speed sensor TOYOTA CELICA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 35 of 346

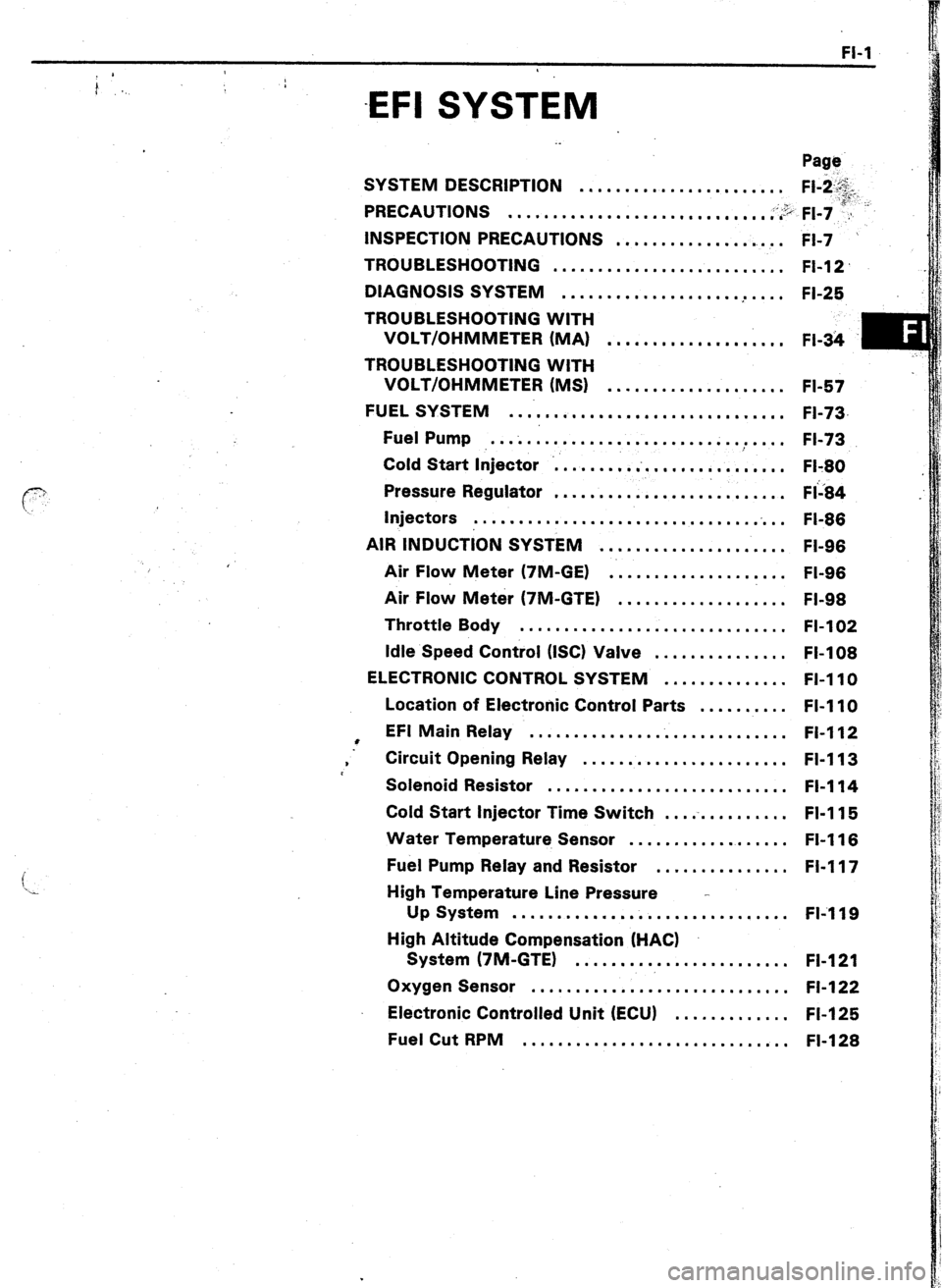

FI-1

i’.. ;

-EFI SYSTEM

i

‘x

. .

Page

SYSTEM DESCRIPTION

....................... Fl-i.&.

PRECAUTIONS

;;:“, F,-, ;a”“- .............................. . ....

INSPECTION PRECAUTIONS

FI-7 . ....................

TROUBLESHOOTING

.......................... FI-12

DIAGNOSIS SYSTEM

.................... .

.... FI-25

TROUBLESHOOTING WITH

VOLT/OHMMETER (MA)

.................... FI-34

m

.:

TROUBLESHOOTING WITH

VOLT/OHMMETER (MS)

.................... FI-57

FUEL SYSTEM

................................ FI-73,

Fuel Pump ..................................

FI-73

Cold Start Injector ...........................

Fl-80

Pressure Regulator

.......................... FI’i84 ..

Injectors

.............................. ..i ..

FI-86

AIR INDUCTION SYSTEM

..................... FI-96

Air Flow Meter (7M-GE)

..................... FI-96

Air Flow Meter (7M-GTE)

................... FI-98

Throttle Body

.............................. FI-102

Idle Speed Control (ISC) Valve

............... FI-108

ELECTRONIC CONTROL SYSTEM .............. FI-110

Location of Electronic Control Parts .......... FI-110

l EFI Main Relay

............................. Fl-112

. Circuit Opening Relay ....................... FI-113

Solenoid Resistor

........................... Fl-114

Cold Start Injector Time Switch ...............

FI-115

Water Temperature Sensor ..................

FI-116

Fuel Pump Relay and Resistor ............... FI-117

High Temperature Line Pressure -

Up System ............................... FIi119

High Altitude Compensation (HACK

System (7M-GTE)

........................ FI-121

Oxygen Sensor .............................

FI-122

Electronic Controlled Unit (ECU) .............

