light TOYOTA CELICA 1987 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 62 of 346

EFI SYSTEM; Diagnosis System

S)

------) -.

I Fl281

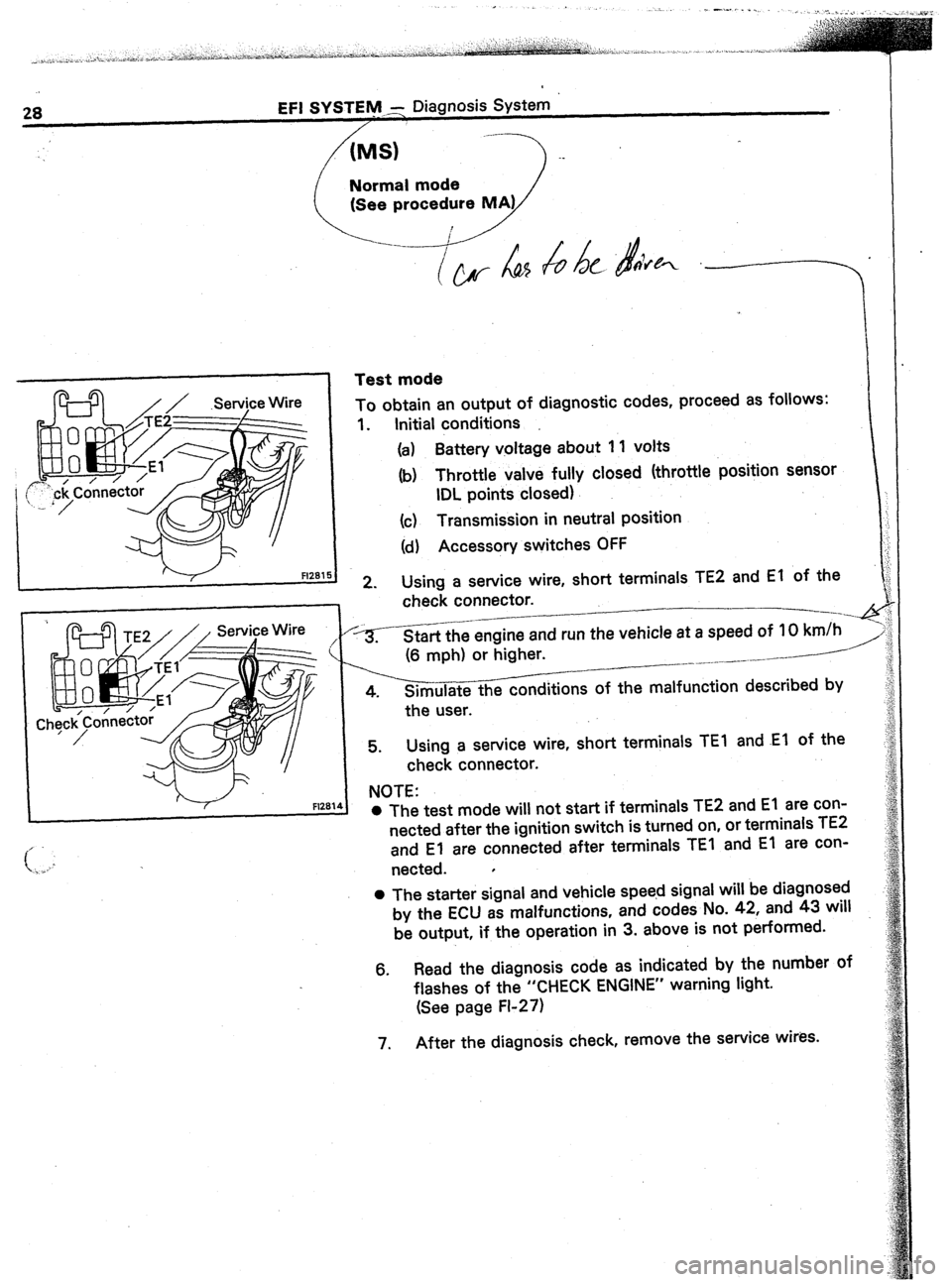

Test mode

i

To obtain an output of diagnostic codes, proceed as follows:

1. Initial conditions

(a) Battery voltage about 1 1 volts

(b) Throttle valve fully closed (throttle position sensor

IDL points closed)

(c) Transmission in neutral position

(d) Accessory switches OFF

2. Using a service wire, short terminals TE2 and El of the j

check connector.

-----.-q

*-heengine and run the vehicle at a speed of IO km/h I

(6 mph) or higher. __-- /---’

_ ___ _.--.--.

4. Simulate the conditions of the malfunction described by

the user.

5. Using a service wire, short terminals TEl and .El of the

check connector.

NOTE:

l The test mode will not start if terminals TE2 and El are con-

nected after the ignition switch is turned on, or terminals TE2

and El are connected after terminals TEI and El are con-

nected.

l

0 The starter signal and vehicle speed signal will be diagnosed

by the ECU as malfunctions, and codes No. 42, and 43 will

be output, if the operation in 3. above is not performed.

6. Read the diagnosis code as indicated by the number of

flashes of the “CHECK ENGINE” warning light.

(See page FI-27)

7. After the diagnosis check, remove the service wires.

Page 63 of 346

EFI SYSTEM - Diagnosis System FI-29

MS EFI 15iA

LHD

EFI 15A

EFI 15A

R16C

FI26:

