brake TOYOTA CELICA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 45 of 346

EFI SYSTEM

- inspection Precautions

FI-11

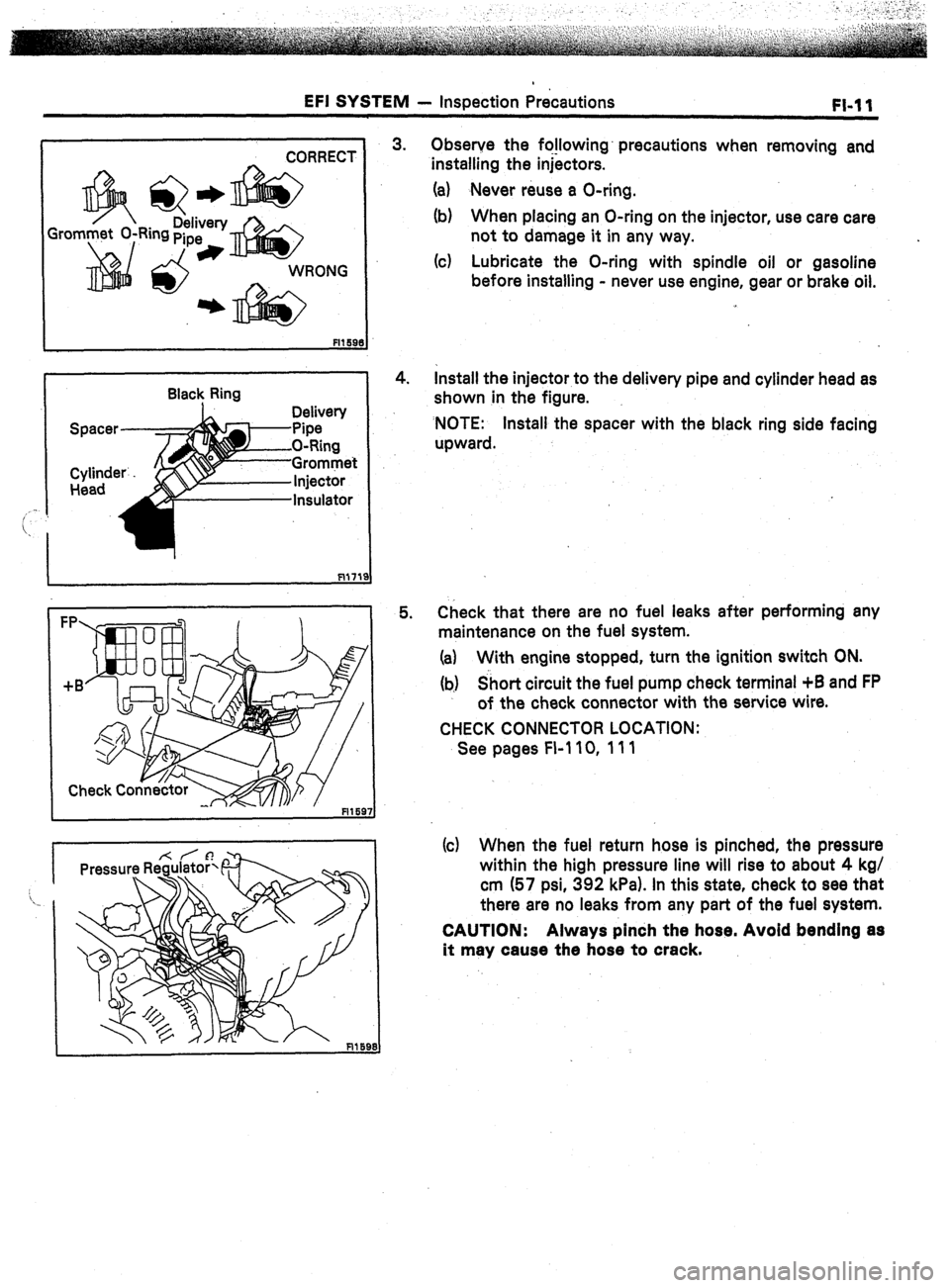

I CORRECT i

Gro

Q * Delivery

Ring pipe

*

Black Ring

Delivew

Pipe -

O-Ring

-Grommet

3.

4.

5. Observe the fo!lowing’ precautions when removing and

installing the injectors.

(a) Never reuse a O-ring.

(b) When placing an O-ring on the injector, use care care

not to damage it in any way.

