ECU TOYOTA CELICA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 6 of 346

IN-4 Identification Information,

INTRODUCTION - General Repair Instructions

IDENTIFICATION INFORMATION

ENGINE SERIAL NUMBER

The engine serial number is stamped on the right side of the

cylinder block.

Seal Lock Adhesive

GENERAL REPAIR INSTRUCTIONS

1. Use fender, seat and floor covers to keep the vehicle clean

and prevent damage.

2.

3. During disassembly, keep parts in order to facilitate

reassembly.

Observe the following:

(a)

(b) Before performing electrical work, disconnect ‘the

negative (-1 cable from the battery terminal.

If it is necessary to disconnect the battery for inspec-

tion or repair, always disconnect the cable from the

negative (-) terminal which is grounded to the vehi-

cle body.

(c) To prevent damage to the battery terminal post,

loosen the terminal nut and raise the cable straight up

without twisting or prying it.

(d) Clean the battery terminal posts and cable terminals

with a shop rag. Do not scrape them with a file or

other abrasive object.

(e)

(f) Install the cable terminal to the battery post with the

nut loose, and tighten the nut after installation. Do

not use a hammer to tap the terminal onto the post.

Be sure the cover for the positive (+I terminal is pro-

perly in place.

4.

5. Check hose and wiring connectors to make sure that they

are secure and correct.

Non-reusable parts

(a)’ Always replace cotter pins gaskets, O-rings, oil seals,

etc. with new ones.

(b) Non-reusable parts are indicated in the component

illustrations by the “+” symbol.

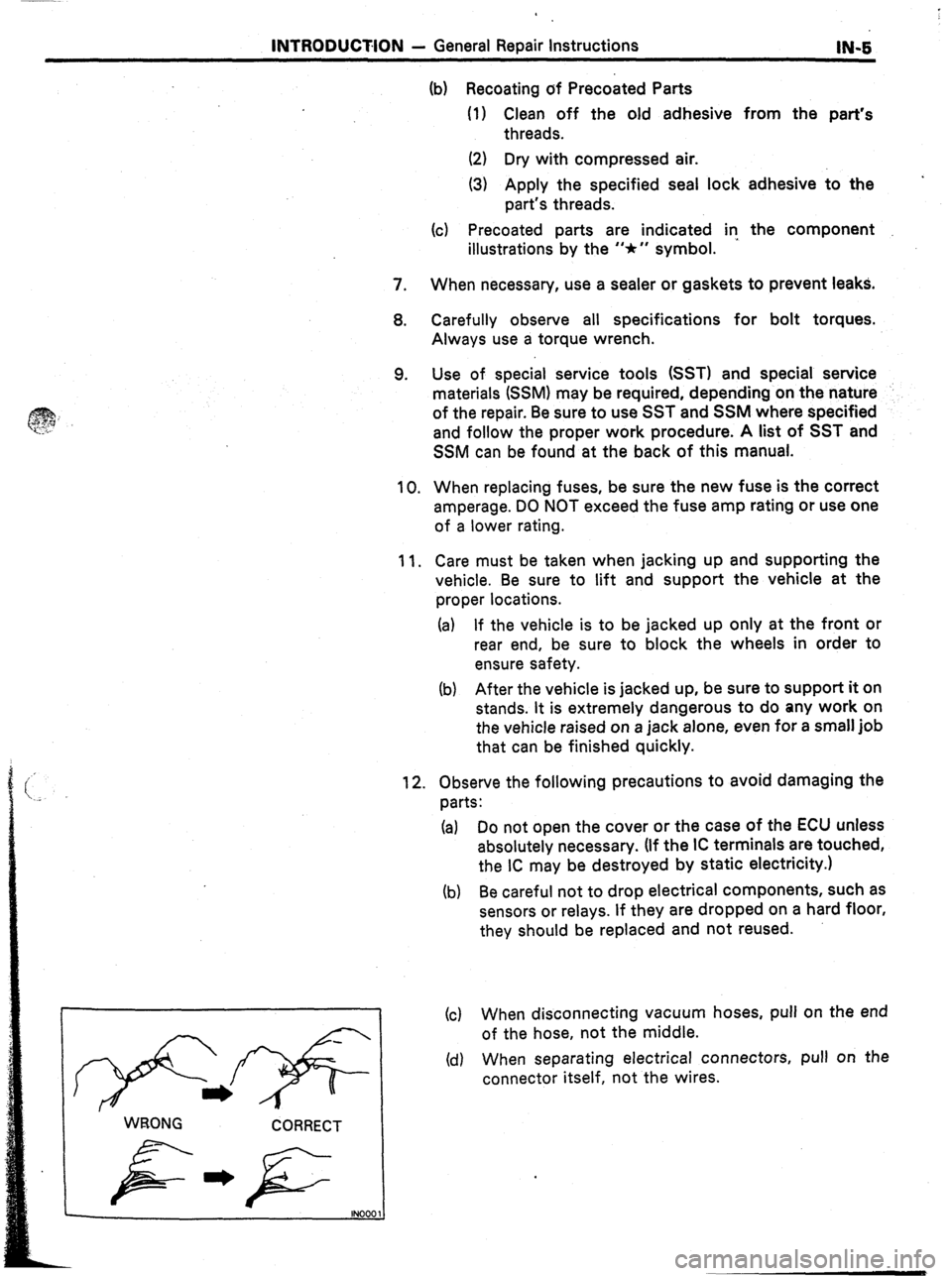

6. Precoated Parts

Precoated parts are the bolts, nuts, etc. which are coated

with a seal lock adhesive at the factory.

