oil filter TOYOTA RAV4 2006 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 198 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLYEM–23

EM

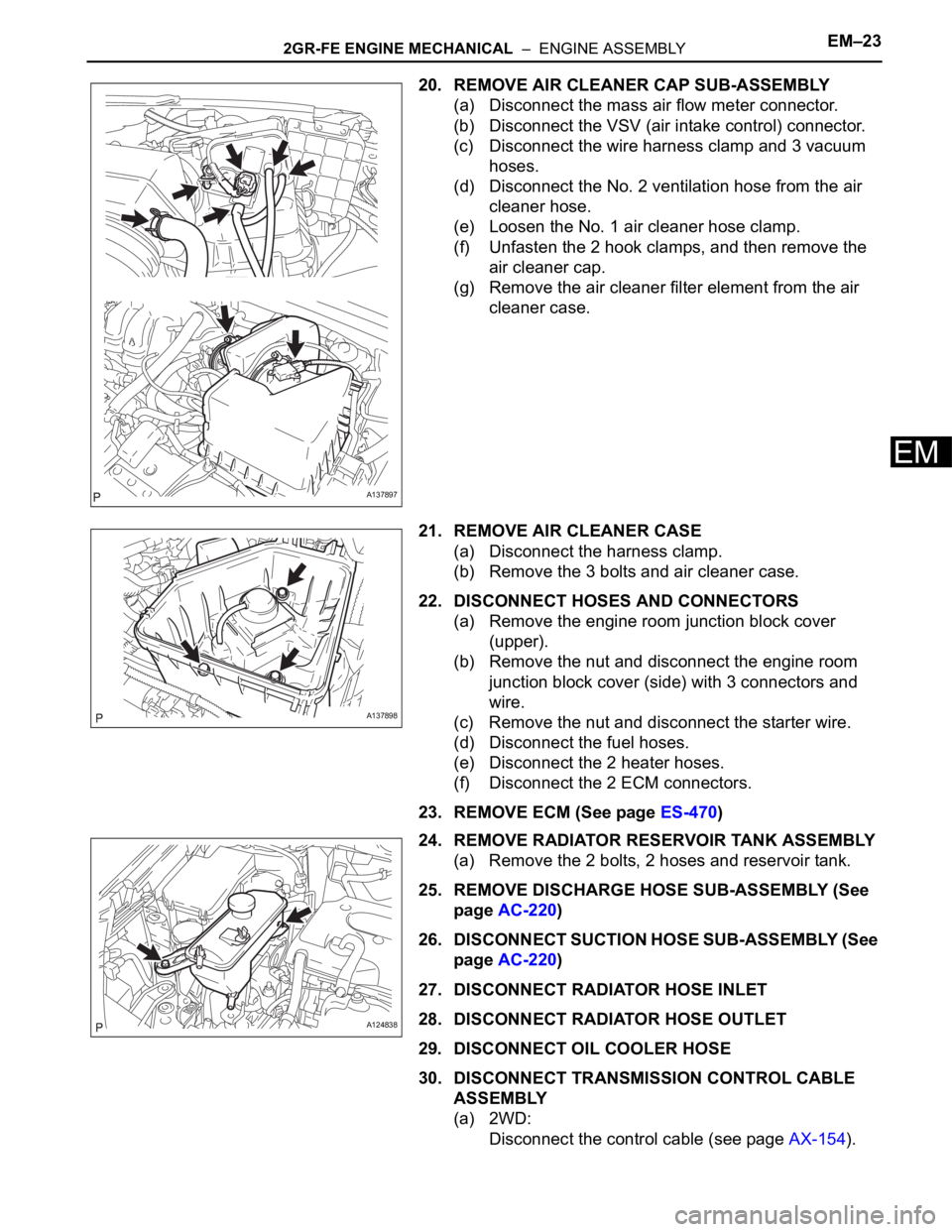

20. REMOVE AIR CLEANER CAP SUB-ASSEMBLY

(a) Disconnect the mass air flow meter connector.

(b) Disconnect the VSV (air intake control) connector.

(c) Disconnect the wire harness clamp and 3 vacuum

hoses.

(d) Disconnect the No. 2 ventilation hose from the air

cleaner hose.

(e) Loosen the No. 1 air cleaner hose clamp.

(f) Unfasten the 2 hook clamps, and then remove the

air cleaner cap.

(g) Remove the air cleaner filter element from the air

cleaner case.

21. REMOVE AIR CLEANER CASE

(a) Disconnect the harness clamp.

(b) Remove the 3 bolts and air cleaner case.

22. DISCONNECT HOSES AND CONNECTORS

(a) Remove the engine room junction block cover

(upper).

(b) Remove the nut and disconnect the engine room

junction block cover (side) with 3 connectors and

wire.

(c) Remove the nut and disconnect the starter wire.

(d) Disconnect the fuel hoses.

(e) Disconnect the 2 heater hoses.

(f) Disconnect the 2 ECM connectors.

23. REMOVE ECM (See page ES-470)

24. REMOVE RADIATOR RESERVOIR TANK ASSEMBLY

(a) Remove the 2 bolts, 2 hoses and reservoir tank.

25. REMOVE DISCHARGE HOSE SUB-ASSEMBLY (See

page AC-220)

26. DISCONNECT SUCTION HOSE SUB-ASSEMBLY (See

page AC-220)

27. DISCONNECT RADIATOR HOSE INLET

28. DISCONNECT RADIATOR HOSE OUTLET

29. DISCONNECT OIL COOLER HOSE

30. DISCONNECT TRANSMISSION CONTROL CABLE

ASSEMBLY

(a) 2WD:

Disconnect the control cable (see page AX-154).

