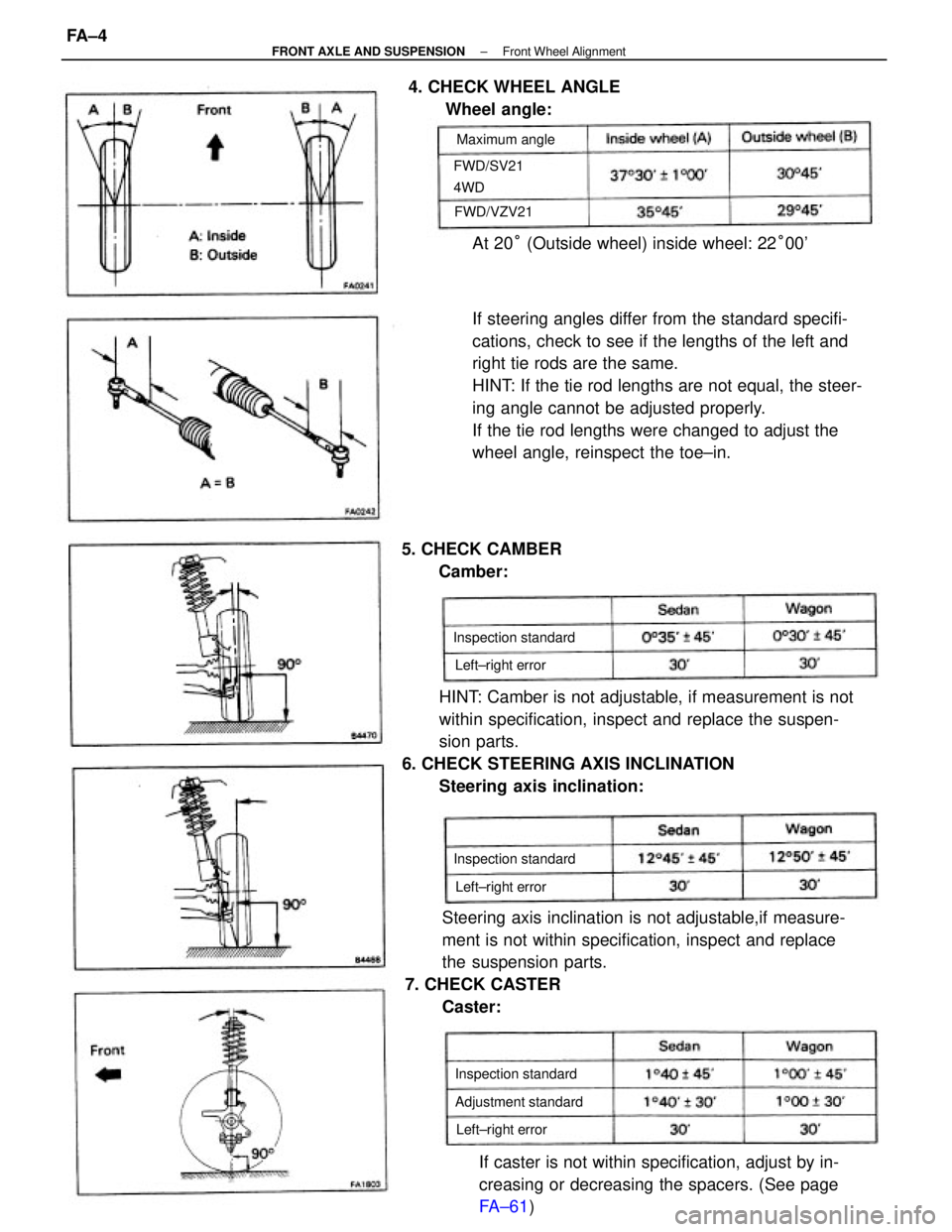

FRONT WHEEL ALIGNMENT

1. MAKE FOLLOWING CHECKS AND CORRECT ANY

PROBLEMS

(a) Check the tires for wear, size and proper inflation.

Cold tire inflation pressure:

FWD/SV21 and 4WD 2.1 kg±cm2 (30 psi, 206 kPa)

FWD/VZV21 2.2 kg±cm2 (31 psi, 216 kPa)

(b) Check the front wheel bearings for looseness.

(c) Check the wheel runout.

Lateral runout: Less than 1.0 mm (0.039 in.)

