ECO mode TOYOTA SIENNA 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 430 of 3000

ES–1242GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

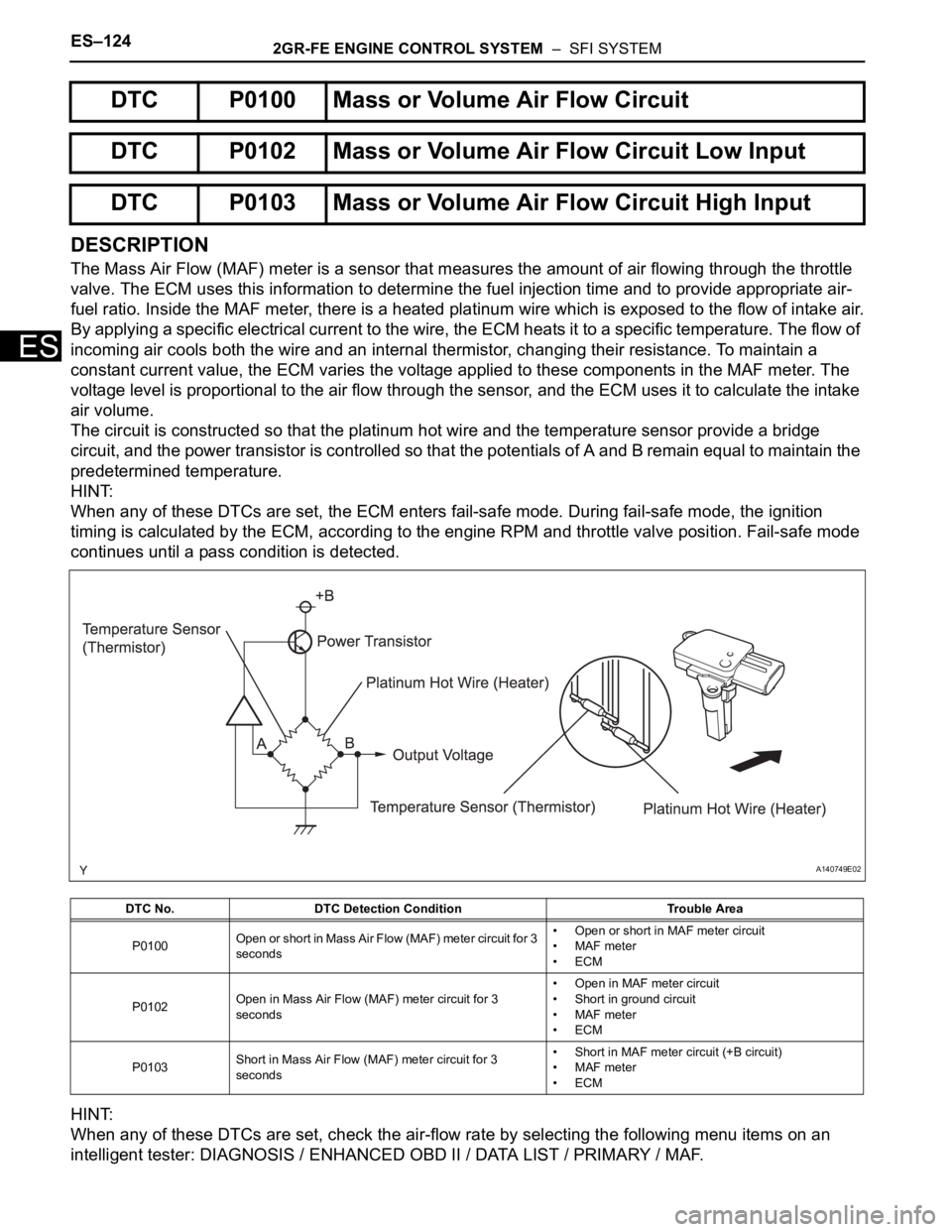

DESCRIPTION

The Mass Air Flow (MAF) meter is a sensor that measures the amount of air flowing through the throttle

valve. The ECM uses this information to determine the fuel injection time and to provide appropriate air-

fuel ratio. Inside the MAF meter, there is a heated platinum wire which is exposed to the flow of intake air.

By applying a specific electrical current to the wire, the ECM heats it to a specific temperature. The flow of

incoming air cools both the wire and an internal thermistor, changing their resistance. To maintain a

constant current value, the ECM varies the voltage applied to these components in the MAF meter. The

voltage level is proportional to the air flow through the sensor, and the ECM uses it to calculate the intake

air volume.

The circuit is constructed so that the platinum hot wire and the temperature sensor provide a bridge

circuit, and the power transistor is controlled so that the potentials of A and B remain equal to maintain the

predetermined temperature.

HINT:

When any of these DTCs are set, the ECM enters fail-safe mode. During fail-safe mode, the ignition

timing is calculated by the ECM, according to the engine RPM and throttle valve position. Fail-safe mode

continues until a pass condition is detected.

HINT:

When any of these DTCs are set, check the air-flow rate by selecting the following menu items on an

intelligent tester: DIAGNOSIS / ENHANCED OBD II / DATA LIST / PRIMARY / MAF.