FI-125

Fuel Cut RPM

.............................. FI-128

Page 40 of 346

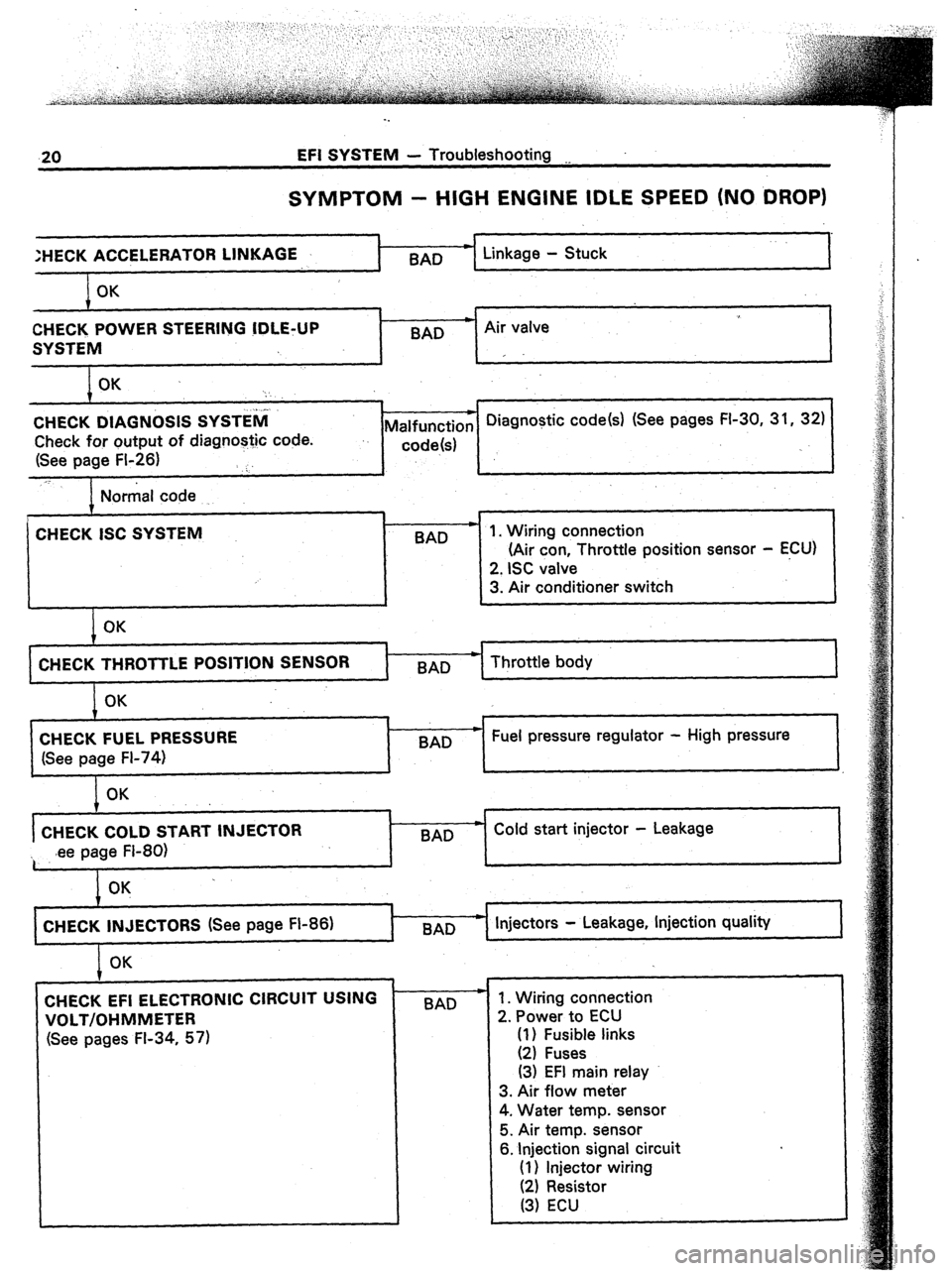

1-6 EFI SYSTEM - System Description

‘he .EFI system is composed of 3 basic sub

;ystems; Fuel Induction, Air Induction and

Ziectronic Control.

FUEL SYSTEM

An electric fuel pump supplies sufficient fuel,

under a constant pressure, to the injectors. These

injectors inject a metered quantity of fuel into the

intake manifold in accordance with signals from

the ECU (Electronic Control Unit).

AIR INDUCTION SYSTEM

The air induction system provides sufficient air for

engine operation.

[3: ‘I

i&TRONIC CONTROL SYSTEM

The 7M-GE, 7M-GTE engines are equipped wifh a

Toyota Computer Control System (TCCS) which

centrally controls the EFI, ESA, Diagnosis systems,

etc. by means of an Electronic Control Unit (ECU -

for-merly EFI computer) employing a microcom-

puter.

By means of the ECU, the TCCS controls the

following functions:

1. Electronic Fuel injection (EFI)

The ECU receivers signals from,various sen-

sors indicating changing engine operating

conditions such as:

Exhaust oxygen content (w/ TWC)

Intake air volume

i Intake air temperature

Coolant temperature

Engine rpm

Vehicle speed

Acceleration/deceleration etc.

These signals are utilized by the ECU to

determine the injection duration necessary for

an optimum air-fuel ratio.

2. Electronic Spark Advance (ESA)

The ECU is programmed with data for

optimum ignition timing under any and all

operating conditions. Using data provided by

sensors which monitor various engine func-

tions (rpm, A/C signal, coolant temperature,

etc.), the microcomputer (ECU) triggers the

spark at precisely the right instant. (See IG

section) 3. Idle Speed Control (IX)

The ECU is programmed with, target idling

speed values to respond to different engine

conditions (coolant temperature, air condi-

tioner on/off, etc.). Sensors transmit signals

to the ECU which control the flow of air

through the bypass of the throttle valve and

adjust idle speed to the target value.

(See pages FI-53, 7 1, 108) ’

4. Diagnosis

The ECU detects any malfunctions or abnor-

malities in the sensor network and tights the

“CHECK ENGINE” warning light on the instru-

ment panel. At the same time, the trouble is

identified and a diagnostic code is recorded

by the ECU.

5. Fail-Safe Function ’

In the event of computer malfunction, a back-

up circuit will take over to provide minimal

drivability. Simultaneously, the “CHECK

ENGINE” warning light will come on.

Page 46 of 346

1-12 EFI SYSTEM - Troubleshooting’

FlO48

TROUBLESH~~TI~~G

. .

TROUBLESHOOTING HlhJTS

1. Engine troubles are usually not caused by the EFI system.

When troubleshooting, always first check the condition of

the other systems.

(a) Electronic source

0 Battery

0 Fusible links

0 Fuses

(b) Body ground

(cl Fuel supply

0 Fuel leakage

0 Fuel filter

0 Fuel pump

(d) Ignition system

0 Spark plug

0 High-tension cord

l Distributor (7M-GE) or cam position sensor (7M-

GTE)

0 Igniter and ignition coil

(e) Air induction system

0 Vacuum leaks

(f) Emission control system

0 PCV system

0 EGR system (w/ EGR)

(g) Others

l Ignition timing (ESA system)

0 Idle speed (ISC system)

-r

2. The most frequent cause of problems is simply a bad don-

tact in wiring connectors. Always make sure that connec-

tions are secure.

When inspecting the connector, pay particular attention to

the following points:

(a) Check to see that the terminals are not bent.

(b) Check to see that the connector is pushed in com-

pletely and locked.

(c) Check to see that there is no signal change when the

connector is slightly tapped or wiggled.

3. Sufficiently troubleshoot for other causes before replac-

ing the ECU. The ECU is of high quality and it is expensive.

