catalytic converter TOYOTA RAV4 2006 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 1 of 2000

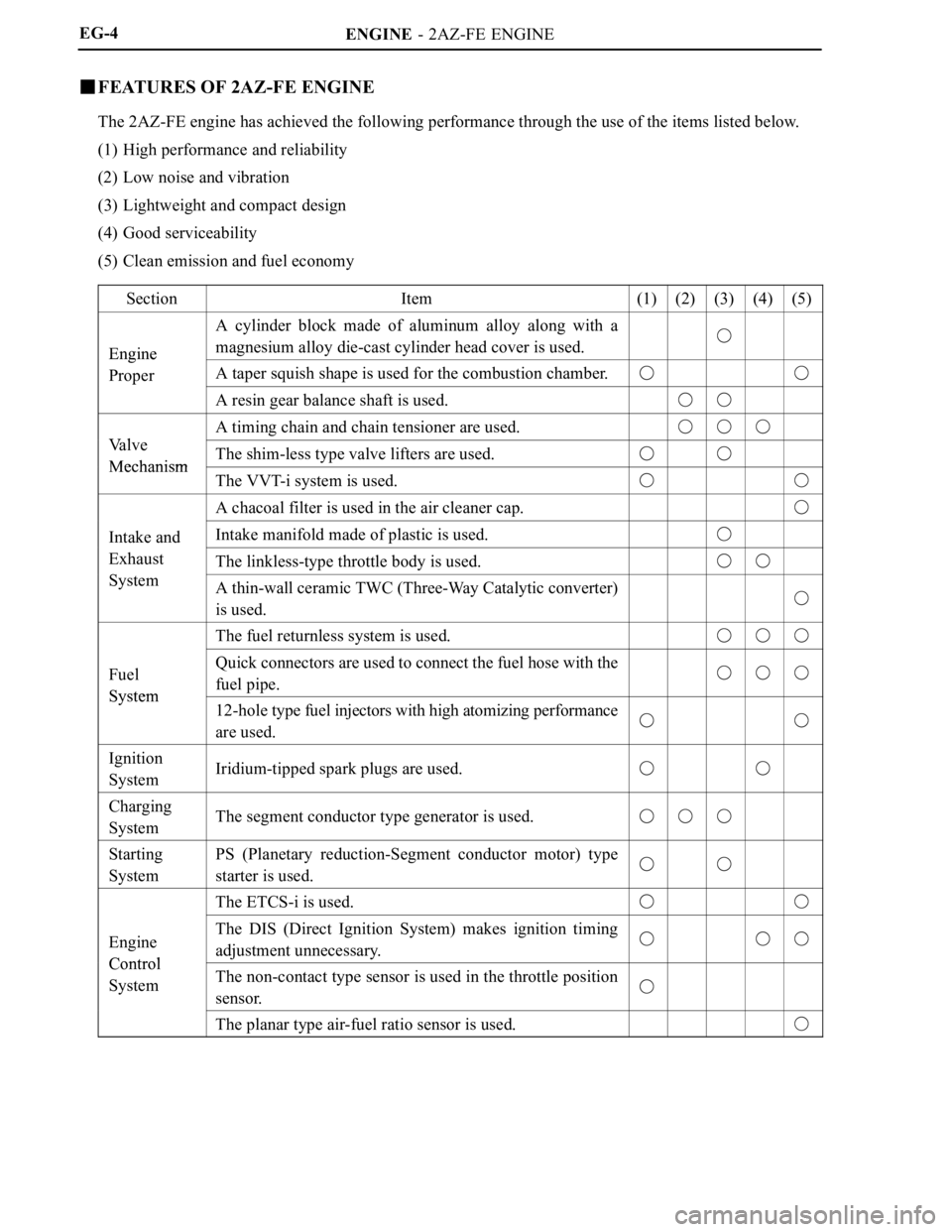

ENGINE - 2AZ-FE ENGINE EG-4

FEATURES OF 2AZ-FE ENGINE

The 2AZ-FE engine has achieved the following performance through the use of the items listed below.

(1) High performance and reliability

(2) Low noise and vibration

(3) Lightweight and compact design

(4) Good serviceability

(5) Clean emission and fuel economy

Section

Item(1)(2)(3)(4)(5)

Engine

A cylinder block made of aluminum alloy along with a

magnesium alloy die-cast cylinder head cover is used.

Engine

ProperA taper squish shape is used for the combustion chamber.p

A resin gear balance shaft is used.

Vl

A timing chain and chain tensioner are used.

Va l v e

MechanismThe shim-less type valve lifters are used.MechanismThe VVT-i system is used.

A chacoal filter is used in the air cleaner cap.

Intake andIntake manifold made of plastic is used.Intake and

ExhaustThe linkless-type throttle body is used.

SystemA thin-wall ceramic TWC (Three-Way Catalytic converter)

is used.

The fuel returnless system is used.

Fuel

System

Quick connectors are used to connect the fuel hose with the

fuel pipe.

System12-hole type fuel injectors with high atomizing performance

are used.

Ignition

SystemIridium-tipped spark plugs are used.

Charging

SystemThe segment conductor type generator is used.

Starting

SystemPS (Planetary reduction-Segment conductor motor) type

starter is used.

The ETCS-i is used.

Engine

Control

The DIS (Direct Ignition System) makes ignition timing

adjustment unnecessary.

Control

SystemThe non-contact type sensor is used in the throttle position

sensor.

The planar type air-fuel ratio sensor is used.