A137897

A137898

A124838

Page 247 of 2000

LU–122GR-FE LUBRICATION – OIL PUMP

LU

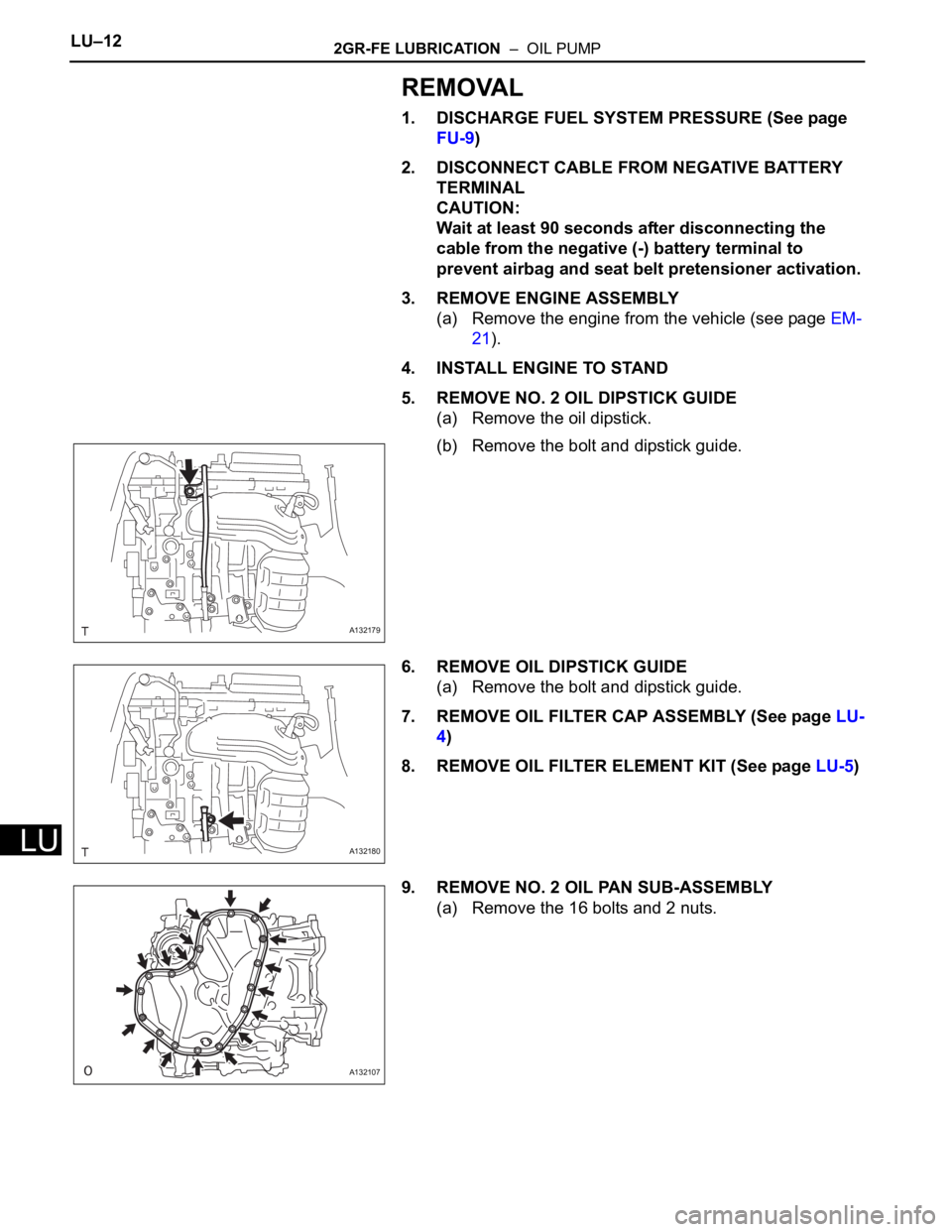

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE (See page

FU-9)

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

3. REMOVE ENGINE ASSEMBLY

(a) Remove the engine from the vehicle (see page EM-

21).

4. INSTALL ENGINE TO STAND

5. REMOVE NO. 2 OIL DIPSTICK GUIDE

(a) Remove the oil dipstick.

(b) Remove the bolt and dipstick guide.

6. REMOVE OIL DIPSTICK GUIDE

(a) Remove the bolt and dipstick guide.

7. REMOVE OIL FILTER CAP ASSEMBLY (See page LU-

4)

8. REMOVE OIL FILTER ELEMENT KIT (See page LU-5)

9. REMOVE NO. 2 OIL PAN SUB-ASSEMBLY

(a) Remove the 16 bolts and 2 nuts.

