brake sensor TOYOTA SIENNA 2007 Service Owner's Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 2007, Model line: SIENNA, Model: TOYOTA SIENNA 2007Pages: 3000, PDF Size: 52.26 MB

Page 804 of 3000

ES–282GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEM

ES

• Vehicle was driven in the city area (or on free-

way) for 10 minutes or more.

(b) Monitor Conditions

(1) Turn the ignition switch off and wait for 6 hours.

HINT:

Do not start the engine until checking Readiness

Monitor status. If the engine is started, the step

described above must be repeated.

(c) Monitor Status

(1) Connect an intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

(3) Turn the tester or scan tool ON.

(4) Check the Readiness Monitor status displayed

on the tester or scan tool.

If the status does not switch to COMPL

(complete), restart the engine, make sure that

the preconditions have been met, and then

perform the Monitor Conditions again.

4. A/F SENSOR AND HO2S MONITORS

(a) Preconditions

The monitor will not run unless:

• 2 minutes or more have elapsed since the engine

was started.

• The Engine Coolant Temperature (ECT) is 75

C

(167

F) or more.

• Cumulative driving time at a vehicle speed of 30

mph (48 km/h) or more exceeds 6 minutes.

• Air-fuel ratio feedback control is performed.

• Fuel-cut control is performed for 8 seconds or

more (for the Rear HO2 Sensor Monitor).

(b) Drive Pattern for front A/F sensor and HO2 sensor.

(1) Connect an intelligent tester to the DLC3.

(2) Turn the ignition switch to the ON position.

(3) Turn the tester ON.

(4) Clear the DTCs.

(5) Start the engine, and warm it up until the ECT

reaches 75

C (167F) or higher.

(6) Drive the vehicle at 38 mph (60 km/h) or more

for at least 10 minutes.

(7) Change the transmission to the 2nd gear.

(8) Accelerate the vehicle to 40 mph (64 km/h) or

more by depressing the accelerator pedal for at

least 10 seconds (Procedure "A").

(9) Soon after performing procedure "A" above,

release the accelerator pedal for at least 4

seconds without depressing the brake pedal, in

order to execute fuel-cut control (Procedure "B").

(10) Allow the vehicle to decelerate until the vehicle

speed declines to less than 6 mph (10 km/h)

(Procedure "C").

(11) Repeat procedures from "A" through "C" above

at least 3 times in one driving cycle.

Page 813 of 3000

2GR-FE ENGINE CONTROL SYSTEM – SFI SYSTEMES–33

ES

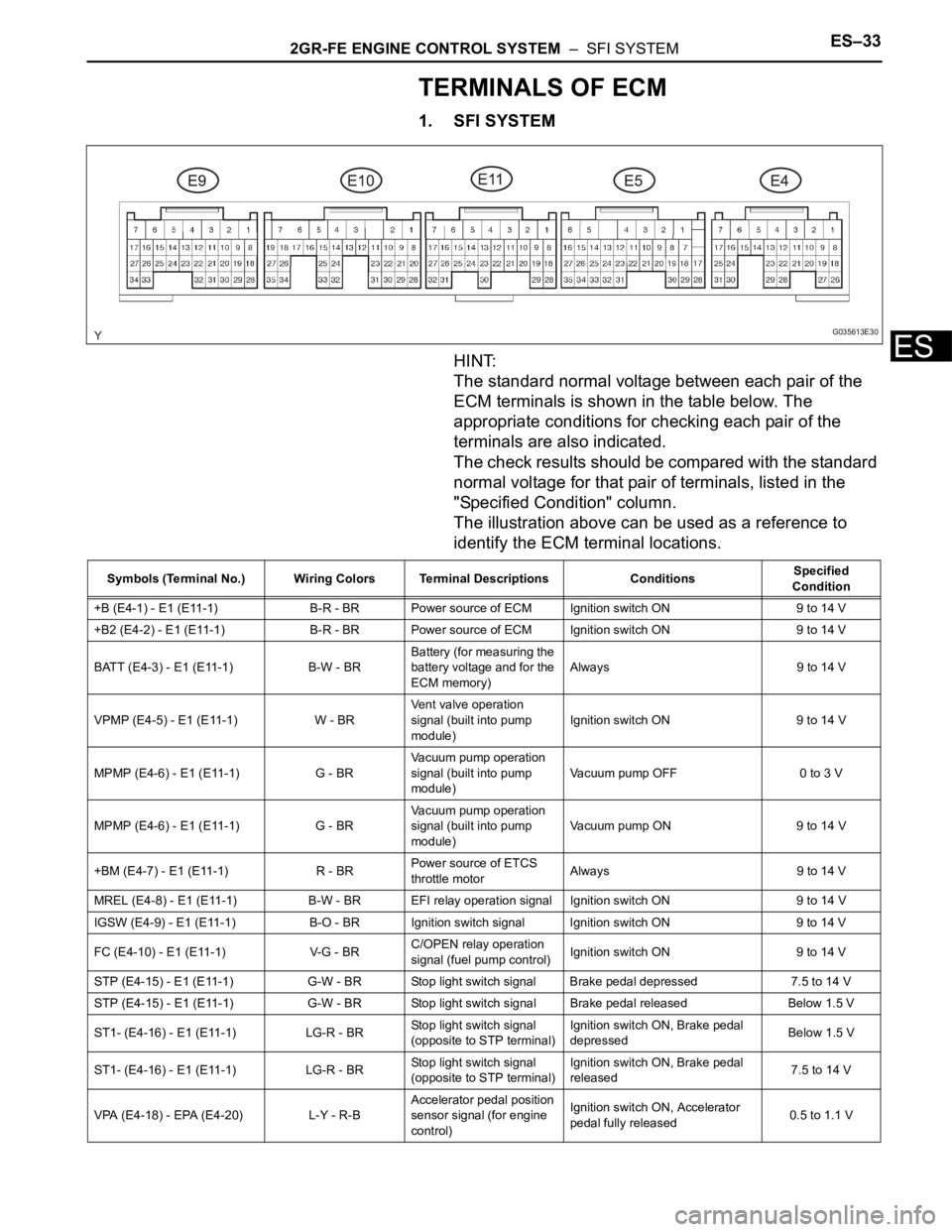

TERMINALS OF ECM

1. SFI SYSTEM

HINT:

The standard normal voltage between each pair of the

ECM terminals is shown in the table below. The

appropriate conditions for checking each pair of the

terminals are also indicated.

The check results should be compared with the standard

normal voltage for that pair of terminals, listed in the

"Specified Condition" column.

The illustration above can be used as a reference to

identify the ECM terminal locations.

