ignition TOYOTA CELICA 1987 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 49 of 346

EFI SYSTEM - Troubleshooting

FI-1 E

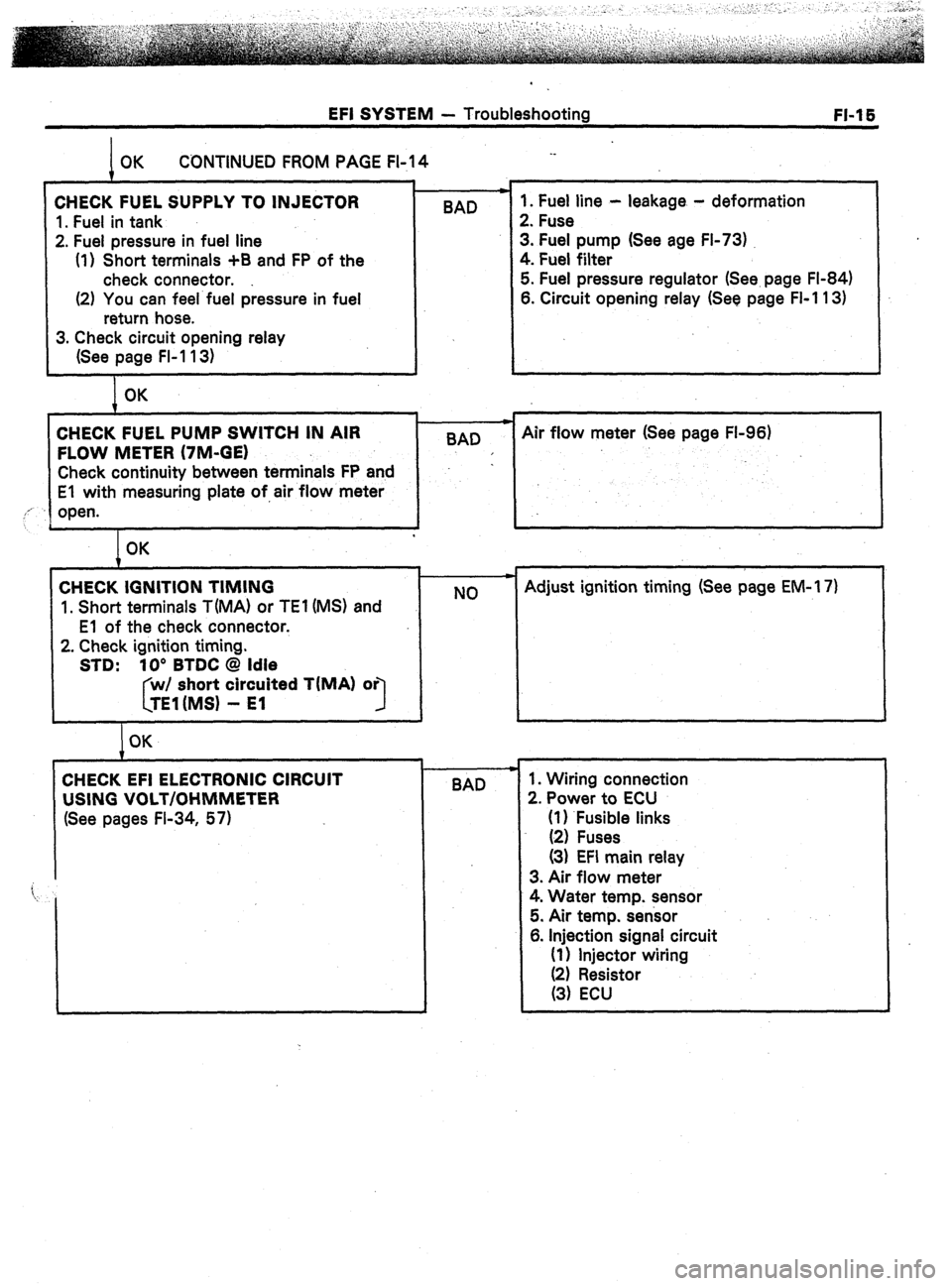

CONTINUED FROM PAGE FI-14 ._

CHECK FUEL SUPPLY TO INJECTOR

1. Fuel in tank

2. Fuel pressure in fuel line

(1) Short terminals +B and FP of the

check connector.

(2) You can feel fuel pressure in fuel

return hose. BAD 1. Fuel line - leakage - deformation

2. Fuse

3. Fuel pump (See age FI-73)

4. Fuel filter

5. Fuel pressure regulator (See. page FI-84)

6. Circuit opening relay (See page FI-1 13)

3. Check circuit opening relay

(See page FI-1 13)

OK

CHECK FUEL PUMP SWITCH IN AIR

FLOW METER (7M-GE)

Check continuity between terminals FP and

El with measuring plate of,air flow meter

,,’

open.

L

I BAD c

Air flow meter (See page FL96)

I OK

CHECK IGNITION TIMING

1. Short terminals T(MA) or TEl (MS) and

El of the check connector.

2. Check ignition timing.

STD: 10’ BTDC @ Idle

short circuited TIMA) or

3

I OK NO Adjust ignition timing (See page EM-l 7)