(d) Check the front suspension for looseness.

(e) Check the steering linkage for looseness.

(f) Check that the front shock absorber function properly

by using the standard bounce test.

If the clearance of the vehicle is not standard, try

to level by locking it down. If still not correct, check

for bad springs or suspension parts.

HINT: Before inspecting wheel alignment, adjust

chassis ground clearance to specification.

3. INSTALL WHEEL ALIGNMENT EQUIPMENT

Follow the specific instructions of the equipment

manufacturer. 2. MEASURE CHASSIS GROUND CLEARANCE

Chassis ground clearance: mm (in.)

FWD/SV21Wagon

Sedan

4WD

FWD

± FRONT AXLE AND SUSPENSIONFront Wheel AlignmentFA ± 3

Page 1361 of 2389

If steering angles differ from the standard specifi-

cations, check to see if the lengths of the left and

right tie rods are the same.

HINT: If the tie rod lengths are not equal, the steer-

ing angle cannot be adjusted properly.

If the tie rod lengths were changed to adjust the

wheel angle, reinspect the toe±in.

HINT: Camber is not adjustable, if measurement is not

within specification, inspect and replace the suspen-

sion parts.

6. CHECK STEERING AXIS INCLINATION

Steering axis inclination:

Steering axis inclination is not adjustable,if measure-

ment is not within specification, inspect and replace

the suspension parts.

7. CHECK CASTER

Caster:

If caster is not within specification, adjust by in-

creasing or decreasing the spacers. (See page

FA±61) At 20° (Outside wheel) inside wheel: 22°00' 4. CHECK WHEEL ANGLE

Wheel angle:

5. CHECK CAMBER

Camber:

Adjustment standard Inspection standard Inspection standard

Inspection standard FWD/SV21

4WDMaximum angle

Left±right error

Left±right error Left±right error FWD/VZV21

± FRONT AXLE AND SUSPENSIONFront Wheel AlignmentFA ± 4

Page 1362 of 2389

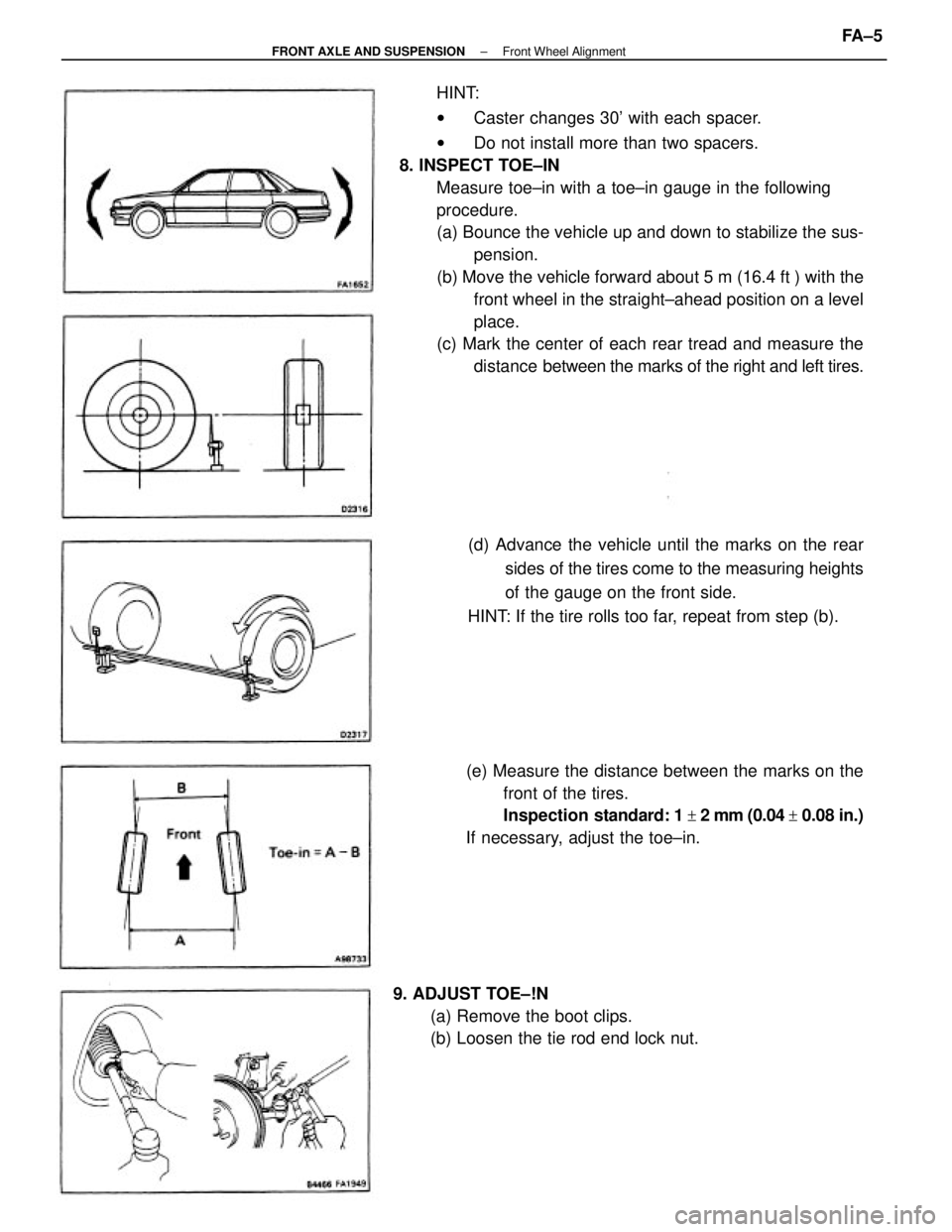

HINT:

wCaster changes 30' with each spacer.

wDo not install more than two spacers.

8. INSPECT TOE±IN

Measure toe±in with a toe±in gauge in the following

procedure.

(a) Bounce the vehicle up and down to stabilize the sus-

pension.

(b) Move the vehicle forward about 5 m (16.4 ft ) with the

front wheel in the straight±ahead position on a level

place.

(c) Mark the center of each rear tread and measure the

distance between the marks of the right and left tires.

(e) Measure the distance between the marks on the

front of the tires.

Inspection standard: 1

+ 2 mm (0.04 + 0.08 in.)

If necessary, adjust the toe±in.(d) Advance the vehicle until the marks on the rear

sides of the tires come to the measuring heights

of the gauge on the front side.

HINT: If the tire rolls too far, repeat from step (b).

9. ADJUST TOE±!N

(a) Remove the boot clips.

(b) Loosen the tie rod end lock nut.