(a) If a precoated part is retightened, loosened or caused

to move in any way, it must be recoated with the

specified adhesive.

Page 7 of 346

INTRODUCTION - General Repair Instructions

IN-S

(b) Recoating of Precoated Parts

(1) Clean off the old adhesive from the part’s

threads.

(2) Dry with compressed air.

(3) Apply the specified seal lock adhesive to the

part’s threads.

(c) Precoated parts are indicated in the component

illustrations by the “*” symbol.

7. When necessary, use a sealer or gaskets to prevent leaks.

8. Carefully observe all specifications for bolt torques.

Always use a torque wrench.

9. Use of special service tools (SST) and special service

materials (SSM) may be required, depending on the nature

of the repair. Be sure to use SST and SSM where specified

and follow the proper work procedure. A list of SST and

SSM can be found at the back of this manual.

10. When replacing fuses, be sure the new fuse is the correct

amperage. DO NOT exceed the fuse amp rating or use one

of a lower rating.

11. Care must be taken when jacking up and supporting the

vehicle. Be sure to lift and support the vehicle at the

proper locations.

(a) If the vehicle is to be jacked up only at the front or

rear end, be sure to block the wheels in order to

ensure safety.

(b) After the vehicle is jacked up, be sure to support it on

stands. It is extremely dangerous to do any work on

the vehicle raised on a jack alone, even for a small job

that can be finished quickly.

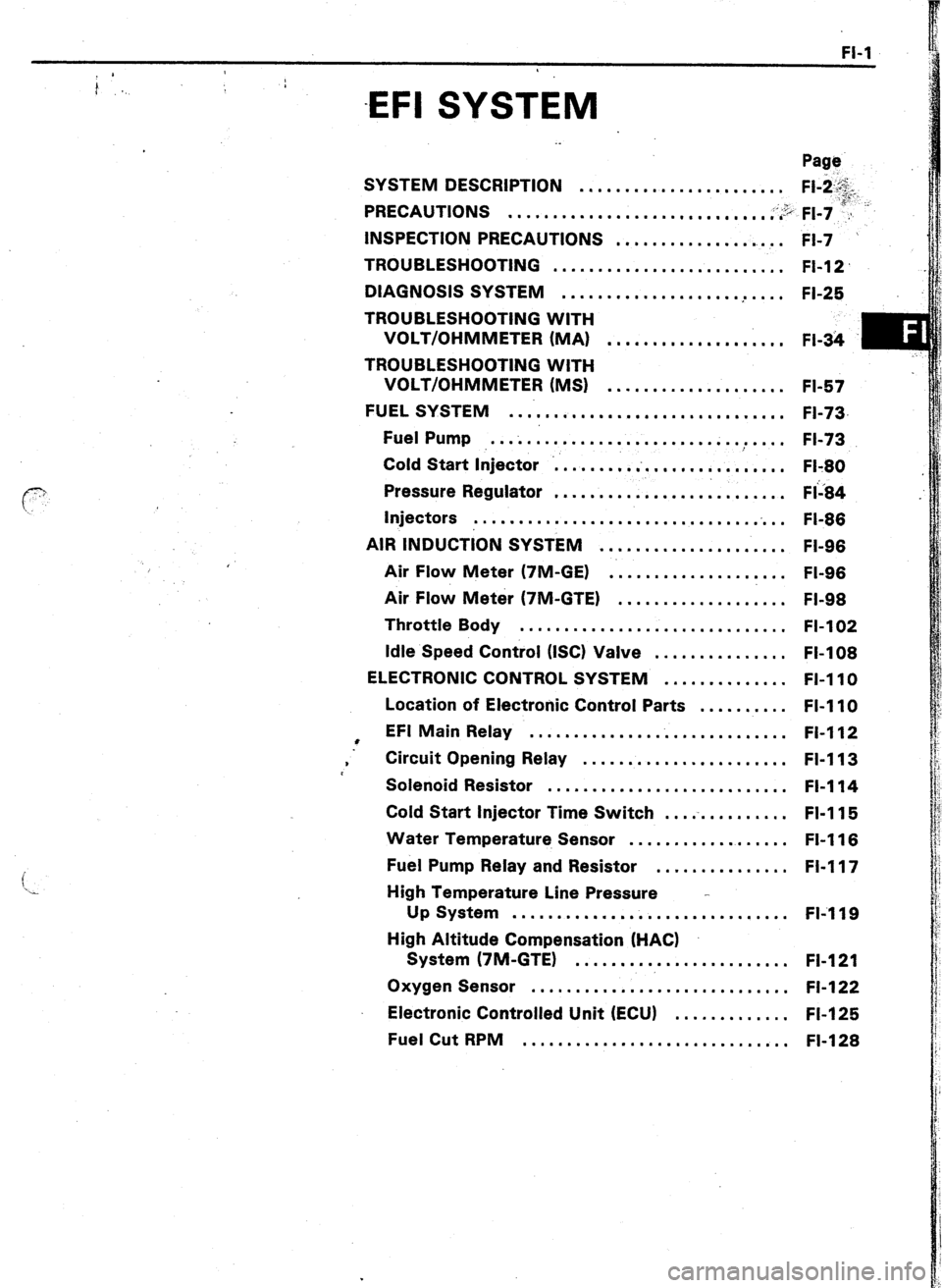

WRONG

CORRECT 12. Observe the following precautions to avoid damaging the

parts:

(a) Do not open the cover or the case of the ECU unless

absolutely necessary. (If the IC terminals are touched,

the IC may be destroyed by static electricity.)

(b) Be careful not to drop electrical components, such as

sensors or relays. If they are dropped on a hard floor,

they should be replaced and not reused.

(c) When disconnecting vacuum hoses, pull on the end

of the hose, not the middle.

(d) When separating electrical connectors, pull on the

connector itself, not the wires.

Page 35 of 346

FI-1

i’.. ;

-EFI SYSTEM

i

‘x

. .

Page

SYSTEM DESCRIPTION

....................... Fl-i.&.

PRECAUTIONS

;;:“, F,-, ;a”“- .............................. . ....

INSPECTION PRECAUTIONS

FI-7 . ....................

TROUBLESHOOTING

.......................... FI-12

DIAGNOSIS SYSTEM

.................... .

.... FI-25

TROUBLESHOOTING WITH

VOLT/OHMMETER (MA)

.................... FI-34

m

.:

TROUBLESHOOTING WITH

VOLT/OHMMETER (MS)

.................... FI-57

FUEL SYSTEM

................................ FI-73,

Fuel Pump ..................................

FI-73

Cold Start Injector ...........................

Fl-80

Pressure Regulator

.......................... FI’i84 ..

Injectors

.............................. ..i ..

FI-86

AIR INDUCTION SYSTEM

..................... FI-96

Air Flow Meter (7M-GE)

..................... FI-96

Air Flow Meter (7M-GTE)

................... FI-98

Throttle Body

.............................. FI-102

Idle Speed Control (ISC) Valve

............... FI-108

ELECTRONIC CONTROL SYSTEM .............. FI-110

Location of Electronic Control Parts .......... FI-110

l EFI Main Relay

............................. Fl-112

. Circuit Opening Relay ....................... FI-113

Solenoid Resistor

........................... Fl-114

Cold Start Injector Time Switch ...............

FI-115

Water Temperature Sensor ..................

FI-116

Fuel Pump Relay and Resistor ............... FI-117

High Temperature Line Pressure -

Up System ............................... FIi119

High Altitude Compensation (HACK

System (7M-GTE)

........................ FI-121

Oxygen Sensor .............................

FI-122

Electronic Controlled Unit (ECU) .............

FI-125

Fuel Cut RPM

.............................. FI-128

Page 36 of 346

Circuit

Opening

Fuel Pump Relay

I

Warning 1

I :..I-, -7-I ECU

P 1

L-

VSV (FPU)

Electronic

Load

di!=

Check C&tnector

A/C Compressc

I-=-

Szeed Sensor

IIIII:IIlI Igniter w/coil

l---it-

Start‘lnjector Time Switch

Water Te&p. Sensor

TWC

Neutral Start

Switch (A/T)

Page 37 of 346

![TOYOTA CELICA 1987 Service Repair Manual Circuit

Opening

Relay Fuel Pump Relay

“CHECK 1 f-- 1 ] : :

llll II :

: :

ENGINE”

Warning

Light ECU

I iIll

+-,llllllllllll

Electronic

Load Air Temp. Sensor

Check Connector 1 1 1 / 1 TOYOTA CELICA 1987 Service Repair Manual Circuit

Opening

Relay Fuel Pump Relay

“CHECK 1 f-- 1 ] : :

llll II :

: :

ENGINE”

Warning

Light ECU

I iIll

+-,llllllllllll

Electronic

Load Air Temp. Sensor

Check Connector 1 1 1 / 1](/img/14/57451/w960_57451-36.png)

Circuit

Opening

Relay Fuel Pump Relay

“CHECK 1 f-- 1 ] : :

llll II :

: :

ENGINE”

Warning

Light ECU

I iIll

+-,llllllllllll

Electronic

Load Air Temp. Sensor

Check Connector 1 1 1 / 1 1 1 1 1 1 1 1

:uator

Igniter w/r-:’ ’

A/C Compressor

& 1 wTwy 1 To Charcoal Canister

Neutral Start

Switch (A/T)