G035613E30

Symbols (Terminal No.) Wiring Colors Terminal Descriptions ConditionsSpecified

Condition

+B (E4-1) - E1 (E11-1) B-R - BR Power source of ECM Ignition switch ON 9 to 14 V

+B2 (E4-2) - E1 (E11-1) B-R - BR Power source of ECM Ignition switch ON 9 to 14 V

BATT (E4-3) - E1 (E11-1) B-W - BRBattery (for measuring the

battery voltage and for the

ECM memory)Always 9 to 14 V

VPMP (E4-5) - E1 (E11-1) W - BRVent valve operation

signal (built into pump

module)Ignition switch ON 9 to 14 V

MPMP (E4-6) - E1 (E11-1) G - BRVacuum pump operation

signal (built into pump

module)Vacuum pump OFF 0 to 3 V

MPMP (E4-6) - E1 (E11-1) G - BRVacuum pump operation

signal (built into pump

module)Vacuum pump ON 9 to 14 V

+BM (E4-7) - E1 (E11-1) R - BRPower source of ETCS

throttle motorAlways 9 to 14 V

MREL (E4-8) - E1 (E11-1) B-W - BR EFI relay operation signal Ignition switch ON 9 to 14 V

IGSW (E4-9) - E1 (E11-1) B-O - BRIgnition switch signal Ignition switch ON 9 to 14 V

FC (E4-10) - E1 (E11-1) V-G - BRC/OPEN relay operation

signal (fuel pump control)Ignition switch ON 9 to 14 V

STP (E4-15) - E1 (E11-1) G-W - BR Stop light switch signal Brake pedal depressed 7.5 to 14 V

STP (E4-15) - E1 (E11-1) G-W - BR Stop light switch signal Brake pedal released Below 1.5 V

ST1- (E4-16) - E1 (E11-1) LG-R - BRStop light switch signal

(opposite to STP terminal)Ignition switch ON, Brake pedal

depressedBelow 1.5 V

ST1- (E4-16) - E1 (E11-1) LG-R - BRStop light switch signal

(opposite to STP terminal)Ignition switch ON, Brake pedal

released7.5 to 14 V

VPA (E4-18) - EPA (E4-20) L-Y - R-BAccelerator pedal position

sensor signal (for engine

control)Ignition switch ON, Accelerator

pedal fully released0.5 to 1.1 V

Page 934 of 3000

EM–42GR-FE ENGINE MECHANICAL – ENGINE

EM

(h) Install the 6 ignition coils.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

(i) Install the intake air surge tank (See page ES-522).

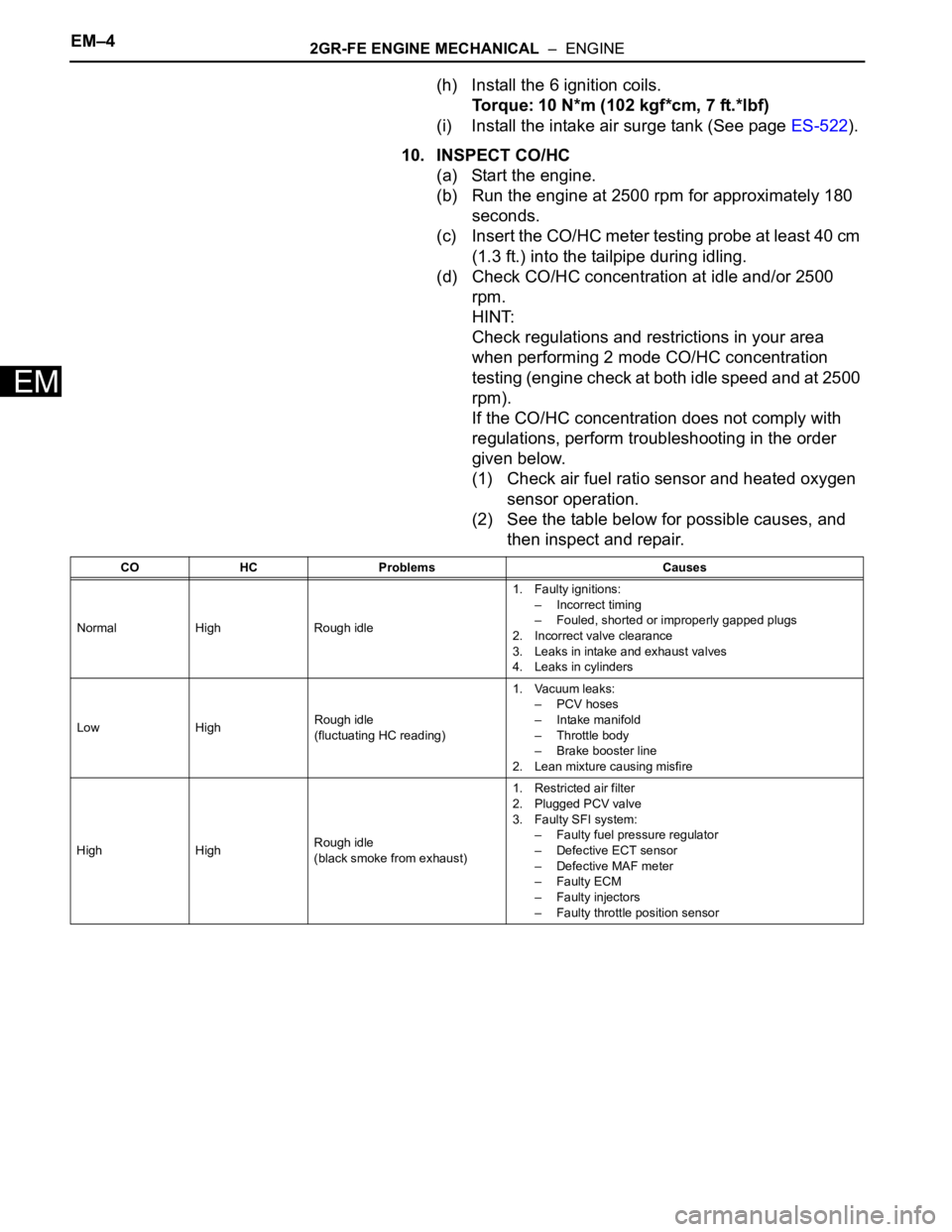

10. INSPECT CO/HC

(a) Start the engine.

(b) Run the engine at 2500 rpm for approximately 180

seconds.

(c) Insert the CO/HC meter testing probe at least 40 cm

(1.3 ft.) into the tailpipe during idling.

(d) Check CO/HC concentration at idle and/or 2500

rpm.

HINT:

Check regulations and restrictions in your area

when performing 2 mode CO/HC concentration

testing (engine check at both idle speed and at 2500

rpm).

If the CO/HC concentration does not comply with

regulations, perform troubleshooting in the order

given below.

(1) Check air fuel ratio sensor and heated oxygen

sensor operation.

(2) See the table below for possible causes, and

then inspect and repair.

CO HC Problems Causes

Normal High Rough idle1. Faulty ignitions:

– Incorrect timing

– Fouled, shorted or improperly gapped plugs

2. Incorrect valve clearance

3. Leaks in intake and exhaust valves

4. Leaks in cylinders

Low HighRough idle

(fluctuating HC reading)1. Vacuum leaks:

– PCV hoses

– Intake manifold

– Throttle body

– Brake booster line

2. Lean mixture causing misfire

High HighRough idle

(black smoke from exhaust)1. Restricted air filter

2. Plugged PCV valve

3. Faulty SFI system:

– Faulty fuel pressure regulator

– Defective ECT sensor

– Defective MAF meter

–Faulty ECM

– Faulty injectors

– Faulty throttle position sensor

Page 1408 of 3000

AX–42U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEM

AX

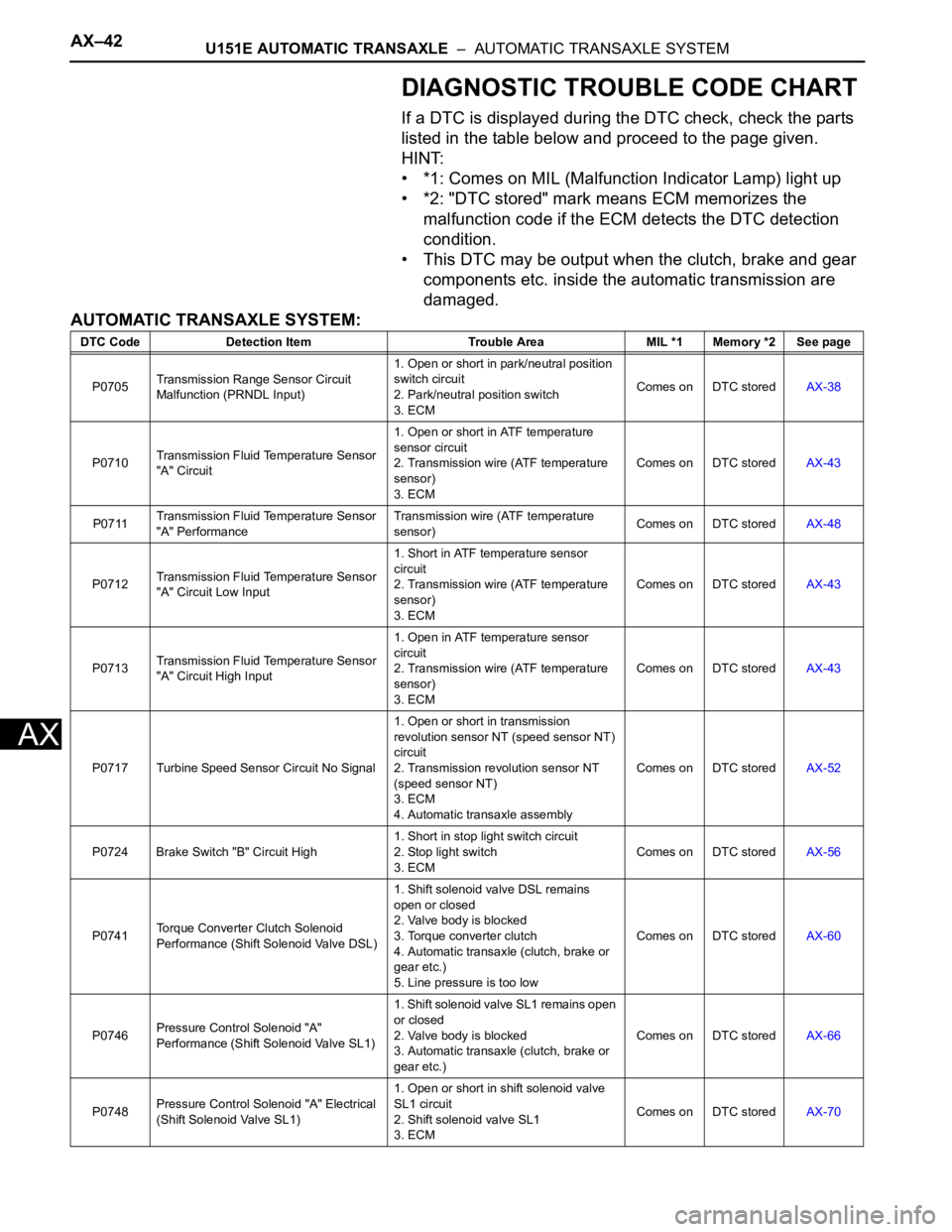

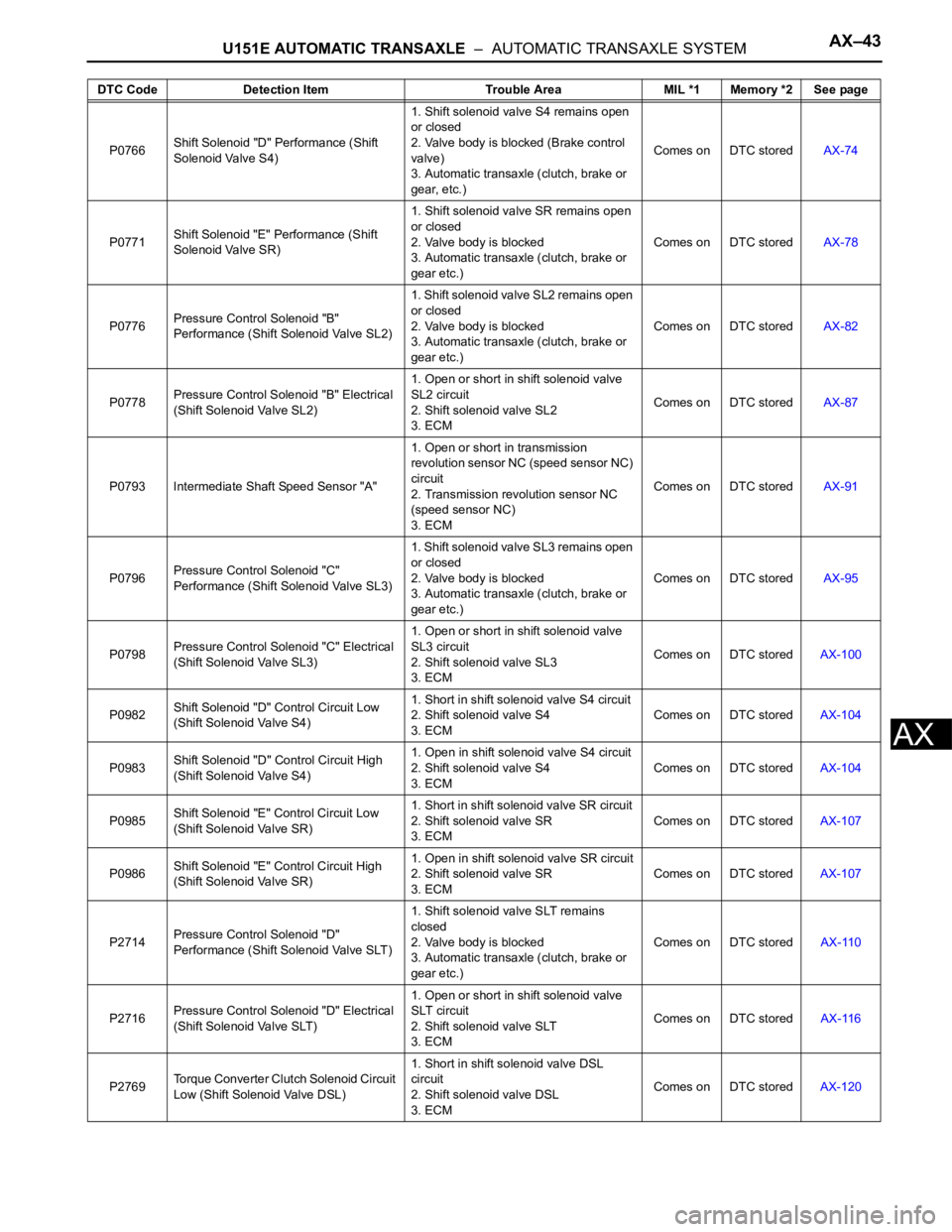

DIAGNOSTIC TROUBLE CODE CHART

If a DTC is displayed during the DTC check, check the parts

listed in the table below and proceed to the page given.

HINT:

• *1: Comes on MIL (Malfunction Indicator Lamp) light up

• *2: "DTC stored" mark means ECM memorizes the

malfunction code if the ECM detects the DTC detection

condition.

• This DTC may be output when the clutch, brake and gear

components etc. inside the automatic transmission are

damaged.