± FRONT AXLE AND SUSPENSIONFront Wheel AlignmentFA ± 5

Page 1363 of 2389

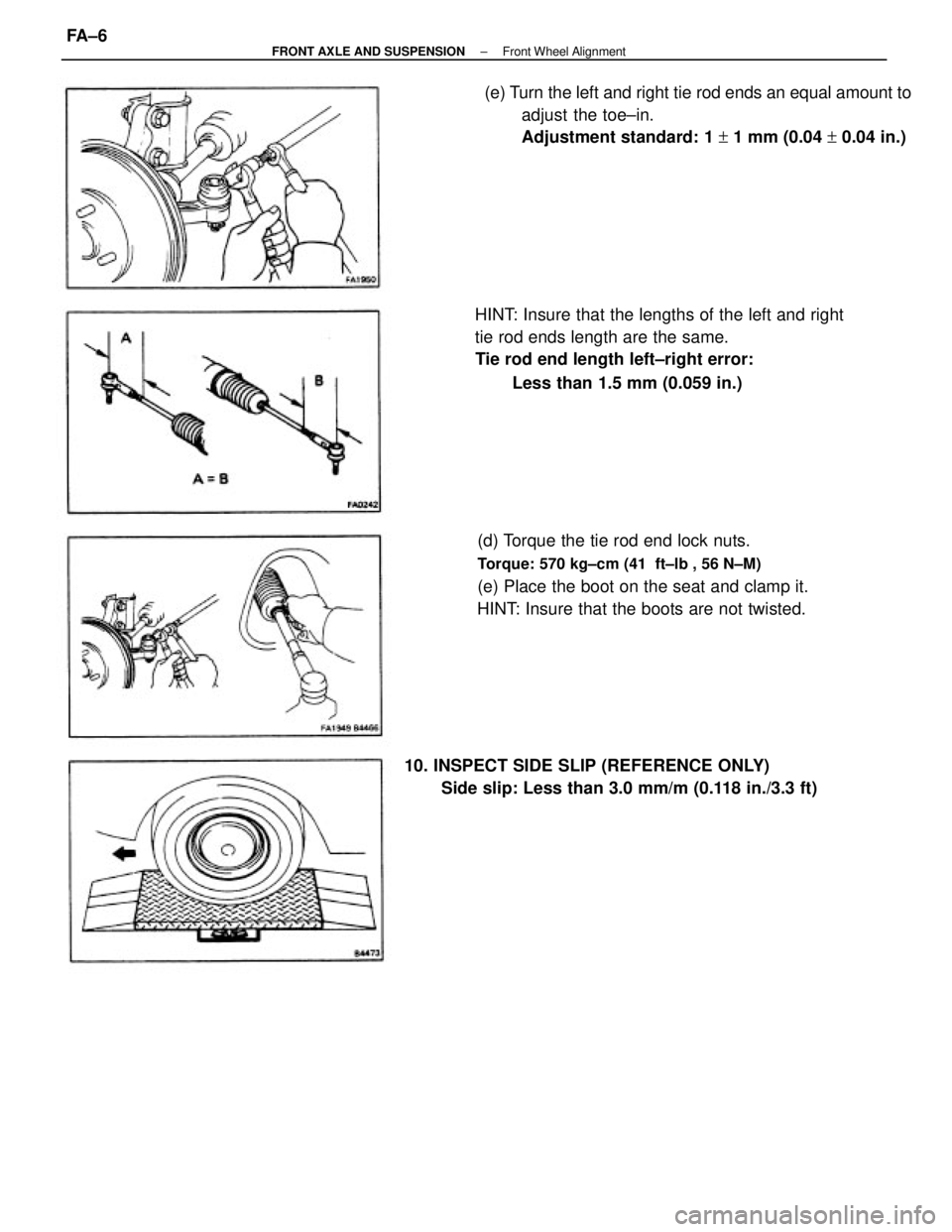

HINT: Insure that the lengths of the left and right

tie rod ends length are the same.

Tie rod end length left±right error:

Less than 1.5 mm (0.059 in.)

(d) Torque the tie rod end lock nuts.

Torque: 570 kg±cm (41 ft±lb , 56 N±M)

(e) Place the boot on the seat and clamp it.

HINT: Insure that the boots are not twisted.(e) Turn the left and right tie rod ends an equal amount to

adjust the toe±in.

Adjustment standard: 1 + 1 mm (0.04 + 0.04 in.)

10. INSPECT SIDE SLIP (REFERENCE ONLY)

Side slip: Less than 3.0 mm/m (0.118 in./3.3 ft)

