oil dipstick TOYOTA CELICA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 42 of 346

-8 EFI SYSTEM -.- Inspection Precautions

IF VEHICLE IS EQUIPPED WITH MOBILE

RADIO SYSTEM (HAM, CB, ETC)

The ECU has been designed so that it will not be affected by

outside interference.

However, if your vehicle is equipped with a CB radio

transceiver, etc. (even one with about 10 W output), it may, at

times, have an affect upon ECU operation, especially if the

antenna and feeder are installed nearby.

Therefore, observe the following precautions:

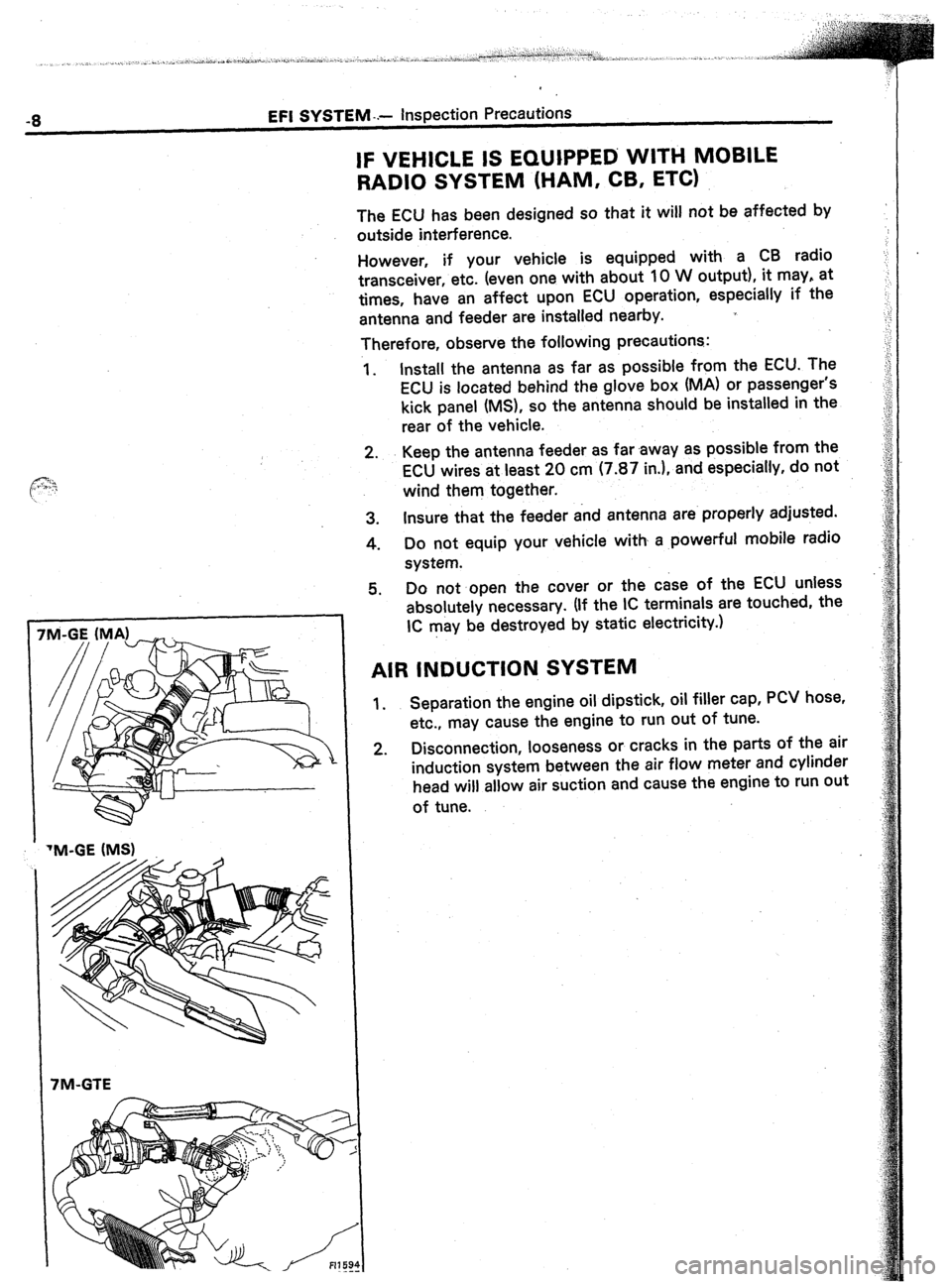

1. Install the antenna as far as possible from the ECU. The

ECU is located behind the glove box (MA) or passenger’s

kick panel (MS), so the antenna should be installed in the

rear of the vehicle.

2. Keep the antenna feeder as far .away as possible from the

ECU wires at least 20 cm (7.87 in.), and especially, do not

wind them together.

3. Insure that the feeder and antenna are properly adjusted.

4. Do not equip your vehicle with a powerful mobile radio

system.

Do not open the cover or the case of the ECU unless

absolutely necessary. (If the IC terminals are touched, the

. . .

IC may be destroyed by static electricity.1

AIR INDUCTION SYSTEM

1.

2. Separation the engine oil dipstick, oil filler cap, PCV hose,

etc., may cause the engine to run out of tune.

Disconnection, looseness or cracks in the parts of the air

induction system between the air flow meter and cylinder

head will allow air suction and cause the engine to run out

of tune.