Page 54 of 346

.20 EFI SYSTEM - Troubleshooting __

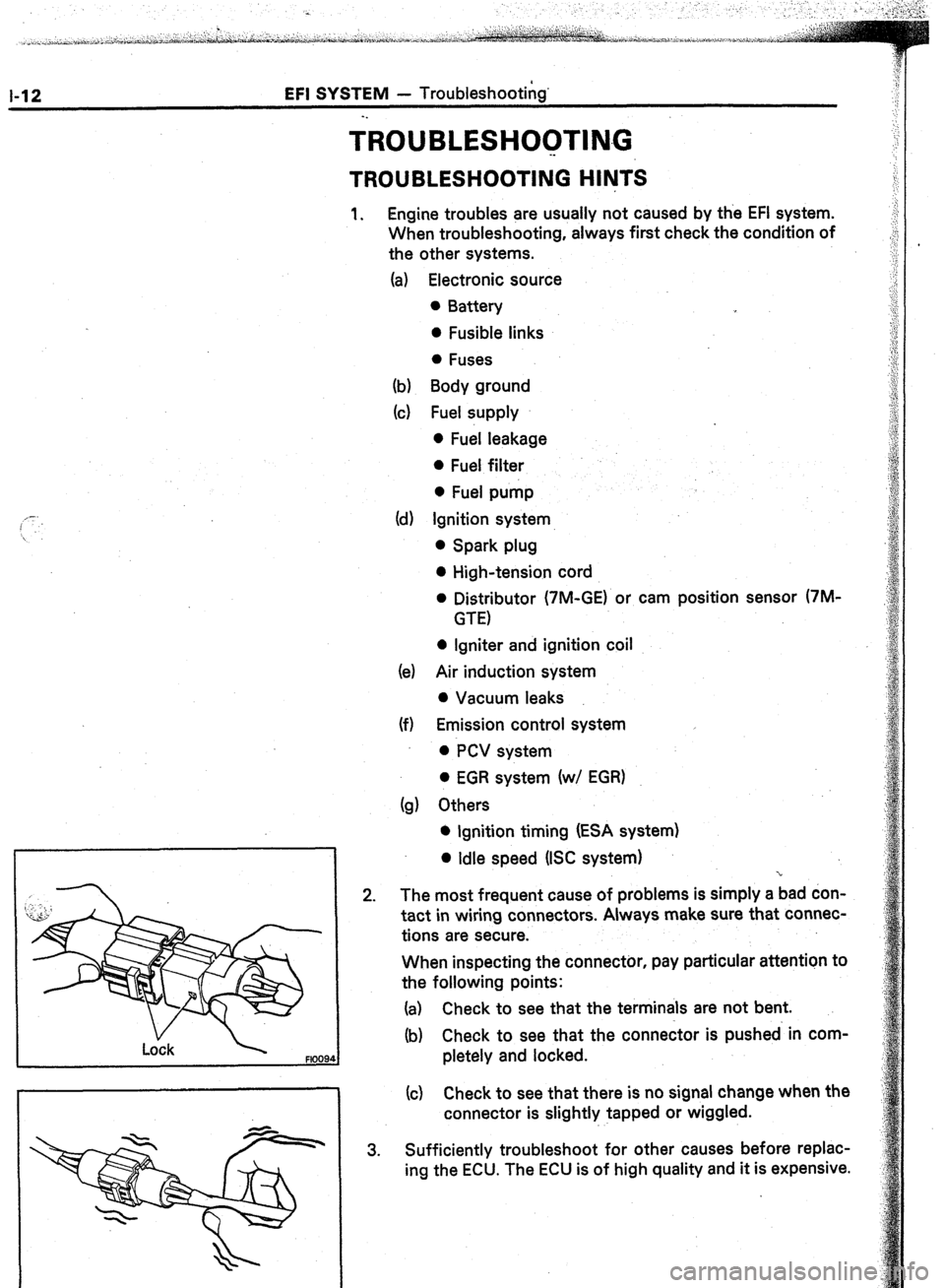

SYMPTOM - HIGH ENGINE IDLE SPEED (NO DROP)

:HECK ACCELERA

OK

CHECK POWER STEERING !DLE+JP

SYSTEM

OK .

‘:

j..l.

CHECK DIAGNOSIS SYSTEM

Check for output of diagnostic code.

(See page FI-26) ‘:.

_T I Linkage - Stuck

I

9

BAD * Air valve

I

r

* Diagnostic code(s) (See pages FI-30, 31, 32)

Malfunction

..

code!s)

Normal code

.

CHECK ISC SYSTEM

BAD

I

OK

71

(Air con Throttle posrtron sensor - ECU)

1 CHECK THROTTLE POSITION SENSOR

t-x- Throttle body

OK

CHECK FUEL PRESSURE

(See page FI-74) 7

BAD w Fuel pressure regulator - High pressure

OK

CHECK COLD START INJECTOR

~ .ee page FI-80) BAD w Cold start injector - Leakage

CHECK INJECTORS (See page FI-86)

I Injectors - Leakage, Injection quality

I OK

CHECK EFI ELECTRONIC CIRCUIT USING

VOLT/OHMMETER

(See pages FI-34, 57) BAD - 1. Wiring connection

2. Power to ECU

(1) Fusible links

(2) Fuses

(3) EFI main relay

3. Air flow meter

4. Water temp. sensor

5. Air temp. sensor

6. Injection signal circuit

(1) Injector wiring

(2) Resistor

(3) ECU

Page 62 of 346

EFI SYSTEM; Diagnosis System

S)

------) -.