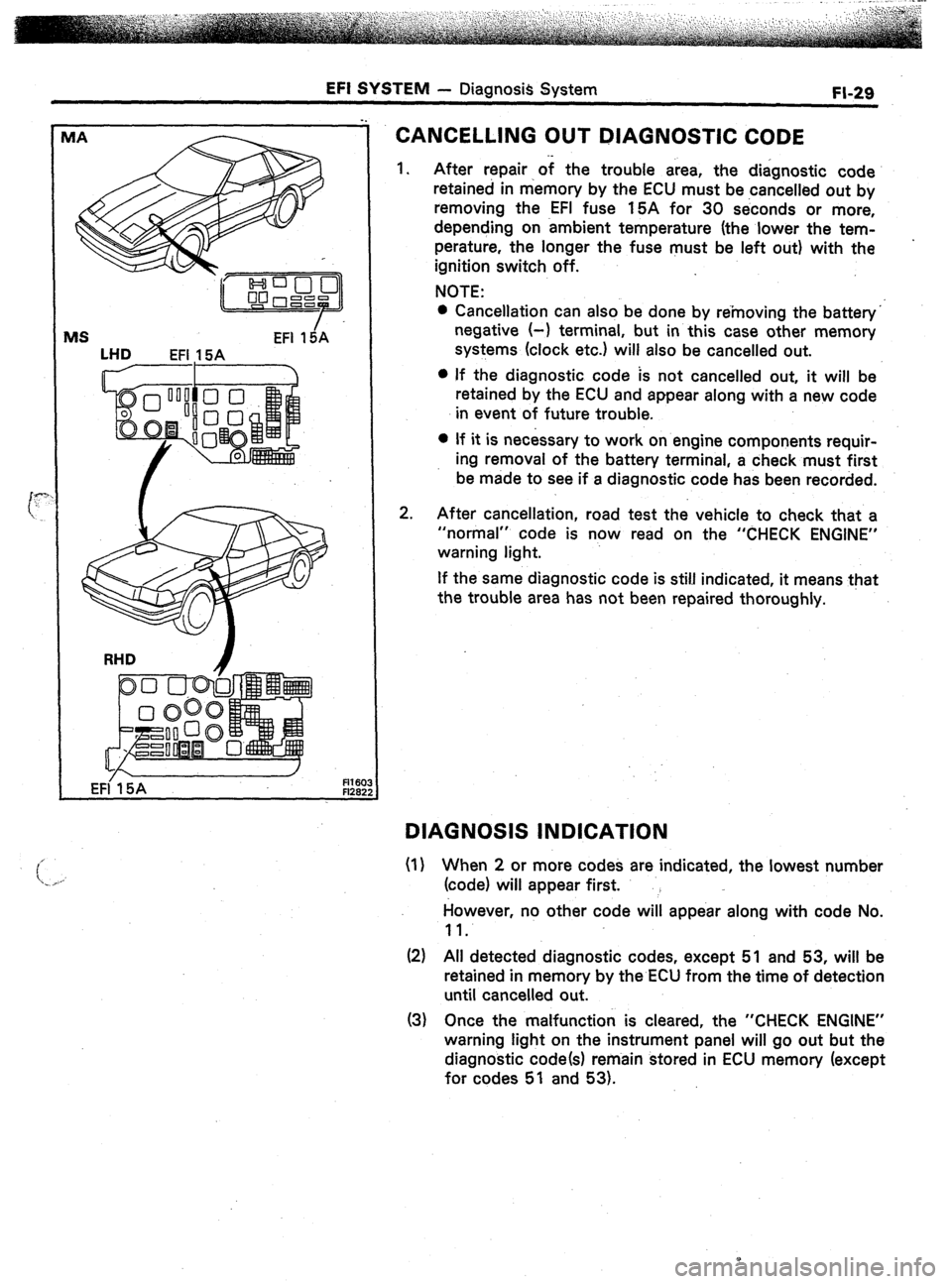

CANCELLING OUT DIAGNOSTIC CODE

1.

2. After repair of the trouble area, the diagnostic code

retained in memory by the ECU must be cancelled out by

removing the EFI fuse 15A for 30 seconds or more,

depending on ambient temperature (the lower the tem-

perature, the longer the fuse must be left out) with the

ignition switch off.

NOTE:

l Cancellation can also be done by removing the battery”

negative (-1 terminal, but in this case other memory

systems (clock etc.) will also be cancelled out.

l If the diagnostic code is not cancelled out, it will be

retained by the ECU and appear along with a new code

in event of future trouble.

l If it is necessary to work on engine components requir-

ing removal of the battery terminal, a check must first

be made to see if a diagnostic code has been recorded.

After cancellation, road test the vehicle to check that a

“normal” code is now read on the “CHECK ENGINE”

warning light.

If the same diagnostic code is still indicated, it means that

the trouble area has not been repaired thoroughly.

DIAGNOSIS INDICATION

(I) When 2 or more codes are indicated, the lowest number

(code) will appear first.

However, no other code will appear along with code No.

11.

(2) All detected diagnostic codes, except 51 and 53, will be

retained in memory by the ECU from the time of detection

until cancelled out.

(3) Once the malfunction is cleared, the “CHECK ENGINE”

warning light on the instrument panel will go out but the

diagnostic code(s) remain stored in ECU memory (except

for codes 51 and 53).

Page 67 of 346

EFI SYSTEM

- Diagnosis System

FI-33

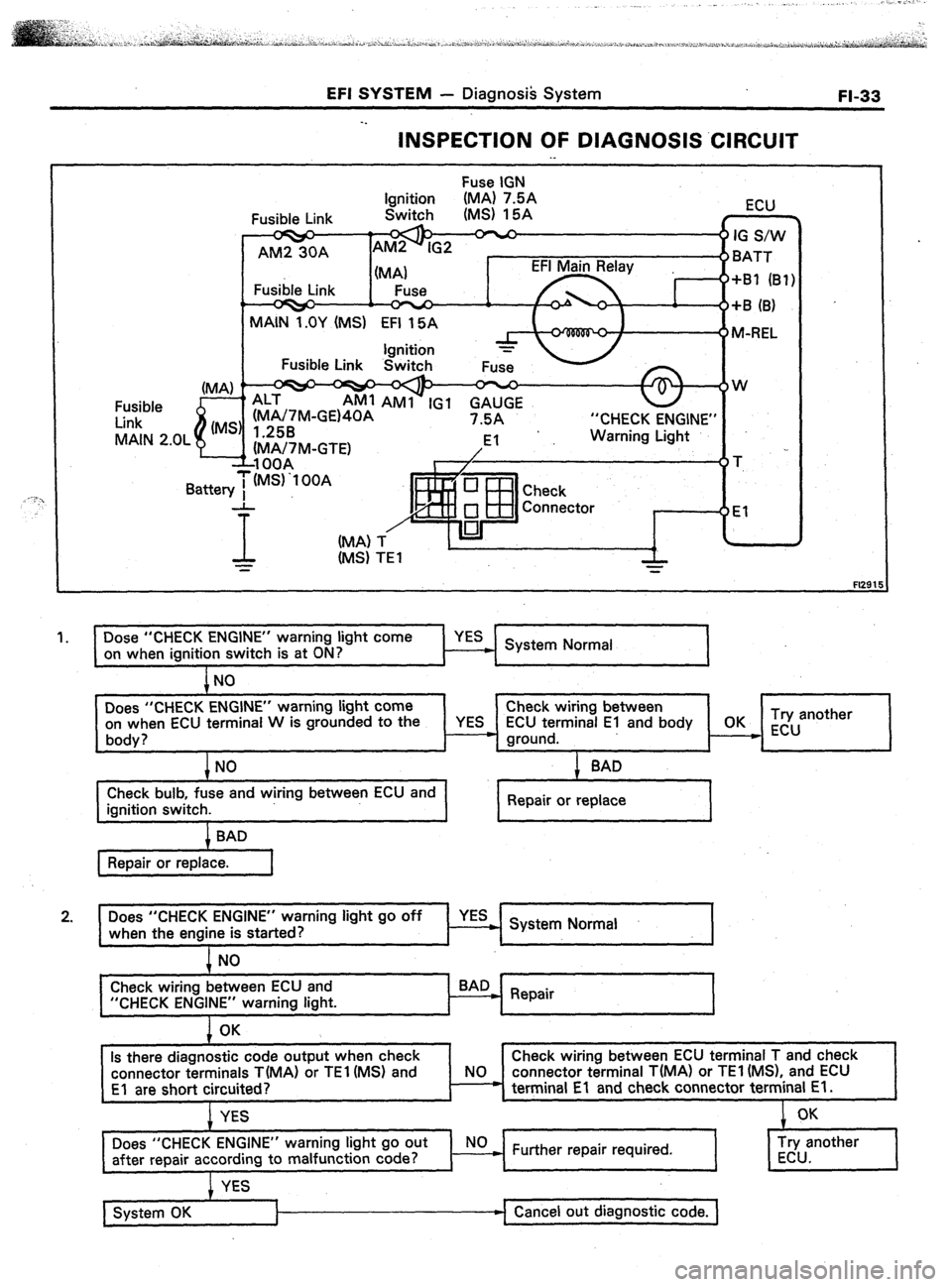

INSPECTION OF DIAGNOSIS .ClRCUlT

._

Fuse IGN

“CHECK ENGINE”

Fl291

1.

