key TOYOTA CELICA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 196 of 346

4

EM-34 ENGINE MECHANICAL - Timing Belt

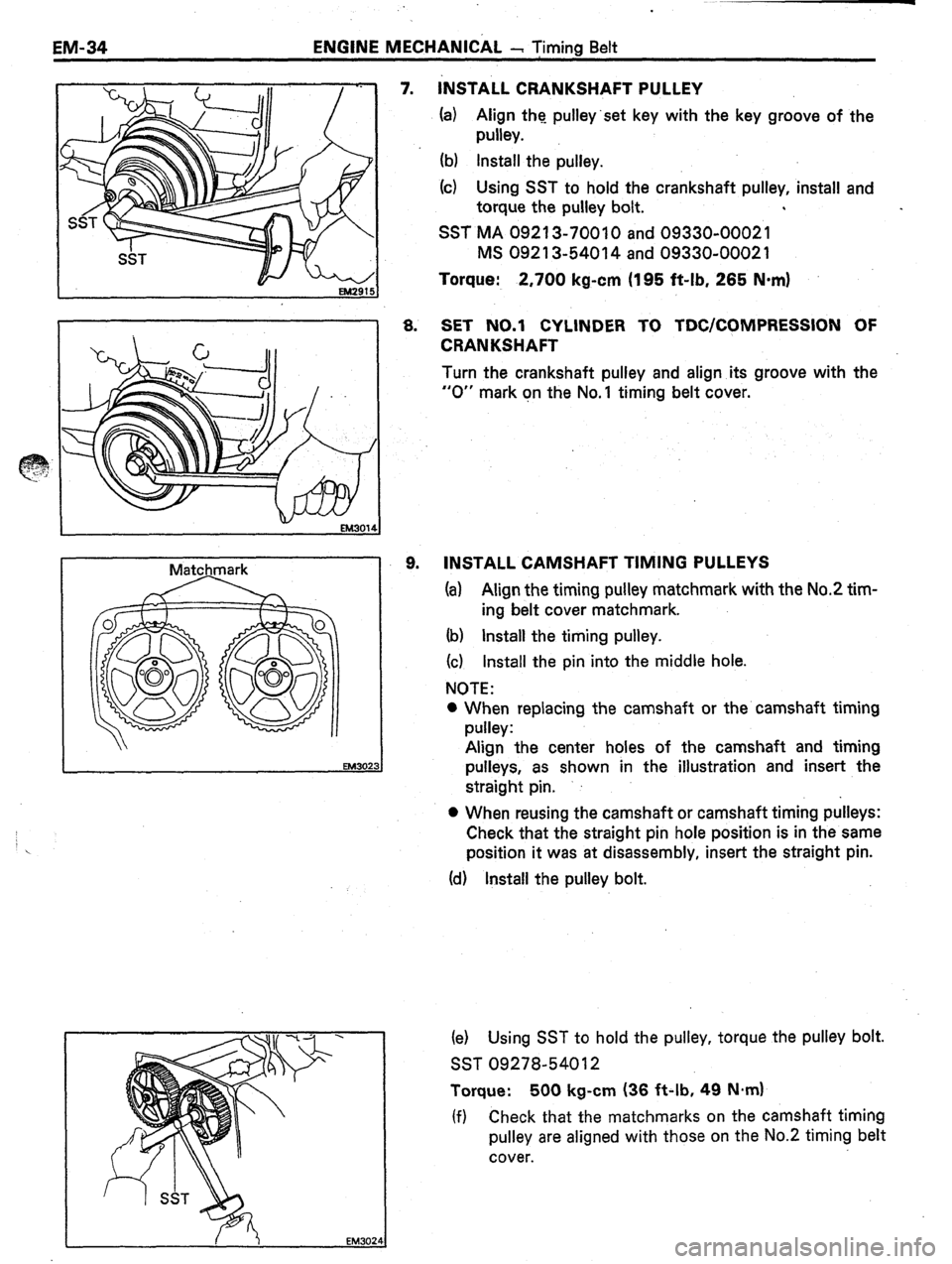

Matchmark

7. INSTALL CRANKSHAFT PULLEY

(a) Align the pulley’set key with the key groove of the

pulley.