Page 17 of 2000

ENGINE - 2AZ-FE ENGINE

01NEG37Y

Mesh Type Gasket

01NEG38Y

TWC EG-20

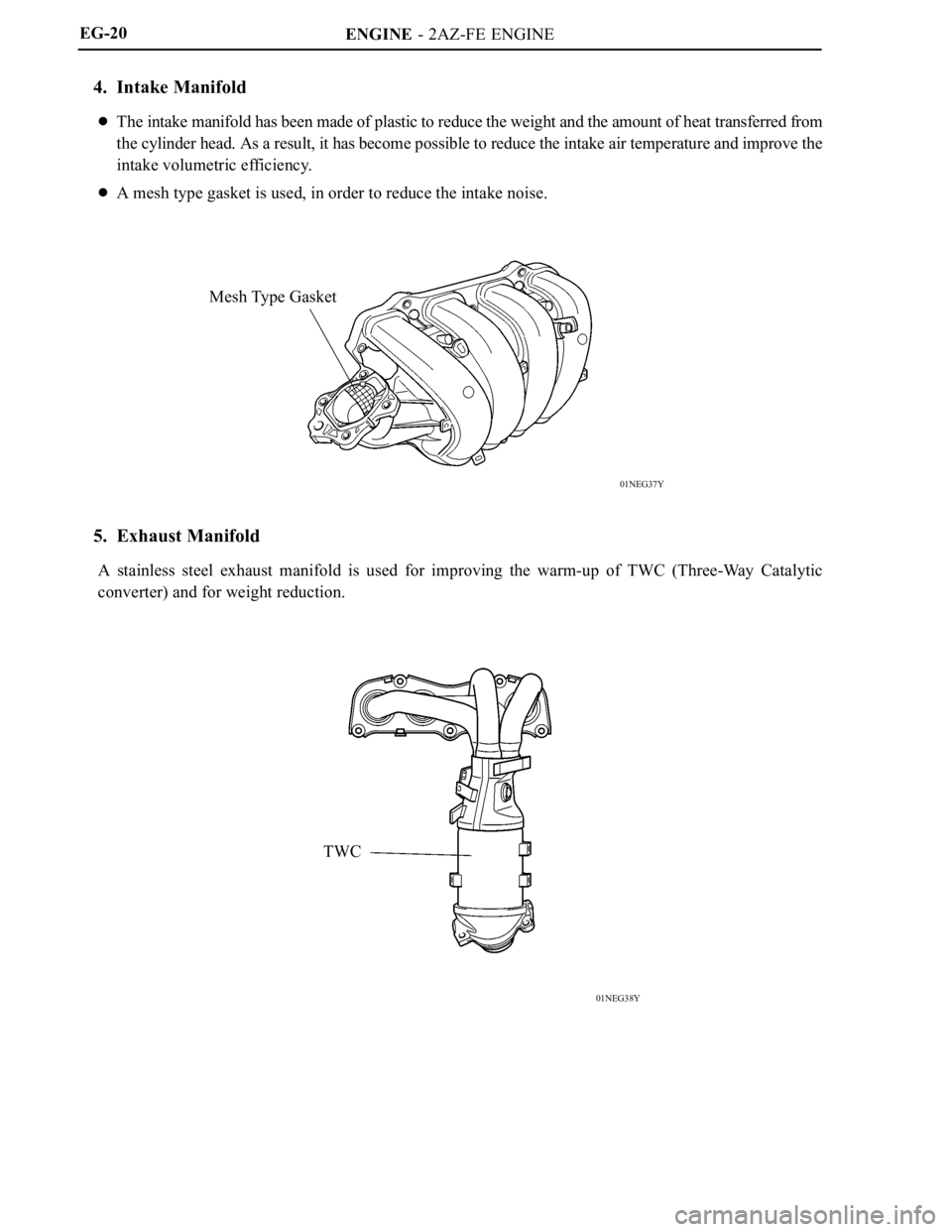

4. Intake Manifold

The intake manifold has been made of plastic to reduce the weight and the amount of heat transferred from

the cylinder head. As a result, it has become possible to reduce the intake air temperature and improve the

intake volumetric efficiency.

A mesh type gasket is used, in order to reduce the intake noise.

5. Exhaust Manifold

A stainless steel exhaust manifold is used for improving the warm-up of TWC (Three-Way Catalytic

converter) and for weight reduction.