TM-GE (MS)

7M-GTE

Page 48 of 346

EFI SYSTEM - Troubleshootina

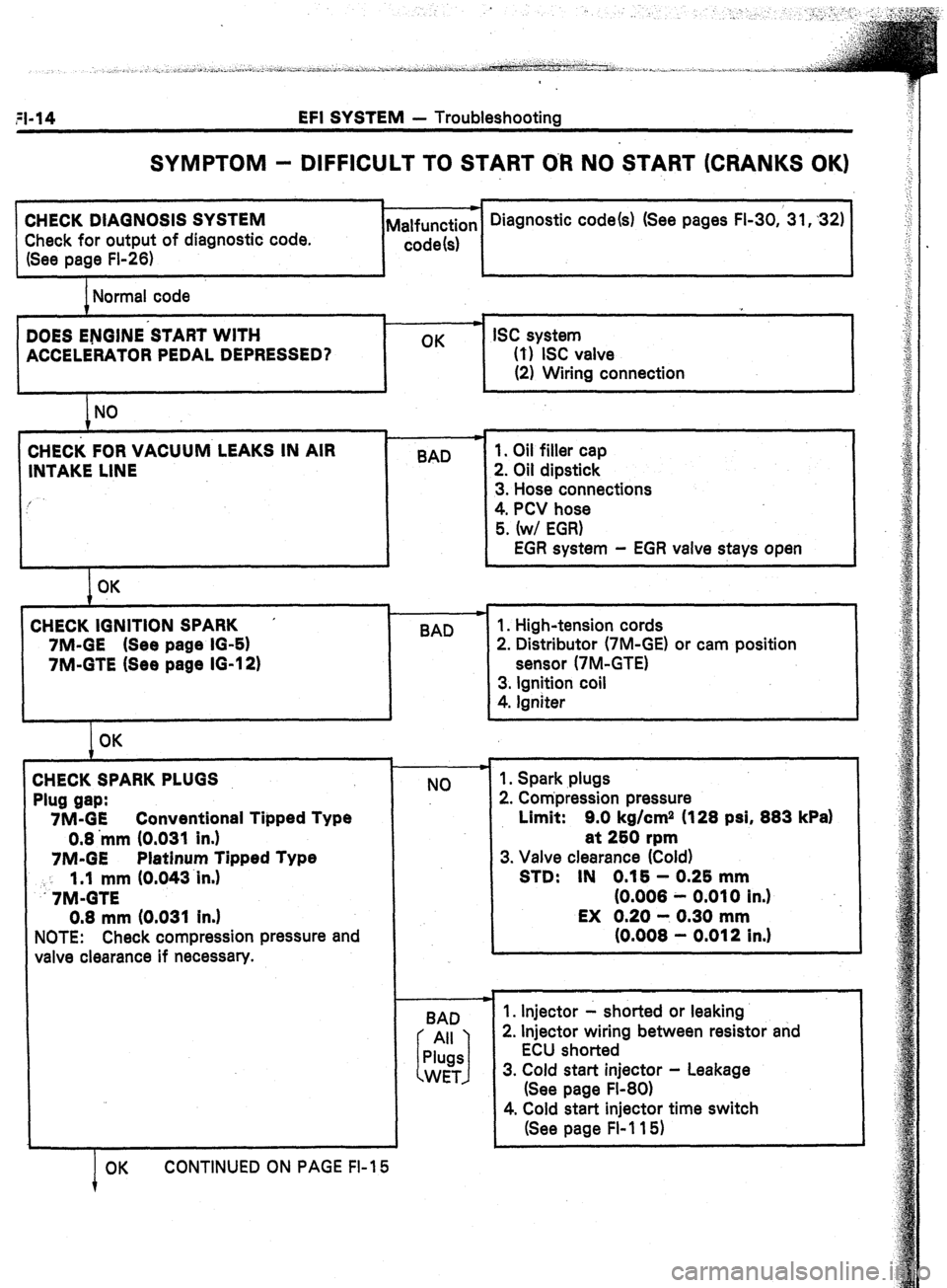

SYMPTOM - DIFFICULT TO START O-R NO START (CRANKS OK)

CHECK DIAGNOSIS SYSTEM

Check for output of diagnostic code.

(See page FI-26) Diagnostic code(s) (See pages FI-30,‘31,32)

Normal code

DOES ENGINE’START WITH

ACCELERATORPEDALDEPRESSED? OK ISC system

0) ISC valve

(2) Wiring connection

i NO I

CHECK FOR VACUUM LEAKS IN AIR I

BAD

INTAKE LINE

I OK

CHECK IGNITION SPARK ’

7M-GE (See page IO-61

7M-GTE (See page IG-12)

t OK

CHECKSPARKPLUGS

Plug gap:

7M-GE Conventional Tipped Type

0.8 ‘mm (0.031 In.)

7M-GE Platinum Tipped Type

: : 1.1 mm (0.043~in.)

.7M-GTE

0.8 mm (0.031 In.)

NOTE: Check compression pressure and

valve clearance if necessary.

OK CONTINUED ON PAGE FI-15

!

I

.

BAD 1. Oil filler cap

2. Oil dipstick

3. Hose connections

4. PCV hose

5. (w/ EGR)

EGR system - EGR valve stays open

1. High-tension cords

2. Distributor (‘IM-GE) or cam position

sensor (7M-GTE)

3. Ignition coil

4. Igniter

+

NO

BAD 1. Spark plugs

2. Compression pressure

Limit: 9.0 kg/cm2 (128 psi, 883 kPa)

at 250 rpm

3. Valve clearance (Cold)

STD: IN 0.16 - 0.25 mm

(0.008 - 0.010 in.)

EX 0.20 - 0.30 mm

(0.008 - 0.012 in.1

1. Injector - shorted or leaking

2. Injector wiring between resistor and

ECU shorted

3. Cold start injector - Leakage

(See page Fl-80)

4. Cold start injector time switch

(See page Fl-115)

Page 55 of 346

EFI SYSTEM - Troubleshooting

FI-21

-.