(b) Install the pulley.

(c) Using SST to hold the crankshaft pulley, install and

torque the pulley bolt. .

SST MA 09213-70010 and 09330-00021

MS 092 13-54014 and 09330-00021

Torque: 2,700 kg-cm (195 ft-lb, 265 N-m) 8.

SET NO.1 CYLINDER TO TDC/COMPRESSION OF

CRANKSHAFT

Turn the crankshaft pulley and align its groove with the

“0” mark on the No.1 timing belt cover.

9. INSTALL CAMSHAFT TIMING PULLEYS

(a) Align the timing pulley matchmark with the No.2 tim-

ing belt cover matchmark.

(b) Install the timing pulley.

(c) Install the pin into the middle hole.

NOTE:

l When replacing the camshaft or the camshaft timing

pulley:

Align the center holes of the camshaft and timing

pulleys, as shown in the illustration and insert the

straight pin.

l When reusing the camshaft or camshaft timing pulleys:

Check that the straight pin hole position is in the same

position it was at disassembly, insert the straight pin.

(d) Install the pulley bolt.

(e) Using SST to hold the pulley, torque the pulley bolt.

SST 09278-54012

Torque: 500 kg-cm (36 ft-lb, 49 N-m)

(f) Check that the matchmarks on the camshaft timing

pulley are aligned with those on the No.2 timing belt

cover.

Page 268 of 346

IG-14 IGNITION.SYSTEM - On-Vehicle Inspection (7M-GTE)