I Fl281

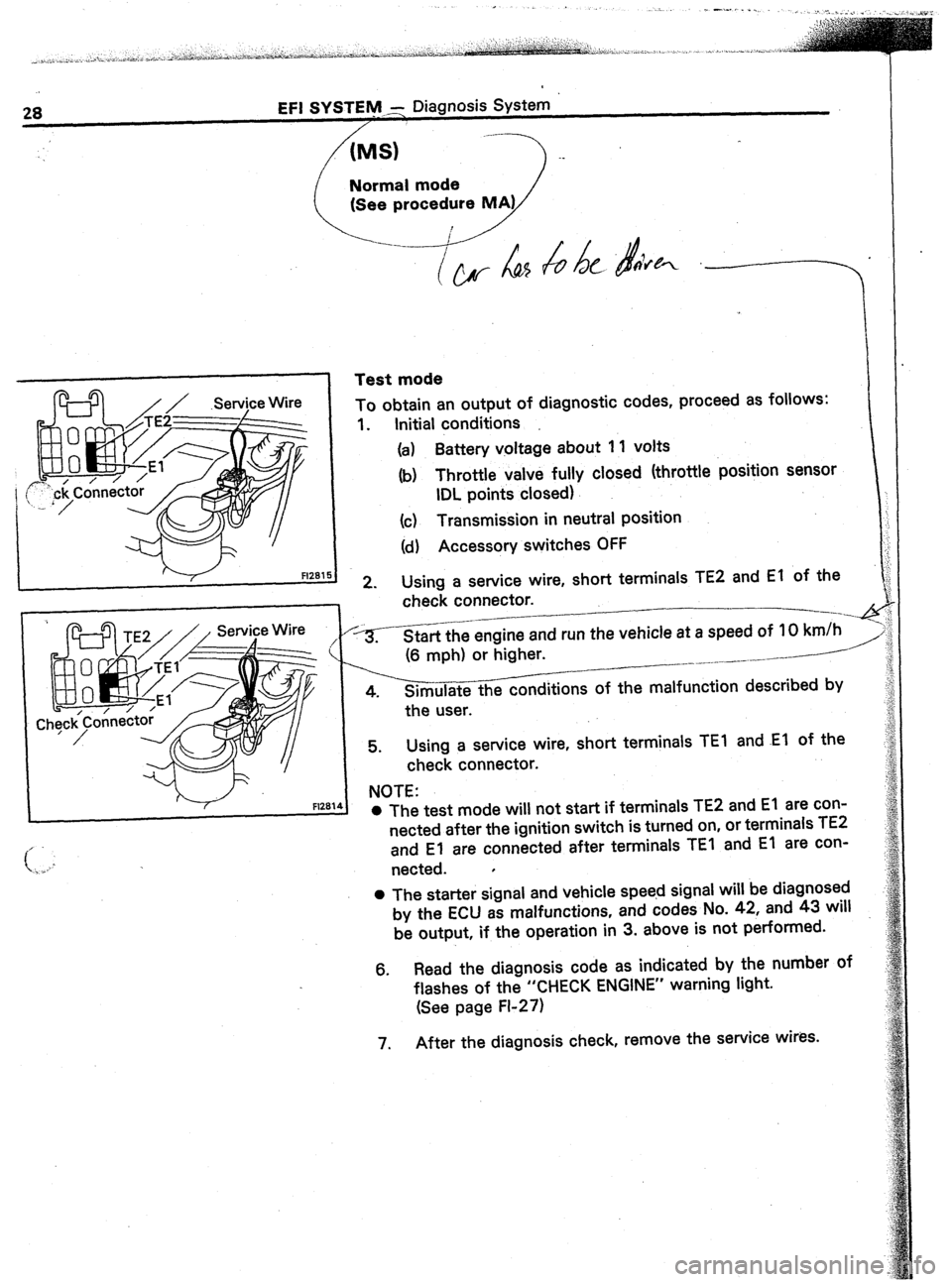

Test mode

i

To obtain an output of diagnostic codes, proceed as follows:

1. Initial conditions

(a) Battery voltage about 1 1 volts

(b) Throttle valve fully closed (throttle position sensor

IDL points closed)

(c) Transmission in neutral position

(d) Accessory switches OFF

2. Using a service wire, short terminals TE2 and El of the j

check connector.

-----.-q

*-heengine and run the vehicle at a speed of IO km/h I

(6 mph) or higher. __-- /---’

_ ___ _.--.--.

4. Simulate the conditions of the malfunction described by

the user.

5. Using a service wire, short terminals TEl and .El of the

check connector.

NOTE:

l The test mode will not start if terminals TE2 and El are con-

nected after the ignition switch is turned on, or terminals TE2

and El are connected after terminals TEI and El are con-

nected.

l

0 The starter signal and vehicle speed signal will be diagnosed

by the ECU as malfunctions, and codes No. 42, and 43 will

be output, if the operation in 3. above is not performed.

6. Read the diagnosis code as indicated by the number of

flashes of the “CHECK ENGINE” warning light.

(See page FI-27)

7. After the diagnosis check, remove the service wires.

Page 65 of 346

EFI SYSTEM

- Diagnosis System

FI-31

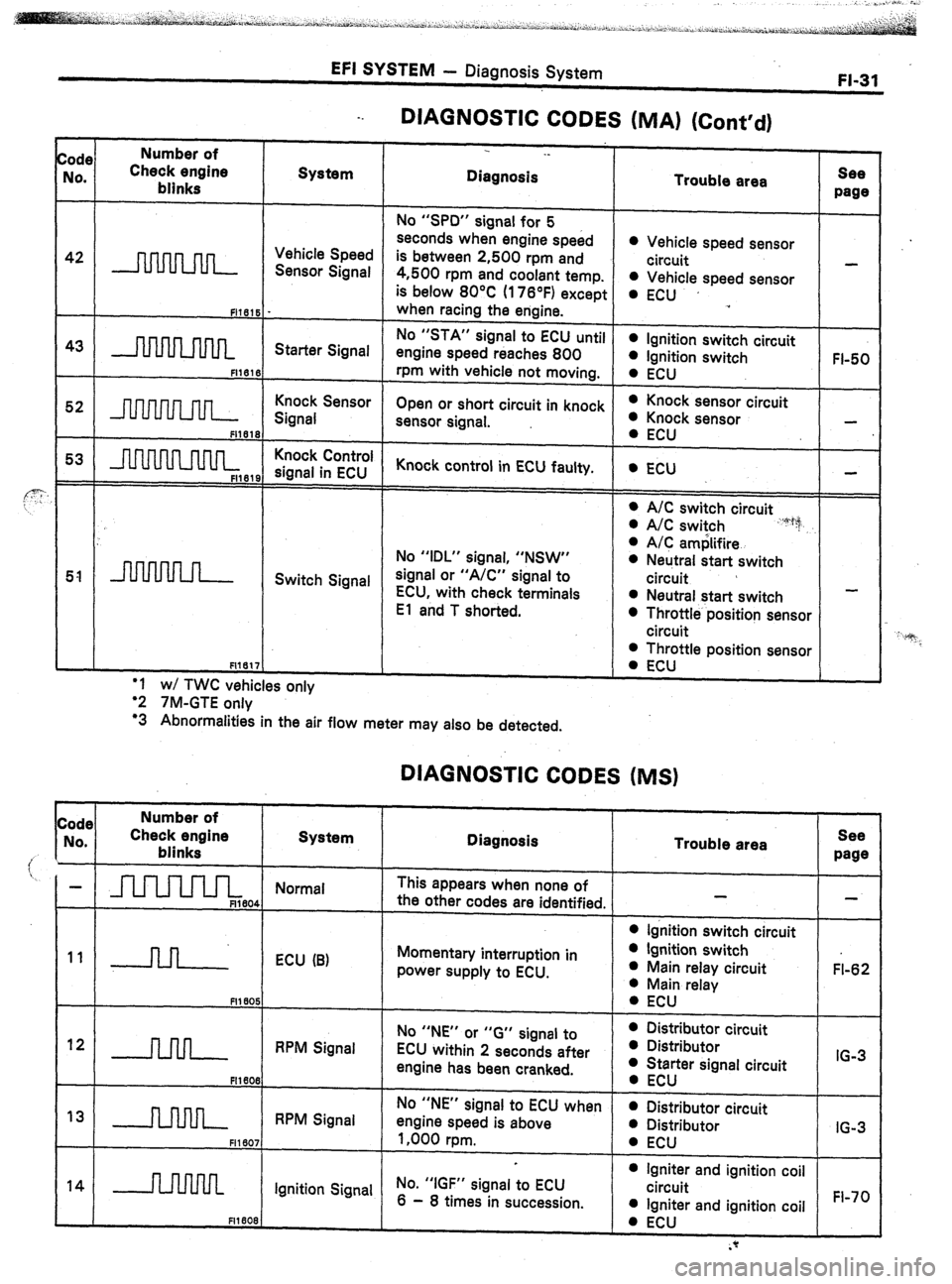

DIAGNOSTIC CODES (MA) (Cont’d) __

:odc

No. Number of

Check engine

blinks Diagnosis System See

page

FL50 Trouble area

l Vehicle speed sensor

circuit

l Vehicle speed sensor

. ECU ’

I

l Ignition switch circuit

l Ignition switch

l ECU

l Knock sensor circuit

l Knock sensor

l ECU

. ECU

l A/C switch circuit

l A/C switch ‘“q

l A/C am&fire

l Neutral start switch

circuit ’

l Neutral start switch

0 Throttle position sensor

circuit

l Throttle position sensor

l ECU Vehicle Speed

Sensor Signal

Starter Signal No “SPD” signal for 5

seconds when engine speed

is between 2,500 rpm and

4,500 rpm and coolant temp.

is below 80°C (176’F) except

when racing the engine.

