engine TOYOTA SIENNA 2007 Service Repair Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 403 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–97

ES

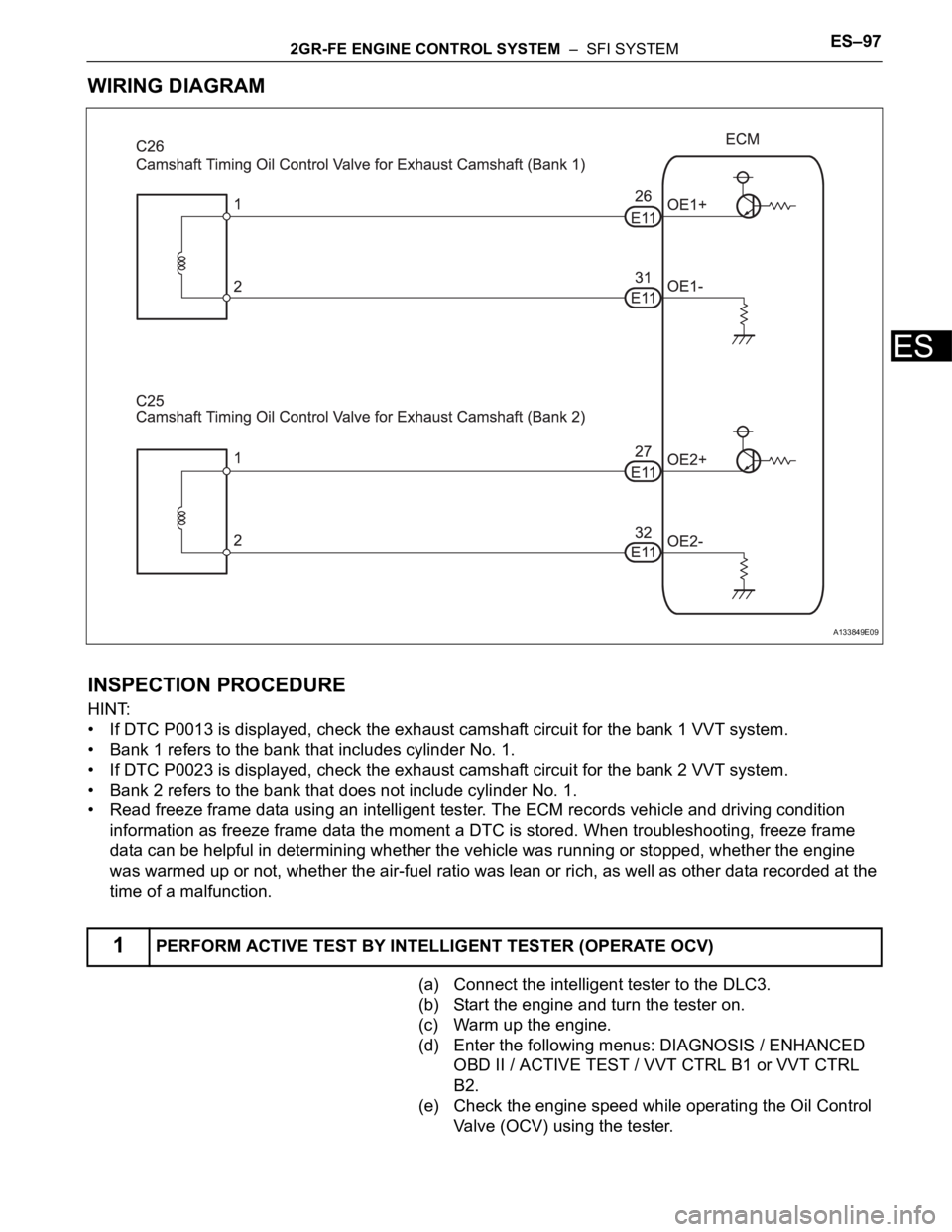

WIRING DIAGRAM

INSPECTION PROCEDURE

HINT:

• If DTC P0013 is displayed, check the exhaust camshaft circuit for the bank 1 VVT system.

• Bank 1 refers to the bank that includes cylinder No. 1.

• If DTC P0023 is displayed, check the exhaust camshaft circuit for the bank 2 VVT system.

• Bank 2 refers to the bank that does not include cylinder No. 1.

• Read freeze frame data using an intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame

data can be helpful in determining whether the vehicle was running or stopped, whether the engine

was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the

time of a malfunction.

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine and turn the tester on.

(c) Warm up the engine.

(d) Enter the following menus: DIAGNOSIS / ENHANCED

OBD II / ACTIVE TEST / VVT CTRL B1 or VVT CTRL

B2.

(e) Check the engine speed while operating the Oil Control

Valve (OCV) using the tester.

1PERFORM ACTIVE TEST BY INTELLIGENT TESTER (OPERATE OCV)

A133849E09

Page 404 of 3000

ES–982GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

OK

NG

OK

(a) Disconnect the C26 or C25 camshaft timing oil control

valve (OCV) connector.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

(c) Reconnect the OCV connector.