BAD 1. Wiring connection

2. Power to ECU

(1) .Fusible links

(2) Fuses

(3) EFI main relay

3. Air flow meter

4. Water temp. sensor

5. Air temp. sensor

6. Injection signal circuit

(1) Injector wiring

Page 50 of 346

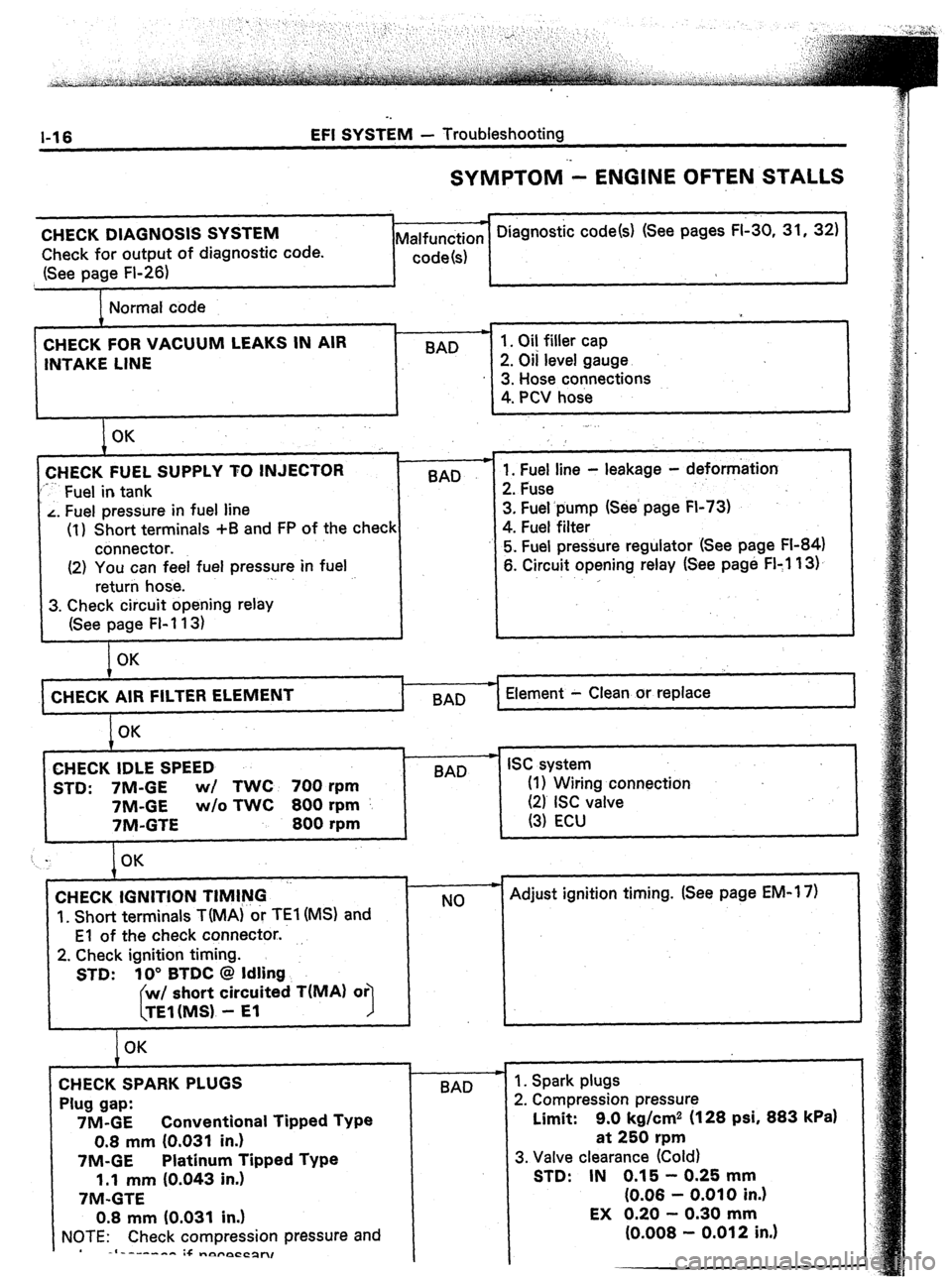

l-16 EFI SYSTEM - Troubleshooting

SYMPTOM - ENGINE OFTEN STALLS

CHECK DIAGNOSIS SYSTEM

Check for output of diagnostic code.

(See page Fl-26) * Diagnostic code(s) (See pages FI-30, 31, 32)

Malfunction

code(s)

Normal code

CHECK FOR VACUUM LEAKS IN AIR

INTAKE LINE BAD 1. Oil filler cap

2. Oil level gauge

3. Hose connections

4. PCV hose

I OK

CHECK FUEL SUPPLY TO INJECTOR

‘*-- Fuel in tank BAD

L. Fuel pressure in fuel line

(1) Short terminals +B and FP of the check

connector.

(2) You can feel fuel pressure in fuel

return hose. .

3. Check circuit opening relay

(See page FI-113) .

1. Fuel line - leakage - deformation

2. Fuse

3. Fuel.pump (See’ page FI-73)

4. Fuel filter

5. Fuel pressure regulator (See page FI-84)

6. Circuit opening relay (See page FI:1 13).

,

OK

CHECK AIR FILTER

I BAD Element - Clean or replace

OK

CHECK IDLE SPEED

STD: 7M-GE wl TWC 700 rpm

7M-GE w/o TWC 800 rpm

7M-GTE 800 rpm

t w

BAD ISC system

(I 1 Wiring connection

(21 ISC valve

(3) ECU

CHECK IGNITION TIMING ‘-

‘I. Short terminals TiMA) or TEl (MS) and

El of the check connector..

2. Check ignition timing.

STD: 10” BTDC @ Idling

short circuited T(MA) or

1

OK

CHECK SPARK PLUGS

Plug gap:

7M-GE Conventional Tipped Type

0.8 mm (0.031 in.)

7M-GE Platinum Tipped Type

1.1 mm (0.043 in.)

7M-GTE

0.8 mm (0.031 in.)

NOTE: Check compression pressure and

-I------- :+ -nyrpCCpn, c

NO

-I-

BAD - Adjust ignition timing. (See page EM-1 7)

1. Spark plugs

2. Compression pressure

Limit: 9.0 kg/cm2 (128 psi, 883

kPa)

at 250 rpm

3. Valve clearance (Cold)

STD: IN 0.15 - 0.25 mm

(0.06 - 0.010 in.)