Page 40 of 346

1-6 EFI SYSTEM - System Description

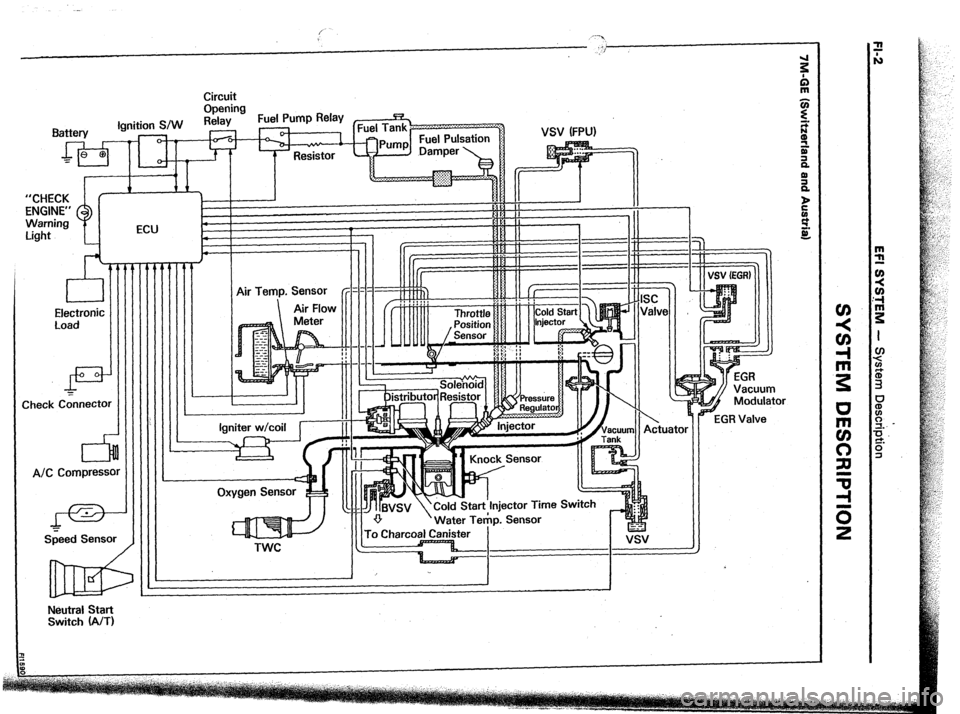

‘he .EFI system is composed of 3 basic sub

;ystems; Fuel Induction, Air Induction and

Ziectronic Control.

FUEL SYSTEM

An electric fuel pump supplies sufficient fuel,

under a constant pressure, to the injectors. These

injectors inject a metered quantity of fuel into the

intake manifold in accordance with signals from

the ECU (Electronic Control Unit).

AIR INDUCTION SYSTEM

The air induction system provides sufficient air for

engine operation.

[3: ‘I

i&TRONIC CONTROL SYSTEM

The 7M-GE, 7M-GTE engines are equipped wifh a

Toyota Computer Control System (TCCS) which

centrally controls the EFI, ESA, Diagnosis systems,

etc. by means of an Electronic Control Unit (ECU -

for-merly EFI computer) employing a microcom-

puter.

By means of the ECU, the TCCS controls the

following functions:

1. Electronic Fuel injection (EFI)

The ECU receivers signals from,various sen-

sors indicating changing engine operating

conditions such as:

Exhaust oxygen content (w/ TWC)

Intake air volume

i Intake air temperature

Coolant temperature

Engine rpm

Vehicle speed

Acceleration/deceleration etc.

These signals are utilized by the ECU to

determine the injection duration necessary for

an optimum air-fuel ratio.

2. Electronic Spark Advance (ESA)

The ECU is programmed with data for

optimum ignition timing under any and all

operating conditions. Using data provided by

sensors which monitor various engine func-

tions (rpm, A/C signal, coolant temperature,

etc.), the microcomputer (ECU) triggers the

spark at precisely the right instant. (See IG

section) 3. Idle Speed Control (IX)

The ECU is programmed with, target idling

speed values to respond to different engine

conditions (coolant temperature, air condi-

tioner on/off, etc.). Sensors transmit signals

to the ECU which control the flow of air

through the bypass of the throttle valve and

adjust idle speed to the target value.

(See pages FI-53, 7 1, 108) ’

4. Diagnosis

The ECU detects any malfunctions or abnor-

malities in the sensor network and tights the

“CHECK ENGINE” warning light on the instru-

ment panel. At the same time, the trouble is

identified and a diagnostic code is recorded

by the ECU.

5. Fail-Safe Function ’

In the event of computer malfunction, a back-

up circuit will take over to provide minimal

drivability. Simultaneously, the “CHECK

ENGINE” warning light will come on.

Page 41 of 346

EFI SYSTEM

- Precautions, Inspection Precautions

FI-7

PRECAUTIONS

._

1. Before working on the fuel system, disconnect the

negative terminal from the battery.

NOTE: Any diagnosis code retained by the computer will

be erased when the battery terminal is removed.

Therefore, if necessary, read the diagnosis before

removimg the battery terminal.

2. Do not smoke or work near an open flame when work-

ing on the fuel system.