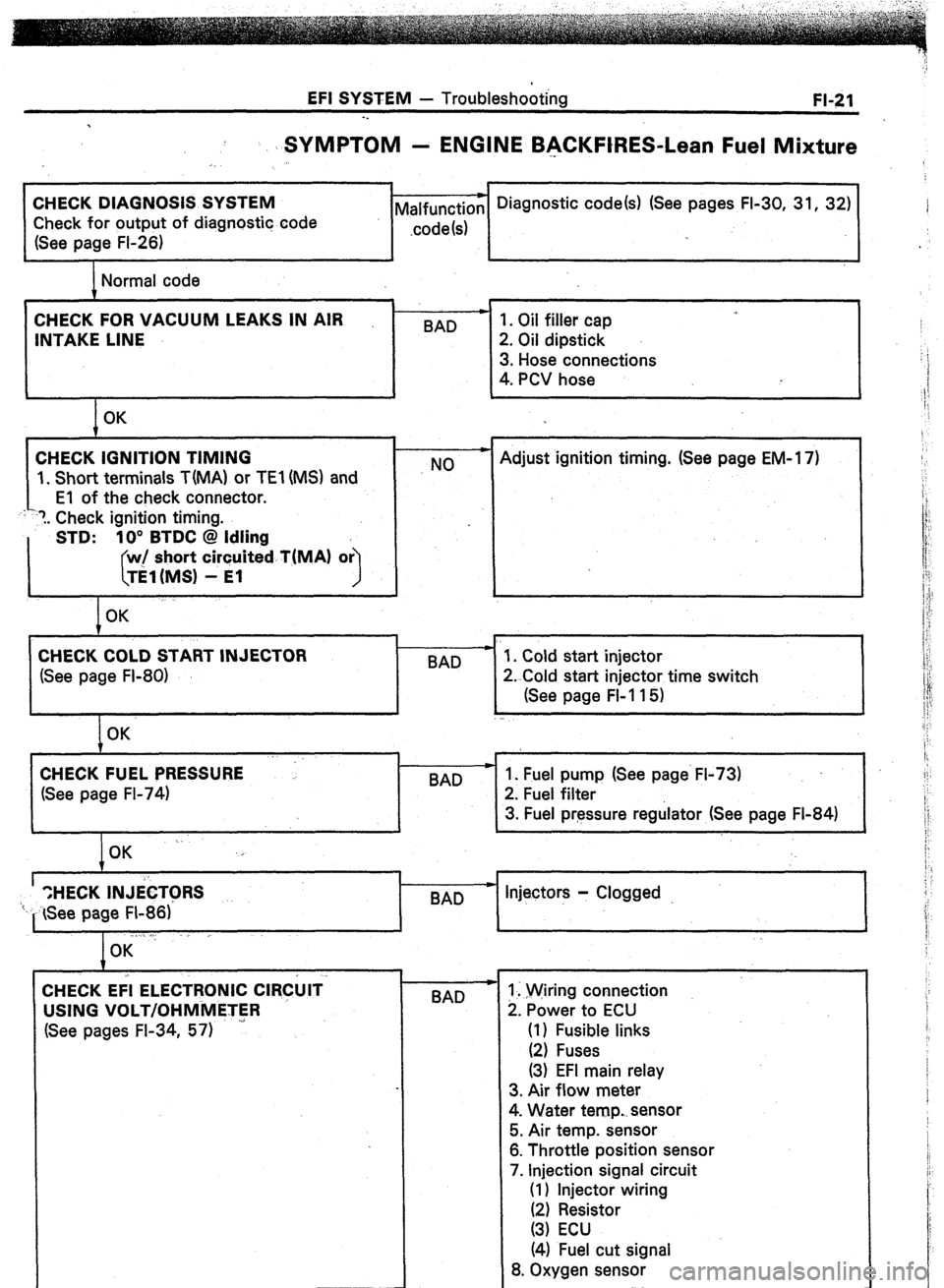

SYMPTOM - ENGINE BACKFtRES-Lean Fuel Mixture

CHECK DIAGNOSIS SYSTEM

Check for output of diagnostic code

(See page FI-26) Malfunction --) Diagnostic code(s) (See pages FI-30, 31, 32)

.code 1s) j

,

Normal code

CHECK FOR VACUUM LEAKS IN AIR

INTAKE LINE

1. Short terminals T(MA) or TEl (MS) and BAD -

NO 1. Oil filler cap

2. Oil dipstick

3. Hose connections

4. PCV hose

Adjust ignition timing. (See page EM-1 7)

1. Cold start injector

2. Cold start injector time switch

(See page FI-115)

CHECK FUEL PRESSURE

(See page FI-74)

I

I

BAD 1. Fuel pump (See page‘ FI-73)

2. Fuel filter

3. Fuel pressure regulator (See page Fl-84)

I

’ “,HECK INJib

‘I- See page FI-86)’ - Injectors - Clogged

BAD

. ., .l

I OK

CHECK Eii ELECTRONIC ClR&lT

USING VOLT/OHMMETER

(See pages FI-34, 57)

4

BAD 1. Wiring connection

2. Power to ECU

(1) Fusible links

(2) Fuses

(3) EFI main relay

3. Air flow meter

4. Water temp. sensor

5. Air temp. sensor

6. Throttle position sensor

7. Injection signal circuit

(1) Injector wiring

Ii, zesstor

(4) Fuel cut signal

8. Oxygen sensor

Page 203 of 346

.

