ignition coil TOYOTA RAV4 2006 Service Owner's Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 629 of 2000

2AZ-FE ENGINE MECHANICAL – CYLINDER HEADEM–85

EM

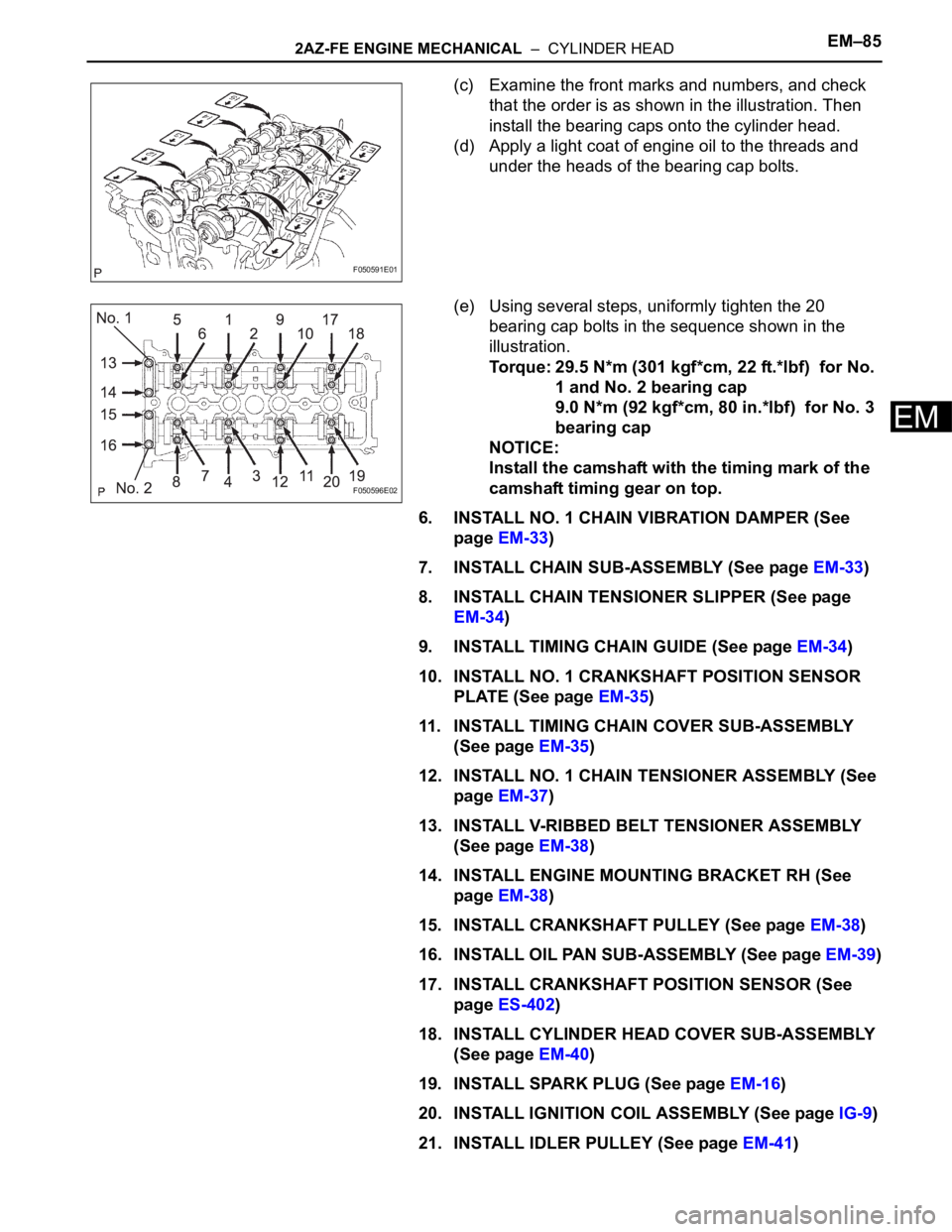

(c) Examine the front marks and numbers, and check

that the order is as shown in the illustration. Then

install the bearing caps onto the cylinder head.

(d) Apply a light coat of engine oil to the threads and

under the heads of the bearing cap bolts.

(e) Using several steps, uniformly tighten the 20

bearing cap bolts in the sequence shown in the

illustration.

Torque: 29.5 N*m (301 kgf*cm, 22 ft.*lbf) for No.

1 and No. 2 bearing cap

9.0 N*m (92 kgf*cm, 80 in.*lbf) for No. 3

bearing cap

NOTICE:

Install the camshaft with the timing mark of the

camshaft timing gear on top.