DTC P0100 Mass or Volume Air Flow Circuit

DTC P0102 Mass or Volume Air Flow Circuit Low Input

DTC P0103 Mass or Volume Air Flow Circuit High Input

DTC No. DTC Detection Condition Trouble Area

P0100Open or short in Mass Air Flow (MAF) meter circuit for 3

seconds• Open or short in MAF meter circuit

• MAF meter

•ECM

P0102Open in Mass Air Flow (MAF) meter circuit for 3

seconds• Open in MAF meter circuit

• Short in ground circuit

• MAF meter

•ECM

P0103Short in Mass Air Flow (MAF) meter circuit for 3

seconds• Short in MAF meter circuit (+B circuit)

• MAF meter

•ECM

A140749E02

Page 438 of 3000

ES–1322GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

DESCRIPTION

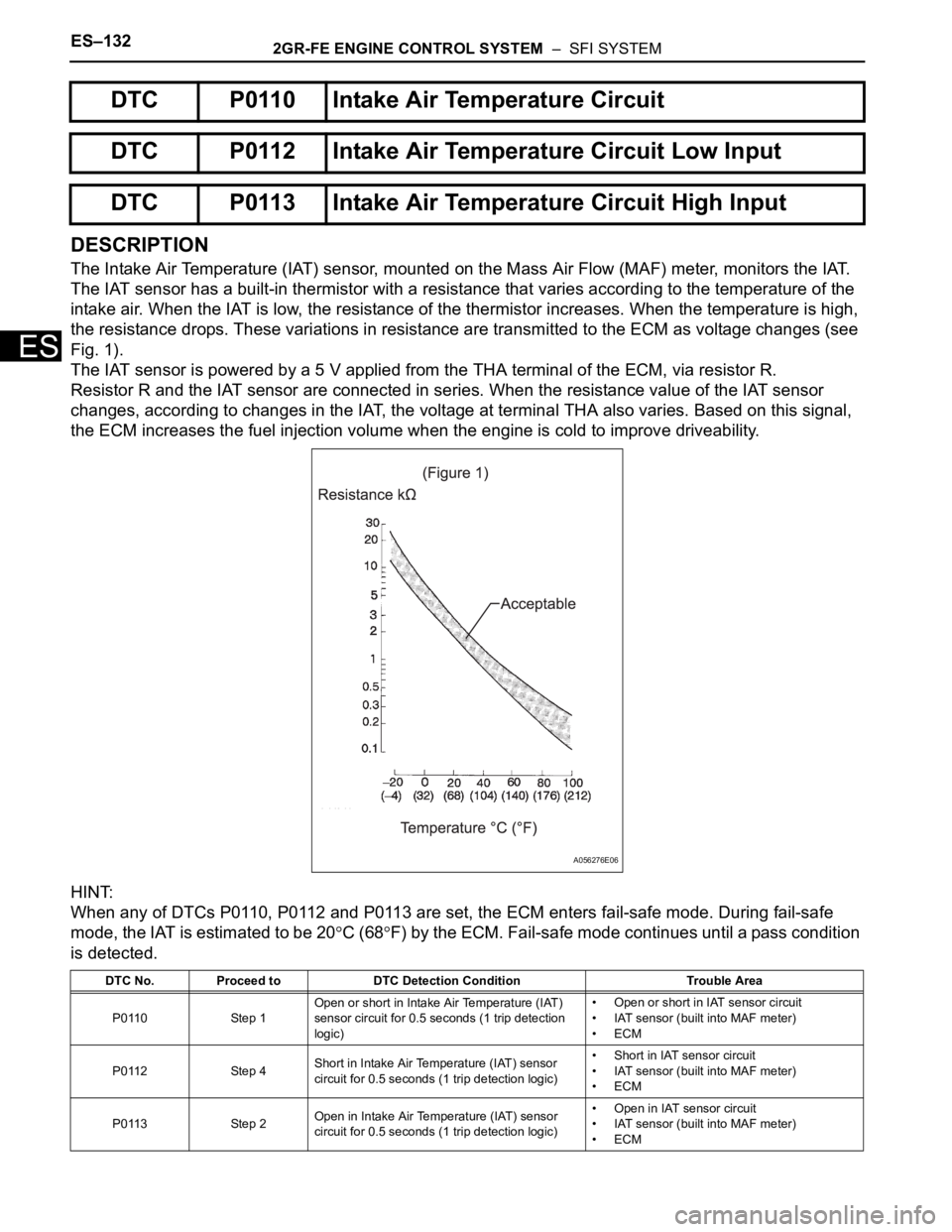

The Intake Air Temperature (IAT) sensor, mounted on the Mass Air Flow (MAF) meter, monitors the IAT.

The IAT sensor has a built-in thermistor with a resistance that varies according to the temperature of the

intake air. When the IAT is low, the resistance of the thermistor increases. When the temperature is high,

the resistance drops. These variations in resistance are transmitted to the ECM as voltage changes (see

Fig. 1).

The IAT sensor is powered by a 5 V applied from the THA terminal of the ECM, via resistor R.

Resistor R and the IAT sensor are connected in series. When the resistance value of the IAT sensor

changes, according to changes in the IAT, the voltage at terminal THA also varies. Based on this signal,

the ECM increases the fuel injection volume when the engine is cold to improve driveability.

HINT:

When any of DTCs P0110, P0112 and P0113 are set, the ECM enters fail-safe mode. During fail-safe

mode, the IAT is estimated to be 20

C (68F) by the ECM. Fail-safe mode continues until a pass condition

is detected.