ENGINE MECHANICAL - Cylinder Head

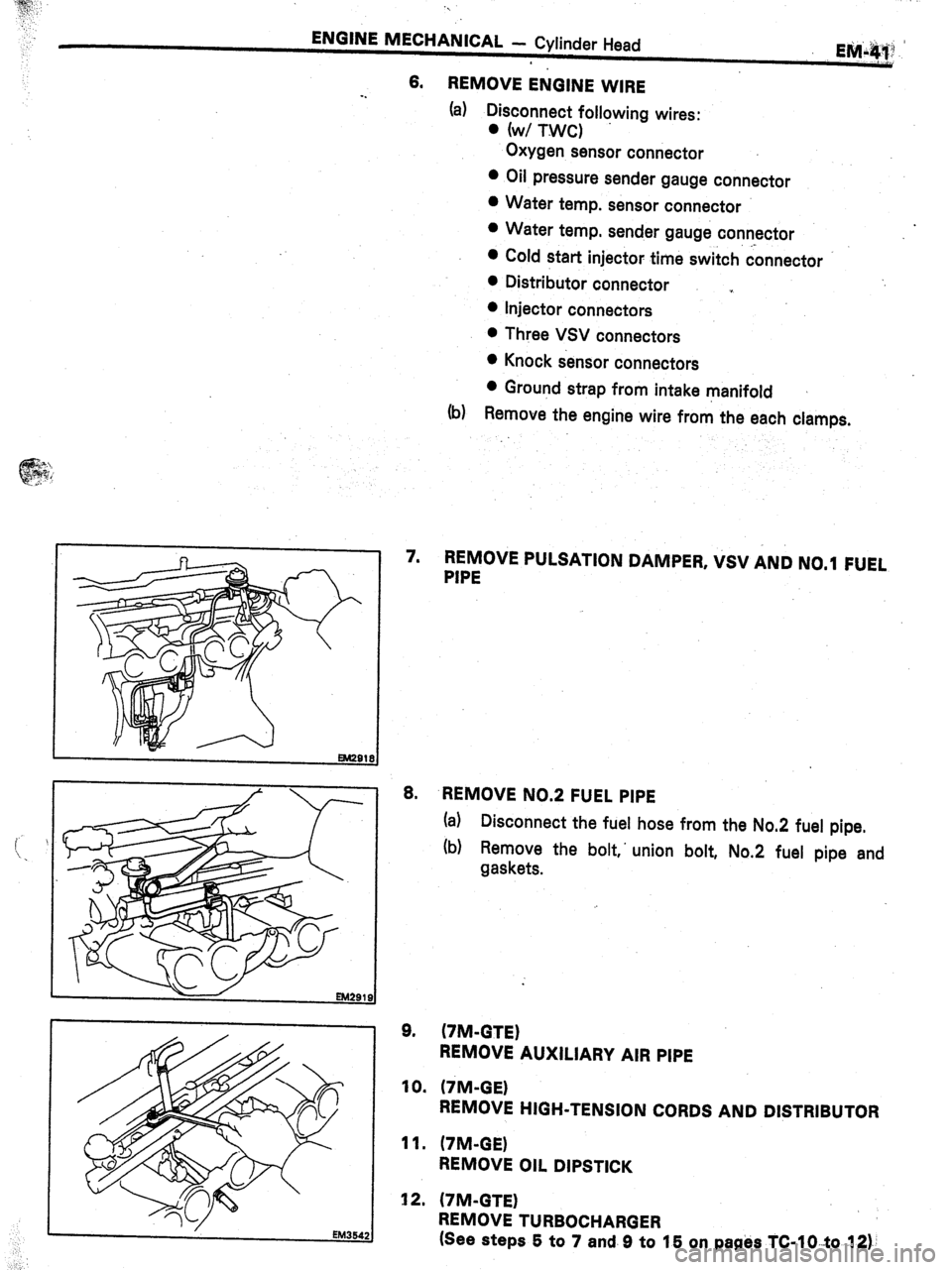

-. 6. REMOVE ENGINE WIRE

(a) Disconnect following wires:

. fw/ TWC)

Oxygen sensor connector

l Oil pressure sender gauge connector

l Water temp. sensor connector

l Water temp. sender gauge connector

_-

l Cold start injector time switch connector

l Distributor connector

.,

l Injector connectors

l Three VSV connectors

l Knock sensor connectors

l Ground strap from intake manifold

(b) Remove the engine wire from the each clamps.

7.

REMOVE PULSATION DAMPER, VSV AND NO.1 FUEL

PIPE

6.

REMOVE NO.2 FUEL PIPE

(a) Disconnect the fuel hose from the No.2 fuel pipe.

(b) Remove the bolt,’ union bolt, No.2 fuel pipe and

gaskets.

9. (7M-GTE)

REMOVE AUXILIARY AIR PIPE

10. (7M-GE)

REMOVE HIGH-TENSION CORDS AND DISTRIBUTOR

11. (7M-GE)

REMOVE OIL DIPSTICK

12. (7M-GTE)

REMOVE TURBOCHARGER

(See steps 5 to 7 and 9 to 15 on pages TC-IO-to 12):

Page 223 of 346

ENGINE MECHANICAL- - .Cyli,nder Head

I.