A132179

A132180

A132107

Page 303 of 2000

PREPARATION – 2AZ-FE LUBRICATIONPP–25

PP

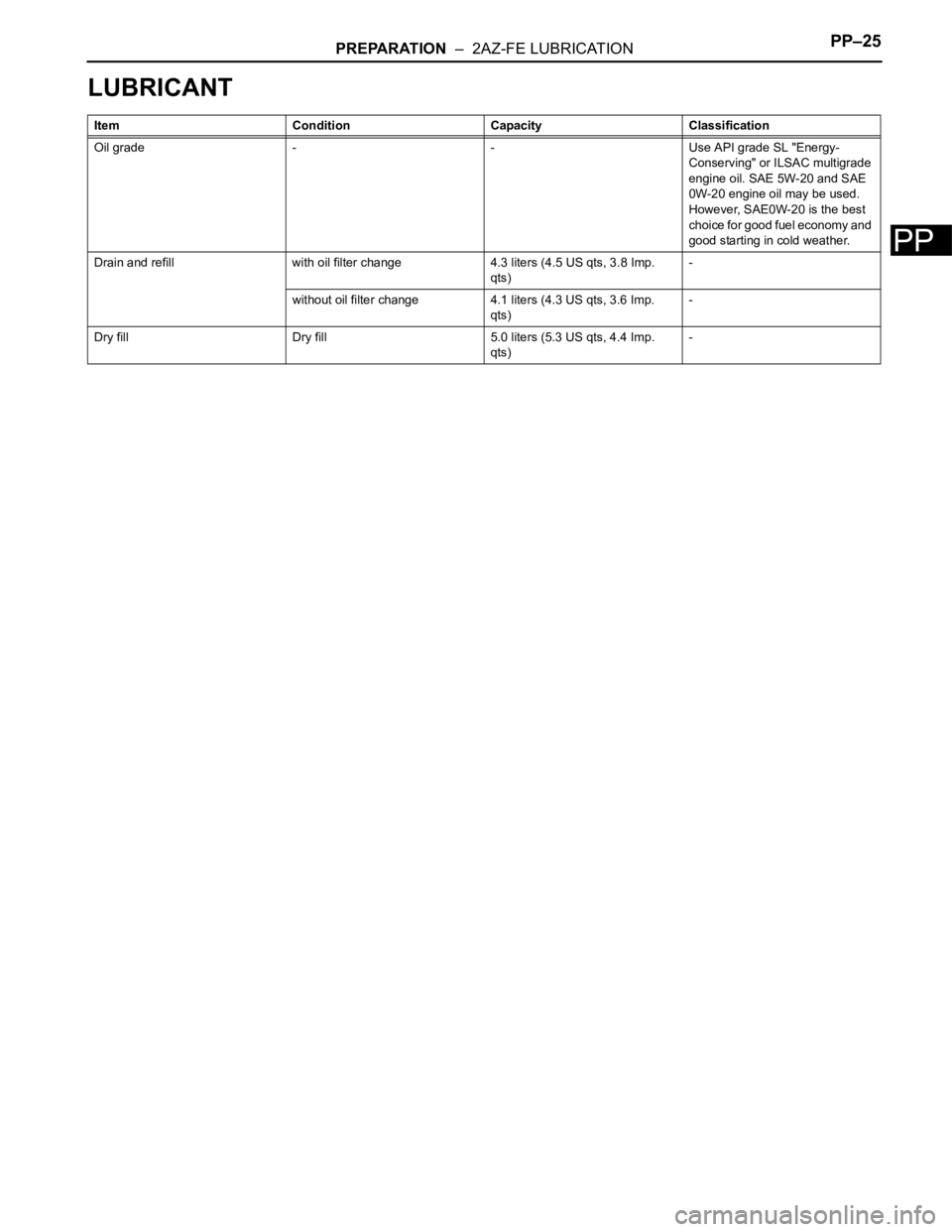

LUBRICANT

Item Condition Capacity Classification

Oil grade - - Use API grade SL "Energy-

Conserving" or ILSAC multigrade

engine oil. SAE 5W-20 and SAE

0W-20 engine oil may be used.

However, SAE0W-20 is the best

choice for good fuel economy and

good starting in cold weather.

Drain and refill with oil filter change 4.3 liters (4.5 US qts, 3.8 Imp.

qts)-

without oil filter change 4.1 liters (4.3 US qts, 3.6 Imp.

qts)-

Dry fill Dry fill 5.0 liters (5.3 US qts, 4.4 Imp.