6. INSTALL NO. 1 CHAIN VIBRATION DAMPER (See

page EM-33)

7. INSTALL CHAIN SUB-ASSEMBLY (See page EM-33)

8. INSTALL CHAIN TENSIONER SLIPPER (See page

EM-34)

9. INSTALL TIMING CHAIN GUIDE (See page EM-34)

10. INSTALL NO. 1 CRANKSHAFT POSITION SENSOR

PLATE (See page EM-35)

11. INSTALL TIMING CHAIN COVER SUB-ASSEMBLY

(See page EM-35)

12. INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY (See

page EM-37)

13. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY

(See page EM-38)

14. INSTALL ENGINE MOUNTING BRACKET RH (See

page EM-38)

15. INSTALL CRANKSHAFT PULLEY (See page EM-38)

16. INSTALL OIL PAN SUB-ASSEMBLY (See page EM-39)

17. INSTALL CRANKSHAFT POSITION SENSOR (See

page ES-402)

18. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY

(See page EM-40)

19. INSTALL SPARK PLUG (See page EM-16)

20. INSTALL IGNITION COIL ASSEMBLY (See page IG-9)

21. INSTALL IDLER PULLEY (See page EM-41)

F050591E01

F050596E02

Page 650 of 2000

2AZ-FE ENGINE MECHANICAL – ENGINE UNITEM–123

EM

DISASSEMBLY

1. REMOVE IDLER PULLEY (See page EM-23)

2. REMOVE OIL DIPSTICK

3. REMOVE OIL DIPSTICK GUIDE (See page EM-57)

4. REMOVE MANIFOLD STAY (See page EM-57)

5. REMOVE NO. 2 MANIFOLD STAY (See page EM-58)

6. REMOVE NO. 1 EXHAUST MANIFOLD HEAT

INSULATOR (See page EM-58)

7. REMOVE EXHAUST MANIFOLD CONVERTER SUB-

ASSEMBLY (See page EM-58)

8. REMOVE WATER INLET (See page CO-15)

9. REMOVE THERMOSTAT

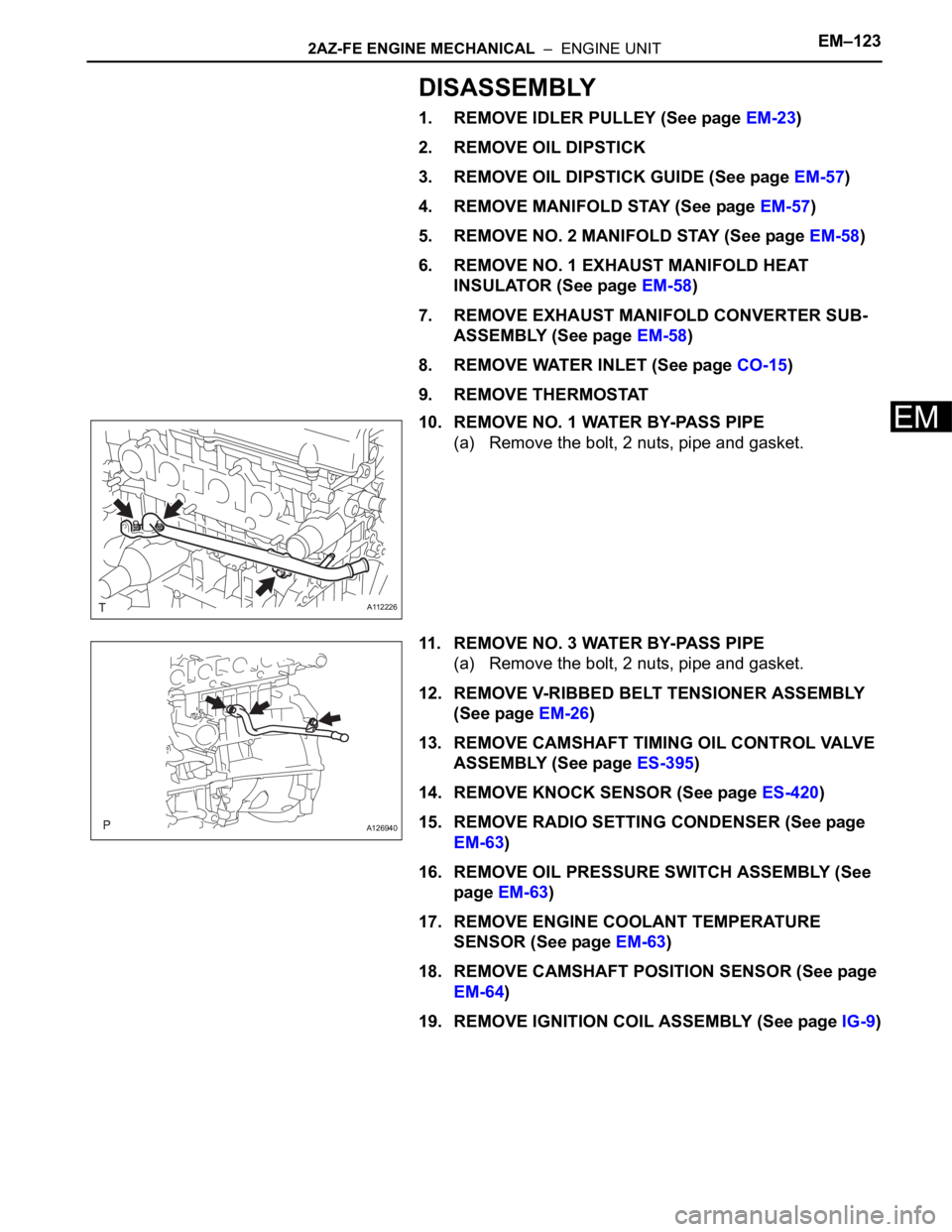

10. REMOVE NO. 1 WATER BY-PASS PIPE

(a) Remove the bolt, 2 nuts, pipe and gasket.