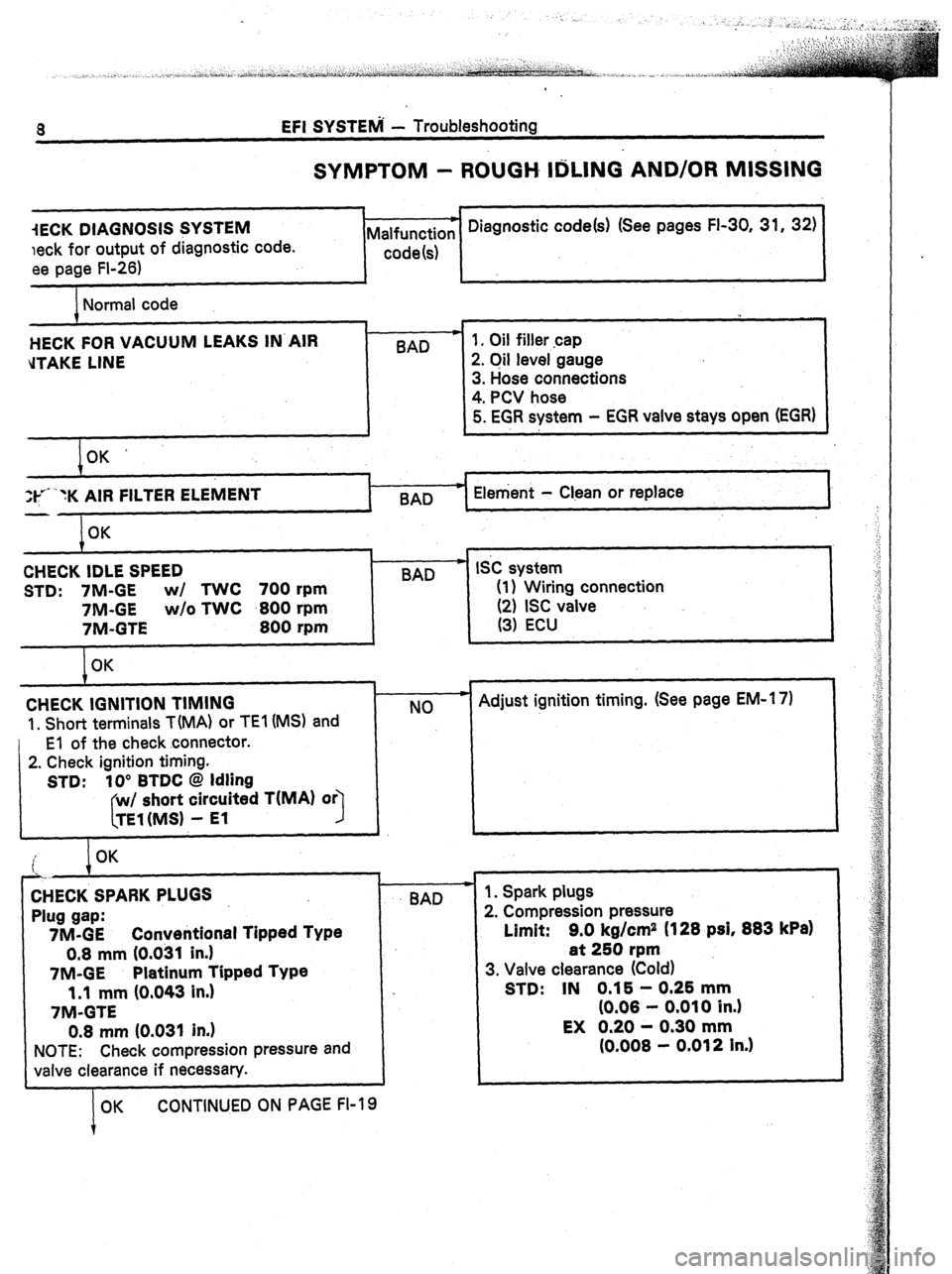

Page 52 of 346

a EFI SYSTEM - Troubleshooting

SYMPTOM - ROUGH IrIiLlNG AND/OR MISSING

iECK DIAGNOSIS SYSTEM

leek for output of diagnostic code.

ee page FI-26)

1 -c Diagnostic code(s) (See pages FI-30, 31, 32)

Malfunction

code(s)

Normal code

HECK FOR VACUUM LEAKS IN’AIR

d-FAKE LINE

I OK’

If* “K AIR FILTER

ELEMENT Element - Clean or replace

I

I 1, Oil filler cap

2. Oil level gauge

3. Hose connections

4. PCV hose

5. EGR system - EGR vaive stays open (EGR)

OK

CHECK IDLE SPEED

STD: 7M-GE w/ TWC 700 rpm

7M-GE w/o TWC 800 rpm

7M-GTE

800 rpm

OK

,

BAD SC system

(1) Wiring connection

(2) ISC valve

(3) ECU

CHECK IGNITION TIMING

1, Short terminals T(MA) or TEI (MS) and

El of the check connector.

2. Check ignition timing.

STD: IO” BTDC @ Idling

w/ short circuited T(MA)

I TEl(MS1 - El NO F Adjust ignition timing. (See page EM-l 7)

i OK

‘.

7

I

CHECK SPARK PLUGS

Plug gap:

7M-GE Converitional Tipped Type

0.8 mm (0.031 in.)

7M-GE Platinum Tipped Type

1.1 mm (0,043 in.)

7M-GTE

0.8 mm (0.031 in.)

NOTE: Check compression pressure and

valve clearance if necessary.

OK CONTINUED ON PAGE FI-19 BAD 1. Spark plugs

2. Compression pressure

Limit: 9.0 kg/cm2 (128 psi, 883

kPa)

at 250 rpm

3. Valve clearance (Cold)

STD: IN 0.15 - 0.25 mm

(0.08 - 0.010 in.)

EX 0.20 - 0.30 mm

(0.008 - 0.012 in.)