Page 67 of 2000

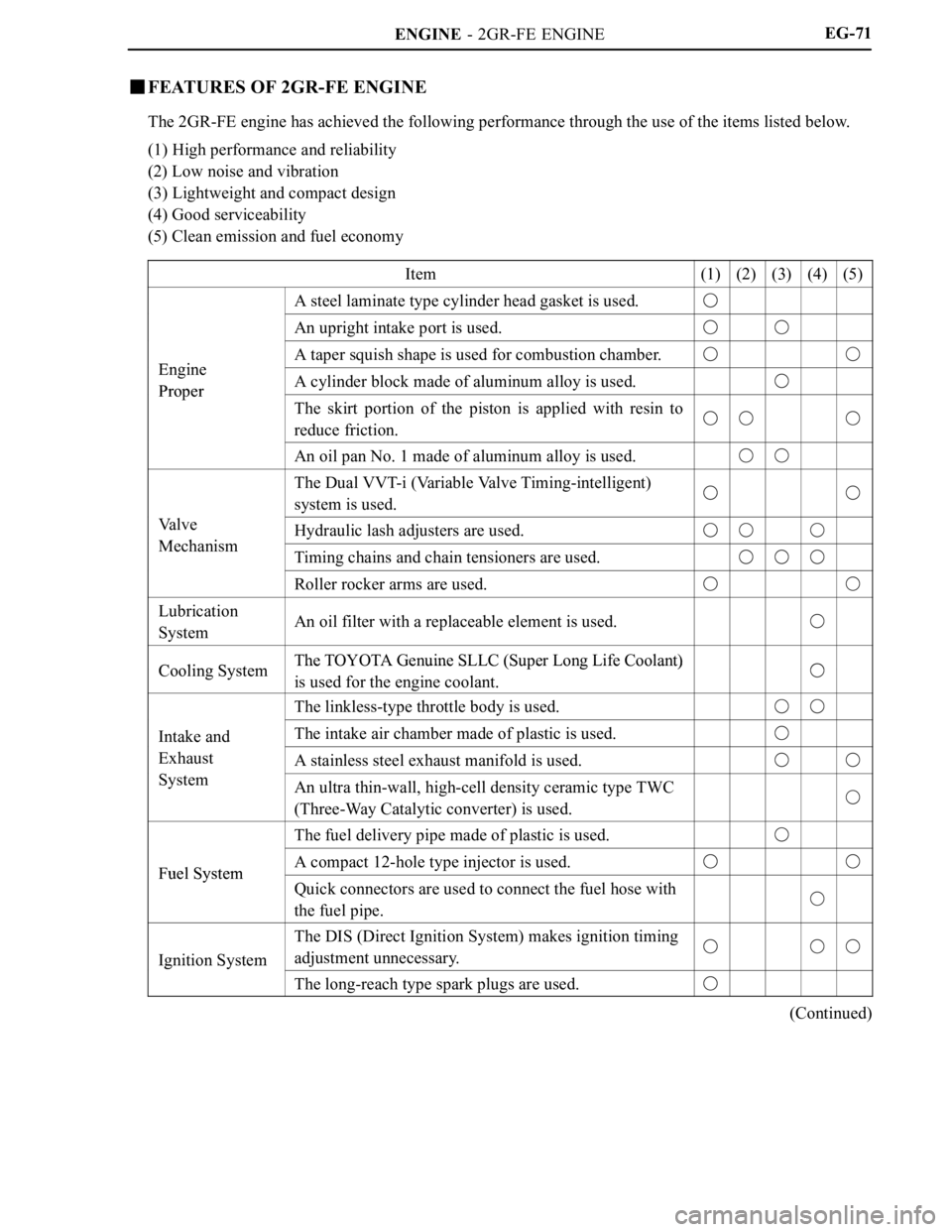

ENGINE - 2GR-FE ENGINEEG-71

FEATURES OF 2GR-FE ENGINE

The 2GR-FE engine has achieved the following performance through the use of the items listed below.

(1) High performance and reliability

(2) Low noise and vibration

(3) Lightweight and compact design

(4) Good serviceability

(5) Clean emission and fuel economy

Item

(1)(2)(3)(4)(5)

A steel laminate type cylinder head gasket is used.

An upright intake port is used.

EngineA taper squish shape is used for combustion chamber.Engine

ProperA cylinder block made of aluminum alloy is used.Proper

The skirt portion of the piston is applied with resin to

reduce friction.

An oil pan No. 1 made of aluminum alloy is used.

The Dual VVT-i (Variable Valve Timing-intelligent)

system is used.

Va l v e

Mh i

Hydraulic lash adjusters are used.

MechanismTiming chains and chain tensioners are used.

Roller rocker arms are used.

Lubrication

SystemAn oil filter with a replaceable element is used.

Cooling SystemThe TOYOTA Genuine SLLC (Super Long Life Coolant)Cooling SystemThe TOYOTA Genuine SLLC (Super Long Life Coolant)

is used for the engine coolant.

The linkless-type throttle body is used.

Intake andThe intake air chamber made of plastic is used.Intake and

Exhaust

S

A stainless steel exhaust manifold is used.

SystemAn ultra thin-wall, high-cell density ceramic type TWC

(Three-Way Catalytic converter) is used.

The fuel delivery pipe made of plastic is used.

Fuel SystemA compact 12-hole type injector is used.Fuel SystemQuick connectors are used to connect the fuel hose with

the fuel pipe.

Ignition System

The DIS (Direct Ignition System) makes ignition timing

adjustment unnecessary.

Ignition System

The long-reach type spark plugs are used.

(Continued)