AUTOMATIC TRANSAXLE SYSTEM:

DTC Code Detection Item Trouble Area MIL *1 Memory *2 See page

P0705Transmission Range Sensor Circuit

Malfunction (PRNDL Input)1. Open or short in park/neutral position

switch circuit

2. Park/neutral position switch

3. ECMComes on DTC storedAX-38

P0710Transmission Fluid Temperature Sensor

"A" Circuit1. Open or short in ATF temperature

sensor circuit

2. Transmission wire (ATF temperature

sensor)

3. ECMComes on DTC storedAX-43

P0711Transmission Fluid Temperature Sensor

"A" PerformanceTransmission wire (ATF temperature

sensor)Comes on DTC storedAX-48

P0712Transmission Fluid Temperature Sensor

"A" Circuit Low Input1. Short in ATF temperature sensor

circuit

2. Transmission wire (ATF temperature

sensor)

3. ECMComes on DTC storedAX-43

P0713Transmission Fluid Temperature Sensor

"A" Circuit High Input1. Open in ATF temperature sensor

circuit

2. Transmission wire (ATF temperature

sensor)

3. ECMComes on DTC storedAX-43

P0717 Turbine Speed Sensor Circuit No Signal1. Open or short in transmission

revolution sensor NT (speed sensor NT)

circuit

2. Transmission revolution sensor NT

(speed sensor NT)

3. ECM

4. Automatic transaxle assemblyComes on DTC storedAX-52

P0724 Brake Switch "B" Circuit High1. Short in stop light switch circuit

2. Stop light switch

3. ECMComes on DTC storedAX-56

P0741Torque Converter Clutch Solenoid

Performance (Shift Solenoid Valve DSL)1. Shift solenoid valve DSL remains

open or closed

2. Valve body is blocked

3. Torque converter clutch

4. Automatic transaxle (clutch, brake or

gear etc.)

5. Line pressure is too lowComes on DTC storedAX-60

P0746Pressure Control Solenoid "A"

Performance (Shift Solenoid Valve SL1)1. Shift solenoid valve SL1 remains open

or closed

2. Valve body is blocked

3. Automatic transaxle (clutch, brake or

gear etc.)Comes on DTC storedAX-66

P0748Pressure Control Solenoid "A" Electrical

(Shift Solenoid Valve SL1)1. Open or short in shift solenoid valve

SL1 circuit

2. Shift solenoid valve SL1

3. ECMComes on DTC storedAX-70

Page 1409 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–43

AX

P0766Shift Solenoid "D" Performance (Shift

Solenoid Valve S4)1. Shift solenoid valve S4 remains open

or closed

2. Valve body is blocked (Brake control

valve)

3. Automatic transaxle (clutch, brake or

gear, etc.)Comes on DTC storedAX-74

P0771Shift Solenoid "E" Performance (Shift

Solenoid Valve SR)1. Shift solenoid valve SR remains open

or closed

2. Valve body is blocked

3. Automatic transaxle (clutch, brake or

gear etc.)Comes on DTC storedAX-78

P0776Pressure Control Solenoid "B"

Performance (Shift Solenoid Valve SL2)1. Shift solenoid valve SL2 remains open

or closed

2. Valve body is blocked

3. Automatic transaxle (clutch, brake or

gear etc.)Comes on DTC storedAX-82

P0778Pressure Control Solenoid "B" Electrical

(Shift Solenoid Valve SL2)1. Open or short in shift solenoid valve

SL2 circuit

2. Shift solenoid valve SL2

3. ECMComes on DTC storedAX-87

P0793 Intermediate Shaft Speed Sensor "A"1. Open or short in transmission

revolution sensor NC (speed sensor NC)

circuit

2. Transmission revolution sensor NC

(speed sensor NC)

3. ECMComes on DTC storedAX-91

P0796Pressure Control Solenoid "C"

Performance (Shift Solenoid Valve SL3)1. Shift solenoid valve SL3 remains open

or closed

2. Valve body is blocked

3. Automatic transaxle (clutch, brake or

gear etc.)Comes on DTC storedAX-95

P0798Pressure Control Solenoid "C" Electrical

(Shift Solenoid Valve SL3)1. Open or short in shift solenoid valve

SL3 circuit

2. Shift solenoid valve SL3

3. ECMComes on DTC storedAX-100

P0982Shift Solenoid "D" Control Circuit Low

(Shift Solenoid Valve S4)1. Short in shift solenoid valve S4 circuit

2. Shift solenoid valve S4

3. ECMComes on DTC storedAX-104

P0983Shift Solenoid "D" Control Circuit High

(Shift Solenoid Valve S4)1. Open in shift solenoid valve S4 circuit

2. Shift solenoid valve S4

3. ECMComes on DTC storedAX-104

P0985Shift Solenoid "E" Control Circuit Low

(Shift Solenoid Valve SR)1. Short in shift solenoid valve SR circuit

2. Shift solenoid valve SR

3. ECMComes on DTC storedAX-107

P0986Shift Solenoid "E" Control Circuit High

(Shift Solenoid Valve SR)1. Open in shift solenoid valve SR circuit

2. Shift solenoid valve SR

3. ECMComes on DTC storedAX-107

P2714Pressure Control Solenoid "D"