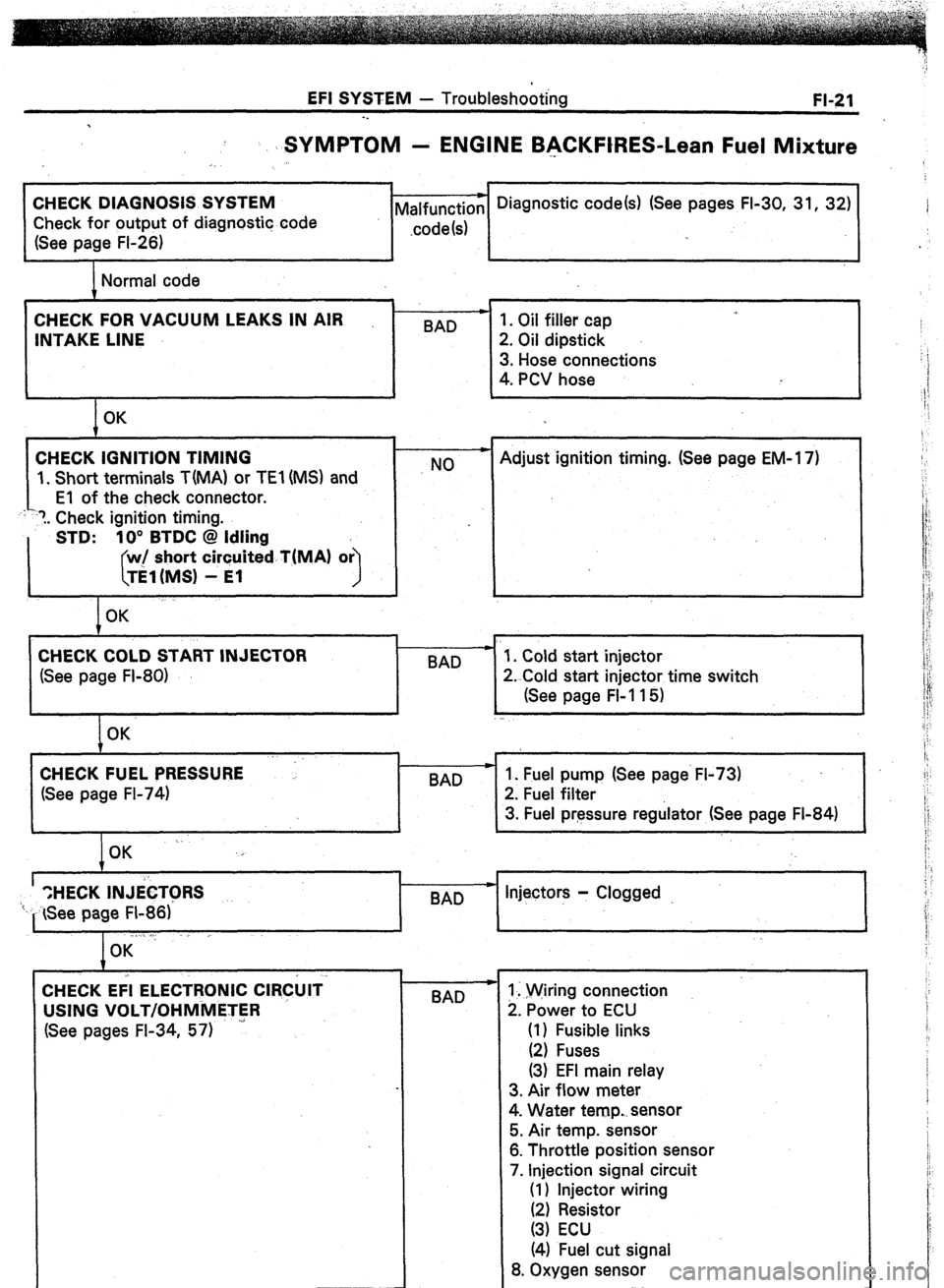

Page 55 of 346

EFI SYSTEM - Troubleshooting

FI-21

-.

SYMPTOM - ENGINE BACKFtRES-Lean Fuel Mixture

CHECK DIAGNOSIS SYSTEM

Check for output of diagnostic code

(See page FI-26) Malfunction --) Diagnostic code(s) (See pages FI-30, 31, 32)

.code 1s) j

,

Normal code

CHECK FOR VACUUM LEAKS IN AIR

INTAKE LINE

1. Short terminals T(MA) or TEl (MS) and BAD -

NO 1. Oil filler cap

2. Oil dipstick

3. Hose connections

4. PCV hose

Adjust ignition timing. (See page EM-1 7)

1. Cold start injector

2. Cold start injector time switch

(See page FI-115)

CHECK FUEL PRESSURE

(See page FI-74)

I

I

BAD 1. Fuel pump (See page‘ FI-73)

2. Fuel filter

3. Fuel pressure regulator (See page Fl-84)

I

’ “,HECK INJib

‘I- See page FI-86)’ - Injectors - Clogged

BAD

. ., .l

I OK

CHECK Eii ELECTRONIC ClR&lT

USING VOLT/OHMMETER

(See pages FI-34, 57)

4

BAD 1. Wiring connection

2. Power to ECU

(1) Fusible links

(2) Fuses

(3) EFI main relay

3. Air flow meter

4. Water temp. sensor

5. Air temp. sensor

6. Throttle position sensor

7. Injection signal circuit

(1) Injector wiring

Ii, zesstor

(4) Fuel cut signal

8. Oxygen sensor

Page 56 of 346

Ii-22 EFI SYSiiM - Troubleshooting

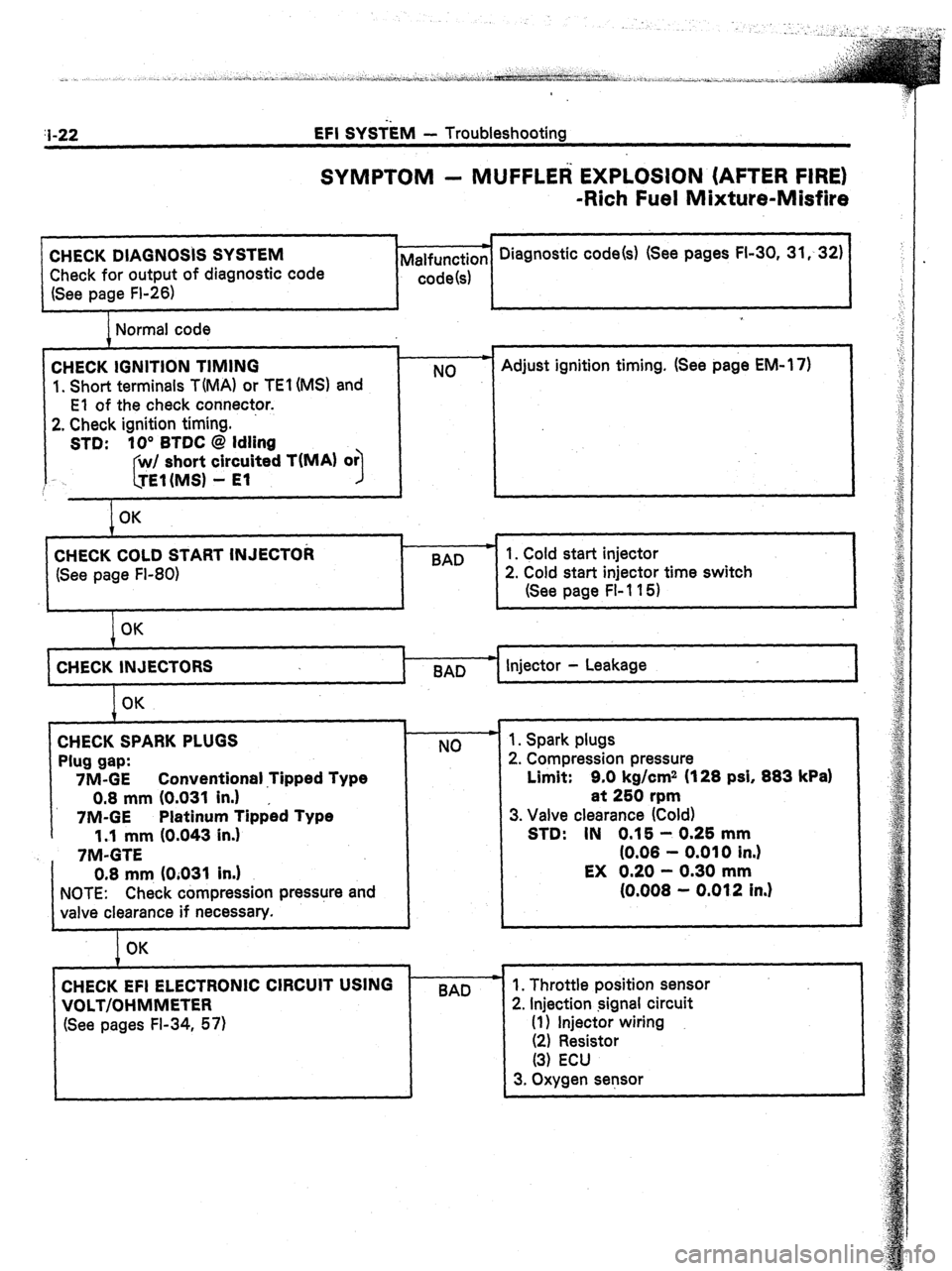

SYMPTOM - MUFFLER EXPLOSION (AFTER FIRE)

-Rich Fuel Mixture-Misfire

CHECK DIAGNOSIS SYSTEM

Check for output of diagnostic code

(See page FI-26) pm Diagnostic code(s) (See pages Fl-30, 31, 32)

Malfunction

code(s)

4

c

Normal code

CHECK IGNITION TIMING

1. Short terminals TiMA) or TEl (MS) and

El of the check connector.