DTC P0110 Intake Air Temperature Circuit

DTC P0112 Intake Air Temperature Circuit Low Input

DTC P0113 Intake Air Temperature Circuit High Input

DTC No. Proceed to DTC Detection Condition Trouble Area

P0110 Step 1Open or short in Intake Air Temperature (IAT)

sensor circuit for 0.5 seconds (1 trip detection

logic)• Open or short in IAT sensor circuit

• IAT sensor (built into MAF meter)

•ECM

P0112 Step 4Short in Intake Air Temperature (IAT) sensor

circuit for 0.5 seconds (1 trip detection logic)• Short in IAT sensor circuit

• IAT sensor (built into MAF meter)

•ECM

P0113 Step 2Open in Intake Air Temperature (IAT) sensor

circuit for 0.5 seconds (1 trip detection logic)• Open in IAT sensor circuit

• IAT sensor (built into MAF meter)

•ECM

A056276E06

Page 447 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–141

ES

DESCRIPTION

A thermistor is built into the Engine Coolant Temperature (ECT) sensor, of which the resistance value

varies according to the ECT.

The structure of the sensor and its connection to the ECM are the same as those of the Intake Air

Temperature (IAT) sensor.

HINT:

When any of DTCs P0115, P0117 and P0118 are set, the ECM enters fail-safe mode. During fail-safe

mode, the ECT is estimated to be 80

C (176F) by the ECM. Fail-safe mode continues until a pass

condition is detected.

HINT:

When any of these DTCs are set, check the ECT by selecting the following menu items on the intelligent

tester: DIAGNOSIS / ENHANCED OBD II / DATA LIST / PRIMARY / COOLANT TEMP.

MONITOR DESCRIPTION

The Engine Coolant Temperature (ECT) sensor is used to monitor the ECT. The ECT sensor has a

thermistor with a resistance that varies according to the temperature of the engine coolant. When the

coolant temperature becomes low, the resistance in the thermistor increases. When the temperature

becomes high, the resistance drops.

These variations in resistance are reflected in the voltage output from the sensor. The ECM monitors the

sensor voltage and uses this value to calculate the ECT. When the sensor output voltage deviates from

the normal operating range, the ECM interprets this as a fault in the ECT sensor and sets a DTC.

Example:

If the sensor voltage output is -40

C (-40F) for 0.5 seconds or more, the ECM determines that there is an

open in the ECT sensor circuit, and sets DTC P0118. Conversely, if the voltage output is more than 140

C

(284

F) for 0.5 seconds or more, the ECM determines that there is a short in the sensor circuit, and sets

DTC P0117.

If the malfunction is not repaired successfully, a DTC is set 0.5 seconds after the engine is next started.

MONITOR STRATEGY

DTC P0115 Engine Coolant Temperature Circuit

DTC P0117 Engine Coolant Temperature Circuit Low Input

DTC P0118 Engine Coolant Temperature Circuit High Input

DTC No. Proceed to DTC Detection Condition Trouble Area

P0115 Step 1Open or short in Engine Coolant Temperature

(ECT) sensor circuit for 0.5 seconds (1 trip

detection logic)• Open or short in ECT sensor circuit

• ECT sensor

•ECM

P0117 Step 4Short in Engine Coolant Temperature (ECT)

sensor circuit for 0.5 seconds (1 trip detection

logic)• Short in ECT sensor circuit

• ECT sensor

•ECM

P0118 Step 2Open in Engine Coolant Temperature (ECT)

sensor circuit for 0.5 seconds (1 trip detection

logic)• Open in ECT sensor circuit

• ECT sensor

•ECM

Temperature Displayed Malfunctions

-40

C (-40F) Open circuit

140

C (284F) or higher Short circuit

Related DTCsP0115: Engine coolant temperature sensor open/short (Fluctuating)

P0117: Engine coolant temperature sensor short (Low electrical voltage)

P0118: Engine coolant temperature sensor open (High electrical voltage)

Page 467 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–161

ES

FAIL-SAFE

When this DTC, as well as other DTCs relating to ETCS (Electronic Throttle Control System)

malfunctions, is set, the ECM enters fail-safe mode. During fail-safe mode, the ECM cuts the current to

the throttle actuator off, and the throttle valve is returned to a 6.5

throttle angle by the return spring. The

ECM then adjusts the engine output by controlling the fuel injection (intermittent fuel-cut) and ignition

timing, in accordance with the accelerator pedal opening angle, to allow the vehicle to continue at a

minimal speed. If the accelerator pedal is depressed slowly, the vehicle can be driven slowly.

Fail-safe mode continues until a pass condition is detected, and the ignition switch is then turned off.

INSPECTION PROCEDURE

HINT:

Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition

information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data

can be helpful in determining whether the vehicle was running or stopped, whether the engine was

warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of

a malfunction.

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester ON.

(d) Enter the following menus: DIAGNOSIS / ENHANCED

OBD II / DTC INFO / CURRENT CODES.

(e) Read the DTC.

Result

HINT:

If any DTCs other than P0121 are output, troubleshoot

those DTCs first.