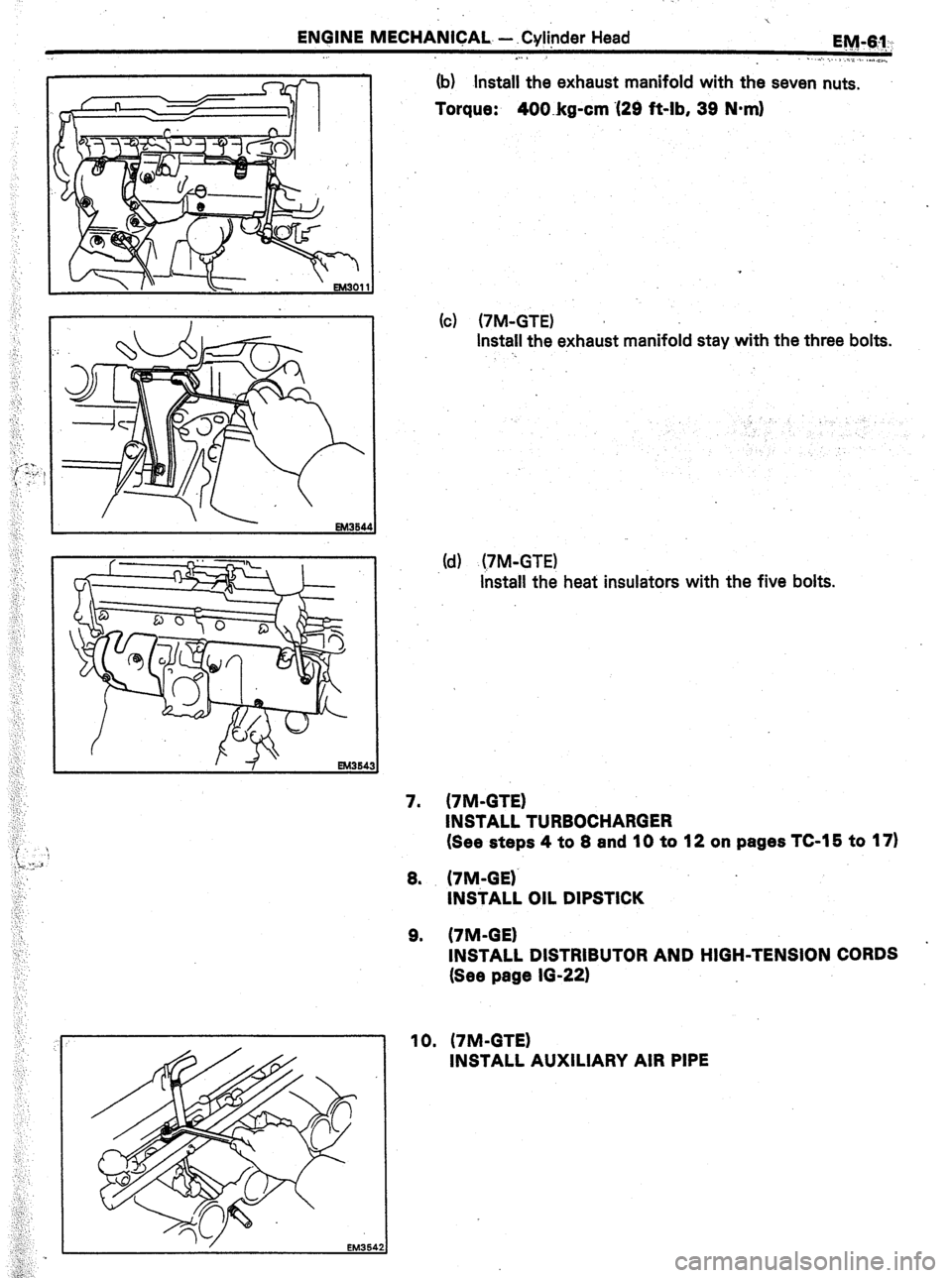

(b) Install the

exhaust manifold with the seven nuts.

Torque: 400.kg-cm ‘(29 ft-lb, 39 N-m)

(c) (7M-GTE)

Install the exhaust manifold stay with the three bolts.

‘.

.(d) (TM-GTE)

install the heat insulators with the five bolts.

7. (7M-GTE)

INSTALL TURBOCHARGER

(See steps 4 to 8 and 10 to 12 on pages TC-15 to 17)

8. (7M-GE)‘

INSTALL OIL DIPSTICK

9. (7M-GE)

.

INSTALL DISTRIBUTOR AND HIGH-TENSION CORDS

(See page 10-22)

Page 284 of 346

LUBRICATION SYSTEM - Description

.,LU-3

A pressure feeding lubrication system has been

adopted to supply oil to the moving parts of this

engine. The lubrication system consists of an oil

pan, oil pump, oil filter and other external parts

which supply oil to the moving parts in the engine

block. The oil circuit is shown in the illustration at

the top of the previous page. Oil from the oil pan is

pumped up by the oil pump. After it passes

through the oil filter, it is fed through the various

oil holes in the crankshaft and cylinder block. After

passing through the cylinder block and performing

its lubricating function, the oil is returned by gra-

vity to the oil pan. A dipstick on the side of the

cylinder block is provided to check the oil level.

OIL PUMP

The oil pump pumps up oil from the oil pan and

sends it under pressure to the various parts of the

engine. An oil strainer is mounted in front of the

inlet to the oil pump. The oil pump itself is a gear

pump, which uses a drive gear and driven gear

inside the pump body. When the drive gear

rotates, the driven gear rotates in the opposite

direction. When the gear teeth disengage oil is

drak n in, and when the gear teeth engage oil is

discharged.

OIL PRESSURE REGULATOR

At high engine speeds, the engine oil supplied

bY thr oil pump exceeds the capacity of the engine

10 utiiize it.

For that reason, the oil pressure regula-

tor i ,>rks to prevent an oversupply of oil. During

norm.tl oil

supply, a coil spring and valve keep the

bYPcls:s closed, but when too much oil is being fed,

the I’tt’essure becomes extremely high, overpower-

9 the force of the spring and opening the valves.

This ;:ilows the excess oil to flow through the

Yalvtj :snd return to the oil pan. Olii FILTER

The oil filter is a full flow type filter with a built-

in paper filter element. Particles of :metal ‘from

wear, a&born dirt, carbon and other impurities can ’

get in the oil during use and could cause acceler-

ated wear or siezing if allowed to circulate through

the engine. The oil filter, integrated into the oil line,

removes these impurities as the oil passes through

it. The filter is mounted outside the engine to

simplify replacement of the filter element. A relief

valve is also included ahead of the filter element to

relieve the high oil pressure in case the filter ele-

ment becomes clogged with impurities. The relief

valve opens when the oil pressure overpowers the

force of the spring. Oil passing through the relief

valve bypasses the oil filter and flows directly into

the main oil hole in the engine.

Page 286 of 346

rutmwCiA rlON SYSTEM - Oil Pressure Che,ck’:q. .’ ‘f,“,; .! . ,_ _,, __ _ ,-tiu,e