No “STA” signal to ECU until

engine speed reaches 800

rpm with vehicle not moving.

Knock Sensor

Signal Open or short circuit in knock

sensor signal. 42

FI161

FHBl

Fl181

FIlei

52

Knock control in ECU faulty. Knock Control

signal in ECU

No “IDL” signal, “NSW”

signal or “A/C” signal to

ECU, with check terminals

El and T shorted. Switch Signal

‘1 WI TWC vehicles only

‘2 7M-GTE only

“3 Abnormalities in the air flow meter may also be detected.

DIAGNOSTIC CODES (MS)

Number of

Check engine

System

blinks

m Normal

fl1604

nn ECU (B) Diagnosis

This appears when none of

the other codes are identified.

Momentary interruption in

power supply to ECU. Trouble area See

page

l Ignition switch circuit

l Ignition switch

l Main relay circuit

l Main relay

l ECU FI-62

l Distributor circuit

0 Distributor

l Starter signal circuit

. ECU IG-3

l Distributor circuit

l Distributor

. ECU IG-3

l Igniter and ignition coil 11

FI1605

n nn RPM Signal No “NE” or “G” signal to

ECU within 2 seconds after

engine has been cranked.

FHBOB

nnnn, RPM Signal No “NE” signal to ECU when

engine speed is above

Fl1807 1,000 rpm. 12

-

13

-

14

-LJUlJUL 1 Ignition Signal 1 * No. “IGF” signal to ECU

6 - 8 times in succession. circuit

0 Igniter and ignition coil

. ECU

.t Fl-70

Page 66 of 346

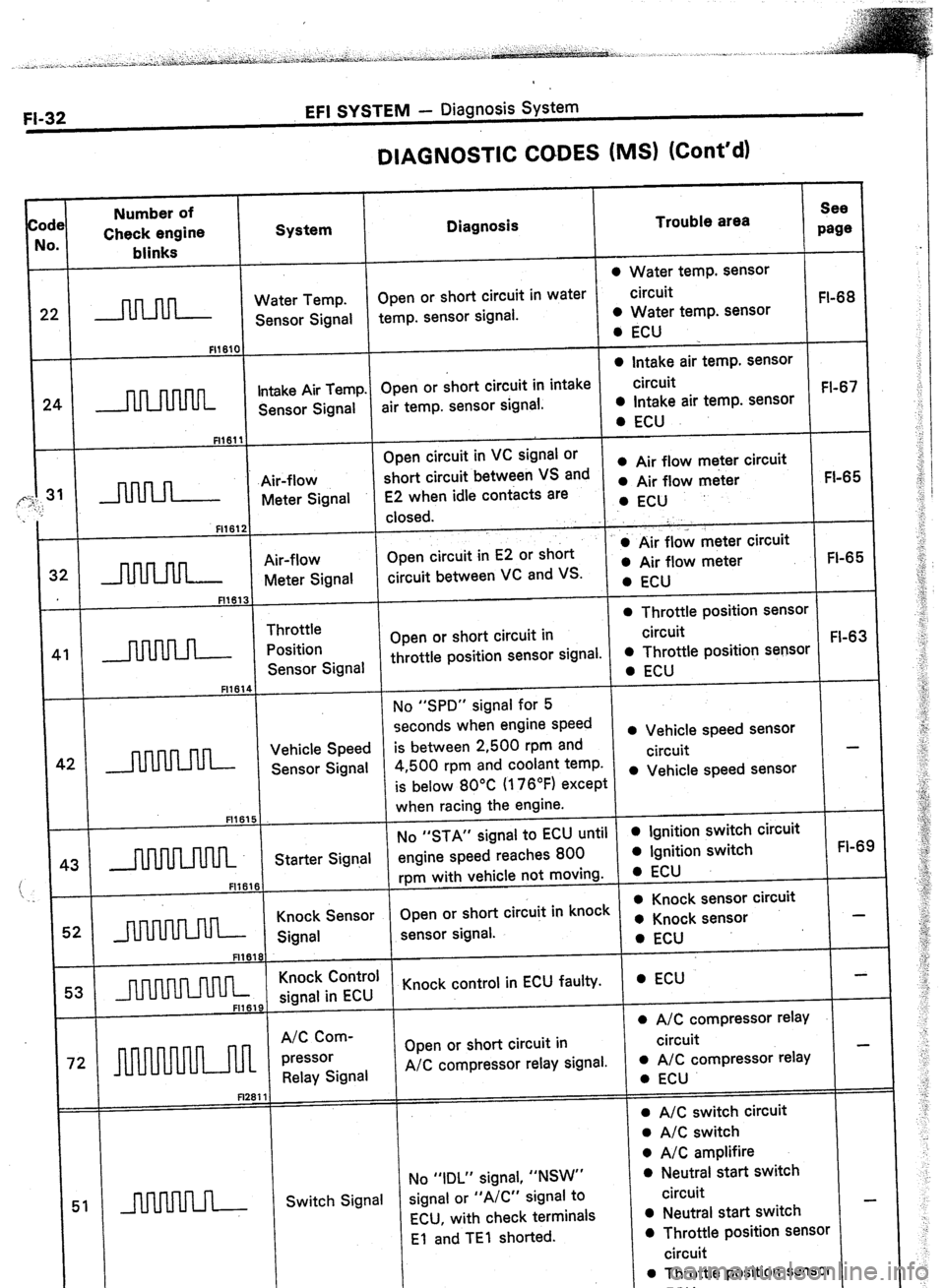

FI-32 EFI SYSTEM - Diagnosis System

1 ode -

: Number of See

Check engine System Diagnosis Trouble area

paw

blinks

0 Water temp. sensor

. .

clrcult m n FI-68

0 Water temp. sensor

0 ECU _

FllBlO 0 Intake air temp. sensor

r

JUMJJJL Intake Air Temp. Open or short circuit in intake circuit

FI-67

Sensor Signal air temp. sensor signal. 0 intake air temp. sensor

. ECU

fll611

Open circuit in VC signal or

0 Air flow meter circuit

JJJJ n f

‘. ‘( <;

closed.