B

A

1CHECK ANY OTHER DTC OUTPUT (IN ADDITION TO DTC P0121)

Display (DTC output) Proceed to

P0121 A

P0121 and other DTCs B

GO TO DTC CHART

REPLACE THROTTLE BODY

Page 486 of 3000

ES–1802GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

OK

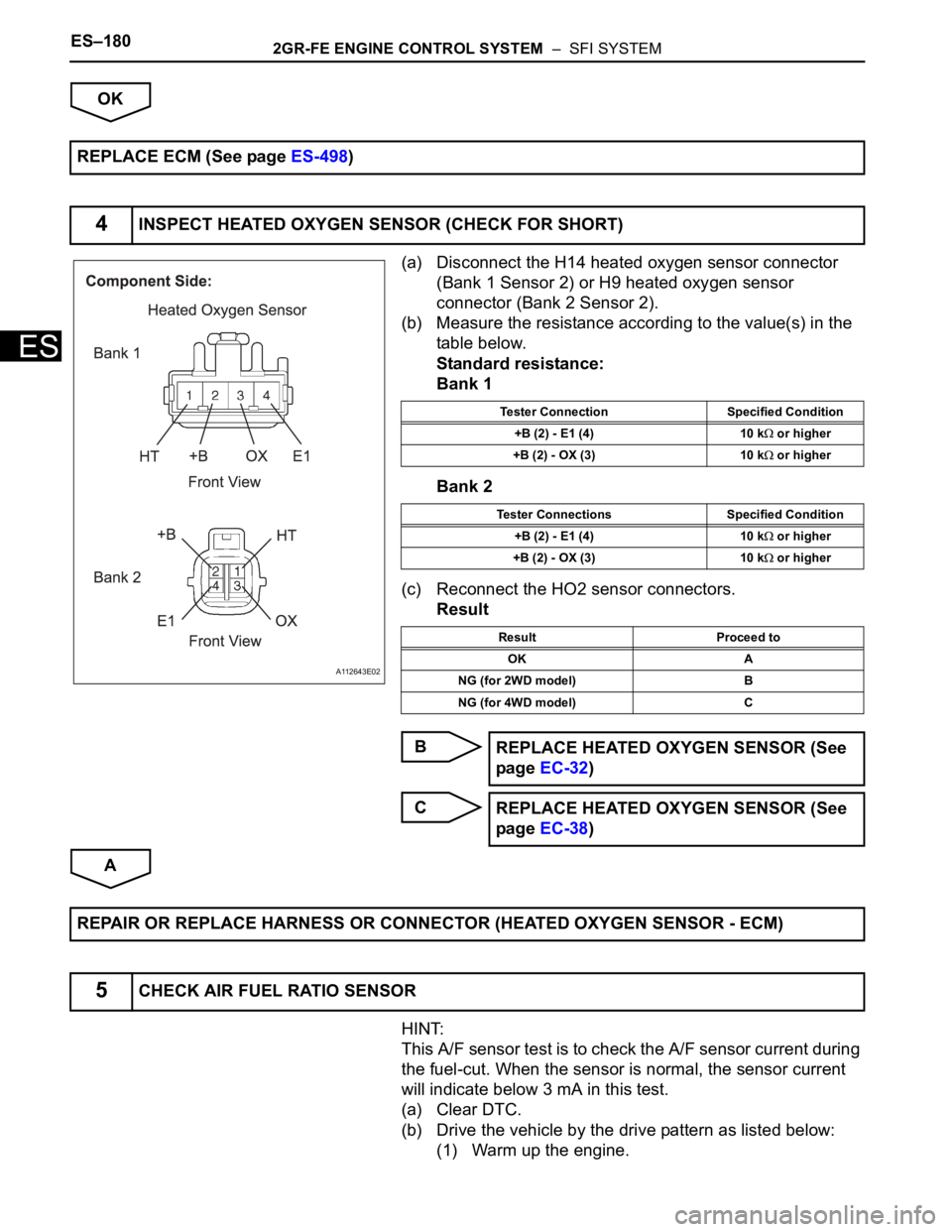

(a) Disconnect the H14 heated oxygen sensor connector

(Bank 1 Sensor 2) or H9 heated oxygen sensor

connector (Bank 2 Sensor 2).

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Bank 1

Bank 2

(c) Reconnect the HO2 sensor connectors.

Result

B

C

A

HINT:

This A/F sensor test is to check the A/F sensor current during

the fuel-cut. When the sensor is normal, the sensor current

will indicate below 3 mA in this test.

(a) Clear DTC.

(b) Drive the vehicle by the drive pattern as listed below:

(1) Warm up the engine. REPLACE ECM (See page ES-498)

4INSPECT HEATED OXYGEN SENSOR (CHECK FOR SHORT)

A112643E02

Tester Connection Specified Condition

+B (2) - E1 (4) 10 k

or higher

+B (2) - OX (3) 10 k

or higher

Tester Connections Specified Condition

+B (2) - E1 (4) 10 k

or higher

+B (2) - OX (3) 10 k

or higher

Result Proceed to

OK A

NG (for 2WD model) B

NG (for 4WD model) C

REPLACE HEATED OXYGEN SENSOR (See

page EC-32)

REPLACE HEATED OXYGEN SENSOR (See

page EC-38)

REPAIR OR REPLACE HARNESS OR CONNECTOR (HEATED OXYGEN SENSOR - ECM)