I Dose “CHECK ENGINE” warning light come

on when ignition switch is at ON?

l-l YES System Normal

Does “CHECK ENGINE” warning light come Check wiring between

on when ECU terminal W is grounded to the

YES ECU terminal El and body OK Try another

body? - ground. __c ECU

+NO

Check bulb, fuse and wiring between ECU and

ignition switch. + SAD

Repair or replace

Does “CHECK ENGINE” warning light go off

when the engine is started? YES

. System Normal

NO

Check wiring between ECU and

“CHECK ENGINE” warning light.

1 OK

Is there diagnostic code output when check

connector terminals T(MA) or TEl (MS) and

El are short circuited? t

Check wiring between ECU terminal T and check

NO connector terminal T(MA) or TEl (MS), and ECU

* terminal El and check connector terminal El.

I I

I I

YES

Does “CHECK ENGINE” warning light go out NO

after repair according to malfunction code? ) Further repair required.

&

System OK Cancel out diagnostic code.

Page 69 of 346

EFI SYSTEM - Troubleshooting with Volt/Ohmmeter (MA)

FI-35

. .

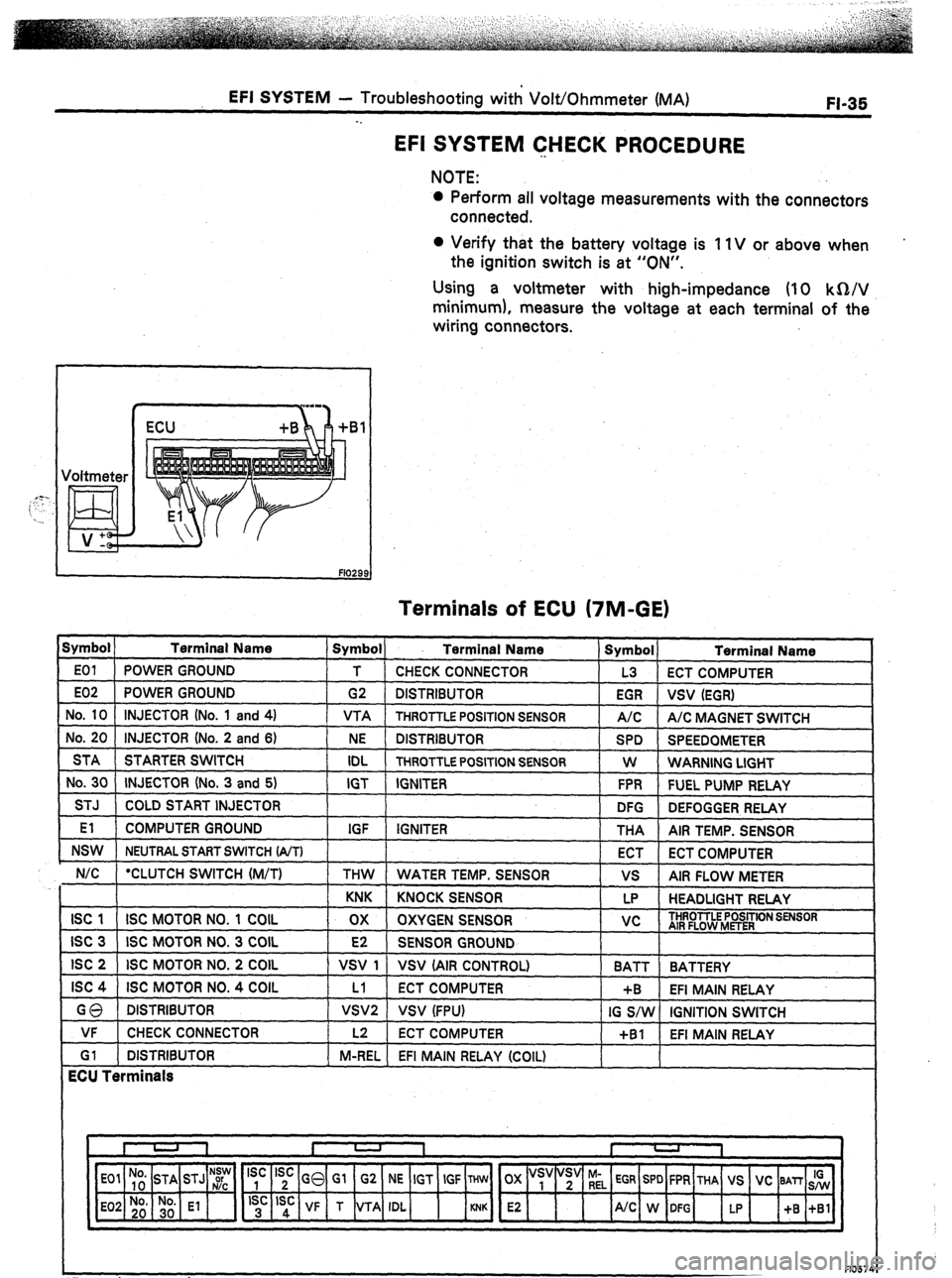

EFI SYSTEM CHECK PROCEDURE

NOTE:

l Perform all voltage measurements with the connectors

connected.

0 Verify that the battery voltage is 11V or above when

the ignition switch is at “ON”.

Using a voltmeter with high-impedance (IO kQ/V

minimum), measure the voltage at each terminal of the

wiring connectors.

I ) ECU +B

Terminals of ECU (7M-GE)

Symbol ) Terminal Name

E01 POWER GROUND

E02 POWER GROUND

No. 10 INJECTOR (No. 1 and 4)

No. 20 INJECTOR (No. 2 and 6)

STA STARTER SWITCH

No. 30 INJECTOR (No. 3 and 5)

STJ COLD START INJECTOR

El COMPUTER GROUND

NSW NEUTRAL START SWITCH (A/T)

N/C *CLUTCH SWITCH (M/T) 1 Symbol) Terminal Name

T CHECK CONNECTOR

G2 DISTRIBUTOR

VTA THROTTLE POSITION SENSOR

NE DISTRIBUTOR

IDL THROTTLE POSITION SENSOR

IGT IGNITER

IGF IGNITER

THW WATER TEMP. SENSOR Symbol

Terminal Name

L3 ECT COMPUTER

EGR

vsv (EGR)

A/C A/C MAGNET SWITCH

SPD SPEEDOMETER

W WARNING LIGHT

FPR FUEL PUMP RELAY

DFG

DEFOGGER RELAY

THA

AIR TEMP. SENSOR

ECT

ECT COMPUTER

vs AIR FLOW METER

KNK KNOCK SENSOR LP HEADLIGHT RELAY

ISC 1 ISC MOTOR NO. 1 COIL ox OXYGEN SENSOR vc THROTTLE POSITION SENSOR

AIR FLOW METER

ISC 3 ISC MOTOR NO. 3 COIL E2 SENSOR GROUND

ISC 2 ISC MOTOR NO. 2 COIL VSV 1 VSV (AIR CONTROL)