(c) Lubricate the O-ring with spindle oil or gasoline

before installing - never use engine, gear or brake oil.

Install the injector to the delivery pipe and cylinder head as

shown in the figure.

‘NOTE: Install the spacer with the black ring side facing

upward.

Check that there are no fuel leaks after performing any

maintenance on the fuel system.

(a) With engine stopped, turn the ignition switch ON.

(b) Short circuit the fuel pump check terminal +B and FP

of the check connector with the service wire.

CHECK CONNECTOR LOCATION:

See pages FI-110, 111

(c) When the fuel return hose is pinched, the pressure

within the high pressure line will rise to about 4 kg/

cm (57 psi, 392 kPa). In this state, check to see that

there are no leaks from any part of the fuel system.

CAUTION: Always pinch the hose. Avoid bending as

it may cause the hose to crack.

Page 57 of 346

EFI SYSTEM - Troubleshooting

FI-23

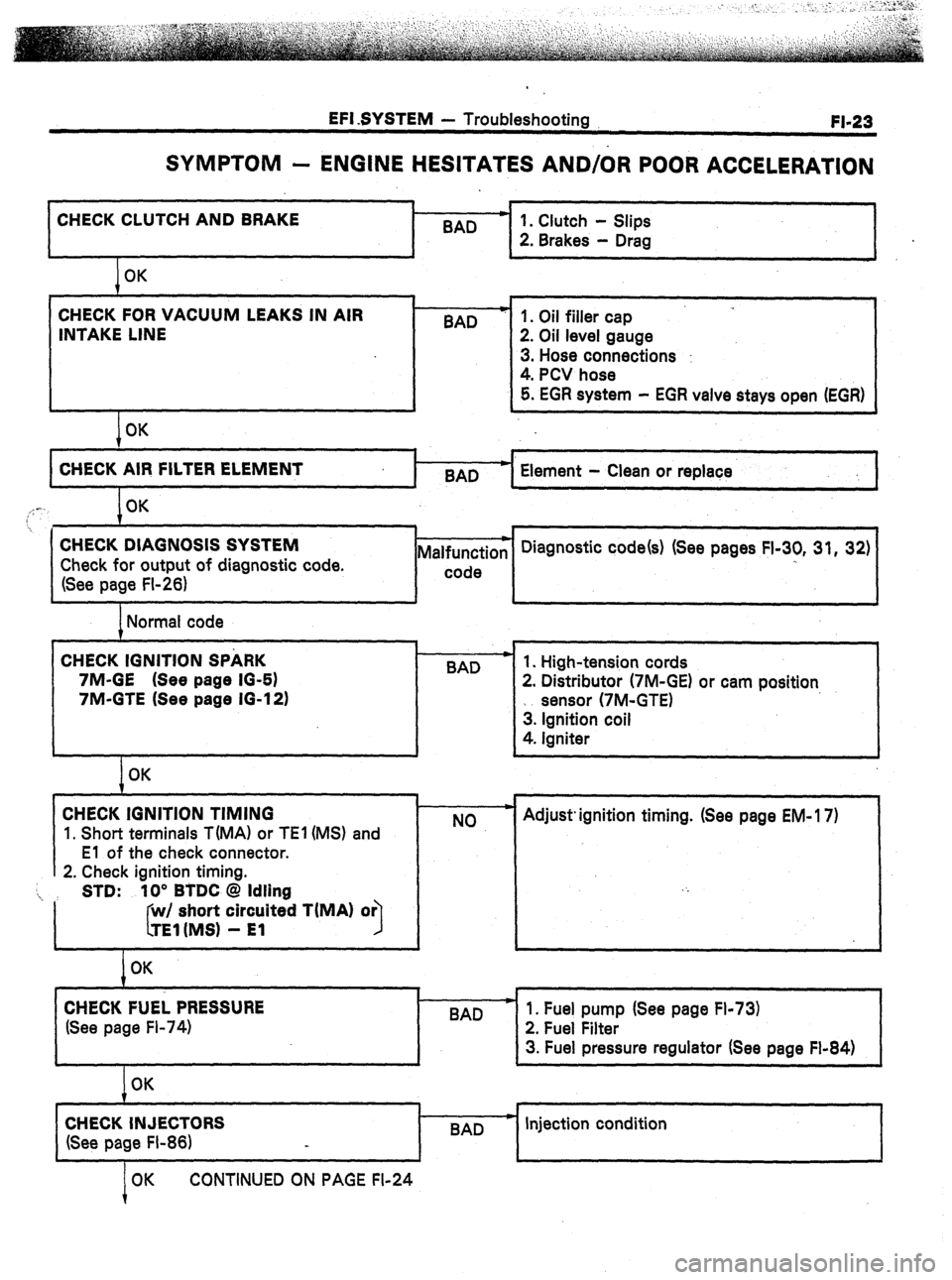

SYMPTOM - ENGINE HESITATES AND/OR POOR ACCELERATION

CHECK CLUTCH AND BRAKE .

