turn signal TOYOTA CELICA 1987 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1987, Model line: CELICA, Model: TOYOTA CELICA 1987Pages: 346, PDF Size: 35.13 MB

Page 49 of 346

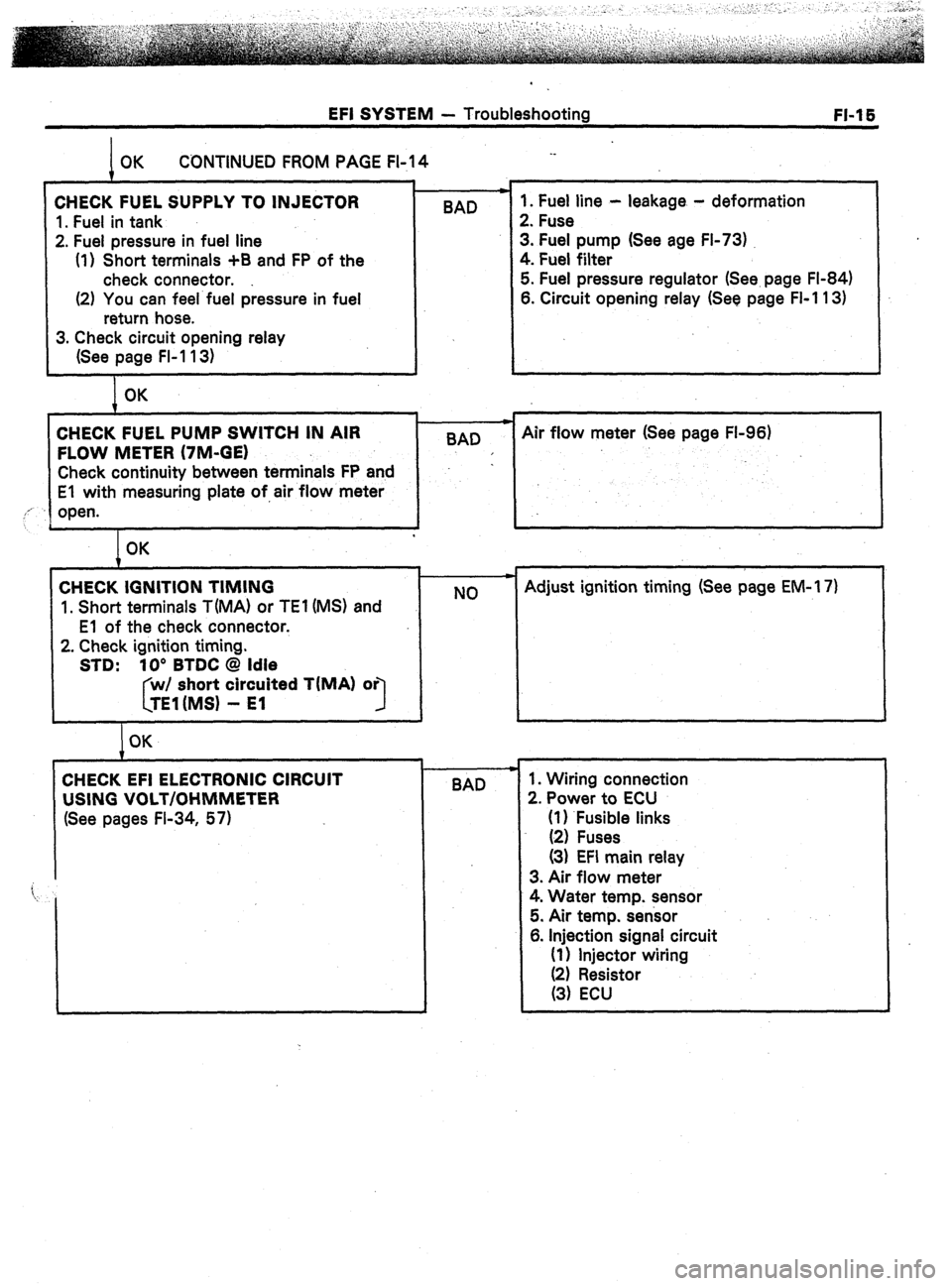

EFI SYSTEM - Troubleshooting

FI-1 E

CONTINUED FROM PAGE FI-14 ._

CHECK FUEL SUPPLY TO INJECTOR

1. Fuel in tank

2. Fuel pressure in fuel line

(1) Short terminals +B and FP of the

check connector.