Page 89 of 2000

ENGINE - 2GR-FE ENGINE

01MEG14Y

TWC

Right Bank Exhaust

ManifoldTWC

Left Bank Exhaust

ManifoldUltra

Thin-Wall

01MEG16Y

Exhaust Front PipeExhaust Center PipeTailpipe

Sub Muffler

Ball Joint

Main Muffler

TWC

Ball Joint

Spring

Bolt

Gasket Ball JointEG-93

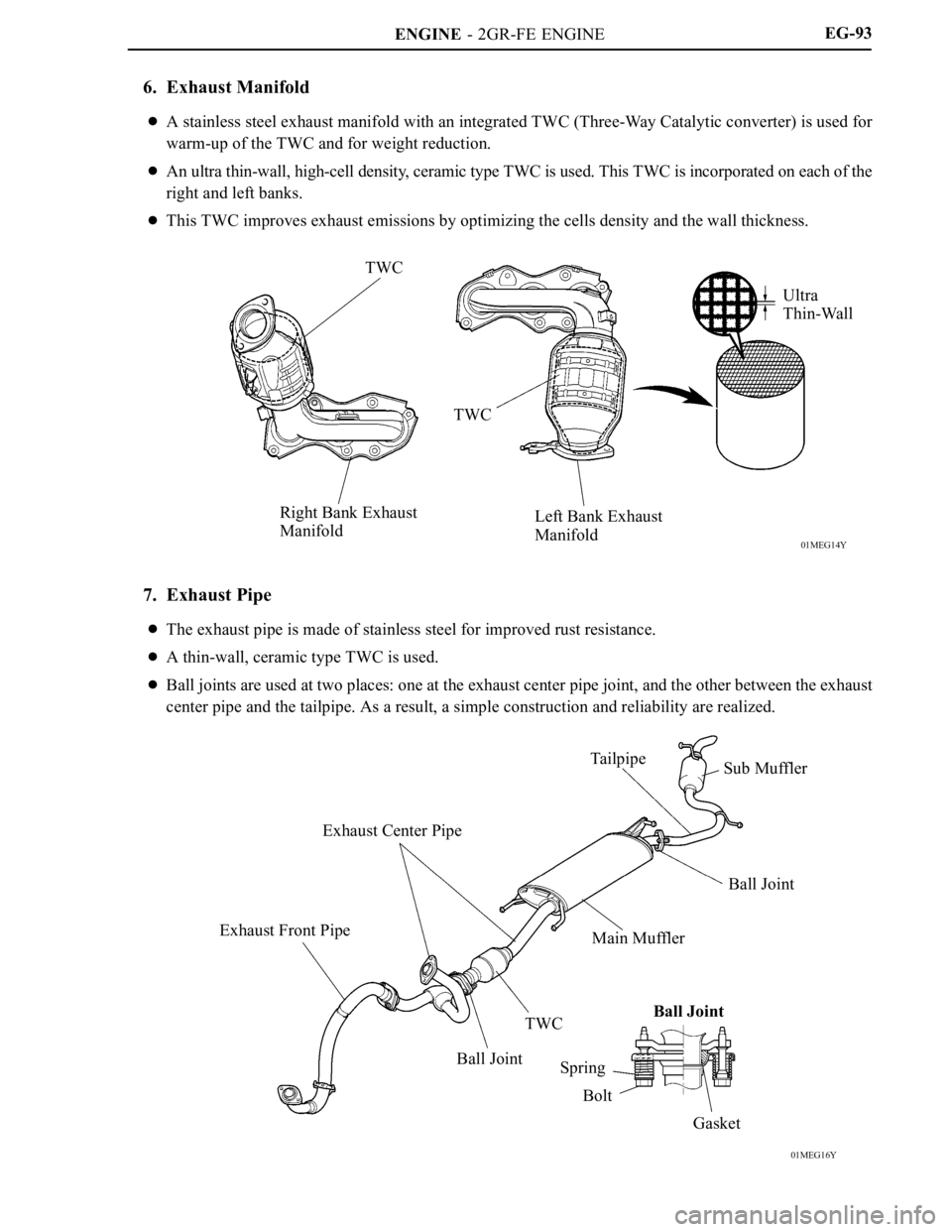

6. Exhaust Manifold

A stainless steel exhaust manifold with an integrated TWC (Three-Way Catalytic converter) is used for

warm-up of the TWC and for weight reduction.

An ultra thin-wall, high-cell density, ceramic type TWC is used. This TWC is incorporated on each of the

right and left banks.

This TWC improves exhaust emissions by optimizing the cells density and the wall thickness.

7. Exhaust Pipe

The exhaust pipe is made of stainless steel for improved rust resistance.

A thin-wall, ceramic type TWC is used.

Ball joints are used at two places: one at the exhaust center pipe joint, and the other between the exhaust

center pipe and the tailpipe. As a result, a simple construction and reliability are realized.

Page 221 of 2000

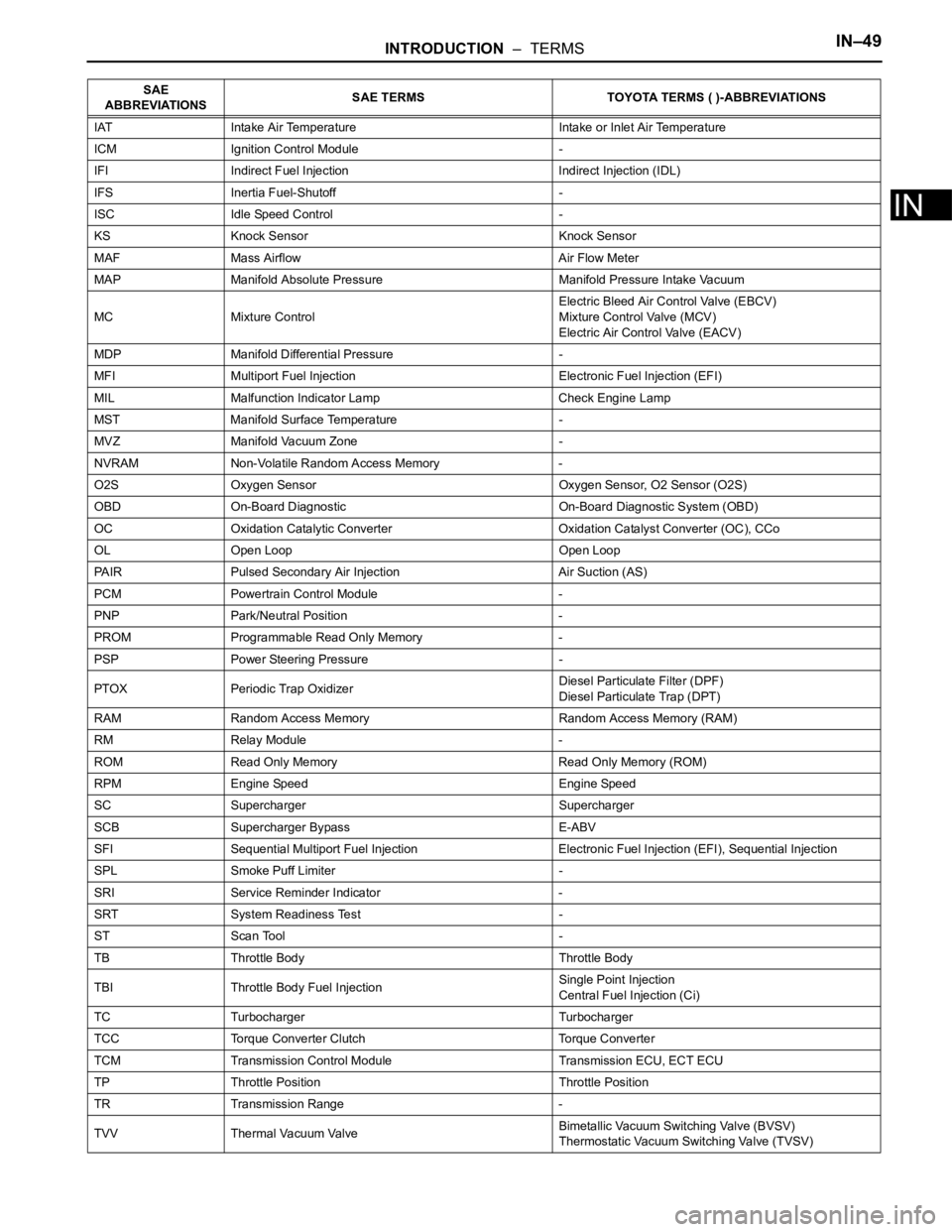

INTRODUCTION – TERMSIN–49

IN

IAT Intake Air Temperature Intake or Inlet Air Temperature

ICM Ignition Control Module -

IFI Indirect Fuel Injection Indirect Injection (IDL)

IFS Inertia Fuel-Shutoff -

ISC Idle Speed Control -

KS Knock Sensor Knock Sensor

MAF Mass Airflow Air Flow Meter

MAP Manifold Absolute Pressure Manifold Pressure Intake Vacuum

MC Mixture ControlElectric Bleed Air Control Valve (EBCV)

Mixture Control Valve (MCV)

Electric Air Control Valve (EACV)

MDP Manifold Differential Pressure -

MFI Multiport Fuel Injection Electronic Fuel Injection (EFI)