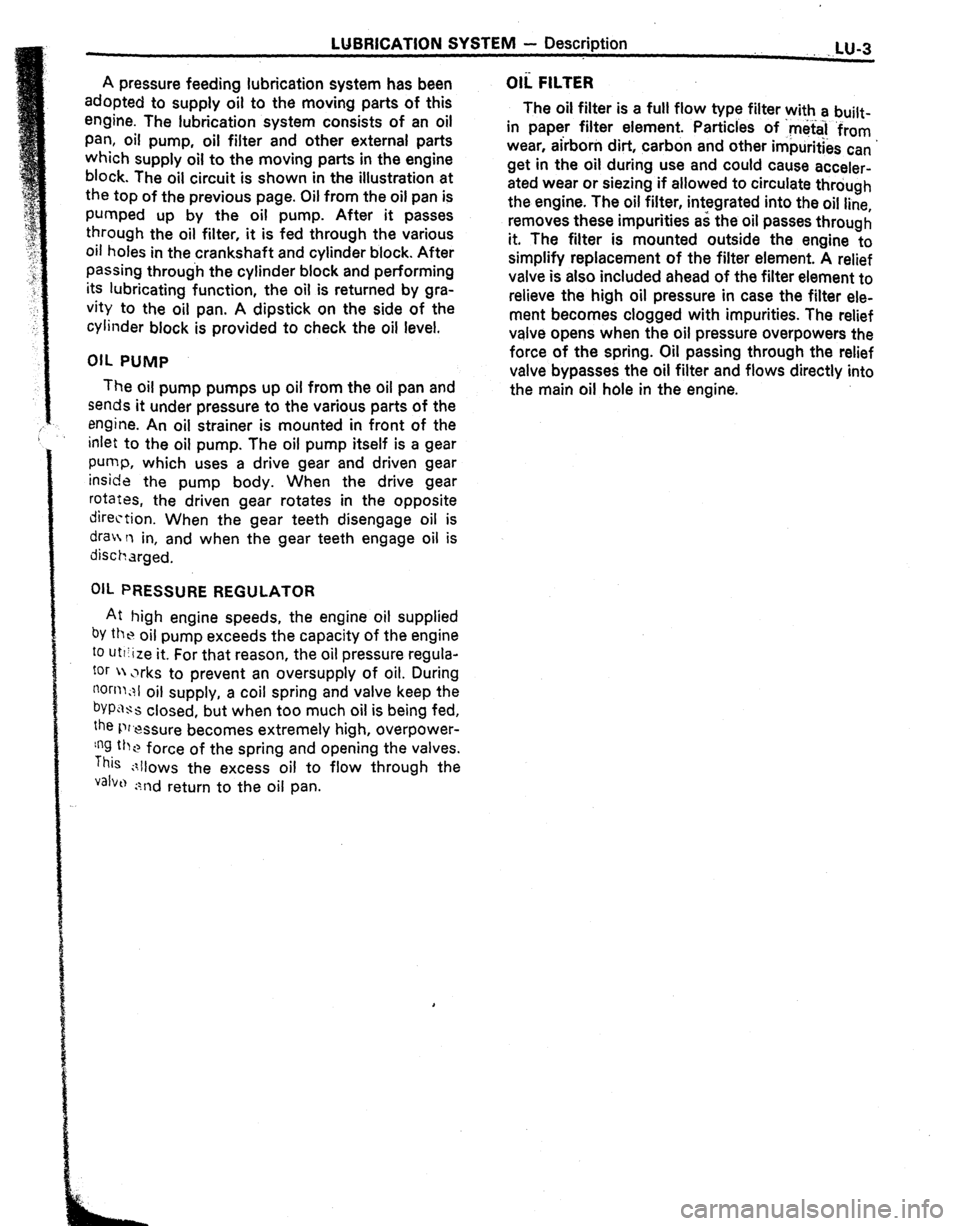

Recommended

Viscositv (SAE):

I 1 1 1 h T-29 -,a 7 “F-20 0 TEMPEAATURE LY

I I b I I I I

I

z 4 16 36

/

RANGE ANTICIPA$O B&i% NEXT OIL CHANGE 100 ._. .-- . . .

?’ OIL PR,ESSURE’($liCK . .._.

-. - -_-. _

. _ _.. _ _...