(2) You can feel fuel pressure in fuel

return hose. BAD 1. Fuel line - leakage - deformation

2. Fuse

3. Fuel pump (See age FI-73)

4. Fuel filter

5. Fuel pressure regulator (See. page FI-84)

6. Circuit opening relay (See page FI-1 13)

3. Check circuit opening relay

(See page FI-1 13)

OK

CHECK FUEL PUMP SWITCH IN AIR

FLOW METER (7M-GE)

Check continuity between terminals FP and

El with measuring plate of,air flow meter

,,’

open.

L

I BAD c

Air flow meter (See page FL96)

I OK

CHECK IGNITION TIMING

1. Short terminals T(MA) or TEl (MS) and

El of the check connector.

2. Check ignition timing.

STD: 10’ BTDC @ Idle

short circuited TIMA) or

3

I OK NO Adjust ignition timing (See page EM-l 7)

BAD 1. Wiring connection

2. Power to ECU

(1) .Fusible links

(2) Fuses

(3) EFI main relay

3. Air flow meter

4. Water temp. sensor

5. Air temp. sensor

6. Injection signal circuit

(1) Injector wiring

Page 62 of 346

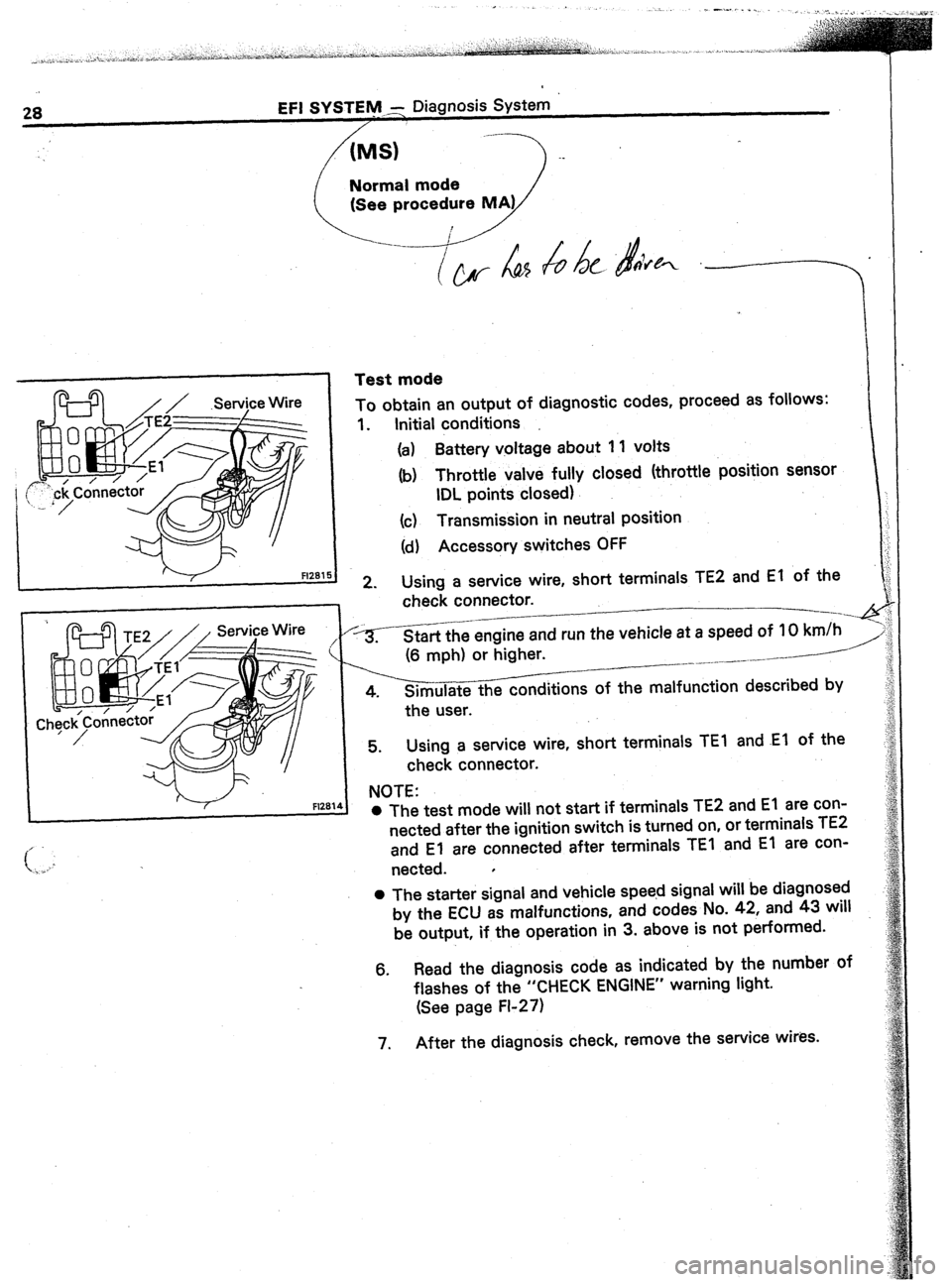

EFI SYSTEM; Diagnosis System

S)

------) -.

I Fl281

Test mode

i

To obtain an output of diagnostic codes, proceed as follows:

1. Initial conditions

(a) Battery voltage about 1 1 volts

(b) Throttle valve fully closed (throttle position sensor

IDL points closed)

(c) Transmission in neutral position

(d) Accessory switches OFF

2. Using a service wire, short terminals TE2 and El of the j

check connector.

-----.-q

*-heengine and run the vehicle at a speed of IO km/h I

(6 mph) or higher. __-- /---’

_ ___ _.--.--.

4. Simulate the conditions of the malfunction described by

the user.

5. Using a service wire, short terminals TEl and .El of the

check connector.

NOTE:

l The test mode will not start if terminals TE2 and El are con-

nected after the ignition switch is turned on, or terminals TE2

and El are connected after terminals TEI and El are con-

nected.

l

0 The starter signal and vehicle speed signal will be diagnosed

by the ECU as malfunctions, and codes No. 42, and 43 will

be output, if the operation in 3. above is not performed.

6. Read the diagnosis code as indicated by the number of

flashes of the “CHECK ENGINE” warning light.

(See page FI-27)