MIL Malfunction Indicator Lamp Check Engine Lamp

MST Manifold Surface Temperature -

MVZ Manifold Vacuum Zone -

NVRAM Non-Volatile Random Access Memory -

O2S Oxygen Sensor Oxygen Sensor, O2 Sensor (O2S)

OBD On-Board Diagnostic On-Board Diagnostic System (OBD)

OC Oxidation Catalytic Converter Oxidation Catalyst Converter (OC), CCo

OL Open Loop Open Loop

PAIR Pulsed Secondary Air Injection Air Suction (AS)

PCM Powertrain Control Module -

PNP Park/Neutral Position -

PROM Programmable Read Only Memory -

PSP Power Steering Pressure -

PTOX Periodic Trap OxidizerDiesel Particulate Filter (DPF)

Diesel Particulate Trap (DPT)

RAM Random Access Memory Random Access Memory (RAM)

RM Relay Module -

ROM Read Only Memory Read Only Memory (ROM)

RPM Engine Speed Engine Speed

SC Supercharger Supercharger

SCB Supercharger Bypass E-ABV

SFI Sequential Multiport Fuel Injection Electronic Fuel Injection (EFI), Sequential Injection

SPL Smoke Puff Limiter -

SRI Service Reminder Indicator -

SRT System Readiness Test -

ST Scan Tool -

TB Throttle Body Throttle Body

TBI Throttle Body Fuel InjectionSingle Point Injection

Central Fuel Injection (Ci)

TC Turbocharger Turbocharger

TCC Torque Converter Clutch Torque Converter

TCM Transmission Control Module Transmission ECU, ECT ECU

TP Throttle Position Throttle Position

TR Transmission Range -

TVV Thermal Vacuum ValveBimetallic Vacuum Switching Valve (BVSV)

Thermostatic Vacuum Switching Valve (TVSV) SAE

ABBREVIATIONSSAE TERMS TOYOTA TERMS ( )-ABBREVIATIONS

Page 222 of 2000

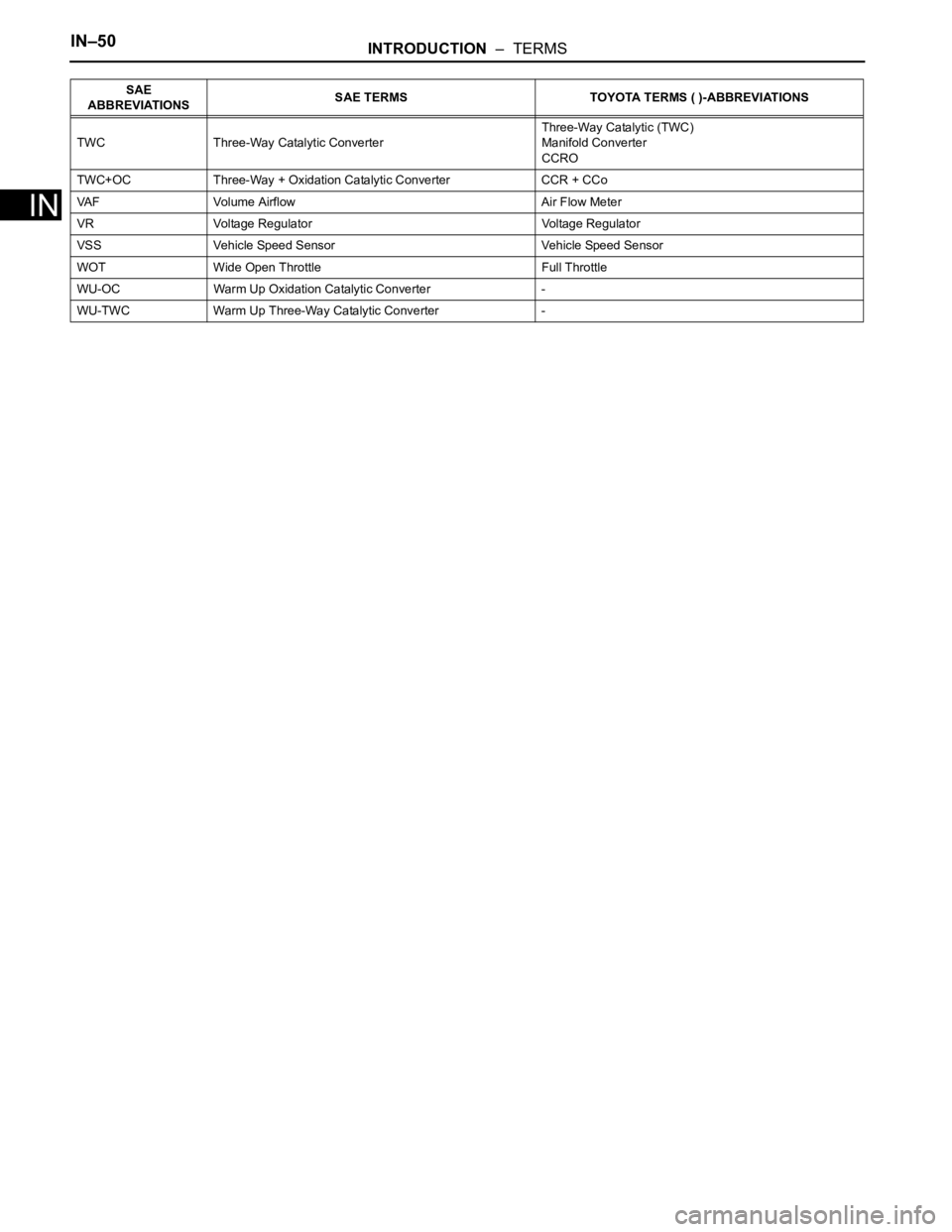

IN–50INTRODUCTION – TERMS

IN

TWC Three-Way Catalytic ConverterThree-Way Catalytic (TWC)