BAD

I

I 1

1 OK

CHECK FOR VACUUM LEAKS IN AIR

INTAKE LINE

I OK BAD

I-

1. Clutch - Slips

2. Brakes - Drag

1. Oil filler cap

2. Oil level gauge

3. Hose connections :

4. PCV hose

5. EGR system - EGR valve stays open (EGR)

4

CHECK AIR FILTER ELEMENT

BAD Element - Clean or replace

I

,,: -. OK

7

. . 1 i , 1

CHECK DIAGNOSIS SYSTEM

Check for output of diagnostic code.

(See page FI-26) Malfunction

I-- code Diagnostic code(s) (See pages FI-30, 31, 32)

I

I I I J

1 Normal code

CHECK IGNITION SPARK

7M-GE (See page IO-61

7M-GTE (See page 16-12) .

BAD

I

I OK

CHECK IGNITION TIMING

1. Short terminals T(MA1 or TEl (MS) and

El of the check connector.

2. Check ignition timing.

‘i, STD: 10” BTDC @ Idling

I short circuited TiMA) or

I

I OK

CHECK FUEL PRESSURE

(See page Fl-74) 1. High-tension cords

2. Distributor (7M-GE) or cam position

sensor (7M-GTE)

3. Ignition coil

4. Igniter

NO Adjust. ignition timing. (See page EM- 17)