OK

NG

Tester Operation Specified Condition

OCV OFF Normal engine speed

OCV ON Engine idles roughly or stalls (soon after OCV switched from OFF to ON)

Go to step 2

CHECK FOR INTERMITTENT PROBLEMS

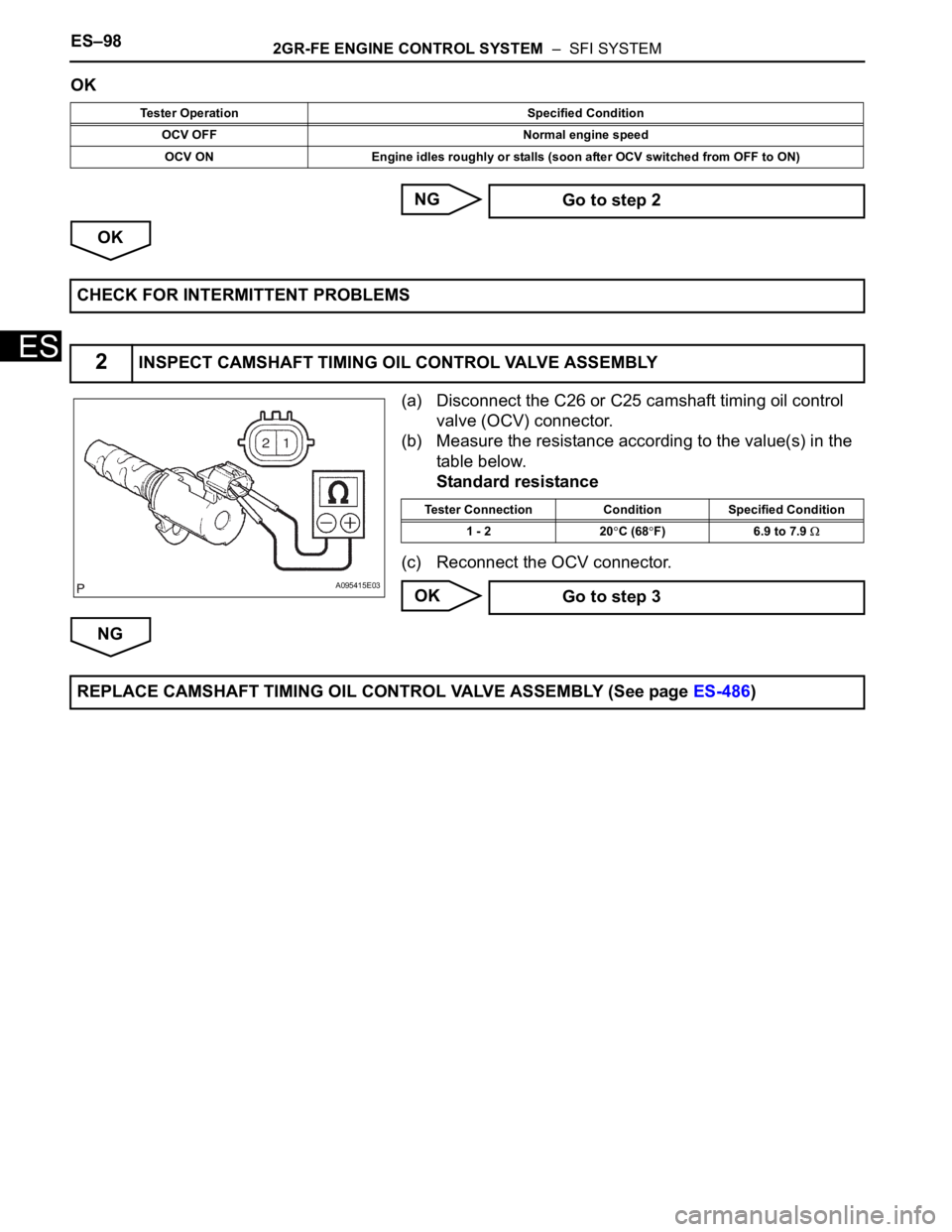

2INSPECT CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY

A095415E03

Tester Connection Condition Specified Condition

1 - 2 20

C (68F) 6.9 to 7.9

Go to step 3

REPLACE CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (See page ES-486)