3. Keep gasoline off rubber or leather parts.

INSPECTION PRECAUTl.ONS

MAINTENANCE PRECAUTIONS

1. INSURE CORRECT ENGINE TUNE-UP

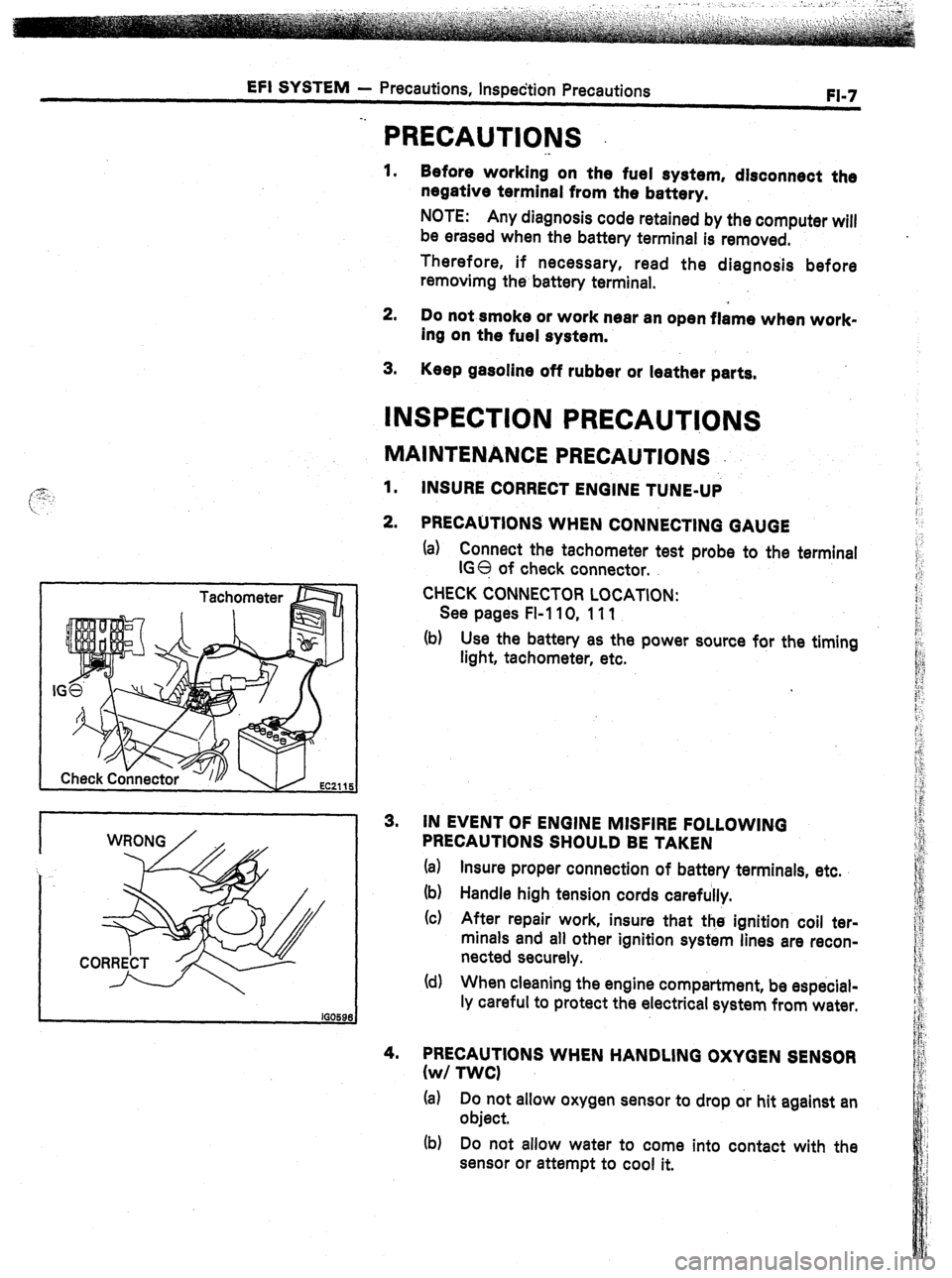

2. PRECAUTIONS WHEN CONNECTING GAUGE

(a) Connect the tachometer test probe to the terminal

IGO of check connector.

CHECK CONNECTOR LOCATION:

See pages FI-110, 111

(b) Use the battery as the power source for the timing

light, tachometer, etc.

3. IN EVENT OF ENGINE MISFIRE FOLLOWING

PRECAUTIONS SHOULD BE TAKEN

(a) Insure proper connection of battery terminals, etc.

(b) Handle high tension cords carefully.

(c) After repair work, insure that the ignition coil ter-

minals and all other ignition system lines are recon-

nected securely.

(d) When cleaning the engine compartment, be especial-

ly careful to protect the electrical system from water.

4. PRECAUTIONS WHEN HANDLING OXYGEN SENSOR

(w/ TWCI

(a) Do not allow oxygen sensor to drop or hit against an

object.

(b) Do not allow water to come into contact with the

sensor or attempt to cool it.

Page 42 of 346

-8 EFI SYSTEM -.- Inspection Precautions

IF VEHICLE IS EQUIPPED WITH MOBILE

RADIO SYSTEM (HAM, CB, ETC)

The ECU has been designed so that it will not be affected by

outside interference.

However, if your vehicle is equipped with a CB radio

transceiver, etc. (even one with about 10 W output), it may, at

times, have an affect upon ECU operation, especially if the

antenna and feeder are installed nearby.