qts)-

Page 305 of 2000

PREPARATION – 2GR-FE LUBRICATIONPP–25

PP

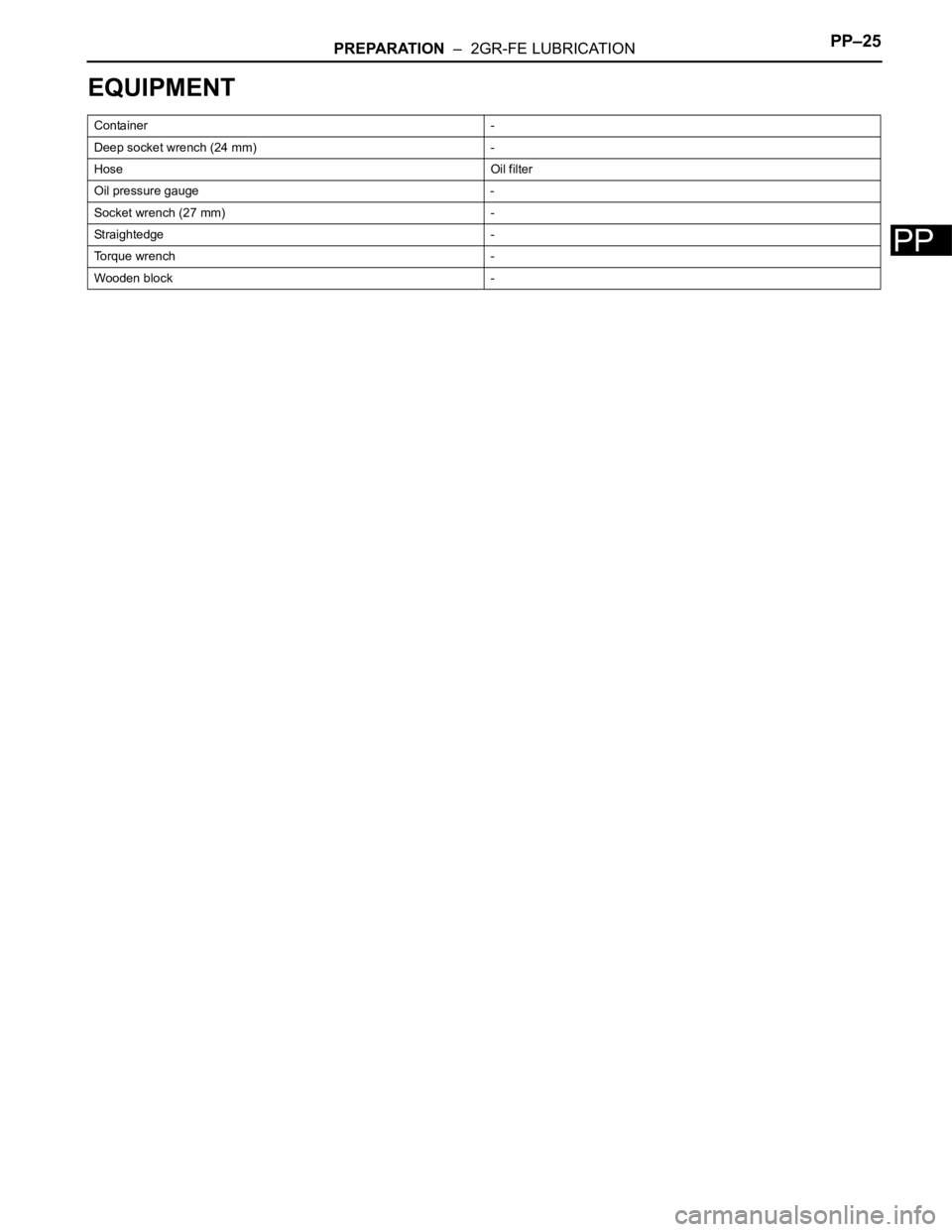

EQUIPMENT

Container -

Deep socket wrench (24 mm) -

Hose Oil filter

Oil pressure gauge -

Socket wrench (27 mm) -

Straightedge -

Torque wrench -

Wooden block -

Page 306 of 2000

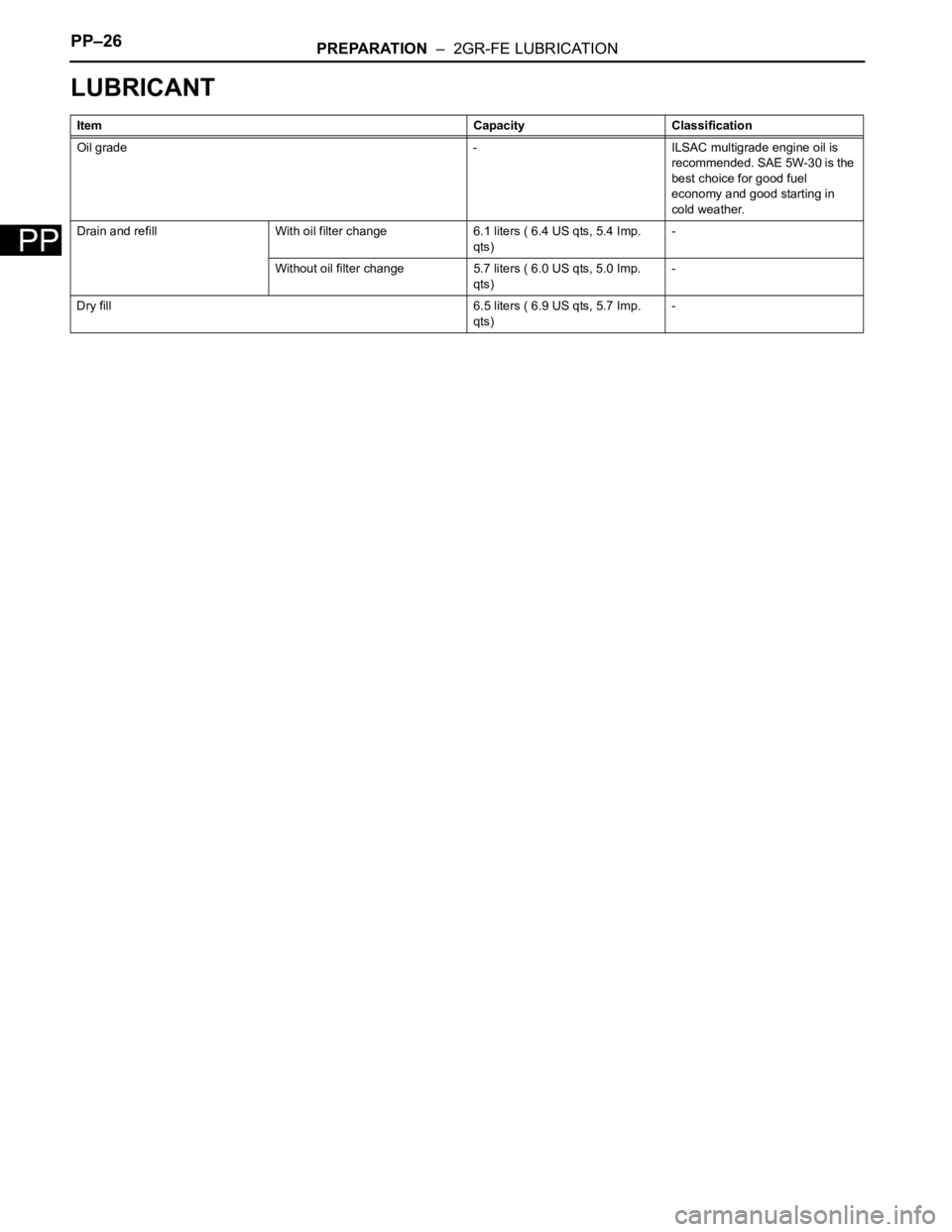

PP–26PREPARATION – 2GR-FE LUBRICATION

PP

LUBRICANT

Item Capacity Classification

Oil grade - ILSAC multigrade engine oil is

recommended. SAE 5W-30 is the

best choice for good fuel

economy and good starting in

cold weather.

Drain and refill With oil filter change 6.1 liters ( 6.4 US qts, 5.4 Imp.

qts)-

Without oil filter change 5.7 liters ( 6.0 US qts, 5.0 Imp.

qts)-

Dry fill 6.5 liters ( 6.9 US qts, 5.7 Imp.