Page 405 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–99

ES

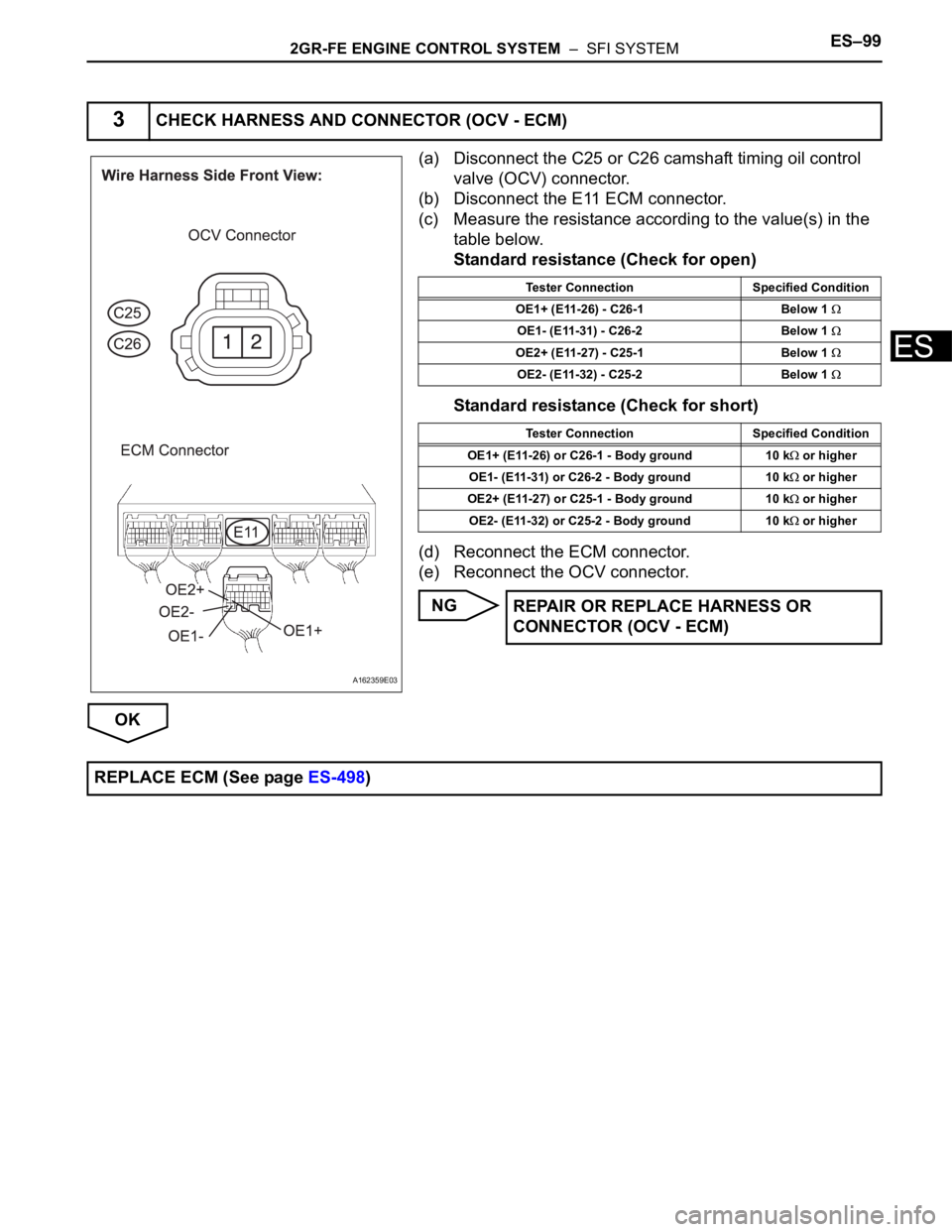

(a) Disconnect the C25 or C26 camshaft timing oil control

valve (OCV) connector.

(b) Disconnect the E11 ECM connector.

(c) Measure the resistance according to the value(s) in the

table below.

Standard resistance (Check for open)

Standard resistance (Check for short)

(d) Reconnect the ECM connector.

(e) Reconnect the OCV connector.

NG

OK

3CHECK HARNESS AND CONNECTOR (OCV - ECM)

A162359E03

Tester Connection Specified Condition

OE1+ (E11-26) - C26-1 Below 1

OE1- (E11-31) - C26-2 Below 1

OE2+ (E11-27) - C25-1 Below 1

OE2- (E11-32) - C25-2 Below 1

Tester Connection Specified Condition

OE1+ (E11-26) or C26-1 - Body ground 10 k

or higher

OE1- (E11-31) or C26-2 - Body ground 10 k

or higher

OE2+ (E11-27) or C25-1 - Body ground 10 k

or higher

OE2- (E11-32) or C25-2 - Body ground 10 k

or higher

REPAIR OR REPLACE HARNESS OR

CONNECTOR (OCV - ECM)

REPLACE ECM (See page ES-498)