Performance (Shift Solenoid Valve SLT)1. Shift solenoid valve SLT remains

closed

2. Valve body is blocked

3. Automatic transaxle (clutch, brake or

gear etc.)Comes on DTC stored

AX-110

P2716Pressure Control Solenoid "D" Electrical

(Shift Solenoid Valve SLT)1. Open or short in shift solenoid valve

SLT circuit

2. Shift solenoid valve SLT

3. ECMComes on DTC storedAX-116

P2769Torque Converter Clutch Solenoid Circuit

Low (Shift Solenoid Valve DSL)1. Short in shift solenoid valve DSL

circuit

2. Shift solenoid valve DSL

3. ECMComes on DTC storedAX-120 DTC Code Detection Item Trouble Area MIL *1 Memory *2 See page

Page 1429 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–63

AX

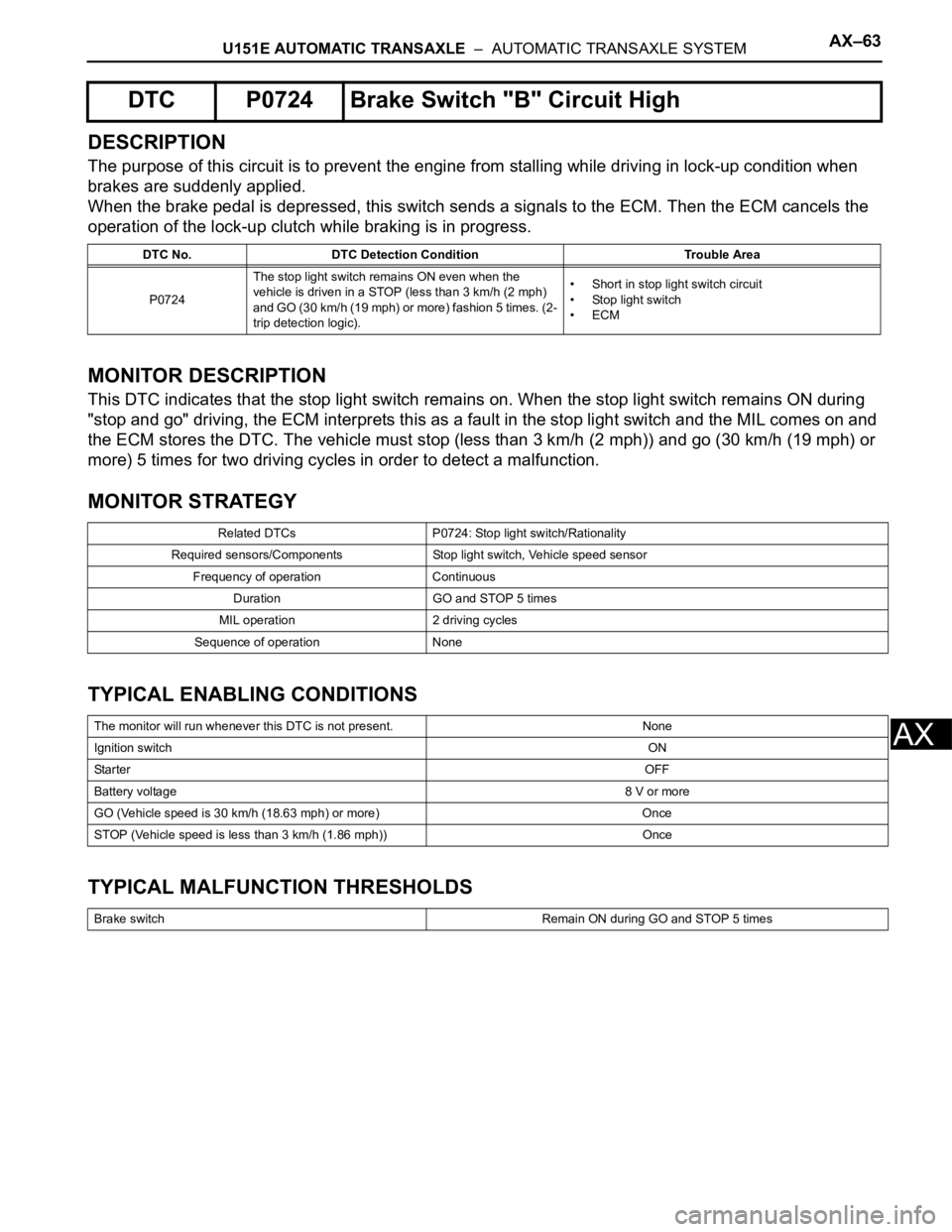

DESCRIPTION

The purpose of this circuit is to prevent the engine from stalling while driving in lock-up condition when

brakes are suddenly applied.

When the brake pedal is depressed, this switch sends a signals to the ECM. Then the ECM cancels the

operation of the lock-up clutch while braking is in progress.

MONITOR DESCRIPTION

This DTC indicates that the stop light switch remains on. When the stop light switch remains ON during

"stop and go" driving, the ECM interprets this as a fault in the stop light switch and the MIL comes on and

the ECM stores the DTC. The vehicle must stop (less than 3 km/h (2 mph)) and go (30 km/h (19 mph) or

more) 5 times for two driving cycles in order to detect a malfunction.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

TYPICAL MALFUNCTION THRESHOLDS

DTC P0724 Brake Switch "B" Circuit High

DTC No. DTC Detection Condition Trouble Area

P0724The stop light switch remains ON even when the

vehicle is driven in a STOP (less than 3 km/h (2 mph)

and GO (30 km/h (19 mph) or more) fashion 5 times. (2-

trip detection logic).• Short in stop light switch circuit

• Stop light switch

•ECM

Related DTCs P0724: Stop light switch/Rationality

Required sensors/Components Stop light switch, Vehicle speed sensor

Frequency of operation Continuous

Duration GO and STOP 5 times

MIL operation 2 driving cycles

Sequence of operation None

The monitor will run whenever this DTC is not present. None

Ignition switchON

Sta r t e rOFF

Battery voltage8 V or more

GO (Vehicle speed is 30 km/h (18.63 mph) or more) Once

STOP (Vehicle speed is less than 3 km/h (1.86 mph)) Once

Brake switch Remain ON during GO and STOP 5 times

Page 1433 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–67

AX

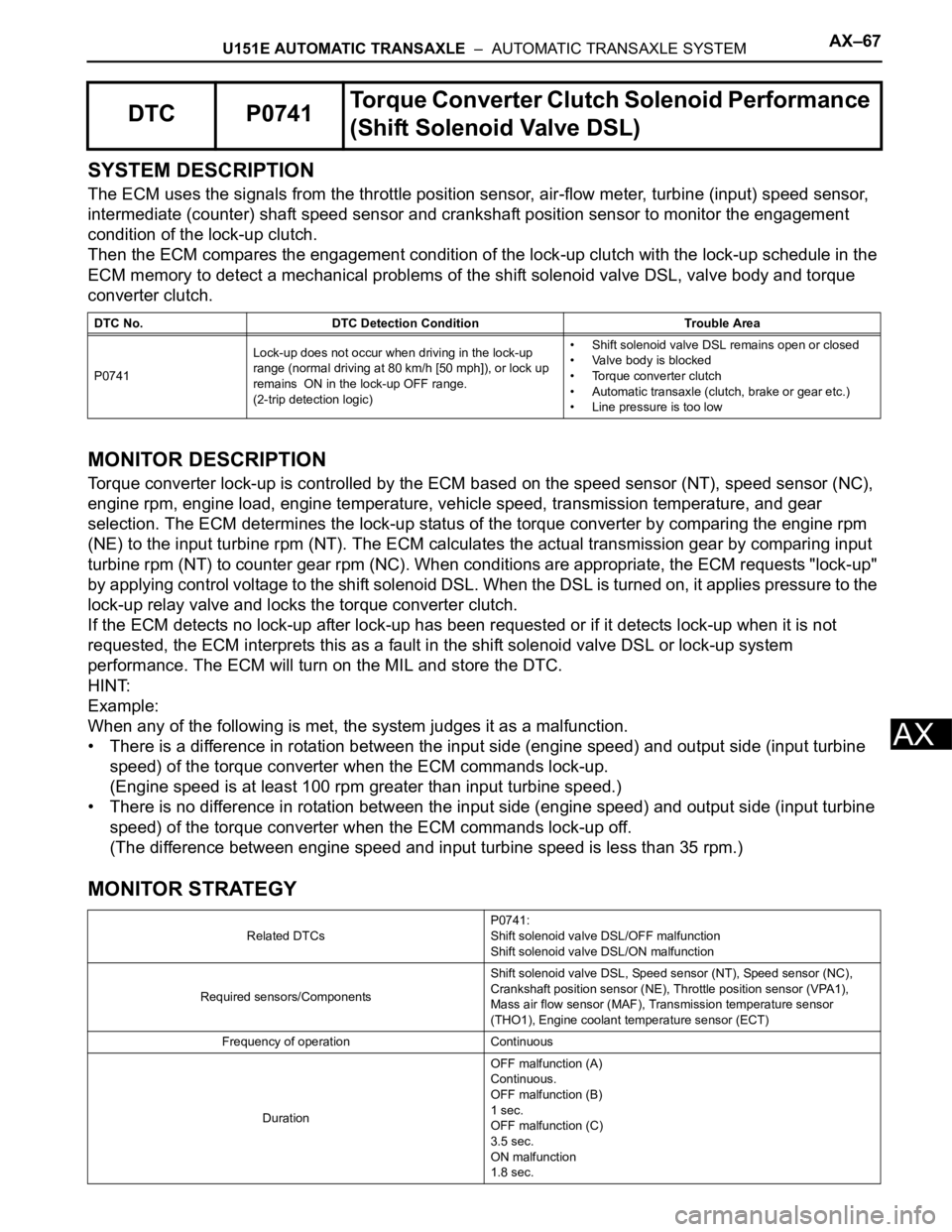

SYSTEM DESCRIPTION

The ECM uses the signals from the throttle position sensor, air-flow meter, turbine (input) speed sensor,

intermediate (counter) shaft speed sensor and crankshaft position sensor to monitor the engagement

condition of the lock-up clutch.