± FRONT AXLE AND SUSPENSIONFront Wheel AlignmentFA ± 6

Page 1371 of 2389

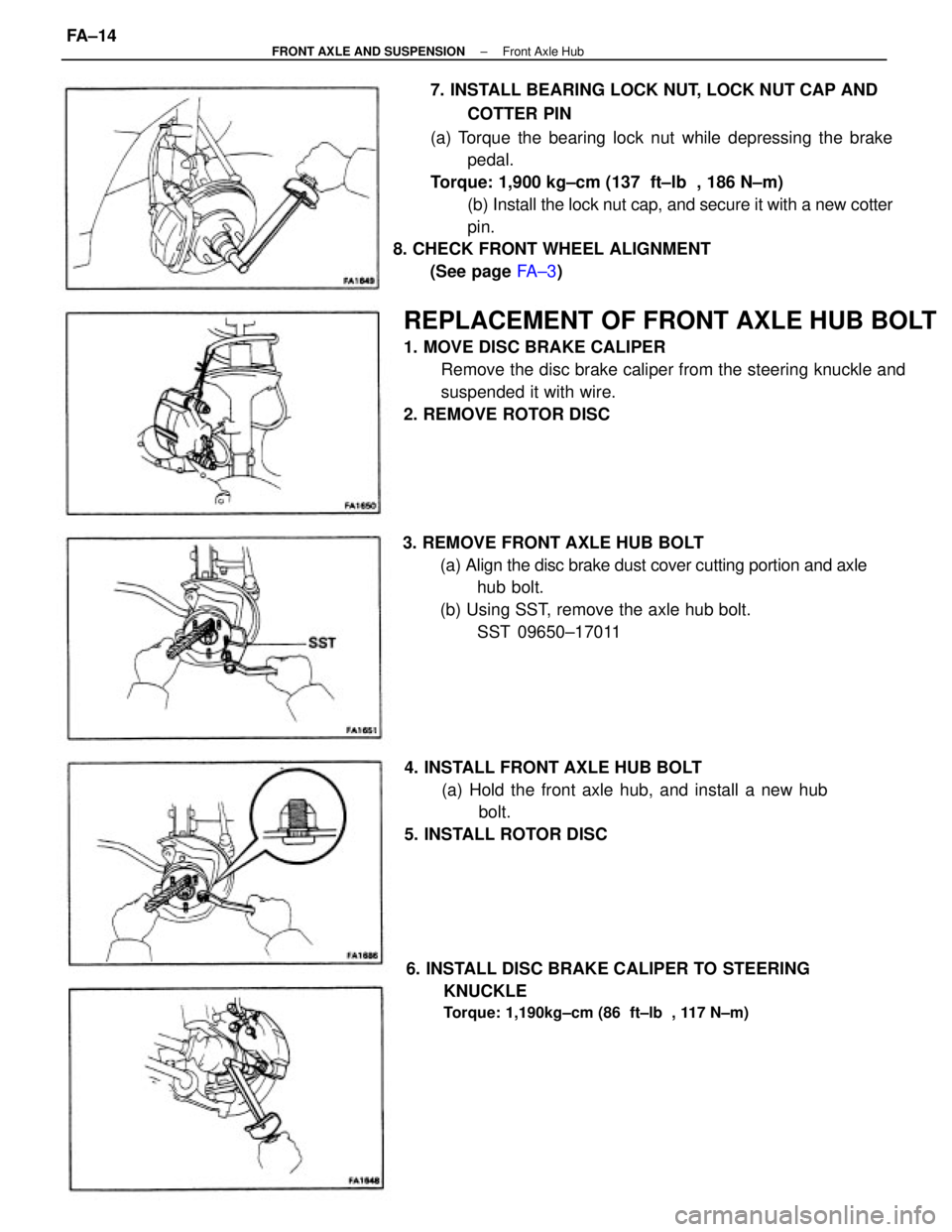

7. INSTALL BEARING LOCK NUT, LOCK NUT CAP AND

COTTER PIN

(a) Torque the bearing lock nut while depressing the brake

pedal.

Torque: 1,900 kg±cm (137 ft±lb , 186 N±m)

(b) Install the lock nut cap, and secure it with a new cotter

pin.

8. CHECK FRONT WHEEL ALIGNMENT

(See page FA ± 3)

REPLACEMENT OF FRONT AXLE HUB BOLT

1. MOVE DISC BRAKE CALIPER

Remove the disc brake caliper from the steering knuckle and

suspended it with wire.

2. REMOVE ROTOR DISC

3. REMOVE FRONT AXLE HUB BOLT

(a) Align the disc brake dust cover cutting portion and axle

hub bolt.

(b) Using SST, remove the axle hub bolt.

SST 09650±17011

6. INSTALL DISC BRAKE CALIPER TO STEERING

KNUCKLE

Torque: 1,190kg±cm (86 ft±lb , 117 N±m)

4. INSTALL FRONT AXLE HUB BOLT

(a) Hold the front axle hub, and install a new hub

bolt.