2. Check ignition timing.

STD: IO” BTDC @ Idling

w/ short circuited TfMA) or

C TEl(MS) - El I

OK NO

BAD

I-

Adjust ignition timing. (See page EM- 17)

I

1. Cold start injector

2. Cold start injector time switch

(See page FI- 115)

1

CHECK INJECTORS

BAD injector - Leakage

I

I OK

CHECK SPARK PLUGS

Plug gap:

7M-GE Conventional .Tipped Type

0.8 mm (0.031 in.)

7M-GE Platinum Tipped Type

1.1 mm (0.043 in.)

7M-GTE

0.8 mm (OiO31 in.)

NOTE: Check compression pressure and

valve clearance if necessary.

OK

CHECK EFI ELECTRONIC CIRCUIT USING

VOLT/OHMMETER

(See pages Fl-34, 57) NO

BAD - 1. Spark plugs

2. Compression pressure

Limit: 9.0 kg/cm2 (128 psi, 883

kPa)

at 250 rpm

3. Valve clearance (Cold)

STD: IN 0.15 - 0.25 mm

(0.06 - 0.010 in.)

EX 0.20 - 0.30 mm

(0.006 - 0.012 in.)

i

1. Throttle position sensor

2. Injection signal circuit

(I) Injector wiring

(2) Resistor

(3) ECU

3. Oxygen sensor

Page 57 of 346

EFI SYSTEM - Troubleshooting

FI-23

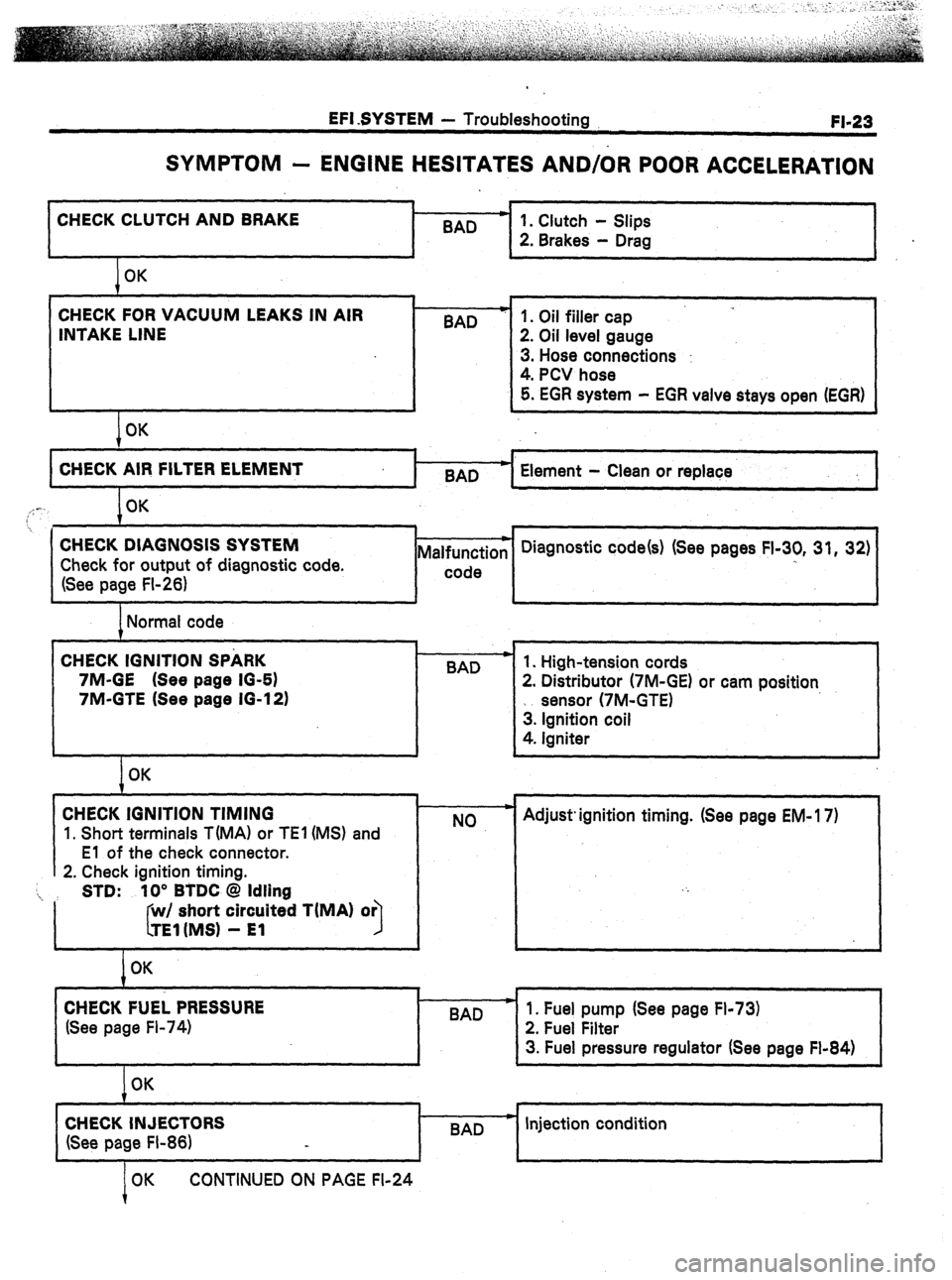

SYMPTOM - ENGINE HESITATES AND/OR POOR ACCELERATION

CHECK CLUTCH AND BRAKE .