qts)-

Page 380 of 2000

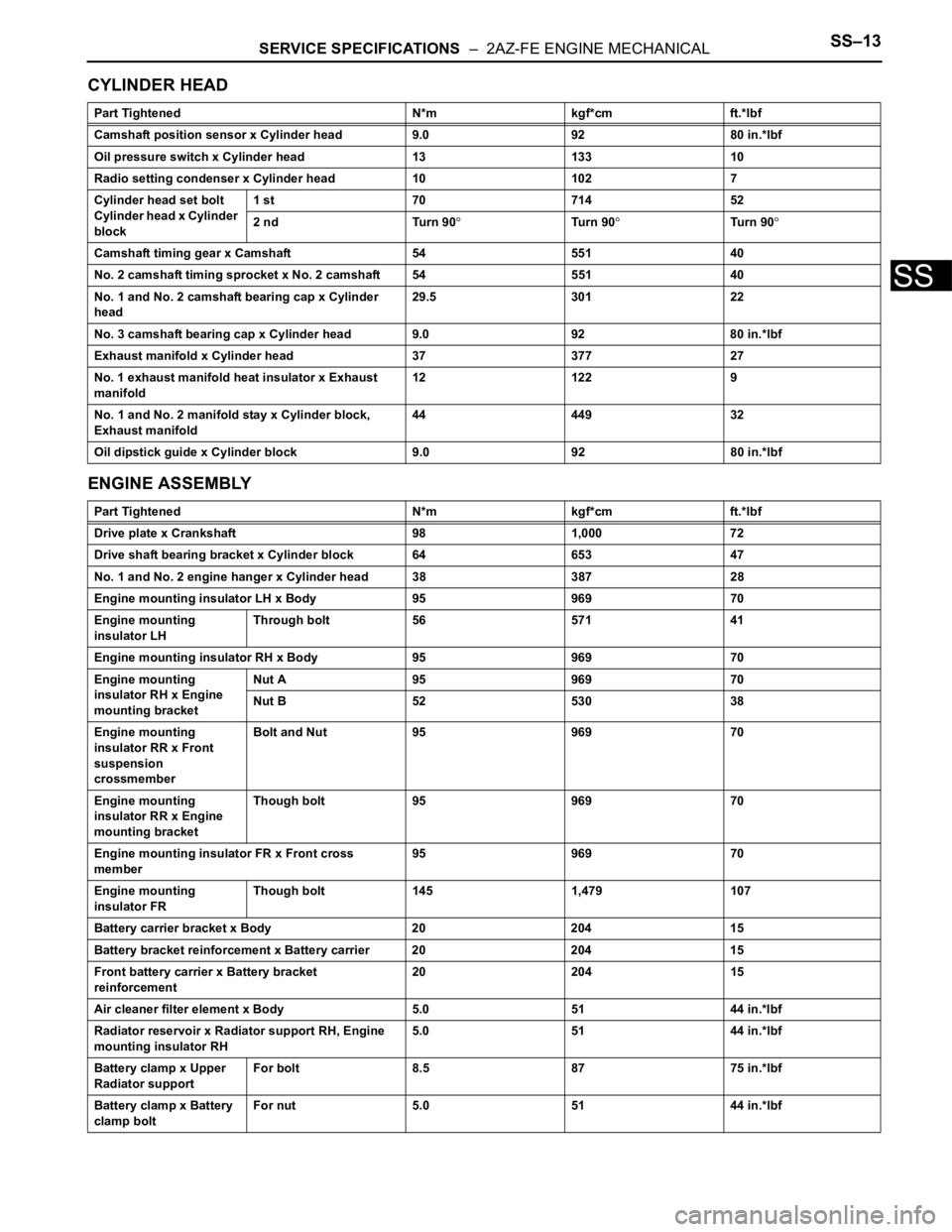

SERVICE SPECIFICATIONS – 2AZ-FE ENGINE MECHANICALSS–13

SS

CYLINDER HEAD

ENGINE ASSEMBLY

Part Tightened N*m kgf*cm ft.*lbf

Camshaft position sensor x Cylinder head 9.0 92 80 in.*lbf

Oil pressure switch x Cylinder head 13 133 10

Radio setting condenser x Cylinder head 10 102 7

Cylinder head set bolt

Cylinder head x Cylinder

block1 st 70 714 52

2 nd Turn 90

Tu r n 9 0Tu r n 9 0

Camshaft timing gear x Camshaft 54 551 40

No. 2 camshaft timing sprocket x No. 2 camshaft 54 551 40

No. 1 and No. 2 camshaft bearing cap x Cylinder

head29.5 301 22

No. 3 camshaft bearing cap x Cylinder head 9.0 92 80 in.*lbf

Exhaust manifold x Cylinder head 37 377 27

No. 1 exhaust manifold heat insulator x Exhaust

manifold12 122 9

No. 1 and No. 2 manifold stay x Cylinder block,

Exhaust manifold44 449 32

Oil dipstick guide x Cylinder block 9.0 92 80 in.*lbf

Part Tightened N*m kgf*cm ft.*lbf

Drive plate x Crankshaft 98 1,000 72

Drive shaft bearing bracket x Cylinder block 64 653 47

No. 1 and No. 2 engine hanger x Cylinder head 38 387 28

Engine mounting insulator LH x Body 95 969 70

Engine mounting

insulator LHThrough bolt 56 571 41

Engine mounting insulator RH x Body 95 969 70

Engine mounting

insulator RH x Engine

mounting bracketNut A 95 969 70

Nut B 52 530 38

Engine mounting

insulator RR x Front

suspension

crossmemberBolt and Nut 95 969 70

Engine mounting

insulator RR x Engine

mounting bracketThough bolt 95 969 70

Engine mounting insulator FR x Front cross

member95 969 70

Engine mounting

insulator FRThough bolt 145 1,479 107

Battery carrier bracket x Body 20 204 15

Battery bracket reinforcement x Battery carrier 20 204 15