11. REMOVE NO. 3 WATER BY-PASS PIPE

(a) Remove the bolt, 2 nuts, pipe and gasket.

12. REMOVE V-RIBBED BELT TENSIONER ASSEMBLY

(See page EM-26)

13. REMOVE CAMSHAFT TIMING OIL CONTROL VALVE

ASSEMBLY (See page ES-395)

14. REMOVE KNOCK SENSOR (See page ES-420)

15. REMOVE RADIO SETTING CONDENSER (See page

EM-63)

16. REMOVE OIL PRESSURE SWITCH ASSEMBLY (See

page EM-63)

17. REMOVE ENGINE COOLANT TEMPERATURE

SENSOR (See page EM-63)

18. REMOVE CAMSHAFT POSITION SENSOR (See page

EM-64)

19. REMOVE IGNITION COIL ASSEMBLY (See page IG-9)

A112226

A126940

Page 680 of 2000

EM–342GR-FE ENGINE MECHANICAL – ENGINE ASSEMBLY

EM

(c) Install and uniformly tighten the 6 bolts and 4 nuts in

several passes.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

(d) Connect the 6 fuel injector connectors.

19. INSTALL FUEL INJECTOR ASSEMBLY (See page FU-

16)

20. INSTALL NO. 2 ENGINE MOUNTING STAY RH

(a) Install the mounting stay with the bolt.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

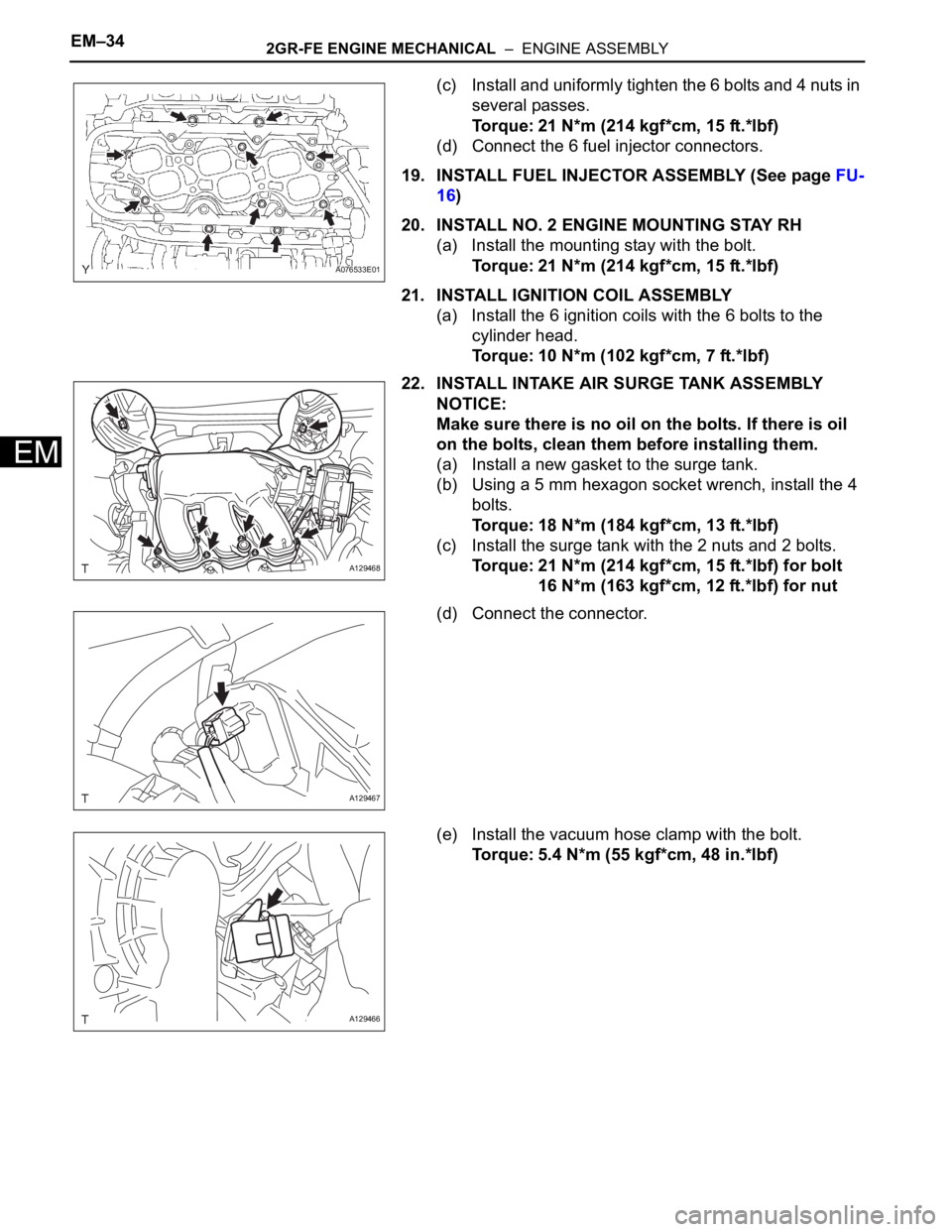

21. INSTALL IGNITION COIL ASSEMBLY

(a) Install the 6 ignition coils with the 6 bolts to the

cylinder head.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

22. INSTALL INTAKE AIR SURGE TANK ASSEMBLY

NOTICE:

Make sure there is no oil on the bolts. If there is oil

on the bolts, clean them before installing them.