5. INSTALL ROTOR DISC

± FRONT AXLE AND SUSPENSIONFront Axle HubFA±14

Page 1384 of 2389

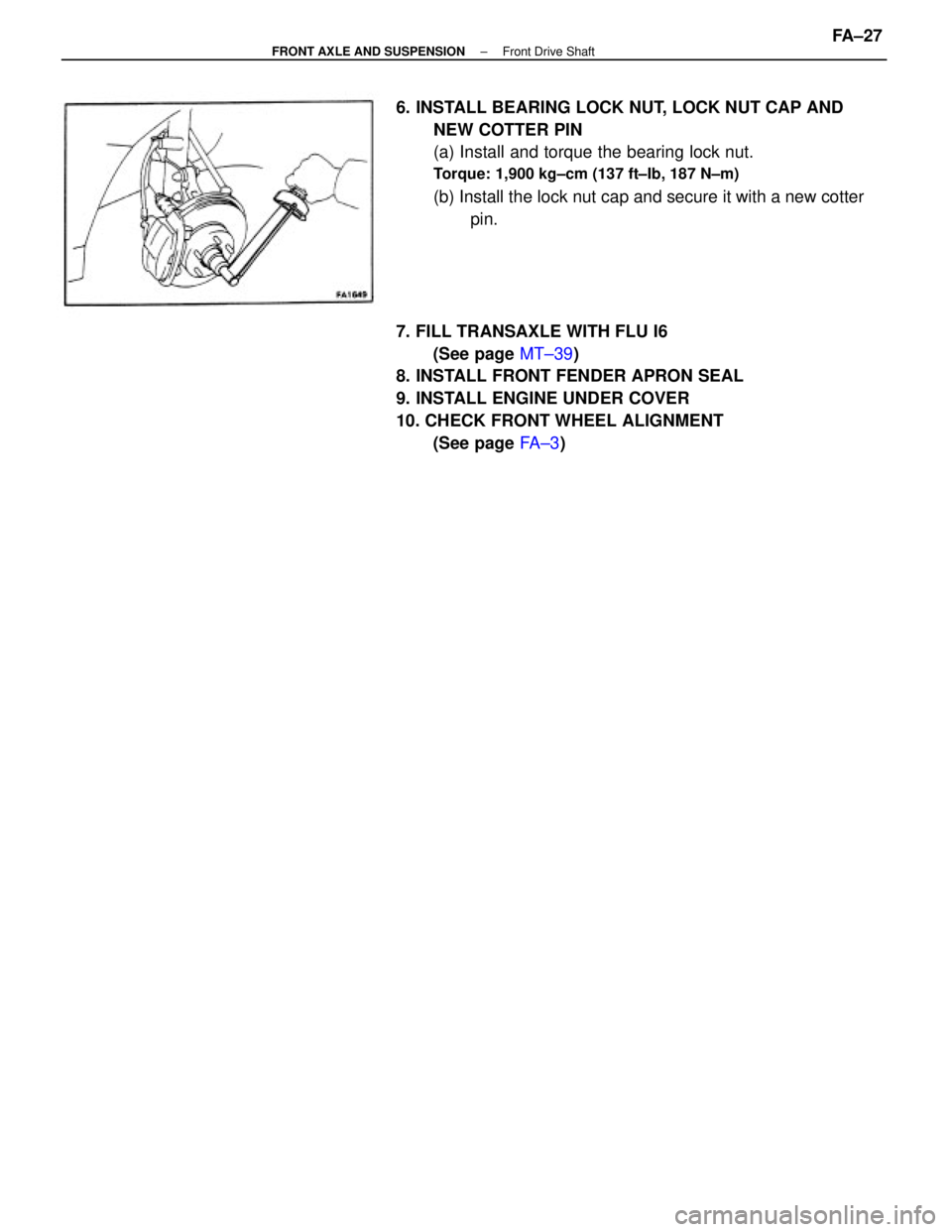

6. INSTALL BEARING LOCK NUT, LOCK NUT CAP AND

NEW COTTER PIN

(a) Install and torque the bearing lock nut.

Torque: 1,900 kg±cm (137 ft±Ib, 187 N±m)

(b) Install the lock nut cap and secure it with a new cotter

pin.

7. FILL TRANSAXLE WITH FLU I6

(See page MT±39)

8. INSTALL FRONT FENDER APRON SEAL

9. INSTALL ENGINE UNDER COVER

10. CHECK FRONT WHEEL ALIGNMENT

(See page FA±3)