BATT BATTERY

ISC 4 ISC MOTOR NO. 4 COIL Ll ECT COMPUTER +B EFI MAIN RELAY

GQ DISTRIBUTOR VSVP VSV (FPU) IG S/W IGNITION SWITCH

VF CHECK CONNECTOR

Gl DISTRIBUTOR

ECU Terminals 1 L2 ECT COMPUTER

+Bl EFI MAIN RELAY

1 M-REL EFI MAIN RELAY (COIL)

*For cruise control

F10574

Page 70 of 346

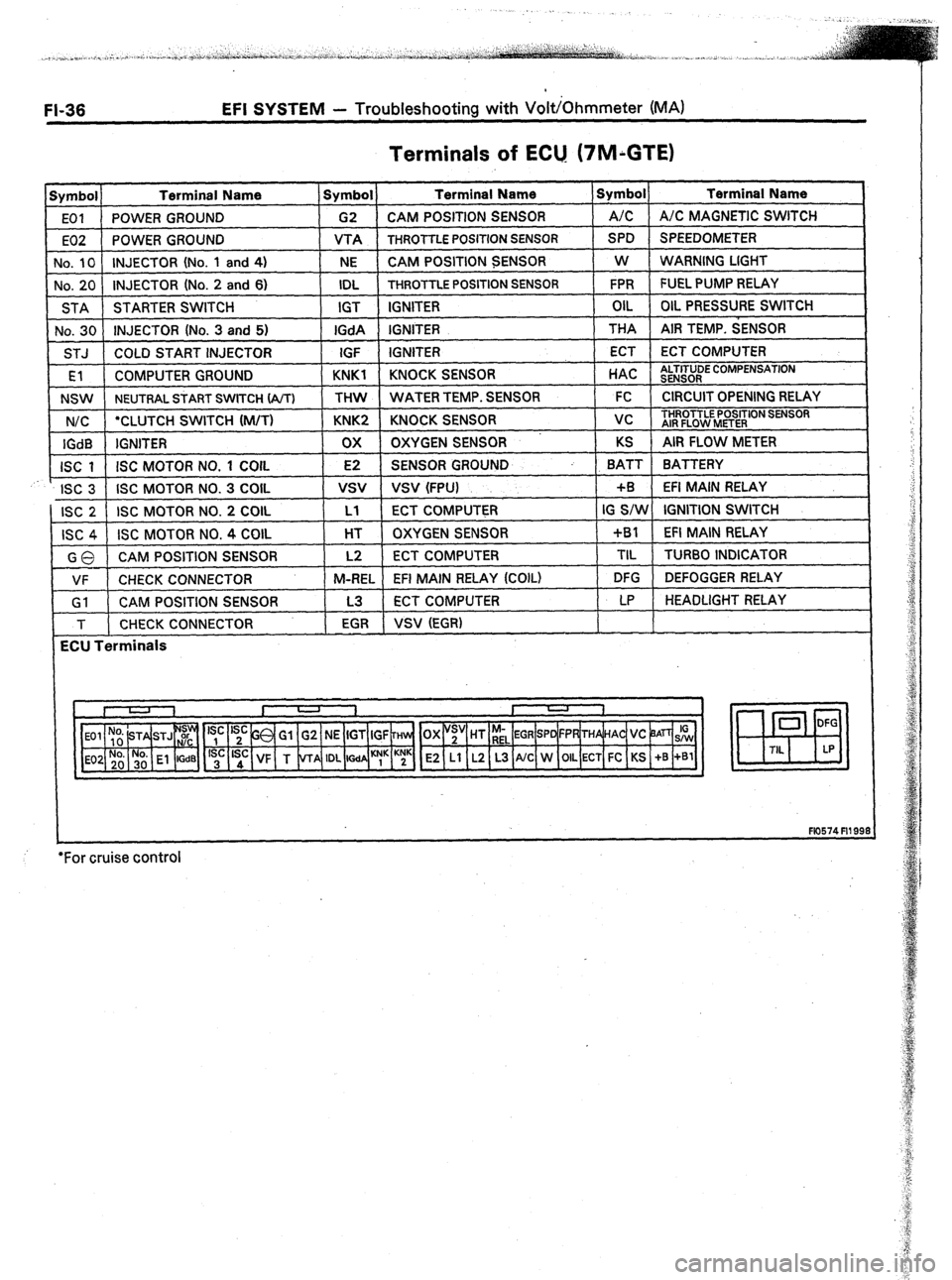

FI-36 EFI SYSTEM - Troubleshooting with VoltjOhmmeter (MA)

Terminals of ECU. (7M;GTE)

Symbol Terminal Name Symbol Terminal Name Symbol Terminal Name

EOI POWER GROUND G2 CAM POSITION SENSOR A/C A/C MAGNETIC SWITCH

E02 POWER GROUND VTA

THROTTLE POSITION SENSOR SPD SPEEDOMETER

No, 10 INJECTOR (No. 1 and 4)

NE CAM POSITION SENSOR W

WARNING LIGHT

No. 20 INJECTOR (No. 2 and 6) IDL

THROTTLE POSITION SENSOR FPR FUEL PUMP RELAY

STA STARTER SWITCH IGT IGNITER OIL OIL PRESSURE SWITCH

No. 30 INJECTOR (No. 3 and 5) IGdA IGNITER THA AIR TEMP. SENSOR

STJ COLD START INJECTOR

IGF IGNITER ECT ECT COMPUTER

rEl COMPUTER GROUND KNKl KNOCK SENSOR

t HAC 1 tl

NSW

NEUTRAL START SWITCH (A/T) THW WATER TEMP. S

N/C ‘CLUTCH SWITCH (M/T) KNK2 KNOCK SENSOR 1 vc ) THROTTLE

AIR

FLOW I

LTITUDE COMPENSATION

, .xNSOR

ENSOR 1 FC 1 CIRCUITOPENING RELAY I

IGdB IGNITER ox OXYGEN SENSOR KS AIR FLOW METER

ISC 1 ISC MOTOR NO. 1 COIL E2 SENSOR GROUND BATT BATTERY

r

ISC 3 ISC MOTOR NO. 3 COIL

vsv VSV (FPU) +B EFI MAIN RELAY

ISC 2 ISC MOTOR NO. 2 COIL Ll ECT COMPUTER IG S/W IGNITION SWITCH

ISC 4 ISC MOTOR NO. 4 COIL HT OXYGEN SENSOR +Bl EFI MAIN RELAY

GO CAM POSITION SENSOR L2 ECT COMPUTER TIL

TURBO INDICATOR

VF CHECK CONNECTOR M-REL

EFI MAIN RELAY (COIL) DFG DEFOGGER RELAY

Gl CAM POSITION SENSOR L3 ECT COMPUTER LP HEADLIGHT RELAY

T CHECK CONNECTOR

EGR VSV (EGR)

ECU Terminals

E2 Ll L2 L3 A/C W OIL ECT FC KS +B +Bl

+

F10574 Fll 99:

*For cruise control

Page 71 of 346

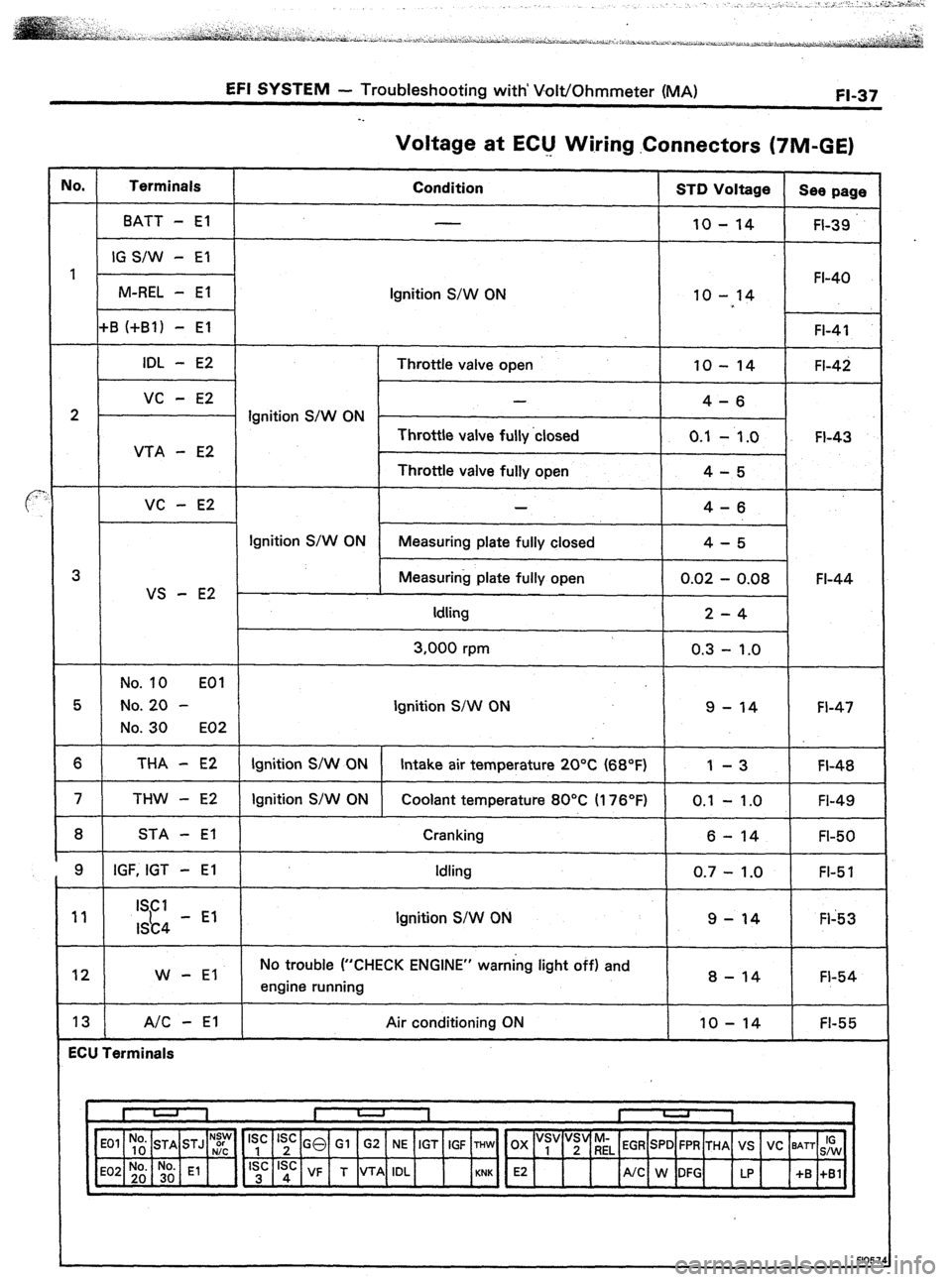

EFI SYSTEM - Troubleshooting with’ Volt/Ohmmeter (MA) FI-37

Voltage at EClJ Wiring .Connectors (TIM-GE)