(a) Install a new gasket to the surge tank.

(b) Using a 5 mm hexagon socket wrench, install the 4

bolts.

Torque: 18 N*m (184 kgf*cm, 13 ft.*lbf)

(c) Install the surge tank with the 2 nuts and 2 bolts.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf) for bolt

16 N*m (163 kgf*cm, 12 ft.*lbf) for nut

(d) Connect the connector.

(e) Install the vacuum hose clamp with the bolt.

Torque: 5.4 N*m (55 kgf*cm, 48 in.*lbf)

A076533E01

A129468

A129467

A129466

Page 885 of 2000

2AZ-FE IGNITION – IGNITION SYSTEMIG–5

IG

ON-VEHICLE INSPECTION

1. CHECK IGNITION COIL ASSEMBLY AND PERFORM

SPARK TEST

NOTICE:

In this section, the terms "cold" and "hot" refer to

the temperature of the coils. "Cold" means

approximately -10 to 50

C (14 to 122F). "Hot" means

approximately 50 to 100

C (122 to 212F).

(a) Check the DTCs.

NOTICE:

If a DTC is present, perform troubleshooting in

accordance with the procedure for that DTC.

(b) Check that sparks occur.

(1) Remove the No. 1 engine cover.

(2) Remove the bolt and ignition coil.

(3) Using a 16 mm spark plug wrench, remove the

spark plug.

(4) Disconnect the 4 fuel injector connectors.

(5) Install the spark plug into the ignition coil, and

then connect the ignition coil connectors.

(6) Ground the spark plug.

(7) Check that sparks occur at the spark plug while

the engine is being cranked.

NOTICE:

• Be sure to ground the spark plugs when

checking them.

• If the ignition coil has been struck or

dropped, replace it.

• Do not crank the engine for more than 2

seconds.

If sparks do not occur, Perform the spark test.

(8) Using a 16 mm plug wrench, install the spark

plug.

Torque: 25 N*m (254 kgf*cm, 18 ft.*lbf)

A124849E01

A097448E01

A124396

Page 886 of 2000

IG–62AZ-FE IGNITION – IGNITION SYSTEM

IG

(9) Install the ignition coil with the bolt.

Torque: 9.0 N*m (92 kgf*cm, 80 in.*lbf)

(10) Connect the 4 fuel injector connectors.

(11) Install the No. 1 engine cover.

(c) Spark test flow chart.

(1) Check that the ignition coil connector is

securely connected.

Result

(2) Perform the spark test on each ignition coil.