Manifold Converter

CCRO

TWC+OC Three-Way + Oxidation Catalytic Converter CCR + CCo

VAF Volume Airflow Air Flow Meter

VR Voltage Regulator Voltage Regulator

VSS Vehicle Speed Sensor Vehicle Speed Sensor

WOT Wide Open Throttle Full Throttle

WU-OC Warm Up Oxidation Catalytic Converter -

WU-TWC Warm Up Three-Way Catalytic Converter -SAE

ABBREVIATIONSSAE TERMS TOYOTA TERMS ( )-ABBREVIATIONS

Page 1951 of 2000

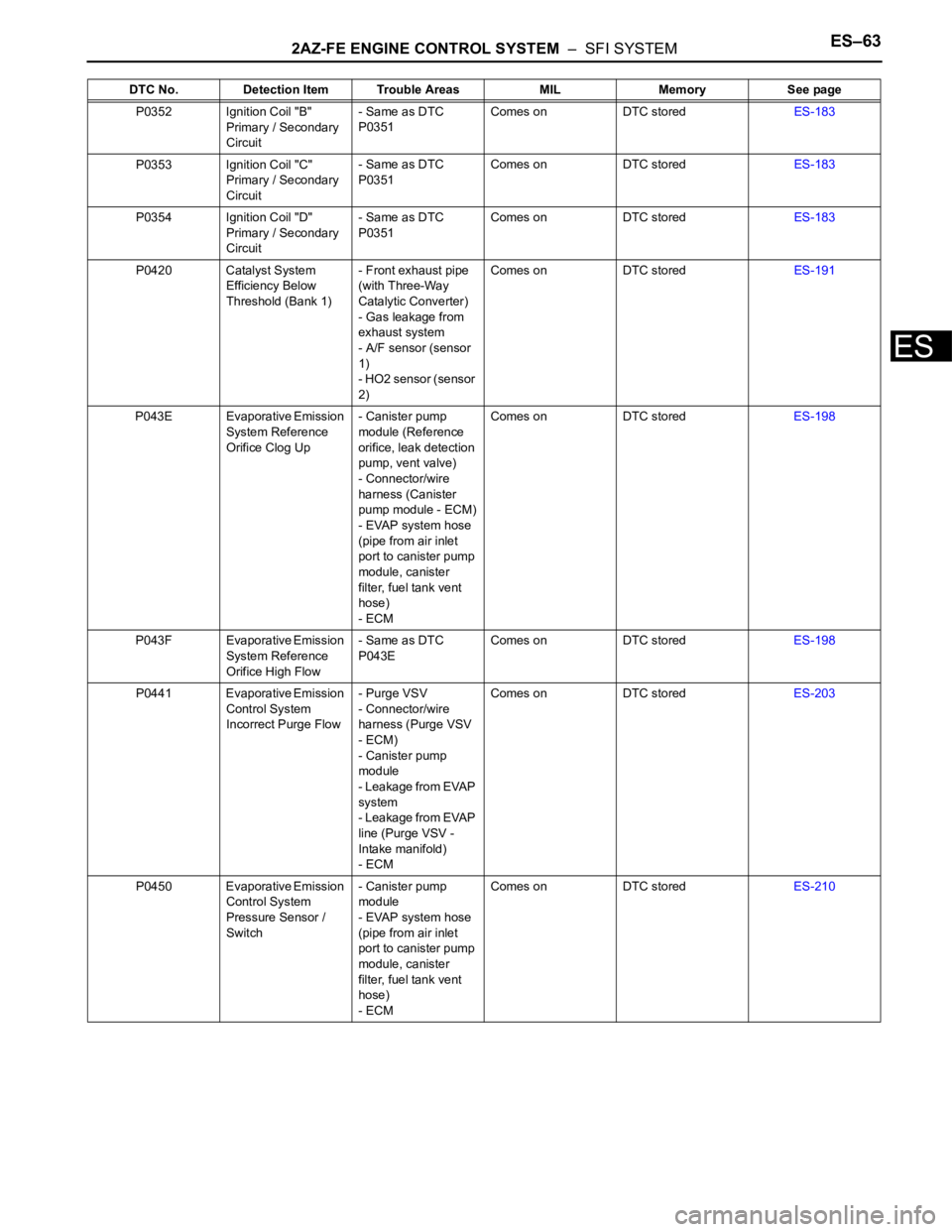

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–63

ES

P0352 Ignition Coil "B"

Primary / Secondary

Circuit- Same as DTC

P0351Comes on DTC storedES-183

P0353 Ignition Coil "C"

Primary / Secondary

Circuit- Same as DTC

P0351Comes on DTC storedES-183

P0354 Ignition Coil "D"

Primary / Secondary

Circuit- Same as DTC

P0351Comes on DTC storedES-183

P0420 Catalyst System

Efficiency Below

Threshold (Bank 1)- Front exhaust pipe

(with Three-Way

Catalytic Converter)

- Gas leakage from

exhaust system

- A/F sensor (sensor

1)

- HO2 sensor (sensor

2)Comes on DTC storedES-191

P043E Evaporative Emission

System Reference

Orifice Clog Up- Canister pump

module (Reference

orifice, leak detection

pump, vent valve)

- Connector/wire

harness (Canister

pump module - ECM)

- EVAP system hose

(pipe from air inlet

port to canister pump

module, canister

filter, fuel tank vent

hose)

- ECMComes on DTC storedES-198

P043F Evaporative Emission

System Reference

Orifice High Flow- Same as DTC

P043EComes on DTC storedES-198

P0441 Evaporative Emission

Control System

Incorrect Purge Flow- Purge VSV

- Connector/wire

harness (Purge VSV

- ECM)

- Canister pump

module

- Leakage from EVAP

system

- Leakage from EVAP

line (Purge VSV -

Intake manifold)

- ECMComes on DTC storedES-203

P0450 Evaporative Emission

Control System

Pressure Sensor /

Switch- Canister pump

module

- EVAP system hose

(pipe from air inlet

port to canister pump

module, canister

filter, fuel tank vent

hose)

- ECMComes on DTC storedES-210 DTC No. Detection Item Trouble Areas MIL Memory See page