Page 406 of 3000

ES–1002GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

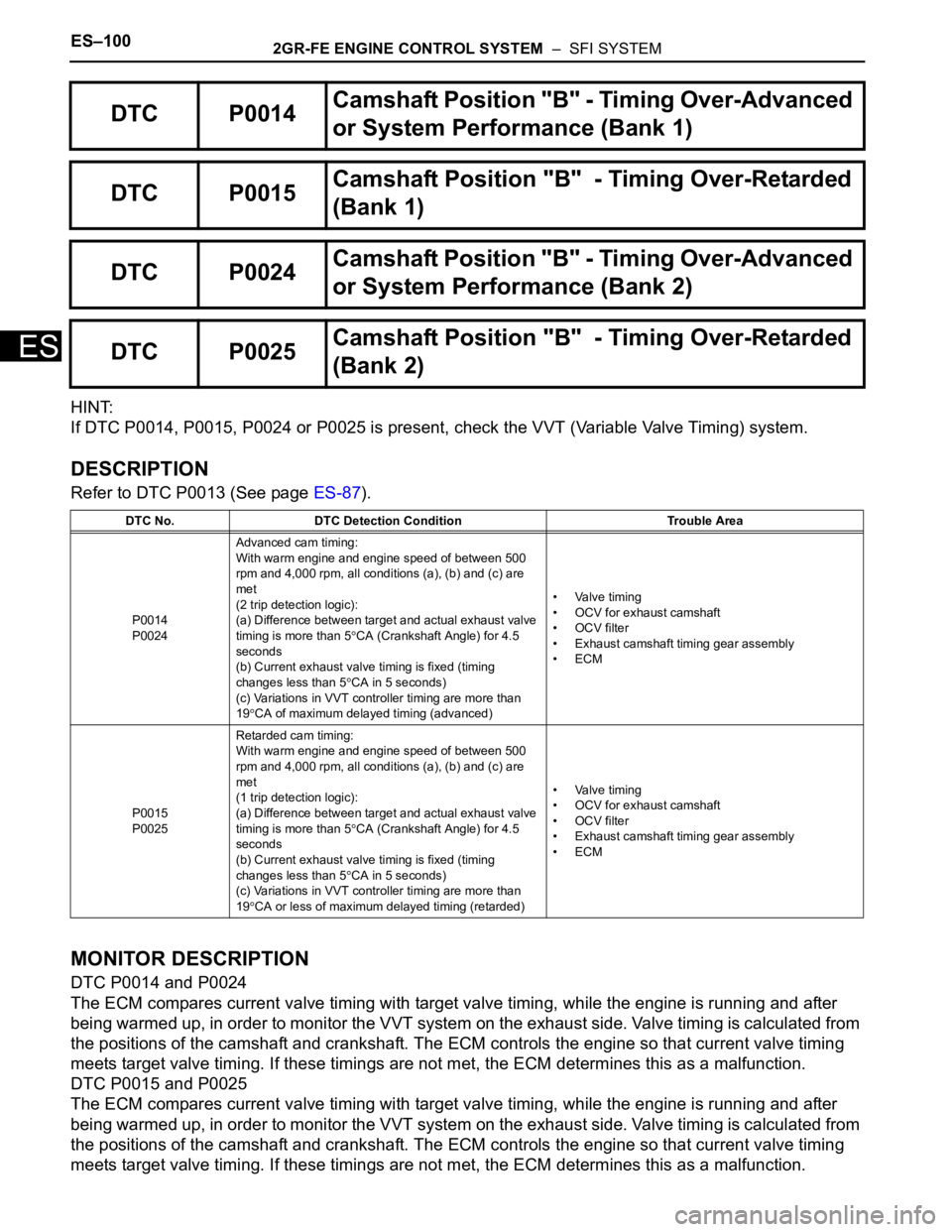

HINT:

If DTC P0014, P0015, P0024 or P0025 is present, check the VVT (Variable Valve Timing) system.

DESCRIPTION

Refer to DTC P0013 (See page ES-87).

MONITOR DESCRIPTION

DTC P0014 and P0024

The ECM compares current valve timing with target valve timing, while the engine is running and after

being warmed up, in order to monitor the VVT system on the exhaust side. Valve timing is calculated from

the positions of the camshaft and crankshaft. The ECM controls the engine so that current valve timing

meets target valve timing. If these timings are not met, the ECM determines this as a malfunction.

DTC P0015 and P0025

The ECM compares current valve timing with target valve timing, while the engine is running and after

being warmed up, in order to monitor the VVT system on the exhaust side. Valve timing is calculated from

the positions of the camshaft and crankshaft. The ECM controls the engine so that current valve timing

meets target valve timing. If these timings are not met, the ECM determines this as a malfunction.

DTC P0014Camshaft Position "B" - Timing Over-Advanced

or System Performance (Bank 1)

DTC P0015Camshaft Position "B" - Timing Over-Retarded

(Bank 1)

DTC P0024Camshaft Position "B" - Timing Over-Advanced

or System Performance (Bank 2)

DTC P0025Camshaft Position "B" - Timing Over-Retarded

(Bank 2)

DTC No. DTC Detection Condition Trouble Area

P0014

P0024Advanced cam timing:

With warm engine and engine speed of between 500

rpm and 4,000 rpm, all conditions (a), (b) and (c) are

met

(2 trip detection logic):

(a) Difference between target and actual exhaust valve

timing is more than 5

CA (Crankshaft Angle) for 4.5

seconds

(b) Current exhaust valve timing is fixed (timing

changes less than 5

CA in 5 seconds)

(c) Variations in VVT controller timing are more than

19

CA of maximum delayed timing (advanced)• Valve timing

• OCV for exhaust camshaft

• OCV filter

• Exhaust camshaft timing gear assembly

•ECM

P0015

P0025Retarded cam timing:

With warm engine and engine speed of between 500

rpm and 4,000 rpm, all conditions (a), (b) and (c) are

met

(1 trip detection logic):

(a) Difference between target and actual exhaust valve

timing is more than 5

CA (Crankshaft Angle) for 4.5

seconds

(b) Current exhaust valve timing is fixed (timing

changes less than 5

CA in 5 seconds)

(c) Variations in VVT controller timing are more than

19

CA or less of maximum delayed timing (retarded)• Valve timing

• OCV for exhaust camshaft

• OCV filter

• Exhaust camshaft timing gear assembly

•ECM

Page 407 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–101

ES

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

Advanced camshaft timing:

Retarded camshaft timing:

If the difference between the target and actual camshaft timings is greater than the specified value, the

ECM operates the VVT actuator.

Then, the ECM monitors the camshaft timing change for 5 seconds.

WIRING DIAGRAM

Refer to DTC P0013 (See page ES-89).

INSPECTION PROCEDURE

HINT:

• If DTC P0014 or P0015 is displayed, check the bank 1 VVT system circuit.

• Bank 1 refers to the bank that includes cylinder No. 1.

• If DTC P0024 or P0025 is displayed, check the bank 2 VVT system circuit.

• Bank 2 refers to the bank that does not include cylinder No. 1.

Related DTCsP0014: Advanced exhaust camshaft timing (bank 1)

P0015: Retarded exhaust camshaft timing (bank 1)

P0024: Advanced exhaust camshaft timing (bank 2)

P0025: Retarded exhaust camshaft timing (bank 2)

Required Sensors / Components (Main) VVT OCV and VVT Actuator

Required Sensors / Components (Related)P0014 and P0015:

Exhaust camshaft control actuator bank 1

Exhaust OCV bank 1

P0024 and P0025:

Exhaust camshaft control actuator bank 2

Exhaust OCV bank 2

Frequency of Operation Continuously

Duration Less than 10 seconds

MIL OperationP0014 and P0024: Immediate

P0015 and P0025: 2 driving cycles

Sequence of Operation None

The monitor will run whenever these DTCs are not

presentNone

Battery voltage 11 V or more

Engine RPM 500 to 4000 rpm

Engine coolant temperature 75 to 100

C (167 to 212F)

Valve timing No change

Valve timing Advanced position

Valve timing No change

Valve timing Retarded position

Abnormal bankAdvanced timing over

(Valve timing is out of specified range)Retarded timing over

(Valve timing is out of specified range)

Bank 1 P0014 P0015

Bank 2 P0024 P0025

Page 408 of 3000

ES–1022GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

• Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame

data can be helpful in determining whether the vehicle was running or stopped, whether the engine

was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the

time of a malfunction.