± FRONT AXLE AND SUSPENSIONFront Drive ShaftFA±27

Page 1397 of 2389

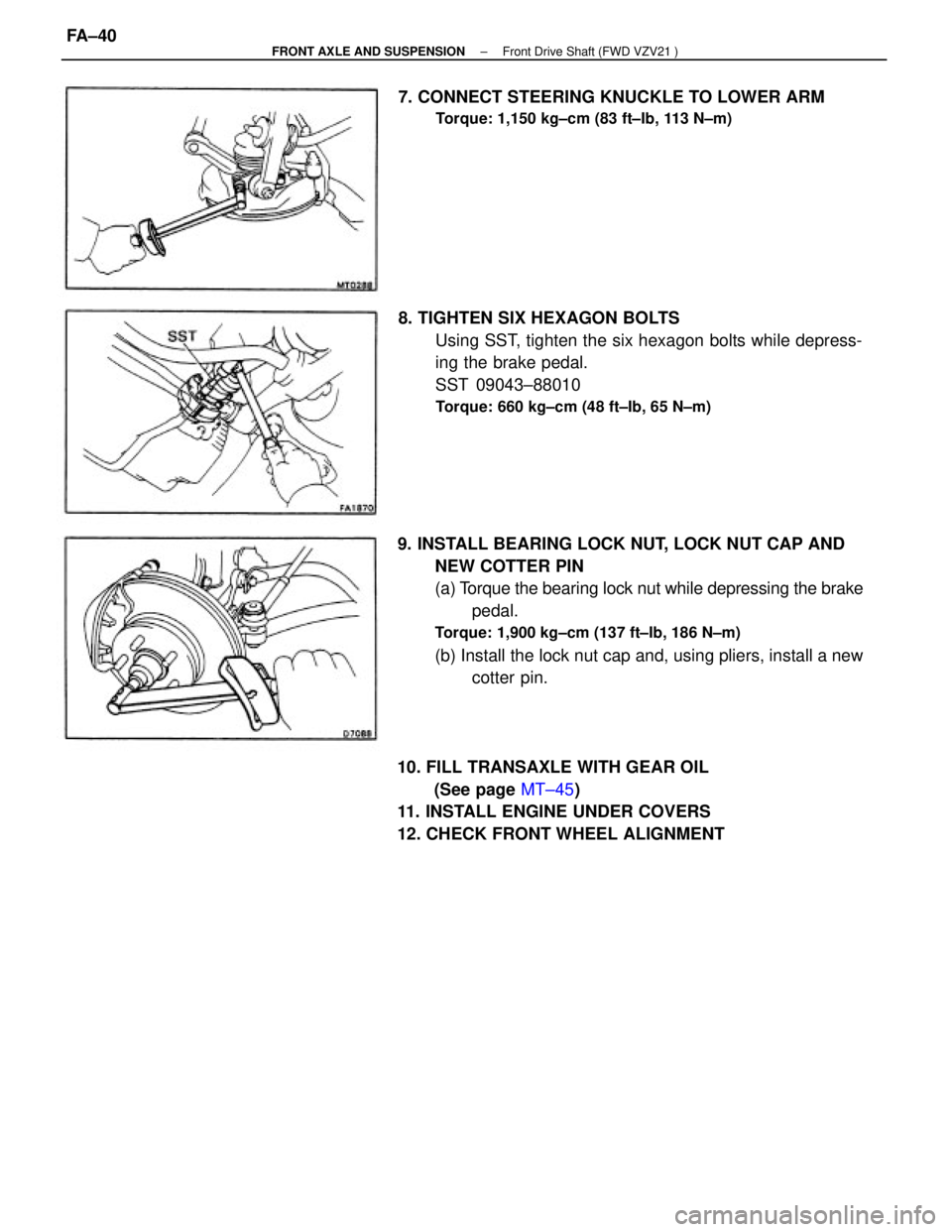

9. INSTALL BEARING LOCK NUT, LOCK NUT CAP AND

NEW COTTER PIN

(a) Torque the bearing lock nut while depressing the brake

pedal.

Torque: 1,900 kg±cm (137 ft±Ib, 186 N±m)

(b) Install the lock nut cap and, using pliers, install a new

cotter pin. 8. TIGHTEN SIX HEXAGON BOLTS

Using SST, tighten the six hexagon bolts while depress-

ing the brake pedal.

SST 09043±88010

Torque: 660 kg±cm (48 ft±Ib, 65 N±m)

10. FILL TRANSAXLE WITH GEAR OIL

(See page MT±45)

11. INSTALL ENGINE UNDER COVERS

12. CHECK FRONT WHEEL ALIGNMENT7. CONNECT STEERING KNUCKLE TO LOWER ARM

Torque: 1,150 kg±cm (83 ft±Ib, 113 N±m)