Then the ECM compares the engagement condition of the lock-up clutch with the lock-up schedule in the

ECM memory to detect a mechanical problems of the shift solenoid valve DSL, valve body and torque

converter clutch.

MONITOR DESCRIPTION

Torque converter lock-up is controlled by the ECM based on the speed sensor (NT), speed sensor (NC),

engine rpm, engine load, engine temperature, vehicle speed, transmission temperature, and gear

selection. The ECM determines the lock-up status of the torque converter by comparing the engine rpm

(NE) to the input turbine rpm (NT). The ECM calculates the actual transmission gear by comparing input

turbine rpm (NT) to counter gear rpm (NC). When conditions are appropriate, the ECM requests "lock-up"

by applying control voltage to the shift solenoid DSL. When the DSL is turned on, it applies pressure to the

lock-up relay valve and locks the torque converter clutch.

If the ECM detects no lock-up after lock-up has been requested or if it detects lock-up when it is not

requested, the ECM interprets this as a fault in the shift solenoid valve DSL or lock-up system

performance. The ECM will turn on the MIL and store the DTC.

HINT:

Example:

When any of the following is met, the system judges it as a malfunction.

• There is a difference in rotation between the input side (engine speed) and output side (input turbine

speed) of the torque converter when the ECM commands lock-up.

(Engine speed is at least 100 rpm greater than input turbine speed.)

• There is no difference in rotation between the input side (engine speed) and output side (input turbine

speed) of the torque converter when the ECM commands lock-up off.

(The difference between engine speed and input turbine speed is less than 35 rpm.)

MONITOR STRATEGY

DTC P0741Torque Converter Clutch Solenoid Performance

(Shift Solenoid Valve DSL)

DTC No. DTC Detection Condition Trouble Area

P0741Lock-up does not occur when driving in the lock-up

range (normal driving at 80 km/h [50 mph]), or lock up

remains ON in the lock-up OFF range.

(2-trip detection logic)• Shift solenoid valve DSL remains open or closed

• Valve body is blocked

• Torque converter clutch

• Automatic transaxle (clutch, brake or gear etc.)

• Line pressure is too low

Related DTCsP0741:

Shift solenoid valve DSL/OFF malfunction

Shift solenoid valve DSL/ON malfunction

Required sensors/ComponentsShift solenoid valve DSL, Speed sensor (NT), Speed sensor (NC),

Crankshaft position sensor (NE), Throttle position sensor (VPA1),

Mass air flow sensor (MAF), Transmission temperature sensor

(THO1), Engine coolant temperature sensor (ECT)

Frequency of operation Continuous

DurationOFF malfunction (A)

Continuous.

OFF malfunction (B)

1 sec.

OFF malfunction (C)

3.5 sec.

ON malfunction

1.8 sec.

Page 1439 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–73

AX

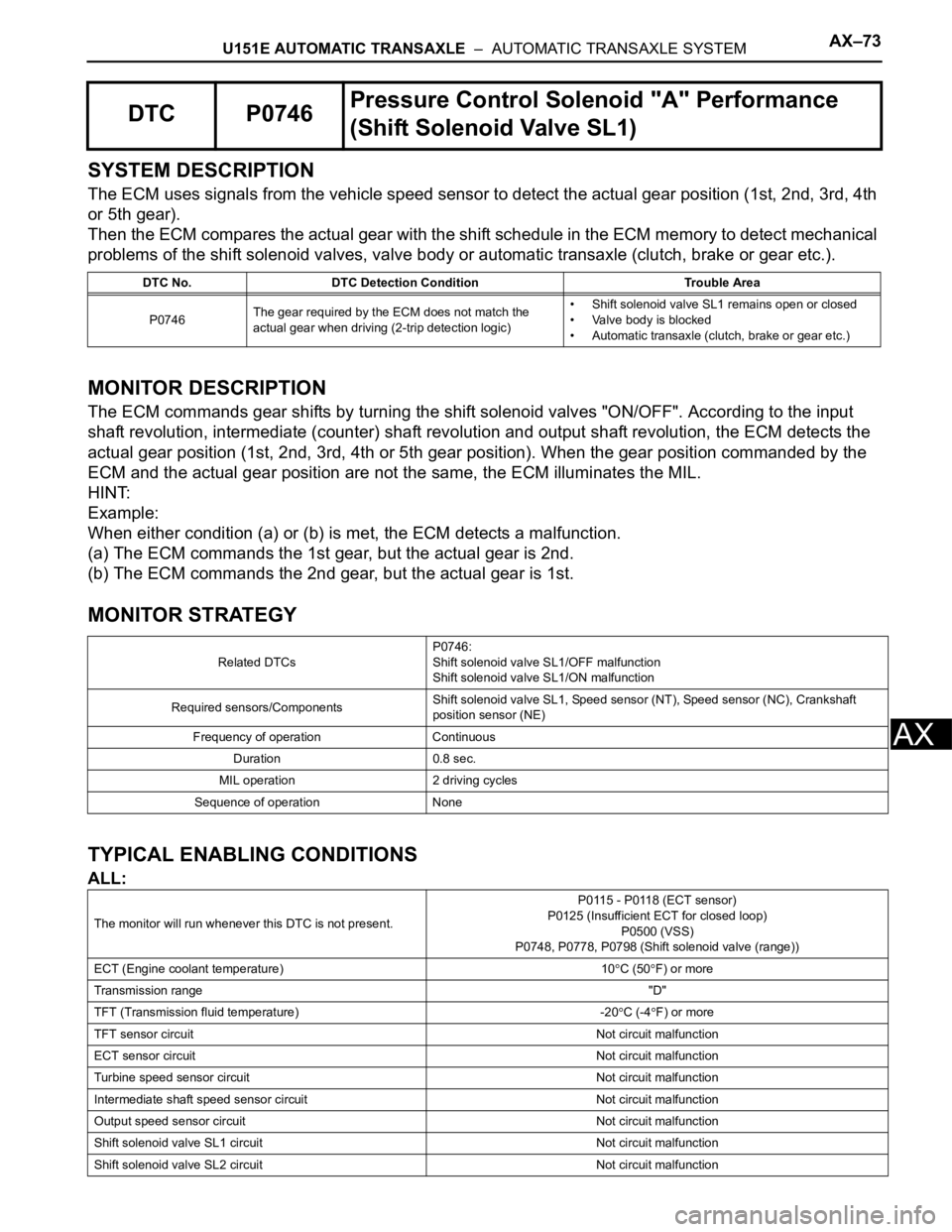

SYSTEM DESCRIPTION

The ECM uses signals from the vehicle speed sensor to detect the actual gear position (1st, 2nd, 3rd, 4th

or 5th gear).

Then the ECM compares the actual gear with the shift schedule in the ECM memory to detect mechanical

problems of the shift solenoid valves, valve body or automatic transaxle (clutch, brake or gear etc.).