INSPECTIoN OF IGNlTlOhi COIL-

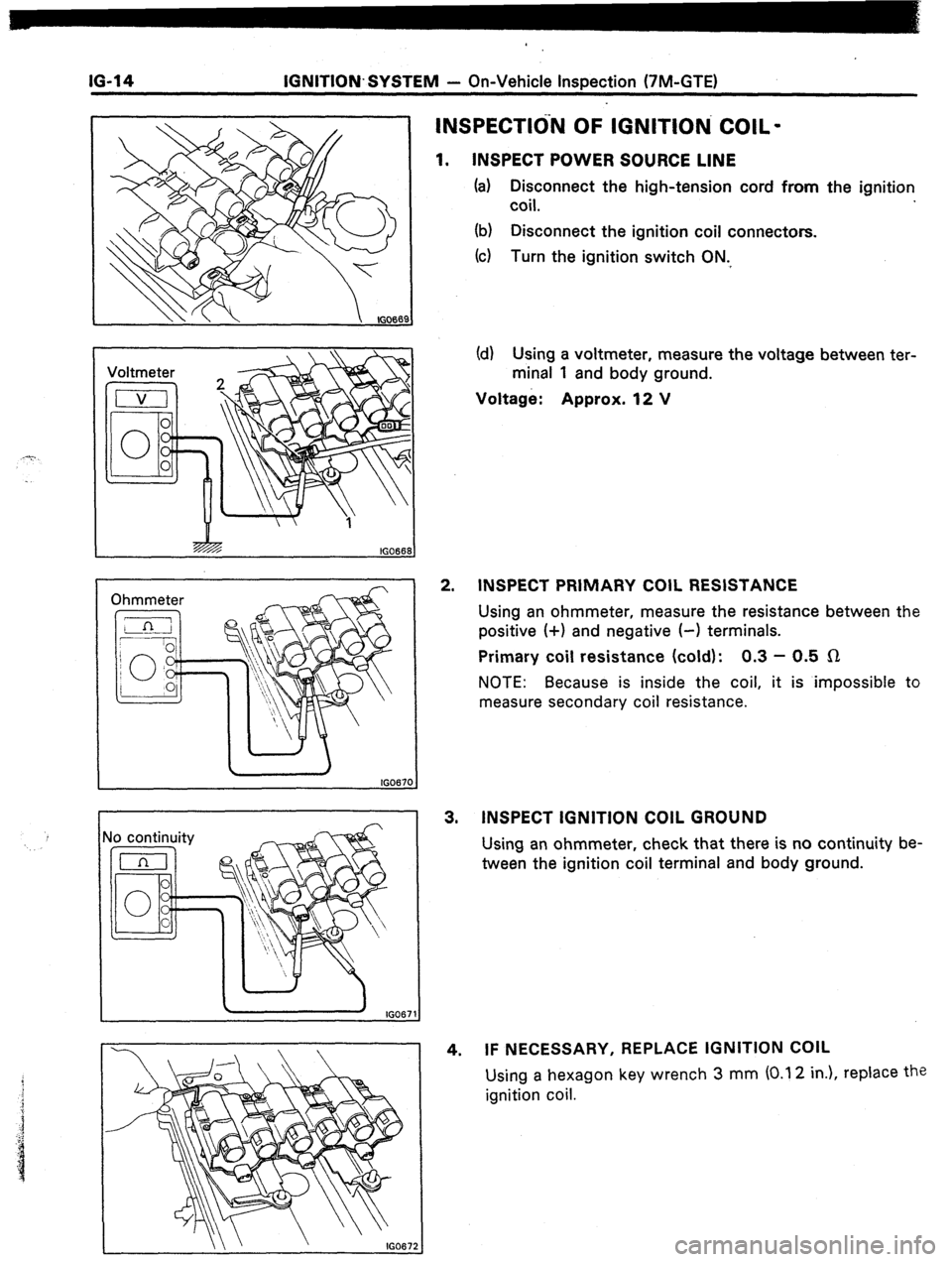

1. INSPECT POWER SOURCE LINE

(a) Disconnect the high-tension cord from the ignition

coil.

(b) Disconnect the ignition coil connectors.

(c) Turn the ignition switch ON,

Voltmeter

ccl

0

!I

0 0

dz 160668

I IGOt

I - IG067

I \ ’ IG087'

(d) Using a voltmeter, measure the voltage between ter-

minal 1 and body ground.

Voltage: Approx. 12 V

2. INSPECT PRIMARY COIL RESISTANCE

Using an ohmmeter, measure the resistance between the

positive (+I and negative (-1 terminals.

Primary coil resistance (cold): 0.3 - 0.5 R

NOTE: Because is inside the coil, it is impossible to

measure secondary coil resistance.

3. INSPECT IGNITION COIL GROUND

Using an ohmmeter, check that there is no continuity be-

tween the ignition coil terminal and body ground.

4. IF NECESSARY, REPLACE IGNITION COIL

Using a hexagon key wrench 3 mm (0.12 in.), replace the

ignition coil.