5CHECK AIR FUEL RATIO SENSOR

Page 491 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–185

ES

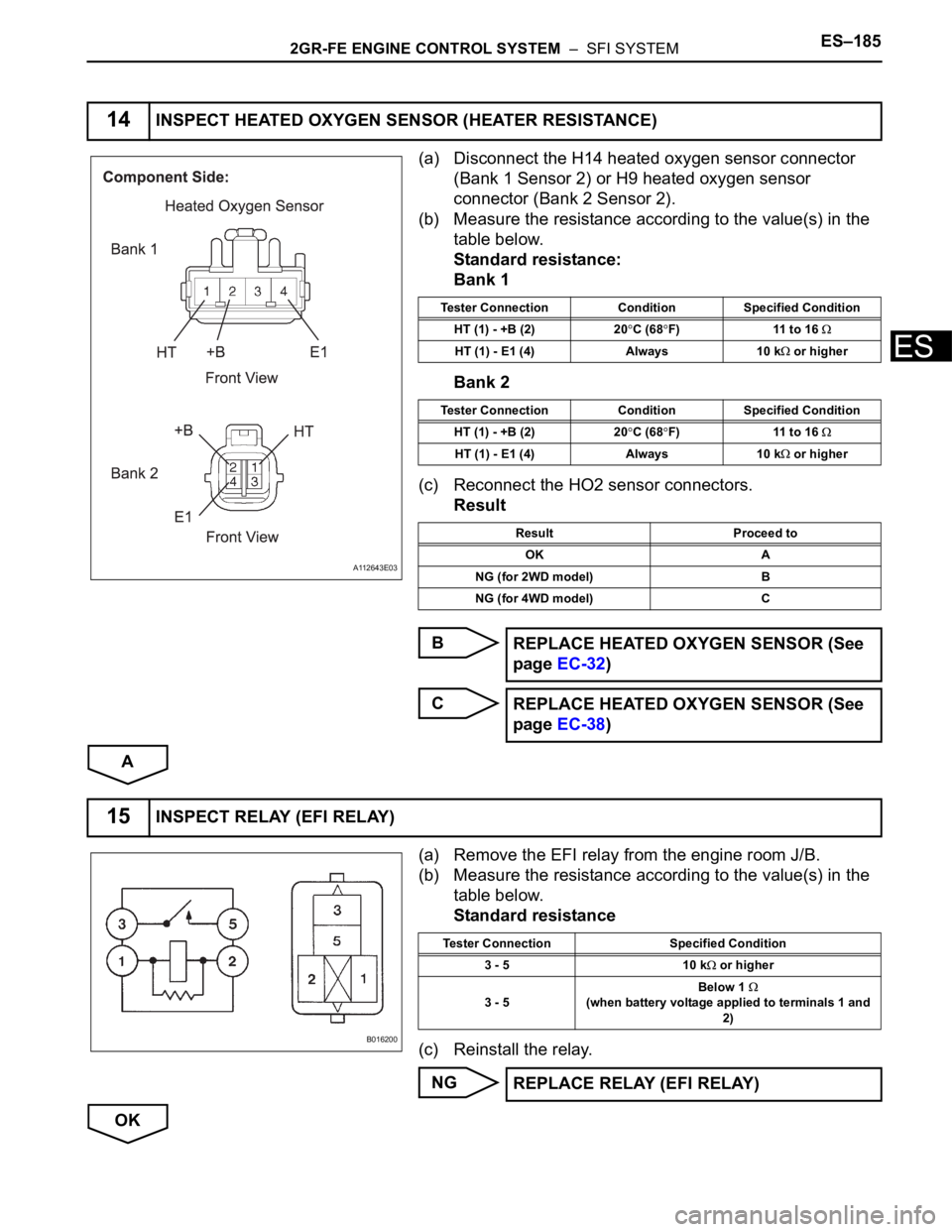

(a) Disconnect the H14 heated oxygen sensor connector

(Bank 1 Sensor 2) or H9 heated oxygen sensor

connector (Bank 2 Sensor 2).

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Bank 1

Bank 2

(c) Reconnect the HO2 sensor connectors.

Result

B

C

A

(a) Remove the EFI relay from the engine room J/B.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

(c) Reinstall the relay.

NG

OK

14INSPECT HEATED OXYGEN SENSOR (HEATER RESISTANCE)

A112643E03

Tester Connection Condition Specified Condition

HT (1) - +B (2) 20

C (68F) 11 to 16

HT (1) - E1 (4) Always 10 k or higher

Tester Connection Condition Specified Condition

HT (1) - +B (2) 20

C (68F) 11 to 16

HT (1) - E1 (4) Always 10 k or higher

Result Proceed to

OK A

NG (for 2WD model) B

NG (for 4WD model) C

REPLACE HEATED OXYGEN SENSOR (See

page EC-32)

REPLACE HEATED OXYGEN SENSOR (See

page EC-38)

15INSPECT RELAY (EFI RELAY)

B016200

Tester Connection Specified Condition

3 - 5 10 k

or higher

3 - 5Below 1

(when battery voltage applied to terminals 1 and

2)

REPLACE RELAY (EFI RELAY)