IO. Terminals

Condition STD Voltage

See page

BATT - El

10 - 14 FI-39

IG S/W - El

1 FI-40

M-REL - El

Ignition S/W ON 10 - 14

+B (+Bl) - El FI-41

IDL - E2 Throttle valve open 10 - 14 FI-42

vc - E2 -

4-6

2 Ignition S/W ON -

Throttle valve fully ‘closed 0.1

- 1.0 FI-43

VTA - E2

Throttle valve fully open 4-5

VC - E2 4-6

Ignition S/W ON

Measuring plate fully closed 4-5

3 Measuring plate fully open 0.02 - 0.08 FI-44

VS - E2

Idling 2-4

3,000 rpm 0.3 - 1.0

No. 10 EOI

5 No. 20 - Ignition S/W ON 9 - 14 FI-47

No. 30 E02

6 THA - E2 Ignition S/W ON Intake air temperature 20°C (68°F) 1 -3 FI-48

7 THW - E2 Ignition S/W ON Coolant temperature 80°C II 76’F) 0.1 - 1 .O

FI-49

8 STA - El Cranking

6 - 14 FI-50

9 IGF, IGT - El Idling

0.7 - 1.0 FI-5 1

11 ISCI

I&4 - El Ignition S/W ON 9-14 Fl-53

12 W - El No trouble (“CHECK ENGINE” warning light off) and

engine running 8 - 14 FI-54

13 A/C - El Air conditioning ON IO - 14 FI-55

ECU Terminals

‘~,~] E2 4

/UC W:G up +S :,:I

N:y Is’ Is’ GO Gl G2 NE IGT IGF THW OX “s, “;“riL EGR SPD FPR THA VS VC BATT IG

F1057

Page 72 of 346

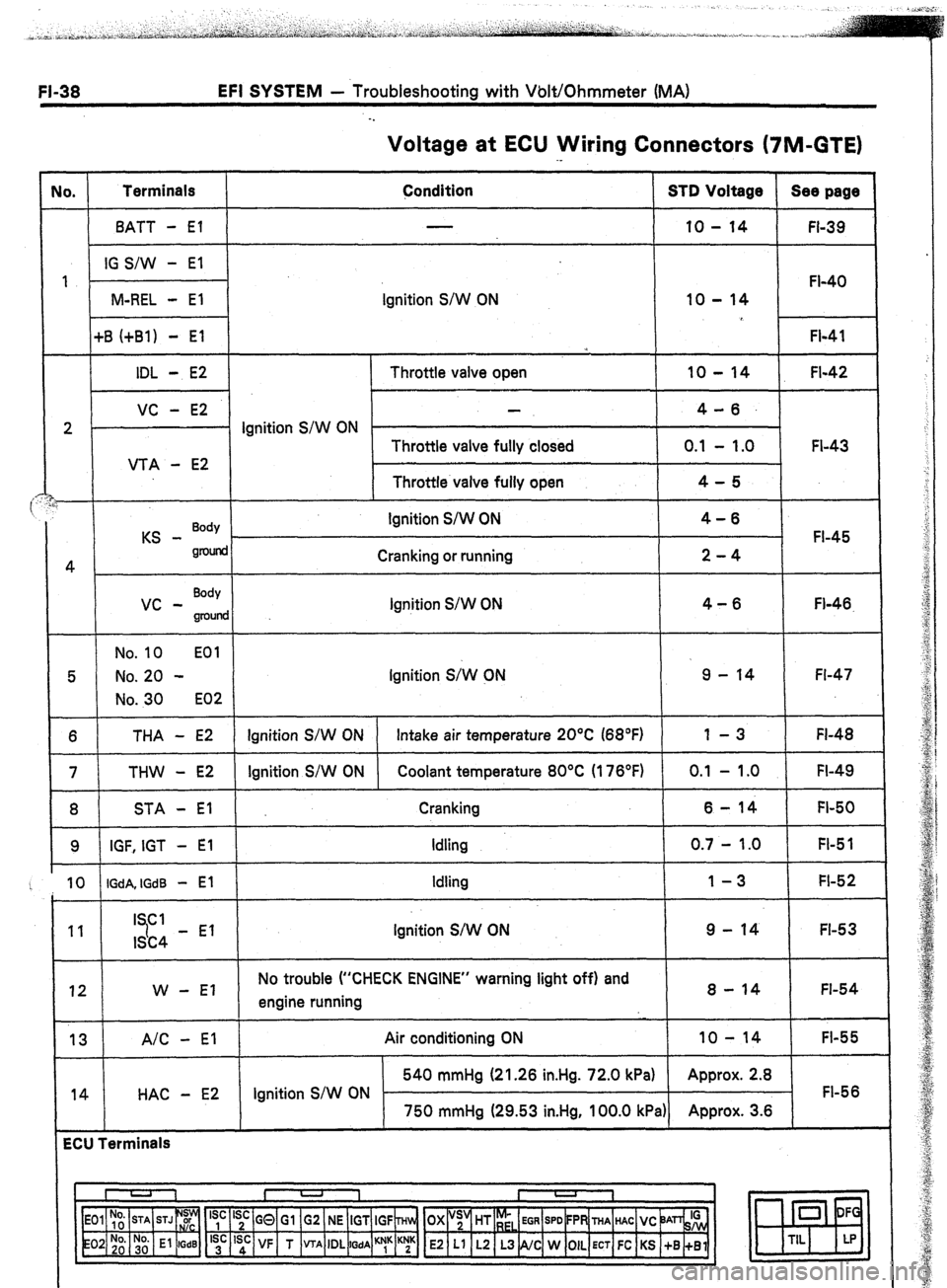

EFI SYSTEM - Troubleshooting with Volt/Ohmmeter (MA)

. .

Voltage at ECU Wiring Connectors (7M-GTE)

No. Terminals

Condition STD Voltage Sea page

BATT - El 10 - 14

FI-39

IG S/W - El

1

FI-40

M-REL - El Ignition S/W ON 10 - 14

+B (+Bl) - El

FI-41

*

IDL - E2 Throttle valve open 10 - 14 FI-42

VC - E2 4-6.

2 . Ignition S/W ON

Throttle valve fully closed 0.1 - 1.0 FI-43

VTA - E2

Throttle valve fully open 4-5

i

KS - Body Ignition S/W ON 4-6

FI-45

gnMid

4 Cranking or running 2-4

vc - Body

Ignition S/W ON 4-6

groulld Fl-46.