Front battery carrier x Battery bracket

reinforcement20 204 15

Air cleaner filter element x Body 5.0 51 44 in.*lbf

Radiator reservoir x Radiator support RH, Engine

mounting insulator RH5.0 51 44 in.*lbf

Battery clamp x Upper

Radiator supportFor bolt 8.5 87 75 in.*lbf

Battery clamp x Battery

clamp boltFor nut 5.0 51 44 in.*lbf

Page 381 of 2000

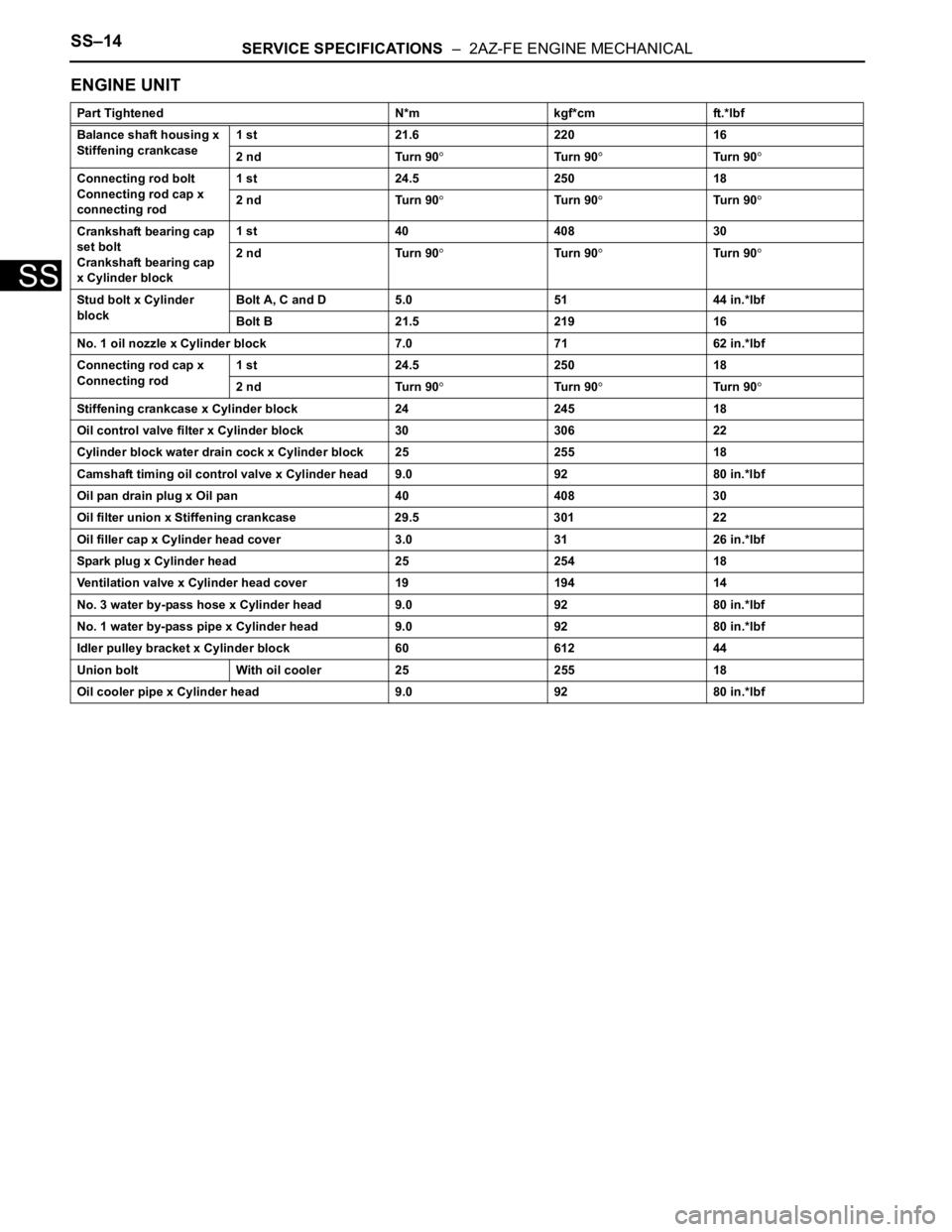

SS–14SERVICE SPECIFICATIONS – 2AZ-FE ENGINE MECHANICAL

SS

ENGINE UNIT

Part Tightened N*m kgf*cm ft.*lbf

Balance shaft housing x

Stiffening crankcase1 st 21.6 220 16

2 nd Turn 90

Tu r n 9 0Tu r n 9 0

Connecting rod bolt

Connecting rod cap x

connecting rod1 st 24.5 250 18

2 nd Turn 90

Tu r n 9 0Tu r n 9 0

Crankshaft bearing cap

set bolt

Crankshaft bearing cap

x Cylinder block1 st 40 408 30

2 nd Turn 90

Tu r n 9 0Tu r n 9 0

Stud bolt x Cylinder

blockBolt A, C and D 5.0 51 44 in.*lbf

Bolt B 21.5 219 16

No. 1 oil nozzle x Cylinder block 7.0 71 62 in.*lbf

Connecting rod cap x

Connecting rod1 st 24.5 250 18

2 nd Turn 90

Tu r n 9 0Tu r n 9 0

Stiffening crankcase x Cylinder block 24 245 18

Oil control valve filter x Cylinder block 30 306 22

Cylinder block water drain cock x Cylinder block 25 255 18

Camshaft timing oil control valve x Cylinder head 9.0 92 80 in.*lbf

Oil pan drain plug x Oil pan 40 408 30

Oil filter union x Stiffening crankcase 29.5 301 22

Oil filler cap x Cylinder head cover 3.0 31 26 in.*lbf

Spark plug x Cylinder head 25 254 18

Ventilation valve x Cylinder head cover 19 194 14

No. 3 water by-pass hose x Cylinder head 9.0 92 80 in.*lbf

No. 1 water by-pass pipe x Cylinder head 9.0 92 80 in.*lbf

Idler pulley bracket x Cylinder block 60 612 44