1. Replace the ignition coil with a normal one.

2. Perform the spark test again.

Result

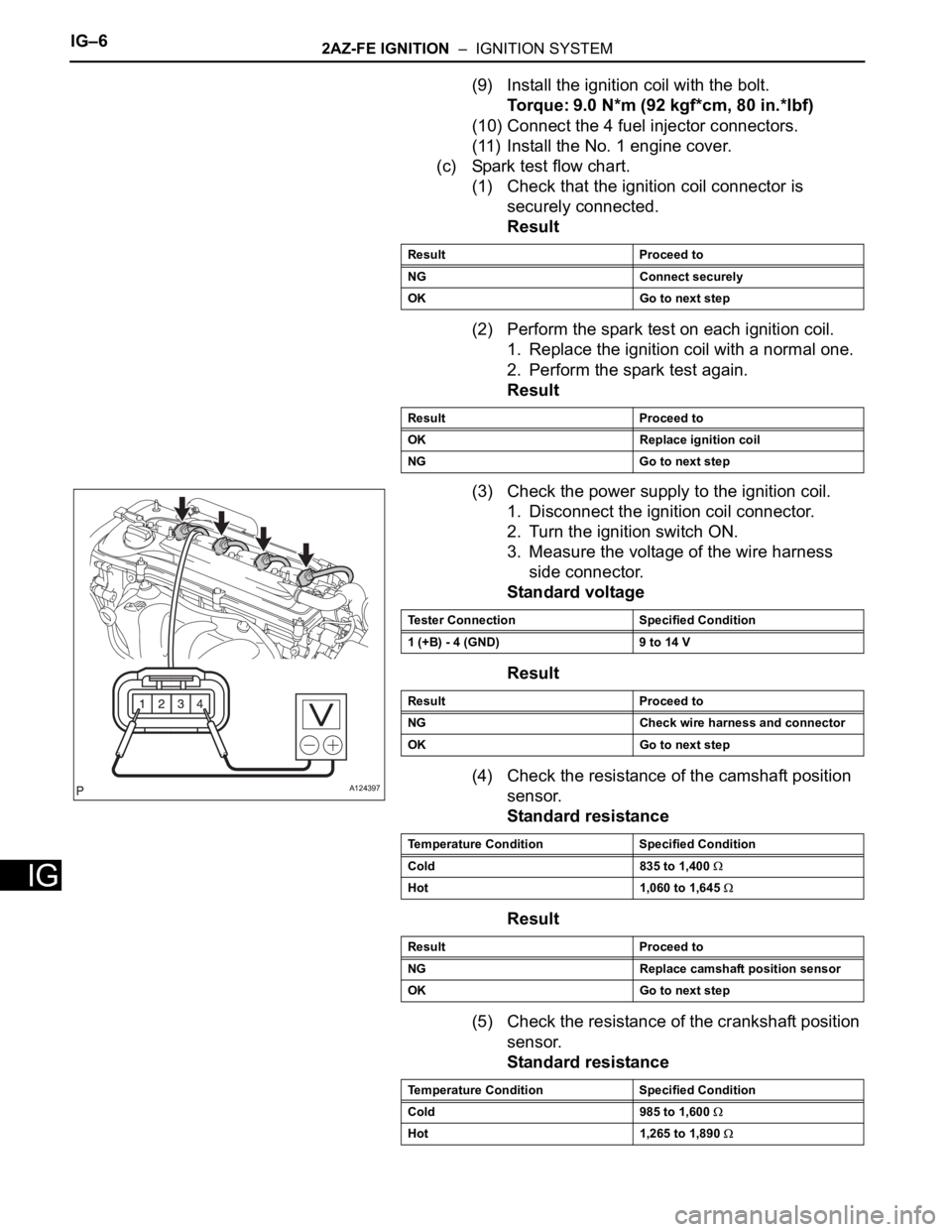

(3) Check the power supply to the ignition coil.

1. Disconnect the ignition coil connector.

2. Turn the ignition switch ON.

3. Measure the voltage of the wire harness

side connector.

Standard voltage

Result

(4) Check the resistance of the camshaft position

sensor.

Standard resistance

Result

(5) Check the resistance of the crankshaft position

sensor.

Standard resistance

Result Proceed to

NG Connect securely

OK Go to next step

Result Proceed to

OK Replace ignition coil

NG Go to next step

A124397

Tester Connection Specified Condition

1 (+B) - 4 (GND) 9 to 14 V

Result Proceed to

NG Check wire harness and connector

OK Go to next step

Temperature Condition Specified Condition

Cold 835 to 1,400

Hot 1,060 to 1,645

Result Proceed to

NG Replace camshaft position sensor

OK Go to next step

Temperature Condition Specified Condition

Cold 985 to 1,600

Hot 1,265 to 1,890

Page 887 of 2000

2AZ-FE IGNITION – IGNITION SYSTEMIG–7

IG

Result

(6) Check the IGT signal from the ECM.