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the

tester on.

(c) Select the following menu items: DIAGNOSIS /

ENHANCED OBD II / DTC INFO / CURRENT CODES.

(d) Read the DTCs.

Result

HINT:

If any DTCs other than P0014, P0015, P0024 or P0025

are output, troubleshoot those DTCs first.

B

A

(a) Connect the intelligent tester to the DLC3.

(b) Start the engine and turn the tester on.

(c) Warm up the engine.

(d) Select the following menu items on the tester:

DIAGNOSIS / ENHANCED OBD II / ACTIVE TEST /

VVT EX B1 or VVT EX B2.

(e) Check the engine speed while operating the Oil Control

Valve (OCV) using the tester.

OK

NG

OK

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the

tester on.

(c) Clear the DTCs (See page ES-39).

1CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P0014, P0015, P0024 OR

P0025)

Display (DTC Output) Proceed to

P0014, P0015, P0024 or P0025 A

P0014, P0015, P0024 or P0025 and other DTCs B

GO TO DTC CHART (See page ES-56)

2PERFORM ACTIVE TEST BY INTELLIGENT TESTER (OPERATE OCV)

Tester Operation Specified Condition

OCV OFF Normal engine idle speed

OCV ON Engine idles roughly or stalls (soon after OCV switched from OFF to ON)

Go to step 4

3CHECK WHETHER DTC OUTPUT RECURS (DTC P0014, P0015, P0024 OR P0025)

Page 409 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–103

ES

(d) Start the engine and warm it up.

(e) Select the check mode using the tester (See page ES-

43).

(f) Drive the vehicle for more than 10 minutes.

(g) Read the DTCs using the tester.

OK:

No DTC output.

NG

OK

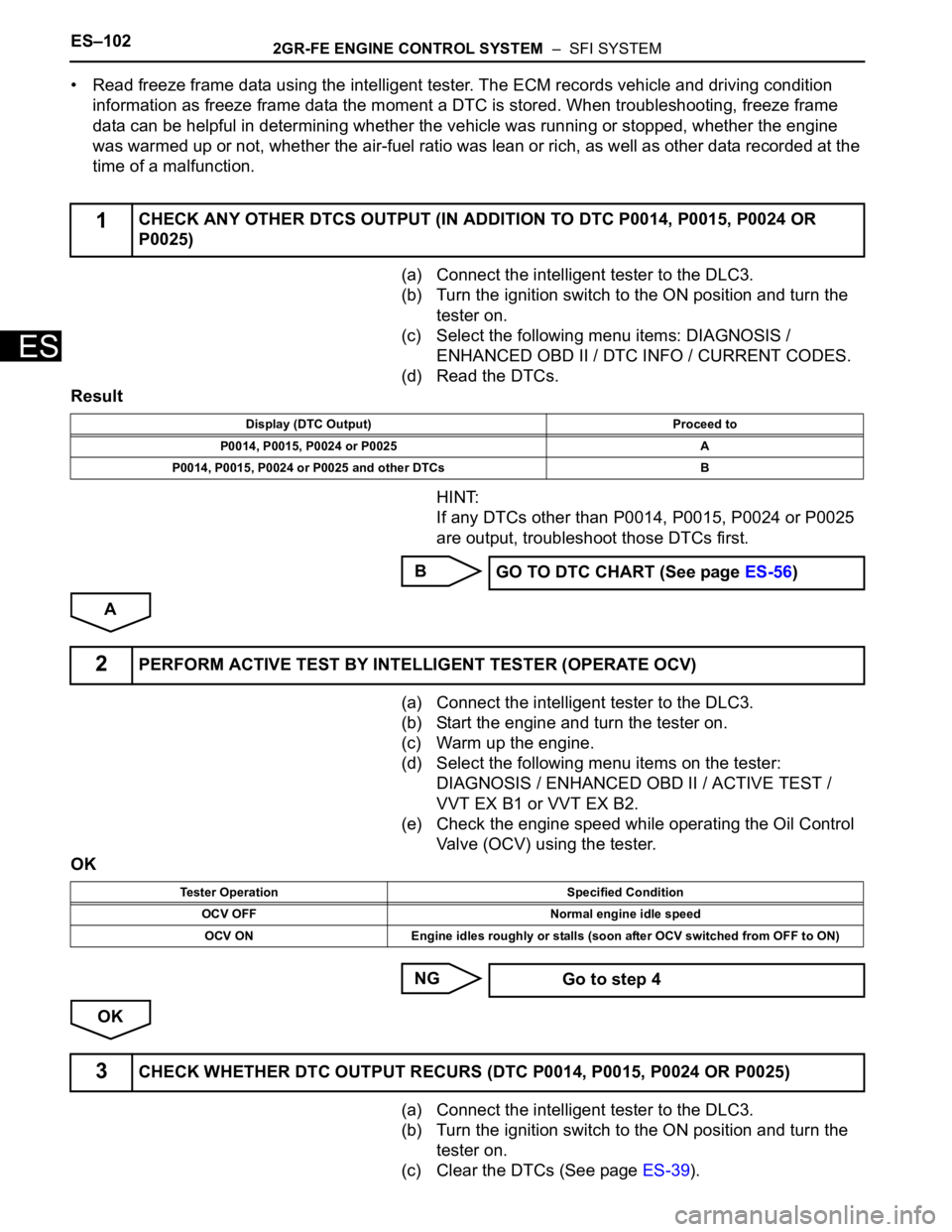

(a) Remove the cylinder head covers RH and LH.