Page 290 of 346

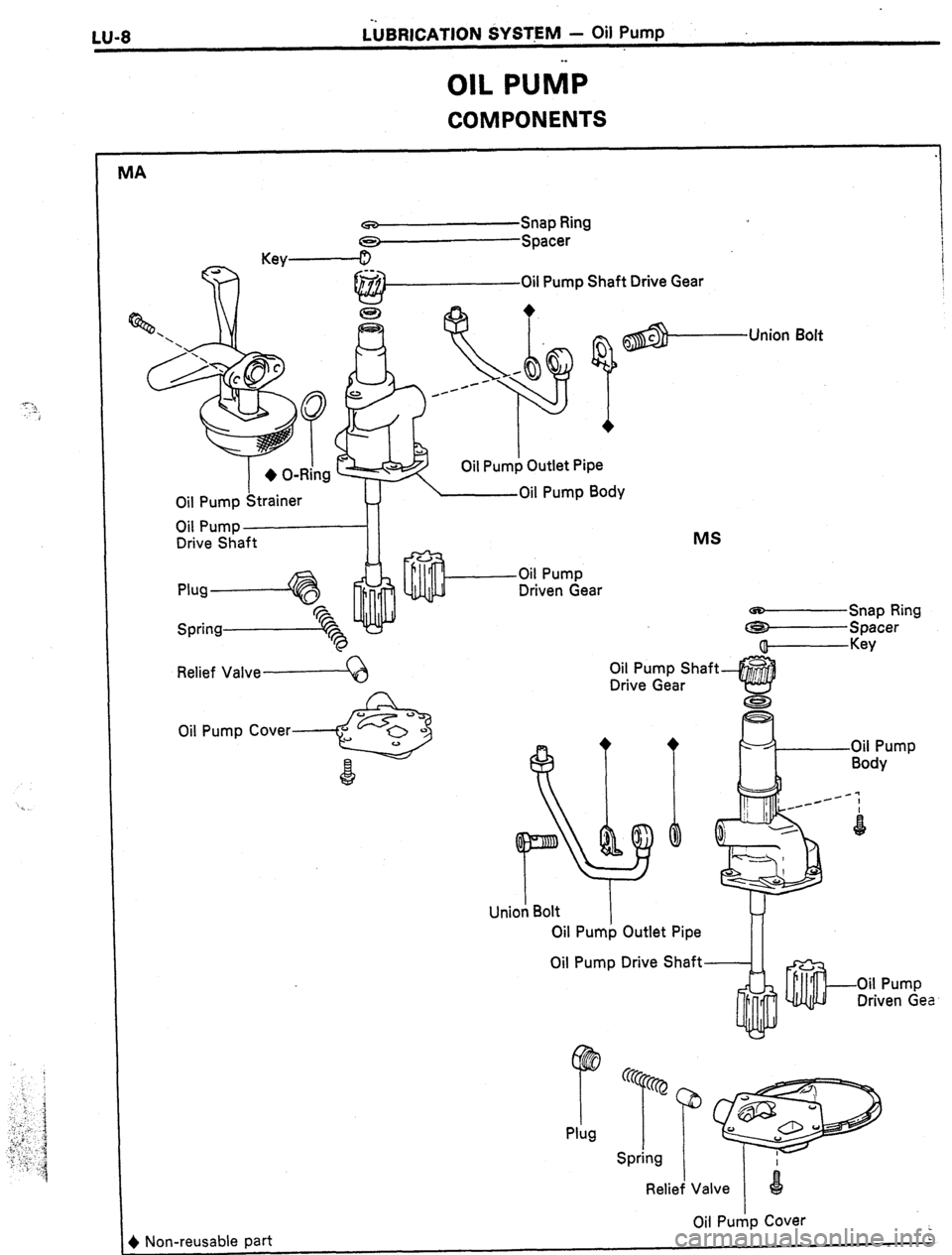

LU-8 LilBRIcATION SYSTEM - Oil Pump

OIL PUhiP

COMPONENTS

Snap Ring

Oil Pump Shaft Drive Gear

Union Bolt

MS

Relief Valve:Q Iriven Gear

-Snap Ring

cs Spacer

- @------Key

Oil Pump Cover-9

Oil Pump Outlet Pipe

Oil Pump Drive Shaft

Oil Pump Cover

+ Non-reusable part

Page 292 of 346

LUBRlCATlON SYSTEM - Oil Pump

LUO531

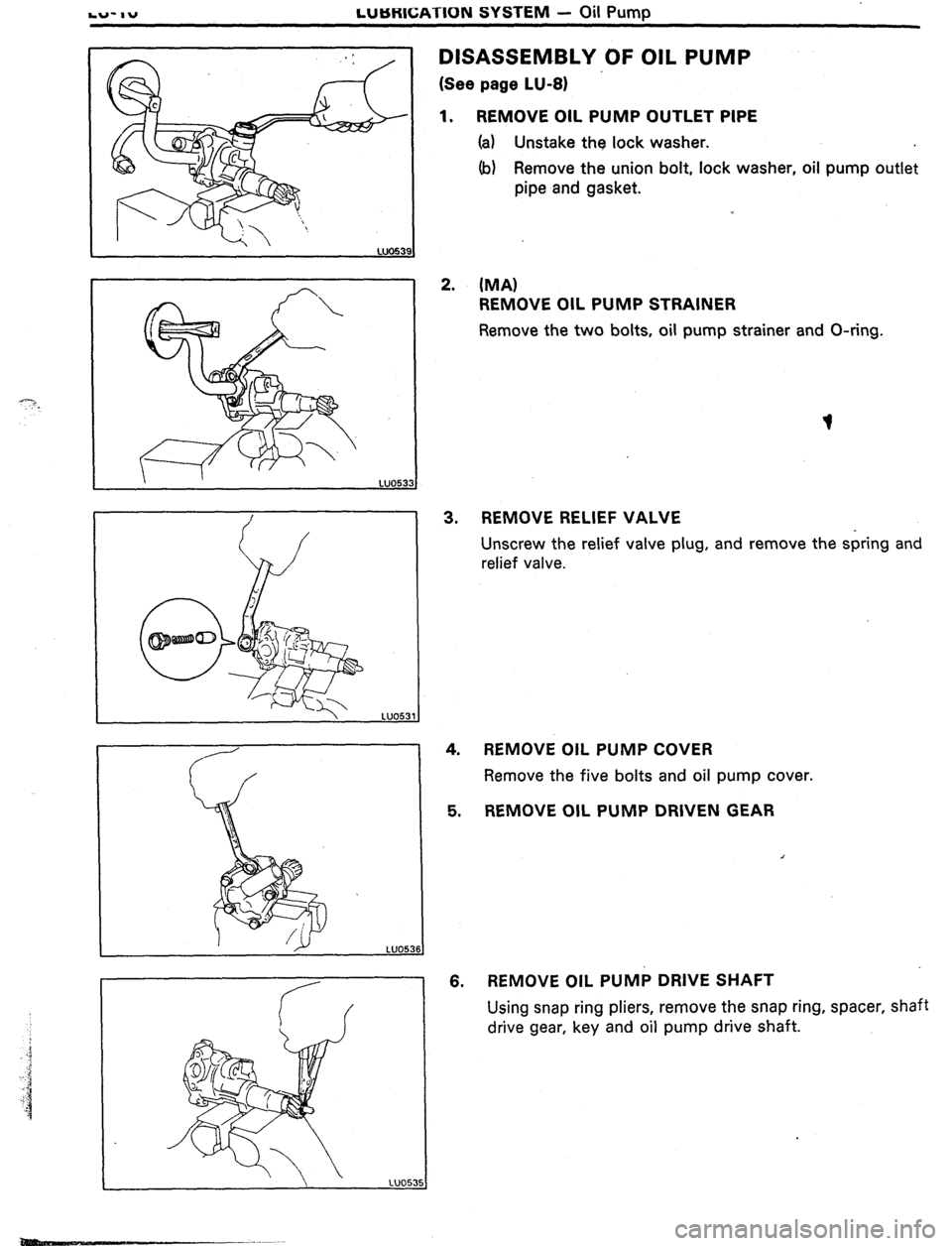

DISASSEMBLY OF OIL PUMP

(See page LU-8)

1. REMOVE OIL PUMP OUTLET PIPE

(a) Unstake the lock washer.

(b) Remove the union bolt, lock washer, oil pump outlet

pipe and gasket.

2. (MA)

REMOVE OIL PUMP STRAINER

Remove the two bolts, oil pump strainer and O-ring.

3. REMOVE RELIEF VALVE

Unscrew the relief valve plug, and remove the spring and

relief valve.

4.

REMOVE

OIL PUMP COVER

Remove the five bolts and oil pump cover.

5. REMOVE OIL PUMP DRIVEN GEAR

6. REMOVE OIL PUMP DRIVE SHAFT

Using snap ring pliers, remove the snap ring, spacer, shaft

drive gear, key and oil pump drive shaft.

?

Page 294 of 346

LU-12

-.