MONITOR DESCRIPTION

The ECM commands gear shifts by turning the shift solenoid valves "ON/OFF". According to the input

shaft revolution, intermediate (counter) shaft revolution and output shaft revolution, the ECM detects the

actual gear position (1st, 2nd, 3rd, 4th or 5th gear position). When the gear position commanded by the

ECM and the actual gear position are not the same, the ECM illuminates the MIL.

HINT:

Example:

When either condition (a) or (b) is met, the ECM detects a malfunction.

(a) The ECM commands the 1st gear, but the actual gear is 2nd.

(b) The ECM commands the 2nd gear, but the actual gear is 1st.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

ALL:

DTC P0746Pressure Control Solenoid "A" Performance

(Shift Solenoid Valve SL1)

DTC No. DTC Detection Condition Trouble Area

P0746The gear required by the ECM does not match the

actual gear when driving (2-trip detection logic)• Shift solenoid valve SL1 remains open or closed

• Valve body is blocked

• Automatic transaxle (clutch, brake or gear etc.)

Related DTCsP0746:

Shift solenoid valve SL1/OFF malfunction

Shift solenoid valve SL1/ON malfunction

Required sensors/ComponentsShift solenoid valve SL1, Speed sensor (NT), Speed sensor (NC), Crankshaft

position sensor (NE)

Frequency of operation Continuous

Duration 0.8 sec.

MIL operation 2 driving cycles

Sequence of operation None

The monitor will run whenever this DTC is not present.P0115 - P0118 (ECT sensor)

P0125 (Insufficient ECT for closed loop)

P0500 (VSS)

P0748, P0778, P0798 (Shift solenoid valve (range))

ECT (Engine coolant temperature) 10

C (50F) or more

Transmission range"D"

TFT (Transmission fluid temperature) -20

C (-4F) or more

TFT sensor circuitNot circuit malfunction

ECT sensor circuitNot circuit malfunction

Turbine speed sensor circuit Not circuit malfunction

Intermediate shaft speed sensor circuit Not circuit malfunction

Output speed sensor circuit Not circuit malfunction

Shift solenoid valve SL1 circuit Not circuit malfunction

Shift solenoid valve SL2 circuit Not circuit malfunction

Page 1447 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–81

AX

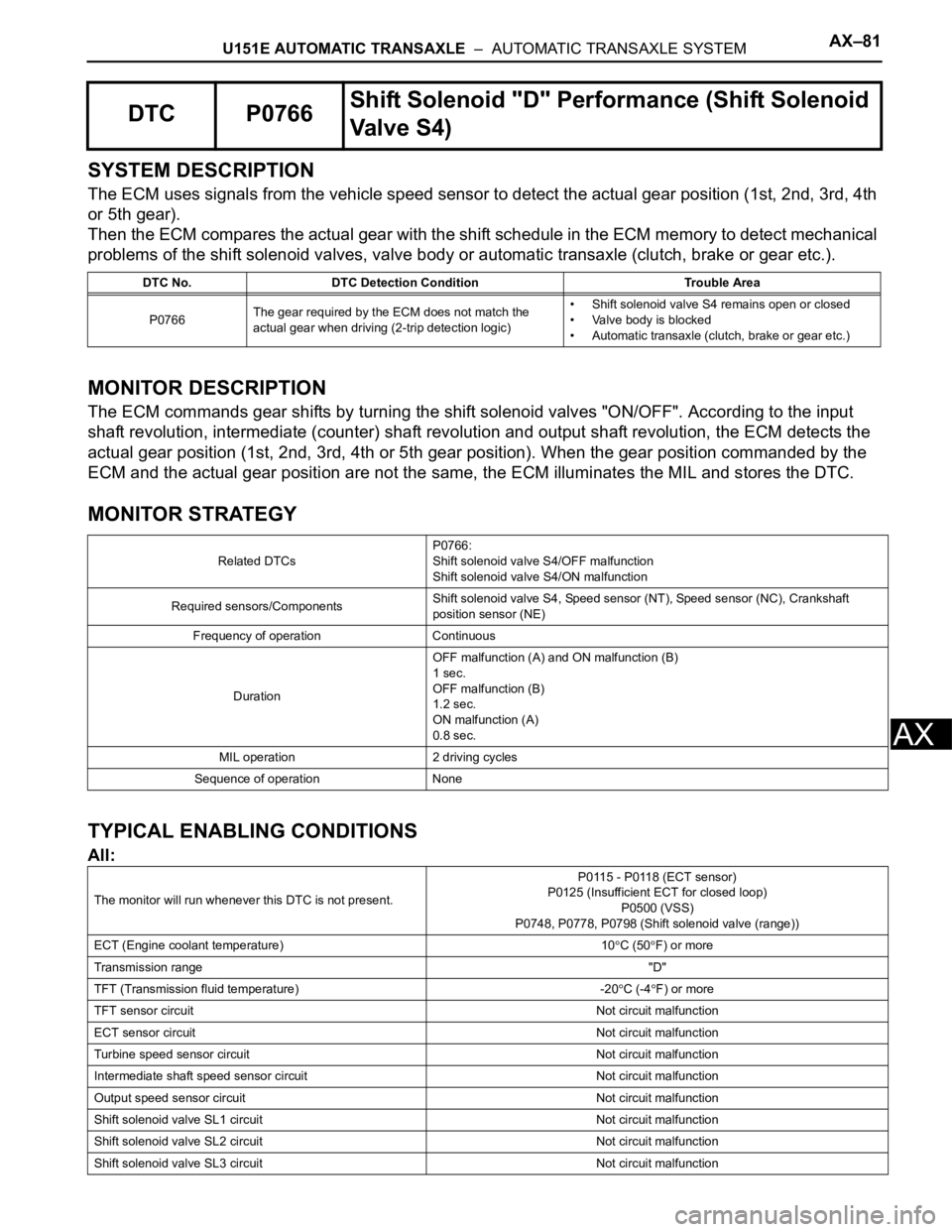

SYSTEM DESCRIPTION

The ECM uses signals from the vehicle speed sensor to detect the actual gear position (1st, 2nd, 3rd, 4th

or 5th gear).

Then the ECM compares the actual gear with the shift schedule in the ECM memory to detect mechanical

problems of the shift solenoid valves, valve body or automatic transaxle (clutch, brake or gear etc.).

MONITOR DESCRIPTION

The ECM commands gear shifts by turning the shift solenoid valves "ON/OFF". According to the input

shaft revolution, intermediate (counter) shaft revolution and output shaft revolution, the ECM detects the

actual gear position (1st, 2nd, 3rd, 4th or 5th gear position). When the gear position commanded by the

ECM and the actual gear position are not the same, the ECM illuminates the MIL and stores the DTC.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

All:

DTC P0766Shift Solenoid "D" Performance (Shift Solenoid

Valve S4)

DTC No. DTC Detection Condition Trouble Area

P0766The gear required by the ECM does not match the

actual gear when driving (2-trip detection logic)• Shift solenoid valve S4 remains open or closed

• Valve body is blocked

• Automatic transaxle (clutch, brake or gear etc.)

Related DTCsP0766:

Shift solenoid valve S4/OFF malfunction

Shift solenoid valve S4/ON malfunction

Required sensors/ComponentsShift solenoid valve S4, Speed sensor (NT), Speed sensor (NC), Crankshaft

position sensor (NE)

Frequency of operation Continuous

DurationOFF malfunction (A) and ON malfunction (B)

1 sec.