(b) Turn the crankshaft to align the matchmarks of the

crankshaft.

(c) Align the notch of the crankshaft pulley to the "0"

position.

(d) Check if the matchmarks of the camshaft pulley and

camshaft bearing cap align.

(e) Turn the crankshaft clockwise by 360

if the matchmarks

do not align. Check if they align once again.

OK:

The matchmarks of the camshaft pulley and the

camshaft bearing cap align when the notch of the

crankshaft pulley is in the "0" position.

NG

OK Go to step 4

SYSTEM IS OK

4CHECK VALVE TIMING (CHECK FOR LOOSE AND JUMP TEETH ON TIMING CHAIN)

A135015E01

ADJUST VALVE TIMING

Page 410 of 3000

ES–1042GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

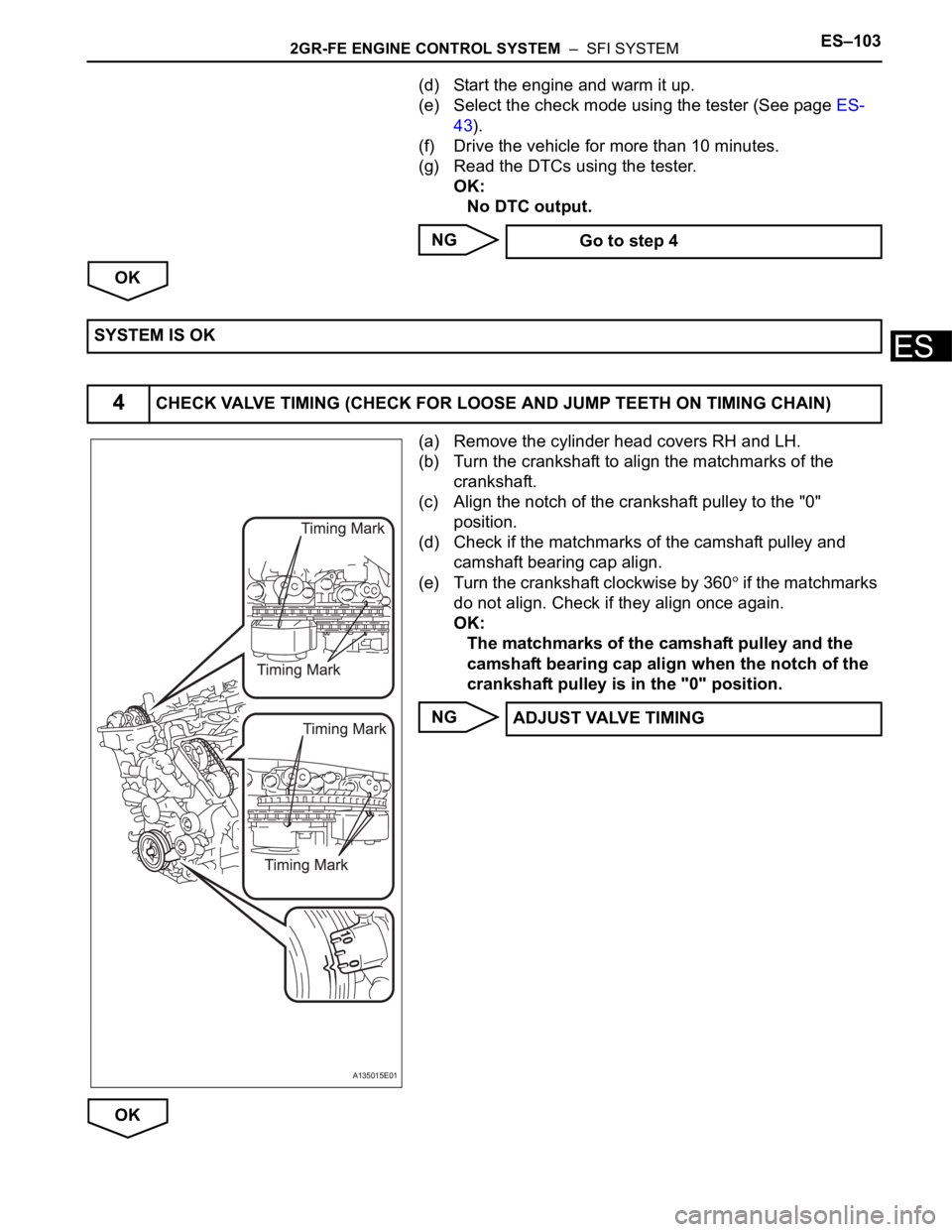

(a) Remove the OCV.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

(c) Apply positive battery voltage to terminal 1 and negative

battery voltage to terminal 2. Check the valve operation.

OK:

Valve moves quickly.

(d) Reinstall the OCV.