Therefore, observe the following precautions:

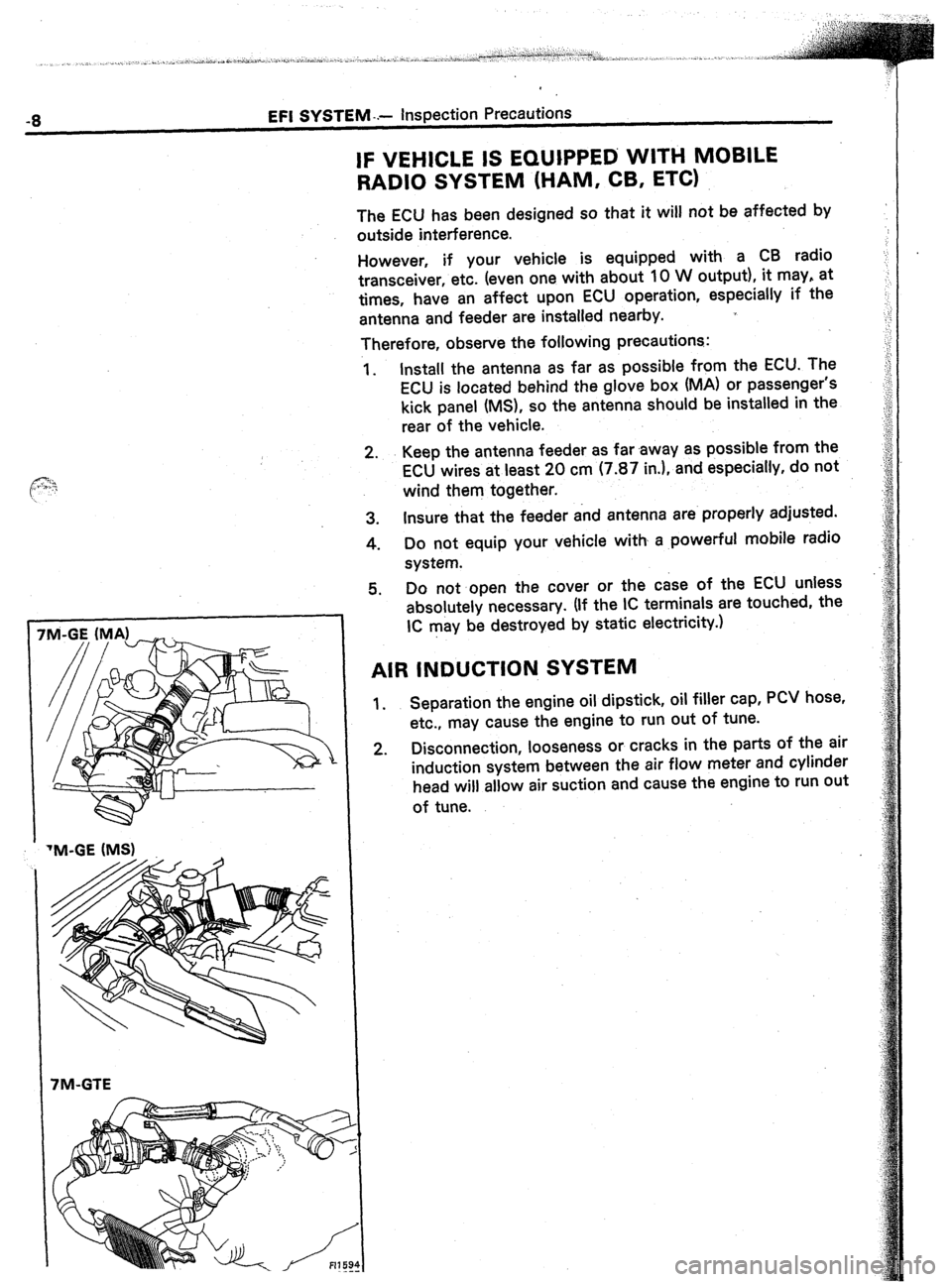

1. Install the antenna as far as possible from the ECU. The

ECU is located behind the glove box (MA) or passenger’s

kick panel (MS), so the antenna should be installed in the

rear of the vehicle.

2. Keep the antenna feeder as far .away as possible from the

ECU wires at least 20 cm (7.87 in.), and especially, do not

wind them together.

3. Insure that the feeder and antenna are properly adjusted.

4. Do not equip your vehicle with a powerful mobile radio

system.

Do not open the cover or the case of the ECU unless

absolutely necessary. (If the IC terminals are touched, the

. . .

IC may be destroyed by static electricity.1

AIR INDUCTION SYSTEM

1.

2. Separation the engine oil dipstick, oil filler cap, PCV hose,

etc., may cause the engine to run out of tune.

Disconnection, looseness or cracks in the parts of the air

induction system between the air flow meter and cylinder

head will allow air suction and cause the engine to run out

of tune.

TM-GE (MS)

7M-GTE

Page 43 of 346

EFI SYSTEM - inspection Precautions

FI-9

FM066

FlOO95 FlOO91

ELECTRONIC CONTROL SYSTEM

1.

2.

3. Before removing EFI wiring connectors, terminals, etc.,

first disconnect-the power-by either turning the ignition

switch OFF or disconnecting the battery terminals.