No. 10 EOl

5 No. 20 - Ignition S;W CN 9 - 14 Fl-47

No. 30 E02

6 THA - E2 Ignition S/W ON Intake air temperature 20°C (68°F) 1 -3 FI-48

7 THW - E2 Ignition S/W ON Coolant temperature 80°C (176°F) 0.1 - 1 .O FI-49

8 STA - El Cranking 6-14 FI-50

9 IGF, IGT - El Idling 0.7 - 1.0 FI-5 1

10 IGdA, IGdB - El Idling 1-3 FI-52

11 I Cl

7 9 - 14 FI-53

ISC4 - El Ignition S/W ON

12 W - El No trouble (“CHECK ENGINE” warning light off) and

engine running 8 - 14 FI-54

13 A/C - El

14 HAC - E2 Air conditioning ON 10 - 14

FI-55

540 mmHg (21.26 in.Hg. 72.0 kPa) Approx. 2.8

Ignition S/W ON FI-56

750 mmHg (29.53 in.Hg, 100.0 kPa) Approx. 3.6

ECU Terminals

I U 1 I -

I

1

‘yc ‘;c GQ Gl G2 NE IGT IGF ~Hln, OX “;’ HT r;,

EGR SPD FPR THA HAC VC ‘JAn& 0 DF

‘;’ ‘sd: VF T VTA IDL

WA ““1” K;K E2 Ll L2 L3 NC W OIL ECT FC KS +B +Bl m

TIL LP

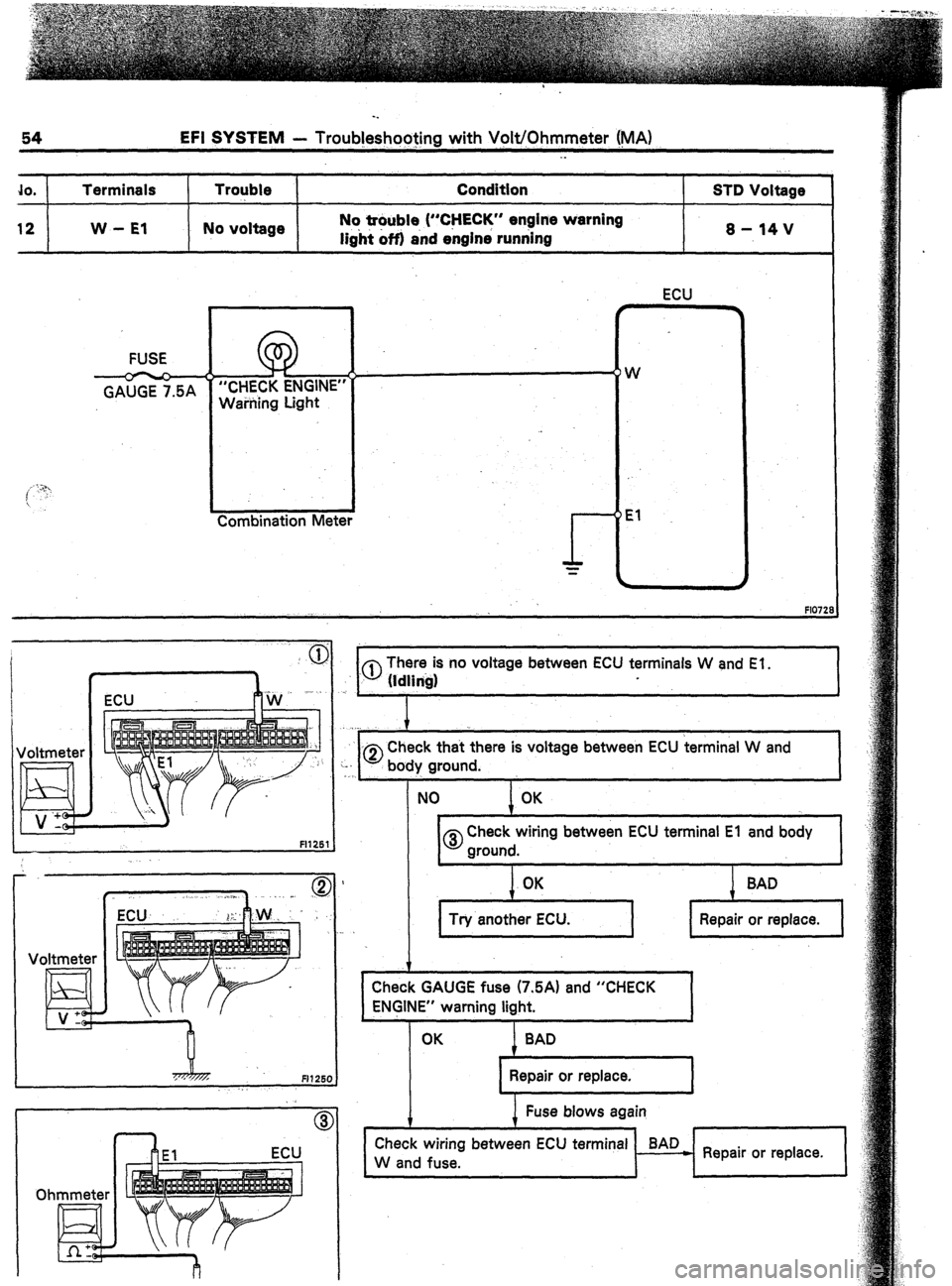

Page 88 of 346

EFI SYSTEM - Troub!eshoo$ng with Volt/Ohmmeter (MA)

. .

JO. Terminals

12 W - El Trouble

No voltage Condition

Nq @uble, (“CHECK” engine warning

light off) and engine running STD Voltage

s-14v

FUSE

GAUGE 7.5A

i

f “CHECK ENGINE”

Wahiing Light

Combination Mete W

El

FlO7

Joltmeter

EL v “_

Fl1251

1

Voltmeter

FH25C

. .

~0 There is no voltage between ECU terminals W and El.

(Idlin$

,

.

I 0

Check that there is voltage between ECU terminal W and

I

hod

Q;

0 Check wiring between ECU terminal El and body

Check GAUGE fuse (7.5A) and “CHECK

ENGINE” warning light.

I I

I Repair or replace.

I

1

Check wiring between ECU terminal BAD

*

W and fuse. Repair or replace.

I I

1 I

Page 92 of 346

jS EFI SYSTEM - Troubleshooting with Volt/Ohmmeter (MS)

-.

0

“B”

Fl294.

ECU

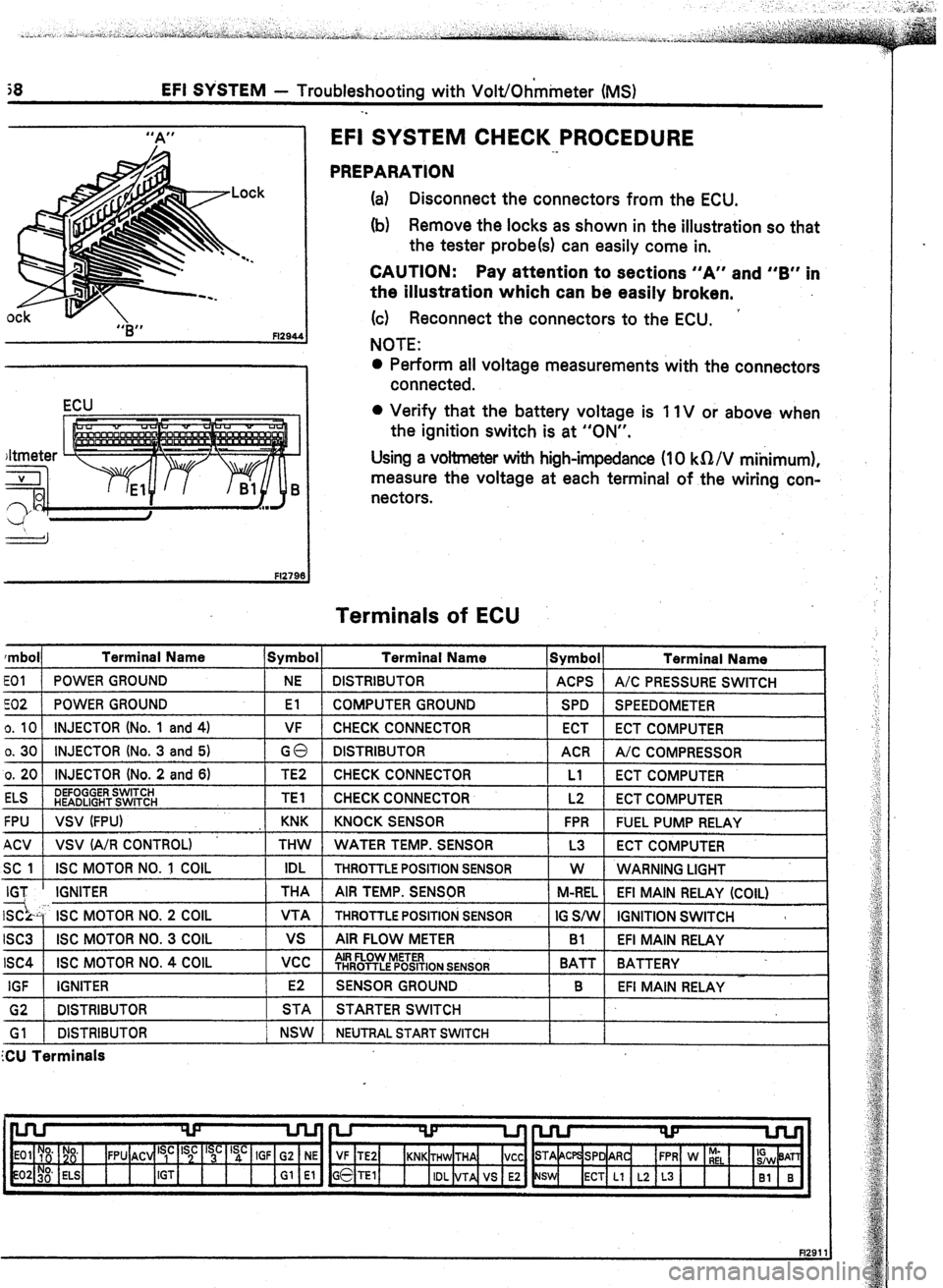

EFI SYSTEM CHECK PROCEDURE

._

PREPARATION

(a) Disconnect the connectors from the ECU.

(b) Remove the locks as shown in the illustration so that

the tester probe(s) can easily come in.

CAUTION: Pay attention to sections “A” and “B” in

the illustration which can be easily broken,

(c) Reconnect the connectors to the ECU.

’

NOTE:

0 Perform ail voltage measurements with the connectors

connected.

0 Verify that the battery voltage is 1 IV or above when

the ignition switch is at “ON”.

Using a voltmeter with high-impedance (10 kQ/V mihimum),

measure the voltage at each terminal of the wiring con-

nectors.