NG

OK

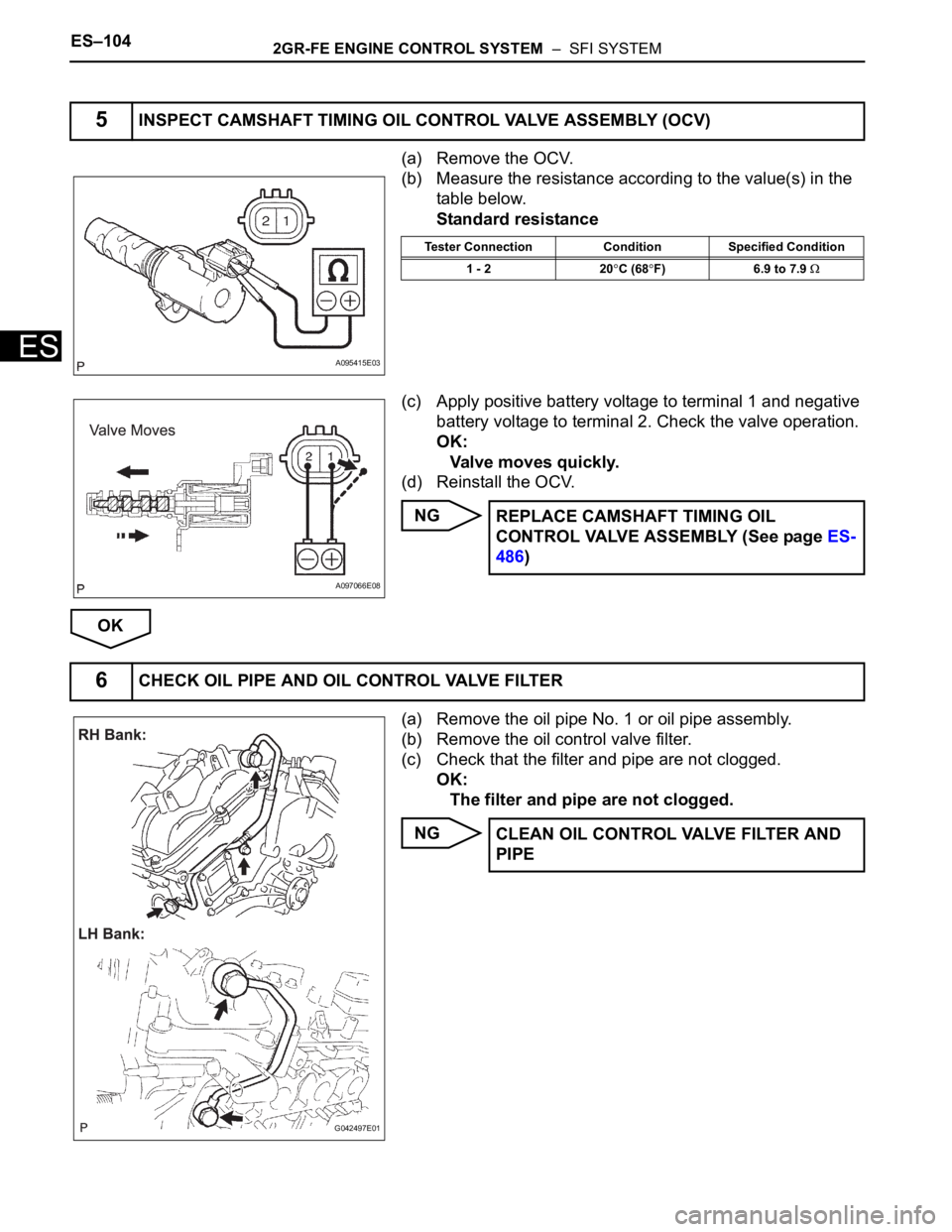

(a) Remove the oil pipe No. 1 or oil pipe assembly.

(b) Remove the oil control valve filter.

(c) Check that the filter and pipe are not clogged.

OK:

The filter and pipe are not clogged.

NG

5INSPECT CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (OCV)

A095415E03

Tester Connection Condition Specified Condition

1 - 2 20

C (68F) 6.9 to 7.9

A097066E08

REPLACE CAMSHAFT TIMING OIL

CONTROL VALVE ASSEMBLY (See page ES-

486)

6CHECK OIL PIPE AND OIL CONTROL VALVE FILTER

G042497E01

CLEAN OIL CONTROL VALVE FILTER AND

PIPE

Page 411 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–105

ES

OK

NEXT

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position and turn the

tester on.

(c) Clear the DTCs (See page ES-39).

(d) Start the engine and warm it up.

(e) Select the check mode using the tester (See page ES-

43).

(f) Drive the vehicle for more than 10 minutes.

(g) Confirm that no DTC is set using the tester.

OK:

No DTC output.

HINT:

DTC P0014, P0015, P0024 or P0025 is output when

foreign objects in engine oil are caught in some parts of

the system. These codes will stay registered even if the

system returns to normal after a short time. These

foreign objects are then captured by the oil filter, thus

eliminating the source of the problem.

NG

OK

7REPLACE CAMSHAFT TIMING GEAR ASSEMBLY

8CHECK WHETHER DTC OUTPUT RECURS

REPLACE ECM (See page ES-498)