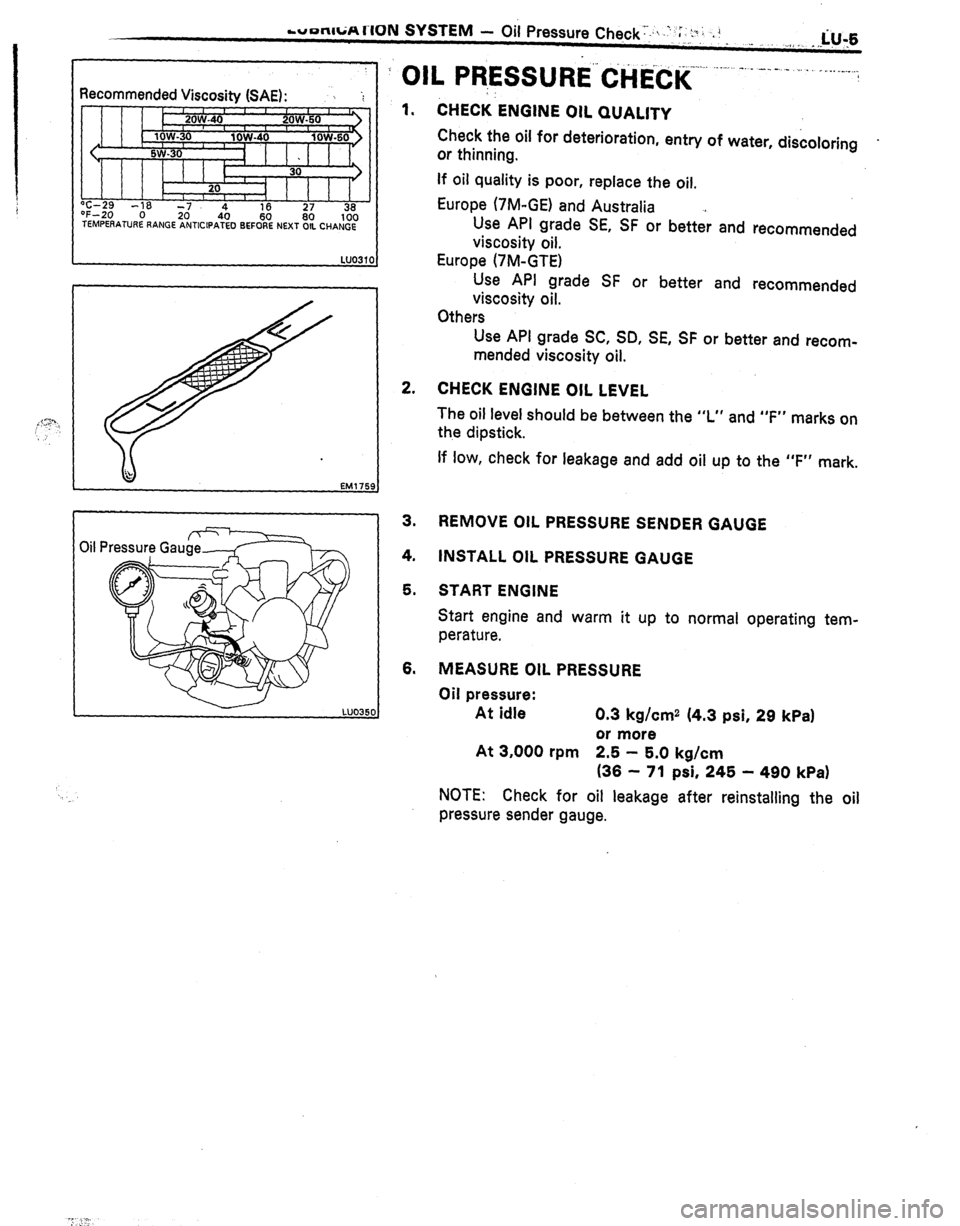

1. 1 CHECK-ENGINE OIL QUALITY

Check the oil for deterioration, entry of water, discoloring .

or thinning.

2.

3.

4.

5.

6. If oil quality is poor, replace the oil,

Europe (‘IM-GE) and Australia *

Use API grade SE, SF or better and recommended

viscosity oil.

Europe (7M-GTE)

Use API grade SF or better and recommended

viscosity oil.

Others

Use API grade SC, SD, SE, SF or better and recom-

mended viscosity oil.

CHECK ENGINE OIL LEVEL

The oil level should be between the “L” and “F” marks on

the dipstick.

If low, check for leakage and add oil up to the “F” mark.

REMOVE OIL PRESSURE SENDER GAUGE

INSTALL OIL PRESSURE GAUGE

START ENGINE

Start engine and warm it up to normal operating tem-

perature.

MEASURE OIL PRESSURE

Oil pressure:

At idle 0.3 kg/cm2 (4.3 psi, 29 kPa1

or more

At 3,000 rpm 2.5 - 5.0 kg/cm

(36 - 71 psi, 245 - 490 kPa1

NOTE: Check for oil leakage after reinstalling the oil

pressure sender gauge.

Page 291 of 346

LUbRlCATlON SYSTEM - Oil Pump

._ ul~9

LUO526

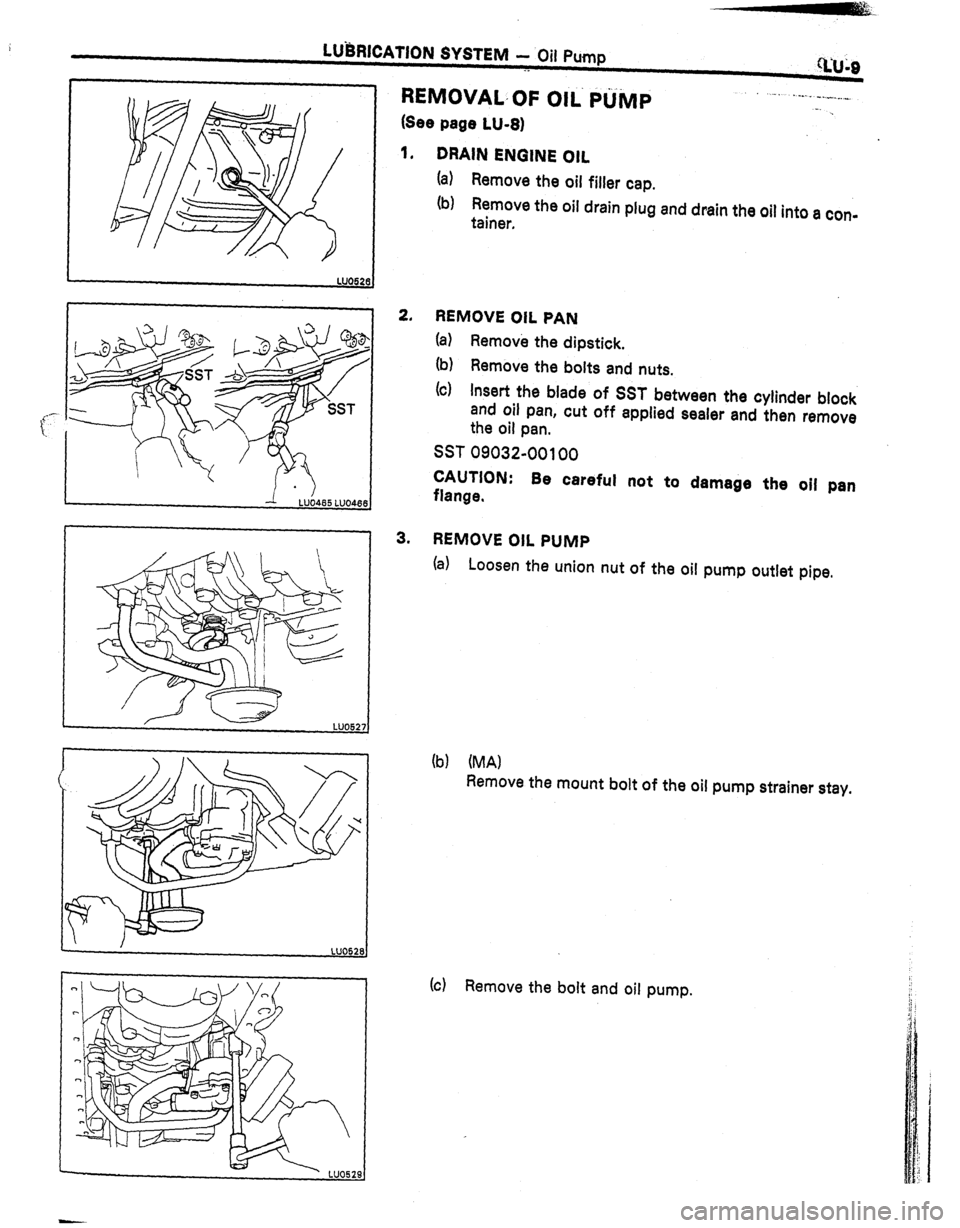

REMOVAL,OF OIli Prli&lP

(See page LU-8)

-, . .--- -._.____.