When installing a battery, be especially careful not to

incorrectly connect the positive and negative cables.

Do not permit parts to receive a severe impact during

removal or installation. Handle all EEI parts carefully.

especially the ECU.

4. Do not be careless during troubleshooting as there are

numerous transistor circuits and even slight terminal con-

tact can cause further troubles.

5.

6. Do not open the ECU cover.

When inspecting during rainy weather, take care to pre-

vent entry of water. Also, when washing the engine com-

.partment, prevent water from getting on the EFI parts and

wiring connectors.

7. Parts should be replaced as an assembly.

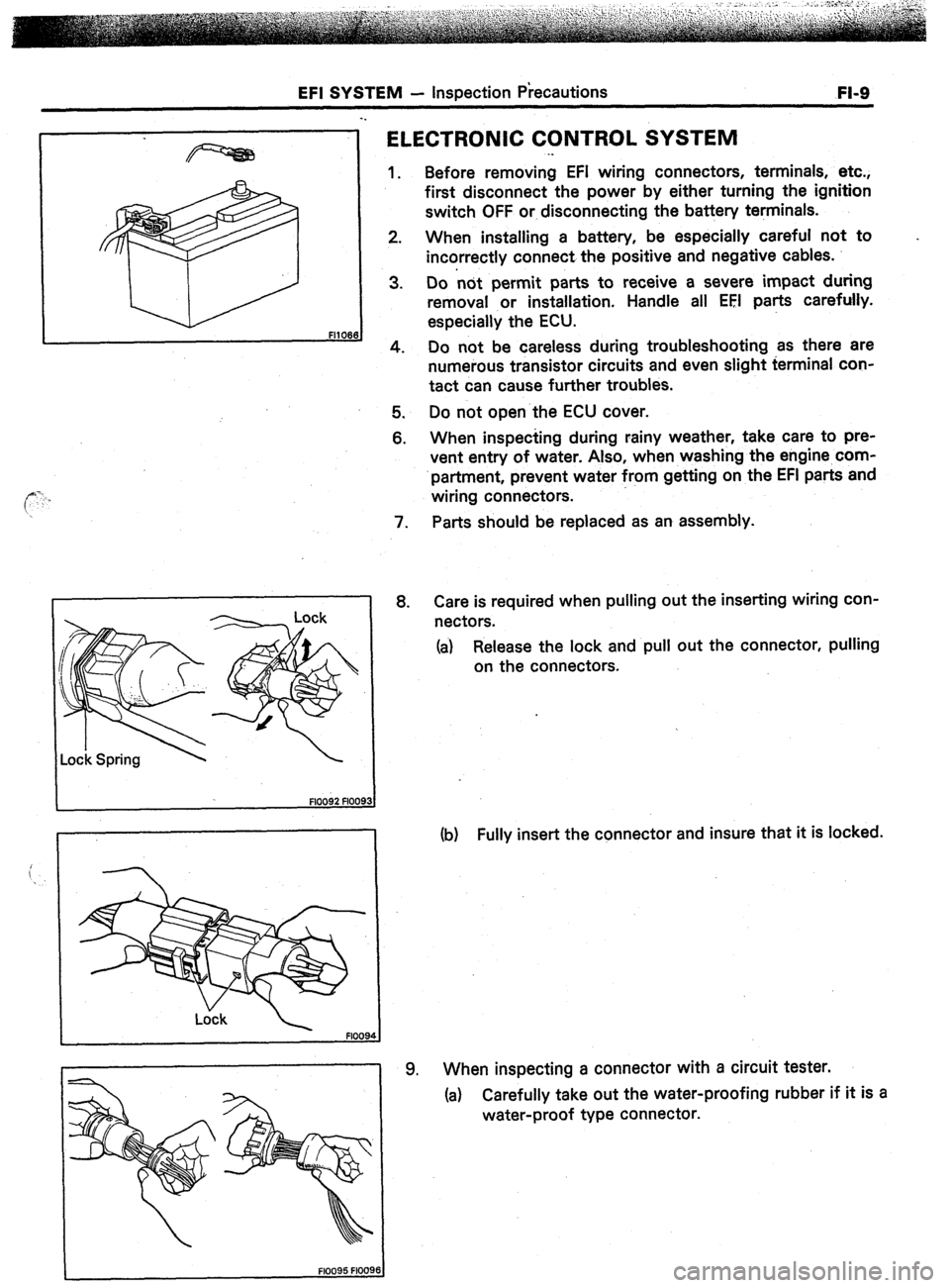

8. Care is required when pulling out the inserting wiring con-

nectors.

(a) Release the lock and pull out the connector, pulling

on the connectors. .

(b) Fully insert the connector and insure that it is locked.

9. When inspecting a connector with a circuit tester.

(a) Carefully take out the water-proofing rubber if it is a

water-proof type connector.

Page 44 of 346

FI-10 EFI SYSTEM - inspection Precautions

L Fco97 FlOO91

I

. FI159

i. 4 Gasket

New

‘Gasket

I / FM067 FHOE

Fulcrum Length

19

54

-.