7. After the diagnosis check, remove the service wires.

Page 259 of 346

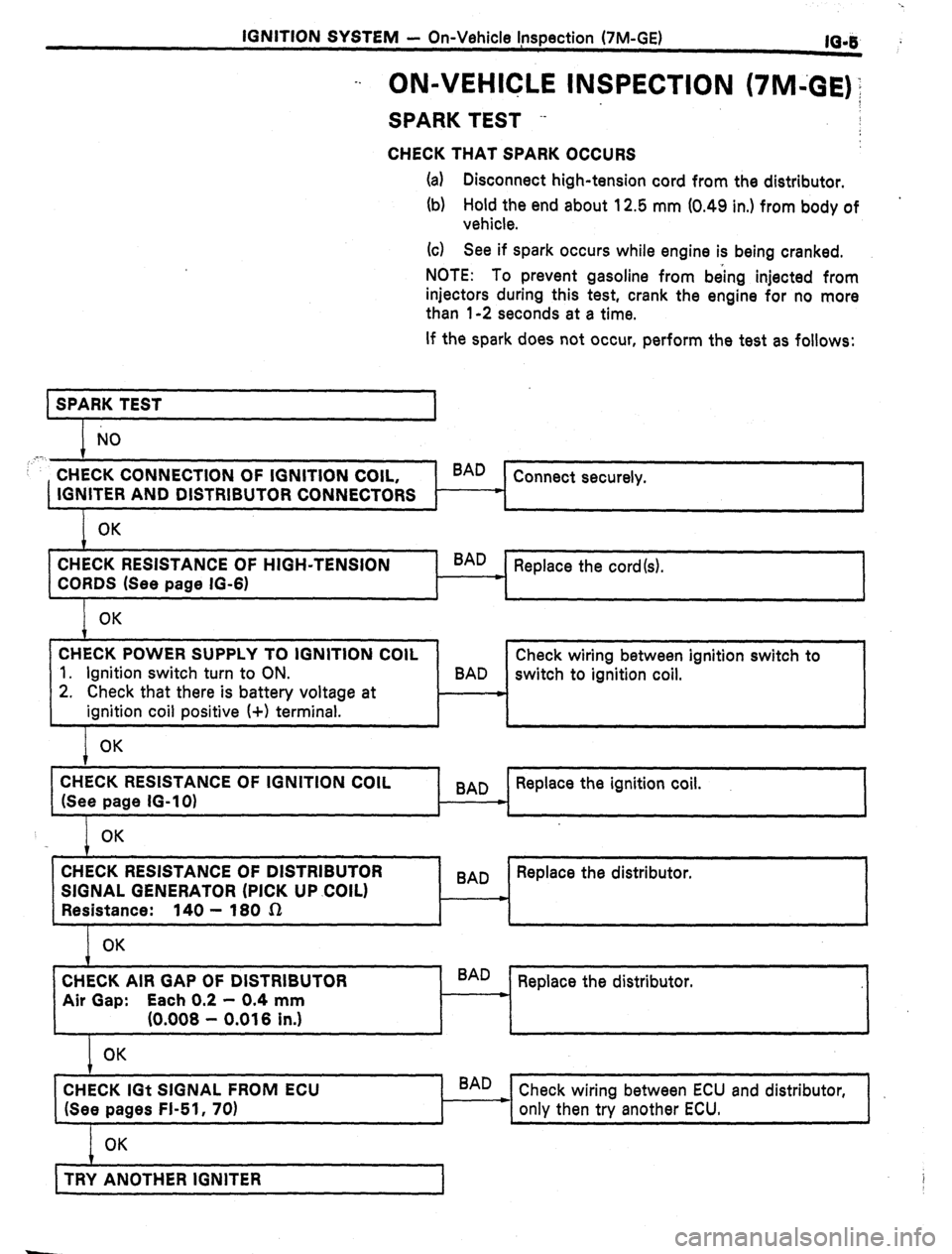

IGNITION SYSTEM - On-Vehicle Inspection (7M-GE)

IO-6 *

-. ON-VEHICLE INSPECTION (7M43E)‘;

SPARK TEST --

CHECK THAT SPARK OCCURS

(a) Disconnect high-tension cord from the distributor.

(b) Hold the end about 12.5 mm (0.49 in.) from body of

vehicle.

(G) See if spark occurs while engine is being cranked.

NOTE: To prevent gasoline from being injected from

injectors during this test, crank the engine for no more

than l-2 seconds at a time.

If the spark does not occur, perform the test as follows:

SPARK TEST

1

NO

,‘.

CHECK CONNECTION OF IGNITION COIL, BAD

Connect securely.

IGNITER AND DISTRIBUTOR CONNECTORS c

OK

CHECK RESISTANCE OF HIGH-TENSION

CORDS (See page IG-6) ’ BAD

Replace the cord(s).

OK

CHECK POWER SUPPLY TO IGNITION COIL

1. Ignition switch turn to ON.

2. Check that there is battery voltage at

ignition coil positive I+) terminal. Check wiring between ignition switch to

BAD

switch to ignition coil.

OK

CHECK RESISTANCE OF IGNITION COIL

(See page IG-10) 9

BAD Replace the ignition coil.

*

OK

1 , , 1

CHECK RESISTANCE OF DISTRIBUTOR

SIGNAL GENERATOR (PICK UP .COIL)

Resistance: 140 - 180 sz

OK BAD Replace the distributor.

m

CHECK AIR GAP OF DISTRIBUTOR

Air Gap: Each 0.2 - 0.4 mm

(0.008 - 0.016 in.) BAD

Replace the distributor.

L

OK

CHECK IGt SIGNAL FROM ECU

(See pages FI-51, 70) BAD

Check wiring between ECU and distributor,

only then try another ECU.

OK

t ,

TRY ANOTHER IGNITER

1 i