F11612 .

i Air flow meter circuit

DIAGNOSTIC CODES (MS) (Cont’d)

4-65

32

Fl1613 I I

I 0 Throttle position sensor

Open or short circuit in circuit

41 throttle position sensor signal.

! 0 Throttle position sensor

. ECU

Fl1614

No “SPD” signal for 5

seconds when engine speed

0 Vehicle speed sensor

42 nnnruvl

is below 80°C (176°F) except

when racing the engine.

fl16151

I

No “STA” sianal to ECU until 0 Ignition switch circuit

43

i m Starter Signal /~~n~i,‘,pee~;~ct-;~~~ng : ;;;on switch FI-6!

FM

FM

? -. Fl1616 .^

0 Knock sensor circuit

52

.I JjJJMJjn Eyn$ Sensor ~~n~op:~~ circuit in knock : :gk sensor

53

I F11616

w6,9 Kn$c~i~“,“,‘;“’ Knock control in ECU faulty. l ECU

0 A/C compressor relay

A/C Com-

Open or short circuit in circuit

pressor

Relay Signal A/C compressor relay signal. a A/C compressor relay

. ECU

f12611

0 A/C switch circuit Z

51

No “IDL” signal, “NSW” 0 A/C switch

0 A/C amplifire l Neutral start switch

circuit

0 Neutral start switch

0 Throttle position sensor

circuit

I F11617

0 Throttle position Sensor

. ECU

Page 69 of 346

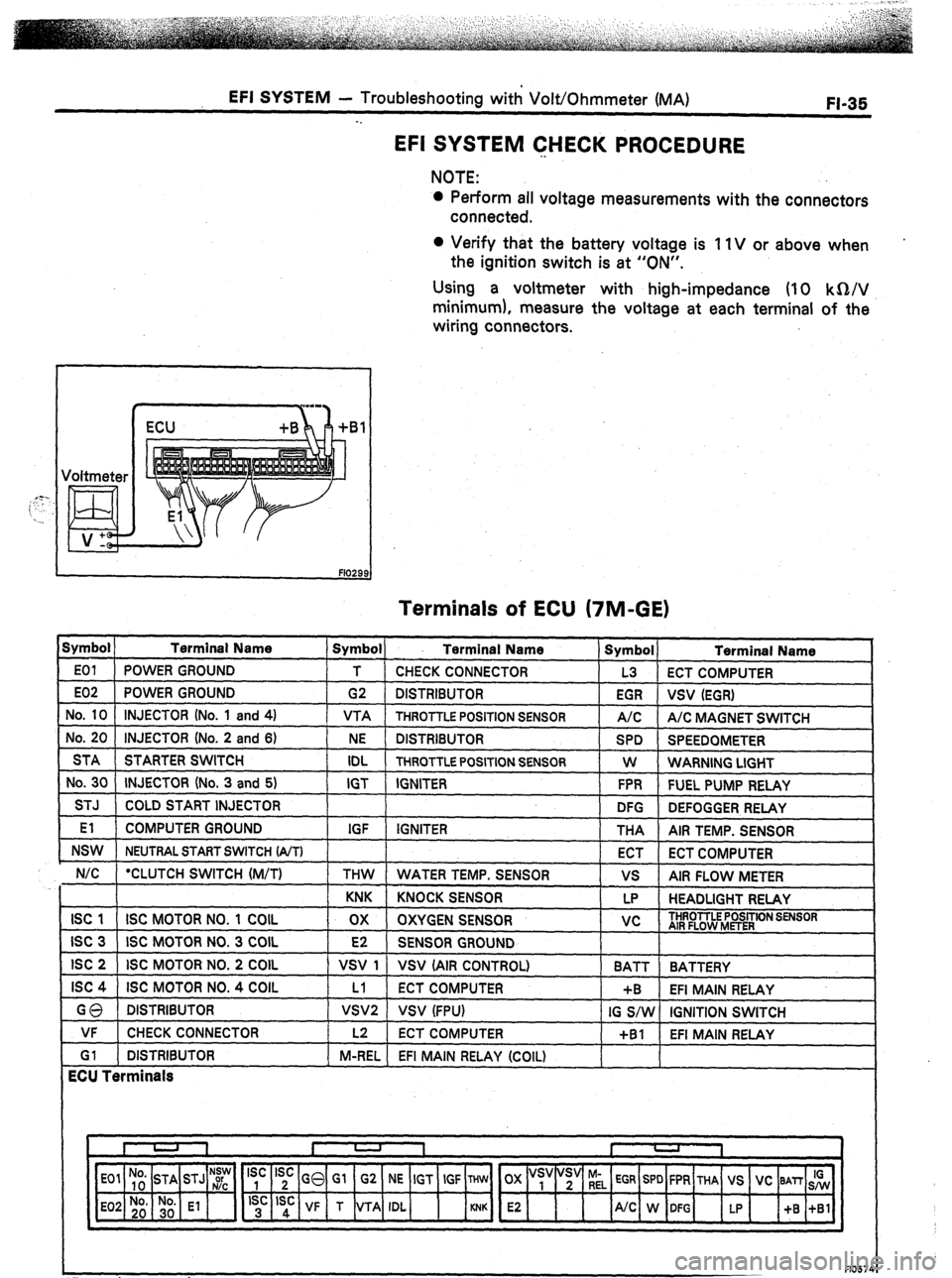

EFI SYSTEM - Troubleshooting with Volt/Ohmmeter (MA)

FI-35

. .

EFI SYSTEM CHECK PROCEDURE

NOTE:

l Perform all voltage measurements with the connectors

connected.

0 Verify that the battery voltage is 11V or above when

the ignition switch is at “ON”.

Using a voltmeter with high-impedance (IO kQ/V

minimum), measure the voltage at each terminal of the

wiring connectors.

I ) ECU +B

Terminals of ECU (7M-GE)

Symbol ) Terminal Name

E01 POWER GROUND

E02 POWER GROUND

No. 10 INJECTOR (No. 1 and 4)

No. 20 INJECTOR (No. 2 and 6)

STA STARTER SWITCH

No. 30 INJECTOR (No. 3 and 5)

STJ COLD START INJECTOR

El COMPUTER GROUND

NSW NEUTRAL START SWITCH (A/T)

N/C *CLUTCH SWITCH (M/T) 1 Symbol) Terminal Name

T CHECK CONNECTOR

G2 DISTRIBUTOR

VTA THROTTLE POSITION SENSOR

NE DISTRIBUTOR

IDL THROTTLE POSITION SENSOR

IGT IGNITER

IGF IGNITER

THW WATER TEMP. SENSOR Symbol

Terminal Name

L3 ECT COMPUTER

EGR

vsv (EGR)