Page 502 of 3000

ES–1962GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

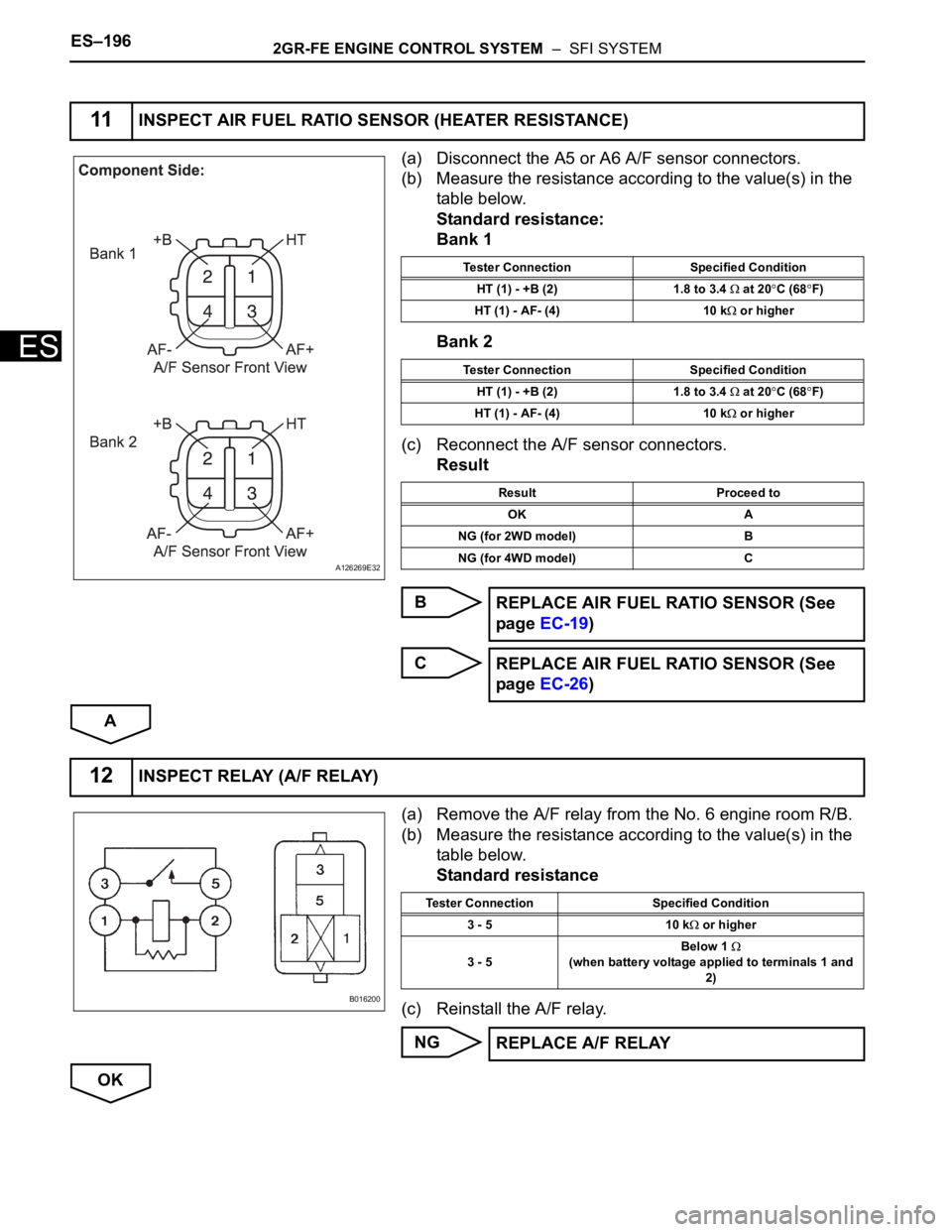

(a) Disconnect the A5 or A6 A/F sensor connectors.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance:

Bank 1

Bank 2

(c) Reconnect the A/F sensor connectors.

Result

B

C

A

(a) Remove the A/F relay from the No. 6 engine room R/B.

(b) Measure the resistance according to the value(s) in the

table below.

Standard resistance

(c) Reinstall the A/F relay.

NG

OK

11INSPECT AIR FUEL RATIO SENSOR (HEATER RESISTANCE)

A126269E32

Tester Connection Specified Condition

HT (1) - +B (2) 1.8 to 3.4

at 20C (68F)

HT (1) - AF- (4) 10 k

or higher

Tester Connection Specified Condition

HT (1) - +B (2) 1.8 to 3.4

at 20C (68F)

HT (1) - AF- (4) 10 k

or higher

Result Proceed to

OK A

NG (for 2WD model) B

NG (for 4WD model) C

REPLACE AIR FUEL RATIO SENSOR (See

page EC-19)

REPLACE AIR FUEL RATIO SENSOR (See

page EC-26)

12INSPECT RELAY (A/F RELAY)

B016200

Tester Connection Specified Condition

3 - 5 10 k

or higher

3 - 5Below 1

(when battery voltage applied to terminals 1 and

2)