BAD

I

I 1

1 OK

CHECK FOR VACUUM LEAKS IN AIR

INTAKE LINE

I OK BAD

I-

1. Clutch - Slips

2. Brakes - Drag

1. Oil filler cap

2. Oil level gauge

3. Hose connections :

4. PCV hose

5. EGR system - EGR valve stays open (EGR)

4

CHECK AIR FILTER ELEMENT

BAD Element - Clean or replace

I

,,: -. OK

7

. . 1 i , 1

CHECK DIAGNOSIS SYSTEM

Check for output of diagnostic code.

(See page FI-26) Malfunction

I-- code Diagnostic code(s) (See pages FI-30, 31, 32)

I

I I I J

1 Normal code

CHECK IGNITION SPARK

7M-GE (See page IO-61

7M-GTE (See page 16-12) .

BAD

I

I OK

CHECK IGNITION TIMING

1. Short terminals T(MA1 or TEl (MS) and

El of the check connector.

2. Check ignition timing.

‘i, STD: 10” BTDC @ Idling

I short circuited TiMA) or

I

I OK

CHECK FUEL PRESSURE

(See page Fl-74) 1. High-tension cords

2. Distributor (7M-GE) or cam position

sensor (7M-GTE)

3. Ignition coil

4. Igniter

NO Adjust. ignition timing. (See page EM- 17)

I

I

BAD

I

1. Fuel pump (See page Fl-73)

2. Fuel Filter

3. Fuel pressure regulator (See page Fl-84)

1

OK

CHECK INJECTORS

(See page FI-86) BAD c Injection condition

OK CONTINUED ON PAGE FI-24

Page 59 of 346

EFI SYSTEM - Diagnosis System

. .

DIAGNOSIS SYSTEM

__ --

FL25

(MA)

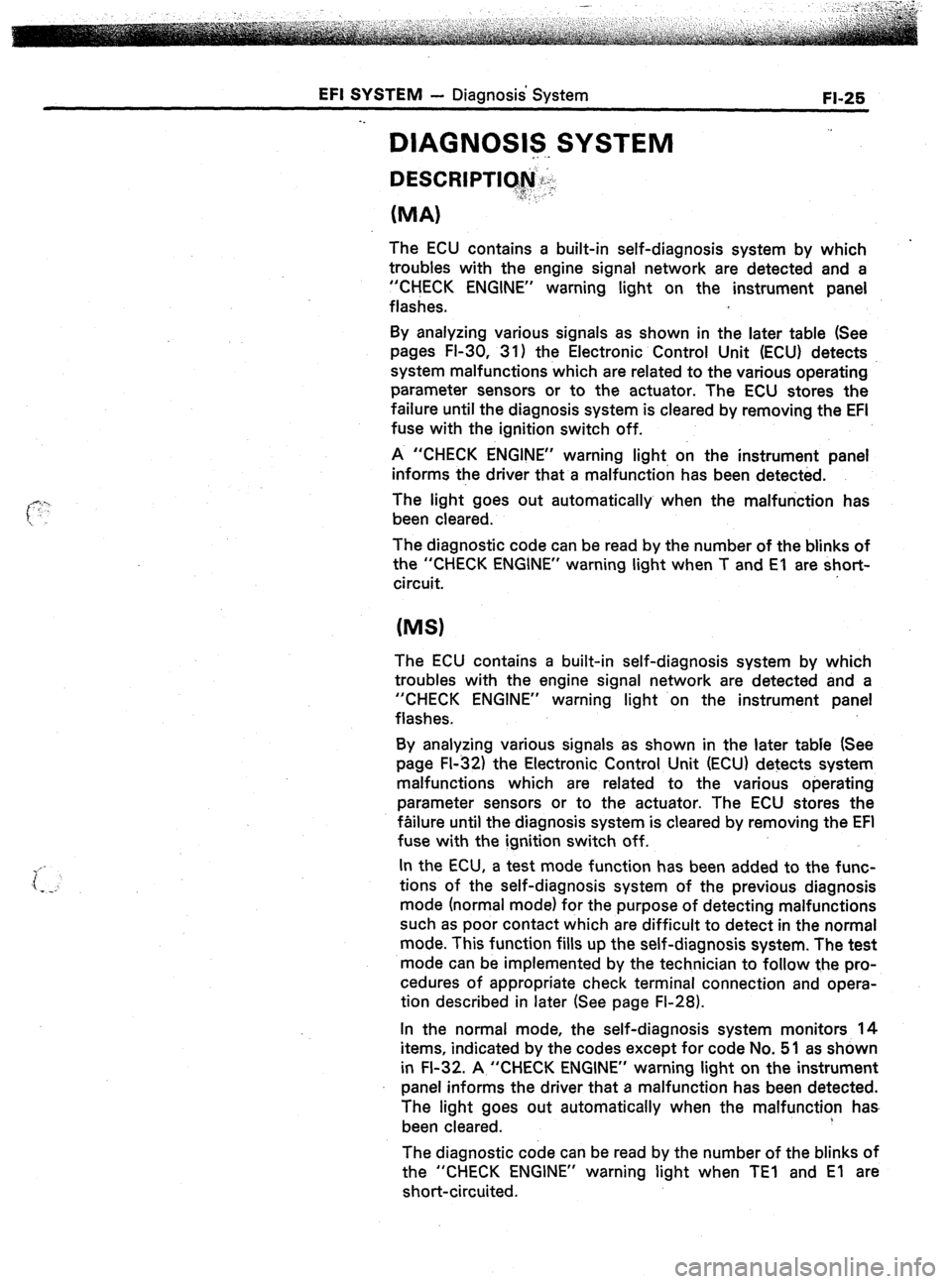

The ECU contains a built-in self-diagnosis system by which

troubles with the engine signal network are detected and a

“CHECK ENGINE” warning light on the instrument panel

flashes,

By analyzing various signals as shown in the later table (See

pages Fl-30, 31) the Electronic Control Unit (ECU) detects

system malfunctions which are related to the various operating

parameter sensors or to the actuator. The ECU stores the

failure until the diagnosis system is cleared by removing the EFI

fuse with the ignition switch off.

A “CHECK ENGINE” warning light on the instrument panel

informs the driver that a malfunction has been detected.

The light goes out automatically when the malfunction has

been cleared.

The diagnostic code can be read by the number of the blinks of

the “CHECK ENGINE” warning light when T and El are short-

circuit.

(MS)

The ECU contains a built-in self-diagnosis system by which

troubles with the engine signal network are detected and a

“CHECK ENGINE” warning light on the instrument panel

flashes.

By analyzing various signals as shown in the later table (See

page FI-32) the Electronic Control Unit (ECU) detects system

malfunctions which are related to the various operating

parameter sensors or to the actuator. The ECU stores the

failure until the diagnosis system is cleared by removing the EFI

fuse with the ignition switch off.