-.

1.

DRAIN ENGINE OIL

(a) Remove the oil filler cap.

(b) Remove the oil drain plug and drain the oil into a con-

tainer.

2. REMOVE OIL PAN

(a) Remove the dipstick.

(b) Remove the bolts and nuts.

(c) Insert the blade of SST between the cylinder block

and oil pan, cut off applied sealer and then remove

the oil pan.

SST 09032-00100

CAUTION: Be careful not to damage the oil pan

flange.

3. REMOVE OIL PUMP

(a) Loosen the union nut of the oil pump outlet pipe.

(b) (MA)

Remove the mount bolt of the oil pump strainer stay.

(c) Remove the bolt and oil pump.

Page 345 of 346

8 SYS

NTEM - - Turbocharger

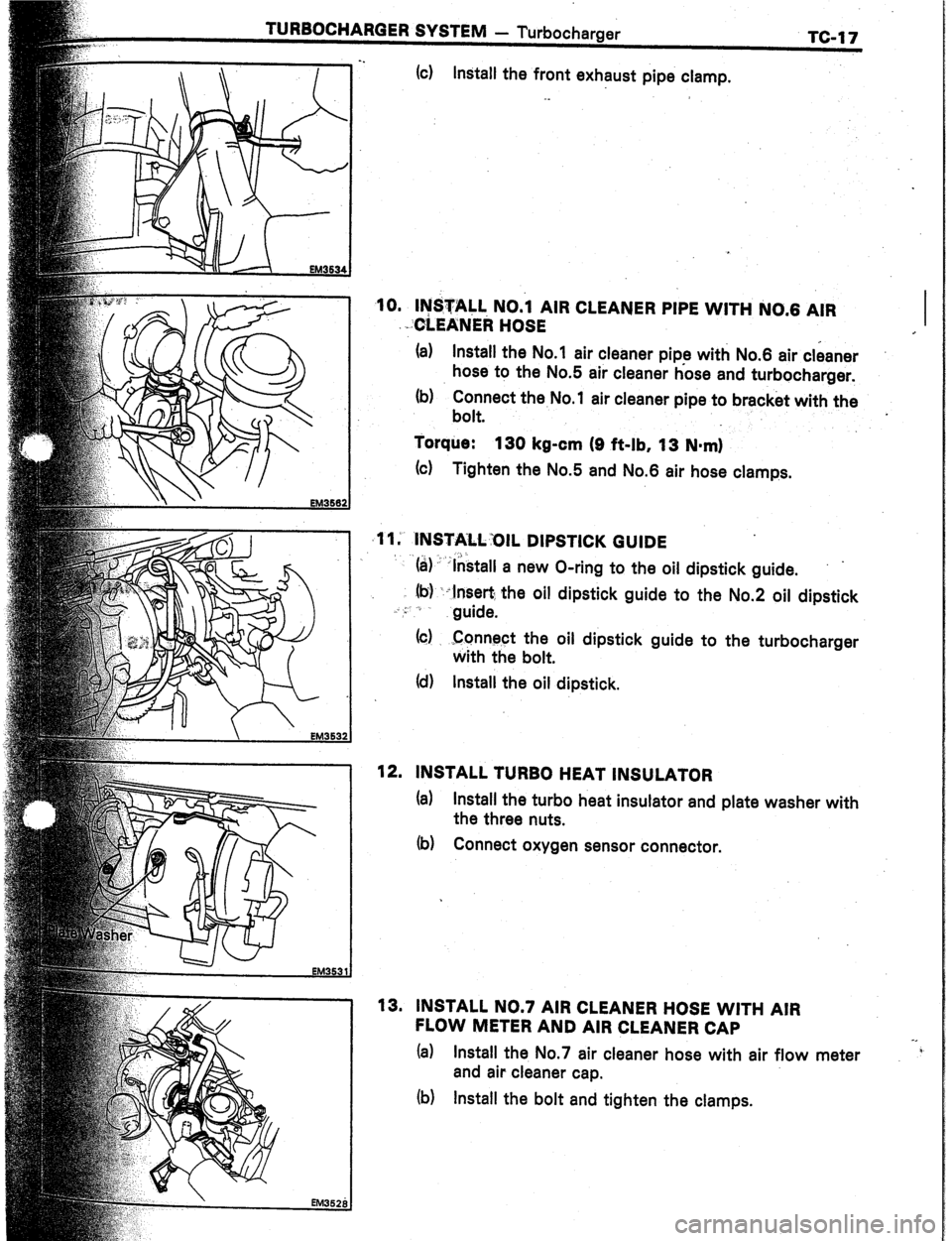

(cl Install

the front exhaust pipe

clamp. TC-17

10. Ih$TA& NO.1 AIR CLEANER PIPE WITH NO.6 AIR

.-GLEANER HOSE I

.

(a)

Install the No.1 air cleaner pipe with No.6 air cleaner

hose to the No.5 air cleaner hose and turbocharger.

(b) Connect the No.1 air cleaner pipe to bracket with the

bolt.

Torque:

130 kg-cm (9 ft-lb, 13 N-m)

(c) Tighten the No.5 and No.6 air hose clamps.

11 i INSTALL “OIL DIPSTICK GUIDE

‘(a) ‘.‘lnstall a new O-ring to the oil dipstick guide.

lb) ,-insert the oil dipstick guide to the No.2 oil dipstick

: ‘/

guide.

(c) Connect the oil dipstick guide to the turbocharger

with the bolt.

(d) Install the oil dipstick.

12. INSTALL TURBO HEAT INSULATOR

(a) Install the turbo heat insulator and plate washer with

the three nuts.

(b) Connect oxygen sensor connector.

13. INSTALL NO.7 AIR CLEANER HOSE WITH AIR

FLOW METER AND AIR CLEANER CAP

(a) Install the No.7 air cleaner hose with air flow meter

and air cleaner cap.

(b) Install the bolt and tighten the clamps.