Union bolt With oil cooler 25 255 18

Oil cooler pipe x Cylinder head 9.0 92 80 in.*lbf

Page 468 of 2000

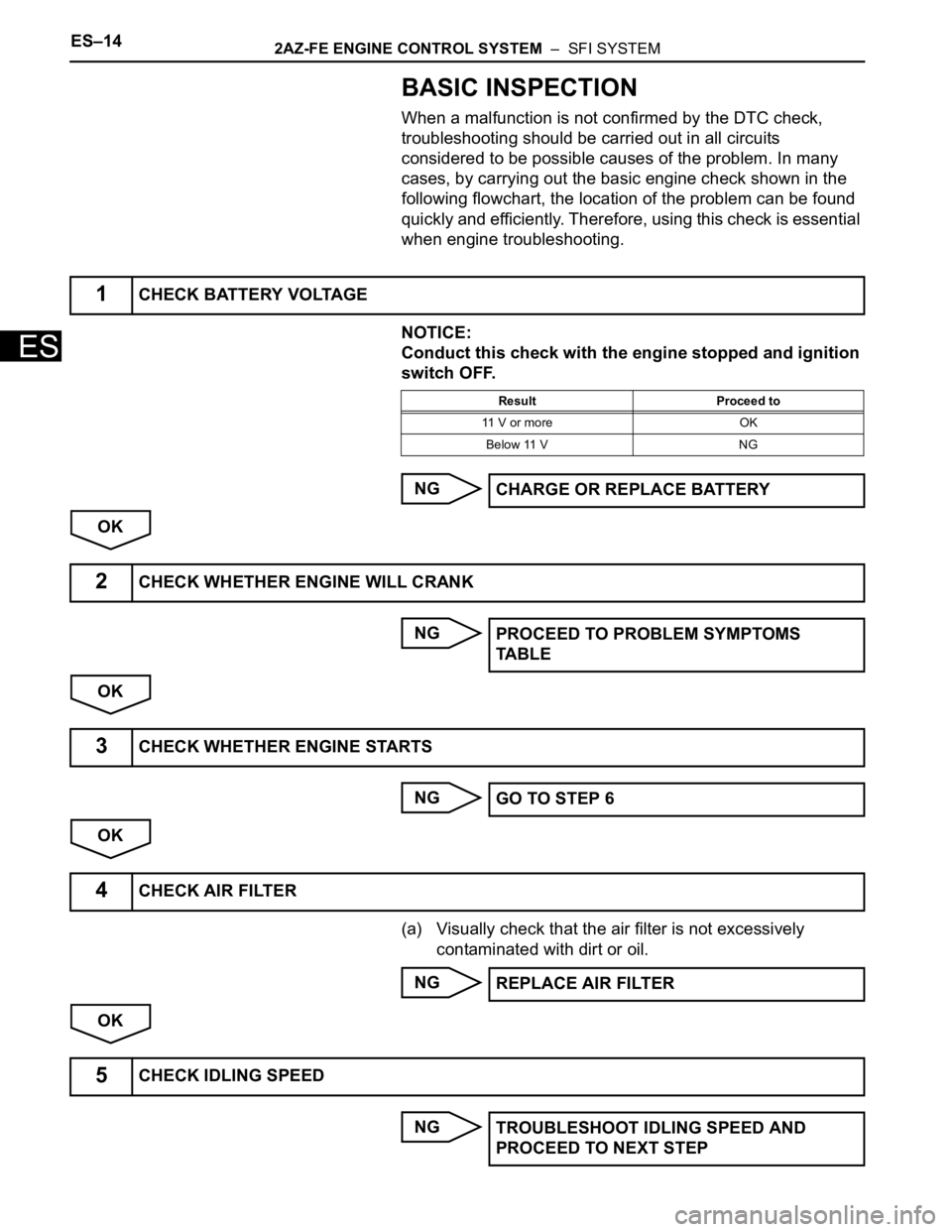

ES–142AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

BASIC INSPECTION

When a malfunction is not confirmed by the DTC check,

troubleshooting should be carried out in all circuits

considered to be possible causes of the problem. In many

cases, by carrying out the basic engine check shown in the

following flowchart, the location of the problem can be found

quickly and efficiently. Therefore, using this check is essential

when engine troubleshooting.

NOTICE:

Conduct this check with the engine stopped and ignition

switch OFF.

NG

OK

NG

OK

NG

OK

(a) Visually check that the air filter is not excessively

contaminated with dirt or oil.

NG

OK

NG

1CHECK BATTERY VOLTAGE

Result Proceed to

11 V or more OK

Below 11 V NG

CHARGE OR REPLACE BATTERY

2CHECK WHETHER ENGINE WILL CRANK

PROCEED TO PROBLEM SYMPTOMS

TA B L E

3CHECK WHETHER ENGINE STARTS

GO TO STEP 6

4CHECK AIR FILTER

REPLACE AIR FILTER

5CHECK IDLING SPEED

TROUBLESHOOT IDLING SPEED AND

PROCEED TO NEXT STEP

Page 540 of 2000

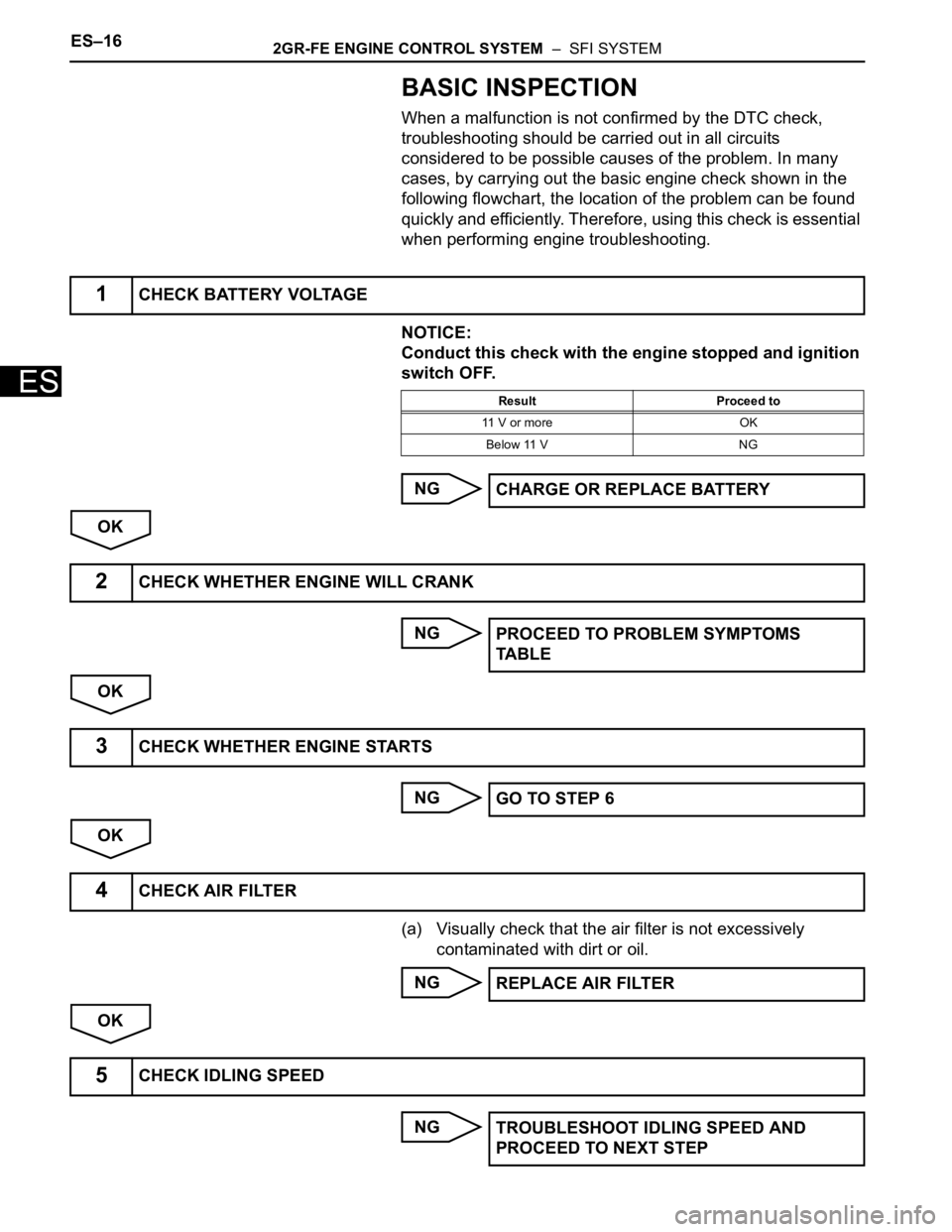

ES–162GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

BASIC INSPECTION

When a malfunction is not confirmed by the DTC check,

troubleshooting should be carried out in all circuits

considered to be possible causes of the problem. In many

cases, by carrying out the basic engine check shown in the

following flowchart, the location of the problem can be found

quickly and efficiently. Therefore, using this check is essential

when performing engine troubleshooting.