Page 1969 of 2000

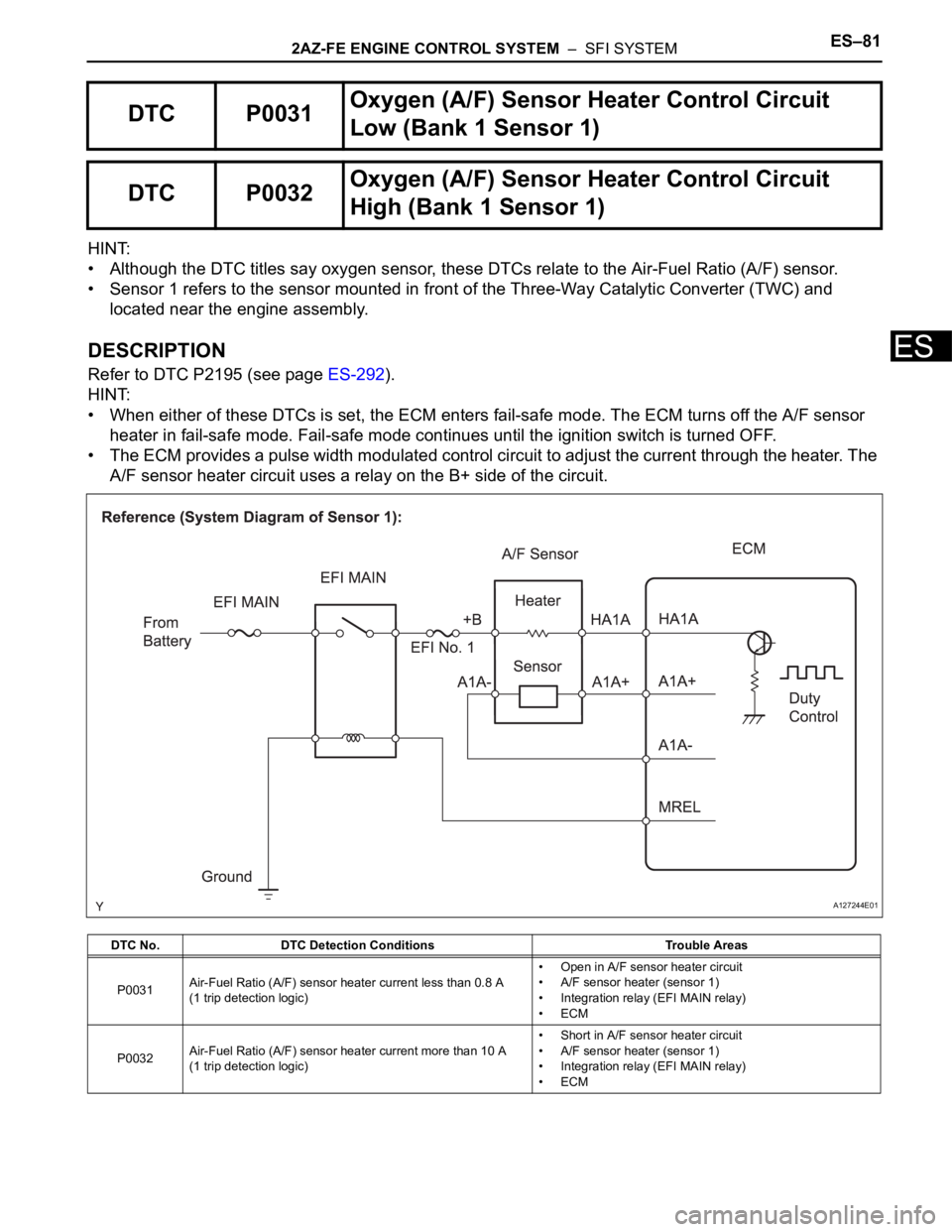

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–81

ES

HINT:

• Although the DTC titles say oxygen sensor, these DTCs relate to the Air-Fuel Ratio (A/F) sensor.

• Sensor 1 refers to the sensor mounted in front of the Three-Way Catalytic Converter (TWC) and

located near the engine assembly.

DESCRIPTION

Refer to DTC P2195 (see page ES-292).

HINT:

• When either of these DTCs is set, the ECM enters fail-safe mode. The ECM turns off the A/F sensor

heater in fail-safe mode. Fail-safe mode continues until the ignition switch is turned OFF.

• The ECM provides a pulse width modulated control circuit to adjust the current through the heater. The

A/F sensor heater circuit uses a relay on the B+ side of the circuit.

DTC P0031Oxygen (A/F) Sensor Heater Control Circuit

Low (Bank 1 Sensor 1)

DTC P0032Oxygen (A/F) Sensor Heater Control Circuit

High (Bank 1 Sensor 1)

DTC No. DTC Detection Conditions Trouble Areas

P0031Air-Fuel Ratio (A/F) sensor heater current less than 0.8 A

(1 trip detection logic)• Open in A/F sensor heater circuit

• A/F sensor heater (sensor 1)

• Integration relay (EFI MAIN relay)

•ECM

P0032Air-Fuel Ratio (A/F) sensor heater current more than 10 A

(1 trip detection logic)• Short in A/F sensor heater circuit

• A/F sensor heater (sensor 1)

• Integration relay (EFI MAIN relay)

•ECM

A127244E01

Page 1970 of 2000

ES–822AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

MONITOR DESCRIPTION

The ECM uses information from the Air-Fuel Ratio (A/F) sensor to regulate the air-fuel ratio and keep it

close to the stoichiometric level. This maximizes the ability of the Three-Way Catalytic Converter (TWC) to

purify the exhaust gases.

The A/F sensor detects oxygen levels in the exhaust gas and transmits the information to the ECM. The

inner surface of the sensor element is exposed to the outside air. The outer surface of the sensor element

is exposed to the exhaust gas. The sensor element is made of platinum coated zirconia and includes an

integrated heating element.

The zirconia element generates a small voltage when there is a large difference in the oxygen

concentrations between the exhaust gas and outside air. The platinum coating amplifies this voltage

generation.

The A/F sensor is more efficient when heated. When the exhaust gas temperature is low, the sensor

cannot generate useful voltage signals without supplementary heating. The ECM regulates the

supplementary heating using a duty-cycle approach to adjust the average current in the sensor heater

element. If the heater current is outside the normal range, the signal transmitted by the A/F sensor

becomes inaccurate, as a result, the ECM is unable to regulate air-fuel ratio properly.

When the current in the A/F sensor heater is outside the normal operating range, the ECM interprets this

as a malfunction in the sensor heater and sets a DTC.