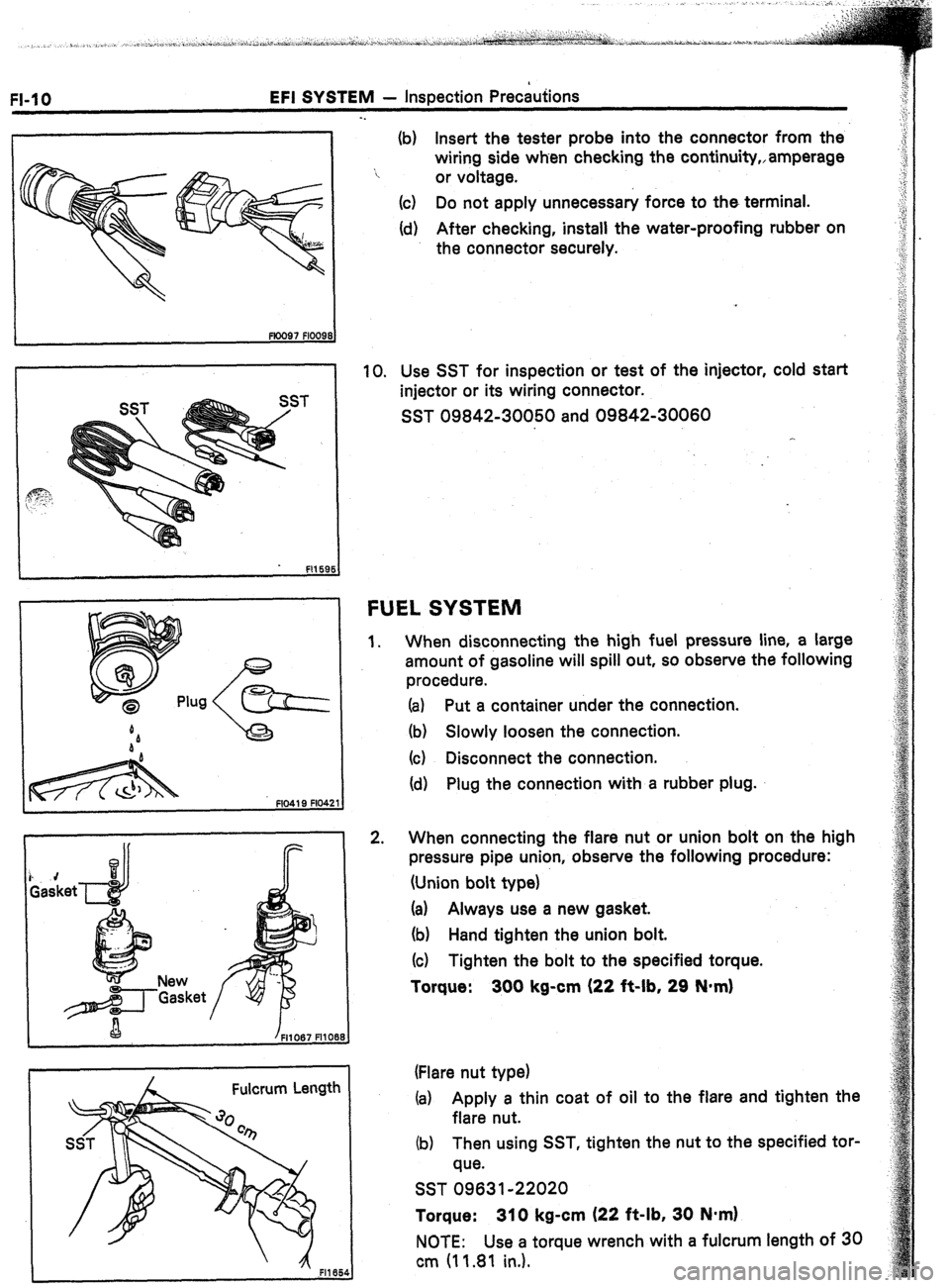

(b) insert the tester probe into the connector from the

wiring side when-checking the continuity,,amperage

L

or voltage.

(c) Do not apply unnecessary force to the terminal.

(d) After checking, install the water-proofing rubber on

the connector securely.

10. Use SST for inspection or test of the injector, cold start

injector or its wiring connector.

SST 09842-30050 and 09842-30060

FUEL SYSTEM

1.

2. When disconnecting the high fuel pressure line, a large

amount of gasoline will spill out, so observe the following

procedure.

(a) Put a container under the connection.

(b) Slowly loosen the connection.

(c) Disconnect the connection.

(d) Plug the connection with a rubber plug.

When connecting the flare nut or union bolt on the high

pressure pipe union, observe the following procedure:

(Union bolt type)

(a) Always use a new gasket.

(b) Hand tighten the union bolt.

(c) Tighten the bolt to the specified torque.

Torque: 300 kg-cm (22 it-lb, 29 N*m)

(Flare nut type)

(a) Apply a thin coat of oil to the flare and tighten the

flare nut.

(b) Then using SST, tighten the nut to the specified tor-

que.

SST 09631-22020

Torque: 310 kg-cm (22 ft-lb, 30 N*m)

NOTE: Use a torque wrench with a fulcrum length of 30

cm (11.81 in.).