Result

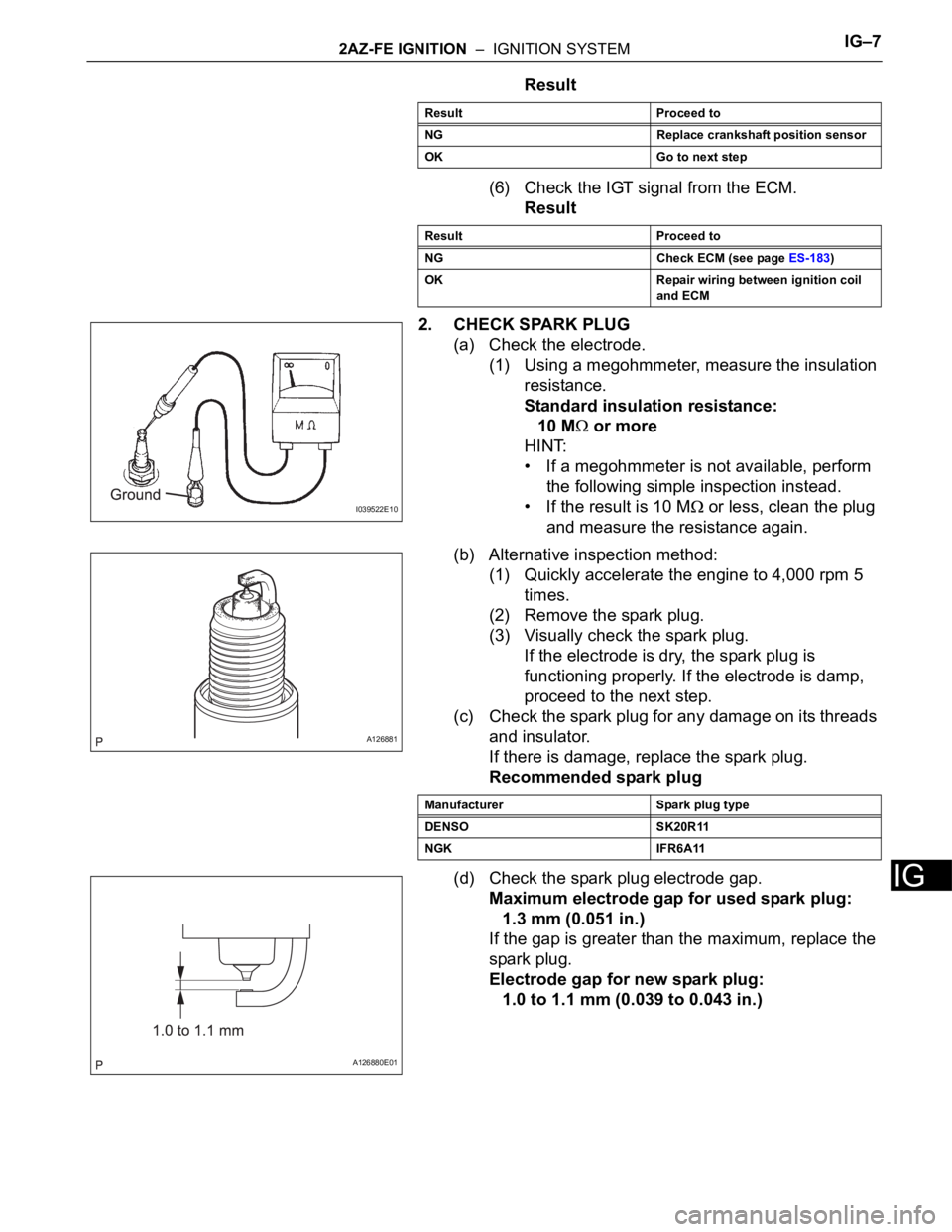

2. CHECK SPARK PLUG

(a) Check the electrode.

(1) Using a megohmmeter, measure the insulation

resistance.

Standard insulation resistance:

10 M

or more

HINT:

• If a megohmmeter is not available, perform

the following simple inspection instead.

• If the result is 10 M

or less, clean the plug

and measure the resistance again.

(b) Alternative inspection method:

(1) Quickly accelerate the engine to 4,000 rpm 5

times.

(2) Remove the spark plug.

(3) Visually check the spark plug.

If the electrode is dry, the spark plug is

functioning properly. If the electrode is damp,

proceed to the next step.

(c) Check the spark plug for any damage on its threads

and insulator.

If there is damage, replace the spark plug.

Recommended spark plug

(d) Check the spark plug electrode gap.

Maximum electrode gap for used spark plug:

1.3 mm (0.051 in.)

If the gap is greater than the maximum, replace the

spark plug.

Electrode gap for new spark plug:

1.0 to 1.1 mm (0.039 to 0.043 in.)

Result Proceed to

NG Replace crankshaft position sensor

OK Go to next step

Result Proceed to

NG Check ECM (see page ES-183)

OK Repair wiring between ignition coil

and ECM

I039522E10

A126881

Manufacturer Spark plug type

DENSO SK20R11

NGK IFR6A11

A126880E01

Page 895 of 2000

2GR-FE IGNITION – IGNITION SYSTEMIG–5

IG

ON-VEHICLE INSPECTION

1. CHECK IGNITION COIL ASSEMBLY AND PERFORM

SPARK TEST

NOTICE:

In this section, the terms "Cold" and "Hot" refer to

the temperature of the sensor. "Cold" means

approximately -10 to 50

C (14 to 122F). "Hot" means

approximately 50 to 100

C (122 to 212F).

(a) Check the DTCs.

NOTICE:

If a DTC is present, perform troubleshooting in

accordance with the procedure for that DTC.