Example:

The ECM sets DTC P0032 when the current in the A/F sensor heater is more than 10 A. Conversely,

when the heater current is less than 0.8 A, DTC P0031 is set.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

All:

P0031:

P0032:

TYPICAL MALFUNCTION THRESHOLDS

P0031:

P0032:

Related DTCsP0031: A/F sensor heater open/short (Low electrical current)

P0032: A/F sensor heater open/short (High electrical current)

Required Sensors/Components (Main) A/F sensor heater

Required Sensors/Components (Related) -

Frequency of Operation Continuous

Duration 10 seconds

MIL Operation Immediate

Sequence of Operation None

Monitor runs whenever following DTCs not present None

Battery voltage 10.5 V or more

A/F sensor heater duty-cycle ratio 50 % or more

Time after engine start 10 seconds or more

Time after engine start 10 seconds or more

A/F sensor heater current Less than 0.8 A

A/F sensor heater current More than 10 A

Page 1977 of 2000

2AZ-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–89

ES

TYPICAL MALFUNCTION THRESHOLDS

P0037:

P0038:

P0141 (Heater performance monitor check):

COMPONENT OPERATING RANGE

WIRING DIAGRAM

Refer to DTC P0136 (see page ES-136).

CONFIRMATION DRIVING PATTERN

These DTCs are detected when the engine idles for 110 seconds or more.

INSPECTION PROCEDURE

HINT:

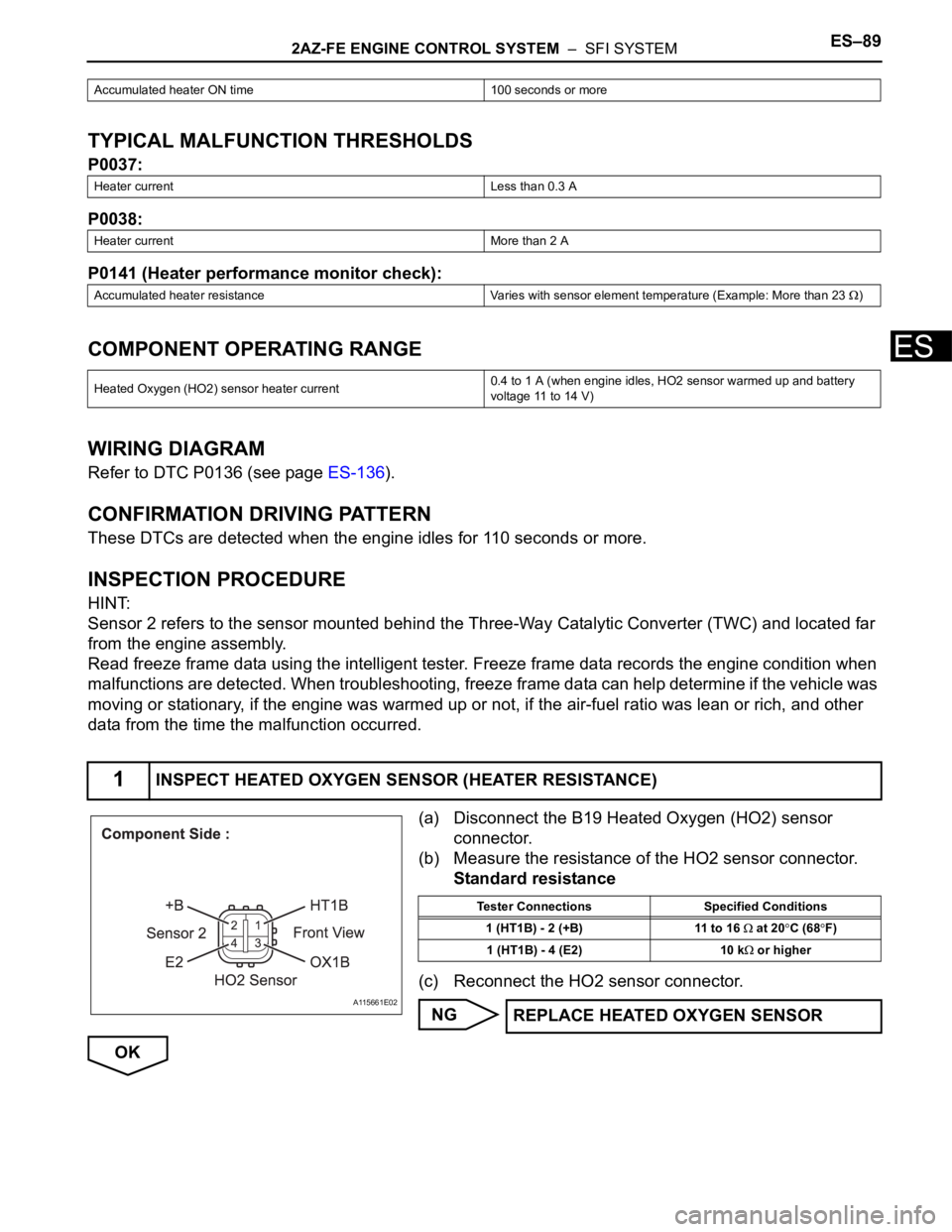

Sensor 2 refers to the sensor mounted behind the Three-Way Catalytic Converter (TWC) and located far

from the engine assembly.

Read freeze frame data using the intelligent tester. Freeze frame data records the engine condition when

malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was

moving or stationary, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other

data from the time the malfunction occurred.

(a) Disconnect the B19 Heated Oxygen (HO2) sensor

connector.

(b) Measure the resistance of the HO2 sensor connector.

Standard resistance

(c) Reconnect the HO2 sensor connector.

NG

OK

Accumulated heater ON time 100 seconds or more

Heater current Less than 0.3 A

Heater current More than 2 A

Accumulated heater resistance Varies with sensor element temperature (Example: More than 23

)

Heated Oxygen (HO2) sensor heater current0.4 to 1 A (when engine idles, HO2 sensor warmed up and battery

voltage 11 to 14 V)

1INSPECT HEATED OXYGEN SENSOR (HEATER RESISTANCE)

A115661E02

Tester Connections Specified Conditions

1 (HT1B) - 2 (+B) 11 to 16

at 20C (68F)

1 (HT1B) - 4 (E2) 10 k

or higher

REPLACE HEATED OXYGEN SENSOR