In the ECU, a test mode function has been added to the func-

tions of the self-diagnosis system of the previous diagnosis

mode (normal mode) for the purpose of detecting malfunctions

such as poor contact which are difficult to detect in the normal

mode. This function fills up the self-diagnosis system. The test

mode can be implemented by the technician to follow the pro-

cedures of appropriate check terminal connection and opera-

tion described in later (See page FI-28).

In the normal mode, the self-diagnosis system monitors 14

items, indicated by the codes except for code No. 51 as shown

in FI-32. A “CHECK ENGINE” warning light on the instrument

panel informs the driver that a malfunction has been detected.

The light goes out automatically when the malfunction has

been cleared.

The diagnostic code can be read by the number of the blinks of

the “CHECK ENGINE” warning light when TEl and El are

short-circuited.

Page 60 of 346

FI-26 EFI SYSTEM - Diagnosis System

-.

i

“CHECK ENGINE” Warning Light In the test mode, seven items, indicated by code

24, 41, 42, 43, and 5 1, as shown in FI-32 are m

malfunction is detected in any one of the systems

code Nos. 13, 22, 24, and 41 the ECU lights the “CHECK

ENGINE” warning light to warm the technician that the mal-

function has been detected. In this case, TE2 and El terminals

on the check connector should be connected as shown later

(See page FI-28)

In the test mode, for all seven conditions shown above in code

Nos. 13 - 51, even if the malfunction is corrected, the mal-

function is stored in the ECU memory while the ignition switch

remains on. Also, when a malfunction occurs for-the four con-

ditions from code Nos. 13 - 41, the “CHECK ENGINE” warning

light remains on. However, once the ignition switch is turned to

OFF, the ECU erases all of the malfunctions in the memory. The

diagnostic mode (normal or test) and the output of the “CHECK

ENGINE” warning light can be selected by the TEl , TE2 and El

terminal connections on the check connector, as shown in the

later.

“CHECK ENGINE” WARNING LIGHT CHECK

1. The “CHECK ENGINE” warning light will come on when

the ignitiorqw:@ch is placed at ON and the engine is not

running. -y.

2. When the engine is started, the “CHECK ENGINE” warning

light should go out.

If the light remains on, the diagnosis system has detected

a malfunction or abnormality in the system.

OUTPUT OF DIAGNOSIS CODES

(MA)

To obtain an output of diagnostic codes, proceed as follows:

1. Initial conditions ,’

(a)’ Battery voltage about 11 volts

(b) Throttle valve fully closed (throttle position sensor

IDL points closed)

(cl Transmission in neutral position

(d) Accessory switches OFF

2. Turn the ignition switch to ON. Do not start the engine.

Page 62 of 346

EFI SYSTEM; Diagnosis System

S)

------) -.

I Fl281

Test mode

i

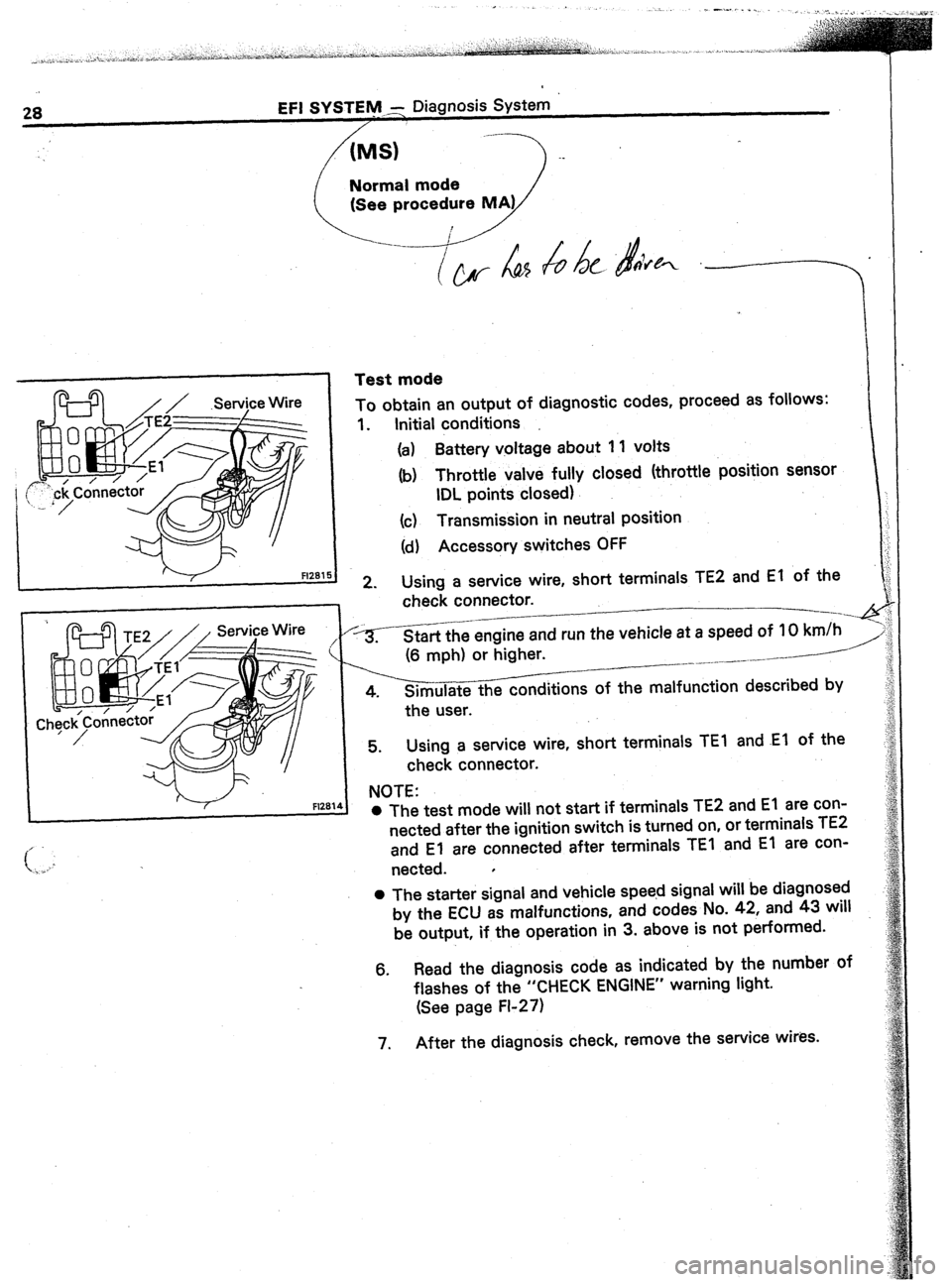

To obtain an output of diagnostic codes, proceed as follows:

1. Initial conditions

(a) Battery voltage about 1 1 volts

(b) Throttle valve fully closed (throttle position sensor

IDL points closed)

(c) Transmission in neutral position

(d) Accessory switches OFF

2. Using a service wire, short terminals TE2 and El of the j

check connector.