± FRONT AXLE AND SUSPENSIONFront Drive Shaft (FWD VZV21 )FA±40

Page 1407 of 2389

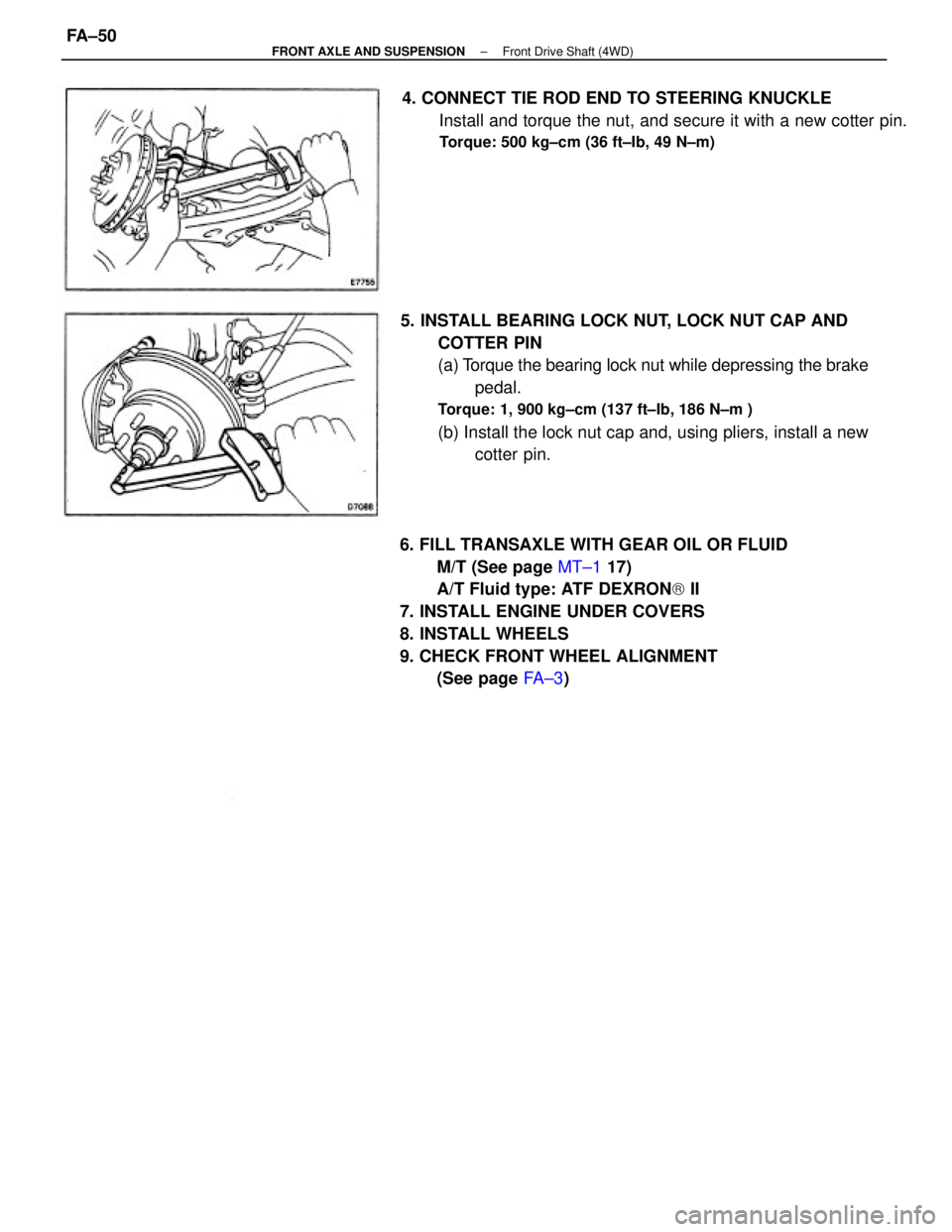

6. FILL TRANSAXLE WITH GEAR OIL OR FLUID

M/T (See page MT±1 17)

A/T Fluid type: ATF DEXRON) II

7. INSTALL ENGINE UNDER COVERS

8. INSTALL WHEELS

9. CHECK FRONT WHEEL ALIGNMENT

(See page FA ± 3) 5. INSTALL BEARING LOCK NUT, LOCK NUT CAP AND

COTTER PIN

(a) Torque the bearing lock nut while depressing the brake

pedal.

Torque: 1, 900 kg±cm (137 ft±Ib, 186 N±m )

(b) Install the lock nut cap and, using pliers, install a new

cotter pin. 4. CONNECT TIE ROD END TO STEERING KNUCKLE

Install and torque the nut, and secure it with a new cotter pin.

Torque: 500 kg±cm (36 ft±Ib, 49 N±m)

± FRONT AXLE AND SUSPENSIONFront Drive Shaft (4WD)FA±50