OFF malfunction (B)

1.2 sec.

ON malfunction (A)

0.8 sec.

MIL operation 2 driving cycles

Sequence of operation None

The monitor will run whenever this DTC is not present.P0115 - P0118 (ECT sensor)

P0125 (Insufficient ECT for closed loop)

P0500 (VSS)

P0748, P0778, P0798 (Shift solenoid valve (range))

ECT (Engine coolant temperature) 10

C (50F) or more

Transmission range"D"

TFT (Transmission fluid temperature) -20

C (-4F) or more

TFT sensor circuitNot circuit malfunction

ECT sensor circuitNot circuit malfunction

Turbine speed sensor circuit Not circuit malfunction

Intermediate shaft speed sensor circuit Not circuit malfunction

Output speed sensor circuit Not circuit malfunction

Shift solenoid valve SL1 circuit Not circuit malfunction

Shift solenoid valve SL2 circuit Not circuit malfunction

Shift solenoid valve SL3 circuit Not circuit malfunction

Page 1451 of 3000

U151E AUTOMATIC TRANSAXLE – AUTOMATIC TRANSAXLE SYSTEMAX–85

AX

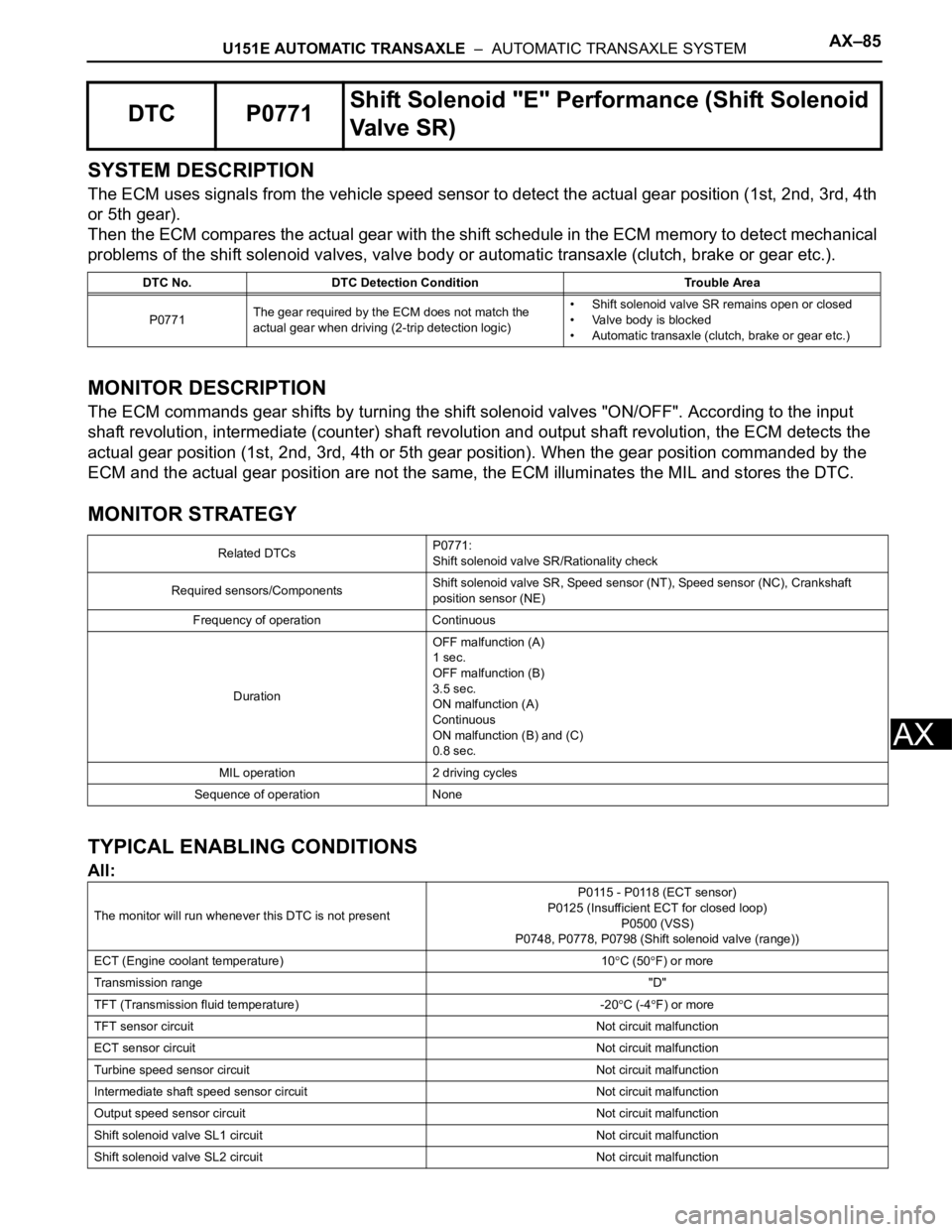

SYSTEM DESCRIPTION

The ECM uses signals from the vehicle speed sensor to detect the actual gear position (1st, 2nd, 3rd, 4th

or 5th gear).

Then the ECM compares the actual gear with the shift schedule in the ECM memory to detect mechanical

problems of the shift solenoid valves, valve body or automatic transaxle (clutch, brake or gear etc.).

MONITOR DESCRIPTION

The ECM commands gear shifts by turning the shift solenoid valves "ON/OFF". According to the input

shaft revolution, intermediate (counter) shaft revolution and output shaft revolution, the ECM detects the

actual gear position (1st, 2nd, 3rd, 4th or 5th gear position). When the gear position commanded by the

ECM and the actual gear position are not the same, the ECM illuminates the MIL and stores the DTC.

MONITOR STRATEGY

TYPICAL ENABLING CONDITIONS

All:

DTC P0771Shift Solenoid "E" Performance (Shift Solenoid

Va l v e S R )

DTC No. DTC Detection Condition Trouble Area

P0771The gear required by the ECM does not match the

actual gear when driving (2-trip detection logic)• Shift solenoid valve SR remains open or closed

• Valve body is blocked

• Automatic transaxle (clutch, brake or gear etc.)

Related DTCsP0771:

Shift solenoid valve SR/Rationality check

Required sensors/ComponentsShift solenoid valve SR, Speed sensor (NT), Speed sensor (NC), Crankshaft

position sensor (NE)

Frequency of operation Continuous

DurationOFF malfunction (A)

1 sec.

OFF malfunction (B)

3.5 sec.

ON malfunction (A)

Continuous

ON malfunction (B) and (C)

0.8 sec.

MIL operation 2 driving cycles

Sequence of operation None

The monitor will run whenever this DTC is not presentP0115 - P0118 (ECT sensor)

P0125 (Insufficient ECT for closed loop)

P0500 (VSS)

P0748, P0778, P0798 (Shift solenoid valve (range))

ECT (Engine coolant temperature) 10

C (50F) or more

Transmission range"D"

TFT (Transmission fluid temperature) -20

C (-4F) or more

TFT sensor circuitNot circuit malfunction

ECT sensor circuitNot circuit malfunction

Turbine speed sensor circuit Not circuit malfunction

Intermediate shaft speed sensor circuit Not circuit malfunction

Output speed sensor circuit Not circuit malfunction

Shift solenoid valve SL1 circuit Not circuit malfunction

Shift solenoid valve SL2 circuit Not circuit malfunction