SYSTEM IS OK

Page 412 of 3000

ES–1062GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

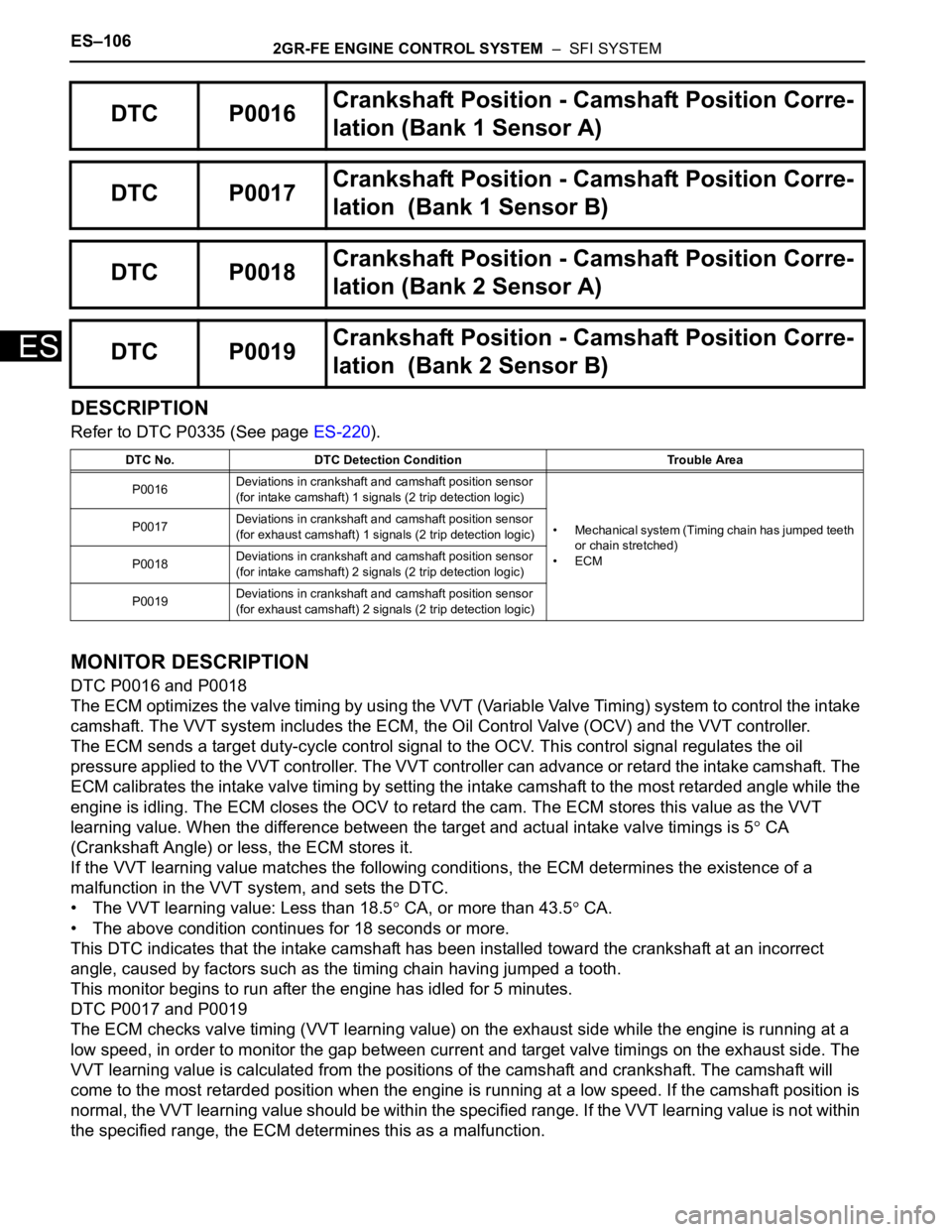

DESCRIPTION

Refer to DTC P0335 (See page ES-220).

MONITOR DESCRIPTION

DTC P0016 and P0018

The ECM optimizes the valve timing by using the VVT (Variable Valve Timing) system to control the intake

camshaft. The VVT system includes the ECM, the Oil Control Valve (OCV) and the VVT controller.

The ECM sends a target duty-cycle control signal to the OCV. This control signal regulates the oil

pressure applied to the VVT controller. The VVT controller can advance or retard the intake camshaft. The

ECM calibrates the intake valve timing by setting the intake camshaft to the most retarded angle while the

engine is idling. The ECM closes the OCV to retard the cam. The ECM stores this value as the VVT

learning value. When the difference between the target and actual intake valve timings is 5

CA

(Crankshaft Angle) or less, the ECM stores it.

If the VVT learning value matches the following conditions, the ECM determines the existence of a

malfunction in the VVT system, and sets the DTC.

• The VVT learning value: Less than 18.5

CA, or more than 43.5 CA.

• The above condition continues for 18 seconds or more.

This DTC indicates that the intake camshaft has been installed toward the crankshaft at an incorrect

angle, caused by factors such as the timing chain having jumped a tooth.

This monitor begins to run after the engine has idled for 5 minutes.

DTC P0017 and P0019

The ECM checks valve timing (VVT learning value) on the exhaust side while the engine is running at a

low speed, in order to monitor the gap between current and target valve timings on the exhaust side. The

VVT learning value is calculated from the positions of the camshaft and crankshaft. The camshaft will

come to the most retarded position when the engine is running at a low speed. If the camshaft position is

normal, the VVT learning value should be within the specified range. If the VVT learning value is not within

the specified range, the ECM determines this as a malfunction.

DTC P0016Crankshaft Position - Camshaft Position Corre-

lation (Bank 1 Sensor A)

DTC P0017Crankshaft Position - Camshaft Position Corre-

lation (Bank 1 Sensor B)

DTC P0018Crankshaft Position - Camshaft Position Corre-

lation (Bank 2 Sensor A)

DTC P0019Crankshaft Position - Camshaft Position Corre-

lation (Bank 2 Sensor B)

DTC No. DTC Detection Condition Trouble Area

P0016Deviations in crankshaft and camshaft position sensor

(for intake camshaft) 1 signals (2 trip detection logic)

• Mechanical system (Timing chain has jumped teeth

or chain stretched)

•ECM P0017Deviations in crankshaft and camshaft position sensor

(for exhaust camshaft) 1 signals (2 trip detection logic)

P0018Deviations in crankshaft and camshaft position sensor

(for intake camshaft) 2 signals (2 trip detection logic)

P0019Deviations in crankshaft and camshaft position sensor

(for exhaust camshaft) 2 signals (2 trip detection logic)