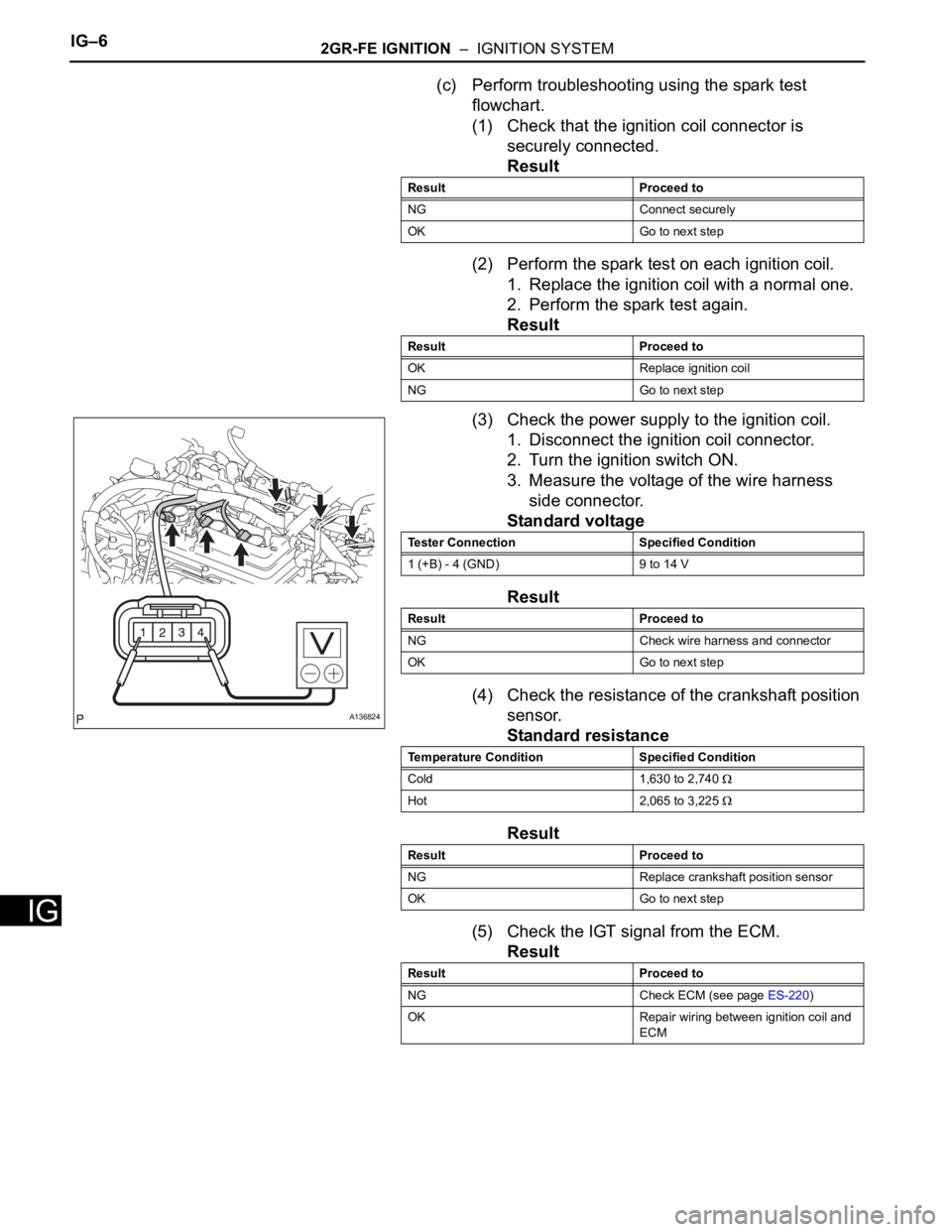

(b) Check that sparks occur.

(1) Remove the V-bank cover.

(2) Remove the intake air surge tank (see page

EM-27).

(3) Remove the bolt and ignition coil.

(4) Using a 16 mm spark plug wrench, remove the

spark plug.

(5) Disconnect the 6 fuel injector connectors.

(6) Install the spark plug into the ignition coil, and

then connect the ignition coil connectors.

(7) Ground the spark plug.

(8) Check that sparks occur at the spark plug while

the engine is being cranked.

NOTICE:

• Be sure to ground the spark plugs when

checking them.

• If the ignition coil has been struck or

dropped, replace it.

• Do not crank the engine for more than 2

seconds.

If sparks do not occur, perform troubleshooting

using the spark test flowchart.

(9) Using a 16 mm plug wrench, install the spark

plug.

Torque: 25 N*m (254 kgf*cm, 18 ft.*lbf)

(10) Install the ignition coil with the bolt.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

(11) Connect the 6 fuel injector connectors.

(12) Install the intake air surge tank (see page EM-

34).

(13) Install the V-bank cover.

A136823

A136826

Page 896 of 2000

IG–62GR-FE IGNITION – IGNITION SYSTEM

IG

(c) Perform troubleshooting using the spark test

flowchart.

(1) Check that the ignition coil connector is

securely connected.

Result

(2) Perform the spark test on each ignition coil.

1. Replace the ignition coil with a normal one.

2. Perform the spark test again.

Result

(3) Check the power supply to the ignition coil.

1. Disconnect the ignition coil connector.

2. Turn the ignition switch ON.

3. Measure the voltage of the wire harness

side connector.

Standard voltage

Result

(4) Check the resistance of the crankshaft position

sensor.

Standard resistance

Result

(5) Check the IGT signal from the ECM.

Result

Result Proceed to

NG Connect securely

OK Go to next step

Result Proceed to

OK Replace ignition coil

NG Go to next step

A136824

Tester Connection Specified Condition

1 (+B) - 4 (GND) 9 to 14 V

Result Proceed to

NG Check wire harness and connector

OK Go to next step

Temperature Condition Specified Condition

Cold 1,630 to 2,740

Hot 2,065 to 3,225

Result Proceed to

NG Replace crankshaft position sensor

OK Go to next step

Result Proceed to

NG Check ECM (see page ES-220)

OK Repair wiring between ignition coil and

ECM

Page 1793 of 2000

EI–22ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM

EI

2. PERFORM ACTIVE TEST

HINT:

Performing the intelligent tester's ACTIVE TEST allows

relay, VSV, actuator and other items to be operated

without removing any parts. Performing the ACTIVE

TEST early in troubleshooting is one way to save time.

The DATA LIST can be displayed during the ACTIVE

TEST.

(a) Connect the intelligent tester (with CAN VIM) to the

DLC3.

(b) Turn the ignition switch ON and turn the tester ON.

(c) Select the following menu items: DIAGNOSIS /

OBD/MOBD / IMMOBILISER / ACTIVE TEST.

(d) Perform the ACTIVE TEST by referring to the table

below.

Transponder key ECU:

+B+B judgment / NORMAL or

BREAKNORMAL: Battery supply is

normal

BREAK: Battery supply is

malfunctioning-

ANTENNA COILTransponder key coil condition /

NORMAL or FAILNORMAL: Transponder key coil

is normal

FAIL: Transponder key coil is

malfunctioning- ItemMeasurement Item / Display

(Range)Normal Condition Diagnostic Note

Item Test Details Diagnostic Note

SECURITY INDIC Turns security indicator light / ON or OFF -

Page 1799 of 2000

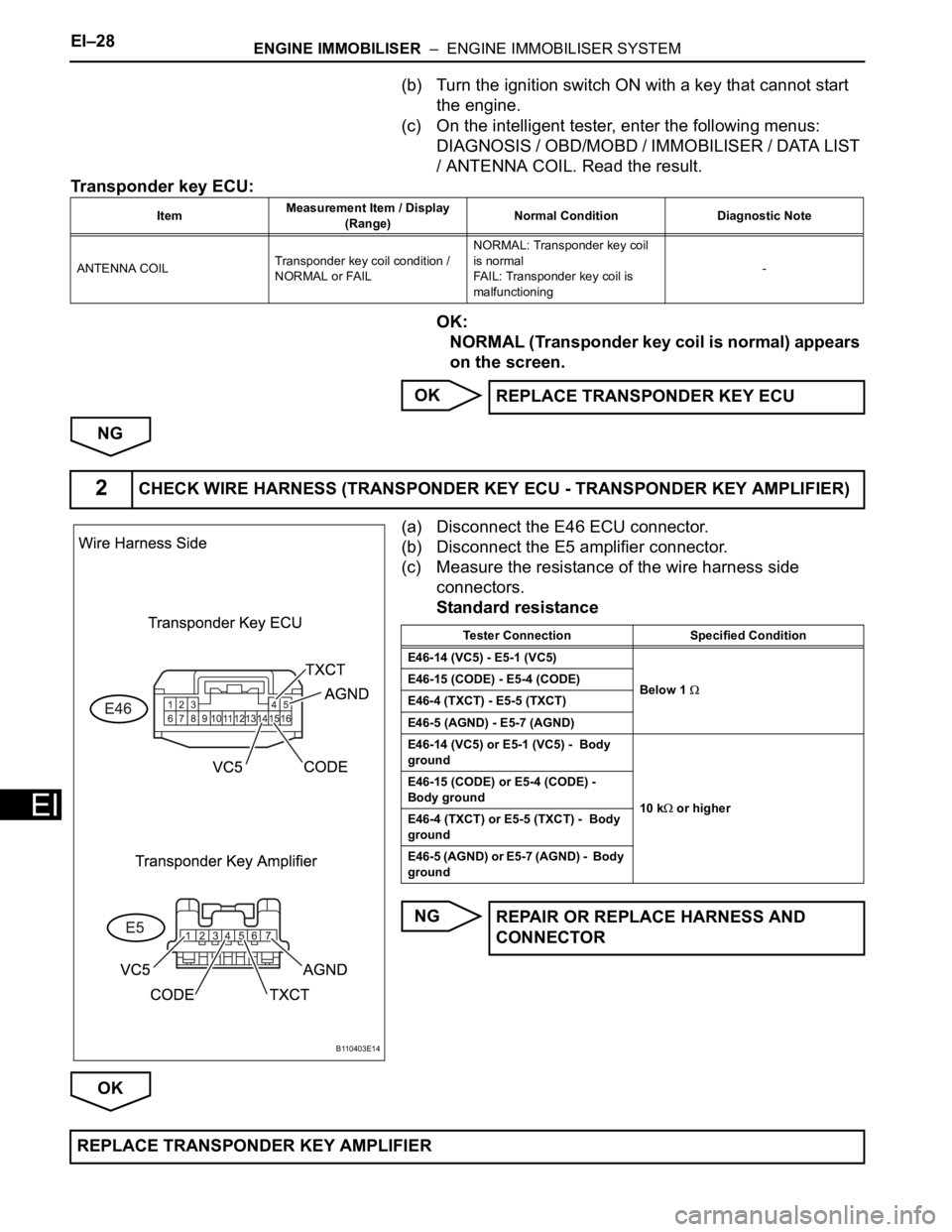

EI–28ENGINE IMMOBILISER – ENGINE IMMOBILISER SYSTEM

EI

(b) Turn the ignition switch ON with a key that cannot start

the engine.

(c) On the intelligent tester, enter the following menus:

DIAGNOSIS / OBD/MOBD / IMMOBILISER / DATA LIST

/ ANTENNA COIL. Read the result.

Transponder key ECU:

OK:

NORMAL (Transponder key coil is normal) appears

on the screen.

OK

NG

(a) Disconnect the E46 ECU connector.

(b) Disconnect the E5 amplifier connector.

(c) Measure the resistance of the wire harness side

connectors.

Standard resistance

NG

OK

ItemMeasurement Item / Display

(Range)Normal Condition Diagnostic Note

ANTENNA COILTransponder key coil condition /

NORMAL or FAILNORMAL: Transponder key coil

is normal

FAIL: Transponder key coil is

malfunctioning-

REPLACE TRANSPONDER KEY ECU

2CHECK WIRE HARNESS (TRANSPONDER KEY ECU - TRANSPONDER KEY AMPLIFIER)

B110403E14

Tester Connection Specified Condition

E46-14 (VC5) - E5-1 (VC5)

Below 1

E46-15 (CODE) - E5-4 (CODE)

E46-4 (TXCT) - E5-5 (TXCT)

E46-5 (AGND) - E5-7 (AGND)

E46-14 (VC5) or E5-1 (VC5) - Body

ground

10 k

or higher E46-15 (CODE) or E5-4 (CODE) -

Body ground

E46-4 (TXCT) or E5-5 (TXCT) - Body

ground

E46-5 (AGND) or E5-7 (AGND) - Body

ground

REPAIR OR REPLACE HARNESS AND

CONNECTOR

REPLACE TRANSPONDER KEY AMPLIFIER