I

I

BAD

I

1. Fuel pump (See page Fl-73)

2. Fuel Filter

3. Fuel pressure regulator (See page Fl-84)

1

OK

CHECK INJECTORS

(See page FI-86) BAD c Injection condition

OK CONTINUED ON PAGE FI-24

Page 168 of 346

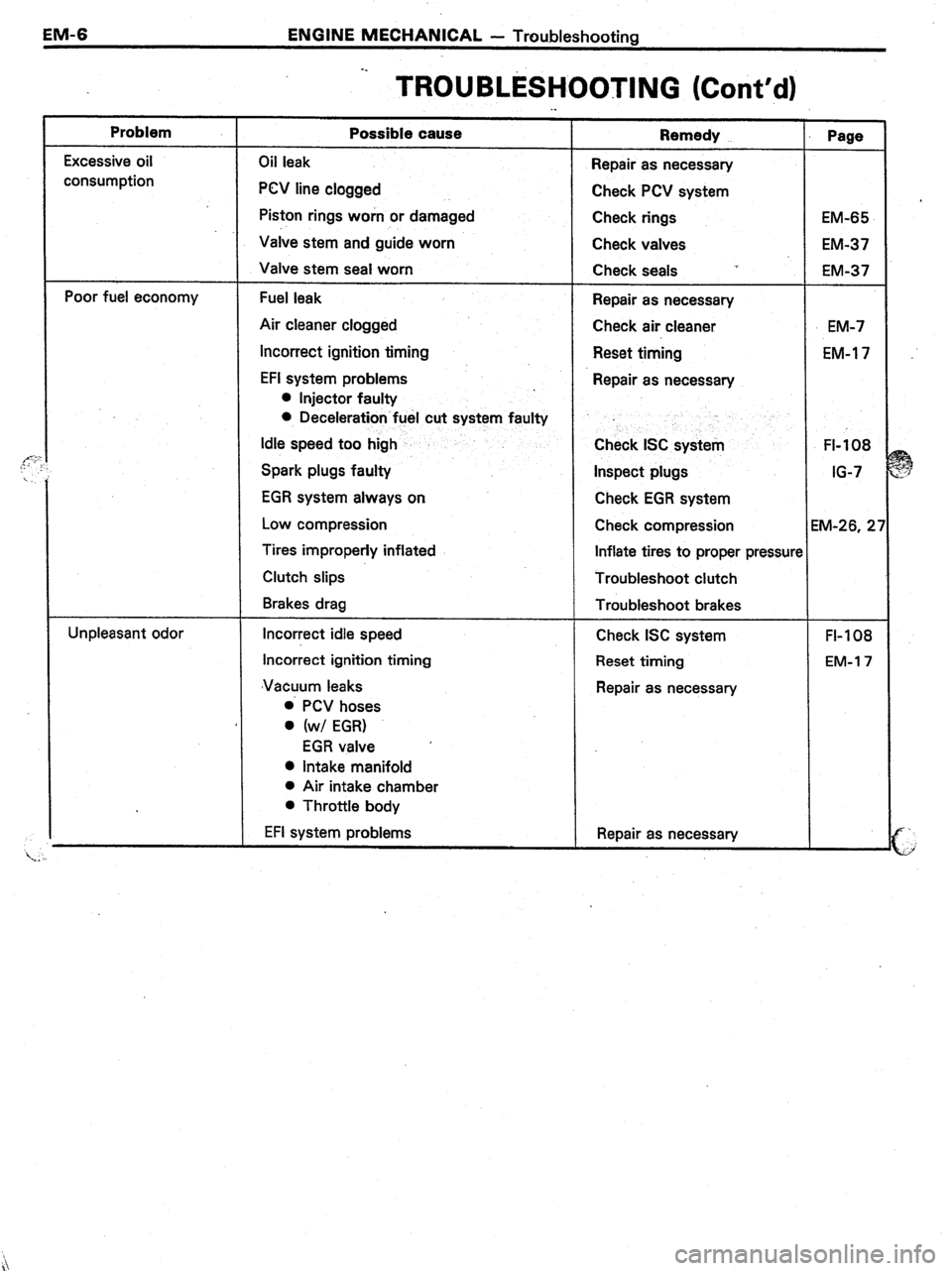

EM-6 ENGINE MECHANICAL - Troubleshooting

Problem

:- Excessive oil

consumption

Poor fuel economy

Unpleasant odor -.

TROUBLESHOOTING (Cont’d) ._

Possible cause

Oil leak

PCV line clogged

Piston rings worn or damaged

Valve stem and guide worn

Valve stem seal worn

Fuel leak

Air cleaner clogged

Incorrect ignition timing

EFI system problems

l Injector faulty

0 Deceleration fuel cut system faulty

Idle speed too high

Spark plugs faulty

EGR system always on

Low compression

Tires improperly inflated

Clutch slips

Brakes drag

Incorrect idle speed

Incorrect ignition timing

‘Vacuum leaks

0 PCV hoses

0 (w/ EGR)

EGR valve ’

0 Intake manifold

l Air intake chamber

l Throttle body

EFI system problems Remedy

Repair as necessary

Check PCV system

Check rings

Check valves

Check seals ~’

Repair as necessary

Check air cleaner

Reset timing

Repair as necessary

Check ISC system

Inspect plugs

Check EGR system

Check compression

Inflate tires to proper pressun

Troubleshoot clutch

Troubleshoot brakes

Check ISC system

Reset timing

Repair as necessary

Repair as necessary Page

EM-65

EM-37

EM-37

EM-7

EM-l 7

FI-108

IG-7

M-26, 2’