-----.-q

*-heengine and run the vehicle at a speed of IO km/h I

(6 mph) or higher. __-- /---’

_ ___ _.--.--.

4. Simulate the conditions of the malfunction described by

the user.

5. Using a service wire, short terminals TEl and .El of the

check connector.

NOTE:

l The test mode will not start if terminals TE2 and El are con-

nected after the ignition switch is turned on, or terminals TE2

and El are connected after terminals TEI and El are con-

nected.

l

0 The starter signal and vehicle speed signal will be diagnosed

by the ECU as malfunctions, and codes No. 42, and 43 will

be output, if the operation in 3. above is not performed.

6. Read the diagnosis code as indicated by the number of

flashes of the “CHECK ENGINE” warning light.

(See page FI-27)

7. After the diagnosis check, remove the service wires.

Page 63 of 346

EFI SYSTEM - Diagnosis System FI-29

MS EFI 15iA

LHD

EFI 15A

EFI 15A

R16C

FI26:

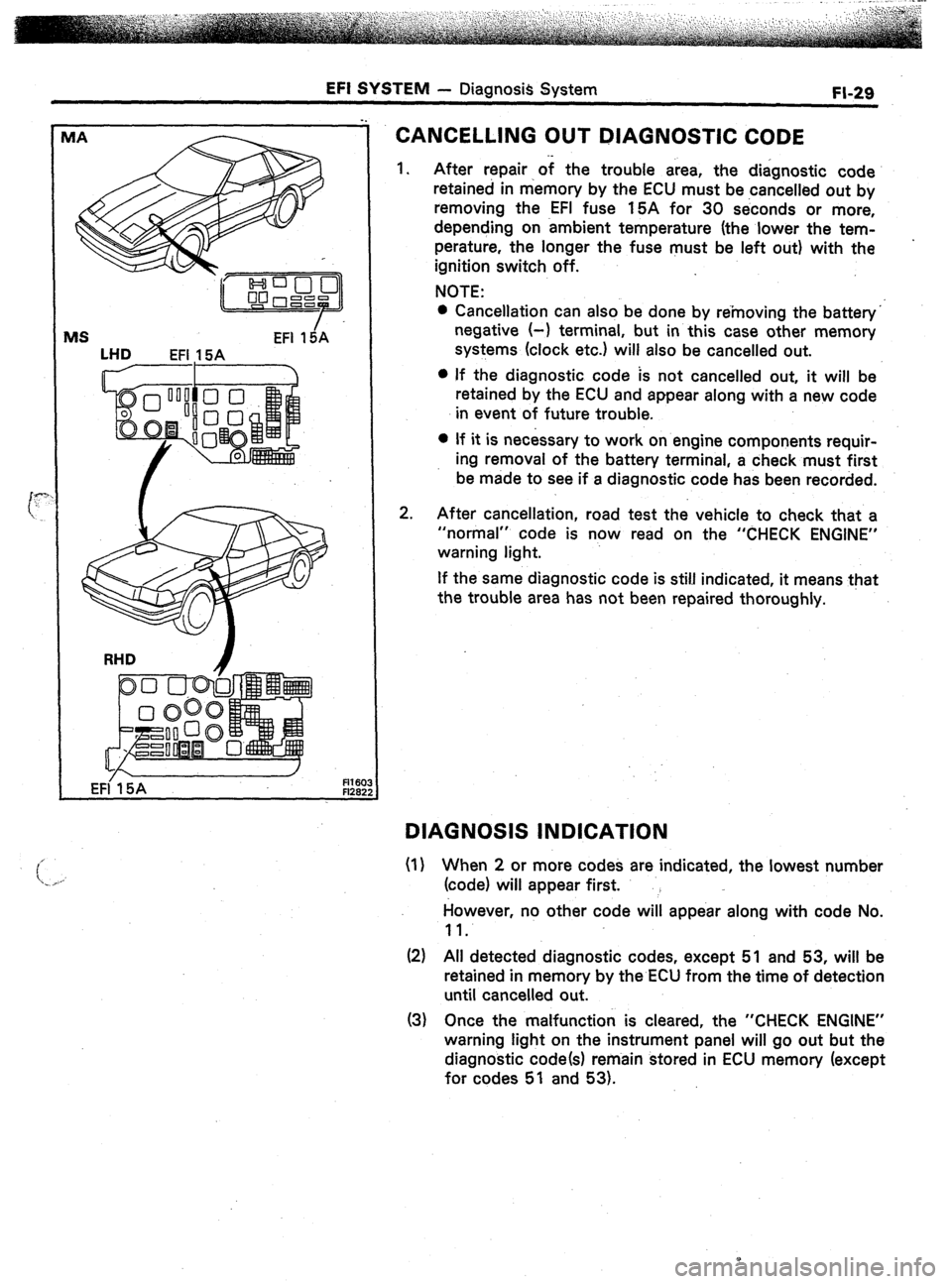

CANCELLING OUT DIAGNOSTIC CODE

1.

2. After repair of the trouble area, the diagnostic code

retained in memory by the ECU must be cancelled out by

removing the EFI fuse 15A for 30 seconds or more,

depending on ambient temperature (the lower the tem-

perature, the longer the fuse must be left out) with the

ignition switch off.

NOTE:

l Cancellation can also be done by removing the battery”

negative (-1 terminal, but in this case other memory

systems (clock etc.) will also be cancelled out.

l If the diagnostic code is not cancelled out, it will be

retained by the ECU and appear along with a new code

in event of future trouble.

l If it is necessary to work on engine components requir-

ing removal of the battery terminal, a check must first

be made to see if a diagnostic code has been recorded.

After cancellation, road test the vehicle to check that a

“normal” code is now read on the “CHECK ENGINE”

warning light.

If the same diagnostic code is still indicated, it means that

the trouble area has not been repaired thoroughly.

DIAGNOSIS INDICATION

(I) When 2 or more codes are indicated, the lowest number

(code) will appear first.

However, no other code will appear along with code No.

11.

(2) All detected diagnostic codes, except 51 and 53, will be

retained in memory by the ECU from the time of detection

until cancelled out.

(3) Once the malfunction is cleared, the “CHECK ENGINE”

warning light on the instrument panel will go out but the

diagnostic code(s) remain stored in ECU memory (except

for codes 51 and 53).