A/C A/C MAGNET SWITCH

SPD SPEEDOMETER

W WARNING LIGHT

FPR FUEL PUMP RELAY

DFG

DEFOGGER RELAY

THA

AIR TEMP. SENSOR

ECT

ECT COMPUTER

vs AIR FLOW METER

KNK KNOCK SENSOR LP HEADLIGHT RELAY

ISC 1 ISC MOTOR NO. 1 COIL ox OXYGEN SENSOR vc THROTTLE POSITION SENSOR

AIR FLOW METER

ISC 3 ISC MOTOR NO. 3 COIL E2 SENSOR GROUND

ISC 2 ISC MOTOR NO. 2 COIL VSV 1 VSV (AIR CONTROL)

BATT BATTERY

ISC 4 ISC MOTOR NO. 4 COIL Ll ECT COMPUTER +B EFI MAIN RELAY

GQ DISTRIBUTOR VSVP VSV (FPU) IG S/W IGNITION SWITCH

VF CHECK CONNECTOR

Gl DISTRIBUTOR

ECU Terminals 1 L2 ECT COMPUTER

+Bl EFI MAIN RELAY

1 M-REL EFI MAIN RELAY (COIL)

*For cruise control

F10574

Page 70 of 346

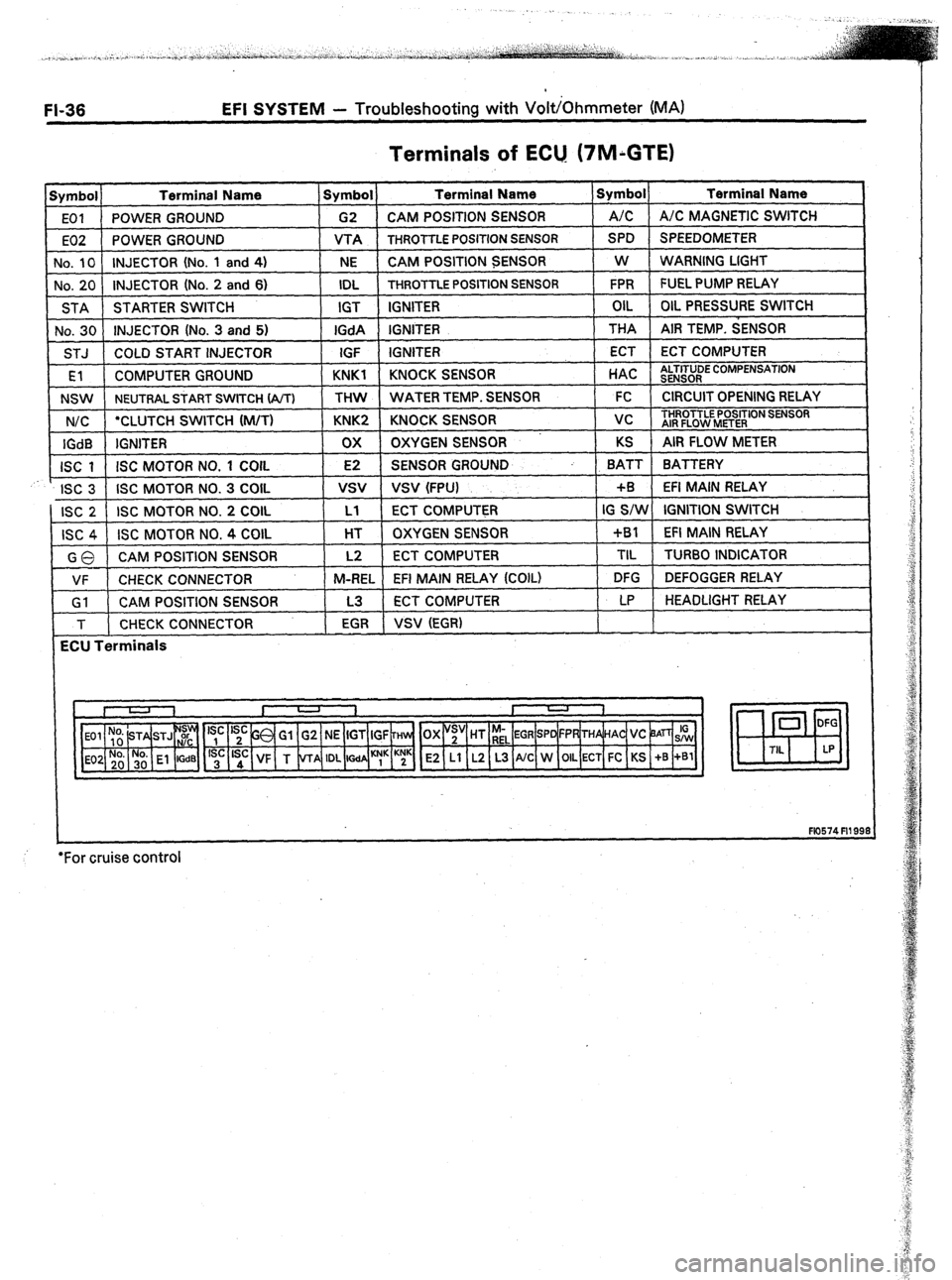

FI-36 EFI SYSTEM - Troubleshooting with VoltjOhmmeter (MA)

Terminals of ECU. (7M;GTE)

Symbol Terminal Name Symbol Terminal Name Symbol Terminal Name

EOI POWER GROUND G2 CAM POSITION SENSOR A/C A/C MAGNETIC SWITCH

E02 POWER GROUND VTA

THROTTLE POSITION SENSOR SPD SPEEDOMETER

No, 10 INJECTOR (No. 1 and 4)

NE CAM POSITION SENSOR W

WARNING LIGHT

No. 20 INJECTOR (No. 2 and 6) IDL

THROTTLE POSITION SENSOR FPR FUEL PUMP RELAY

STA STARTER SWITCH IGT IGNITER OIL OIL PRESSURE SWITCH

No. 30 INJECTOR (No. 3 and 5) IGdA IGNITER THA AIR TEMP. SENSOR

STJ COLD START INJECTOR

IGF IGNITER ECT ECT COMPUTER

rEl COMPUTER GROUND KNKl KNOCK SENSOR

t HAC 1 tl

NSW

NEUTRAL START SWITCH (A/T) THW WATER TEMP. S

N/C ‘CLUTCH SWITCH (M/T) KNK2 KNOCK SENSOR 1 vc ) THROTTLE

AIR

FLOW I

LTITUDE COMPENSATION

, .xNSOR

ENSOR 1 FC 1 CIRCUITOPENING RELAY I

IGdB IGNITER ox OXYGEN SENSOR KS AIR FLOW METER

ISC 1 ISC MOTOR NO. 1 COIL E2 SENSOR GROUND BATT BATTERY

r

ISC 3 ISC MOTOR NO. 3 COIL

vsv VSV (FPU) +B EFI MAIN RELAY

ISC 2 ISC MOTOR NO. 2 COIL Ll ECT COMPUTER IG S/W IGNITION SWITCH

ISC 4 ISC MOTOR NO. 4 COIL HT OXYGEN SENSOR +Bl EFI MAIN RELAY

GO CAM POSITION SENSOR L2 ECT COMPUTER TIL

TURBO INDICATOR

VF CHECK CONNECTOR M-REL

EFI MAIN RELAY (COIL) DFG DEFOGGER RELAY

Gl CAM POSITION SENSOR L3 ECT COMPUTER LP HEADLIGHT RELAY

T CHECK CONNECTOR

EGR VSV (EGR)