Terminals of ECU

rmbol Terminal Name Symbol Terminal Name

Symbol Terminal Name

EOI POWER GROUND NE DISTRIBUTOR ACPS A/C PRESSURE SWITCH

co2 POWER GROUND El COMPUTER GROUND SPD SPEEDOMETER

o. 10 INJECTOR (No. 1 and 4) VF CHECK CONNECTOR ECT ECT COMPUTER

o. 30 INJECTOR (No. 3 and 5)

GO DISTRIBUTOR ACR A/C COMPRESSOR

o. 20 INJECTOR (No. 2 and 6) TE2 CHECK CONNECTOR Ll

ECT COMPUTER

ELS DEFOGGER SWITCH

HEADLIGHT SWITCH TEl CHECK CONNECTOR L2

ECT COMPUTER

FPU VSV (FPU) KNK KNOCK SENSOR FPR FUEL PUMP RELAY

ACV VSV (A/R CONTROL) THW WATER TEMP. SENSOR L3 ECT COMPUTER

SC 1 ISC MOTOR NO. 1 COIL IDL

THROTTLE POSITION SENSOR W

WARNING LIGHT

IGT IGNITER THA AIR TEMP. SENSQR

M-REL EFI MAIN RELAY (COIL)

SC- ISC MOTOR NO. 2 COIL VTA THROlTLE POSITION SENSOR IG SiW IGNITION SWITCH 3

ISC3 ISC MOTOR NO. 3 COIL vs AIR FLOW METER Bl EFI MAIN RELAY

ISC4 ISC MOTOR NO. 4 COIL vcc AIR FLOW METER

THROTTLE POSITION SENSOR BATT BATTERY

IGF IGNITER E2

SENSOR GROUND B

EFI MAIN RELAY

G2 1 DISTRIBUTOR 1 STA 1 STARTER SWITCH

Gl 1 DISTRIBUTOR 1 NSW 1 NEUTRALSTARTSWITCH

ZU Terminals

Page 93 of 346

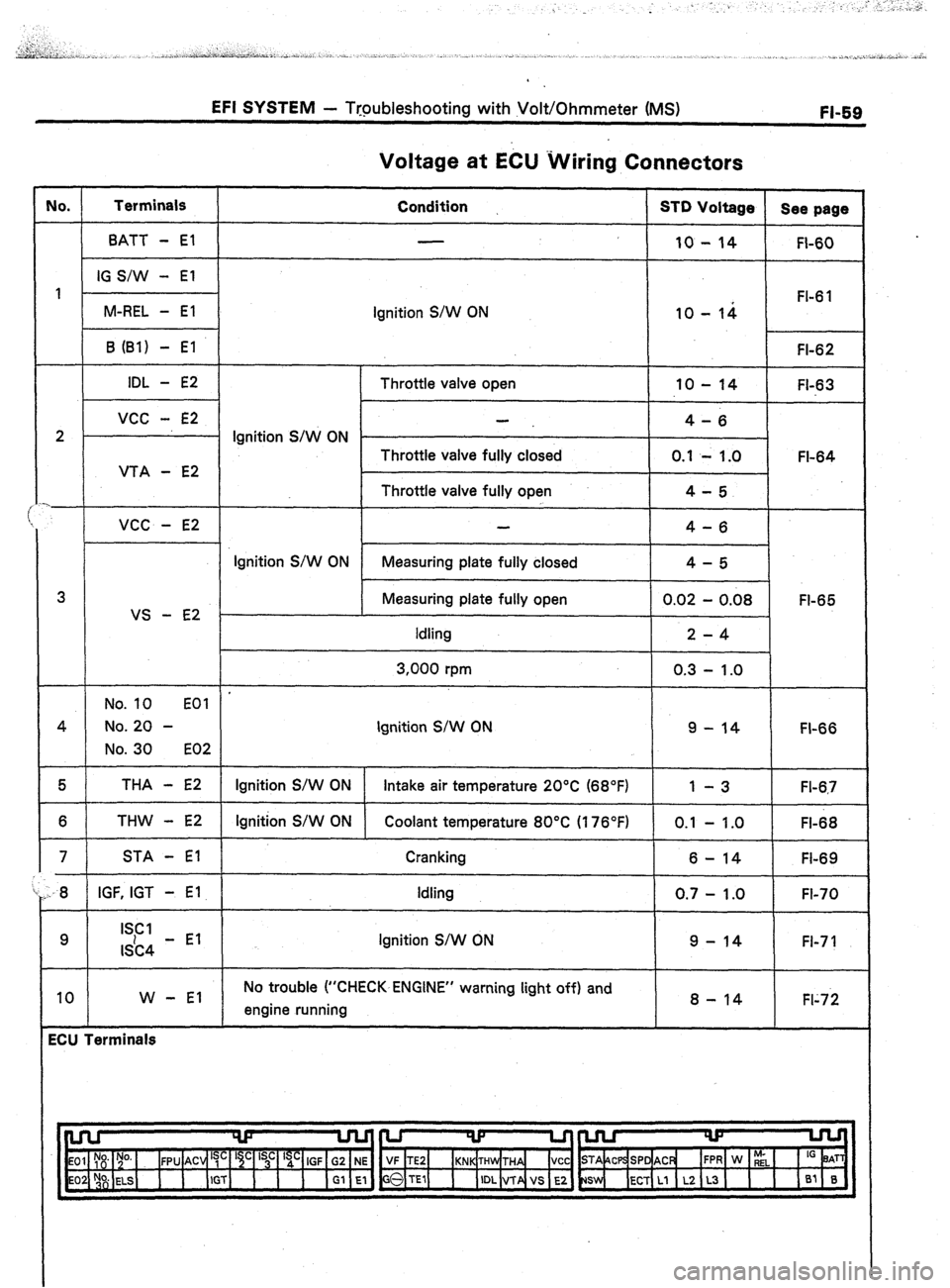

EFI SYSTEM - Ttpbleshooting with Volt/Ohmmeter (MS)

FL59

IO.

I Terminals

BATT - El

IG S/W - El

M-REL - El

2P-

I UTA - E2

3

US - E2

THA - E2

THW - E2

.B / IGF, IGT - El

9 ISCI

lSC4 - El

10

I W - El

ECU Terminals

Voltage at ECU Wiring Connectors

Condition STD Voltage ’

10 - 14

ignition S/W ON

10 - 14

Throttle valve open 10 - 14

4-6

Ignition S/W ON .

Throttle valve fully closed 0.1 - 1.0

Throttle valve fully open

4-5

4-6

Ignition S/W ON Measuring plate fully closed

4-5

Measuring plate fully open

0.02 - 0.08

Idling 2-4

3,000 rpm 0.3 - 1 .o

Ignition S/W ON 9

- 14 FI-66

Ignition S/W ON Intake air temperature 20°C (68°F) 1

-3

Ignition S/W ON

Coolant temperature 80°C (176°F) 0.1 - 1.0

Cranking

6 - 14

Idling 0.7 - 1.0

Ignition S/W ON

9 - 14

No trouble (“CHECK-ENGINE” warning light off) and

engine running 8 - 14 See page

FI-60

FI-6 1

FI-62

FI-63

FI-64

Fl-65

Fl-6.7

FI-68

FI-69

Fl-70

FI-7 1

Fl;72