REPLACE A/F RELAY

Page 513 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–207

ES

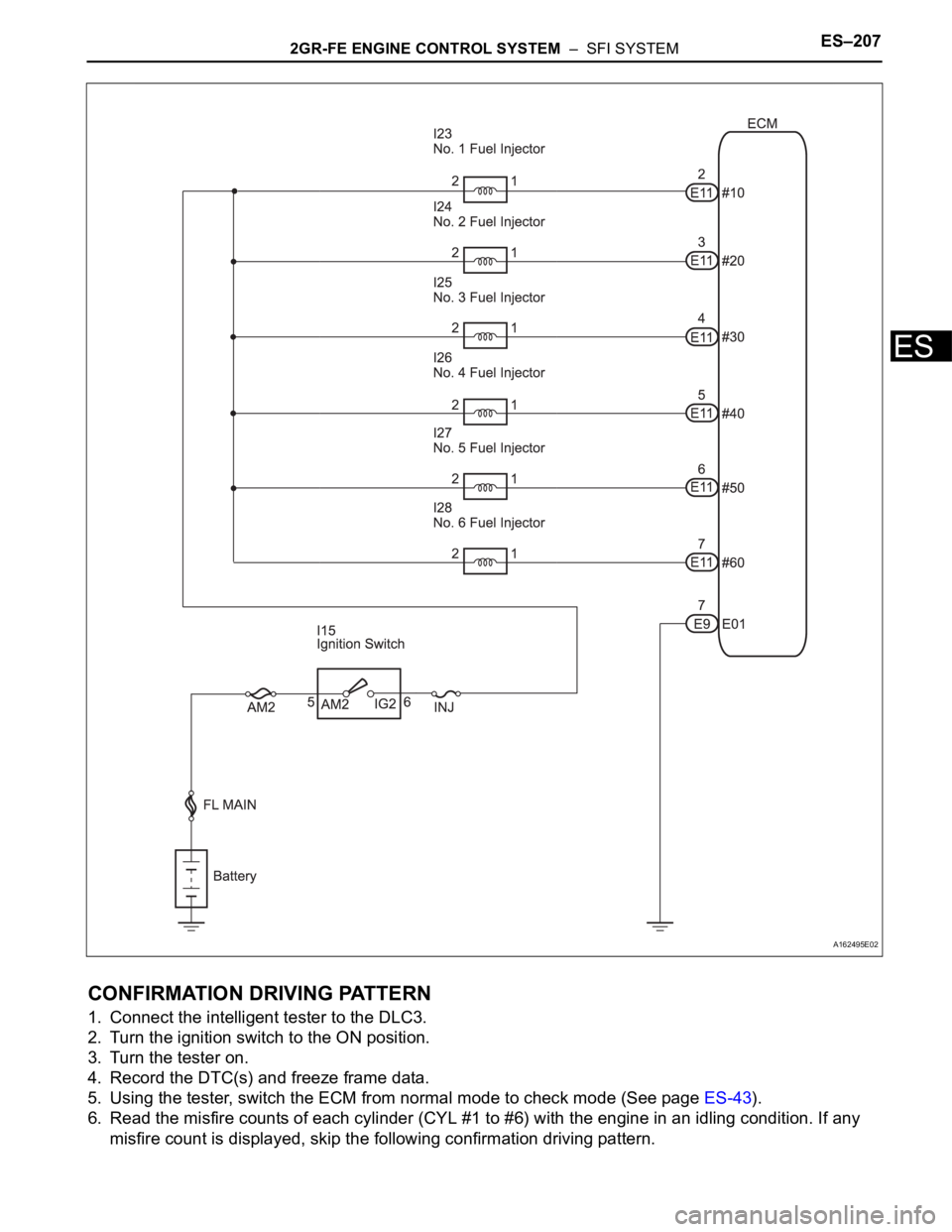

CONFIRMATION DRIVING PATTERN

1. Connect the intelligent tester to the DLC3.

2. Turn the ignition switch to the ON position.

3. Turn the tester on.

4. Record the DTC(s) and freeze frame data.

5. Using the tester, switch the ECM from normal mode to check mode (See page ES-43).

6. Read the misfire counts of each cylinder (CYL #1 to #6) with the engine in an idling condition. If any

misfire count is displayed, skip the following confirmation driving pattern.