ECU Terminals

E2 Ll L2 L3 A/C W OIL ECT FC KS +B +Bl

+

F10574 Fll 99:

*For cruise control

Page 92 of 346

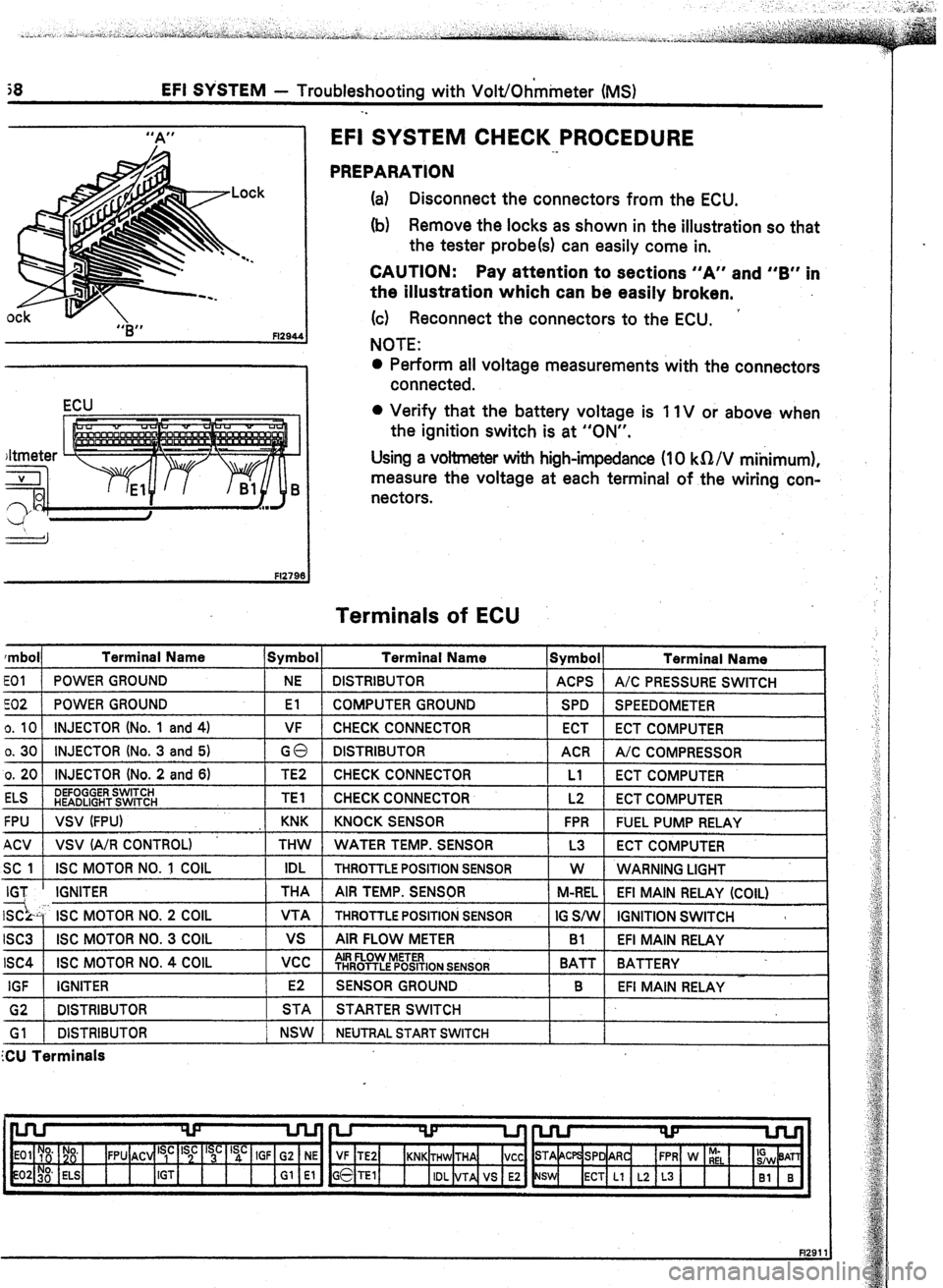

jS EFI SYSTEM - Troubleshooting with Volt/Ohmmeter (MS)

-.

0

“B”

Fl294.

ECU

EFI SYSTEM CHECK PROCEDURE

._

PREPARATION

(a) Disconnect the connectors from the ECU.

(b) Remove the locks as shown in the illustration so that

the tester probe(s) can easily come in.

CAUTION: Pay attention to sections “A” and “B” in

the illustration which can be easily broken,

(c) Reconnect the connectors to the ECU.

’

NOTE:

0 Perform ail voltage measurements with the connectors

connected.

0 Verify that the battery voltage is 1 IV or above when

the ignition switch is at “ON”.

Using a voltmeter with high-impedance (10 kQ/V mihimum),

measure the voltage at each terminal of the wiring con-

nectors.

Terminals of ECU

rmbol Terminal Name Symbol Terminal Name

Symbol Terminal Name

EOI POWER GROUND NE DISTRIBUTOR ACPS A/C PRESSURE SWITCH

co2 POWER GROUND El COMPUTER GROUND SPD SPEEDOMETER

o. 10 INJECTOR (No. 1 and 4) VF CHECK CONNECTOR ECT ECT COMPUTER

o. 30 INJECTOR (No. 3 and 5)

GO DISTRIBUTOR ACR A/C COMPRESSOR

o. 20 INJECTOR (No. 2 and 6) TE2 CHECK CONNECTOR Ll

ECT COMPUTER

ELS DEFOGGER SWITCH

HEADLIGHT SWITCH TEl CHECK CONNECTOR L2

ECT COMPUTER

FPU VSV (FPU) KNK KNOCK SENSOR FPR FUEL PUMP RELAY

ACV VSV (A/R CONTROL) THW WATER TEMP. SENSOR L3 ECT COMPUTER

SC 1 ISC MOTOR NO. 1 COIL IDL

THROTTLE POSITION SENSOR W

WARNING LIGHT

IGT IGNITER THA AIR TEMP. SENSQR

M-REL EFI MAIN RELAY (COIL)

SC- ISC MOTOR NO. 2 COIL VTA THROlTLE POSITION SENSOR IG SiW IGNITION SWITCH 3

ISC3 ISC MOTOR NO. 3 COIL vs AIR FLOW METER Bl EFI MAIN RELAY

ISC4 ISC MOTOR NO. 4 COIL vcc AIR FLOW METER

THROTTLE POSITION SENSOR BATT BATTERY

IGF IGNITER E2

SENSOR GROUND B

EFI MAIN RELAY

G2 1 DISTRIBUTOR 1 STA 1 STARTER SWITCH

Gl 1 DISTRIBUTOR 1 NSW 1 NEUTRALSTARTSWITCH

ZU Terminals