FI-108

EM-l 7

Page 182 of 346

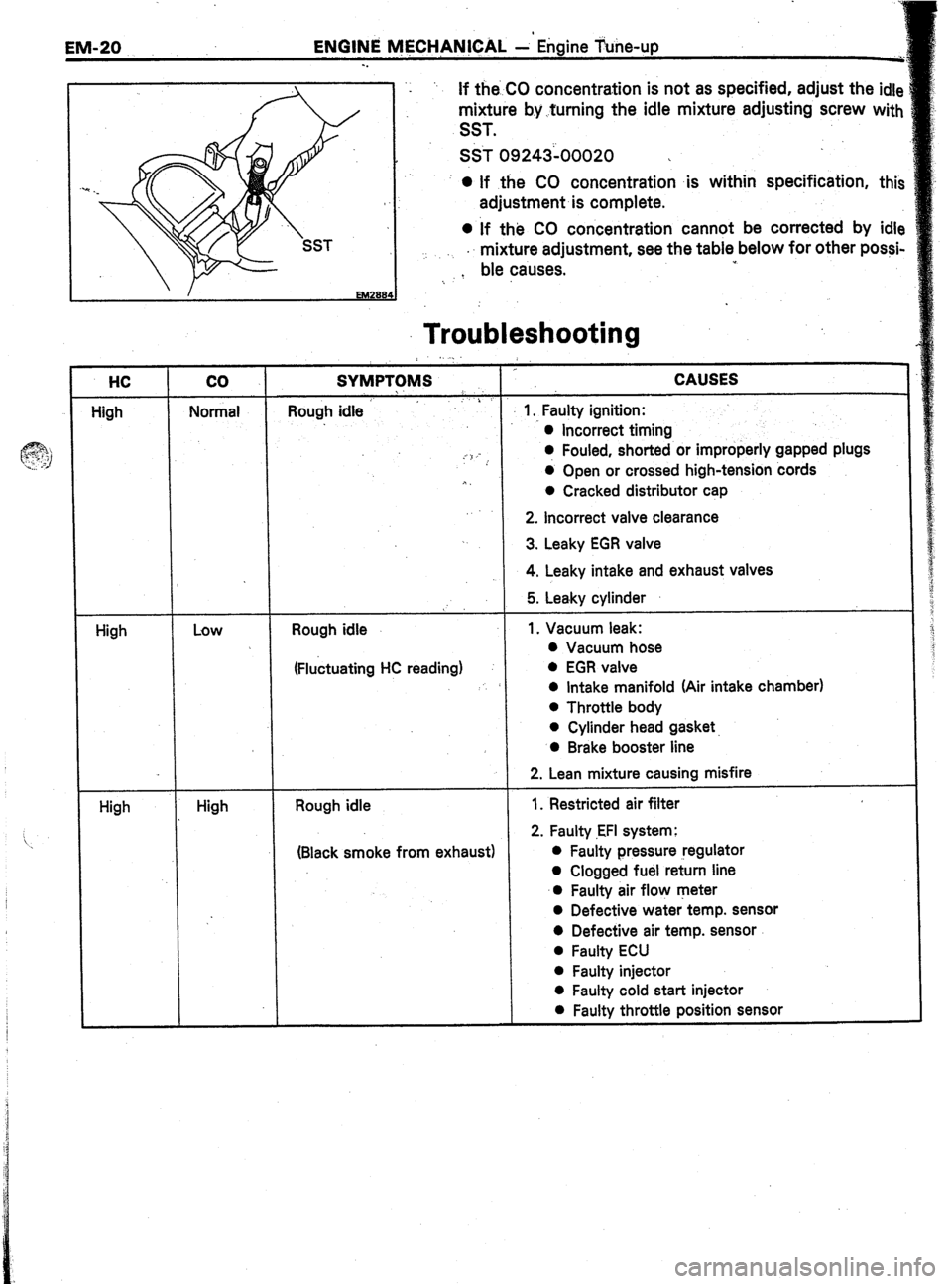

EM-20 ENGIN lVlECHAN!CAL - Engine Tune-up

-.

EM288

c

HC

Aigh

High

High co

Normal

Low

High ‘- ‘, If the CO concentration is not as specified, adjust the idle

mixture by.furning the idle mixture adjusting screw with

SST.

SST 09243-00020 >

0 If the CO concentration is within specification, this

adjustment is complete.

l if the CO concentration cannot be corrected by idle

mixture adjustment, see the table below for other possi-

t ble causes. w

Troubleshooting

SYMPTOMS

Rough idle

’ ’

.-‘:I -

Rough idle

(Fluctuating HC reading)

Rough idle

(Black smoke from exhaust CAUSES

1. Faulty ignition:

0 Incorrect timing

0 Fouled, shorted or improperly gapped plugs

6 Open or crossed high-tension cords

0 Cracked distributor cap

2. Incorrect valve clearance

3. Leaky EGR valve

4. Leaky intake and exhaust valves

5. Lea,kv cvlinder

1. Vacuum leak:

0 Vacuum hose

0 EGR valve

0 Intake manifold (Air intake chamber)

0 Throttle body

l Cylinder head gasket,

0 Brake booster line

2. Lean mixture causing misfire

1. Restricted air filter

2. Faulty ,EFI system:

0 Faulty pressure regulator

0 Clogged fuel return line

0 Faulty air flow meter

0 Defective water temp. sensor

0 Defective air temp. sensor

0 Faulty ECU

l Faulty injector

0 Faulty cold start injector

l Faulty throttle position sensor