A162495E02

Page 514 of 3000

ES–2082GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

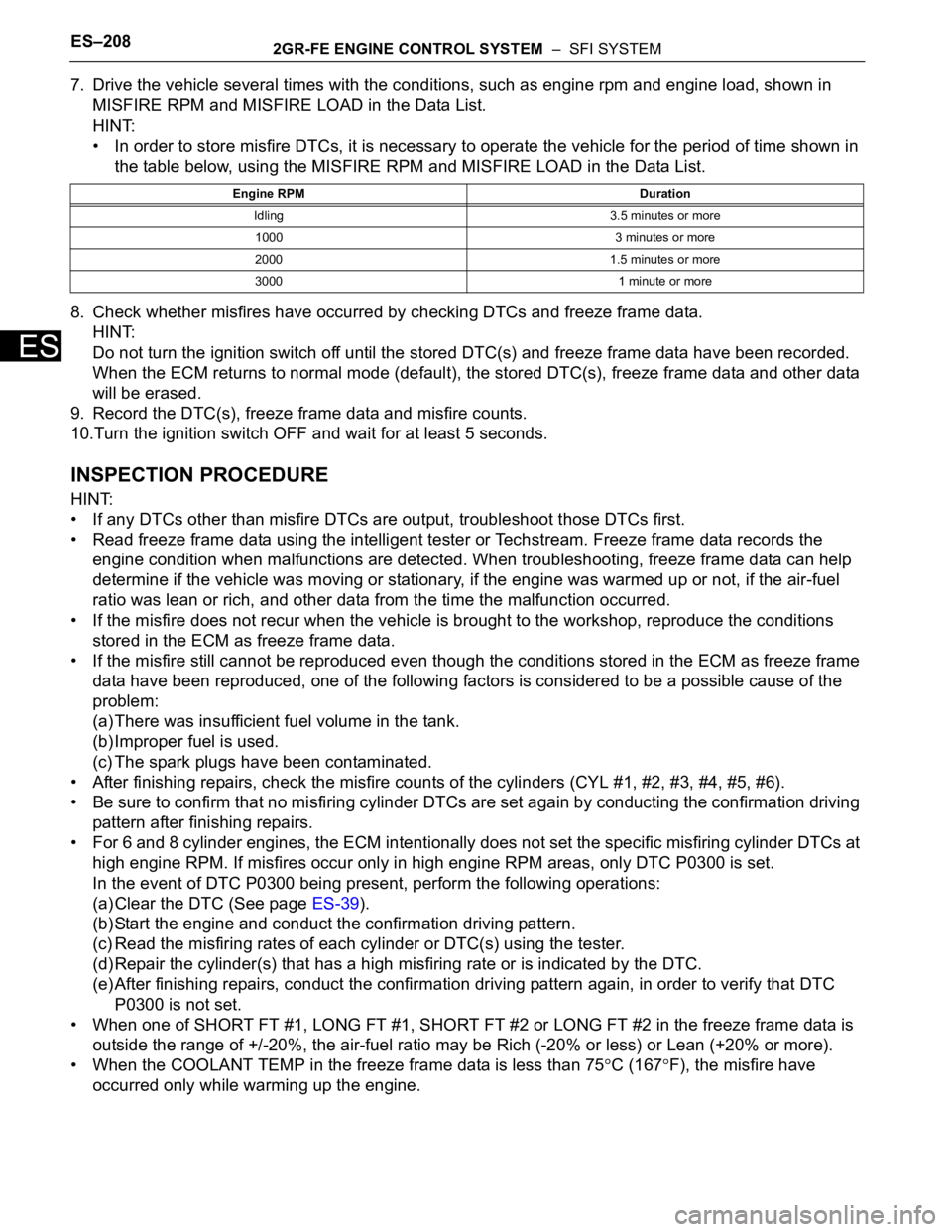

7. Drive the vehicle several times with the conditions, such as engine rpm and engine load, shown in

MISFIRE RPM and MISFIRE LOAD in the Data List.

HINT:

• In order to store misfire DTCs, it is necessary to operate the vehicle for the period of time shown in

the table below, using the MISFIRE RPM and MISFIRE LOAD in the Data List.

8. Check whether misfires have occurred by checking DTCs and freeze frame data.

HINT:

Do not turn the ignition switch off until the stored DTC(s) and freeze frame data have been recorded.

When the ECM returns to normal mode (default), the stored DTC(s), freeze frame data and other data

will be erased.

9. Record the DTC(s), freeze frame data and misfire counts.

10.Turn the ignition switch OFF and wait for at least 5 seconds.

INSPECTION PROCEDURE

HINT:

• If any DTCs other than misfire DTCs are output, troubleshoot those DTCs first.

• Read freeze frame data using the intelligent tester or Techstream. Freeze frame data records the

engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help

determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air-fuel

ratio was lean or rich, and other data from the time the malfunction occurred.

• If the misfire does not recur when the vehicle is brought to the workshop, reproduce the conditions

stored in the ECM as freeze frame data.

• If the misfire still cannot be reproduced even though the conditions stored in the ECM as freeze frame

data have been reproduced, one of the following factors is considered to be a possible cause of the

problem:

(a) There was insufficient fuel volume in the tank.

(b) Improper fuel is used.

(c) The spark plugs have been contaminated.

• After finishing repairs, check the misfire counts of the cylinders (CYL #1, #2, #3, #4, #5, #6).

• Be sure to confirm that no misfiring cylinder DTCs are set again by conducting the confirmation driving

pattern after finishing repairs.

• For 6 and 8 cylinder engines, the ECM intentionally does not set the specific misfiring cylinder DTCs at

high engine RPM. If misfires occur only in high engine RPM areas, only DTC P0300 is set.

In the event of DTC P0300 being present, perform the following operations:

(a) Clear the DTC (See page ES-39).

(b) Start the engine and conduct the confirmation driving pattern.

(c) Read the misfiring rates of each cylinder or DTC(s) using the tester.

(d) Repair the cylinder(s) that has a high misfiring rate or is indicated by the DTC.

(e) After finishing repairs, conduct the confirmation driving pattern again, in order to verify that DTC

P0300 is not set.

• When one of SHORT FT #1, LONG FT #1, SHORT FT #2 or LONG FT #2 in the freeze frame data is

outside the range of +/-20%, the air-fuel ratio may be Rich (-20% or less) or Lean (+20% or more).

• When the COOLANT TEMP in the freeze frame data is less than 75

C (167F), the misfire have

occurred only while warming up the engine.

Engine RPM Duration

Idling 3.5 minutes or more

1000 3 minutes or more

2000 1.5 minutes or more

3000 1 minute or more

Page 602 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–309

ES

NOTICE:

In this operation, the engine must be cold (the same level

as the engine coolant temperature recorded in the freeze

frame data).

(a) Connect the intelligent tester to the DLC3.

(b) Turn the ignition switch to the ON position.

(c) Turn the tester on.

(d) Clear the DTCs (See page ES-39).

(e) Switch the ECM from normal mode to check mode using

the tester (See page ES-43).

(f) Start the engine to idle for a minute.

OK:

Stable fast idling.

(g) Read the DTCs.

OK:

No DTC output.

NEXT

15CHECK WHETHER DTC OUTPUT RECURS (DTC P050A)

END