LUBRICATION SYSTEM - Oij Pump

LUOJS

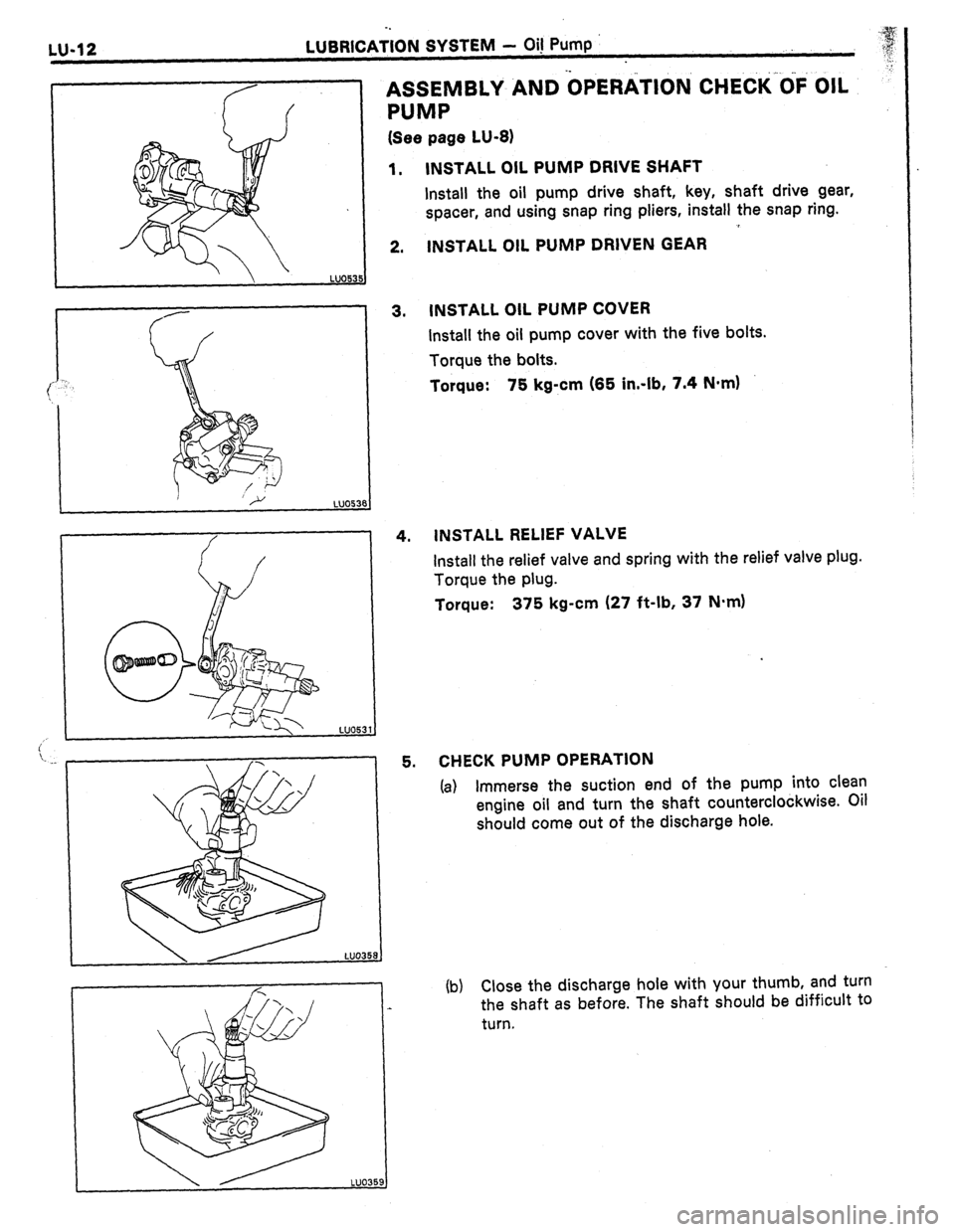

ASSEMBLY AND OPERATION CHECK OF OIL

”

PUMP

(See page LU-8)

5. INSTALL OIL PUMP DRIVE SHAFT

Install the oil pump drive shaft, key, shaft drive gear,

spacer, and using snap ring pliers, install the snap ring.

INSTALL OIL PUMP DRIVEN GEAR

INSTALL OIL PUMP COVER

Install the oil pump cover with the five bolts.

Torque the bolts.

Torque: 75 kg-cm (65 in.-lb, 7.4 N-m)

INSTALL RELIEF VALVE

Install the relief valve and spring with the relief valve plug.

Torque the plug.

Torque:

375 kg-cm (27 ft-lb, 37 N.m)

CHECK PUMP OPERATION

(a) Immerse the suction end of the pump into clean

engine oil and turn the shaft counterclockwise. Oil

should come out of the discharge hole.

(b) Close the discharge hole with your thumb, and turn

the shaft as before. The shaft should be difficult to

turn.