NOTICE:

Conduct this check with the engine stopped and ignition

switch OFF.

NG

OK

NG

OK

NG

OK

(a) Visually check that the air filter is not excessively

contaminated with dirt or oil.

NG

OK

NG

1CHECK BATTERY VOLTAGE

Result Proceed to

11 V or more OK

Below 11 V NG

CHARGE OR REPLACE BATTERY

2CHECK WHETHER ENGINE WILL CRANK

PROCEED TO PROBLEM SYMPTOMS

TA B L E

3CHECK WHETHER ENGINE STARTS

GO TO STEP 6

4CHECK AIR FILTER

REPLACE AIR FILTER

5CHECK IDLING SPEED

TROUBLESHOOT IDLING SPEED AND

PROCEED TO NEXT STEP

Page 651 of 2000

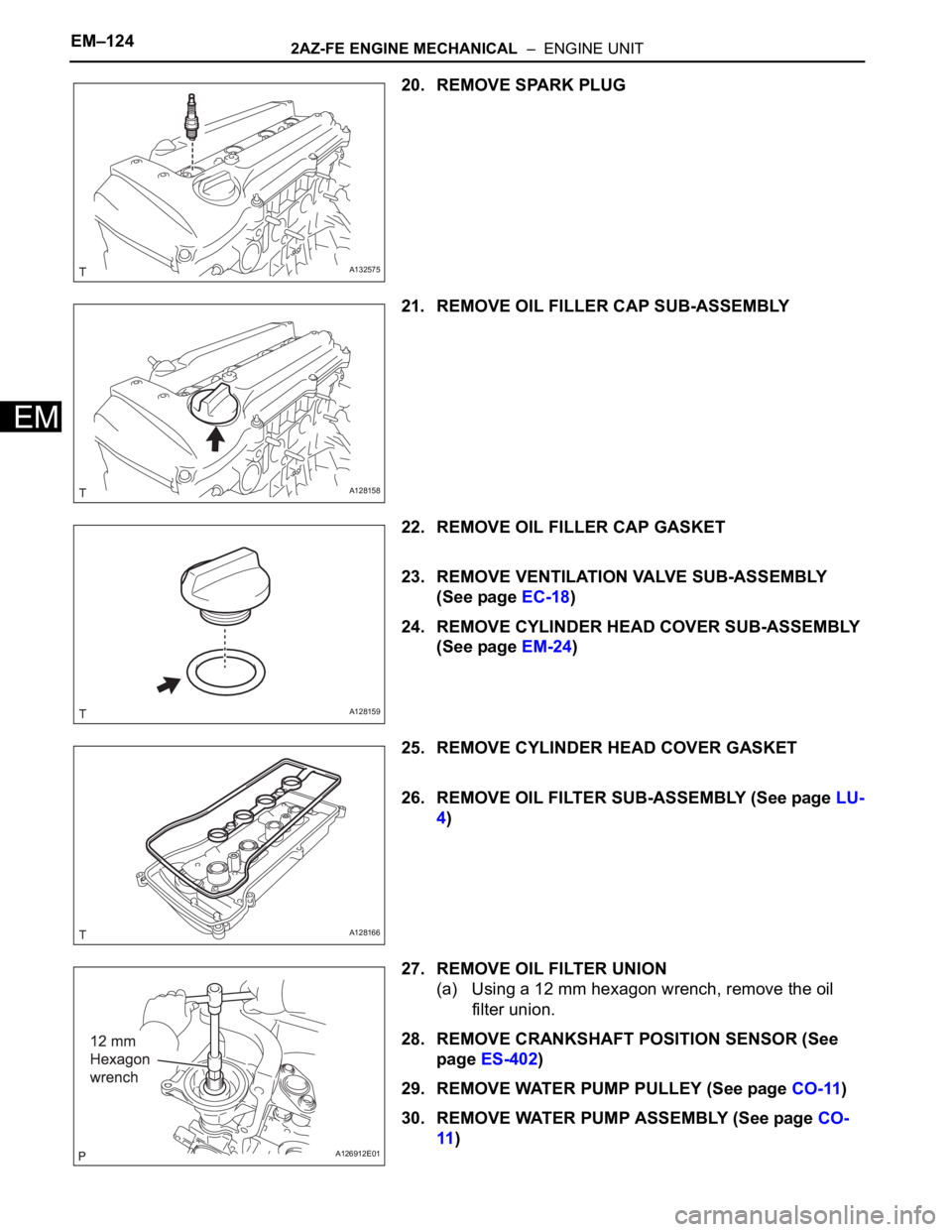

EM–1242AZ-FE ENGINE MECHANICAL – ENGINE UNIT

EM

20. REMOVE SPARK PLUG

21. REMOVE OIL FILLER CAP SUB-ASSEMBLY

22. REMOVE OIL FILLER CAP GASKET

23. REMOVE VENTILATION VALVE SUB-ASSEMBLY

(See page EC-18)

24. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

(See page EM-24)

25. REMOVE CYLINDER HEAD COVER GASKET

26. REMOVE OIL FILTER SUB-ASSEMBLY (See page LU-

4)

27. REMOVE OIL FILTER UNION

(a) Using a 12 mm hexagon wrench, remove the oil

filter union.

28. REMOVE CRANKSHAFT POSITION SENSOR (See

page ES-402)

29. REMOVE WATER PUMP PULLEY (See page CO-11)

30. REMOVE WATER PUMP ASSEMBLY (See page CO-

11)

A132575

A128158

A128159

A128166

A126912E01